JP2006506608A - 低流量の流量計通過を防止するためのバルブ - Google Patents

低流量の流量計通過を防止するためのバルブ Download PDFInfo

- Publication number

- JP2006506608A JP2006506608A JP2004535813A JP2004535813A JP2006506608A JP 2006506608 A JP2006506608 A JP 2006506608A JP 2004535813 A JP2004535813 A JP 2004535813A JP 2004535813 A JP2004535813 A JP 2004535813A JP 2006506608 A JP2006506608 A JP 2006506608A

- Authority

- JP

- Japan

- Prior art keywords

- flow

- valve

- fluid

- threshold

- pressure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000012530 fluid Substances 0.000 claims abstract description 85

- 230000004044 response Effects 0.000 claims abstract description 26

- 230000010349 pulsation Effects 0.000 claims abstract description 15

- 238000007789 sealing Methods 0.000 claims description 56

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 54

- 239000007788 liquid Substances 0.000 claims description 11

- 238000000034 method Methods 0.000 claims description 11

- 238000005259 measurement Methods 0.000 claims description 9

- 238000011144 upstream manufacturing Methods 0.000 claims description 9

- 238000013016 damping Methods 0.000 claims description 8

- 230000005291 magnetic effect Effects 0.000 claims description 6

- 238000006073 displacement reaction Methods 0.000 claims description 4

- 230000000541 pulsatile effect Effects 0.000 claims description 4

- 230000002093 peripheral effect Effects 0.000 claims description 3

- 230000000295 complement effect Effects 0.000 claims description 2

- 239000013013 elastic material Substances 0.000 claims description 2

- 230000005294 ferromagnetic effect Effects 0.000 claims 1

- 230000005389 magnetism Effects 0.000 claims 1

- 230000013011 mating Effects 0.000 claims 1

- 230000000717 retained effect Effects 0.000 claims 1

- 238000007790 scraping Methods 0.000 claims 1

- 238000012544 monitoring process Methods 0.000 description 5

- 230000008901 benefit Effects 0.000 description 4

- 238000013461 design Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 238000009434 installation Methods 0.000 description 2

- 230000008439 repair process Effects 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- 241000195493 Cryptophyta Species 0.000 description 1

- 230000003213 activating effect Effects 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000013505 freshwater Substances 0.000 description 1

- -1 friction device Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F15/00—Details of, or accessories for, apparatus of groups G01F1/00 - G01F13/00 insofar as such details or appliances are not adapted to particular types of such apparatus

- G01F15/02—Compensating or correcting for variations in pressure, density or temperature

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F15/00—Details of, or accessories for, apparatus of groups G01F1/00 - G01F13/00 insofar as such details or appliances are not adapted to particular types of such apparatus

- G01F15/02—Compensating or correcting for variations in pressure, density or temperature

- G01F15/028—Compensating or correcting for variations in pressure, density or temperature for low flow rates

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K15/00—Check valves

- F16K15/02—Check valves with guided rigid valve members

- F16K15/06—Check valves with guided rigid valve members with guided stems

- F16K15/063—Check valves with guided rigid valve members with guided stems the valve being loaded by a spring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K47/00—Means in valves for absorbing fluid energy

- F16K47/01—Damping of valve members

- F16K47/011—Damping of valve members by means of a dashpot

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F1/00—Measuring the volume flow or mass flow of fluid or fluent solid material wherein the fluid passes through a meter in a continuous flow

- G01F1/05—Measuring the volume flow or mass flow of fluid or fluent solid material wherein the fluid passes through a meter in a continuous flow by using mechanical effects

- G01F1/20—Measuring the volume flow or mass flow of fluid or fluent solid material wherein the fluid passes through a meter in a continuous flow by using mechanical effects by detection of dynamic effects of the flow

- G01F1/22—Measuring the volume flow or mass flow of fluid or fluent solid material wherein the fluid passes through a meter in a continuous flow by using mechanical effects by detection of dynamic effects of the flow by variable-area meters, e.g. rotameters

- G01F1/26—Measuring the volume flow or mass flow of fluid or fluent solid material wherein the fluid passes through a meter in a continuous flow by using mechanical effects by detection of dynamic effects of the flow by variable-area meters, e.g. rotameters of the valve type

