EP3581614A1 - Asphaltic sheet materials including expandable graphite - Google Patents

Asphaltic sheet materials including expandable graphite Download PDFInfo

- Publication number

- EP3581614A1 EP3581614A1 EP19182058.8A EP19182058A EP3581614A1 EP 3581614 A1 EP3581614 A1 EP 3581614A1 EP 19182058 A EP19182058 A EP 19182058A EP 3581614 A1 EP3581614 A1 EP 3581614A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- asphaltic

- sheet

- expandable graphite

- asphalt

- styrene

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 title claims abstract description 180

- 239000010439 graphite Substances 0.000 title claims abstract description 176

- 229910002804 graphite Inorganic materials 0.000 title claims abstract description 176

- 239000000463 material Substances 0.000 title description 48

- 239000010426 asphalt Substances 0.000 claims abstract description 144

- 239000011230 binding agent Substances 0.000 claims abstract description 64

- 239000003607 modifier Substances 0.000 claims description 36

- 239000003063 flame retardant Substances 0.000 claims description 34

- 238000000034 method Methods 0.000 claims description 27

- RNFJDJUURJAICM-UHFFFAOYSA-N 2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-triene Chemical compound N=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1 RNFJDJUURJAICM-UHFFFAOYSA-N 0.000 claims description 22

- 229920000468 styrene butadiene styrene block copolymer Polymers 0.000 claims description 19

- 229920001400 block copolymer Polymers 0.000 claims description 15

- -1 polypropylene Polymers 0.000 claims description 13

- 239000004744 fabric Substances 0.000 claims description 9

- 239000004743 Polypropylene Substances 0.000 claims description 8

- RTACIUYXLGWTAE-UHFFFAOYSA-N buta-1,3-diene;2-methylbuta-1,3-diene;styrene Chemical compound C=CC=C.CC(=C)C=C.C=CC1=CC=CC=C1 RTACIUYXLGWTAE-UHFFFAOYSA-N 0.000 claims description 8

- 229910021540 colemanite Inorganic materials 0.000 claims description 8

- 229920001155 polypropylene Polymers 0.000 claims description 8

- 229920000346 polystyrene-polyisoprene block-polystyrene Polymers 0.000 claims description 8

- 229920003048 styrene butadiene rubber Polymers 0.000 claims description 8

- ROGIWVXWXZRRMZ-UHFFFAOYSA-N 2-methylbuta-1,3-diene;styrene Chemical compound CC(=C)C=C.C=CC1=CC=CC=C1 ROGIWVXWXZRRMZ-UHFFFAOYSA-N 0.000 claims description 4

- 239000005062 Polybutadiene Substances 0.000 claims description 4

- 230000001070 adhesive effect Effects 0.000 claims description 4

- 229920001084 poly(chloroprene) Polymers 0.000 claims description 4

- 229920002857 polybutadiene Polymers 0.000 claims description 4

- 229920001195 polyisoprene Polymers 0.000 claims description 4

- 239000002131 composite material Substances 0.000 claims description 3

- 229920000098 polyolefin Polymers 0.000 claims description 2

- 238000010030 laminating Methods 0.000 claims 3

- 239000010410 layer Substances 0.000 description 69

- 229910052799 carbon Inorganic materials 0.000 description 45

- 239000000203 mixture Substances 0.000 description 43

- 229920005989 resin Polymers 0.000 description 42

- 239000011347 resin Substances 0.000 description 42

- 239000002245 particle Substances 0.000 description 29

- 239000012528 membrane Substances 0.000 description 26

- 230000004888 barrier function Effects 0.000 description 19

- 229920000642 polymer Polymers 0.000 description 18

- 230000003014 reinforcing effect Effects 0.000 description 17

- 230000000295 complement effect Effects 0.000 description 16

- 238000009413 insulation Methods 0.000 description 16

- 229910052751 metal Inorganic materials 0.000 description 16

- 239000002184 metal Substances 0.000 description 16

- 239000003921 oil Substances 0.000 description 15

- 235000019198 oils Nutrition 0.000 description 15

- 238000012360 testing method Methods 0.000 description 15

- 239000000945 filler Substances 0.000 description 11

- 239000004114 Ammonium polyphosphate Substances 0.000 description 10

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 10

- 235000019826 ammonium polyphosphate Nutrition 0.000 description 10

- 229920001276 ammonium polyphosphate Polymers 0.000 description 10

- 239000007787 solid Substances 0.000 description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 10

