JP2007010061A - Travel speed variable device - Google Patents

Travel speed variable device Download PDFInfo

- Publication number

- JP2007010061A JP2007010061A JP2005192262A JP2005192262A JP2007010061A JP 2007010061 A JP2007010061 A JP 2007010061A JP 2005192262 A JP2005192262 A JP 2005192262A JP 2005192262 A JP2005192262 A JP 2005192262A JP 2007010061 A JP2007010061 A JP 2007010061A

- Authority

- JP

- Japan

- Prior art keywords

- speed

- reverse

- increase

- hydraulic pump

- amount

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Harvester Elements (AREA)

- Control Of Fluid Gearings (AREA)

Abstract

Description

この発明は、コンバイン等の車輌に利用される走行変速装置に関するものである。 The present invention relates to a travel transmission used for a vehicle such as a combine.

従来より、例えばコンバイン等の作業車輌においては、変速レバーの前後傾動操作によって油圧式無段変速装置を正逆転方向に無段変速して前後進を行うのであるが、作業をしながら走行する前進走行状態から、作業をせずに走行する後進走行状態へ切り換えた際には、この後進走行を機敏に行って移動し、作業能率を向上させることが要望されてきた。 Conventionally, in a working vehicle such as a combine, for example, a hydraulic continuously variable transmission is continuously shifted in the forward / reverse direction by a forward / backward tilting operation of a shift lever, and forward and backward travel is performed. When switching from a traveling state to a reverse traveling state in which the vehicle travels without performing work, it has been desired to improve the work efficiency by moving the advancing backward in an agile manner.

そこで、例えば特許文献1に示すように、走行装置を伝動する油圧無段変速装置において、変速伝動の中立位置から前進側と後進側とへ各々回動操作して順次高速伝動比に変速する変速レバーの、該油圧無段変速装置の変速伝動比を一定比変化させるために要する前進側の変速操作角を、後進側の変速操作角よりも大きく設定する技術が試みられている。

しかしながら、上述の特許文献1記載の構成において、油圧式無段変速装置の油圧モータ側には変速手段を備えておらず、該油圧モータの出力回転を、油圧ポンプの吐出油量の増加による増速以外に増速させる手段はない。 However, in the configuration described in Patent Document 1 described above, the hydraulic motor side of the hydraulic continuously variable transmission is not provided with a transmission means, and the output rotation of the hydraulic motor is increased by increasing the amount of oil discharged from the hydraulic pump. There is no means to increase speed other than speed.

従って、変速レバーの操作量に応じた油圧モータの出力回転を得るためには、この変速レバーから油圧ポンプの吐出油量を調節する斜盤角度調節アームまでを連繋するリンク機構のリンク比を、前進側と後進側とで変更して設定せねばならない。 Therefore, in order to obtain the output rotation of the hydraulic motor according to the operation amount of the speed change lever, the link ratio of the link mechanism that links from this speed change lever to the swash plate angle adjustment arm that adjusts the discharge oil amount of the hydraulic pump, It must be changed and set between the forward side and the reverse side.

このような対策を講じない場合には、変速レバーを一定量だけ後進側に操作した場合、この変速レバーを前進側に同量操作した場合と同じ速度でしか後進走行できず、前述のような作業能率の向上を達することができない。 If such a measure is not taken, when the shift lever is operated backward by a certain amount, the shift lever can be driven backward only at the same speed as when the shift lever is operated forward by the same amount. Improve work efficiency.

この発明は、上述の如き課題を解決するために、次のような技術的手段を講じる。

即ち、請求項1記載の発明は、可変容量型の油圧ポンプ(1)と可変容量型の油圧モータ(2)とから油圧式無段変速装置(3)を構成し、変速操作具(4)の中立域からの前後進変速操作量の増加に応じて前記油圧ポンプ(1)の吐出油量を増加させて油圧モータ(2)の出力回転を正逆転方向に増速させるように連繋すると共に、該変速操作具(4)の後進操作に関連して前記油圧モータ(2)の出力回転を前記油圧ポンプ(1)の吐出油量の増加による増速量よりも大きい増速量で逆転方向に増速させることのできる連繋手段(5)を設けたことを特徴とする走行変速装置としたものである。

In order to solve the above-mentioned problems, the present invention takes the following technical means.

