JP2007151663A - Soft supporter, and manufacturing method for french pile for the same - Google Patents

Soft supporter, and manufacturing method for french pile for the same Download PDFInfo

- Publication number

- JP2007151663A JP2007151663A JP2005347806A JP2005347806A JP2007151663A JP 2007151663 A JP2007151663 A JP 2007151663A JP 2005347806 A JP2005347806 A JP 2005347806A JP 2005347806 A JP2005347806 A JP 2005347806A JP 2007151663 A JP2007151663 A JP 2007151663A

- Authority

- JP

- Japan

- Prior art keywords

- soft supporter

- french pile

- pile

- male member

- french

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Abstract

Description

本発明は医療、スポーツの分野において人体に装着するサポーターに関する。 The present invention relates to a supporter attached to a human body in the fields of medicine and sports.

医療、スポーツの分野において、膝、足首等の体の部位に応じた固定、保護等を目的としてサポーターが使用される。とくに人体への追従のし易さ、装着感の良さ等から比較的薄手のソフトサポーターが使用され、とくに縦横二方向に伸縮性のある起毛ツーウエイ経編地(以下、「フレンチパイル」という。)を本体の表地に使用し、本体の一端に設けた面ファスナー雄部材と係合させて着脱を行うようにしている。 In the medical and sports fields, supporters are used for the purpose of fixation, protection, etc. according to body parts such as knees and ankles. A relatively thin soft supporter is used because it is particularly easy to follow the human body and has a good fit. The raised two-way warp knitted fabric (hereinafter referred to as “French pile”) is particularly stretchable in two directions. Is used for the outer surface of the main body, and is engaged with a hook-and-loop male member provided at one end of the main body for attachment and detachment.

しかし、従来のソフトサポーターでは、とくに医療用のものでは、面ファスナー雄部材による脱着を患者が治癒するまでに、比較的少ない場合でも、300〜500回に亘り繰り返すため、次第にフレンチパイルが折れ曲がり、しわが生じたり、またループ糸が破断して係合力が低下するなどして治療に最適な部位に装着することが困難となる。

このため、装着のため掴まれる末端部に着目し、当該部分の剛性を高めたり、剛性の手掛かりを付設しているが十分ではない(例えば、特許文献1参照)。

However, in the conventional soft supporter, in particular for medical use, since the patient is healed by the hook-and-loop fastener male member, it is repeated 300 to 500 times even if there are relatively few, so the French pile gradually bends, Wrinkles are generated or the loop thread is broken and the engaging force is reduced, so that it becomes difficult to attach to the optimal site for treatment.

For this reason, paying attention to the end part gripped for mounting, the rigidity of the part is increased or a clue of rigidity is attached, but it is not sufficient (for example, see Patent Document 1).

一般に、衣料用としてフレンチパイルのような起毛布帛を使用する場合は、しわがつきやすく、剥がしづらい欠点を改善するため、起毛糸の起毛長を短くしたり、また、起毛布帛に樹脂を含浸して、起毛糸、及び、地組織の屈曲回復性を狙った商品が製造されているが、風合い等に問題がある(例えば、特許文献2参照)。 In general, when using a raised fabric such as French pile for clothing, the length of the raised yarn is shortened or the raised fabric is impregnated with a resin in order to improve the disadvantage that it is easy to wrinkle and is difficult to peel off. In addition, raised yarns and products aiming at bend recovery of the ground structure are manufactured, but there is a problem in the texture and the like (for example, see Patent Document 2).

起毛布帛を使用した面ファスナー雌部材では、係合力の要因として、構成繊維の検討(一般にはナイロン繊維)、各種物性のナイロン繊維の利用や熱圧着性繊維の併用、雌材の組織、目付け、ループ高さ、ループ数等が知られている(例えば、特許文献3参照)。また、繰り返し使用による変形を防止するため、低融点フィラメントを地組織に用いて起毛後に融点よりも高い温度で熱処理する方法がある(例えば、特許文献4参照)。さらにトリコット地組織を起毛によって掻きだし易いループ長に設定する方法等もある(例えば、特許文献5,6,7参照)。しかし、これらは面ファスナーに関するものであってソフトサポーターの本体に関するものではない。 In a surface fastener female member using a raised fabric, as factors of engagement force, examination of constituent fibers (generally nylon fibers), use of nylon fibers of various physical properties and combined use of thermocompression-bonding fibers, female material structure, basis weight, The loop height, the number of loops, and the like are known (see, for example, Patent Document 3). In addition, in order to prevent deformation due to repeated use, there is a method in which a low melting point filament is used for the ground texture and heat treated at a temperature higher than the melting point after raising (for example, see Patent Document 4). Further, there is a method of setting the tricot tissue to a loop length that can be easily scraped by raising (see, for example, Patent Documents 5, 6, and 7). However, these are related to the hook-and-loop fastener, not the soft supporter body.