- 239000000470 constituent Substances 0.000 description 9

- 238000001816 cooling Methods 0.000 description 8

- 239000007788 liquid Substances 0.000 description 8

- 239000003208 petroleum Substances 0.000 description 8

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 7

- 229920006272 aromatic hydrocarbon resin Polymers 0.000 description 7

- 239000004615 ingredient Substances 0.000 description 7

- 230000008569 process Effects 0.000 description 7

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- WSFSSNUMVMOOMR-UHFFFAOYSA-N Formaldehyde Chemical compound O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 description 6

- 230000008901 benefit Effects 0.000 description 6

- 239000011521 glass Substances 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 239000011159 matrix material Substances 0.000 description 6

- 239000005011 phenolic resin Substances 0.000 description 6

- 229920001083 polybutene Polymers 0.000 description 6

- 239000004753 textile Substances 0.000 description 6

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 5

- 125000003118 aryl group Chemical group 0.000 description 5

- 229930195733 hydrocarbon Natural products 0.000 description 5

- 150000002430 hydrocarbons Chemical class 0.000 description 5

- VTHJTEIRLNZDEV-UHFFFAOYSA-L magnesium dihydroxide Chemical compound [OH-].[OH-].[Mg+2] VTHJTEIRLNZDEV-UHFFFAOYSA-L 0.000 description 5

- 239000000347 magnesium hydroxide Substances 0.000 description 5

- 229910001862 magnesium hydroxide Inorganic materials 0.000 description 5

- 238000002156 mixing Methods 0.000 description 5

- 229910052717 sulfur Inorganic materials 0.000 description 5

- 239000011593 sulfur Substances 0.000 description 5

- 229920002633 Kraton (polymer) Polymers 0.000 description 4

- 229920006271 aliphatic hydrocarbon resin Polymers 0.000 description 4

- 150000004945 aromatic hydrocarbons Chemical class 0.000 description 4

- 238000003490 calendering Methods 0.000 description 4

- 239000003795 chemical substances by application Substances 0.000 description 4

- 238000005253 cladding Methods 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 4

- 230000002939 deleterious effect Effects 0.000 description 4

- 150000002148 esters Chemical class 0.000 description 4

- 239000011152 fibreglass Substances 0.000 description 4

- 239000002609 medium Substances 0.000 description 4

- 229920001568 phenolic resin Polymers 0.000 description 4

- 229920000728 polyester Polymers 0.000 description 4

- 230000002787 reinforcement Effects 0.000 description 4

- BIKXLKXABVUSMH-UHFFFAOYSA-N trizinc;diborate Chemical compound [Zn+2].[Zn+2].[Zn+2].[O-]B([O-])[O-].[O-]B([O-])[O-] BIKXLKXABVUSMH-UHFFFAOYSA-N 0.000 description 4

- WSSSPWUEQFSQQG-UHFFFAOYSA-N 4-methyl-1-pentene Chemical compound CC(C)CC=C WSSSPWUEQFSQQG-UHFFFAOYSA-N 0.000 description 3

- 239000004606 Fillers/Extenders Substances 0.000 description 3

- 235000019738 Limestone Nutrition 0.000 description 3

- 125000000217 alkyl group Chemical group 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 125000004122 cyclic group Chemical group 0.000 description 3

- 239000006028 limestone Substances 0.000 description 3

- 239000000155 melt Substances 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 239000004576 sand Substances 0.000 description 3