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F15/00—Details of, or accessories for, apparatus of groups G01F1/00 - G01F13/00 insofar as such details or appliances are not adapted to particular types of such apparatus

- G01F15/005—Valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K2200/00—Details of valves

- F16K2200/40—Bleeding means in closed position of the valve, e.g. bleeding passages

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/0318—Processes

- Y10T137/0396—Involving pressure control

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/3367—Larner-Johnson type valves; i.e., telescoping internal valve in expanded flow line section

- Y10T137/3421—Line condition change responsive

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7837—Direct response valves [i.e., check valve type]

- Y10T137/7847—With leak passage

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7837—Direct response valves [i.e., check valve type]

- Y10T137/785—With retarder or dashpot

- Y10T137/7851—End of valve forms dashpot chamber

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7837—Direct response valves [i.e., check valve type]

- Y10T137/7904—Reciprocating valves

- Y10T137/7922—Spring biased

- Y10T137/7929—Spring coaxial with valve

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/7722—Line condition change responsive valves

- Y10T137/7837—Direct response valves [i.e., check valve type]

- Y10T137/7904—Reciprocating valves

- Y10T137/7922—Spring biased

- Y10T137/7929—Spring coaxial with valve

- Y10T137/7936—Spring guides valve head

Landscapes

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Measuring Volume Flow (AREA)

- Check Valves (AREA)

Abstract

Description

Claims (41)

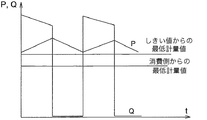

- 流体供給管路とこれを通る流体流を計測するための流量計とを含む流体計量システムであって、前記計器は最低測定流しきい値を有し、前記システムは入口ポートと出口ポートとを有するバルブを更に含み、前記バルブは、その最低測定可能流しきい値を超える流量における開位置とその両ポートにわたる圧力差に応じる圧力脈動位置との間で転移可能であり、前記圧力脈動位置は、最低測定流しきい値未満の流量で通る流体流を本質的に防止する閉位置と、最低測定流しきい値を超える測定可能流量で供給管の中に流体流を入れる開位置との間で変る流体計量システム。

- 前記バルブが常閉圧力制御式バルブである請求項1に記載の流体計量システム。

- 前記バルブが前記流量計の前又は後に隣接して嵌合されている請求項1に記載の流体計量システム。

- 前記バルブが前記流量計と一体である請求項1に記載の流体計量システム。

- 前記供給管路とこれに嵌合された装置の各部分が、前記圧力制御式バルブの下流で、流体アキュムレータとして作用する請求項1に記載の流体計量システム。

- 液体供給網である請求項1に記載の流体計量システム。

- 自治体の上水道網である請求項6に記載の流体計量システム。

- 流体流を測定するための計器を含み、最低測定流しきい値を有し、流れ応答バルブを更に含み、前記流れ応答バルブは、最低測定流しきい値を超える流量でのみ流体流を入れる開位置と、最低測定流しきい値未満の流量で流体流を実質的に抑制する閉位置とを有する流体計量システム。

- 流体供給管路とこれを通る流体流を計測するための計器とを含む流体計量システムであって、前記計器は最低測定流しきい値を有し、前記システムは更に、最低測定しきい値未満の流量で流れを実質的に禁じて、測定可能な量の流体の流れだけを再開するように、脈動特性を有する流れパターンをシステムに分与する流れ応答バルブを含む流体計量システム。

- 前記流れ応答バルブが、その入口と出口にわたる圧力差が最低圧力しきい値を超過するといつでも最低測定流しきい値を超える流量で流体流を入れる開位置と、それを通る流体流を実質的に防止する閉位置との間で転移可能である請求項9に記載の流体計量システム。

- 前記バルブが上流方向への流れを防止する一方向バルブである請求項1に記載の流体計量システム。

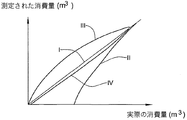

- 最低測定可能しきい値を有する流量計と流れ応答バルブとを含む流体供給管路を通る流体流を計量するための方法であって、前記流れ応答バルブは、最低測定流しきい値未満の流量で通る流体流を本質的に防止し、測定可能な量の流体のみの流れを再開するように、それを通る流れパターンに脈動特性を分与する方法。

