JP2004044590A - タービンバケット上でのシュラウド先端の重なり合いを修理する方法 - Google Patents

タービンバケット上でのシュラウド先端の重なり合いを修理する方法 Download PDFInfo

- Publication number

- JP2004044590A JP2004044590A JP2003183819A JP2003183819A JP2004044590A JP 2004044590 A JP2004044590 A JP 2004044590A JP 2003183819 A JP2003183819 A JP 2003183819A JP 2003183819 A JP2003183819 A JP 2003183819A JP 2004044590 A JP2004044590 A JP 2004044590A

- Authority

- JP

- Japan

- Prior art keywords

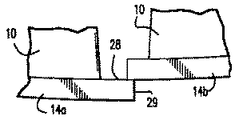

- shroud

- edge

- adjacent

- cover

- overlap

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034 method Methods 0.000 title claims abstract description 23

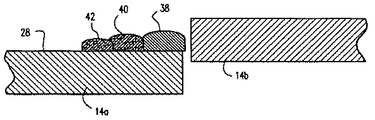

- 239000000463 material Substances 0.000 claims abstract description 38

- 238000003466 welding Methods 0.000 claims abstract description 26

- 239000011324 bead Substances 0.000 abstract description 29

- 229910001347 Stellite Inorganic materials 0.000 description 7

- AHICWQREWHDHHF-UHFFFAOYSA-N chromium;cobalt;iron;manganese;methane;molybdenum;nickel;silicon;tungsten Chemical compound C.[Si].[Cr].[Mn].[Fe].[Co].[Ni].[Mo].[W] AHICWQREWHDHHF-UHFFFAOYSA-N 0.000 description 7

- 238000011065 in-situ storage Methods 0.000 description 4

- 229910001119 inconels 625 Inorganic materials 0.000 description 4

- 238000007689 inspection Methods 0.000 description 4

- 239000000567 combustion gas Substances 0.000 description 1

- 238000012790 confirmation Methods 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000009193 crawling Effects 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 238000012795 verification Methods 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23P—METAL-WORKING NOT OTHERWISE PROVIDED FOR; COMBINED OPERATIONS; UNIVERSAL MACHINE TOOLS

- B23P6/00—Restoring or reconditioning objects

- B23P6/002—Repairing turbine components, e.g. moving or stationary blades, rotors

- B23P6/007—Repairing turbine components, e.g. moving or stationary blades, rotors using only additive methods, e.g. build-up welding

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/005—Repairing methods or devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

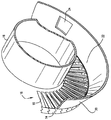

- F01D5/22—Blade-to-blade connections, e.g. for damping vibrations

- F01D5/225—Blade-to-blade connections, e.g. for damping vibrations by shrouding

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/49318—Repairing or disassembling

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/4932—Turbomachine making

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49732—Repairing by attaching repair preform, e.g., remaking, restoring, or patching

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49732—Repairing by attaching repair preform, e.g., remaking, restoring, or patching

- Y10T29/49734—Repairing by attaching repair preform, e.g., remaking, restoring, or patching and removing damaged material

- Y10T29/49737—Metallurgically attaching preform

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49746—Repairing by applying fluent material, e.g., coating, casting

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Butt Welding And Welding Of Specific Article (AREA)

- Arc Welding In General (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/184,045 US6701616B2 (en) | 2002-06-28 | 2002-06-28 | Method of repairing shroud tip overlap on turbine buckets |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004044590A true JP2004044590A (ja) | 2004-02-12 |

| JP2004044590A5 JP2004044590A5 (enExample) | 2006-08-10 |

Family

ID=29717944

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003183819A Pending JP2004044590A (ja) | 2002-06-28 | 2003-06-27 | タービンバケット上でのシュラウド先端の重なり合いを修理する方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6701616B2 (enExample) |

