EP3736401B2 - Schlitten und führungsschienenanordnung für schiebetürpaneele - Google Patents

Schlitten und führungsschienenanordnung für schiebetürpaneele Download PDFInfo

- Publication number

- EP3736401B2 EP3736401B2 EP20173031.4A EP20173031A EP3736401B2 EP 3736401 B2 EP3736401 B2 EP 3736401B2 EP 20173031 A EP20173031 A EP 20173031A EP 3736401 B2 EP3736401 B2 EP 3736401B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- carriage

- guiding rail

- lateral

- assembly

- insert

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D15/00—Suspension arrangements for wings

- E05D15/06—Suspension arrangements for wings for wings sliding horizontally more or less in their own plane

- E05D15/0621—Details, e.g. suspension or supporting guides

- E05D15/0626—Details, e.g. suspension or supporting guides for wings suspended at the top

- E05D15/063—Details, e.g. suspension or supporting guides for wings suspended at the top on wheels with fixed axis

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/60—Suspension or transmission members; Accessories therefor

- E05Y2201/622—Suspension or transmission members elements

- E05Y2201/64—Carriers

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/60—Suspension or transmission members; Accessories therefor

- E05Y2201/622—Suspension or transmission members elements

- E05Y2201/708—Sliders

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2800/00—Details, accessories and auxiliary operations not otherwise provided for

- E05Y2800/26—Form or shape

- E05Y2800/33—Form or shape having protrusions

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/10—Application of doors, windows, wings or fittings thereof for buildings or parts thereof

- E05Y2900/13—Type of wing

- E05Y2900/132—Doors

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/10—Application of doors, windows, wings or fittings thereof for buildings or parts thereof

- E05Y2900/13—Type of wing

- E05Y2900/132—Doors

- E05Y2900/14—Doors disappearing in pockets of a wall, e.g. so-called pocket doors

Definitions

- the present invention relates to a carriage and guiding rail assembly for sliding door panels, in particular for door panels suitable for being exposed to unbalancing forces in a direction that is not parallel to the sliding direction of the carriage, such as door panels installed on boats, means of transportation or door panels installed outdoor and therefore exposed to climatic actions, such as wind, and also door panels suitable for being installed in walls or ceilings that are not planar to the floor.

- a sliding door is suitable for opening and closing an opening defined by a secondary frame in a fixed structure.

- a carriage is fixed to the door panel.

- the carriage slides in a guiding rail obtained with a section fixed to the secondary frame that defines the opening.

- the secondary frame may be omitted.

- a clearance is provided between the body of the carriage and the guiding rail. Therefore, if the door panel is exposed to unbalancing forces in a direction that is not parallel to the sliding direction of the carriage, the carriage moves in the guiding rail in transverse direction, cannot slide and gets jammed, or the door panel might slide incorrectly, not being perpendicular to the floor.

- EP2586945 discloses a carriage for sliding doors according to the preamble of claim 1.

- the purpose of the present invention is to eliminate the drawbacks of the prior art, by disclosing a carriage and guiding rail assembly for sliding doors that is efficient, reliable, practical, versatile and easy to make and install.

- the carriage and guiding rail assembly for sliding door panels according to the invention is defined by claim 1.

- the carriage and guiding rail assembly according to the invention is described.

- the carriage is generally indicated with reference numeral 100.

- the carriage (100) comprises a body (1) shaped as a plate suitable for being disposed along a vertical plane.

- the body (1) of the carriage has a lower shank (12) that protrudes in lower position to receive connection means (not shown) for connecting the body (1) to a door panel (not shown).

- the connection means can be a vertical pin or a bolt that is fixed to a flange connected to an upper edge of the door panel.

- the lower shank (12) can be accessed through a hole (13) with upper counterbore.

- the hole (13) has a vertical axis, is opened on top and is centrally disposed in the body of the carriage.

- connection means consist in a vertical pin that rotates freely and is provided with an upper head that penetrates the counterbore of the hole (13).

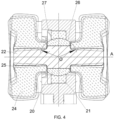

- the body (1) has two through holes (10) with horizontal axis. Each through hole (10) defines a housing (11) wherein a rolling support (2) is mounted.

- the rolling support (2) can be a bearing that comprises an external ring (20) that is revolvingly mounted on an internal ring (21).

- a shaft (22) is mounted in the internal ring (20) of the bearing.