本発明は面ファスナー雄部材との着脱を繰り返しても、本体の変形が少なく、適切な部位に安定して装着することができるソフトサポーターおよびソフトサポーター用フレンチパイルの製造方法を提供することを課題とする。 It is an object of the present invention to provide a soft supporter and a method of manufacturing a soft pile for a soft supporter that can be stably attached to an appropriate site with little deformation of the main body even when the surface fastener male member is repeatedly attached and detached. And

本発明によれば、上記課題は下記により達成される。面ファスナー雄部材と本体の表地であるフレンチパイルとを係合させて装着するソフトサポーターにおいて、前記本体が、剛軟性が、JIS L1096に規定するカンチレバー法によって測定したときに60〜140mmであって、表地であるフレンチパイルと係合したときの幅方向の引っ張りせん断強さが6.0〜8.0N/cm2、剥離強さが2.0〜3.5N/cmとなる面ファスナー雄部材を、表地であるフレンチパイルに、負荷荷重0.5±0.2N/cm2で押し付け、着脱を500回繰り返したときに、当該係合した部分において生じるカール角度が60度以下であることを特徴とする(請求項1の発明)。 According to the present invention, the above-described object is achieved by the following. In the soft supporter that engages and mounts the surface fastener male member and the French pile that is the outer surface of the main body, the main body has a stiffness of 60 to 140 mm when measured by the cantilever method defined in JIS L1096. The male member for a hook-and-loop fastener having a tensile shear strength in the width direction of 6.0 to 8.0 N / cm 2 and a peel strength of 2.0 to 3.5 N / cm when engaged with the French pile as the outer material. Is pressed against the French pile, which is the outer material, with a load of 0.5 ± 0.2 N / cm 2 , and when the attachment / detachment is repeated 500 times, the curl angle generated in the engaged portion is 60 degrees or less. It is characterized (Invention of Claim 1).

前記請求項1の発明の実施態様としては、下記請求項2ないし5の発明が好ましい。前記請求項1に記載のソフトサポーターにおいて、前記係合した部分において生じるカール角度が40度以下であることを特徴とする(請求項2の発明)。また、前記請求項1又は2に記載のソフトサポーターにおいて、前記本体がフレンチパイルを表地としたラミネートであることを特徴とする(請求項3の発明)。さらに、前記請求項1乃至3のいずれか1項に記載のソフトサポーターにおいて、ソフトサポーターに取り付けられた前記面ファスナー雄部材が、当該ソフトサポーターの本体の表地であるフレンチパイルと係合したときの幅方向の引っ張りせん断強さが3.5〜9.0N/cm2、剥離強さが0.6〜5.5N/cmであることを特徴とする(請求項4の発明)。また、前記請求項1乃至4のいずれか1項に記載のソフトサポーターにおいて、前記フレンチパイルの起毛高さが略1mm、コースが60〜65本/25.4mmであることを特徴とする(請求項5の発明)。

As an embodiment of the invention of

ソフトサポーター用フレンチパイルの製造方法の発明としては、ソフトサポーターの本体表地として面ファスナー雄部材と係合させて使用されるフレンチパイルの製造方法において、起毛高さが略1mm、生機から仕上げの収縮率がコースで20%以上であることを特徴とする(請求項6の発明)。また、前記請求項6に記載のソフトサポーター用フレンチパイルの製造方法において、前記生機から仕上げの収縮率がコースで20〜40%であることを特徴とする(請求項7の発明)。 The invention of a method for manufacturing a French pile for a soft supporter includes a method for manufacturing a French pile used by engaging a male member of a hook-and-loop fastener as a main surface of the soft supporter. The rate is 20% or more in the course (invention of claim 6). Moreover, in the manufacturing method of the French pile for soft supporters of the said Claim 6, the shrinkage | contraction rate of finishing from the said raw machine is 20 to 40% on a course (invention of Claim 7), It is characterized by the above-mentioned.

本発明によれば、面ファスナー雄部材との着脱を繰り返しても、本体の変形が少なく、適切な部位に安定して装着することができるソフトサポーター、ならびにソフトサポーターに好適なフレンチパイルの製造方法が提供できる。 ADVANTAGE OF THE INVENTION According to this invention, even if it repeats attachment / detachment with a hook_and_loop | surface fastener male member, there is little deformation | transformation of a main body, and the manufacturing method of the French pile suitable for a soft supporter which can be stably mounted | worn to an appropriate site | part Can be provided.

本発明の実施形態について以下に述べる。なお、ソフトサポーターの具体的な構成や評価結果等については、後述する実施例の項で述べる。 Embodiments of the present invention are described below. The specific configuration and evaluation results of the soft supporter will be described in the example section described later.