That is, according to the first aspect of the present invention, a hydraulic continuously variable transmission (3) is constituted by a variable displacement hydraulic pump (1) and a variable displacement hydraulic motor (2), and a transmission operation tool (4). As the amount of oil discharged from the hydraulic pump (1) increases in response to an increase in the forward / reverse shift operation amount from the neutral range, the output rotation of the hydraulic motor (2) is increased in the forward / reverse direction. In the reverse direction, the output rotation of the hydraulic motor (2) is reversed with a speed increase amount greater than the speed increase amount due to the increase in the discharge oil amount of the hydraulic pump (1) in relation to the reverse operation of the speed change operation tool (4). The present invention is a travel transmission device characterized in that a connecting means (5) capable of increasing the speed is provided.

しかして、変速操作具4を中立域から前進側へ操作すると、油圧ポンプ1の吐出油量が増加してこの吐出油を受ける油圧モータ2の出力回転が正転方向に増速し、この走行変速装置を搭載する車体は前進方向へ増速される。一方、変速操作具4を中立域から後進側へ操作すると、油圧ポンプ1の吐出油量が増加すると共に、連繋手段5によって油圧モータ2の出力回転が前記油圧ポンプ1の吐出油量の増加による増速量よりも大きい増速量で逆転方向に増速され、この走行変速装置を搭載する車体は後進方向へ機敏に増速される。

Thus, when the transmission operating tool 4 is operated from the neutral range to the forward side, the amount of oil discharged from the hydraulic pump 1 increases, and the output rotation of the

また、請求項2記載の発明は、可変容量型の油圧ポンプ(1)と可変容量型の油圧モータ(2)とから油圧式無段変速装置(3)を構成し、変速操作具(4)の中立域からの前後進変速操作量の増加に応じて前記油圧ポンプ(1)の斜盤角度を調節して該油圧ポンプ(1)の吐出油量を増加させて油圧モータ(2)の出力回転を正逆転方向に増速させるように連繋すると共に、該変速操作具(4)の後進操作に関連して前記油圧モータ(2)の斜盤角度を自動的に調節して該油圧モータ(2)の出力回転を前記油圧ポンプ(1)の斜盤角度の調節による増速量よりも大きい増速量で逆転方向に増速させることのできる連繋手段(5)を設けたことを特徴とする走行変速装置としたものである。 According to a second aspect of the present invention, a hydraulic continuously variable transmission (3) is constituted by a variable displacement hydraulic pump (1) and a variable displacement hydraulic motor (2), and a transmission operation tool (4). Output of the hydraulic motor (2) by adjusting the swash plate angle of the hydraulic pump (1) in accordance with an increase in the forward / reverse speed change operation amount from the neutral range, and increasing the amount of oil discharged from the hydraulic pump (1). The hydraulic motor (2) is linked to increase the rotation speed in the forward / reverse direction and automatically adjusts the swash plate angle of the hydraulic motor (2) in relation to the reverse operation of the speed change operation tool (4). Characterized in that there is provided linking means (5) capable of increasing the output rotation of 2) in the reverse direction by a speed increase amount larger than the speed increase amount by adjusting the swash plate angle of the hydraulic pump (1). This is a traveling transmission device.