- the shaft (22) has two ends (23) that protrude laterally from the body (1) in order to be fixed in holes (25) of wheels (24).

- the shaft (22) can be fixed to the internal ring (20) or can be free to rotate inside the internal ring (20).

- the rolling support (2) can consist in a bush with a hole wherein the shaft (22) rotates freely.

- a stop ring (28) can be mounted in the housing (11) of the body to retain the rolling support (2). Obviously, the stop ring (28) can be replaced with other retention systems in order to retain the bearing.

- the rolling support (2) is a bearing

- the axial section of the internal ring (20) of the support has an external convex surface (26), which is shaped as an arc of circle and slides on a concave surface (27), which is shaped as an arc of circle, of the external ring of the bearing.

- the arc of circle of the concave surface (27) of the internal ring has the same radius of curvature as the arc of circle of the convex surface (26) of the external ring, and the arc of circle of the concave surface (27) of the internal ring is longer than the arc of circle of the convex surface (26) of the external ring.

- the shaft (22) has an axis (A) and a center of rotation (O) in a median point of the shaft, in such a way that the axis (A) of the shaft can be inclined in any direction relative to the center of rotation (O).

- Fig. 4 shows the situation wherein the axis (A) of the shaft (22) can be inclined relative to a horizontal axis by an angle of approximately +/- 10-15°, in such a way to adjust to the guiding rail wherein the carriage slides.

- the body (1) of the carriage has a front housing (14) suitable for removably receiving a front insert (3) that protrudes frontally from the body of the carriage.

- the front insert (3) is made of soft anti-noise material, and acts as buffer in order to stop against an end-of-travel stop disposed in the guiding rail of the carriage. In view of the above, the front insert (3) eliminates the noise caused when the carriage is stopped against the end-of-travel stop.

- the front housing (14) of the body of the carriage has a C-shaped longitudinal section.

- the front insert (3) has a cylindrical, parallelepiped or cubic shape or a tapered shape, such as a truncated conical or truncated pyramidal shape, with a rounded or flat head (30).

- the front insert (3) has a back collar (31) that protrudes outwards in order to be inserted and retained in the front housing (14) of the body.

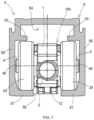

- the body (1) of the carriage has two lateral housings (15) that protrude laterally from the body (1) in opposite directions.

- Each lateral housing (15) is disposed between two wheels (24).

- the lateral housings (15) consist in cylindrical shanks that protrude laterally from the body (1) in diametrically opposite directions relative to the axis of the hole (13) with vertical axis of the body of the carriage.

- Each lateral housing (15) has a cylindrical hole (16) suitable for removably receiving a lateral insert (4) that protrudes laterally from the body of the carriage.

- the lateral insert (4) has a cylindrical shape and a head (40) that can be rounded or flat. The head (40) of the lateral insert protrudes laterally from the body of the carriage, in a higher degree than the wheels (24).

- the lateral insert (4) or at least the head (40) of the lateral insert is made of a material with a low friction coefficient, such as a self-lubricating material like polytetrafluoroethylene (PTFE), which is known on the market with the Teflon trademark.

- PTFE polytetrafluoroethylene

- Fig. 6 shows a guiding rail (5) suitable for being fixed to a secondary frame or to a wall or ceiling of a fixed structure.

- the guiding rail (5) consists in a section with a substantially C-shaped cross-section.

- the guiding rail (5) comprises two lateral walls (50) that continue with two separate lower walls (51) in such a way to define a lower longitudinal groove (52) that allows for the sliding movement of the connection means connected to the lower shank (12) of the body of the carriage.

- the wheels (24) of the carriage can roll on the lower walls (51) of the guiding rail.

- the guiding rail can comprise two longitudinal ribs (53) that extend inside the guiding rail in parallel direction to the lower walls (51) in such a way to define an upper housing (54) with a C-shape and a lower housing (55) wherein the carriage (100) slides.

- the wheels (24) of the carriage can roll on the lower walls (51) of the guiding rail and are disposed under the ribs (53) of the guiding rail.

- the heads (40) of the lateral inserts slide on the lateral walls (50) of the guiding rail in such a way to hold the carriage (100) in a perfectly centered position inside the guiding rail. In this way, the lateral inserts (4) can act as slides.