- システムを通る平均流体流が時間を通じて一定のままであり、供給管路を通る平均流体流が時間を通じて一定のままであり、本発明の前記システムによって分与される流量の変動は認識不可能である請求項12に記載の流体流を計量するための方法。

- 前記流れ応答バルブが前記流量計に隣接して嵌合されているか、又は前記流量計と一体として嵌合されている請求項12に記載の流体流を計量するための方法。

- 前記供給管路とこれに嵌合された装置との部分が、前記圧力制御式バルブの下流で流体アキュムレータとして作用する請求項12に記載の流体流を計量するための方法。

- 供給管路の上流側に連結可能な入口ポート及び供給管路の下流側に連結可能な出口ポートと、前記入口ポートと前記出口ポートとの間に延在する制御室と、前記制御室の内部に配置されて、封止表面域を有する入口封止表面と制御表面域を有する制御部分とを有する封止部材と、前記制御室を通る最低流しきい値を決定する流出開口とを含むバルブであって、前記封止部材はこの封止部材にわたる圧力差に応じて開位置と閉位置との間で転置するバルブ。

- 常閉流れ応答バルブであって、前記封止部材が偏位して前記入口ポートと封止係合する請求項16に記載のバルブ。

- 前記封止部材がばねにより偏位して前記入口ポートと封止係合する請求項17に記載のバルブ。

- 前記封止部材が磁気によって偏位して前記入口ポートと封止係合する請求項17に記載のバルブ。

- 前記封止部材が強磁性部材を含み、装置のハウジングに固定磁気偏位部材が嵌合されて、これにより前記封止部材を偏位して前記入口ポートと封止係合させる請求項19に記載のバルブ。

- 前記封止部材が弾性材料によって被覆されている請求項20に記載のバルブ。

- 流体供給管路に脈動流体流れパターンを分与し、封止位置と開位置との間に延在し、前記供給管路を通る平均流体流が時間を通じて一定のままであり、本発明のシステムによって分与される流量の変動は認識不可能である請求項16に記載のバルブ。

- 前記封止表面域が前記制御表面域よりも小さい請求項16に記載のバルブ。

- 前記流出開口が装置のハウジングと前記制御部分との間の隙間である請求項16に記載のバルブ。

- 前記封止部材の下流側において流速を増加し、これによって前記封止部材に作用する封止力とは反対の方向の力を生じさせるように、前記開位置において流れ制限部が形成される請求項17に記載のバルブ。

- 前記表面域が前記バルブの前記ハウジングの円筒状内腔であり、前記内腔は拡張部を伴って形成され、前記封止部材は前記拡張部に対応するテーパー部分を伴って形成され、前記封止部材が開位置に転置したときにヘッド・ロスを生じさせ、その結果バルブの開く力を増加する請求項24に記載のバルブ。

- 一方向バルブであって、上流方向への流れを防止する請求項16に記載のバルブ。

- 最低測定流しきい値を有する流量計を含む流れ計量システム用の流れ応答バルブであって、前記最低測定可能流しきい値を超える流量における開位置とその両ポートにわたる圧力差に応じる圧力脈動位置との間で転移可能であり、前記圧力脈動位置は、最低測定流しきい値未満の流量で通る流体流を本質的に防止する閉位置と、最低測定流しきい値を超える測定可能流量で供給管の中に流体流を入れる開位置との間で変る流れ応答バルブ。

- 最低測定流しきい値を有する流量計を含む流れ計量システム用の流れ応答バルブであって、前記最低測定可能流しきい値を超える流量における開位置と前記バルブの入口ポートと出口ポートとにわたる圧力差に応じる圧力脈動位置との間で転移可能であり、前記圧力脈動位置は、最低測定流しきい値未満の流量で通る流体流を本質的に防止する閉位置と、前記最低測定流しきい値を超える測定可能流量で前記供給管の中に流体流を入れる開位置との間で変り、前記バルブは脈動位置の開いた状態において前記バルブを通る流体流を遅延させるための一時停止機構を更に含む流れ応答バルブ。

- 前記一時停止機構が圧力応答封止組立体を含み、前記圧力応答封止組立体は、軸方向に転置可能なプランジャと静止カップ部材とを含み、これらの間に減衰組立体が受け入れられて前記プランジャの軸方向転置を減衰する請求項29に記載のバルブ。