しかして、変速操作具4を中立域から前進側へ操作すると、油圧ポンプ1の斜盤角度が大きくなり、該油圧ポンプ1の吐出油量が増加してこの吐出油を受ける油圧モータ2の出力回転が正転方向に増速し、この走行変速装置を搭載する車体は前進方向へ増速される。一方、変速操作具4を中立域から後進側へ操作すると、油圧ポンプ1の斜盤角度が大きくなって該油圧ポンプ1の吐出油量が増加すると共に、連繋手段5によって油圧モータ2の斜盤角度が自動的に小さくなって該油圧モータ2の出力回転が前記油圧ポンプ1の吐出油量の増加による増速量よりも大きい増速量で逆転方向に増速され、この走行変速装置を搭載する車体は後進方向へ機敏に増速される。

Accordingly, when the speed changer 4 is operated from the neutral range to the forward side, the swash plate angle of the hydraulic pump 1 increases, the amount of oil discharged from the hydraulic pump 1 increases, and the output of the

請求項1記載の発明によると、変速操作具4の後進側への操作によって、油圧モータ2の出力回転を油圧ポンプ1の吐出油量の増加による増速量よりも大きい増速量で逆転方向に増速して、この走行変速装置を搭載する車体を後進方向へ機敏に増速させることができ、例えば前進による作業走行と後進による非作業走行とを繰り返すような作業形態において作業能率を向上させることができる。

According to the first aspect of the invention, the reverse rotation direction of the output rotation of the

また、請求項2記載の発明によると、変速操作具4の後進側への操作に連繋した油圧モータ2の斜版角度の自動的な調節によって、油圧モータ2の出力回転を油圧ポンプ1の吐出油量の増加による増速量よりも大きい増速量で逆転方向に増速して、この走行変速装置を搭載する車体を後進方向へ機敏に増速させることができ、例えば前進による作業走行と後進による非作業走行とを繰り返すような作業形態において作業能率を向上させることができる。

According to the second aspect of the present invention, the output rotation of the

この発明における走行変速装置の実施の形態を、自脱型コンバインを例示して説明する。

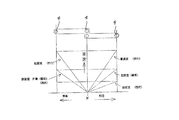

図1、図2に示すように、このコンバインは、クローラ6を巻回した左右の走行装置7,7の上側に、操縦部8と脱穀装置9と穀粒貯留装置10とを搭載し、前記脱穀装置9の前側に刈取装置11を刈取上下用油圧シリンダ12の伸縮作動によって昇降調節自在に設けて構成する。

An embodiment of a traveling transmission apparatus according to the present invention will be described by exemplifying a self-detaching combine.

As shown in FIGS. 1 and 2, this combine is equipped with a

前記刈取装置11は、機体の前部に立設した刈取懸架台13の上部に、刈取後フレーム13の後側上端部を上下回動自在に支持し、該刈取後フレーム13の前側下端部側に、分草杆14と引起装置15と掻込装置16と株元搬送装置17と刈刃装置18とから成る刈取前処理装置を設けて構成する。

The

前記脱穀装置9は、上部の扱室に内装軸架した扱胴19および処理胴20と、該扱室の後側に軸架した排塵ファン21と、下部の選別室に内装した揺動選別棚22と唐箕23と一番螺旋24と二番螺旋25と、前記一番螺旋24に連動する一番揚穀螺旋26と前記二番螺旋25に連動する二番揚穀螺旋27とから構成する。

The threshing device 9 includes a handling cylinder 19 and a

前記穀粒貯留装置10は、タンク本体の底部に軸架した底部搬送螺旋28と該底部搬送螺旋28に連動してタンク本体の後側において穀粒を揚穀する揚穀螺旋29と、該揚穀螺旋29の上端部に上下回動自在に連動する排出螺旋30とから構成する。

The grain storage device 10 includes a bottom conveying spiral 28 pivoted on the bottom of the tank body, a cerealing spiral 29 for cerealing grains on the rear side of the tank body in conjunction with the

前記左右の走行装置7,7は、ミッションケース31から駆動される左右の駆動輪32,32及びこの後方に配置する複数の転輪33,33群に対して左右のクローラ6,6を巻回して構成する。