| EP (1) | EP1375823A3 (enExample) |

| JP (1) | JP2004044590A (enExample) |

| KR (1) | KR100789038B1 (enExample) |

| CZ (1) | CZ20031254A3 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005297066A (ja) * | 2004-04-08 | 2005-10-27 | General Electric Co <Ge> | 溶接法 |

| JP2011033020A (ja) * | 2009-07-31 | 2011-02-17 | General Electric Co <Ge> | タービンエンジン用のロータブレード |

| KR101135665B1 (ko) | 2009-08-14 | 2012-04-13 | 두산중공업 주식회사 | 터빈로터의 버켓커버 조립방법 |

| JP2013538965A (ja) * | 2010-07-27 | 2013-10-17 | シーメンス アクティエンゲゼルシャフト | 半体シェルを溶接するための方法 |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10328310A1 (de) * | 2003-06-23 | 2005-01-13 | Alstom Technology Ltd | Verfahren zum Modifizieren der Kopplungsgeometrie bei Deckbandsegmenten von Turbinenlaufschaufeln |

| US7774104B2 (en) * | 2006-12-27 | 2010-08-10 | Fujitsu Ten Limited | Electronic apparatus and electronic system |

| US20080145227A1 (en) * | 2006-12-19 | 2008-06-19 | Mark Stefan Maier | Methods and apparatus for load transfer in rotor assemblies |

| US7762004B2 (en) * | 2007-01-31 | 2010-07-27 | General Electric Company | Inspection tool for measuring bucket Z notch position |

| US9643286B2 (en) * | 2007-04-05 | 2017-05-09 | United Technologies Corporation | Method of repairing a turbine engine component |

| EP2154079A1 (en) * | 2008-07-01 | 2010-02-17 | Rehrig Pacific Company | Bakery tray |

| US9567860B2 (en) | 2012-11-27 | 2017-02-14 | General Electric Company | Fixture for an airfoil shroud and method for modifying an airfoil shroud |

| EP2792848A1 (de) * | 2013-04-17 | 2014-10-22 | Siemens Aktiengesellschaft | Verfahren zum Wiederherstellen der Deckplattenvorspannung einer Turbinenbeschaufelung |

| US9151587B2 (en) | 2013-11-11 | 2015-10-06 | General Electric Company | Bucket tip shroud measurement fixture and method of measuring bucket tip shroud orientation |

| US9611753B2 (en) | 2014-04-29 | 2017-04-04 | General Electric Company | Apparatus and method for inspecting a turbine blade tip shroud |

| US9542739B1 (en) | 2015-08-12 | 2017-01-10 | General Electric Company | Virtual turbomachine blade contact gap inspection |

| US10013752B2 (en) * | 2016-11-18 | 2018-07-03 | General Electric Company | Virtual blade inspection |

| FR3079847B1 (fr) * | 2018-04-10 | 2023-11-10 | Safran Aircraft Engines | Procede de fabrication d'un element aubage metallique d'une turbomachine d'aeronef |

| US20190337102A1 (en) * | 2018-05-07 | 2019-11-07 | General Electric Company | Interlocking Stage of Airfoils |

| CN112935705B (zh) * | 2021-03-23 | 2022-08-23 | 中国能源建设集团西北电力建设工程有限公司 | 一种金属表面焊接修复工艺 |

| JP7756559B2 (ja) * | 2021-12-22 | 2025-10-20 | 三菱重工業株式会社 | 回転機械 |

| CN115502654B (zh) * | 2022-09-14 | 2024-06-18 | 哈电发电设备国家工程研究中心有限公司 | 一种汽轮机钛合金叶片围带间隙修复插片及间隙修复方法 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE407352B (sv) * | 1976-07-19 | 1979-03-26 | Centro Maskin Goteborg Ab | Forfarande och anordning vid gashyvling av en emnesyta for avlegsnande av ytdefekter |

| US4291448A (en) * | 1977-12-12 | 1981-09-29 | Turbine Components Corporation | Method of restoring the shrouds of turbine blades |

| US4589175A (en) * | 1980-06-02 | 1986-05-20 | United Technologies Corporation | Method for restoring a face on the shroud of a rotor blade |