- 238000009738 saturating Methods 0.000 description 3

- 239000000377 silicon dioxide Substances 0.000 description 3

- 229920001059 synthetic polymer Polymers 0.000 description 3

- 239000000454 talc Substances 0.000 description 3

- 229910052623 talc Inorganic materials 0.000 description 3

- 229920001169 thermoplastic Polymers 0.000 description 3

- 239000002023 wood Substances 0.000 description 3

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 2

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 2

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 2

- 239000013032 Hydrocarbon resin Substances 0.000 description 2

- 229920000877 Melamine resin Polymers 0.000 description 2

- IMNFDUFMRHMDMM-UHFFFAOYSA-N N-Heptane Chemical compound CCCCCCC IMNFDUFMRHMDMM-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 2

- 229920000388 Polyphosphate Polymers 0.000 description 2

- 239000004793 Polystyrene Substances 0.000 description 2

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 2

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical compound C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 2

- KHPCPRHQVVSZAH-HUOMCSJISA-N Rosin Natural products O(C/C=C/c1ccccc1)[C@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 KHPCPRHQVVSZAH-HUOMCSJISA-N 0.000 description 2

- QAOWNCQODCNURD-UHFFFAOYSA-L Sulfate Chemical compound [O-]S([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 description 2

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 2

- RREGISFBPQOLTM-UHFFFAOYSA-N alumane;trihydrate Chemical compound O.O.O.[AlH3] RREGISFBPQOLTM-UHFFFAOYSA-N 0.000 description 2

- 229920013640 amorphous poly alpha olefin Polymers 0.000 description 2

- GHPGOEFPKIHBNM-UHFFFAOYSA-N antimony(3+);oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[Sb+3].[Sb+3] GHPGOEFPKIHBNM-UHFFFAOYSA-N 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 239000002585 base Substances 0.000 description 2

- 238000009833 condensation Methods 0.000 description 2

- 230000005494 condensation Effects 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 238000000113 differential scanning calorimetry Methods 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 229920001971 elastomer Polymers 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 238000005227 gel permeation chromatography Methods 0.000 description 2

- 230000009477 glass transition Effects 0.000 description 2

- 229920006270 hydrocarbon resin Polymers 0.000 description 2

- 230000002687 intercalation Effects 0.000 description 2

- 238000009830 intercalation Methods 0.000 description 2

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 description 2

- 239000004745 nonwoven fabric Substances 0.000 description 2

- 150000002894 organic compounds Chemical class 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 150000002989 phenols Chemical class 0.000 description 2

- 239000013047 polymeric layer Substances 0.000 description 2

- 239000001205 polyphosphate Substances 0.000 description 2

- 235000011176 polyphosphates Nutrition 0.000 description 2

- 229920002223 polystyrene Polymers 0.000 description 2

- 150000003097 polyterpenes Chemical class 0.000 description 2

- 229920006395 saturated elastomer Polymers 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 229920001187 thermosetting polymer Polymers 0.000 description 2

- KHPCPRHQVVSZAH-UHFFFAOYSA-N trans-cinnamyl beta-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OCC=CC1=CC=CC=C1 KHPCPRHQVVSZAH-UHFFFAOYSA-N 0.000 description 2

- VLCLHFYFMCKBRP-UHFFFAOYSA-N tricalcium;diborate Chemical compound [Ca+2].[Ca+2].[Ca+2].[O-]B([O-])[O-].[O-]B([O-])[O-] VLCLHFYFMCKBRP-UHFFFAOYSA-N 0.000 description 2

- 239000002759 woven fabric Substances 0.000 description 2

- KPAPHODVWOVUJL-UHFFFAOYSA-N 1-benzofuran;1h-indene Chemical compound C1=CC=C2CC=CC2=C1.C1=CC=C2OC=CC2=C1 KPAPHODVWOVUJL-UHFFFAOYSA-N 0.000 description 1