- 前記減衰組立体が閉じ込められた空間の中に受け入れられ、前記閉じ込められた空間にはこの中へ入る液体流を制限するために封止スリーブが取り付けられている請求項30に記載のバルブ。

- 前記圧力応答封止組立体が更に、ハウジングの内部に保持されて下流方向にのみ変形可能なダイヤフラム・シールを含む請求項30に記載のバルブ。

- 前記プランジャの周辺縁部が尖っており、前記ハウジングの円筒状表面に対抗して転置するようになされており、これによって表面のごみをかき取る請求項30に記載のバルブ。

- 前記プランジャと前記カップ部材との対向縁部が相補対合形状を有する請求項30に記載のバルブ。

- 前記減衰組立体が一端部においては前記カップ部材を、他端部においては前記プランジャを圧迫する偏位ばねである請求項31に記載のバルブ。

- 前記バルブの閉位置においては、前記プランジャは前記カップ部材から引っ込められて前記ダイヤフラム・シールを封止的に圧迫し、液体は前記バルブを通って流れず、入口圧力Piは出口圧力Poに等しい請求項32に記載のバルブ。

- 前記バルブにわたって生じた圧力差によって前記プランジャが下流に引っ張られ、これに続いて前記ダイヤフラム・シールが変形し、これによって前記バルブを閉じる請求項32に記載のバルブ。

- 前記ダイヤフラム・シールが前記プランジャから離れると結果的に前記プランジャは前記カップ部材に向かって更に転置し、これによって脈動様式で且つ測定可能流量で前記バルブを通る液体流を増加する請求項32に記載のバルブ。

- 前記バルブの開位置において前記プランジャは転置して前記カップ部材と係合し、かなりの流量の液体流を容易にする請求項32に記載のバルブ。

- 前記バルブの完全開位置において前記プランジャが前記カップ部材と対合し、卵状の形状を形成する請求項39に記載のバルブ。

- 流体供給管路とこれを通る流体流を計測するための計器とを含む流体計量システムであって、前記計器は流体流れ応答インペラを含み、最低測定流しきい値を有し、前記システムは更に、前記最低測定しきい値未満の流量で流れを実質的に禁じて、測定可能な量の流体の流れだけを再開するように、脈動特性を有する流れパターンを前記システムに分与する流れ応答バルブを含み、前記バルブは更に、脈動位置の開いた状態において前記バルブを通る流体流を遅延させるための一時停止機構を含むシステム。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IL15174802A IL151748A0 (en) | 2002-09-12 | 2002-09-12 | Fluid metering method and system |

| PCT/IL2003/000727 WO2004025229A1 (en) | 2002-09-12 | 2003-09-04 | Valve for prevention of low flow rates through flow meter |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006506608A true JP2006506608A (ja) | 2006-02-23 |

| JP2006506608A5 JP2006506608A5 (ja) | 2006-10-19 |

Family

ID=29596496

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004535813A Pending JP2006506608A (ja) | 2002-09-12 | 2003-09-04 | 低流量の流量計通過を防止するためのバルブ |

Country Status (17)

| Country | Link |

|---|---|

| US (1) | US7640944B2 (ja) |

| EP (1) | EP1546664B1 (ja) |

| JP (1) | JP2006506608A (ja) |

| KR (1) | KR20050053660A (ja) |

| CN (1) | CN100424479C (ja) |

| AU (1) | AU2003256054B2 (ja) |

| BR (1) | BRPI0314272B1 (ja) |

| CA (1) | CA2499604C (ja) |

| CY (1) | CY1113615T1 (ja) |

| ES (1) | ES2393264T3 (ja) |

| IL (2) | IL151748A0 (ja) |

| MX (1) | MXPA05002766A (ja) |

| PT (1) | PT1546664E (ja) |

| RU (1) | RU2005110675A (ja) |

| SI (1) | SI1546664T1 (ja) |

| WO (1) | WO2004025229A1 (ja) |

| ZA (1) | ZA200502160B (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010255667A (ja) * | 2009-04-21 | 2010-11-11 | Inax Corp | 脈動発生装置 |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100089471A1 (en) * | 2002-09-12 | 2010-04-15 | A.R.I. Flow Control Accessories Ltd. | Valve |

