JP2007198377A - 被冷却鋳造部品、被冷却部品製造方法、鋳造部品表面冷却方法、およびガスタービンエンジンエアフォイル構成要素 - Google Patents

被冷却鋳造部品、被冷却部品製造方法、鋳造部品表面冷却方法、およびガスタービンエンジンエアフォイル構成要素 Download PDFInfo

- Publication number

- JP2007198377A JP2007198377A JP2007010928A JP2007010928A JP2007198377A JP 2007198377 A JP2007198377 A JP 2007198377A JP 2007010928 A JP2007010928 A JP 2007010928A JP 2007010928 A JP2007010928 A JP 2007010928A JP 2007198377 A JP2007198377 A JP 2007198377A

- Authority

- JP

- Japan

- Prior art keywords

- cooled

- passage

- turbine engine

- plenum

- outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000001816 cooling Methods 0.000 title claims abstract description 33

- 238000004519 manufacturing process Methods 0.000 title claims 9

- 239000011888 foil Substances 0.000 title abstract 2

- 238000005266 casting Methods 0.000 claims description 17

- 238000000034 method Methods 0.000 claims description 9

- 238000005553 drilling Methods 0.000 claims description 6

- 239000003870 refractory metal Substances 0.000 claims description 5

- 230000000149 penetrating effect Effects 0.000 claims description 2

- 230000015572 biosynthetic process Effects 0.000 claims 4

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims 2

- 229910052759 nickel Inorganic materials 0.000 claims 1

- 229910000601 superalloy Inorganic materials 0.000 claims 1

- 230000000694 effects Effects 0.000 abstract description 2

- 238000010438 heat treatment Methods 0.000 abstract description 2

- 230000002093 peripheral effect Effects 0.000 abstract description 2

- 238000000465 moulding Methods 0.000 description 3

- 239000000919 ceramic Substances 0.000 description 2

- 238000009760 electrical discharge machining Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000005495 investment casting Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000011253 protective coating Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

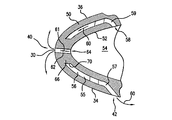

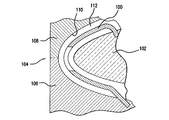

- F01D5/18—Hollow blades, i.e. blades with cooling or heating channels or cavities; Heating, heat-insulating or cooling means on blades

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

- F01D5/18—Hollow blades, i.e. blades with cooling or heating channels or cavities; Heating, heat-insulating or cooling means on blades

- F01D5/186—Film cooling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22C—FOUNDRY MOULDING

- B22C9/00—Moulds or cores; Moulding processes

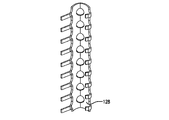

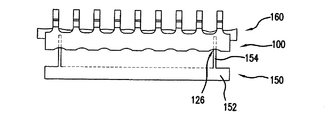

- B22C9/10—Cores; Manufacture or installation of cores

- B22C9/103—Multipart cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D7/00—Casting ingots, e.g. from ferrous metals

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C7/00—Features, components parts, details or accessories, not provided for in, or of interest apart form groups F02C1/00 - F02C6/00; Air intakes for jet-propulsion plants

- F02C7/12—Cooling of plants

- F02C7/16—Cooling of plants characterised by cooling medium

- F02C7/18—Cooling of plants characterised by cooling medium the medium being gaseous, e.g. air

- F02C7/185—Cooling means for reducing the temperature of the cooling air or gas

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/10—Manufacture by removing material

- F05D2230/12—Manufacture by removing material by spark erosion methods

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/10—Manufacture by removing material

- F05D2230/13—Manufacture by removing material using lasers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/20—Manufacture essentially without removing material

- F05D2230/21—Manufacture essentially without removing material by casting

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/20—Manufacture essentially without removing material

- F05D2230/21—Manufacture essentially without removing material by casting

- F05D2230/211—Manufacture essentially without removing material by casting by precision casting, e.g. microfusing or investment casting

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/90—Coating; Surface treatment

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2240/00—Components

- F05D2240/10—Stators

- F05D2240/12—Fluid guiding means, e.g. vanes

- F05D2240/121—Fluid guiding means, e.g. vanes related to the leading edge of a stator vane

