JP2006292097A - Cage for rolling bearing - Google Patents

Cage for rolling bearing Download PDFInfo

- Publication number

- JP2006292097A JP2006292097A JP2005114648A JP2005114648A JP2006292097A JP 2006292097 A JP2006292097 A JP 2006292097A JP 2005114648 A JP2005114648 A JP 2005114648A JP 2005114648 A JP2005114648 A JP 2005114648A JP 2006292097 A JP2006292097 A JP 2006292097A

- Authority

- JP

- Japan

- Prior art keywords

- column

- division

- divided

- cage

- portions

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000005096 rolling process Methods 0.000 title claims abstract description 32

- 210000000078 claw Anatomy 0.000 claims description 14

- 239000011347 resin Substances 0.000 description 9

- 229920005989 resin Polymers 0.000 description 9

- 230000007423 decrease Effects 0.000 description 5

- 230000004323 axial length Effects 0.000 description 4

- 230000008859 change Effects 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 229910000881 Cu alloy Inorganic materials 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/38—Ball cages

- F16C33/3837—Massive or moulded cages having cage pockets surrounding the balls, e.g. machined window cages

- F16C33/3862—Massive or moulded cages having cage pockets surrounding the balls, e.g. machined window cages comprising two annular parts joined together

- F16C33/3875—Massive or moulded cages having cage pockets surrounding the balls, e.g. machined window cages comprising two annular parts joined together made from plastic, e.g. two injection moulded parts joined by a snap fit

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/04—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for radial load mainly

- F16C19/06—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for radial load mainly with a single row or balls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2226/00—Joining parts; Fastening; Assembling or mounting parts

- F16C2226/50—Positive connections

- F16C2226/70—Positive connections with complementary interlocking parts

- F16C2226/74—Positive connections with complementary interlocking parts with snap-fit, e.g. by clips

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rolling Contact Bearings (AREA)

Abstract

Description

本発明は、内輪と外輪との間で転動体を保持する転がり軸受用保持器(以下、保持器)に関するものである。 The present invention relates to a rolling bearing retainer (hereinafter referred to as a retainer) that retains rolling elements between an inner ring and an outer ring.

玉軸受あるいはころ軸受等の保持器には、軽量化等を目的として樹脂製としたものがある。樹脂製の保持器の場合、剛性に劣る。そのため、軸方向に長い樹脂製の保持器の場合では特に、高速回転下の遠心荷重の作用により、外径側へと変形し易い。この場合、高温環境の条件が加わると一層変形し易くなる。保持器の変形は、保持器と転動体との接触面が正規の位置からずれて回転トルクを増大させる、など軸受性能を低下させてしまう。 Some cages such as ball bearings or roller bearings are made of resin for the purpose of weight reduction. In the case of a resin cage, the rigidity is inferior. Therefore, especially in the case of a cage made of resin that is long in the axial direction, it is easily deformed to the outer diameter side due to the action of a centrifugal load under high-speed rotation. In this case, when the condition of high temperature environment is added, it becomes easier to deform. The deformation of the cage deteriorates the bearing performance, for example, the contact surface between the cage and the rolling element is displaced from the normal position to increase the rotational torque.

このような樹脂製の保持器には、組立性、量産性、あるいは取り扱い性等を目的として分割型の保持器としたものがある(特許文献1等参照)。特許文献1の保持器では2つのケージ半割体(円環部)をピンとソケットとで連結する構成としており、連結部(柱部相当部分)の円周方向幅が大きくなり、転動体の収納本数が低下する。また、特許文献2の保持器では、環状の保持器本体の一側面に対向一対の爪を周方向に等間隔に設け、一対の爪間にボール保持用ポケットを形成し、この保持器本体のポケット開口側に環状の蓋体を連結した構成としており、連結部位置での円環部の剛性、強度が低下し、また、耐遠心荷重に劣る。特許文献3の保持器では、円環部の剛性、強度が低下する構成である。 Among such resin cages, there are some which are divided cages for the purpose of assembling, mass production, and handling (see Patent Document 1 and the like). The cage of Patent Document 1 has a structure in which two cage halves (annular parts) are connected by pins and sockets, and the circumferential width of the connecting part (corresponding to the column part) becomes large, so that the rolling elements are stored. The number decreases. Further, in the cage of Patent Document 2, a pair of opposing claws are provided at equal intervals in the circumferential direction on one side surface of the annular cage body, and a ball holding pocket is formed between the pair of claws. An annular lid is connected to the pocket opening side, the rigidity and strength of the annular part at the connecting part position are reduced, and the centrifugal load is inferior. The cage of Patent Document 3 has a configuration in which the rigidity and strength of the annular portion are reduced.