本発明の面ファスナー雄部材と本体の表地であるフレンチパイルとを係合させて装着するソフトサポーターとは、本体が所定の評価方法によってカール角度が60度以下、好ましくは40度以下となるものである。ここで所定の評価方法とは、評価されるフレンチパイルと係合させたとき、幅方向の引っ張りせん断強さが6.0〜8.0N/cm2、剥離強さが2.0〜3.5N/cmとなる面ファスナー雄部材を使用し、フレンチパイルに、負荷荷重0.5±0.2N/cm2で押し付け、着脱を500回繰り返すものである。 The soft supporter to which the male fastener of the present invention and the French pile that is the outer surface of the main body are engaged and mounted is such that the main body has a curl angle of 60 degrees or less, preferably 40 degrees or less, according to a predetermined evaluation method. It is. Here, the predetermined evaluation method is that when engaged with the French pile to be evaluated, the tensile shear strength in the width direction is 6.0 to 8.0 N / cm 2 and the peel strength is 2.0 to 3. A male member with a surface fastener of 5 N / cm is used, pressed against the French pile with a load of 0.5 ± 0.2 N / cm 2 , and the attachment / detachment is repeated 500 times.

本発明のソフトサポーターとは、本体の剛軟性が、JIS L1096に規定するカンチレバー法によって測定したとき、60〜140mm、例えば、80〜120mmである。 With the soft supporter of the present invention, the stiffness of the main body is 60 to 140 mm, for example, 80 to 120 mm, when measured by the cantilever method specified in JIS L1096.

本発明のソフトサポーターを構成する面ファスナー雄部材は、表地であるフレンチパイルと係合したとき、幅方向の引っ張りせん断強さが3.5〜9.0N/cm2、剥離強さが0.6〜5.5N/cmである。この範囲の下限値以下ではソフトサポーターに必要な係合力が得られず、また上限値以上では剥がしづらいだけでなく折れ曲がりやカールが発生しやすくなる。引っ張りせん断強さと剥離強さはソフトサポーターの用途、種類によって異なるが、比較的係合力の大きいものでは、引っ張りせん断強さが6.0〜8.0N/cm2、剥離強さが2.0〜3.5N/cmである。フックの形状、材質は問わない。フレンチパイルを連続して製造したときの布帛の流れに平行な方向を「流れ方向」、流れに垂直な方向を「幅方向」といい、流れ方向の編み目の連なりをウエール数、幅方向の編み目の連なりをコース数という。面ファスナーと係合したときの引っ張りせん断強さ、剥離強さは、流れ方向、幅方向ともほぼ同じであるが厳密には異なる。 The surface fastener male member constituting the soft supporter of the present invention has a tensile shear strength in the width direction of 3.5 to 9.0 N / cm 2 and a peel strength of 0.00 when engaged with the French pile as the outer material. 6 to 5.5 N / cm. Below the lower limit of this range, the engagement force required for the soft supporter cannot be obtained, and when it exceeds the upper limit, not only is it difficult to peel off, but bending and curling tend to occur. The tensile shear strength and peel strength differ depending on the use and type of the soft supporter, but those having a relatively large engaging force have a tensile shear strength of 6.0 to 8.0 N / cm 2 and a peel strength of 2.0. ~ 3.5 N / cm. The shape and material of the hook are not limited. The direction parallel to the fabric flow when the French pile is continuously manufactured is called the “flow direction”, the direction perpendicular to the flow is called the “width direction”, the series of stitches in the flow direction is the number of wales, and the stitches in the width direction This is called the number of courses. The tensile shear strength and peel strength when engaged with the hook-and-loop fastener are substantially the same in the flow direction and the width direction, but are strictly different.

本発明のソフトサポーターの本体とは、膝、足首等の体の部位に装着され、ソフトサポーターのほぼ全体の形状を成すものである。本体は、1枚の生地から形成することができるが、適当な大きさに裁断した生地を縫製や接着によりつなぎ合わせて形成することもできる。また、体表面との追従性、適度な圧迫性や操作性を向上させるために、他の伸縮性の生地を部分的に用いてもよい。本体の伸縮性は、生地を構成する繊維の特性やその混紡の割合、生地同士の組合せパターン等により自由に調整することができる。 The main body of the soft supporter of the present invention is attached to a body part such as a knee or an ankle, and forms almost the entire shape of the soft supporter. The main body can be formed from one piece of cloth, but can also be formed by joining cloths cut into an appropriate size by sewing or bonding. In addition, other stretchable fabrics may be partially used in order to improve the followability with the body surface, appropriate pressure and operability. The stretchability of the main body can be freely adjusted by the characteristics of the fibers constituting the fabric, the blend ratio, the combination pattern of the fabrics, and the like.