- the lateral inserts (4) are very useful when the carriage (100) is used in furnishings for boats because they reduce the lateral clearance between carriage and rail. In fact, the lateral inserts (4) prevent the carriage (100) from skidding in case of an anomalous lateral movement of the door panel (for example in rough sea conditions).

- the lateral inserts (4) can be extracted from their housings and replaced with inserts of different heights, according to the space that is left between the carriage and the lateral walls (50) of the guiding rail.

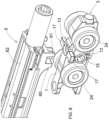

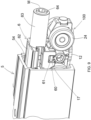

- the body (1) of the carriage has two lateral elements (17) that protrude laterally from the body (1) in opposite directions.

- the lateral elements (17) are disposed above the lateral housings (15) in diametrically opposite directions relative to the axis of the hole (13) with vertical axis of the body of the carriage.

- the lateral elements (17) of the body of the carriage are suitable for being fastened by a fastening system (60) provided in a first type of accessory (6) suitable for being connected to the carriage (100) and for sliding inside the guiding rail (5).

- the fastening system (60) comprises two U-shaped housings (61) suitable for fastening and retaining the lateral elements (17) of the body of the carriage.

- the first type of accessory (6) can be an accessory for the closing/return of the door panel when the door panel is opened or closed.

- the first type of accessory (6) comprises a section (62) suitable for sliding inside the upper housing (54) of the guiding rail.

- the section (62) supports an internally empty cylinder (63) with an axial hole (64) suitable for receiving a pin (M) made of magnetic material and fixed to the secondary frame, when the carriage (100) is approaching an end-of-travel position.

- the cylinder (63) is made of a conductive magnetic metal material. Therefore, when the pin (M) penetrates the hole (64) of the cylinder, a magnetic field is generated to return and retain the carriage (100).

- the body (1) of the carriage has two back elements (18) that protrude at the back from the body (1) in such a way to define a U-shaped housing suitable for receiving a fastener (70) of a second type of accessory (7).

- the second type of accessory (7) is suitable for being connected to the carriage (100) and for sliding inside the guiding rail (5).

- the fastener (70) of the second type of accessory is shaped like a parallelepiped block and is disposed at a front end of the second type of accessory.

- the fastener (70) of the second type of accessory comprises a hole (71) with vertical axis.

- the back elements (18) of the body of the carriage comprise holes (18a) suitable for receiving screw or bolt means (B) that penetrate the hole (71) of the fastener (70) of the second type of accessory.

- the second type of accessory (7) comprises a section (72) with a height that is substantially equal to the height of the carriage (100) in order to slide inside the lower housing (55) of the sliding rail. Wheels (73) are mounted at a back end of the section (72) of the second type of accessory.

- a hook-slider (74) protrudes in upper position from the section (71) and slides in a longitudinal groove (75) of the section (71) that is open on top.

- the hook-slider (74) is fastened to an activator that is blocked in position in an upper portion of the guiding rail.

- the hook-slider (74) is connected to a return spring (79) disposed inside the section (71).

- Two guiding pins (76, 78) for each side are integral with the hook-slider (74) and slide in an L-shaped groove (77) obtained in the two lateral walls of the section (71).

- a coupling (8) is disposed between the back elements (18) of the body of the carriage and the fastener (70) of the second type of accessory (7).

- the coupling (8) comprises a hole (80) with vertical axis disposed in a parallelepiped block suitable for being disposed in the housing between the two back elements (18) of the body of the carriage.

- the hole (80) of the coupling is disposed in register with the holes (18a) of the back elements of the body of the carriage, in such a way that the screw or bolt means (B) penetrate the holes (18a, 80) of the back elements of the body of the carriage and of the coupling.

- the coupling (8) has two back elements (81) that define a U-shaped housing that receives the fastener (70) of the second type of accessory.

- the back elements (81) of the coupling are provided with holes (82) with horizontal axis.

- the fastener (70) of the second type of accessory is provided with holes (71) with horizontal axis.

- Screw or bolt means (B1) penetrate the holes (82) of the back elements of the coupling and the holes (71a) of the fastener of the second type of accessory in order to fasten the fastener of the second type of accessory to the coupling (8).