| US5197191A (en) * | 1991-03-04 | 1993-03-30 | General Electric Company | Repair of airfoil edges |

| CA2284759C (en) * | 1998-10-05 | 2006-11-28 | Mahmud U. Islam | Process for manufacturing or repairing turbine engine or compressor components |

| US6164916A (en) * | 1998-11-02 | 2000-12-26 | General Electric Company | Method of applying wear-resistant materials to turbine blades, and turbine blades having wear-resistant materials |

| US6233822B1 (en) * | 1998-12-22 | 2001-05-22 | General Electric Company | Repair of high pressure turbine shrouds |

-

2002

- 2002-06-28 US US10/184,045 patent/US6701616B2/en not_active Expired - Lifetime

-

2003

- 2003-05-06 CZ CZ20031254A patent/CZ20031254A3/cs unknown

- 2003-06-25 EP EP03254006A patent/EP1375823A3/en not_active Withdrawn

- 2003-06-27 JP JP2003183819A patent/JP2004044590A/ja active Pending

- 2003-06-27 KR KR1020030042284A patent/KR100789038B1/ko not_active Expired - Fee Related

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005297066A (ja) * | 2004-04-08 | 2005-10-27 | General Electric Co <Ge> | 溶接法 |

| JP2011033020A (ja) * | 2009-07-31 | 2011-02-17 | General Electric Co <Ge> | タービンエンジン用のロータブレード |

| KR101135665B1 (ko) | 2009-08-14 | 2012-04-13 | 두산중공업 주식회사 | 터빈로터의 버켓커버 조립방법 |

| JP2013538965A (ja) * | 2010-07-27 | 2013-10-17 | シーメンス アクティエンゲゼルシャフト | 半体シェルを溶接するための方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US6701616B2 (en) | 2004-03-09 |

| KR20040002755A (ko) | 2004-01-07 |

| CZ20031254A3 (cs) | 2004-02-18 |

| KR100789038B1 (ko) | 2007-12-26 |

| US20040000050A1 (en) | 2004-01-01 |

| EP1375823A2 (en) | 2004-01-02 |

| EP1375823A3 (en) | 2005-09-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2004044590A (ja) | タービンバケット上でのシュラウド先端の重なり合いを修理する方法 | |

| CN100467200C (zh) | 一种涡轮导向器弧段的修复方法 | |

| CA2405335C (en) | Gas turbine engine compressor blade restoration | |

| US8510926B2 (en) | Method for repairing a gas turbine engine component | |

| US20080216300A1 (en) | Splitter fairing repair | |

| US8601689B2 (en) | Method and apparatus to repair a turbomachine rotor wheel | |

| US7469452B2 (en) | Impeller weld restraining fixture | |

| JP4659968B2 (ja) | タービンノズルセグメントとその修理方法 | |

| JP4588318B2 (ja) | タービンシュラウド支持体の一部分を交換する方法 | |

| JP2017031970A (ja) | 圧縮機用パッチリング、および圧縮機用パッチリングを取り付ける方法 | |

| JP5214280B2 (ja) | タービンノズルセグメント及びその補修方法 | |

| US8230569B2 (en) | Repair of case flange with bolt holes | |

| CA2529337A1 (en) | Turbine nozzle segment and method of repairing same | |

| US20120039707A1 (en) | Method of repairing knife edge seals | |

| US20150165569A1 (en) | Repair of turbine engine components using waterjet ablation process | |

| EP1564371A2 (en) | Method of repair for cast article | |

| US9206702B2 (en) | Method for repairing a shroud tile of a gas turbine | |

| US9145792B2 (en) | Fixture assembly for repairing a shroud tile of a gas turbine | |

| US10563533B2 (en) | Repair or remanufacture of blade outer air seals for a gas turbine engine | |

| JP2004044497A (ja) | タービン動翼の保守方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060622 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060622 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20080725 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080729 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20090106 |