The left and right

図2に示すように、前記ミッションケース31内においては、上部の入力軸34に対して副変速ギヤ35を軸方向に摺動のみ自在に設け、該副変速ギヤ35を、入力軸34の下手側に配置した中間軸36に固定する変速ギヤ37群に対して択一的に噛み合わせることによって、高速(走行)、中速(標準)、低速(倒伏)の3段の副変速機構38を構成する。該副変速ギヤ35の摺動は、前記操縦部8に設ける副変速レバー39の前後傾動操作によって行われる構成とする。更に、前記中間軸36に固定した出力ギヤ40を下手側のサイドクラッチ軸41の中央部に設けたセンターギヤ42に噛み合わせ、該センターギヤ42の左右両側に左右のサイドクラッチギヤ43,43を係合離脱摺動自在に設け、該左右のサイドクラッチギヤ43,43の外側にサイドブレーキ44,44を配置する。そして、更に下手側に設ける左右の車軸45,45の内側端部に固定したホイルギヤ46,46を前記左右のサイドクラッチギヤ43,43に噛み合わせる。前記駆動輪32,32は前記左右の車軸45,45の外側端部に固定する。

As shown in FIG. 2, in the

また、前記ミッションケース31の上部外側には、分岐伝動ケース47を取り付け、該分岐伝動ケース47内において、前記入力軸34の突出端側に固定したギヤ48と、中間のフィードチェン駆動軸49に固定した中間ギヤ50と、静油圧式無段変速装置(油圧式無段変速装置)3の出力軸51をスプライン連結した軸に設けるギヤ52とを噛み合わせて設ける。

Further, a

前記ミッションケース31の上部の入力軸34の突出端には、ワンウェイクラッチ53を介して刈取出力プーリ54を取り付け、一方、前記刈取装置11における刈取後フレーム13の後上端部に配置した刈取入力プーリ55との間に刈取伝動ベルト56を巻き掛けてテンション式の刈取クラッチを構成する。また、前記フィードチェン駆動軸49の突出はにフィードチェン出力プーリ57を取り付け、フィードチェン伝動軸58の内端部にワンウェイクラッチ59を介して取り付けた入力プーリ60との間に伝動ベルト61を巻き掛け、該伝動ベルト61に張力を付与するテンションローラ62を設けてフィードチェンクラッチ63を構成する。

A cutting output pulley 54 is attached to the protruding end of the

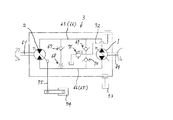

そして、前記分岐伝動ケー47の上部内側に静油圧式無段変速装置3を取り付ける。該静油圧式無段変速装置3は、図3に示すように、入力軸64によって駆動されて作動油を吐出するプランジャ型の油圧ポンプ1と、該油圧ポンプ1からの吐出油を受けて出力軸51を駆動回転させるプランジャ型の油圧モータ2との間を、前進側(正転側)の高圧油路65と後進側(逆転側)の低圧油路66とによって接続して閉回路を形成した構成である。また、該高圧油路65と低圧油路66との間を、逆止弁67および絞り弁68を直列に接続した油路で短絡すると共に、高圧油路65と低圧油路66との夫々から逆向きの逆止弁69,70を介してリリーフバルブ71を下手に有するチャージ油路72に接続する。該チャージ油路72は前述の閉回路のリーク油をオイルタンク73から補給するためのものである。また、前記油圧ポンプ1と油圧モータ2とは、夫々、内部の斜盤の角度を調節することにより、プランジャの容量が変更されて、吐出油量および吸込油量が変更できる構成とし、前記油圧ポンプ1の斜盤角度は、前記操縦部8に設ける主変速レバー4の前後傾動により、リンク機構を介して変更されるように機械的に連繋する。また、前記油圧モータ2の斜盤角度は、電動モータ式のHSTモータ斜盤切り換えアクチュエータ74の作動によって連動ロッド75を介して操作されるように構成する。