- CBXRMKZFYQISIV-UHFFFAOYSA-N 1-n,1-n,1-n',1-n',2-n,2-n,2-n',2-n'-octamethylethene-1,1,2,2-tetramine Chemical compound CN(C)C(N(C)C)=C(N(C)C)N(C)C CBXRMKZFYQISIV-UHFFFAOYSA-N 0.000 description 1

- 239000004594 Masterbatch (MB) Substances 0.000 description 1

- UFWIBTONFRDIAS-UHFFFAOYSA-N Naphthalene Chemical compound C1=CC=CC2=CC=CC=C21 UFWIBTONFRDIAS-UHFFFAOYSA-N 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 229920006372 Soltex Polymers 0.000 description 1

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 150000001299 aldehydes Chemical class 0.000 description 1

- 150000001338 aliphatic hydrocarbons Chemical class 0.000 description 1

- 229910052783 alkali metal Inorganic materials 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- WNROFYMDJYEPJX-UHFFFAOYSA-K aluminium hydroxide Chemical compound [OH-].[OH-].[OH-].[Al+3] WNROFYMDJYEPJX-UHFFFAOYSA-K 0.000 description 1

- 229910021502 aluminium hydroxide Inorganic materials 0.000 description 1

- VSCWAEJMTAWNJL-UHFFFAOYSA-K aluminium trichloride Chemical class Cl[Al](Cl)Cl VSCWAEJMTAWNJL-UHFFFAOYSA-K 0.000 description 1

- 150000008064 anhydrides Chemical class 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 239000010692 aromatic oil Substances 0.000 description 1

- 229910052785 arsenic Inorganic materials 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 229910001730 borate mineral Inorganic materials 0.000 description 1

- 239000010429 borate mineral Substances 0.000 description 1

- 239000011449 brick Substances 0.000 description 1

- 239000004566 building material Substances 0.000 description 1

- 229910000019 calcium carbonate Inorganic materials 0.000 description 1

- QGJOPFRUJISHPQ-NJFSPNSNSA-N carbon disulfide-14c Chemical compound S=[14C]=S QGJOPFRUJISHPQ-NJFSPNSNSA-N 0.000 description 1

- 238000006555 catalytic reaction Methods 0.000 description 1

- 150000008280 chlorinated hydrocarbons Chemical class 0.000 description 1

- 150000001805 chlorine compounds Chemical class 0.000 description 1

- 239000004567 concrete Substances 0.000 description 1

- 238000006482 condensation reaction Methods 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 238000002425 crystallisation Methods 0.000 description 1

- 230000008025 crystallization Effects 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 239000000539 dimer Substances 0.000 description 1

- 230000000447 dimerizing effect Effects 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 239000002612 dispersion medium Substances 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000009970 fire resistant effect Effects 0.000 description 1

- 230000009969 flowable effect Effects 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- 229910001679 gibbsite Inorganic materials 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 239000010440 gypsum Substances 0.000 description 1

- 229910052602 gypsum Inorganic materials 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 150000002391 heterocyclic compounds Chemical class 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- QAOWNCQODCNURD-UHFFFAOYSA-M hydrogensulfate Chemical compound OS([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-M 0.000 description 1

- 239000011256 inorganic filler Substances 0.000 description 1

- 229910003475 inorganic filler Inorganic materials 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- ZLNQQNXFFQJAID-UHFFFAOYSA-L magnesium carbonate Chemical compound [Mg+2].[O-]C([O-])=O ZLNQQNXFFQJAID-UHFFFAOYSA-L 0.000 description 1

- 239000001095 magnesium carbonate Substances 0.000 description 1

- 229910000021 magnesium carbonate Inorganic materials 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 229910001507 metal halide Inorganic materials 0.000 description 1