本発明の本体の生地は、少なくとも面ファスナー雄部材と係合する表地がフレンチパイルで構成されていればよく、フレンチパイル単体でも、またフレンチパイルを他の素材とラミネートや縫製した複合材料でもよい。ラミネートや縫製する素材には、天然繊維、化学繊維よりなる織布、編布、不織布、パイル生地、プラスチックフォームなどを単独又は任意に選択組合せて形成することができる。その具体的な素材としては、例えば、綿、ウール、レーヨン、アクリル、ポリアミド、ポリエステル、ポリウレタン、塩化ビニリデン等の繊維を適宜組合せてなる、よこ編み布の天竺、経編み布のジャージ生地、パワーネットのような弾性糸混紡編物、ダブルラッシェル生地の立体編物等が使用できる。さらに、これらの生地とゴム発泡体(クロロプレンゴム、天然ゴム、ブチルゴム、スチレン・ブタジェンゴム、イソプレンゴム等)、ウレタンゴム(圧縮ウレタン)等の材料を積層することができる。ラミネートには、ウレタン系やポリエステル系の接着剤が使用できる。 The fabric of the main body of the present invention is not limited as long as at least the outer surface engaged with the surface fastener male member is constituted by a French pile, and may be a French pile alone or a composite material obtained by laminating or sewing a French pile with other materials. . As a material to be laminated or sewn, a woven fabric, a knitted fabric, a non-woven fabric, a pile fabric, a plastic foam, or the like made of natural fibers or chemical fibers can be formed singly or arbitrarily in combination. Specific materials include, for example, weft knitted fabrics, warp knitted fabrics, power nets, which are appropriately combined with cotton, wool, rayon, acrylic, polyamide, polyester, polyurethane, vinylidene chloride and other fibers. An elastic yarn blended knitted fabric such as the above, a three-dimensional knitted fabric of a double raschel fabric, etc. Furthermore, these fabrics and rubber foams (chloroprene rubber, natural rubber, butyl rubber, styrene / butadiene rubber, isoprene rubber, etc.), urethane rubber (compressed urethane) and the like can be laminated. For laminating, urethane or polyester adhesives can be used.

本発明のフレンチパイルとは、ポリアミド(Ny)糸やポリエステル糸の経編(トリコット)組織にポリウレタン(Pu)糸を挿入した組織で縦横方向に伸縮性を有するツーウエイ経編地を、起毛、中間ヒートセット、染色、ヒートセットの仕上げを施して製造したものである。使用される糸の材質、太さ、編み組織、起毛の方法等は限定されないが、起毛高さが略1mm、仕上げ後のコースが60〜65本/25.4mmのもの、または起毛高さが略1mm、生機から仕上げの収縮率がコースで20%以上、とくに20〜40%となるように製造されたものが好ましい。いずれの場合でも、起毛高さが0.3mm以下では面ファスナー雄部材のフックがループに引っかからず、係合することができず、また1.5mm以上ではカールしやすくなる。 The French pile of the present invention is a structure in which a polyurethane (Pu) yarn is inserted into a warp knitting (tricot) structure of polyamide (Ny) yarn or polyester yarn, and a two-way warp knitted fabric having stretchability in the vertical and horizontal directions. It is manufactured by heat setting, dyeing, and heat setting finishing. The material, thickness, knitting structure, raising method, etc. of the yarn used are not limited, but the raising height is about 1 mm, the finished course is 60-65 / 25.4 mm, or the raising height is It is preferably about 1 mm and manufactured from the raw machine so that the finishing shrinkage is 20% or more, especially 20 to 40%. In any case, when the raised height is 0.3 mm or less, the hook of the hook-and-loop fastener male member is not caught by the loop and cannot be engaged, and when the raised height is 1.5 mm or more, curling tends to occur.

本発明のソフトサポーターの構造は、とくに限定されないが、例えば、膝装具に適用した場合には、ほぼ四角形状に形成され、上辺は下辺より若干長く、左右側辺のほぼ中央にほぼ凹所を備えた本体に、一方の側辺の末端近傍の内側には面ファスナーが取り付けられる。面ファスナーを取り付けた他方の側辺の表側が面ファスナーと係合する。 The structure of the soft supporter of the present invention is not particularly limited. For example, when applied to a knee brace, the soft supporter is formed in a substantially rectangular shape, the upper side is slightly longer than the lower side, and a recess is formed in the approximate center of the left and right side sides. A hook-and-loop fastener is attached to the inside of the main body provided near the end of one side. The front side of the other side to which the hook-and-loop fastener is attached engages with the hook-and-loop fastener.

以下、本発明を実施例により具体的に説明する(図1〜4参照)。 Hereinafter, the present invention will be specifically described with reference to Examples (see FIGS. 1 to 4).