The hydrostatic continuously

更に、前記静油圧式無段変速装置3の入力軸64の突出端部には、該静油圧式無段変速装置3用の冷却ファン76を取り付け、該入力軸64の突出中間部には、エンジンEの出力軸77から出力プーリ78と伝動ベルト79とを介して駆動力が入力される入力プーリ80を取り付ける。また、前記出力軸77に取り付けた脱穀出力プーリ81からベルト伝動機構82を介して、前記扱胴19、処理胴20、排塵ファン21、揺動選別棚22、唐箕23、一番螺旋24、二番螺旋25を連動して駆動するように構成する。また、前記出力軸77に取り付けた排出出力プーリ83からベルト伝動機構82等を介して前記底部搬送螺旋28を連動して駆動するように構成する。

Further, a cooling

また、前記操縦部8の側部操作パ85に立設する副変速レバー39から副変速ロッド84を介して前記副変速ギヤ35を摺動させる副変速シフタ85を回動操作するように構成すると共に、前記主変速レバー4から主変速ロッド86を介して前記静油圧式無段変速装置3の油圧ポンプ1の斜盤角度を操作するように構成する。また、前記副変速レバー39の基部には、該副変速レバー39の操作位置を検出する副変速走行シフトセンサー87を設け、前記主変速レバー4の基部には該主変速レバー4の後進側傾動を検出する後進検出センサー88と、刈取クラッチレバー89の基部には該刈取クラッチレバー89が入り側に操作されたことを検出する刈取クラッチ入りセンサー90とを設ける。また、前記刈取後フレーム13の上下回動量から機体に対する刈取装置11の高さを検出する刈取高さ検出センサー91を設ける。

Further, the auxiliary transmission shifter 85 that slides the

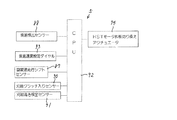

そして、図4に示すように、コントローラ92の入力側に、前記後進検出センサー88と、操縦部8の前部操作パネルに設ける後進速度設定ダイヤル93と、前記副変速走行シフトセンサー87と、刈取クラッチ入りセンサー90と、刈取高さ検出センサー91とを接続する一方、該コントローラ92の出力側に、前記HSTモータ斜盤切り換えアクチュエータ74を接続する。これが連繋手段5である。

As shown in FIG. 4, on the input side of the

以上の構成により、主変速レバー4を前進側に操作すると、主変速ロッド86を介して静油圧式無段変速装置3の油圧ポンプ1の斜盤角度が大きくなって吐出油量が増加し、油圧モータ2への送油量の増加によって該油圧モータ2の出力軸51が正転側に増速し、コンバインは前進側に増速する。

With the above configuration, when the main speed change lever 4 is operated forward, the swash plate angle of the hydraulic pump 1 of the hydrostatic continuously

一方、前記主変速レバー4を後進側に操作すると、この操作状態が後進検出センサー88によって検出され、コントローラ92から前記HSTモータ斜盤切り換えアクチュエータ74へ出力がなされて、油圧モータ2の斜盤角度が小さくなって1回転に必要な油量が減少し、この結果、該油圧モータ2の出力軸51が逆転側に増速し、コンバインは後進側に増速する。

On the other hand, when the main speed change lever 4 is operated to the reverse side, this operation state is detected by the

従って、後進時には油圧モータ2の斜盤角度が小さくなることにより、主変速レバー4の前進側への操作角度と後進側への操作角度とが同じであっても、油圧モータ2の出力軸51の出力回転速度は、前進側よりも後進側のほうが大きくなる。これによって、主変速レバー4の前進側への操作角度と後進側への操作角度とが同じであった場合には、前進走行速度よりも後進走行速度のほうが大きくなる。

