BACKGROUND OF THE INVENTION

-

The present invention relates to a yarn processing facility.

-

Patent Literature 1 (Published

Japanese Translation of a PCT application No. 2003-526584 ) discloses an apparatus (yarn processing facility) configured to form each winding assembly (wound package) by processing a yarn unwound from a yarn supply package (supply bobbin in Patent Literature 1) and winding the yarn onto a winding bobbin. In this regard, the yarn supply package is formed by winding a yarn onto a yarn supplying bobbin. The yarn processing facility is able to support two yarn supply packages for one winding bobbin. In such a yarn processing facility, when a terminal portion of a yarn in one of the two yarn supply packages is tied (connected) to a start end portion of a yarn in the other of the two yarn supply packages, it is possible to uninterruptedly supply the yarn from the other yarn supply package when one yarn supply package becomes empty. To be more specific, immediately after supply of the yarn from one yarn supply package ends, a node (i.e., yarn connecting portion) of two yarns is pulled so that unwinding of the yarn from the other yarn supply package starts. In this way, the yarn is uninterruptedly supplied.

SUMMARY OF THE INVENTION

-

In the technical field of yarn processing, various improvements have been done to increase the productivity and the quality of products. The inventors of the subject application have continued diligent efforts to develop a yarn processing facility having a novel added value. For example, the present inventors have discussed an idea of significantly improving production management by estimating a timing of running out of a yarn (a timing of the end of unwinding of a yarn) in one yarn supply package from which the yarn is unwound.

-

An object of the present invention is to accurately estimate a timing of the end of unwinding of a yarn from a yarn supply package.

-

According to a first aspect of the invention, a yarn processing facility includes: a yarn processor including a yarn supplying unit which is able to supply at least one yarn, a processing unit configured to process the at least one yarn supplied from the yarn supplying unit, and a winding unit configured to wind the at least one yarn processed by the processing unit; and an information management unit configured to manage information regarding the yarn processor, the yarn supplying unit including: at least one yarn supply package retaining portion to which yarn supply packages each including a yarn are detachably attached and which is able to uninterruptedly supply each yarn when a terminal portion of a yarn in one yarn supply package among the yarn supply packages is connected to a start end portion of a yarn in a next yarn supply package from which the yarn is to be unwound next to the one yarn supply package; and at least one detection unit which is able to detect at least whether unwinding of a yarn from the one yarn supply package ends, and the information management unit being configured to: acquire actual all unwinding time information regarding actual all unwinding time by using a detection result of the at least one detection unit, the actual all unwinding time being actual time from the start to end of unwinding of a yarn from a predetermined first yarn supply package among the yarn supply packages; and acquire corrected estimation information by using the actual all unwinding time information, the corrected estimation information being usable for estimating a timing of the end of unwinding of a yarn from a second yarn supply package from which the yarn is to be unwound after the first yarn supply package.

-

According to this aspect of the present invention, the timing of the end of the unwinding of the yarn from the second yarn supply package is estimated based on the corrected estimation information which is acquired by using the actual all unwinding time information regarding actual time from the start to end of unwinding of a yarn from the first yarn supply package. It is therefore possible to accurately estimate a timing of the end of unwinding of a yarn from a yarn supply package.

-

According to a second aspect of the invention, the yarn processing facility of the first aspect is arranged such that the information management unit is further configured to exclude stopping time, in which unwinding of a yarn from the first yarn supply package is temporarily stopped, from the actual all unwinding time when the stopping time exists between the start and end of the unwinding of the yarn from the first yarn supply package.

-

Because of sudden events such as yarn breakage, e.g., unwinding of a yarn may be temporarily stopped. In such a case, when the stopping time is included in the actual all unwinding time, the accuracy of the actual all unwinding time is decreased. As a result, the accuracy in estimation of a timing of the end of unwinding of a yarn from the second yarn supply package is decreased. This aspect of the present invention makes it possible to suppress the decrease in accuracy of the estimation as compared to a case where the stopping time is included in the actual all unwinding time.

-

According to a third aspect of the invention, the yarn processing facility of the first or second aspect is arranged such that the information management unit is further configured to: store information of at least one system value which is usable for estimating a timing of the end of unwinding of a yarn from the first yarn supply package in advance; calculate at least one predetermined correction value by using the at least one system value and the actual all unwinding time; and acquire the corrected estimation information by using the at least one correction value and the at least one system value.

-

When a timing (hereinafter, this timing will be simply referred to as the end timing) of the end of unwinding of a yarn from a yarn supply package is estimated by a calculation, a difference between the calculated end timing and an actual end timing may be large because of a difference between the at least one stored system value and an actual value of one of various parameters which have effects on the actual end timing. According to this aspect of the present invention, the at least one correction value is calculated based on the actual all unwinding time, and the corrected estimation information is acquired by using the at least one correction value. It is therefore possible to acquire various types of accurate information.

-

According to a fourth aspect of the invention, the yarn processing facility of the third aspect is arranged such that system values include an initial weight setting value which is a setting value of initial weight of the first yarn supply package, a fineness setting value which is a setting value of fineness of a yarn in the first yarn supply package, and an unwinding speed setting value which is a setting value of unwinding speed at which the yarn is unwound from the first yarn supply package.

-

According to this aspect of the present invention, the end timing is estimated by using information which can be typically easily acquired as one of the system values.

-

According to a fifth aspect of the invention, the yarn processing facility of the third or fourth aspect is arranged such that the information management unit is further configured to: be able to calculate initially-estimated all unwinding time, which is an estimated value of time from the start to end of unwinding of a yarn from the first yarn supply package, by using the system values; and acquire, as the at least one correction value, a time correction coefficient calculated by dividing the actual all unwinding time by the initially-estimated all unwinding time.

-

According to this aspect of the present invention, the end timing of the second yarn supply package is accurately estimated by multiplying the initially-estimated all unwinding time by the time correction coefficient.

-

According to a sixth aspect of the invention, the yarn processing facility of the third or fourth aspect is arranged such that the information management unit is further configured to: be able to calculate initially-estimated all unwinding time, which is an estimated value of time from the start to end of unwinding of a yarn from the first yarn supply package, by using the system values; and acquire, as the at least one correction value, a difference value between the actual all unwinding time and the initially-estimated all unwinding time.

-

According to this aspect of the present invention, the end timing of the second yarn supply package is accurately estimated on the premise that the initial length of a yarn in the first yarn supply package is substantially identical with the initial length of a yarn in the second yarn supply package.

-

According to a seventh aspect of the invention, the yarn processing facility of the fourth aspect is arranged such that the information management unit is further configured to acquire a fineness correction coefficient as the at least one correction value by using the actual all unwinding time, the initial weight setting value, the fineness setting value, and the unwinding speed setting value, and the fineness correction coefficient is usable for correcting the fineness.

-

According to this aspect of the present invention, actual fineness of a yarn in the second yarn supply package is accurately estimated by using the fineness correction coefficient. It is therefore possible to accurately estimate a timing of the end of unwinding of the yarn from the second yarn supply package.

-

According to an eighth aspect of the invention, the yarn processing facility of any one of the third to seventh aspects is arranged such that the information management unit is further configured to: after acquiring an initial correction value which is the at least one correction value of the first yarn supply package, acquire an additional correction value which is the at least one correction value of an additional yarn supply package which is different from the first yarn supply package and which is retained by the at least one yarn supply package retaining portion; and acquire an update correction value by using at least the additional correction value.

-

When the update correction value is acquired by using at least the additional correction value, the following both cases are possible: a case where the update correction value is acquired by a calculation with use of the initial correction value and the additional correction value; and a case where the additional correction value is acquired as the update correction value. According to this aspect of the present invention, the accuracy of estimation is further increased by acquiring the update correction value according to need and acquiring, with use of the update correction value, the corrected estimation information.