(サンプルの作成)

試作したフレンチパイルは、糸と編み組織を、フロント(F)層が10本のマルチフィラメントからなるナイロン105/ハーフトリコット編み、ミドル(M)層がモノフィラメントからなるナイロン15/ハーフトリコットまたはデンビー編み、バック(B)層がポリウレタン糸/デンビー編みとした3枚筬による3層編地を生機とした。フロント、バック、ミドルの3層構造のうち、バック層の糸のみは異方向に入っている。

(Create sample)

The prototype French pile has a yarn and knitting structure, nylon 105 / half tricot knitted with 10 multifilaments in the front (F) layer,

次に、この生機に、起毛、中間セット、染色、セットを行って仕上げた。すなわち、まず生機を起毛機の針布ローラに通し生機の糸を引き出しループを形成させる。次に、起毛によって収縮した生地に加熱しながら幅方向に張力を与えて幅を整えて中間セットする。次に常温染色機に投入して精錬・染色する。最後に脱水・乾燥を行い、熱を加えながら幅やシワを整える最終セット工程を加えて仕上げを完了する。 Next, the raw machine was finished by raising, intermediate setting, dyeing and setting. That is, first, the raw machine is passed through the raising cloth of the raising machine, and the yarn of the green machine is drawn out to form a loop. Next, while heating the fabric shrunk by raising, tension is applied in the width direction to adjust the width, and the intermediate set is performed. Next, it is put into a room temperature dyeing machine and refined and dyed. Finally, dehydration and drying are performed, and the finishing is completed by adding a final setting process that adjusts the width and wrinkles while applying heat.

このフレンチパイルに、圧縮ポリウレタンを芯材に、マイクロジャージを裏材とし、接着剤を使用してラミネートした。芯材の圧縮ポリウレタンは、アキレス社製、品番:FJ(密度40.0±3.0kg/m3(JISK7222)、硬さ110±21N(JISK6400−2)、引っ張り強さ75kPa(JISK6400−5)、伸び300%(JISK6400−5)、反発弾性45%(JISK6400−3)、圧縮残留ひずみ4.0%(JISK6400−4)、繰り返し圧縮残留ひずみ2.0%(JISK6400−4))を7mmにスライスし、これを1.5mmに高密度圧縮した。裏材のマイクロジャージは、混率がポリウレタン糸(40d)20%、ポリアミド糸(40d/34f)、目付はコース64〜66本/25.4mm、ウェール53〜55本/25.4mmである。

接着剤は、大日精化(株)製、透湿防水素材、ハイムレンY-119(E)を使用し、塗工量は60g/m2である。ラミネートしたサンプルは、電子顕微鏡で観察して接着剤が含浸した領域でフィラメントの抜けがないことを確認した。

This French pile was laminated using a compression polyurethane as a core material, a micro jersey as a backing material, and an adhesive. Compressed polyurethane as a core material is manufactured by Achilles, product number: FJ (density 40.0 ± 3.0 kg / m 3 (JISK7222), hardness 110 ± 21 N (JISK6400-2), tensile strength 75 kPa (JISK6400-5) , Elongation 300% (JISK6400-5), impact resilience 45% (JISK6400-3), compression residual strain 4.0% (JISK6400-4), repeated compression residual strain 2.0% (JISK6400-4)) to 7 mm Sliced and compacted to 1.5 mm. The backing microjersey has a blending ratio of 20% polyurethane yarn (40d), polyamide yarn (40d / 34f), and a basis weight of 64 to 66 yarns / 25.4 mm and a wale of 53 to 55 yarns / 25.4 mm.

The adhesive used is Dainichi Seika Co., Ltd., a moisture permeable and waterproof material, Heimlen Y-119 (E), and the coating amount is 60 g / m 2 . The laminated sample was observed with an electron microscope, and it was confirmed that there was no missing filament in the region impregnated with the adhesive.

得られたラミネートから、各辺が経編地の流れ、幅方向に平行になるように80mm×80mmにカットし、スチームアイロンでセットして形態を安定化させて評価用のサンプルとした(図1参照)。 The obtained laminate was cut into 80 mm × 80 mm so that each side is parallel to the flow of the warp knitted fabric and in the width direction, and set with a steam iron to stabilize the form to obtain a sample for evaluation (see FIG. 1).

(評価方法)

(1)カール角度の評価

評価に使用した面ファスナー雄部材は市販のクラレ(株)製、マジックテープ(登録商標)A2600を使用した。A2600はフック糸が220d/1f、タテ糸が110d/24f、よこ糸が220d/48fのナイロン66製のフィラメントを使用し、タテ糸密度170本以上/25mm、よこ糸密度52±2本/25mm、厚さが1.85±0.15mmで、フックの高さは1.95±0.15mmで1.6mmと1.1mmの高さでカットされており、フック本数が55〜60個/cm2、水性の樹脂によってバックコーテイングされている。この面ファスナーを幅20mmのテープ状にカットして評価に使用した。

(Evaluation methods)

(1) Evaluation of curl angle The commercially available Kuraray Co., Ltd. make and magic tape (trademark) A2600 were used for the surface fastener male member used for evaluation. A2600 uses nylon 66 filaments with hook yarn of 220d / 1f, warp yarn of 110d / 24f, and weft yarn of 220d / 48f, warp yarn density of 170 threads / 25mm,

A2600を試作したフレンチパイルと係合したとき、実施例1のものでは引っ張りせん断強さが幅方向で6.5N/cm2、剥離強さが2.5N/cm、その他のものでは引っ張りせん断強さが6.0〜8.0N/cm2、剥離強さが2.0〜3.5N/cmであった。 When engaged with the French pile produced as a prototype of A2600, the tensile shear strength in the width direction in Example 1 was 6.5 N / cm 2 , the peel strength was 2.5 N / cm, and in other cases, the tensile shear strength was Saga 6.0~8.0N / cm 2, the peeling strength was 2.0~3.5N / cm.