- the body (1) of the carriage is functional and simultaneously provides all the aforementioned different functions/features, namely:

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Support Devices For Sliding Doors (AREA)

- Lock And Its Accessories (AREA)

- Power-Operated Mechanisms For Wings (AREA)

Claims (10)

- Schlittenanordnung (100) und Führungsschiene (5) für Schiebetüren, wobei die Führungsschiene (5) ein Profil mit einem "C"-förmigen Querschnitt mit Seitenwänden (50) umfasst, wobei der Schlitten (100) umfasst:- einen Körper (1), der die Form einer Platte aufweist, die dazu geeignet ist, entlang einer vertikalen Ebene angeordnet zu werden,- einen unteren Schaft (12), der unten aus dem Körper vorsteht, um Verbindungsmittel zum Verbinden des Körpers (1) des Schlittens mit einem Türblatt aufzunehmen, und- Rollen (24), die drehbar mit dem Körper (1) des Schlittens verbunden und dazu geeignet sind, in der Führungsschiene (5) zu rollen, der Schlitten (100) umfasst ferner:- seitliche Einsätze (4), die in seitlichen Sitzen (15) abnehmbar eingesetzt sind, die an den Seiten des Körpers des Schlittens derart herausgearbeitet sind, dass sie seitlich in entgegengesetzten Richtungen aus dem Körper des Schlittens vorstehen, um auf den Seitenwänden (50) der Führungsschiene zu gleiten; wobei jeder seitliche Einsatz (4) mindestens teilweise aus einem Material mit einem im Vergleich zu den Seitenwänden (50) der Führungsschiene niedrigen Reibungskoeffizienten hergestellt ist; wobei jeder seitliche Einsatz (4) einen Kopf (40) aufweist, der seitlich aus dem Körper des Schlittens in einem höheren Grad als die Räder (24) vorsteht;dadurch gekennzeichnet, dass

die Köpfe (40) der seitlichen Einsätze (4) auf den seitlichen Wänden (50) der Führungsschiene, die als Schieber dienen, derart gleiten, dass sie den Schlitten (100) in einer perfekt zentrierten Position innerhalb der Führungsschiene halten. - Schlittenanordnung (100) und wobei jeder Führungsschiene (5) nach Anspruch 1, wobei die seitlichen Sitze (15), die an den Seiten des Körpers des Schlittens herausgearbeitet sind, zylindrische Schäfte umfassen, die seitlich in entgegengesetzten Richtungen aus dem Körper des Schlittens vorstehen.

- Schlittenanordnung (100) und Führungsschiene (5) nach Anspruch 1 oder 2, wobei jeder seitliche Einsatz (4) eine zylindrische Form aufweist und der Kopf (40) flach oder gerundet sein kann.

- Schlittenanordnung (100) und Führungsschiene (5) nach einem der vorstehenden Ansprüche, wobei der seitliche Einsatz (4) mindestens teilweise aus selbstschmierendem Material, wie Polytetrafluorethylen (PTFE), hergestellt ist.

- Schlittenanordnung (100) und Führungsschiene (5) nach einem der vorstehenden Ansprüche, umfassend ferner einen vorderen Einsatz (3), der auf abnehmbare Weise in einem vorderen Sitz (14) des Körpers des Schlittens montiert ist, wobei der vordere Einsatz (3) aus weichem, geräuschdämpfendem Material hergestellt ist und als Puffer fungiert, um gegen einen Endanschlag in Anschlag zu gehen, der in der Führungsschiene (5) angeordnet ist.

- Schlittenanordnung (100) und Führungsschiene (5) nach Anspruch 5, wobei der vordere Sitz (14) des Körpers des Schlittens einen "C"-förmigen Querschnitt aufweist und der vordere Einsatz (3) die Form eines Zylinders, Quaders, Würfels, sich verjüngenden Kegelstumpfes oder Pyramidenstumpfes aufweist und einen abgerundeten oder flachen Kopf (30) und einen hinteren Bund (31) umfasst, der nach außen vorsteht, um in den vorderen Sitz (14) des Körpers des Schlittens eingesetzt und darin gehalten zu werden.

- Schlittenanordnung (100) und Führungsschiene (5) nach einem der vorstehenden Ansprüche, wobei der Körper (1) des Schlittens zwei seitliche Elemente (17) aufweist, die seitlich aus dem Körper des Schlittens in entgegengesetzte Richtungen vorstehen; wobei die seitlichen Elemente (17) des Körpers des Schlittens dazu geeignet sind, durch ein Befestigungssystem (60) befestigt zu werden, das in einer ersten Art von Zubehör (6) vorgesehen ist, das dazu geeignet ist, mit dem Schlitten (100) verbunden zu werden und in der Führungsschiene (5) zu gleiten.