| US8758333B2 (en) | 2006-04-04 | 2014-06-24 | The Spectranetics Corporation | Laser-assisted guidewire having a variable stiffness shaft |

| DE102006045976B4 (de) * | 2006-09-27 | 2013-01-31 | Krohne Ag | Durchflussmessgerät |

| US20090025471A1 (en) * | 2007-07-23 | 2009-01-29 | Airblock Air Controller, Llc | Air Out Flowing Controller For Cold Waters In Hydraulic Pipeline After The Water Meter |

| DE102008015497A1 (de) * | 2008-03-25 | 2009-10-08 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Magnetventileinheit |

| US20100257916A1 (en) * | 2008-03-27 | 2010-10-14 | Ip Innovative Products, Llc | Accuracy enhancing valve assembly and related method of use |

| US8979828B2 (en) | 2008-07-21 | 2015-03-17 | The Spectranetics Corporation | Tapered liquid light guide |

| US9421065B2 (en) | 2008-04-02 | 2016-08-23 | The Spectranetics Corporation | Liquid light-guide catheter with optically diverging tip |

| US8240329B1 (en) * | 2008-11-14 | 2012-08-14 | Robust Systems Solutions, LLC | Fluid control valve |

| US11083870B2 (en) | 2011-04-11 | 2021-08-10 | The Spectranetics Corporation | Hypotube based support catheter |

| US9162038B2 (en) | 2011-04-11 | 2015-10-20 | The Spectranetics Corporation | Needle and guidewire holder |

| RU2544258C2 (ru) * | 2013-02-19 | 2015-03-20 | Закрытое акционерное общество "Промсервис" | Клапан и система измерения расхода газообразной среды |

| IL232537B (en) | 2014-05-11 | 2019-06-30 | Wint Wi Ltd | flow control system |

| USD814951S1 (en) * | 2014-10-31 | 2018-04-10 | RG5 Meter Company, Inc. | Perpetual measurement chamber |

| US9866258B2 (en) | 2014-08-14 | 2018-01-09 | Michael Lee Gregory | Universal receiver |

| US9568351B1 (en) | 2014-08-14 | 2017-02-14 | Michael Lee Gregory | Water meter technology |

| US10006794B2 (en) * | 2014-08-14 | 2018-06-26 | Michael Lee Gregory | Perpetual meter with noise damping |

| EP3196519B1 (en) * | 2014-09-18 | 2019-06-12 | TLV Co., Ltd. | Backflow prevention apparatus |

| CN105081245A (zh) * | 2015-08-21 | 2015-11-25 | 重庆煜琨珑冶金材料有限公司 | 粉末物料流量调节器 |

| CN105179753A (zh) * | 2015-09-30 | 2015-12-23 | 张家港富瑞特种装备股份有限公司 | 一种限流止回组合阀 |

| CN105784349B (zh) * | 2016-05-18 | 2018-09-18 | 德施普科技发展温州有限公司 | 一种同步增泄智能阀门实验台 |

| CN105841950B (zh) * | 2016-05-18 | 2018-08-24 | 德施普科技发展温州有限公司 | 一种同步增泄智能阀门实验系统 |

| US10648842B2 (en) * | 2016-06-22 | 2020-05-12 | Benoit & Cote Inc. | Fluid flow measuring and control devices and method |

| US10292565B2 (en) | 2016-08-01 | 2019-05-21 | Whirlpool Corporation | Dishwasher with water valve having volumetric flow control |

| US10214881B2 (en) * | 2017-02-10 | 2019-02-26 | Flow Stop, LLC | Water loss detection and control system |

| CN107013741A (zh) * | 2017-05-17 | 2017-08-04 | 南通艾迈特机械有限公司 | 一种阀门的自检结构 |

| CA3066725A1 (en) * | 2017-06-19 | 2018-12-27 | Becton, Dickinson And Company | Priming valve to induce appropriate pressure and flow profile and improve sensor readiness |

| CN112432783A (zh) * | 2020-10-20 | 2021-03-02 | 无锡恒捷磁感技术有限公司 | 一种回油阀流量测量方法 |

| BE1028867B1 (nl) * | 2020-12-08 | 2022-07-11 | Hydroko | Een tegendrukinrichting voor een ultrasone watermeter |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6014120A (ja) * | 1983-06-16 | 1985-01-24 | ダンフオス・エ−・エス | 流量計及び測定精度を高める付属装置を有する流量測定装置 |