図1,2に評価の状況を模式的に示す。図1は本発明のソフトサポーターの評価方法に関する説明図、図2はカール角度測定の説明図であって、(a)はサンプルの上面図、(b)は側面図を示す。サンプル10をテーブル上に置き、両側を押さえ、面ファスナー雄部材20を中央部の同一個所に、負荷荷重0.5±0.2N/cm2で押し付け、面ファスナーの長手方向の一端から引き剥がした(図1)。この操作を1秒間に2回の割合で繰り返した。また面ファスナーの着脱方向はフレンチパイルの流れ方向、幅方向を別々に行った。 1 and 2 schematically show the evaluation situation. FIG. 1 is an explanatory diagram regarding a method for evaluating a soft supporter of the present invention, FIG. 2 is an explanatory diagram of curl angle measurement, (a) is a top view of a sample, and (b) is a side view. Place the sample 10 on a table, hold both sides, press the male fastener 20 on the same part in the center with a load of 0.5 ± 0.2 N / cm 2 , and peel off from the longitudinal end of the fastener. (FIG. 1). This operation was repeated twice per second. In addition, the direction of attaching and detaching the hook-and-loop fastener was performed separately for the flow direction and the width direction of the French pile.

着脱500回後のサンプル10をテーブル上に静置してカール角度を測定した(図2)。本評価方法によれば着脱を繰り返したサンプルは面ファスナー雄部材との係合面を内側にして当該部分がカールし、カールが生じた係合面の両側は曲面形状に変形することなく、ほぼ初期の平面形状を維持するので、再現性よくカールの量(カール角度)を定量的に評価することができる。 The sample 10 after 500 attachments / detachments was left on the table and the curl angle was measured (FIG. 2). According to this evaluation method, the sample repeatedly attached and detached is curled with the engagement surface with the surface fastener male member facing inward, and the both sides of the engagement surface where the curl is generated are substantially deformed without being deformed into a curved shape. Since the initial planar shape is maintained, the curl amount (curl angle) can be quantitatively evaluated with good reproducibility.

(2)装着性の評価

カール角度を測定した素材を使用してソフトサポーターを作成し、500回装着を繰り返したときの装着性を下記基準で評価した。

○:装着に支障がない。

×:装着に支障がある。

ここで、装着に支障があるとは、サポーター本体生地がカールして適切な位置に係合させるために手間がかかったり、さらにはサポーター本体生地が収縮したため装着時に面ファスナー雄部材が直接皮膚に当って不快感を生じることである。装着に支障がないとはこれらの問題が感じられないことである。

(2) Evaluation of wearability A soft supporter was created using a material whose curl angle was measured, and the wearability when wearing was repeated 500 times was evaluated according to the following criteria.

○: There is no problem in wearing.

×: There is a problem in wearing.

Here, the trouble in wearing means that the supporter body cloth curls and engages in an appropriate position, and further, the supporter body cloth shrinks, so that the male member of the surface fastener is directly applied to the skin at the time of wearing. It will cause discomfort. If there is no problem in wearing, these problems cannot be felt.

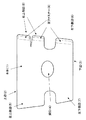

図3は装着性の評価を行った膝関節装具の平面図である。膝関節装具の本体1は、フレンチパイルをラミネートとした1枚の生地から形成され、全体として上辺2が下辺3より若干長いほぼ台形状である。身体の膝に対応してほぼ中央に開口4が設けられ、大腿部に対応して左上側辺5と右上側辺6が,下腿部に対応して左下側辺7と右下側辺8が帯状に形成されている。右上側辺6は装着を容易にするため上下に二分割されている。上側辺5,6と下側辺7,8は膝部の屈曲に対応して所定距離離間している。右側辺6,8の端部近傍の裏面には面ファスナー雄部材としての面ファスナーA2600(9)が取り付けられ、それぞれの面ファスナー雄部材の寸法は、大腿部では上下とも幅35mm、長さ70mm、下腿部では幅35mm、長さ100mmである。身体に巻きつけたとき、それぞれの面ファスナー雄部材9を左側辺5,7の表地と係合させて装着する。

FIG. 3 is a plan view of a knee joint orthosis that has been evaluated for wearability. The

(評価の結果)

実施例と比較例の構造、製法、評価結果を図4に示す。なお比較例は市販品である。

(As a result of evaluation)

FIG. 4 shows structures, production methods, and evaluation results of Examples and Comparative Examples. The comparative example is a commercial product.