以上により、樹脂製保持器では、樹脂製であることによる高速回転下での剛性や強度の不足を考慮する必要があるが、分割型とした場合に、連結部の強度を確保する必要から転動体の収納本数が低下するような構成となったり、複雑な構成となったりする一方、転動体の収納本数の維持等を図ると、剛性や強度が低下してくる構成となる、という製作上、困難な課題を抱えている。 As described above, in the resin cage, it is necessary to consider the lack of rigidity and strength under high-speed rotation due to being made of resin, but in the case of the split type, it is necessary to secure the strength of the connecting portion. In production, the number of moving objects stored may be reduced, or the structure may be complicated, while maintaining the number of moving objects stored may reduce rigidity and strength. Have difficult challenges.

なお、保持器を両円環部のうちの一方の円環部だけを分割可能とし、組立時には分割した円環部を柱部の先端部と連結する構成とした分割型とすることが考えられるが、構造的に強度が不足し易い連結部が当該一方の円環部のみに集中するおそれがある上、連結部位置の偏りにより軸方向両側での保持器重量が均衡化しにくく、高速回転下での上記した課題を残すものとなる。なお、上記課題を解決するに際しては、連結部の組み込みにより保持器重量が増大化することは遠心荷重の増大化を抑制するためにも回避する必要がある。 In addition, it is conceivable that the cage is a split type in which only one of the two annular portions can be divided and the divided annular portion is connected to the tip portion of the column portion during assembly. However, there is a risk that the connecting part whose strength is structurally insufficient will be concentrated only on the one annular part, and the weight of the cage on both sides in the axial direction is difficult to be balanced due to the deviation of the connecting part, so This will leave the above-mentioned problems. In order to solve the above-mentioned problem, it is necessary to avoid an increase in the weight of the cage due to the incorporation of the connecting portion in order to suppress an increase in centrifugal load.

さらに、以上のことは樹脂製の保持器だけに必ずしも限定された課題ではなく、例えば、銅合金製の削り出し保持器など、遠心荷重により変形を受ける可能性がある保持器にも同様に派生し得る課題である。

本発明により解決する課題は、転動体の収納本数の低下を来さず、保持器が重量化することなく、高速回転時の遠心荷重を受けても容易に変形しにくい、要求する剛性と強度とを確保することを可能とした保持器を提供することである。 The problem to be solved by the present invention is that the number of rolling elements accommodated does not decrease, the cage does not increase in weight, and is not easily deformed even when subjected to a centrifugal load during high-speed rotation, and the required rigidity and strength It is an object of the present invention to provide a cage capable of ensuring the above.

本発明による転がり軸受用保持器は、軸方向で平行に対向する一対の円環状をなす円環部と両円環部間を軸方向に延びかつ円周方向等間隔に配列されて当該両円環部に一体とされた複数の柱部とを備え、複数の柱部の円周方向間の空孔に転動体を保持するポケットを構成する転がり軸受用保持器において、当該保持器が、柱部の中途位置から軸方向に分割されてそれぞれが円環部と柱部の軸方向分割部分(柱分割部)とを備えかつ両柱分割部の先端側端面の内径側に半径方向に重ね合わされて相互に連結される連結部を備えた2つの分割体から構成されていることを特徴とするものである。 A rolling bearing retainer according to the present invention includes a pair of annular portions facing in parallel in the axial direction and an annular portion extending between the annular portions in the axial direction and arranged at equal intervals in the circumferential direction. A rolling bearing retainer comprising a plurality of pillar portions integrated with the ring portion, and forming a pocket for retaining a rolling element in a space between the circumferential directions of the plurality of pillar portions. Are divided in the axial direction from the middle position of each part, and each of them is provided with an annular part and an axially divided part (column divided part) of the column part, and is superimposed in the radial direction on the inner diameter side of the end surface on the front end side of both column divided parts It is comprised from two division bodies provided with the connection part mutually connected.

本発明の転がり軸受用保持器は、玉軸受、ころ軸受等の転がり軸受全般に適用することができる保持器であり、また、その材料に限定されるものではない。 The cage for rolling bearings of the present invention is a cage that can be applied to all rolling bearings such as ball bearings and roller bearings, and is not limited to the material thereof.