-

According to a ninth aspect of the invention, the yarn processing facility of any one of the third to eighth aspects is arranged such that the yarn processor is able to simultaneously process yarns, the yarn supplying unit includes yarn supply package retaining portions and detection units provided to correspond to the yarn supply package retaining portions, and the information management unit is further configured to: acquire correction values of the yarn supply package retaining portions by using detection results of the detection units; acquire an integrated correction value by using the correction values; and acquire the corrected estimation information of the yarn supply package retaining portions by using the integrated correction value and the system values.

-

According to this aspect of the present invention, the accuracy of estimation is further increased by acquiring the integrated correction value with use of the correction values.

-

According to a tenth aspect of the invention, the yarn processing facility of the ninth aspect is arranged such that the integrated correction value is an average value or a median of the correction values.

-

According to this aspect of the present invention, the very reliable integrated correction value is acquired with a simple calculation.

-

According to an eleventh aspect of the invention, the yarn processing facility of any one of the third to tenth aspects is arranged such that the yarn processor is able to simultaneously process yarns, the yarn supplying unit includes yarn supply package retaining portions and detection units provided to correspond to the yarn supply package retaining portions, the information management unit is further configured to: acquire at least one correction value by using a detection result of one of the detection units; and acquire the corrected estimation information of the yarn supply package retaining portions by using the at least one correction value and the system values.

-

When (i) the corrected estimation information is acquired after the detection results of the detection units are acquired and (ii) unwinding of a yarn is stopped for some reason at one of the yarn supply package retaining portions, the start of acquisition of the corrected estimation information may be delayed. According to this aspect of the present invention, when the at least one correction value is acquired, the corrected estimation information of the yarn supply package retaining portions is immediately acquired. It is therefore possible to quickly start the accurate estimation in each of the yarn supply package retaining portions.

-

According to a twelfth aspect of the invention, the yarn processing facility of the first or second aspect is arranged such that the information management unit is further configured to deal with the actual all unwinding time as the corrected estimation information.

-

When the actual all unwinding time is dealt with as the corrected estimation information, information of the actual all unwinding time is not processed but is used as the corrected estimation information. According to this aspect of the present invention, a timing of the end of unwinding of a yarn from the second yarn supply package is estimated by a simple process on the premise that the initial length of a yarn in the first yarn supply package is substantially identical with the initial length of a yarn in the second yarn supply package.

-

According to a thirteenth aspect of the invention, the yarn processing facility of any one of the first to twelfth aspects is arranged such that the information management unit is further configured to acquire, as the corrected estimation information, at least one of: information of corrected estimation time which is an estimated value of time from the start to end of unwinding of a yarn from the second yarn supply package; information of a corrected unwinding end time point which is a time point at which the unwinding of the yarn from the second yarn supply package ends; information of corrected remaining time which is remaining time in which the unwinding of the yarn from the second yarn supply package is possible at a given reference time point; and information of a corrected remaining amount which is a remaining amount of the yarn in the second yarn supply package at the reference time point.

-

According to this aspect of the present invention, the acquired corrected estimation information is utilized for various managements (e.g., preparation of a schedule of replacement of a yarn supply package).

-

According to a fourteenth aspect of the invention, the yarn processing facility of any one of the first to thirteenth aspects is arranged such that the at least one detection unit is able to detect both the start and end of unwinding of a yarn from the one yarn supply package.

-

For example, the information management unit may be configured to determine a timing of the start of the unwinding in such a way that an operator makes a predetermined input in the information management unit. However, this arrangement increases the burden on the operator. According to this aspect of the present invention, because both the actual start and end of the unwinding are detected by the at least one detection unit, the burden on the operator is reduced.

BRIEF DESCRIPTION OF THE DRAWINGS

-

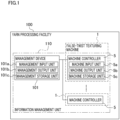

- FIG. 1 is a block diagram of an electric configuration of a yarn processing facility of the present embodiment.

- FIG. 2 is a profile of a false-twist texturing machine.

- FIG. 3 is a schematic diagram of the false-twist texturing machine, expanded along paths of yarns.

- FIG. 4(a) and FIG. 4(b) are graphs each of which shows the relationship between a remaining amount of a yarn in a yarn supply package and time points. FIG. 4(c) is a graph showing the relationship between a wound amount of a yarn onto a winding bobbin and time points.

- FIG. 5 is a flowchart of steps of acquisition of corrected estimation information.

- FIG. 6(a) is a graph showing an estimated remaining amount before a time correction coefficient is acquired. FIG. 6(b) is a graph showing an estimated remaining amount after the time correction coefficient is acquired.

- FIG. 7 is a schematic diagram of an example of various types of information dealt with by an information management unit and how the various types of information are used.

- FIG. 8 is a schematic diagram of an example of various types of information dealt with by an information management unit of a modification and how the various types of information are used.

- FIG. 9 is a schematic diagram of an example of various types of information dealt with by an information management unit of another modification and how the various types of information are used.

- FIG. 10 is a block diagram of an electric configuration of a yarn processing facility of another modification.

- FIG. 11 is a schematic diagram of a false-twist texturing machine of another modification.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

(Outline of Yarn Processing Facility)

-

The following will describe an embodiment of the present invention. A yarn processing facility 100 of the present embodiment will be outlined with reference to a block diagram of FIG. 1. As shown in FIG. 1, the yarn processing facility 100 includes false-twist texturing machines 1 (yarn processors of the present invention) and a management device 101. The false-twist texturing machines 1 are aligned along, e.g., a predetermined frame longitudinal direction (see FIG. 2, etc.). Each false-twist texturing machine 1 is able to perform false twisting of yarns Y (see FIG. 2, etc.) made of synthetic fibers such as polyester and nylon (polyamide fibers). Each yarn Y is, e.g., a multi-filament yarn formed of filaments (not illustrated). As described below, each false-twist texturing machine 1 is configured to form wound packages Pw by processing yarns Y supplied from a yarn supplying unit 2 by means of a processing unit 3 and winding the yarns Y onto winding bobbins Bw attached to a winding unit 4. Each false-twist texturing machine 1 is controlled by a machine controller 5 that is a computer device mounted on each false-twist texturing machine 1.

-

The management device 101 is a host computer used for integrally controlling information acquired by machine controllers 5. The management device 101 includes a management input unit 101a (e.g., a keyboard), a management output unit 101b (e.g., a display), and a management storage unit 101c (e.g., a hard disk). A combination of the management device 101 and the machine controllers 5 is an information management unit 110 of the present embodiment. The information dealt with by the information management unit 110 will be detailed later.

(Overall Structure of False-Twist Texturing Machine)

-

The overall structure of each false-twist texturing machine 1 will be described with reference to FIG. 2 and FIG. 3. FIG. 2 is a profile of each false-twist texturing machine 1. FIG. 3 is a schematic diagram of the false-twist texturing machine 1, expanded along paths of yarns Y (i.e., yarn paths). A direction vertical to the sheet of FIG. 2 is defined as the above-described frame longitudinal direction, and a left-right direction in the sheet is defined as a frame width direction. A direction orthogonal to both the frame longitudinal direction and the frame width direction is defined as an up-down direction (vertical direction) in which the gravity acts. A direction in which each yarn Y runs is defined as a yarn running direction. The false-twist texturing machine 1 includes a yarn supplying unit 2 provided for supplying yarns Y, a processing unit 3 configured to process (false-twist) the yarns Y supplied from the supplying unit 2, a winding unit 4 configured to wind the yarns Y processed by the processing unit 3 onto winding bobbins Bw, and a corresponding machine controller 5.