各条件においてカール角度のバラツキは約±10°であった。着脱の方向(流れ、幅)による有為な差はなかった。実施例のサンプルでは市販品に比べてカール角度が顕著に低減した。 In each condition, the variation in curl angle was about ± 10 °. There was no significant difference depending on the direction of attachment / detachment (flow, width). In the sample of the example, the curl angle was remarkably reduced as compared with the commercially available product.

実施例のラミネートを使用したソフトサポーターでは、500回脱着を繰り返した後も、すべて良好な装着性が得られた。 In the soft supporter using the laminate of the example, good mounting properties were obtained even after repeated desorptions 500 times.

また良好な装着性が得られたものでは、使用したフレンチパイルが、起毛高さが略1mmであって、生機幅から仕上げ幅の収縮率が20〜40%で製造されたものであった。とくに収縮率が27%となるように製造されたサンプルでは最も好ましい結果が得られた。 In the case where good wearability was obtained, the French pile used was manufactured with a raised height of about 1 mm and a shrinkage ratio of 20 to 40% from the raw machine width to the finished width. In particular, the most preferable result was obtained in the sample manufactured so that the shrinkage rate was 27%.

収縮率によってカール角度が異なるメカニズムは不明だが、例えば、次のように推論できる。フレンチパイルのループは地組織に固着されているが、面ファスナー雄部材のフックとの着脱を繰り返すと、ループが上方に引き出され、上方に引き出された長さだけ面内方向では短くなる。ラミネートでは裏打ちされた素材には変化はない。このため表裏で長さが不揃いとなり、この差がカールとなって現れる。所定の収縮率を有するフレンチパイルでは地組織のフィラメントに余裕があるため、面ファスナー雄部材のフックによってフレンチパイルのループが引き出されても、ただちに面内方向の長さが変化しにくいため、カールも生じにくいと考えられる。 The mechanism by which the curl angle varies depending on the shrinkage rate is unknown, but can be inferred as follows, for example. The loop of the French pile is fixed to the ground structure, but when the hook and loop of the hook-and-loop fastener male member is repeatedly attached and detached, the loop is drawn upward and shortened in the in-plane direction by the length drawn upward. In the laminate, the backed material remains the same. For this reason, the lengths are uneven on the front and back sides, and this difference appears as a curl. A French pile with a predetermined shrinkage has a margin in the filament of the ground tissue, so even if the French pile loop is pulled out by the hook of the hook-and-loop fastener male member, the length in the in-plane direction is not easily changed. Is also unlikely to occur.

また、カールが生じやすいフレンチパイルでは、面ファスナー雄部材のフックとの着脱を繰り返すと、ループが上方に引き出されやすいだけでなく、ループの先端が破断して面ファスナー雄部材との係合力を失いやすい。したがって、上記カールが生じにくいフレンチパイルはラミネートの有無にかかわらず、面ファスナーとの係合に適すると考えられる。 In addition, in a French pile where curling is likely to occur, if the hook and loop of the hook-and-loop fastener male member are repeatedly attached and detached, not only the loop is easily pulled upward, but also the loop tip breaks and the engaging force with the hook-and-loop fastener male member is increased. Easy to lose. Therefore, it is considered that the French pile that is less likely to curl is suitable for engagement with a hook-and-loop fastener regardless of whether or not there is a laminate.

1:本体、2:上辺、3:下辺、4:開口、5:左上側辺、6:右上側辺、7:左下側辺、8:右下側辺、9:面ファスナー、10:サンプル、20:面ファスナー雄部材。 1: main body, 2: upper side, 3: lower side, 4: opening, 5: upper left side, 6: upper right side, 7: lower left side, 8: lower right side, 9: hook-and-loop fastener, 10: sample, 20: A surface fastener male member.

Claims (7)

剛軟性が、JIS L1096に規定するカンチレバー法によって測定したときに60〜140mmであって、

表地であるフレンチパイルと係合したときの幅方向の引っ張りせん断強さが6.0〜8.0N/cm2、剥離強さが2.0〜3.5N/cmとなる面ファスナー雄部材を、表地であるフレンチパイルに、負荷荷重0.5±0.2N/cm2で押し付け、着脱を500回繰り返したときに、当該係合した部分において生じるカール角度が60度以下である

ことを特徴とするソフトサポーター。 In the soft supporter that engages and attaches the surface fastener male member and the French pile that is the outer surface of the main body, the main body includes:

The bending resistance is 60 to 140 mm when measured by the cantilever method specified in JIS L1096,

A surface fastener male member having a tensile shear strength in the width direction of 6.0 to 8.0 N / cm 2 and a peel strength of 2.0 to 3.5 N / cm when engaged with a French pile as an outer material. The curl angle generated in the engaged portion is 60 degrees or less when the outer pile is pressed against the French pile at a load of 0.5 ± 0.2 N / cm 2 and is repeatedly attached and detached 500 times. Soft supporter.