Accordingly, the swash plate angle of the

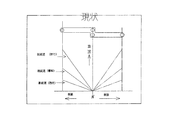

この状態を図5に示す。

該図5は、横軸を主変速レバー4の傾動操作位置とし、縦軸を車速としたグラフであり、前進走行側においては、副変速(走行)、副変速(標準)、副変速(倒伏)の二点鎖線のラインにて示すように、車速は各固定の異なった変速比率で直線的に上昇する。一方、後進走行側においては、副変速を副変速(走行)と副変速(標準)と副変速(倒伏)とのいずれの変速位置としても、実線のラインにて示すように、車速は一定の比率で直線的に上昇し、この上昇比率は、前記前進走行側における副変速(走行)と同等のものとなる。また、主変速レバー4を前進最高速位置にした状態での車速と、主変速レバー4を後進最高速位置にした状態での車速とは略同一に設定する。また、副変速(走行)での後進最高速度と副変速(標準)での後進最高速度とを略同一とすることにより、操縦者の速度感覚が副変速位置にかかわらずに略一定となり、操作の安全性が高まる。

This state is shown in FIG.

FIG. 5 is a graph in which the horizontal axis is the tilting operation position of the main shift lever 4 and the vertical axis is the vehicle speed. On the forward travel side, the sub-shift (running), the sub-shift (standard), and the sub-shift (slope) ), The vehicle speed increases linearly at different fixed speed ratios. On the other hand, on the reverse travel side, the vehicle speed is constant as shown by the solid line, regardless of whether the sub-shift is the sub-shift (travel), the sub-shift (standard), or the sub-shift (slope). The ratio increases linearly, and this increase ratio is equivalent to the sub-shift (travel) on the forward travel side. The vehicle speed when the main transmission lever 4 is in the forward highest speed position and the vehicle speed when the main transmission lever 4 is in the reverse highest speed position are set to be substantially the same. In addition, by making the maximum reverse speed at the sub-shift (travel) and the maximum reverse speed at the sub-shift (standard) substantially the same, the driver's speed sensation becomes substantially constant regardless of the sub-shift position. Increased safety.

また、前記後進速度設定ダイヤル93を操作することにより、前記後進走行側における車速の増速比率を任意に変更することができる。即ち、図5における実線のラインの勾配を任意に変更できるものである。これにより、操縦者の習熟度に応じて後進速度の増速率を調節でき、安全性および作業能率を向上させることができる。尚、この実線のラインの勾配の変更範囲は、所定の幅に規制するとよい。

Further, by operating the reverse

尚、前記後進速度設定ダイヤル93は、操縦部8の前側操作パネル上において、外側寄り位置に立設する操向操作レバーと、中央部のモニターとの間に配置するとよい。また、該ダイヤルの周囲に沿って、「高」、「中」、「低」の文字を表示する。

The reverse

また、前記副変速レバー39を「走行」の位置に操作した場合には、この操作位置を副変速走行シフトセンサー87によって検出し、前述のように主変速レバー4が後進側に操作された場合に、コントローラ92からHSTモータ斜盤切り換えアクチュエータ74への出力が規制されて、油圧モータ2の斜盤角度が小さくならないか又は僅かしか小さくならないように制御される。これにより、後進時の増速比率を低く抑えて、高速後進による危険を回避すると共に、油圧モータ2の斜盤角度が小さくなることによる該油圧モータ2の出力トルクの低下を抑えてコンバインが走行不能の状態に陥るのを防止することができる。

When the

また、図6に示すように、後進時において、副変速(倒伏)の場合の増速比率を、副変速(標準)の場合の増速比率に合わせるように、前記コントローラ92からHSTモータ斜盤切り換えアクチュエータ74への出力を設定してもよい。これにより、副変速(倒伏)による後進走行速度が副変速(標準)による後進走行速度と同じになり、作業能率を向上させることができるものである。また、副変速(標準)あるいは副変速(倒伏)の状態において、後進走行速度を複数段に切り換えられるように構成してもよい。このように後進速度を複数段に任意に切り換えることにより、操縦者の習熟度合いに応じて、安全に能率良く作業が行え、後進走行速度の切り換えを2段切り換えとすれば、操縦者にわかりやすく、操縦者が戸惑わずに操作することができる。