-

The yarn supplying unit 2 includes a creel stand 6 retaining yarn supply packages Ps, and is configured to supply the yarns Y to the processing unit 3. The processing unit 3 is configured to unwind the yarns Y from the yarn supplying unit 2 and to process the yarns Y. In the processing unit 3, the following members are placed in this order from the upstream side in the yarn running direction: first feed rollers 11; twist-stopping guides 12; first heaters 13; coolers 14; false-twisting devices 15; second feed rollers 16; second heaters 17; and third feed rollers 18. Each of these elements of the processing unit 3 is provided for, e.g., each of later-described spindles 9 (see FIG. 3). The winding unit 4 includes plural winding devices 19. Each winding device 19 is configured to wind a yarn Y for which false twisting has been performed by the processing unit 3 onto a winding bobbin Bw and to form a wound package Pw. The winding unit 4 is provided with automatic doffers 10 which correspond to the respective winding devices 19 and which are configured to replace formed wound packages Pw with empty winding bobbins Bw.

-

The machine controller 5 is configured to control the yarn supplying unit 2, the processing unit 3, and the winding unit 4. The machine controller 5 is, e.g., a typical computer device. The machine controller 5 includes a machine input unit 5a (operation unit of the present invention), a machine output unit 5b, and a machine storage unit 5c (see FIG. 1). The machine input unit 5a is, e.g., an unillustrated touch panel and/or keyboard and is operable by an operator. The machine output unit 5b includes, e.g., an unillustrated display and is able to output information. The machine storage unit 5c is arranged to store various types of information used for controlling the yarn supplying unit 2, processing unit 3, and winding unit 4. Based on the various types of information, the machine controller 5 controls the yarn supplying unit 2, processing unit 3, and winding unit 4. Alternatively, the machine controller 5 may indirectly control the yarn supplying unit 2, processing unit 3, and winding unit 4 through unillustrated controllers (not illustrated) configured to control these members. The machine controller 5 is electrically connected to the management device 101 that is a host computer. The management device 101 is able to perform later-described determinations and/or calculations by using information acquired by the machine controller 5.

-

The false-twist texturing machine 1 includes a main frame 7 and a winding base 8 that are spaced apart from each other in the frame width direction. The main frame 7 and the winding base 8 are substantially identical in length in the frame longitudinal direction. The main frame 7 and the winding base 8 oppose each other in the frame width direction. The false-twist texturing machine 1 includes units which are termed spans each of which includes a pair of the main frame 7 and the winding base 8. In one span, each device is placed so that the false twisting is simultaneously performable for the yarns Y running while being aligned in the frame longitudinal direction. In the false-twist texturing machine 1, the spans are placed in a left-right symmetrical manner to the sheet, with a center line C of the frame width direction of the main frame 7 being set as a symmetry axis (main frame 7 is shared between the left span and the right span). The spans are aligned in the frame longitudinal direction.

-

A group of elements through which a single yarn Y supplied from the yarn supplying unit 2 passes before reaching the winding unit 4 is termed a spindle. To put it differently, the false-twist texturing machine 1 includes the spindles 9 (see FIG. 3) the number of which is identical with the number of wound packages Pw that can be simultaneously formed. Roughly speaking, the spindles 9 are aligned along the frame longitudinal direction. The inclusion relation is as follows: one false-twist texturing machine 1 includes plural spans, and each of the spans includes plural spindles 9. The false-twist texturing machine 1 is able to false-twist the yarns Y at the spindles 9 to which the yarns Y are threaded.

(Yarn Supplying Unit)

-

The structure of the yarn supplying unit 2 will be described with reference to FIG. 2 and FIG. 3. The creel stand 6 of the yarn supplying unit 2 includes yarn supply package retaining portions 20 (see FIG. 3) provided to correspond to the respective spindles 9. Each yarn supply package retaining portion 20 is arranged so that two yarn supply packages Ps are attachable thereto and detachable therefrom. In other words, each yarn supply package retaining portion 20 has two package attachment units 21. For the sake of convenience, one of the two package attachment units 21 is termed a first attachment unit 22, and the other of these units is termed a second attachment unit 23. Each of the first attachment unit 22 and the second attachment unit 23 is arranged so that one yarn supply package Ps is attachable thereto and detachable therefrom. The attachment and detachment of each yarn supply package Ps to and from a corresponding package attachment unit 21 are performed by, e.g., an operator.

-

Each yarn supply package retaining portion 20 of the yarn supplying unit 2 is able to uninterruptedly supply a yarn Y in a manner described below. For example, as shown in FIG. 3, one of the yarn supply packages Ps, i.e., a yarn supply package PsA (one yarn supply package of the present invention) is attached to the first attachment unit 22. Furthermore, the other of the yarn supply packages Ps, i.e., a yarn supply package PsB (next yarn supply package of the present invention) is attached to the second attachment unit 23. The yarn Y is unwound from the yarn supply package PsA. A terminal portion of the yarn Y in the yarn supply package PsA is tied (connected) to a start end portion of a yarn Y in the yarn supply package PsB. With this arrangement, a node K (yarn connecting portion) is formed between two yarns Y. This makes it possible to uninterruptedly supply the yarn Y from the yarn supply package PsB after the yarn supply package PsA becomes empty. To be more specific, immediately after (i) supply of the yarn Y from the yarn supply package PsA ends and (ii) the yarn supply package PsA becomes empty, the node K is pulled toward the downstream side in the yarn running direction (i.e., toward the winding device 19) so that the yarn Y is unwound from the yarn supply package PsB. In other words, after unwinding of a yarn Y from a yarn supply package Ps attached to one package attachment unit 21 ends, unwinding of a yarn Y from the next yarn supply package Ps attached to the other package attachment unit 21 starts. Hereinafter, for the sake of convenience, such a matter is referred to as yarn supply package switching. In this way, the yarn Y is uninterruptedly supplied. Thereafter, the yarn supply package Ps (yarn supplying bobbin Bs) having become empty is replaced with a new yarn supply package Ps by, e.g., the operator.

-

On the downstream side in the yarn running direction of each yarn supply

package retaining portion 20, a yarn detection sensor 24 (detection unit of the present invention) is provided. The

yarn detection sensor 24 is able to detect which one of the attachment units, i.e., the

first attachment unit 22 and or

second attachment unit 23 is supplying the yarn Y. As shown in

FIG. 3, the

yarn detection sensor 24 includes a

first detection unit 25 and a

second detection unit 26. The

first detection unit 25 is able to detect whether the yarn Y is being supplied from the

first attachment unit 22. The

second detection unit 26 is able to detect whether the yarn Y is being supplied from the

second attachment unit 23. Each of the

first detection unit 25 and the

second detection unit 26 is, e.g., an optical sensor configured to optically detect the yarn Y. For details of the

yarn detection sensor 24, see

Japanese Patent No. 5873105 , for example. Alternatively, each of the

first detection unit 25 and the

second detection unit 26 may be, e.g., a contact sensor.

(Processing Unit)

-

The structure of the processing unit 3 will be described with reference to FIG. 2 and FIG. 3. The following will describe a part of the processing unit 3, which corresponds to one spindle 9.

-

A first feed roller 11 is configured to unwind a yarn Y from one yarn supply package Ps attached to the yarn supplying unit 2 and to feed the yarn Y to a first heater 13. The first feed roller 11 is provided upstream of a twist-stopping guide 12 in the yarn running direction. The conveyance speed of conveying the yarn Y by the first feed roller 11 is substantially identical with an unwinding speed V (see FIG. 3; hereinafter, this may be referred to as just the unwinding speed) at which the yarn Y is unwound from the yarn supply package Ps. In this regard, information indicating a setting value of the conveyance speed of conveying the yarn Y by the first feed roller 11 is stored in, e.g., the machine controller 5 in advance. An unillustrated cutter may be provided upstream of the first feed roller 11 in the yarn running direction.

-

In this case, when yarn breakage occurs, the yarn Y is cut by the cutter so that the yarn Y is prevented from being unintentionally wound onto a rotating member such as the first feed roller 11.