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2240/00—Components

- F05D2240/20—Rotors

- F05D2240/30—Characteristics of rotor blades, i.e. of any element transforming dynamic fluid energy to or from rotational energy and being attached to a rotor

- F05D2240/303—Characteristics of rotor blades, i.e. of any element transforming dynamic fluid energy to or from rotational energy and being attached to a rotor related to the leading edge of a rotor blade

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2260/00—Function

- F05D2260/20—Heat transfer, e.g. cooling

- F05D2260/204—Heat transfer, e.g. cooling by the use of microcircuits

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2300/00—Materials; Properties thereof

- F05D2300/60—Properties or characteristics given to material by treatment or manufacturing

- F05D2300/611—Coating

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T50/00—Aeronautics or air transport

- Y02T50/60—Efficient propulsion technologies, e.g. for aircraft

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Valve Housings (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/340,911 US7322795B2 (en) | 2006-01-27 | 2006-01-27 | Firm cooling method and hole manufacture |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007198377A true JP2007198377A (ja) | 2007-08-09 |

| JP2007198377A5 JP2007198377A5 (enExample) | 2008-03-27 |

Family

ID=37873107

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007010928A Pending JP2007198377A (ja) | 2006-01-27 | 2007-01-22 | 被冷却鋳造部品、被冷却部品製造方法、鋳造部品表面冷却方法、およびガスタービンエンジンエアフォイル構成要素 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7322795B2 (enExample) |

| EP (1) | EP1813775B1 (enExample) |

| JP (1) | JP2007198377A (enExample) |

| KR (1) | KR20070078685A (enExample) |

| CN (1) | CN101008327A (enExample) |

| SG (1) | SG134205A1 (enExample) |

| TW (1) | TW200728594A (enExample) |

Families Citing this family (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7625179B2 (en) * | 2006-09-13 | 2009-12-01 | United Technologies Corporation | Airfoil thermal management with microcircuit cooling |

| US8066052B2 (en) * | 2007-06-07 | 2011-11-29 | United Technologies Corporation | Cooled wall thickness control |

| US20090314748A1 (en) * | 2008-06-21 | 2009-12-24 | United Technologies Corporation | Ultrasonic assisted electrodischarge machining |

| US8157527B2 (en) * | 2008-07-03 | 2012-04-17 | United Technologies Corporation | Airfoil with tapered radial cooling passage |

| US8572844B2 (en) * | 2008-08-29 | 2013-11-05 | United Technologies Corporation | Airfoil with leading edge cooling passage |

| US8303252B2 (en) * | 2008-10-16 | 2012-11-06 | United Technologies Corporation | Airfoil with cooling passage providing variable heat transfer rate |

| US8109725B2 (en) | 2008-12-15 | 2012-02-07 | United Technologies Corporation | Airfoil with wrapped leading edge cooling passage |

| US20130078418A1 (en) * | 2011-09-23 | 2013-03-28 | General Electric Company | Components with cooling channels and methods of manufacture |

| US8967957B2 (en) * | 2011-11-03 | 2015-03-03 | General Electric Company | Rotating airfoil component of a turbomachine |

| US9249670B2 (en) | 2011-12-15 | 2016-02-02 | General Electric Company | Components with microchannel cooling |

| CH706090A1 (de) * | 2012-02-17 | 2013-08-30 | Alstom Technology Ltd | Verfahren zum Herstellen eines oberflächennahen Kühlkanals in einem thermisch hoch beanspruchten Bauteil sowie Bauteil mit einem solchen Kanal. |

| US20130280093A1 (en) | 2012-04-24 | 2013-10-24 | Mark F. Zelesky | Gas turbine engine core providing exterior airfoil portion |

| EP2956257B1 (en) * | 2013-02-12 | 2022-07-13 | Raytheon Technologies Corporation | Gas turbine engine component cooling passage and space eating core |

| EP2971667B1 (en) | 2013-03-15 | 2024-06-12 | RTX Corporation | Component for a gas turbine engine and method of manufacturing a component for a gas turbine engine |