- Schlittenanordnung (100) und Führungsschiene (5) nach einem der vorstehenden Ansprüche, wobei der Körper (1) des Schlittens zwei hintere Element (18) aufweist, die hinten aus dem Körper des Schlittens derart vorstehen, dass ein "U"-förmiger Sitz definiert wird, der dazu geeignet ist, ein Befestigungselement (70) aufzunehmen, das in einer zweiten Art von Zubehör (7) vorgesehen ist, das dazu geeignet ist, mit dem Schlitten (100) verbunden zu werden und in der Führungsschiene (5) zu gleiten.

- Schlittenanordnung (100) und Führungsschiene (5) nach einem der Ansprüche von 1 bis 7, wobei der Körper (1) des Schlittens zwei hintere Elemente (18) aufweist, die hinten aus dem Körper des Schlittens derart vorstehen, dass ein "U"-förmiger Sitz definiert wird, der dazu geeignet ist, ein Verbindungselement (8) aufzunehmen, das mit einem Befestigungselement (70) verbunden wird, das in einer zweiten Art von Zubehör (7) vorgesehen ist, das dazu geeignet ist, mit dem Schlitten (100) verbunden zu werden und in der Führungsschiene (5) zu gleiten.

- Schlittenanordnung (100) und Führungsschiene (5) nach einem der vorstehenden Ansprüche, umfassend ferner zwei Träger (2), die in Sitzen (11) des Körpers des Schlittens montiert sind; wobei jeder Träger (2) ein Lager ist, das einen äußeren Ring (20) umfasst, der drehbar auf einem inneren Ring (21) montiert ist; wobei der äußere Ring (21) in dem Sitz (11) des Körpers des Schlittens befestigt ist und die Welle (22) in den inneren Ring (20) des Lagers eingesetzt ist; wobei die Welle (22) mit zwei Endabschnitten (23) versehen ist, die seitlich aus dem Körper (1) vorstehen, um an den Rollen (24) befestigt zu werden; wobei der axiale Querschnitt des inneren Ringes (20) des Lagers eine konvexe kreisbogenförmige Außenoberfläche (26) aufweist und auf einer konkaven kreisbogenförmigen Oberfläche (27) des äußeren Ringes des Lagers gleitet.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT102019000006579A IT201900006579A1 (it) | 2019-05-06 | 2019-05-06 | Carrello per ante scorrevoli |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3736401A1 EP3736401A1 (de) | 2020-11-11 |

| EP3736401B1 EP3736401B1 (de) | 2022-03-30 |

| EP3736401B2 true EP3736401B2 (de) | 2025-05-07 |

Family

ID=67513663

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20173031.4A Active EP3736401B2 (de) | 2019-05-06 | 2020-05-05 | Schlitten und führungsschienenanordnung für schiebetürpaneele |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP3736401B2 (de) |

| ES (1) | ES2921431T3 (de) |

| IT (1) | IT201900006579A1 (de) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102023210534A1 (de) * | 2023-10-25 | 2025-04-30 | Aug. Winkhaus SE & Co. KG | Laufwagen zum Verschieben eines Flügels eines Fensters |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3193870A (en) † | 1963-04-25 | 1965-07-13 | Lawrence Brothers | Truck assembly for sliding doors |

| WO2007075075A1 (en) † | 2005-12-29 | 2007-07-05 | Kwang-Seok Lee | Method and apparatus for window closing in the sliding window system |

| WO2010019692A1 (en) † | 2008-08-14 | 2010-02-18 | Hettich-Heinze Gmbh & Co. Kg | Carriage for a door |

| EP2636834A1 (de) † | 2012-03-07 | 2013-09-11 | Sliding S.R.L. | Wagenanordnung zum Tragen und Handhaben von Schiebetafeln von Möbeln oder Türen |

| US20150047150A1 (en) † | 2012-03-30 | 2015-02-19 | Nifco Inc. | Movable body assistance device |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008044252A1 (en) * | 2006-10-10 | 2008-04-17 | Luigi Maifredi | Door moving system with rotation and translation and method for mounting such a system |

| ITTV20110149A1 (it) * | 2011-10-31 | 2013-05-01 | Eclisse Srl | Struttura di carrello |