-

The twist-stopping guide 12 is provided to prevent twist of the yarn Y from being propagated to the upstream side of the twist-stopping guide 12 in the yarn running direction. The twist of the yarn Y is formed by a false-twisting device 15. The twist-stopping guide 12 is provided downstream of the first feed roller 11 in the yarn running direction and upstream of a first heater 13 in the yarn running direction.

-

The first heater 13 is configured to heat the yarn Y fed from the first feed roller 11. The first heater 13 is provided downstream of the twist-stopping guide 12 in the yarn running direction and upstream of a cooler 14 in the yarn running direction. For the sake of simplicity, the first heater 13 of the present embodiment is configured to heat a single yarn Y. However, the disclosure is not limited to this. The first heater 13 may be able to simultaneously heat plural yarns Y.

-

The cooler 14 is configured to cool the yarn Y heated by the first heater 13. The cooler 14 is provided downstream of the first heater 13 in the yarn running direction and upstream of the false-twisting device 15 in the yarn running direction. For the sake of simplicity, the cooler 14 of the present embodiment is configured to cool a single yarn Y. However, the disclosure is not limited to this. The cooler 14 may be able to simultaneously cool plural yarns Y.

-

The false-twisting device 15 is configured to twist the yarn Y. The false-twisting device 15 is, e.g., a so-called disc-friction false-twisting device. However, the disclosure is not limited to this. The false-twisting device 15 is provided downstream of the cooler 14 in the yarn running direction and upstream of a second feed roller 16 in the yarn running direction.

-

The second feed roller 16 is configured to feed the yarn Y processed by the false-twisting device 15 to a second heater 17. The conveyance speed of conveying the yarn Y by the second feed roller 16 is higher than the conveyance speed of conveying the yarn Y by the first feed roller 11. The yarn Y is therefore drawn between the first feed roller 11 and the second feed roller 16. In this regard, information indicating a setting value of the conveyance speed of conveying the yarn Y by the second feed roller 16 is stored in, e.g., the machine controller 5 in advance.

-

The second heater 17 is configured to heat the yarn Y fed from the second feed roller 16. The second heater 17 extends along the vertical direction. For the sake of simplicity, the second heater 17 of the present embodiment is configured to heat a single yarn Y. However, the disclosure is not limited to this. The second heater 17 may be able to simultaneously heat plural yarns Y.

-

A third feed roller 18 is configured to feed the yarn Y heated by the second heater 17 to a winding device 19. The conveyance speed of conveying the yarn Y by the third feed roller 18 is lower than the conveyance speed of conveying the yarn Y by the second feed roller 16. The yarn Y is therefore relaxed between the second feed roller 16 and the third feed roller 18. In this regard, information indicating a setting value of the conveyance speed of conveying the yarn Y by the third feed roller 18 is stored in, e.g., the machine controller 5 in advance.

-

In the processing unit 3 arranged as described above, the yarn Y drawn between the first feed roller 11 and the second feed roller 16 is twisted by the false-twisting device 15. The twist formed by the false-twisting device 15 propagates to the twist-stopping guide 12, but does not propagate to the upstream side of the twist-stopping guide 12 in the yarn running direction. The yarn Y which is twisted and drawn is heated by the first heater 13 and thermally set. After that, the yarn Y is cooled by the cooler 14. The yarn Y is untwisted on the downstream side of the false-twisting device 15 in the yarn running direction. However, each filament is maintained to be wavy in shape on account of the thermal setting described above. Subsequently, the yarn Y false-twisted by the false-twisting device 15 is thermally set by the second heater 17 while being relaxed between the second feed roller 16 and the third feed roller 18, and then the yarn Y is guided to the downstream side in the yarn running direction. Finally, the yarn Y fed from the third feed roller 18 is wound onto a winding bobbin Bw by the winding device 19. As a result, one wound package Pw is formed.

(Winding Unit)

-

The structure of the winding unit 4 will be described with reference to FIG. 2 and FIG. 3. The winding unit 4 includes (i) the winding devices 19 configured to wind yarns Y onto winding bobbins Bw and (ii) the automatic doffers 10 (see FIG. 2) provided to correspond to the respective winding devices 19. One winding device 19 belongs to one spindle 9 (see FIG. 3). Each winding device 19 includes, e.g., a fulcrum guide 31, a traverse unit 32, a cradle 33, and a winding roller 34. The fulcrum guide 31 is a guide which is a fulcrum when a yarn Y is traversed. The traverse unit 32 is configured to traverse the yarn Y by means of, e.g., a traverse guide 35 attached to an endless belt driven by a motor in a reciprocating manner. The cradle 33 is able to support a winding bobbin Bw (wound package Pw) to be rotatable. The winding roller 34 is configured to rotate the wound package Pw and to apply contact pressure to the surface of the wound package Pw. The winding roller 34 is, e.g., rotationally driven by an unillustrated motor while being in contact with the surface of the wound package Pw. With this arrangement, the wound package Pw is rotationally driven by the friction force, and the shape of the wound package Pw is adjusted by the contact pressure applied to the surface of the wound package Pw. Instead of rotationally driving the winding roller 34, the wound package Pw may be directly rotated by an unillustrated motor.

-

Each

automatic doffer 10 is configured to detach the wound package Pw from the winding

device 19 and to attach an empty winding bobbin Bw to the winding

device 19. To put it differently, at the winding

unit 4, the

automatic doffer 10 is able to replace a wound package Pw having been formed with an empty winding bobbin Bw. The

automatic doffer 10 is provided with an unillustrated cutter which is able to cut the yarn Y in the vicinity of the wound package Pw. As the running yarn Y is cut by the cutter, formation of the wound package Pw is finished. After being cut by the cutter, the yarn Y is kept unwound from the yarn supply package Ps and kept supplied toward the winding

device 19 at a speed which is substantially the same as the speed of winding the yarn Y onto the winding bobbin Bw. The

automatic doffer 10 includes an unillustrated suction which is able to suck, capture, and retain the running yarn Y supplied to the winding

device 19, in a period from the finish of the formation of the wound package Pw to start of winding of the yarn Y onto the next winding bobbin Bw. Before the yarn Y is threaded to the next winding bobbin Bw to which the yarn Y is to be wound next, a part of the yarn Y sucked by the suction is sucked and removed. For details of the structure of the

automatic doffer 10, etc., for example, see

Japanese Laid-Open Patent Publication No. H6-212521 .

-

For example, an unillustrated yarn threading device is provided in the vicinity of the winding device 19. The yarn threading device is configured to thread the yarn Y onto the empty winding bobbin Bw attached to the winding device 19.

-

In the winding unit 4 structured as described above, the yarn Y which is fed from the above-described third feed roller 18 is wound onto the winding bobbin Bw by each winding device 19, and the wound package Pw is formed (winding process). As the cutter of the automatic doffer 10 cuts the yarn Y, the winding process of winding the yarn Y onto the winding bobbin Bw is finished. Almost at the same time, the yarn Y supplied to the winding device 19 is sucked and retained by the suction, and the wound package Pw is detached from the cradle 33 by the automatic doffer 10. Immediately thereafter, the automatic doffer 10 attaches a new winding bobbin Bw to the cradle 33. Subsequently, the yarn threading device threads the yarn Y to the new winding bobbin Bw. Thereafter, it becomes possible to start winding of the yarn Y onto the new winding bobbin Bw.