| CN103452595A (zh) * | 2013-09-25 | 2013-12-18 | 青岛科技大学 | 一种提高冷却效率的新型气膜孔 |

| WO2015060973A1 (en) * | 2013-10-23 | 2015-04-30 | United Technologies Corporation | Turbine airfoil cooling core exit |

| US9061349B2 (en) * | 2013-11-07 | 2015-06-23 | Siemens Aktiengesellschaft | Investment casting method for gas turbine engine vane segment |

| EP3124135B1 (en) * | 2014-03-28 | 2019-05-29 | IHI Corporation | CASTING MOLD, METHOD OF MANUFACTURING SAME, Ti-Al ALLOY CAST PRODUCT, AND METHOD OF CASTING SAME |

| US10329921B2 (en) | 2014-10-24 | 2019-06-25 | United Technologies Corporation | Cooling configuration for a component |

| US10578305B2 (en) | 2014-11-03 | 2020-03-03 | Siemens Aktiengesellschaft | Bruner assembly |

| US9579714B1 (en) | 2015-12-17 | 2017-02-28 | General Electric Company | Method and assembly for forming components having internal passages using a lattice structure |

| US9968991B2 (en) | 2015-12-17 | 2018-05-15 | General Electric Company | Method and assembly for forming components having internal passages using a lattice structure |

| US10099276B2 (en) | 2015-12-17 | 2018-10-16 | General Electric Company | Method and assembly for forming components having an internal passage defined therein |

| US10137499B2 (en) | 2015-12-17 | 2018-11-27 | General Electric Company | Method and assembly for forming components having an internal passage defined therein |

| US10099284B2 (en) | 2015-12-17 | 2018-10-16 | General Electric Company | Method and assembly for forming components having a catalyzed internal passage defined therein |

| US10046389B2 (en) | 2015-12-17 | 2018-08-14 | General Electric Company | Method and assembly for forming components having internal passages using a jacketed core |

| US10099283B2 (en) | 2015-12-17 | 2018-10-16 | General Electric Company | Method and assembly for forming components having an internal passage defined therein |

| US10150158B2 (en) | 2015-12-17 | 2018-12-11 | General Electric Company | Method and assembly for forming components having internal passages using a jacketed core |

| US10118217B2 (en) | 2015-12-17 | 2018-11-06 | General Electric Company | Method and assembly for forming components having internal passages using a jacketed core |

| US9987677B2 (en) | 2015-12-17 | 2018-06-05 | General Electric Company | Method and assembly for forming components having internal passages using a jacketed core |

| US10286450B2 (en) | 2016-04-27 | 2019-05-14 | General Electric Company | Method and assembly for forming components using a jacketed core |

| US10335853B2 (en) | 2016-04-27 | 2019-07-02 | General Electric Company | Method and assembly for forming components using a jacketed core |

| US20170335692A1 (en) * | 2016-05-20 | 2017-11-23 | United Technologies Corporation | Refractory metal core and components formed thereby |

| US10323569B2 (en) | 2016-05-20 | 2019-06-18 | United Technologies Corporation | Core assemblies and gas turbine engine components formed therefrom |

| US20180238175A1 (en) * | 2017-02-21 | 2018-08-23 | General Electric Company | Method and Device for Retaining Position of a Consumable Core |

| US20190218917A1 (en) | 2018-01-17 | 2019-07-18 | General Electric Company | Engine component with set of cooling holes |

| CN112145234B (zh) * | 2020-09-24 | 2021-08-20 | 大连理工大学 | 一种ω型回转腔层板冷却结构 |

| CN112643298B (zh) * | 2020-12-25 | 2021-07-23 | 浙江燃创透平机械股份有限公司 | 一种热泵系统中燃气轮机静叶片的导流管及制备方法 |

| US11572803B1 (en) * | 2022-08-01 | 2023-02-07 | General Electric Company | Turbine airfoil with leading edge cooling passage(s) coupled via plenum to film cooling holes, and related method |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE755567A (fr) * | 1969-12-01 | 1971-02-15 | Gen Electric | Structure d'aube fixe, pour moteur a turbines a gaz et arrangement de reglage de temperature associe |

| US5405242A (en) * | 1990-07-09 | 1995-04-11 | United Technologies Corporation | Cooled vane |