- 150000005309 metal halides Chemical class 0.000 description 1

- QLTDWCHQCKHGGO-UHFFFAOYSA-N methane;sulfuric acid Chemical compound C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.C.OS(O)(=O)=O.OS(O)(=O)=O.OS(O)(=O)=O.OS(O)(=O)=O.OS(O)(=O)=O.OS(O)(=O)=O.OS(O)(=O)=O QLTDWCHQCKHGGO-UHFFFAOYSA-N 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 235000010755 mineral Nutrition 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229920005615 natural polymer Polymers 0.000 description 1

- 239000000025 natural resin Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 150000002823 nitrates Chemical class 0.000 description 1

- CLNYHERYALISIR-UHFFFAOYSA-N nona-1,3-diene Chemical compound CCCCCC=CC=C CLNYHERYALISIR-UHFFFAOYSA-N 0.000 description 1

- 150000007524 organic acids Chemical class 0.000 description 1

- 235000005985 organic acids Nutrition 0.000 description 1

- 238000002103 osmometry Methods 0.000 description 1

- 239000007800 oxidant agent Substances 0.000 description 1

- 239000010690 paraffinic oil Substances 0.000 description 1

- 238000004525 petroleum distillation Methods 0.000 description 1

- 239000012071 phase Substances 0.000 description 1

- 239000011120 plywood Substances 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 229920000582 polyisocyanurate Polymers 0.000 description 1

- 239000011495 polyisocyanurate Substances 0.000 description 1

- 230000000379 polymerizing effect Effects 0.000 description 1

- 229920005862 polyol Polymers 0.000 description 1

- 150000003077 polyols Chemical class 0.000 description 1

- 239000001294 propane Substances 0.000 description 1

- QQONPFPTGQHPMA-UHFFFAOYSA-N propylene Natural products CC=C QQONPFPTGQHPMA-UHFFFAOYSA-N 0.000 description 1

- 125000004805 propylene group Chemical group [H]C([H])([H])C([H])([*:1])C([H])([H])[*:2] 0.000 description 1

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 1

- 229920005604 random copolymer Polymers 0.000 description 1

- 238000007670 refining Methods 0.000 description 1

- 229920003987 resole Polymers 0.000 description 1

- 239000011435 rock Substances 0.000 description 1

- 239000005060 rubber Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 125000003011 styrenyl group Chemical group [H]\C(*)=C(/[H])C1=C([H])C([H])=C([H])C([H])=C1[H] 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 150000003467 sulfuric acid derivatives Chemical class 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 239000000057 synthetic resin Substances 0.000 description 1

- 150000003505 terpenes Chemical class 0.000 description 1

- 235000007586 terpenes Nutrition 0.000 description 1

- 229910052716 thallium Inorganic materials 0.000 description 1

- 238000005979 thermal decomposition reaction Methods 0.000 description 1

- 229920002725 thermoplastic elastomer Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 239000011573 trace mineral Substances 0.000 description 1

- 235000013619 trace mineral Nutrition 0.000 description 1

- 229910052720 vanadium Inorganic materials 0.000 description 1

- GPPXJZIENCGNKB-UHFFFAOYSA-N vanadium Chemical compound [V]#[V] GPPXJZIENCGNKB-UHFFFAOYSA-N 0.000 description 1

- 239000012808 vapor phase Substances 0.000 description 1

- 235000015112 vegetable and seed oil Nutrition 0.000 description 1

- 239000008158 vegetable oil Substances 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 238000004078 waterproofing Methods 0.000 description 1

- 239000001993 wax Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B11/00—Layered products comprising a layer of bituminous or tarry substances

- B32B11/04—Layered products comprising a layer of bituminous or tarry substances comprising such bituminous or tarry substance as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B11/046—Layered products comprising a layer of bituminous or tarry substances comprising such bituminous or tarry substance as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B11/00—Layered products comprising a layer of bituminous or tarry substances

- B32B11/04—Layered products comprising a layer of bituminous or tarry substances comprising such bituminous or tarry substance as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B11/00—Layered products comprising a layer of bituminous or tarry substances