本発明の転がり軸受用保持器は、一方の分割体が円環部だけという不均衡な分割・組立構成ではなく、2つの分割体が、それぞれ、円環部と柱分割部とを備えた均衡がとれた分割・組立構成となっているので、一方の分割体が円環部の構造では、例えばころ軸受保持器で、ころ長さが長い構成に適用した時ころ長さに合せて一方の分割体の柱部のみを長く形成し、その結果柱部の剛性、強度が低下する恐れがあるが、本発明の保持器では分割位置の設定により、高速回転時に作用する遠心荷重により変形を防止する上で極めて重要な重量均衡を容易に確保することができる。また、特に重要なことは連結部位置が軸方向全体に亘り均衡をとることができることである。そのため、高速回転時での遠心荷重に対して変形を効果的に防止することができるようになる。もちろん、両分割体それぞれの連結部は半径方向に重なり合うので耐遠心荷重性が高められている上に軸方向の連結力を確保することができる。 The cage for a rolling bearing according to the present invention is not an unbalanced division / assembly configuration in which one divided body is only an annular portion, and two divided bodies are each provided with an annular portion and a column divided portion. Since it has a split / assembled configuration with one ring, when one split body has a ring structure, for example, a roller bearing retainer, when applied to a configuration with a long roller length, Only the column part of the divided body is formed long, and as a result, the rigidity and strength of the column part may be reduced. However, in the cage of the present invention, deformation is prevented by centrifugal load acting at high speed rotation by setting the division position. Therefore, it is possible to easily ensure a weight balance that is extremely important for this purpose. Also particularly important is that the position of the connecting portion can be balanced over the entire axial direction. Therefore, it becomes possible to effectively prevent deformation against a centrifugal load during high-speed rotation. Of course, since the connecting portions of the two divided bodies overlap in the radial direction, the anti-centrifugal load resistance is enhanced, and the axial connecting force can be secured.

以上のように、本発明では、両分割体が共に円環部だけでなく柱分割部を備えているという従来には無い構造を有しており、柱分割部の軸方向長さを設定することにより、柱部の剛性、強度の低下の抑制に加えて、剛性、強度の軸方向上、円周方向上の均衡を設定することができるものである。すなわち、本発明によると、例えば、柱分割部の軸方向長さを円周方向1つおき、あるいは複数おきに長く設定し、円周方向1つおき、あるいは複数おきに短く設定することができる。この設定により、連結部位置が円周方向交互に両円環部に対して遠近均衡した位置となり、高速回転時の回転速度の変動による遠心荷重の強弱変化および遠心荷重の強弱に変化する位置の移動等(ポケット内の転動体の位置、変形、潤滑剤等の粘度変化、環境温度の推移等に起因する)に対して、長期にわたり均衡がとれたものとすることができる。 As described above, in the present invention, both of the divided bodies have an unprecedented structure in which not only the annular portion but also the column divided portion is provided, and the axial length of the column divided portion is set. Thus, in addition to suppressing the decrease in rigidity and strength of the column part, it is possible to set a balance between rigidity and strength in the axial direction and in the circumferential direction. That is, according to the present invention, for example, the length in the axial direction of the pillar dividing portion can be set longer every other circumferential direction or every plural number, and shorter every other circumferential direction or every other plural number. . With this setting, the position of the connecting part becomes a perspective equilibrium with respect to both annular parts alternately in the circumferential direction, and the position of the position where the centrifugal load changes due to fluctuations in the rotational speed during high-speed rotation and the position where the centrifugal load changes. It can be balanced over a long period of time with respect to movement, etc. (due to the position of rolling elements in the pocket, deformation, viscosity change such as lubricant, transition of environmental temperature, etc.).

以上により、本発明では、遠心荷重の強弱変化、周囲温度の変化、転がり軸受の組み込み位置の環境変化に対応して、分割型であるにもかかわらず、柱分割部の連結部での連結強度、両柱分割部からなる柱部自体の剛性や強度を確保することができる。特に、保持器材料が樹脂製等の剛性や強度が課題とされる材料で構成されても、転動体の収納本数を維持することができるとともに、保持器重量増を来すことなく、変形しにくく、かつ、トルク増大を抑制することができる保持器を提供することができる。 As described above, according to the present invention, the connection strength at the connecting portion of the column split portion in spite of the split type in response to the change in the strength of the centrifugal load, the change in the ambient temperature, and the environmental change in the mounting position of the rolling bearing. In addition, the rigidity and strength of the pillar part itself composed of both pillar split parts can be ensured. In particular, even if the cage material is made of a material such as a resin that is required to have rigidity and strength, the number of rolling elements can be maintained and the cage can be deformed without increasing the weight of the cage. It is difficult to provide a cage that can suppress an increase in torque.