-

The inventors of the subject application conceived of an idea described below, in order to significantly improve production management as compared to known production management. The inventors of the subject application conceived of an idea of providing a means for knowing, at a desired timing, (i) the remaining amount of the yarn Y (yarn remaining amount; hereinafter, this may be referred to as just the remaining amount) after a part of the yarn Y is unwound from the yarn supply package Ps and/or (ii) the time (remaining time; hereinafter, this may be referred to as just the remaining time) in which the yarn Y can be supplied from the yarn supply package Ps. Alternatively, the time from the start to end of unwinding of the yarn Y from the yarn supply package Ps (i.e., to running out of the yarn Y in the yarn supply package Ps) and/or when unwinding of the yarn Y from the yarn supply package Ps ends may be estimated. As such information is known, a timing of running out of the yarn Y in the yarn supply package Ps from which the yarn Y is unwound can be estimated. In the present embodiment, the information management unit 110 is configured to perform information processing described later in order to accurately estimate a timing of the end of unwinding of the yarn Y from the yarn supply package Ps. In a specific example, the information management unit 110 is configured to acquire and manage various types of information regarding matters shown in graphs of FIG. 4(a) to FIG. 4(c). Unless otherwise stated, the following explanation deals with only a predetermined spindle 9 among the spindles 9.

(Specific Example of Matters)

-

Before specifically explaining information acquired by the information management unit 110, matters shown in the graphs of FIG. 4(a) to FIG. 4(c) as examples and time points at which the respective matters occur will be described first in order to assist the understanding of the explanation given later. The information management unit 110 is configured to acquire information of at least one of the matters shown in the graphs of FIG. 4(a) to FIG. 4(c). (The details will be given later.) Each time point described below is not a time point which is estimated by any means but a time point at which a corresponding matter actually occurs.

-

FIG. 4(a) is a graph showing the relationship between the remaining amount (vertical axis) of a yarn Y in each yarn supply package Ps (to be more specific, yarn supply packages Ps1, Ps3) attached to the first attachment unit 22 and time points (horizontal axis). FIG. 4(b) is a graph showing the relationship between the remaining amount (vertical axis) of the yarn Y in each yarn supply package Ps (to be more specific, a yarn supply package Ps2) attached to the second attachment unit 23 and time points (horizontal axis). FIG. 4(c) is a graph showing the relationship between the wound amount (vertical axis) of a yarn Y onto each winding bobbin Bw (to be more specific, winding bobbins Bw1, Bw2, Bw3, Bw4, Bw5, and Bw6) and time points (horizontal axis). In all of the graphs of FIG. 4(a) to FIG. 4(c), a time point t0 at which unwinding of a yarn Y from the yarn supply package Ps1 starts is the origin. In the present embodiment, the weight (initial weight; hereinafter, this may be referred to as just the initial weight) of each yarn supply package Ps in a state in which a yarn Y is not unwound from each yarn supply package Ps at all (i.e., fully-wound yarn supply package Ps) is always WF.

-

To begin with, before the time point t0, the fully wound yarn supply package Ps1 is attached to the first attachment unit 22. The weight of the yarn Y in the yarn supply package Ps1 is identical with the initial weight WF. Furthermore, before the time point t0, the fully-wound yarn supply package Ps2 is attached to the second attachment unit 23. A terminal portion of the yarn Y in the yarn supply package Ps1 is tied to a start end portion of a yarn Y in the yarn supply package Ps2, and hence a node K is formed. At the time point t0, yarn threading to each element at the spindle 9 starts. Furthermore, at the time point t0, unwinding of the yarn Y from the fully-wound yarn supply package Ps1 starts. At a time point ts1 immediately after the time point t0, the yarn threading to the winding bobbin Bw1 attached to the winding device 19 is completed and winding of the yarn Y onto the winding bobbin Bw1 starts. In this regard, after the unwinding of the yarn Y from the yarn supply package Ps1 starts, the yarn Y is sucked and captured by the suction until the yarn threading to the winding bobbin Bw1 is completed. In the present embodiment, the unwinding speed of the yarn Y in the yarn threading is substantially identical with the unwinding speed (the above-described unwinding speed V) in the winding of the yarn Y onto the winding bobbin Bw. A difference between the time point ts1 and the time point t0 is the time from the start to completion of the yarn threading.

-

The remaining amount (remaining weight) of the yarn Y in the yarn supply package Ps1 decreases and the wound amount (wound weight) of the yarn Y wound on the winding bobbin Bw1 increases over time. At a time point te1, as the cutter of the automatic doffer 10 cuts the yarn Y, the winding process of winding the yarn Y onto the winding bobbin Bw1 is finished. Therefore, the time point te1 is a winding end time point at which the winding of the yarn Y onto the winding bobbin Bw1 ends (i.e., the formation of the wound package Pw1 ends). The remaining weight of the yarn supply package Ps1 at this time is W1. Onto the winding bobbin Bw1, only the yarn Y supplied from the yarn supply package Ps1 is wound. The cutting of the yarn Y by the cutter, the sucking and capturing of the yarn Y by the suction (i.e., start of sucking and removal of the yarn Y), and the detachment of the winding bobbin Bw1 (wound package Pw1) from the cradle 33 are almost simultaneously done. At a time point ts2 immediately after the time point te1, the attachment of the winding bobbin Bw2 to the cradle 33 by the automatic doffer 10 is completed and the winding process of winding the yarn Y onto the winding bobbin Bw2 starts (i.e., the winding bobbin replacement is completed). There is a slight time lag tL (see FIG. 4(c)) between the winding end time point (time point te1) of the winding bobbin Bw1 and a winding start time point (time point ts2) of the winding bobbin Bw2 onto which the yarn Y is to be wound next to the winding bobbin Bw1. As described above, even when the replacement of the winding bobbin Bw is performed, the yarn Y is unwound from the yarn supply package Ps at the same speed as the speed of winding the yarn Y onto the winding bobbin Bw. Subsequently, the winding process of winding the yarn Y onto the winding bobbin Bw2 (formation of the wound package Pw2) ends at a time point te2. The winding process of winding the yarn Y onto the winding bobbin Bw3 then starts at a time point ts3.

-

At a time point ta1 (see FIG. 4(a)) that is later than the time point ts3, the yarn supply package Ps1 attached to the first attachment unit 22 becomes empty. Therefore, the time point ta1 is an unwinding end time point at which the unwinding of the yarn Y from the yarn supply package Ps1 ends. At the same time as the yarn supply package Ps1 becomes empty, at a time point tb1 (=time point ta1), the node K formed as the yarn Y in the yarn supply package Ps1 is tied with the yarn Y in the yarn supply package Ps2 is pulled toward the winding device 19. As a result, the yarn Y starts to be unwound from the yarn supply package Ps2 attached to the second attachment unit 23. Therefore, the time point tb1 is an unwinding start time point at which the unwinding of the yarn Y from the yarn supply package Ps2 starts (i.e., the yarn Y starts to be unwound) . Thereafter, at a time point te3, the winding process of winding the yarn Y onto the winding bobbin Bw3 (i.e., formation of the wound package Pw3) ends. Onto the winding bobbin Bw3, both the yarn Y unwound from the yarn supply package Ps1 and the yarn Y unwound from the yarn supply package Ps2 are wound. The wound package Pw3 includes the node K. Thereafter, at a time point ts4, the winding process of winding the yarn Y onto the winding bobbin Bw4 starts. At a time point te4, the winding process of winding the yarn Y onto the winding bobbin Bw4 (i.e., formation of a wound package Pw4) ends. Onto the winding bobbin Bw4, only the yarn Y unwound from the yarn supply package Ps2 is wound.

-

At a time point which is later than the time point ta1 and is before the yarn supply package Ps2 becomes empty (e.g., at a time point ta2), the operator detaches the empty yarn supply package Ps1 from the first attachment unit 22 and attaches the fully-wound yarn supply package Ps3 to the first attachment unit 22 (yarn supply package replacement). The remaining weight of the yarn supply package Ps3 at this time is the initial weight WF. Thereafter, at a suitable timing, a terminal portion of the yarn Y in the yarn supply package Ps2 is tied with (connected to) a start end portion of a yarn Y in the yarn supply package Ps3 by the operator so that a node K (see FIG. 3) is formed. The operator may manually perform a tying operation (connecting operation). Alternatively, for example, the operator may perform the tying operation by operating an unillustrated portable tying device.