| US5290143A (en) * | 1992-11-02 | 1994-03-01 | Allied Signal | Bicast vane and shroud rings |

| US5779437A (en) * | 1996-10-31 | 1998-07-14 | Pratt & Whitney Canada Inc. | Cooling passages for airfoil leading edge |

| US5931638A (en) | 1997-08-07 | 1999-08-03 | United Technologies Corporation | Turbomachinery airfoil with optimized heat transfer |

| US7281895B2 (en) * | 2003-10-30 | 2007-10-16 | Siemens Power Generation, Inc. | Cooling system for a turbine vane |

| US6929054B2 (en) | 2003-12-19 | 2005-08-16 | United Technologies Corporation | Investment casting cores |

-

2006

- 2006-01-27 US US11/340,911 patent/US7322795B2/en active Active

- 2006-06-02 TW TW095119739A patent/TW200728594A/zh unknown

- 2006-07-11 KR KR1020060064901A patent/KR20070078685A/ko not_active Abandoned

- 2006-08-07 SG SG200605326-8A patent/SG134205A1/en unknown

-

2007

- 2007-01-22 JP JP2007010928A patent/JP2007198377A/ja active Pending

- 2007-01-24 EP EP07250282.6A patent/EP1813775B1/en active Active

- 2007-01-26 CN CNA2007100061734A patent/CN101008327A/zh active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| US7322795B2 (en) | 2008-01-29 |

| TW200728594A (en) | 2007-08-01 |

| EP1813775A2 (en) | 2007-08-01 |

| CN101008327A (zh) | 2007-08-01 |

| KR20070078685A (ko) | 2007-08-01 |

| SG134205A1 (en) | 2007-08-29 |

| US20070177975A1 (en) | 2007-08-02 |

| EP1813775B1 (en) | 2016-07-06 |

| EP1813775A3 (en) | 2010-11-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2007198377A (ja) | 被冷却鋳造部品、被冷却部品製造方法、鋳造部品表面冷却方法、およびガスタービンエンジンエアフォイル構成要素 | |

| EP1849965B1 (en) | Vane platform cooling | |

| EP1895098B1 (en) | Improved High Effectiveness Cooled Turbine Blade | |

| US8292581B2 (en) | Air cooled turbine blades and methods of manufacturing | |

| US10196917B2 (en) | Blade outer air seal with cored passages | |

| JP4416287B2 (ja) | 内部冷却翼形部品並びに冷却方法 | |

| EP2246133B1 (en) | RMC-defined tip blowing slots for turbine blades | |

| EP1010859B1 (en) | Cooling system for a turbine airfoil having a three pass cooling circuit | |

| JP2007061902A (ja) | インベストメント鋳造用模型製造方法およびその製造装置、ならびに鋳造コア | |

| JP2004308659A (ja) | タービン要素およびタービンブレードの製造方法 | |

| JP6613803B2 (ja) | 翼、これを備えているガスタービン、及び翼の製造方法 | |

| JP2007198377A5 (enExample) | ||

| KR20090127913A (ko) | 가스 터빈 엔진의 안내 날개 어셈블리에 대한 안내 날개 덕트 요소 | |

| JP2007132342A (ja) | タービンエンジン構成要素、耐火金属コアならびにエアフォイル部の形成工程 | |

| EP1923152B1 (en) | Trubine blade casting method | |

| JP2008019861A (ja) | タービンエンジン構成要素 | |

| JP4208504B2 (ja) | ガスタービンエンジン翼形部の耐用寿命を延ばすための方法及び装置 | |

| WO2014108318A1 (en) | Blade for a turbomachine | |

| US6619912B2 (en) | Turbine blade or vane | |

| US10024190B1 (en) | Apparatus and process for forming an air cooled turbine airfoil with a cooling air channel and discharge slot in a thin wall | |

| EP2752554A1 (en) | Blade for a turbomachine | |

| JP2007170392A (ja) | 動翼用エアフォイル及びタービン翼 | |

| US11885230B2 (en) | Airfoil with internal crossover passages and pin array |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080213 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20080213 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20080222 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080318 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20080812 |