本発明の1つの態様として、一方の分割体の柱分割部が円周方向交互に配置した軸方向に長い柱分割部と短い柱分割部との組み合わせであり、他方の分割体の柱分割部が円周方向交互に配置した軸方向に長い柱分割部と短い柱分割部との組み合わせであり、また前記両連結部の一方が、係合爪部を備え、他方が前記係合爪部が挿入される係止凹所と該係止凹所内に設けられ前記係合爪部が半径方向に重なって軸方向に抜け止めされた状態で係止する係止部とを備える。 As one aspect of the present invention, the column division portion of one divided body is a combination of a long column division portion and a short column division portion arranged in the circumferential direction alternately arranged in the circumferential direction, and the column division portion of the other division body Is a combination of axially long column divided portions and short column divided portions arranged alternately in the circumferential direction, and one of the two connecting portions includes an engaging claw portion, and the other includes the engaging claw portion. A locking recess to be inserted, and a locking portion that is provided in the locking recess and locks in a state where the engaging claw overlaps in the radial direction and is prevented from coming off in the axial direction.

本発明の1つの態様として、一方の分割体が軸方向に長い柱分割部と短い柱分割部とがこの順序で円周方向一方に一体に並設されてなる第1柱分割部ペアを備え、他方の分割体が軸方向に短い柱分割部と長い柱分割部とがこの順序で円周方向一方に一体に並設されてなる第2柱分割部ペアを備えており、両第1、第2柱分割部ペアは互いの連結部で相互に連結されている。 As one aspect of the present invention, one divided body includes a first column dividing portion pair in which a long column dividing portion and a short column dividing portion are integrally arranged in one side in the circumferential direction in this order. The other divided body includes a second column divided portion pair in which a column divided portion which is short in the axial direction and a long column divided portion are integrally arranged in one side in the circumferential direction in this order. The 2nd pillar division part pair is mutually connected by the mutual connection part.

この態様によると、円周方向に軸方向に長い柱分割部が並列された状態となるので、柱部の剛性および強度を向上することができる。 According to this aspect, since the column split portions that are long in the axial direction in the circumferential direction are arranged in parallel, the rigidity and strength of the column portions can be improved.

本発明の1つの態様として、長い柱分割部の外径側に半径方向内向きの段部が設けられてあり、短い柱分割部の外径側が軸方向に延長されて延長部が形成されてあり、段部上に延長部が径方向から重ね合わされている。 As one aspect of the present invention, a radially inward stepped portion is provided on the outer diameter side of the long column division portion, and the extension portion is formed by extending the outer diameter side of the short column division portion in the axial direction. Yes, the extension is superimposed on the step from the radial direction.

この態様によると、段部と延長部との重ね合わせにより、大きい遠心荷重を受けることができるようになるととともに、連結部を両分割体の円周方向の位置決めとして用いることができるようになる。 According to this aspect, it is possible to receive a large centrifugal load due to the overlapping of the stepped portion and the extending portion, and it is possible to use the connecting portion as the circumferential positioning of both divided bodies.

本発明によると、転動体の収納本数の低下を来さず、重量化することなく、高速回転時の遠心荷重に対して、より変形しにくい剛性と強度とを有する保持器を提供することができる。 According to the present invention, it is possible to provide a cage having rigidity and strength that is less likely to be deformed with respect to a centrifugal load during high-speed rotation without reducing the number of rolling elements stored and without increasing the weight. it can.

以下、本発明の実施の形態に係る保持器を、添付図面を参照して詳細に説明する。 Hereinafter, a cage according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

(実施の形態1)

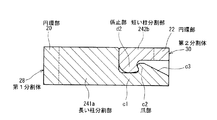

図1は実施の形態1の保持器を備えた転がり軸受の断面図、図2は図1に示す保持器の斜視図、図3は、同保持器の分割体の斜視図、図4は図2のA−A線断面図である。

(Embodiment 1)

1 is a cross-sectional view of a rolling bearing provided with the cage of Embodiment 1, FIG. 2 is a perspective view of the cage shown in FIG. 1, FIG. 3 is a perspective view of a divided body of the cage, and FIG. It is AA sectional view taken on the line of 2. FIG.

これらの図を参照して、転がり軸受10は、深溝型玉軸受であり、外輪12と、内輪14と、これら外輪12と内輪14との間に介装される複数の転動体(玉)16と、複数の転動体16を転動自在に保持する分割型の保持器18とを備える。保持器18は樹脂製であり、組立状態で、軸方向に対向する第1、第2円環部20,22と、両円環部20,22間に円周方向等間隔に配列された複数の柱部24とから構成され、両円環部20,22と柱部24との間の空孔は転動体保持用のポケット26とされている。転動体16は軸方向両側の円環部20,22と円周方向両側の柱部24とによりポケット26内に両抱きとされている。