Further, as shown in FIG. 6, when the vehicle is moving backward, the

尚、前記後進速度設定ダイヤル93は、前述の前側操作パネルの他に、主変速レバー4の把持部内側面部や副変速レバー39の把持部内側面部や操向レバーの上面部に設ければ、操作性をより向上させることができる。

If the reverse

1 油圧ポンプ

2 油圧モータ

3 油圧式無段変速装置(静油圧式無段変速装置)

4 変速操作具(主変速レバー)

5 連繋手段

DESCRIPTION OF SYMBOLS 1

4 Shifting operation tool (main shifting lever)

5 Connection means

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005192262A JP2007010061A (en) | 2005-06-30 | 2005-06-30 | Travel speed variable device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005192262A JP2007010061A (en) | 2005-06-30 | 2005-06-30 | Travel speed variable device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007010061A true JP2007010061A (en) | 2007-01-18 |

| JP2007010061A5 JP2007010061A5 (en) | 2008-06-19 |

Family

ID=37748842

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005192262A Pending JP2007010061A (en) | 2005-06-30 | 2005-06-30 | Travel speed variable device |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2007010061A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009148202A (en) * | 2007-12-20 | 2009-07-09 | Yanmar Co Ltd | Combine harvester |

| JP2011518284A (en) * | 2008-04-18 | 2011-06-23 | キャタピラー インコーポレイテッド | Directional shift management machine control system |

| JP2013204783A (en) * | 2012-03-29 | 2013-10-07 | Iseki & Co Ltd | Working vehicle |

| CN107771510A (en) * | 2016-08-26 | 2018-03-09 | 苏州宝时得电动工具有限公司 | The stall detection method and intelligent grass-removing of intelligent grass-removing |

-

2005

- 2005-06-30 JP JP2005192262A patent/JP2007010061A/en active Pending

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009148202A (en) * | 2007-12-20 | 2009-07-09 | Yanmar Co Ltd | Combine harvester |

| JP2011518284A (en) * | 2008-04-18 | 2011-06-23 | キャタピラー インコーポレイテッド | Directional shift management machine control system |

| JP2013204783A (en) * | 2012-03-29 | 2013-10-07 | Iseki & Co Ltd | Working vehicle |

| CN107771510A (en) * | 2016-08-26 | 2018-03-09 | 苏州宝时得电动工具有限公司 | The stall detection method and intelligent grass-removing of intelligent grass-removing |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4882373B2 (en) | Combine | |

| JP2007174972A5 (en) | ||

| JP2007010061A (en) | Travel speed variable device | |

| JP4529920B2 (en) | Combine | |

| JP2007010061A5 (en) | ||

| JP2007228837A5 (en) | ||

| JP2007195491A (en) | Combine harvester | |

| JP5035328B2 (en) | Combine | |

| JP5452114B2 (en) | Combine | |

| JP2010178630A (en) | Combined harvester | |

| JP2011110020A5 (en) | ||

| JP5852708B2 (en) | Combine | |

| JP4529898B2 (en) | Combine | |

| JP2004189032A (en) | Traveling device for working vehicle | |

| JP2008301715A (en) | Combine harvester | |

| JP2007029039A (en) | Travel transmission of combine harvester | |

| JP6494477B2 (en) | Agricultural machine | |

| JP2007174971A5 (en) | ||

| JP5739275B2 (en) | Agricultural machine travel transmission device | |

| JP4413169B2 (en) | Agricultural vehicle power transmission | |

| JP5225127B2 (en) | Combine | |

| JP2004217071A (en) | Turning control device for traveling vehicle | |

| JP4906099B2 (en) | Combine | |

| JP2006151388A (en) | Control mechanism for traveling crawler | |

| JP2004024163A (en) | Combine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Effective date: 20080425 Free format text: JAPANESE INTERMEDIATE CODE: A523 |