| JPH0470515A (ja) * | 1990-07-11 | 1992-03-05 | Rinnai Corp | 弁装置付き流量センサ |

| WO1999028722A1 (en) * | 1997-11-27 | 1999-06-10 | Jaakko Oskari Jakobsson | Arrangement for controlling, measuring and/or indicating a flow, especially leakage in piping systems |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1808212A (en) * | 1931-06-02 | Meter | ||

| US832619A (en) * | 1903-10-24 | 1906-10-09 | Nat Meter Company | Water-meter-controlling device. |

| US1808209A (en) * | 1923-12-21 | 1931-06-02 | Earl George Goodell | Fluid metering system and apparatus |

| GB1064396A (en) * | 1964-12-08 | 1967-04-05 | Kent Ltd G | Improvements in or relating to apparatus to ensure accurate working of fluid meters at low flow rates |

| US3990299A (en) * | 1974-05-09 | 1976-11-09 | Kaiser Aerospace And Electronics Corporation | Combined water meter and pressure regulator |

| US4498497A (en) * | 1982-07-16 | 1985-02-12 | Universal Filters, Inc. | Flow meter bypass valve assembly |

| US5218346A (en) | 1991-05-01 | 1993-06-08 | The United States Of America As Represented By The United States Department Of Energy | Low volume flow meter |

| SE9400366D0 (sv) * | 1994-02-04 | 1994-02-04 | Siemens Elema Ab | Ventil för att styra ett gas- eller vätskeflöde |

| CN1075194C (zh) * | 1994-11-25 | 2001-11-21 | 安尼株式会社 | 气体管道内的漏气传感器 |

| US5921276A (en) * | 1995-10-17 | 1999-07-13 | Stream-Flo Industries, Ltd. | Piston-type check valve with diffuser |

| CN2293061Y (zh) * | 1997-01-29 | 1998-09-30 | 辽河石油勘探局锦州采油厂 | 井口油管试压验漏装置 |

| US6132191A (en) * | 1998-05-15 | 2000-10-17 | Scroll Technologies | Check valve for scroll compressor |

| US6648012B2 (en) * | 2001-06-13 | 2003-11-18 | Applied Materials, Inc. | Non-return valve override device |

-

2002

- 2002-09-12 IL IL15174802A patent/IL151748A0/xx unknown

-

2003

- 2003-09-04 JP JP2004535813A patent/JP2006506608A/ja active Pending

- 2003-09-04 ES ES03795187T patent/ES2393264T3/es not_active Expired - Lifetime

- 2003-09-04 RU RU2005110675/28A patent/RU2005110675A/ru not_active Application Discontinuation

- 2003-09-04 US US10/527,198 patent/US7640944B2/en not_active Expired - Lifetime

- 2003-09-04 MX MXPA05002766A patent/MXPA05002766A/es active IP Right Grant

- 2003-09-04 SI SI200332198T patent/SI1546664T1/sl unknown

- 2003-09-04 CA CA 2499604 patent/CA2499604C/en not_active Expired - Fee Related

- 2003-09-04 PT PT03795187T patent/PT1546664E/pt unknown

- 2003-09-04 WO PCT/IL2003/000727 patent/WO2004025229A1/en active Application Filing

- 2003-09-04 AU AU2003256054A patent/AU2003256054B2/en not_active Ceased

- 2003-09-04 EP EP03795187A patent/EP1546664B1/en not_active Expired - Lifetime

- 2003-09-04 BR BRPI0314272A patent/BRPI0314272B1/pt not_active IP Right Cessation

- 2003-09-04 CN CNB038240580A patent/CN100424479C/zh not_active Expired - Fee Related

-

2005

- 2005-03-10 IL IL167383A patent/IL167383A/en unknown

- 2005-03-12 KR KR1020057004337A patent/KR20050053660A/ko not_active Application Discontinuation