- B32B11/02—Layered products comprising a layer of bituminous or tarry substances with fibres or particles being present as additives in the layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B11/00—Layered products comprising a layer of bituminous or tarry substances

- B32B11/10—Layered products comprising a layer of bituminous or tarry substances next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B11/00—Layered products comprising a layer of bituminous or tarry substances

- B32B11/12—Layered products comprising a layer of bituminous or tarry substances next to a particulate layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/16—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by features of a layer formed of particles, e.g. chips, powder or granules

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/0405—Reinforcing macromolecular compounds with loose or coherent fibrous material with inorganic fibres

- C08J5/043—Reinforcing macromolecular compounds with loose or coherent fibrous material with inorganic fibres with glass fibres

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/043—Improving the adhesiveness of the coatings per se, e.g. forming primers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/048—Forming gas barrier coatings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/05—Forming flame retardant coatings or fire resistant coatings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/06—Coating with compositions not containing macromolecular substances

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/38—Boron-containing compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L95/00—Compositions of bituminous materials, e.g. asphalt, tar, pitch

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D195/00—Coating compositions based on bituminous materials, e.g. asphalt, tar, pitch

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K21/00—Fireproofing materials

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D12/00—Non-structural supports for roofing materials, e.g. battens, boards

- E04D12/002—Sheets of flexible material, e.g. roofing tile underlay

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D3/00—Roof covering by making use of flat or curved slabs or stiff sheets

- E04D3/02—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant

- E04D3/18—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of specified materials, or of combinations of materials, not covered by any of groups E04D3/04, E04D3/06 or E04D3/16

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D5/00—Roof covering by making use of flexible material, e.g. supplied in roll form

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D5/00—Roof covering by making use of flexible material, e.g. supplied in roll form

- E04D5/10—Roof covering by making use of flexible material, e.g. supplied in roll form by making use of compounded or laminated materials, e.g. metal foils or plastic films coated with bitumen

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0261—Polyamide fibres

- B32B2262/0269—Aromatic polyamide fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0276—Polyester fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/101—Glass fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/30—Properties of the layers or laminate having particular thermal properties

- B32B2307/306—Resistant to heat

- B32B2307/3065—Flame resistant or retardant, fire resistant or retardant

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2419/00—Buildings or parts thereof

- B32B2419/06—Roofs, roof membranes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2395/00—Bituminous materials, e.g. asphalt, tar or pitch

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2453/00—Characterised by the use of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Derivatives of such polymers

- C08J2453/02—Characterised by the use of block copolymers containing at least one sequence of a polymer obtained by reactions only involving carbon-to-carbon unsaturated bonds; Derivatives of such polymers of vinyl aromatic monomers and conjugated dienes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/38—Boron-containing compounds

- C08K2003/387—Borates

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2555/00—Characteristics of bituminous mixtures

- C08L2555/40—Mixtures based upon bitumen or asphalt containing functional additives

- C08L2555/50—Inorganic non-macromolecular ingredients

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2555/00—Characteristics of bituminous mixtures

- C08L2555/40—Mixtures based upon bitumen or asphalt containing functional additives

- C08L2555/80—Macromolecular constituents

- C08L2555/84—Polymers comprising styrene, e.g., polystyrene, styrene-diene copolymers or styrene-butadiene-styrene copolymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2666/00—Composition of polymers characterized by a further compound in the blend, being organic macromolecular compounds, natural resins, waxes or and bituminous materials, non-macromolecular organic substances, inorganic substances or characterized by their function in the composition

- C08L2666/54—Inorganic substances

- C08L2666/55—Carbon

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31815—Of bituminous or tarry residue

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2213—Coating or impregnation is specified as weather proof, water vapor resistant, or moisture resistant

Definitions

- Embodiments of the present invention are directed toward asphaltic sheet materials that include expandable graphite. These sheet materials are useful as roofing underlayment, as roofing membranes, and as barrier materials such as air, vapor, and/or moisture barriers.