Referring to these drawings, a rolling

保持器18は、柱部24の中途位置から軸方向2つに分割された2つの分割体28,30から構成されている。第1分割体28は、円環部20と、柱部24を軸方向に分割した分割位置から軸方向一方側に延び断面外形が略矩形形状をなす柱部分(以下、柱分割部という)241とを備える。柱分割部241の先端面は分割面となる。各柱分割部241は、それぞれ、円周方向交互に軸方向長さが長短に相違している。すなわち、柱分割部241は、円周方向1つおきに軸方向長さが長い柱分割部(以下、長い柱分割部という)241aと、円周方向1つおきに軸方向長さが短い柱分割部(以下、短い柱分割部という)241bとされている。長い柱分割部241aと短い柱分割部241bはその先端面の内径側に連結部241c,241dを備えている。

The

第2分割体30は、円環部22と、柱部24の軸方向に分割した分割位置から軸方向他方側に延びで断面外形が略矩形形状をなす柱分割部242とを備える。柱分割部242の先端面は分割面となる。柱分割部242も、柱分割部241と同様に、円周方向交互に軸方向長さが長短に相違している。すなわち、柱分割部242は、円周方向1つおきに長い柱分割部242aと、円周方向1つおきに短い柱分割部242bとされている。長い柱分割部242aと短い柱分割部242bはその先端面の内径側に連結部242c,242dを備えている。

The second divided

各長い柱分割部241a,242aそれぞれの連結部241c,242cは、それらの先端側端面の内径側から当該長い柱分割部241a,242aより小さい断面寸法(半径方向にも円周方向にも小さい寸法)で軸方向に延びる断面矩形形状の胴部c1と、この胴部c1の軸方向端部の外径面から半径方向外向きに立ち上がる弾性変形可能な径方向外向きの係合爪部c2とを備える。この係合爪部c2の外径面は軸方向先端側に向けて半径方向内側に降り斜面となるカム面c3になっている。

The connecting

各短い柱分割部241b,242bそれぞれの連結部241d,242dは、短い柱分割部241b,242bの内側面の内径側から円環部20,22の外側面の内径側に亘る全体にかけて軸方向に切欠かれてなる係止凹所d1を備える。この係止凹所d1の半径方向内方に面する内底面から半径方向内向きに立ち下がる断面略半円形状ないしは半楕円形状ないしは放物線状の係止部d2を備える。長い柱分割部241a,242aの連結部241c,242cそれぞれの係合爪部c2は短い柱分割部241b,242bの連結部241d,242dそれぞれの係止凹所d1に挿入されると、そのカム面c3が係止凹所d1内の係止部d2前面に突き当たる。この突き当たりにより、係合爪部c2は弾性的に半径方向内方に弾性変形することにより係止部d2を乗り越え、乗り越えると弾性復元して係止部d2の背面側に係止され、該係止部d2に軸方向に抜け止め状態にかつ半径方向から重なり合うようにして連結される。

The connecting

以上の構成において、第1、第2分割体28,30は、長い柱分割部241a,242aの連結部241c,242cの各係合爪部c2と,短い柱分割部241b,242bの連結部241d,242dの各係止凹所d1の係止部d2とを軸方向から相互連結することにより互いの柱分割部241,242の端面が軸方向に突き合わされて係止連結される。

In the above-described configuration, the first and second divided

以上の実施の形態1の保持器18においては、第1分割体28の長い柱分割部241aの連結部241cそれぞれと第2分割体30の短い柱分割部242bの連結部242dそれぞれとを相互に連結し、また、第1分割体28の短い柱分割部241bの連結部241dそれぞれと第2分割体30の長い柱分割部242aの連結部242cそれぞれとを相互連結することで、両分割体28,30を連結することができる。

In the

この場合、第1分割体28,30それぞれの長い柱分割部241a,242aが円周方向交互に設けられているので、保持器18の軸方向長さが長くなっても、柱部24の剛性、強度が低下するようなことがない。

In this case, since the long

また、連結部241c,241d,242c,242dは各柱分割部241,242の断面寸法以下であるので、連結部241c,241d,242c,242dを設けても柱分割部241,242の断面寸法が増大しないから、ポケット26の円周方向幅を維持することができ、その結果、転動体16の収納本数が低下するようなことはない。

Further, since the connecting

さらには、連結部241c,242cは胴部c1と係合爪部c2とからなり、これら連結部241c,242cは連結部241d,242dの係止凹所d1内に収納されるので、保持器18寸法は大きくならず、保持器18重量が増大化するようなことはない。

Further, the connecting

特に、実施の形態1の保持器18においては、両分割体28,30は同形であるので、当該分割体28,30を1種類の金型で製作することができ、製作コストを大幅に低減することができる。