-

2019

- 2019-05-06 IT IT102019000006579A patent/IT201900006579A1/it unknown

-

2020

- 2020-05-05 EP EP20173031.4A patent/EP3736401B2/de active Active

- 2020-05-05 ES ES20173031T patent/ES2921431T3/es active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3193870A (en) † | 1963-04-25 | 1965-07-13 | Lawrence Brothers | Truck assembly for sliding doors |

| WO2007075075A1 (en) † | 2005-12-29 | 2007-07-05 | Kwang-Seok Lee | Method and apparatus for window closing in the sliding window system |

| WO2010019692A1 (en) † | 2008-08-14 | 2010-02-18 | Hettich-Heinze Gmbh & Co. Kg | Carriage for a door |

| EP2636834A1 (de) † | 2012-03-07 | 2013-09-11 | Sliding S.R.L. | Wagenanordnung zum Tragen und Handhaben von Schiebetafeln von Möbeln oder Türen |

| US20150047150A1 (en) † | 2012-03-30 | 2015-02-19 | Nifco Inc. | Movable body assistance device |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3736401A1 (de) | 2020-11-11 |

| IT201900006579A1 (it) | 2020-11-06 |

| ES2921431T3 (es) | 2022-08-25 |

| EP3736401B1 (de) | 2022-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5685046A (en) | Motor vehicle double pivot hinge | |

| CA2377526C (en) | Segmented garage door and hinges | |

| US20090102332A1 (en) | Cabinet door locking mechanism | |

| US8844604B2 (en) | Guide assembly | |

| EP3736401B2 (de) | Schlitten und führungsschienenanordnung für schiebetürpaneele | |

| US20180002960A1 (en) | Garage door hinge with noise reduction insert | |

| US4439888A (en) | Substantially concealed hinge for door with recess | |

| EP4015750A1 (de) | Klavierscharniere | |

| US20030200628A1 (en) | Continuous door hinge with multi-plastic bearings | |

| US6513193B1 (en) | Door check mechanism providing an infinite number of stable positions | |

| US20120297686A1 (en) | Door support for glass sliding door and assembly | |

| US5452543A (en) | Window operator track with integral limit stop | |

| US7721387B1 (en) | Track assembly for an overhead door | |

| EP2636834A1 (de) | Wagenanordnung zum Tragen und Handhaben von Schiebetafeln von Möbeln oder Türen | |

| US20040211033A1 (en) | Track assembly for an overhead door | |

| US3874027A (en) | Shock absorbing bearing assembly | |

| KR20170001897U (ko) | 슬라이딩 도어용 가이드 프레임 | |

| US20190186189A1 (en) | Rod securing hinge and method | |

| CN201447981U (zh) | 一种限位铰链 | |

| US20090081012A1 (en) | System and Method for Securing Lift Gate | |

| IL42653A (en) | A hinge for cabinet doors and the like | |

| US20210310302A1 (en) | Universal endlock | |

| CN210105568U (zh) | 一种滑撑的窗扇固定结构 | |

| US4001913A (en) | Door mounting | |

| KR200497066Y1 (ko) | 탑차의 리어 게이트용 힌지장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20210505 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20211025 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BIANCHINI, LUCA Inventor name: PAGLIAROLI, GERARDO |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1479333 Country of ref document: AT Kind code of ref document: T Effective date: 20220415 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602020002394 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220630 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220630 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20220330 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1479333 Country of ref document: AT Kind code of ref document: T Effective date: 20220330 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2921431 Country of ref document: ES Kind code of ref document: T3 Effective date: 20220825 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220701 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220801 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 602020002394 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220730 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 |

|

| 26 | Opposition filed |

Opponent name: GEZE GMBH Effective date: 20221117 |

|

| R26 | Opposition filed (corrected) |

Opponent name: GEZE GMBH Effective date: 20221117 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20220531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220505 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220505 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220531 |

|

| PLBP | Opposition withdrawn |

Free format text: ORIGINAL CODE: 0009264 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20200505 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20220330 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20240505 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240505 |

|

| 27A | Patent maintained in amended form |

Effective date: 20250507 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 602020002394 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250528 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20250612 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250417 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250526 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250601 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250507 |