起毛高さが略1mm、生機から仕上げの収縮率がコースで20%以上であることを特徴とするソフトサポーター用フレンチパイルの製造方法。 In the manufacturing method of the French pile used by engaging with the surface fastener male member as the body surface of the soft supporter,

A method for producing a French pile for a soft supporter, wherein the raised height is about 1 mm, and the shrinkage rate from the raw machine to the finish is 20% or more in the course.

The method of manufacturing a French pile for a soft supporter according to claim 6, wherein the shrinkage of finishing from the raw machine is 20 to 40% in the course.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005347806A JP2007151663A (en) | 2005-12-01 | 2005-12-01 | Soft supporter, and manufacturing method for french pile for the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005347806A JP2007151663A (en) | 2005-12-01 | 2005-12-01 | Soft supporter, and manufacturing method for french pile for the same |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2007151663A true JP2007151663A (en) | 2007-06-21 |

Family

ID=38236778

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005347806A Pending JP2007151663A (en) | 2005-12-01 | 2005-12-01 | Soft supporter, and manufacturing method for french pile for the same |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2007151663A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016533828A (en) * | 2013-09-02 | 2016-11-04 | ミレー イノベーション | Hand braces to support the thumb, especially in the case of thumb CM arthropathy |

| WO2017157537A1 (en) * | 2016-03-14 | 2017-09-21 | Velcro BVBA | Installing printed media |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003290272A (en) * | 2002-04-04 | 2003-10-14 | Alcare Co Ltd | Supporter |

| JP2004236811A (en) * | 2003-02-05 | 2004-08-26 | Alcare Co Ltd | Ankle supporter |

| JP2004242764A (en) * | 2003-02-12 | 2004-09-02 | Alcare Co Ltd | Ankle joint orthosis |

-

2005

- 2005-12-01 JP JP2005347806A patent/JP2007151663A/en active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003290272A (en) * | 2002-04-04 | 2003-10-14 | Alcare Co Ltd | Supporter |

| JP2004236811A (en) * | 2003-02-05 | 2004-08-26 | Alcare Co Ltd | Ankle supporter |

| JP2004242764A (en) * | 2003-02-12 | 2004-09-02 | Alcare Co Ltd | Ankle joint orthosis |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2016533828A (en) * | 2013-09-02 | 2016-11-04 | ミレー イノベーション | Hand braces to support the thumb, especially in the case of thumb CM arthropathy |

| WO2017157537A1 (en) * | 2016-03-14 | 2017-09-21 | Velcro BVBA | Installing printed media |

| CN109074771A (en) * | 2016-03-14 | 2018-12-21 | 维尔克有限公司 | Printed medium is installed |

| CN109074771B (en) * | 2016-03-14 | 2021-04-13 | 维尔克有限公司 | Mounting print media |

| US11027566B2 (en) | 2016-03-14 | 2021-06-08 | Velcro Ip Holdings Llc | Installing printed media |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI516253B (en) | Support | |

| JP5777557B2 (en) | Supporter | |

| US20200196707A1 (en) | Article of footwear with composite upper | |

| JP6544774B2 (en) | Supporter | |

| JP4837324B2 (en) | Laminate sheet for body | |

| JP5013284B1 (en) | Double raschel knitted fabric with piles protruding from the surface of the knitted fabric | |

| TW201538139A (en) | Wrist joint bandage | |

| JP2006219776A (en) | Human body supporting member | |

| JP2007151663A (en) | Soft supporter, and manufacturing method for french pile for the same | |

| JP2001037794A (en) | Assisting implement for body, such as lumbago belt | |

| US20200032435A1 (en) | Warp-Knitted Fabric And Elastic Article | |

| JP2013019074A (en) | Method for manufacturing warp knitted fabric and warp knitted fabric | |

| JP6414643B2 (en) | Bottom clothing | |

| EP3435942B1 (en) | A limb compression garment for applying a compressive force to a limb | |

| JP3741210B2 (en) | Supporter | |

| JP4436911B2 (en) | Three-dimensional warp knitted fabric with stretchability and breathability | |

| JP6018673B2 (en) | Supporter | |

| JP3237012U (en) | Supporter | |

| JPH0510407U (en) | Corset | |

| JP2017093741A (en) | Joint orthosis | |

| JP3217275U (en) | Fixing belt | |

| JP6829042B2 (en) | Waist belt mesh fabric and its manufacturing method | |

| JP2001049558A (en) | Knit for tool for assisting body such as belt for low back pain, and its knitting | |

| WO2011148714A1 (en) | Garment having waist section | |

| JP2009018018A (en) | Body belt used in a state of butting against body |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081128 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20100125 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100205 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20100212 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110209 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110607 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20111018 |