-

Thereafter, the yarn Y is wound onto the winding bobbin Bw5 from a time point ts5 to a time point te5 (i.e., a wound package Pw5 is formed). At a time point tb2 between the time point ts5 and the time point te5, the yarn supply package Ps2 attached to the second attachment unit 23 becomes empty. At the same time as the yarn supply package Ps2 becomes empty, at a time point ta3 (= time point tb2), unwinding of the yarn Y from the yarn supply package Ps3 attached to the first attachment unit 22 starts. Subsequently, the yarn Y is wound onto a winding bobbin Bw6 from a time point ts6 to a time point te6 (i.e., a wound package Pw6 is formed).

(Outline of Basic Information Acquired by Information Management Unit)

-

In consideration of the matters above, to begin with, the outline of basic information acquired by the information management unit 110 in order to perform determinations and/or calculations will be described. As the basic information, for example, the information management unit 110 is configured to acquire initial amount information, unwinding unit amount information, and cumulative time information of each yarn supply package Ps. The initial amount information, unwinding unit amount information, and cumulative time information are usable for acquiring estimation information used for performing various managements regarding the yarn processing facility 100. The estimation information indicates at least one of an estimated value of the remaining amount described below, an estimated value of the remaining time described below, an estimated value of all unwinding time described below, and an estimated value of each unwinding end time point described below. The remaining amount indicates an amount of a yarn Y in each yarn supply package Ps attached to each package attachment unit 21 at a given reference time point. The remaining time indicates the time from a reference time point to the end of unwinding of a yarn Y from each yarn supply package Ps from which the yarn Y is unwound. The all unwinding time indicates a total time from the start to end of unwinding of a yarn Y from each yarn supply package Ps which is a target of estimation. Each unwinding end time point indicates a time point at which unwinding of a yarn Y from a yarn supply package Ps, which is a target of estimation, ends.

-

The information management unit 110 may be configured to also acquire various types of information (information regarding a start time point and end time point of the winding process, etc.) of each wound package Pw. The details of acquisition of these types of information are omitted.

-

The initial amount information is information regarding an initial amount (initial weight or initial length) of a yarn Y in each yarn supply package Ps before unwinding of the yarn Y starts. The initial amount information is set in advance in the machine controller 5 as, e.g., information shared between all yarn supply packages Ps of each spindle 9 in one false-twist texturing machine 1. To be more specific, in the present embodiment, information indicating the above-described initial weight WF and information indicating the fineness (weight per unit length) of the yarn Y are stored in each machine controller 5 as the initial amount information. The unit of the weight of the yarn supply package Ps is, e.g., kilogram. The fineness of the yarn Y is expressed in units of F. The unit of the fineness is, e.g., dtex (decitex). Decitex indicates the weight (gram) of the yarn Y per 10000 meters. The unwinding unit amount information is information regarding an amount of the yarn Y unwound from each yarn supply package Ps per unit time. The unwinding unit amount information is, e.g., information of the above-described unwinding speed V. For the sake of convenience, the unwinding speed V during the winding process is assumed to be substantially constant in the present embodiment. The unit of the unwinding speed is, e.g., m/min. The unwinding unit amount information is set in advance in each machine controller 5 as, e.g., information shared between all spindles 9 in one false-twist texturing machine 1. The machine controller 5 is configured to acquire information of the unwinding speed V based on, e.g., information indicating a setting value of the rotation number of the first feed roller 11. The values of the initial weight WF (initial weight setting value), fineness (fineness setting value), and unwinding speed V (unwinding speed setting value) which are set in advance in the information management unit 110 are included in system values of the present invention.

-

The cumulative time information is information regarding a cumulative value (cumulative time: hereinafter, this may be referred to as just the cumulative time) of the time required for unwinding of the yarn Y from each yarn supply package Ps. For the sake of convenience, the cumulative time of each yarn supply package Ps from which the yarn Y is unwound is referred to as tin. The cumulative time information is acquired as described below. To begin with, for example, when the yarn Y starts to be unwound from the above-described yarn supply package Ps1 at the above-described time point t0, the start of unwinding of the yarn Y is detected by the yarn detection sensor 24. At this time, the machine controller 5 resets tin to a predetermined initial time (reset process). The predetermined initial time is, e.g., 0. The machine controller 5 may acquire and store information of an unwinding start time point (i.e., time point t0) at which the unwinding of the yarn Y from the yarn supply package Ps1 starts. Thereafter, the machine controller 5 increases tin (updates tin) over time during the unwinding of the yarn Y from the yarn supply package Ps. In this regard, for example, when the unwinding of the yarn Y from the yarn supply package Ps is temporarily stopped because of yarn breakage, etc. (i.e., a stopping time exists), the machine controller 5 temporarily stops the update of tin. In this way, the machine controller 5 acquires, as the cumulative time (tin), only the time in which the unwinding of the yarn Y from each yarn supply package Ps is detected by the yarn detection sensor 24. The machine controller 5 is able to acquire the cumulative time information regarding one yarn supply package Ps when the yarn Y is unwound from the one yarn supply package Ps. Typically, when the winding process restarts at the spindle 9 in which the unwinding of the yarn Y is temporarily stopped, the yarn threading to each element at the spindle 9 is required.

-

Based on a detection result of the yarn detection sensor 24, the machine controller 5 determines whether the yarn supply package switching, i.e., switching of the yarn supply package Ps supplying the yarn Y has occurred during the winding process. For example, in FIG. 4(a) and FIG. 4(b), the yarn supply package switching is a matter in which (i) the unwinding of the yarn Y from the yarn supply package Ps1 ends (end of unwinding) and (ii) unwinding of the yarn Y from the yarn supply package Ps2 starts. The machine controller 5 determines that the yarn supply package switching has occurred when the state of the yarn detection sensor 24 is switched from (i) a state of detecting the yarn Y by one of the first detection unit 25 and the second detection unit 26 to (ii) a state of detecting the yarn Y by the other one of the first detection unit 25 and the second detection unit 26. When determining that the yarn supply package switching has occurred, the machine controller 5 performs the above-described reset process to reset tin to a predetermined initial time. Information indicating a time point at which the yarn supply package switching has occurred may be acquired and stored by the machine controller 5 as unwinding start time point information of the yarn supply package Ps2. With this arrangement, the yarn detection sensor 24 is able to detect both the start and end of unwinding of the yarn Y from the yarn supply package Ps1.

-

As described above, the information management unit 110 is configured to acquire the initial amount information, the unwinding unit amount information, and the cumulative time information as the basic information.

(Information Regarding Replacement of Yarn Supply Package and Node)

-

As the explanation regarding the above-described yarn supply package switching, the following will describe information acquired by the information management unit 110 when one empty yarn supply package Ps is replaced with a new yarn supply package Ps during the winding process. When the yarn supply package Ps attached to one package attachment unit 21 is empty, the operator detaches the empty yarn supply package Ps from the one package attachment unit 21 and attaches a new yarn supply package Ps to the one package attachment unit 21. At this time, the operator associates (inputs attachment information) individual information of the new yarn supply package Ps with individual information of the one package attachment unit 21. Thereafter, the operator connects a start end portion of a yarn Y in the new yarn supply package Ps to a terminal portion of a yarn Y in a yarn supply package Ps attached to the other package attachment unit 21, so that a node K is formed. The operator then provides the node K at a predetermined position. Subsequently, the operator inputs, into the machine controller 5, information (this information will be referred to as arrangement information for the sake of convenience) indicating that the node K has been provided at the predetermined position. When such an input is made, the machine controller 5 stores the arrangement information. After that, when the yarn supply package switching has occurred, the machine controller 5 performs the above-described reset process and stores information (this information will be referred to as movement information for the sake of convenience) indicating that the node K has been moved from the predetermined position.