In particular, in the

(実施の形態2)

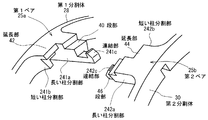

図5は実施の形態2の保持器に係り、図5(a)は一方の分割体28の部分斜視図、図5(b)は他方の分割体30の部分斜視図、図5(c)は両分割体28,30を連結した保持器の部分斜視図である。なお、これらの図において、図1ないし図4と対応する部分には同一の符号を付し、同一の符号に係る部分の詳しい説明は省略する。

(Embodiment 2)

FIG. 5 relates to the cage of the second embodiment, FIG. 5 (a) is a partial perspective view of one divided

図5(a)ないし図5(c)を参照して、第1分割体28の長い柱分割部241aの外径面に径方向内方に下がる段部40を設ける。一方、段部40の高さ、すなわち、長い柱分割部241aに段部40を設けたことにより減少した肉厚分に対応して第2分割体30の短い柱分割部242bにその肉厚分に対応する肉厚でもって軸方向に延長した延長部44を設ける。そして、段部40上に延長部44が重ね合わせるように長い柱分割部241aと短い柱分割部242bとを軸方向に突き合わせる。これによって第1分割体28の長い柱分割部241aに作用する遠心荷重を第2分割体30の短い柱分割部242bの延長部44で受けられるようにする。

With reference to FIG. 5A to FIG. 5C, a stepped portion 40 that falls radially inward is provided on the outer diameter surface of the long

第1分割体28と同様にして、第2分割体30の長い柱分割部242aと第1分割体28の短い柱分割部241bにもそれぞれ段部46と延長部42とを設け、この段部46に延長部42を径方向に係合させ、これによって第2分割体30の長い柱分割部242aに作用する遠心荷重を第1分割体28の短い柱分割部241bの延長部42で受けられるようにする。

Similarly to the first divided

以上の構成により、両分割体28,30は相手側の延長部44,42により遠心荷重を受け止められるので、遠心荷重による変形をより効果的に抑制ないしは防止することができるとともに、この場合の連結部241c,241d,242c,242dは両分割体28,30の円周方向のずれを規制し円周方向の位置決めとして用いることができるようになる。

With the above configuration, since both the divided

(実施の形態3)

図6は、実施の形態3の保持器の部分斜視図、図7は、同保持器の分割体の部分斜視図、図8は図6のB−B線断面図、図9は図6のC−C線断面図である。なお、これらの図において、図1ないし図5と対応する部分には同一の符号を付し、同一の符号に係る部分の詳しい説明は省略する。実施の形態3の保持器においては、第1分割体28で長い柱分割部241aと短い柱分割部241bとが円周方向に隣接配置された第1柱分割部ペア25aとなっている。第2分割体30で長い柱分割部242aと短い柱分割部242bとが円周方向に隣接配置された第2柱分割部ペア25bとなっている。第1分割体28の第1柱分割部ペア25aでは長い柱分割部241aと短い柱分割部241bとが円周方向一方にこの順序で並列配置され、第2分割体30の第2柱分割部ペア25bでは短い柱分割部242bと長い柱分割部242aとが円周方向一方にこの順序で並列配置されている。短い柱分割部241b,242bそれぞれの連結部241d,242dの凹所d1の一部側壁は、長い柱分割部241c,242cの内側面が用いられている。長い柱分割部241a,242aと短い柱分割部241b,242bは実施の形態1と同様の連結部を備えている。

(Embodiment 3)

6 is a partial perspective view of the cage of the third embodiment, FIG. 7 is a partial perspective view of a divided body of the cage, FIG. 8 is a cross-sectional view taken along the line BB of FIG. 6, and FIG. It is CC sectional view taken on the line. In these drawings, parts corresponding to those in FIGS. 1 to 5 are denoted by the same reference numerals, and detailed description of parts corresponding to the same reference numerals is omitted. In the cage according to the third embodiment, the first divided

組立に際しては第1分割体28と第2分割体30とを軸方向に対向配置しそれぞれの連結部を相互連結することにより両分割体28,30が連結されて保持器が組み立てられる。

At the time of assembly, the first divided

以上の実施の形態3の保持器においては、第1分割体28と第2分割体30それぞれの長い柱分割部241a,242aが円周方向に隣接されるので柱部の剛性、強度が向上する。

In the cage of the third embodiment described above, since the long

(実施の形態4)

図10は、実施の形態4の保持器の部分斜視図、図11は、図10の保持器の両分割体の部分斜視図である。なお、これらの図において、図1ないし図9と対応する部分には同一の符号を付し、同一の符号に係る部分の詳しい説明は省略する。

(Embodiment 4)

FIG. 10 is a partial perspective view of the cage of the fourth embodiment, and FIG. 11 is a partial perspective view of both divided bodies of the cage of FIG. In these drawings, parts corresponding to those in FIGS. 1 to 9 are denoted by the same reference numerals, and detailed description of parts corresponding to the same reference numerals is omitted.