- 2005-03-15 ZA ZA200502160A patent/ZA200502160B/en unknown

-

2012

- 2012-10-05 CY CY20121100927T patent/CY1113615T1/el unknown

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6014120A (ja) * | 1983-06-16 | 1985-01-24 | ダンフオス・エ−・エス | 流量計及び測定精度を高める付属装置を有する流量測定装置 |

| JPH0470515A (ja) * | 1990-07-11 | 1992-03-05 | Rinnai Corp | 弁装置付き流量センサ |

| WO1999028722A1 (en) * | 1997-11-27 | 1999-06-10 | Jaakko Oskari Jakobsson | Arrangement for controlling, measuring and/or indicating a flow, especially leakage in piping systems |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010255667A (ja) * | 2009-04-21 | 2010-11-11 | Inax Corp | 脈動発生装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| BRPI0314272B1 (pt) | 2016-05-24 |

| CA2499604A1 (en) | 2004-03-25 |

| IL167383A (en) | 2010-11-30 |

| CN100424479C (zh) | 2008-10-08 |

| CA2499604C (en) | 2014-02-18 |

| CY1113615T1 (el) | 2016-06-22 |

| RU2005110675A (ru) | 2005-09-10 |

| AU2003256054B2 (en) | 2009-11-19 |

| ZA200502160B (en) | 2006-02-22 |

| CN1688873A (zh) | 2005-10-26 |

| US20050268969A1 (en) | 2005-12-08 |

| ES2393264T3 (es) | 2012-12-19 |

| AU2003256054A1 (en) | 2004-04-30 |

| MXPA05002766A (es) | 2005-11-04 |

| WO2004025229A1 (en) | 2004-03-25 |

| PT1546664E (pt) | 2012-10-15 |

| KR20050053660A (ko) | 2005-06-08 |

| EP1546664B1 (en) | 2012-07-11 |

| BR0314272A (pt) | 2005-07-26 |

| SI1546664T1 (sl) | 2012-12-31 |

| US7640944B2 (en) | 2010-01-05 |

| IL151748A0 (en) | 2003-04-10 |

| EP1546664A1 (en) | 2005-06-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2006506608A (ja) | 低流量の流量計通過を防止するためのバルブ | |

| AU711838B2 (en) | System and method for measuring and controlling bidirectional multi-phase fluid flow in a conduit | |

| US20080266125A1 (en) | Method for Actively Monitoring Pipelines | |

| CA2469838C (en) | Water supply system | |

| US5062442A (en) | Apparatus for monitoring a fluid conduit system for leakage points | |

| US7451777B2 (en) | Water conservation safety shut-off valve | |

| US5642752A (en) | Controllable constant flow regulating lift valve | |

| US5905208A (en) | System and method measuring fluid flow in a conduit | |

| NZ564121A (en) | Fluid flow controller | |

| US20200025300A1 (en) | Accuracy enhancing valve assembly and method | |

| US20100089471A1 (en) | Valve | |

| EP2133680A2 (en) | Device for detecting water leaks | |

| KR101687943B1 (ko) | 유량 제어 유닛과 필터 조립체를 가진 정수기 | |

| US20020073768A1 (en) | Fluid flow sensors & leak detection systems | |

| EP0930492A1 (en) | Method of and apparatus for detecting leakages and/or inadvertent consumption of a fluid in a pipeline | |

| KR960031876A (ko) | 부식성 가스 분배 시스템의 압력 조정기 작동 상태 검출 및 평가 방법 | |

| KR101872081B1 (ko) | 상수도 개별 수용가 수도계량기함 설비 | |

| US20240068853A1 (en) | Device for flow and volume measurement and consumption detection in hydrants, hose connections or any type of outlet | |

| KR200219467Y1 (ko) | 수압을 이용한 수돗물 토출량 조절장치 | |

| JPH0740160Y2 (ja) | 液体燃料の配管漏れ検出装置 | |

| GB2369677A (en) | Fluid leak detection by separating measured vibrations into frequency bands and comparing with reference data | |

| FI125291B (fi) | Menetelmä ja laitteisto putkistovuodon tunnistamiseksi ja vuodon rajoittamiseksi | |

| GB2608863A (en) | Water supply diversion device | |

| Fleming et al. | Susceptibility of potable water distribution systems to negative pressure transients | |

| US20190353261A1 (en) | Jump Valve |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060901 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060901 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090708 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090710 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20091013 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20091020 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20091110 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20091117 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100112 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100720 |