(Steps of Acquisition of Estimation Information)

-

The following will describe an example of steps of acquisition of the detailed estimation information by the information management unit 110. The estimation information includes both information acquired by using only the system values and information (corrected estimation information) acquired by using the system values and later-described correction values. Roughly speaking, to begin with, the information management unit 110 acquires (i) information of the all unwinding time estimated by using only the system values (initially-estimated all unwinding time) and (ii) information of the actual time from the start to end of unwinding of a yarn Y from each yarn supply package Ps (actual all unwinding time). The information management unit 110 then calculates time correction coefficients (correction values) by using the initially-estimated all unwinding time and the actual all unwinding time, and acquires various types of the corrected estimation information by using the time correction coefficients and the system values.

-

The steps of acquisition described above are detailed with reference to FIG. 5 to FIG. 7. FIG. 5 is a flowchart of steps of acquisition of estimated correction information. FIG. 6(a) is a graph showing an estimated remaining amount of each yarn supply package Ps before time correction coefficients are acquired. FIG. 6(b) is a graph showing an estimated remaining amount of the yarn supply package Ps after the time correction coefficients are acquired. FIG. 7 is a schematic diagram of an example of various types of information dealt with by the information management unit 110 and how the various types of information are used (which type of information is used in order to acquire which type of information). Information put at a starting point of each dotted-line arrow in FIG. 7 is information used for calculation. Information put at a termination point (arrow-head side) of each dotted-line arrow in FIG. 7 is acquired based on one or more types of information used for calculation.

-

To begin with, when a lot (described later) used in the yarn processing facility 100 has been switched (YES in S101), the machine controller 5 starts the winding process at each spindle 9 and measurement of a difference between the initially-estimated all unwinding time and actual all unwinding time of each spindle 9 (S102). In the present embodiment, the lot indicates the unit of production of wound packages Pw, i.e., a plurality of wound packages Pw formed under the same specifications (e.g., processing conditions including the brand and the unwinding speed) at the spindles 9. That is, the lot in this case may be interpreted as a production condition. For example, when the operator makes a predetermined input indicating the switching of the lot into the machine input unit 5a of the machine controller 5, the information management unit 110 determines that the lot has been switched.

-

When the unwinding of the yarn Y from, e.g., the yarn supply package Ps1 (first yarn supply package of the present invention) at the above-described

predetermined spindle 9 starts, the

yarn detection sensor 24 detects the start of supply of the yarn Y. The

information management unit 110 then performs the reset process based on a detection result of the

detection sensor 24 and starts update of the cumulative time (tin). When the yarn Y is unwound from the yarn supply package Ps1, the

information management unit 110 acquires and stores the initially-estimated all unwinding time of the yarn supply package Ps1 by using only the system values (S103). In this regard, when the initially-estimated all unwinding time is tP (see

FIG. 6(a) and

FIG. 7), tP is calculated based on, e.g., the following equation.

-

The "1000" of this equation indicates a coefficient for converting the unit of a numerator on the right side of this equation to gram. The "10000" of this equation indicates a coefficient for converting the unit of a denominator on the right side of this equation to g/min. The unit of tP is minute. Also in equations described later, the "1000" and the "10000" indicate these respective coefficients.

-

The

information management unit 110 may acquire further information of the yarn supply package Ps1 by using the system values. For example, when the remaining amount of the yarn Y in the yarn supply package Ps1 at one reference time point is WR while the cumulative time at the one reference time point is tin1, the

information management unit 110 may estimate the remaining amount WR based on, e.g., the following equation.

-

Furthermore, when the remaining time in which the yarn supply package Ps1 can supply the yarn Y at the one reference time point is tR, the

information management unit 110 may estimate the remaining time tR based on, e.g., any one of the following equations.

-

The information management unit 110 may estimate a time point (estimated unwinding end time point) at which the unwinding of the yarn Y from the yarn supply package Ps1 ends. The information management unit 110 may store a time point (the above-described time point t0) at which the unwinding of the yarn Y from the yarn supply package Ps1 starts and may acquire a time point obtained by adding tP to t0 as the estimated unwinding end time point of the yarn supply package Ps1.

-

The following describes an acquiring method of the actual all unwinding time. After the storing of the initially-estimated all unwinding time, the yarn detection sensor 24 detects the end of unwinding of the yarn Y from the yarn supply package Ps1 (yarn supply package switching) at one time point (S104) . At this time, as the actual all unwinding time (e.g., tA; see FIG. 6(a) and FIG. 7), the information management unit 110 stores a value of tin in the detection of the yarn supply package switching (S105). After that, the value of tin is reset to a predetermined initial time by the above-described reset process.

-

In this regard, when the unwinding of the yarn Y is temporarily stopped during the winding process (i.e., when a stopping time exists), the information management unit 110 temporarily stops the update of the cumulative time as described above. In other words, when a stopping time exists, the information management unit 110 performs a process of excluding the stopping time from the actual all unwinding time.

-

As a reference, a graph of FIG. 6(a) schematically shows a difference between the initially-estimated all unwinding time and actual all unwinding time of the yarn supply package Ps1. The vertical axis of this graph indicates the remaining amount of the yarn Y, and the horizontal axis of this graph indicates the time points. For simplifying the explanation, the above-described stopping time is assumed not to occur. For example, when the estimated unwinding end time point (see taP in FIG. 6(a)) of the yarn supply package Ps1 is calculated based on the initially-estimated all unwinding time (tP), taP is a time point obtained by adding the initially-estimated all unwinding time tP to the time point t0. Meanwhile, an actual unwinding end time point (the above-described time point ta1) of the yarn supply package Ps1 is a time point obtained by adding the actual all unwinding time (tA) to the time point t0. In this case, a difference between tP and tA (i.e., a difference between the initially-estimated all unwinding time and the actual all unwinding time) is a difference between the estimated unwinding end time point and the actual unwinding end time point. In an example of FIG. 6(a), the actual all unwinding time tA is longer than the initially-estimated all unwinding time tP. Such a difference may occur because of various reasons. For example, the difference occurs when the actual fineness of the yarn Y in the yarn supply package Ps1 is slightly different from the fineness setting value (F).

-

Subsequently, the

information management unit 110 calculates each time correction coefficient by using the initially-estimated all unwinding time and the actual all unwinding time (S106). When the time correction coefficient of the above-described

predetermined spindle 9 is Ct (see

FIG. 7), Ct is calculated based on the following equation.

-

The time correction coefficient (Ct) is a ratio of the actual all unwinding time (tA) to the initially-estimated all unwinding time (tP). When Ct is larger than 1, a pace of unwinding the yarn Y from the yarn supply package Ps1 is slower than the pace originally estimated. On the contrary, when Ct is smaller than 1, a pace of unwinding the yarn Y from the yarn supply package Ps1 is faster than the pace originally estimated. For example, by using the time correction coefficient, a timing of the end of unwinding of the yarn Y from the above-described yarn supply package Ps2 is further accurately estimated. To be more specific, the information management unit 110 is able to acquire the time obtained by multiplying tP by Ct (this acquired time is identical with the actual all unwinding time tA) as an estimated value of the time from the start to end of unwinding of the yarn Y from the yarn supply package Ps2. In this case, an estimated time point at which the unwinding of the yarn Y from the yarn supply package Ps2 ends is substantially identical (see FIG. 6(b)) with an actual time point at which the unwinding of the yarn Y from the yarn supply package Ps2 ends.