実施の形態4においては、実施の形態3の保持器と同様に、第1分割体28側に第1柱分割部ペア25aを備え、第2分割体30側に第2柱分割部ペア25bを備える。そして、実施の形態4では実施の形態2と同様にして、第1分割体28の長い柱分割部241aと第2分割体30の長い柱分割部242aとのそれぞれに径方向の段部40,46を設け、第1分割体28の短い柱分割部241bと第2分割体30の短い柱分割部242bとのそれぞれに軸方向に延長した延長部42,44を設け、これら段部40,46それぞれに延長部44,42を径方向に係合させて、その延長部44,42で遠心荷重を受けるようになっている。

In the fourth embodiment, similar to the cage of the third embodiment, the first pillar divided

以上の構成により、実施の形態4では、第1分割体28と第2分割体30それぞれの長い柱分割部241a,242aが円周方向に隣接されるので柱部の剛性、強度が向上することに加えて、両分割体28,30が相手側の延長部44,42により遠心荷重を受け止められているので、遠心荷重による変形をより効果的に抑制ないしは防止することができるとともに、この場合の連結部241c,241d,242c,242dにより両分割体28,30の円周方向のずれも、より強く規制されて円周方向に位置決めされる。

With the above configuration, in Embodiment 4, since the long column divided

10 転がり軸受

18 保持器

20 円環部

22 円環部

24 柱部

241a 長い柱分割部

241b 短い柱分割部

241c 連結部

241d 連結部

242a 長い柱分割部

242b 短い柱分割部

242c 連結部

242d 連結部

28 第1分割体

30 第2分割体

DESCRIPTION OF

Claims (4)

当該保持器が、柱部の中途位置から軸方向に分割されてそれぞれが円環部と柱部の軸方向分割部分(柱分割部)とを備えかつ両柱分割部の先端側端面の内径側に半径方向に重ね合わされて相互に連結される連結部を備えた2つの分割体から構成されている、ことを特徴とする転がり軸受用保持器。 A pair of annular parts facing in parallel in the axial direction and a plurality of pillars extending between the annular parts in the axial direction and arranged at equal intervals in the circumferential direction and integrated with both annular parts A rolling bearing retainer that constitutes a pocket that holds a rolling element in a hole between circumferential directions of a plurality of column parts,

The cage is divided in the axial direction from the midway position of the column part, each comprising an annular part and an axially divided part (column split part) of the column part, and the inner diameter side of the end surface on the front end side of both column split parts A cage for a rolling bearing, characterized in that the cage is composed of two divided bodies each having a connecting portion that is overlapped in the radial direction and connected to each other.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005114648A JP2006292097A (en) | 2005-04-12 | 2005-04-12 | Cage for rolling bearing |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005114648A JP2006292097A (en) | 2005-04-12 | 2005-04-12 | Cage for rolling bearing |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006292097A true JP2006292097A (en) | 2006-10-26 |

| JP2006292097A5 JP2006292097A5 (en) | 2008-03-21 |

Family

ID=37412863

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005114648A Pending JP2006292097A (en) | 2005-04-12 | 2005-04-12 | Cage for rolling bearing |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2006292097A (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008121817A (en) * | 2006-11-14 | 2008-05-29 | Jtekt Corp | Retainer for rolling bearing |

| EP2031259A2 (en) | 2007-08-31 | 2009-03-04 | JTEKT Corporation | Cage for rolling bearing |

| WO2011098357A1 (en) * | 2010-02-12 | 2011-08-18 | Schaeffler Technologies Gmbh & Co. Kg | Divided plastic cage for a rolling bearing, comprising snap connection |

| JP2012021599A (en) * | 2010-07-15 | 2012-02-02 | Jtekt Corp | Roller bearing cage and roller bearing |

| JP2012026502A (en) * | 2010-07-22 | 2012-02-09 | Ntn Corp | Retainer for ball bearing and ball bearing |

| JP2013079682A (en) * | 2011-10-04 | 2013-05-02 | Ntn Corp | Retainer for ball bearing and ball bearing |

| CN105221567A (en) * | 2015-10-29 | 2016-01-06 | 安徽江淮汽车股份有限公司 | A kind of high axial force deep groove ball bearing and application thereof |

| KR20190102670A (en) * | 2018-02-27 | 2019-09-04 | 셰플러코리아(유) | A Rolling Bearing Having A Cage Hardly Deformed |

| WO2021069013A1 (en) * | 2019-10-10 | 2021-04-15 | Schaeffler Technologies AG & Co. KG | Two-part bearing cage and rolling bearing with a bearing cage of this kind |

| US20230193954A1 (en) * | 2021-06-30 | 2023-06-22 | C&U Company Limited. | Deep groove ball bearing with cage |