-

Subsequently, each time after time correction coefficients of all of the spindles 9 (e.g., spindles 9A to 9Z in FIG. 7) are acquired, the information management unit 110 calculates and stores an average value (integrated correction value of the present invention) of the time correction coefficients (S107). After that, by using the averaged time correction coefficient and the system values, the information management unit 110 acquires various types of the corrected estimation information of a yarn supply package Ps from which the yarn Y is unwound at least after the yarn supply package Ps1 (S108). Hereinafter, for the sake of convenience, the yarn supply package Ps from which the yarn Y is unwound at least after the yarn supply package Ps1 is referred to as the "latter yarn supply package Ps" (second yarn supply package of the present invention). Until the lot switches (NO in S101), the information management unit 110 acquires the corrected estimation information of the spindles 9 of the false-twist texturing machine 1 (i.e., of the yarn supply package retaining portions 20) by using the averaged time correction coefficient.

-

The following describes a specific example of the corrected estimation information. In the present embodiment, the

information management unit 110 is able to acquire, as the corrected estimation information, information of corrected estimation time which is an estimated value of the time from the start to end of unwinding of the yarn Y from the latter yarn supply package Ps. For example, when the averaged time correction coefficient is CtA (see

FIG. 7) while the corrected estimation time is tPc (see

FIG. 7), tPc is calculated based on the following equation.

-

The

information management unit 110 may acquire information indicating a time point at which unwinding of the yarn Y from the latter yarn supply package Ps starts, by using a detection result of the

yarn detection sensor 24. In this case, by using information of a switching time point and information of the corrected estimation time, the

information management unit 110 is able to acquire information of a corrected unwinding end time point at which the unwinding of the yarn Y from the latter yarn supply package Ps ends. The information of the corrected unwinding end time point is encompassed in the corrected estimation information. For example, when the switching time point is at tS (see

FIG. 7) while the corrected unwinding end time point is at tEc (see

FIG. 7), tEc is calculated based on, e.g., any one of the following equations.

-

Furthermore, when the yarn Y is unwound from the latter yarn supply package Ps at one reference time point, the

information management unit 110 is able to acquire information of corrected remaining time which is the remaining time to the end of unwinding of the yarn Y from the latter yarn supply package Ps. To be more specific, at the one reference time point, the

information management unit 110 is able to acquire information of the corrected remaining time by using information of the cumulative time (the above-described tin) regarding the unwinding of the yarn Y from the latter yarn supply package Ps. The information of the corrected remaining time is encompassed in the corrected estimation information. When the corrected remaining time is tRc (see

FIG. 7), tRc is calculated based on, e.g., any one of the following equations.

-

Furthermore, when the yarn Y is unwound from the latter yarn supply package Ps at the one reference time point, the

information management unit 110 is able to acquire information of a corrected remaining amount which is the remaining amount of the yarn Y in the latter yarn supply package Ps. The information of the corrected remaining amount is encompassed in the corrected estimation information. When the corrected remaining amount is WRc (see

FIG. 7), WRc is calculated based on, e.g., the following equation.

-

A time correction coefficient (CtA) of this equation is used as a divisor. This is because, the larger the time correction coefficient is, the more an actual pace of unwinding of the yarn Y from each yarn supply package Ps (i.e., actual pace of decrease of weight of each yarn supply package Ps) lags behind the pace originally estimated.

-

In this way, the information management unit 110 acquires, as the corrected estimation information, at least one of: information of the corrected estimation time; information of the corrected unwinding end time point; information of the corrected remaining time; and information of the corrected remaining amount. These types of information are related to the latter yarn supply package Ps.

-

As described above, a timing of the end of unwinding of the yarn Y from the latter yarn supply package Ps is estimated based on the corrected estimation information which is acquired by using actual all unwinding time information regarding the actual time from the start to end of the unwinding of the yarn Y from the yarn supply package Ps1, etc. It is therefore possible to accurately estimate a timing of the end of unwinding of the yarn Y from the yarn supply package Ps (end timing).

-

When a stopping time exists between the start and end of the unwinding of the yarn Y from the yarn supply package Ps1, the information management unit 110 does not include the stopping time in the actual all unwinding time. It is therefore possible to suppress the decrease in accuracy of estimation as compared to a case where the stopping time is included in the actual all unwinding time.

-

The correction values are calculated based on the actual all unwinding time, and the corrected estimation information is acquired by using the correction values. It is therefore possible to acquire various types of accurate information.

-

The system values include a setting value of the initial weight WF, a setting value of the fineness, and a setting value of the unwinding speed V. In the present embodiment, the end timing is estimated by using information which can be typically easily acquired as one of the system values.

-

The information management unit 110 is able to calculate the initially-estimated all unwinding time by using the system values and to acquire each time correction coefficient calculated by dividing the actual all unwinding time by the initially-estimated all unwinding time. It is therefore possible to accurately estimate the end timing of the latter yarn supply package Ps by multiplying the initially-estimated all unwinding time by the time correction coefficient.

-

The accuracy of estimation is further increased by acquiring the integrated correction value with use of plural time correction coefficients.

-

The average value of the time correction coefficients is calculated as the integrated correction value. It is therefore possible to acquire the very reliable integrated correction value with a simple calculation.

-

The information management unit 110 is configured to acquire, as the corrected estimation information, at least one of: information of the corrected estimation time; information of the corrected unwinding end time point; information of the corrected remaining time; and information of the corrected remaining amount. These types of information are related to the latter yarn supply package Ps. With this arrangement, each type of the acquired corrected estimation information is utilized for various managements (e.g., preparation of a schedule of replacement of the yarn supply package Ps).

-

Because the yarn detection sensor 24 is configured to detect both the actual start and actual end of unwinding, the burden on the operator is reduced as compared to a case where, e.g., the operator makes a predetermined input into the information management unit 110 so as to cause the information management unit 110 to determine that the unwinding has started.

-

The following will describe modifications of the above-described embodiment. The members identical to those in the embodiment described above will be denoted by the same reference numerals, and the explanations thereof are not repeated.

- (1) In the embodiment above, the information management unit 110 is configured to acquire, as a correction value, each time correction coefficient (Ct) obtained by dividing the actual all unwinding time (tA) by the initially-estimated all unwinding time (tP). However, the disclosure is not limited to this. For example as described below, the information management unit 110 may be configured to calculate (acquire) a fineness correction coefficient as each correction value by using the actual all unwinding time, the initial weight setting value, the fineness setting value, and the unwinding speed setting value. The fineness correction coefficient is provided for correcting the fineness of the yarn Y in the yarn supply package Ps1. When the fineness correction coefficient is Cf (see FIG. 8), Cf is calculated based on the equation described later. The actual fineness of the yarn Y in the latter yarn supply package Ps is accurately estimated by using the fineness correction coefficient. This arrangement makes it possible to accurately estimate a timing of the end of unwinding of the yarn Y from the yarn supply package Ps. In this case, the information management unit 110 may be configured to acquire the initially-estimated all unwinding time in advance or may be configured not to acquire the initially-estimated all unwinding time.

-

The following describes the equations described in the embodiment above again. These equations are respectively provided for calculating the initially-estimated all unwinding time (tP) and each time correction coefficient (Ct).

-

These three equations show that Cf is an inverse of Ct. The

information management unit 110 may be configured to calculate and store an average value (integrated correction value of the present invention) of fineness correction coefficients of all of the

spindles 9 after acquiring the fineness correction coefficients. For example, when the averaged fineness correction coefficient is CfA (see

FIG. 8) while the fineness after correction (corrected fineness) is Fc (see 8), Fc is calculate based on the following equation.

-

When the yarn Y is unwound from the latter yarn supply package Ps at one reference time point, the

information management unit 110 may calculate the above-described corrected remaining amount (WRc) based on, e.g., any one of the following equations.

-

Furthermore, the

information management unit 110 may calculate the corrected estimation time (tPc) of the latter yarn supply package Ps based on, e.g., any one of the following equations.

-

Furthermore, the