-

2005

- 2005-04-12 JP JP2005114648A patent/JP2006292097A/en active Pending

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008121817A (en) * | 2006-11-14 | 2008-05-29 | Jtekt Corp | Retainer for rolling bearing |

| EP2031259A2 (en) | 2007-08-31 | 2009-03-04 | JTEKT Corporation | Cage for rolling bearing |

| WO2011098357A1 (en) * | 2010-02-12 | 2011-08-18 | Schaeffler Technologies Gmbh & Co. Kg | Divided plastic cage for a rolling bearing, comprising snap connection |

| JP2012021599A (en) * | 2010-07-15 | 2012-02-02 | Jtekt Corp | Roller bearing cage and roller bearing |

| JP2012026502A (en) * | 2010-07-22 | 2012-02-09 | Ntn Corp | Retainer for ball bearing and ball bearing |

| JP2013079682A (en) * | 2011-10-04 | 2013-05-02 | Ntn Corp | Retainer for ball bearing and ball bearing |

| CN105221567A (en) * | 2015-10-29 | 2016-01-06 | 安徽江淮汽车股份有限公司 | A kind of high axial force deep groove ball bearing and application thereof |

| KR20190102670A (en) * | 2018-02-27 | 2019-09-04 | 셰플러코리아(유) | A Rolling Bearing Having A Cage Hardly Deformed |

| KR102022369B1 (en) * | 2018-02-27 | 2019-09-18 | 셰플러코리아(유) | A Rolling Bearing Having A Cage Hardly Deformed |

| WO2021069013A1 (en) * | 2019-10-10 | 2021-04-15 | Schaeffler Technologies AG & Co. KG | Two-part bearing cage and rolling bearing with a bearing cage of this kind |

| DE102019127287A1 (en) * | 2019-10-10 | 2021-04-15 | Schaeffler Technologies AG & Co. KG | Two-part bearing cage and rolling bearings with such a bearing cage |

| DE102019127287B4 (en) | 2019-10-10 | 2024-01-25 | Schaeffler Technologies AG & Co. KG | Two-part bearing cage and rolling bearings with such a bearing cage |

| US20230193954A1 (en) * | 2021-06-30 | 2023-06-22 | C&U Company Limited. | Deep groove ball bearing with cage |

| US11867231B2 (en) * | 2021-06-30 | 2024-01-09 | C&U Company Limited. | Deep groove ball bearing with cage |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9382947B2 (en) | Retainer for radial roller bearing | |

| JP2009058039A (en) | Cage for rolling bearing | |

| JP2008121817A (en) | Retainer for rolling bearing | |

| US20090290826A1 (en) | Rolling element bearing with different guide pockets | |

| JP2008025608A (en) | Cage for roller bearing | |

| JP2006292097A (en) | Cage for rolling bearing | |

| US9057404B2 (en) | Cage for a rolling bearing, notably for a motor vehicle electric power steering bearing | |

| JP2007146896A (en) | Ball bearing | |

| JP5978578B2 (en) | Ball bearings and cages for ball bearings | |

| EP1847725A1 (en) | Comb-shaped cage for a ball row of a two row angular contact ball bearing | |

| JP5056394B2 (en) | Roller bearing cage and rolling bearing | |

| WO2010061709A1 (en) | Cage-equipped rollers | |

| JP5506354B2 (en) | Rolling bearings and cages for rolling bearings | |

| JP2010156439A (en) | Snap cage and ball bearing | |

| JP2006200677A (en) | Thrust ball bearing | |

| JP2023006671A (en) | Conical roller bearing | |

| JP2005325884A (en) | Roller bearing cage | |

| CN202531655U (en) | Cage for radial needle roller bearing | |

| JP2006125433A (en) | Deep groove ball bearings and combination ball bearings | |

| JP4983410B2 (en) | Ball bearing cage and ball bearing | |

| JP2012112418A (en) | Cage for radial needle bearing | |

| JP2011106509A (en) | Rolling bearing and retainer thereof | |

| JP2006207684A (en) | Rolling bearing | |

| JP2013087844A (en) | Radial roller bearing retainer | |

| JP6269021B2 (en) | Radial roller bearing cage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080131 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080131 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090609 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090611 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090807 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20090908 |