- Asphaltic sheet materials are widely used in the construction industry.

- polymer-modified asphaltic sheet material is used as membrane for waterproofing flat or low-sloped roofs.

- these roofing systems may include multiple layers of asphaltic sheet including base sheets and cap sheets.

- barriers materials such air, vapor, or moisture barriers. These materials are typically used on roofs or vertical surfaces such as walls to provide the desired air, vapor and/or moisture resistance to a structure.

- Still other examples include underlayments, which are used in the roofing industry to provide an extra layer of protection to the roof. This additional protection may provide, among other benefits, water, moisture, thermal, and/or fire resistance.

- underlayment is typically positioned below the external or primary roofing protection, which may include shingles, membranes such as polymeric or asphaltic membranes, roofing tiles, and metal panels or cladding.

- felt paper that is saturated with asphalt has historically been used as underlayment to provide additional water and/or moisture resistance to the roof.

- Other forms of underlayment include synthetic materials such as thermoplastic or thermoset materials formed into sheets.

- fire or flame resistant underlayment may be employed.

- These underlayment may include textiles, including woven and non-woven fabrics, made of fire resistant materials such as fiberglass. These fabrics may include a coating, such as a mineral coating, that further enhances the flame or fire resistance of the underlayment.

- underlayment such as with metal roofing systems

- underlayment such as with metal roofing systems

- first underlayment may be used to provide moisture or water resistance

- second underlayment may be used to provide flame or fire resistance.

- This technique suffers from several drawbacks including the added difficulty of installing multiple underlayments.

- One or more embodiments of the present invention provide an asphaltic sheet comprising an asphaltic component including an asphalt binder and expandable graphite.

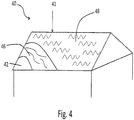

- Still other embodiments of the present invention provide a roof system comprising a roof deck; an underlayment; and one or more metal panels or roofing tilescovering the underlayment, where the underlayment includes an asphaltic component including an asphalt binder and expandable graphite dispersed within the asphalt binder.

- Still other embodiments of the present invention provide a method for producing an asphaltic sheet, the method comprising preparing a molten asphaltic composition by introducing an expandable graphite to an asphalt binder at a temperature below that which will cause deleterious expansion of the expandable graphite, and fabricating an asphaltic sheet with the molten asphaltic composition.

- Still other embodiments of the present invention provide an asphaltic sheet comprising an asphaltic component including an asphalt binder and a layer including expandable graphite, where said layer including expandable graphite is adjacent to said asphaltic component.

- Still other embodiments of the present invention provide a method for producing an asphaltic sheet, the method comprising providing an asphaltic sheet, and applying expandable graphite particles to the asphaltic sheet.

- Embodiments of the present invention are based, at least in part, on the discovery of an asphaltic sheet having an asphaltic component with expandable graphite.

- the asphaltic sheet includes an asphalt component with the expandable graphite dispersed within the asphalt component.

- the asphaltic sheet includes a layer of expandable graphite adjacent to the asphalt component.

- the asphaltic sheet is advantageously resistant to water, moisture, an/or air due to the asphaltic nature of the sheet, and it is also flame resistant due to the presence of the expandable graphite. It is believed that one or more advantages of the present invention derive from the presence of the expandable graphite within or adjacent to the asphaltic component of the sheet.

- the prior art contemplates the use of expandable graphite as a flame retardant

- the prior art does not contemplate incorporating the expandable graphite into the asphaltic component of a sheet material or placing a layer of the expandable graphite adjacent to the asphaltic component.

- Embodiments of the present invention provide a method for incorporating the expandable graphite into the asphaltic component of the sheet without deleteriously expanding the graphite (i.e. the graphite is not expanded to a deleterious degree).

- the asphaltic component of the sheet material further includes a complementary flame retardant material that is believed to synergistically interact with the expandable graphite to provide unexpected flame resistance.

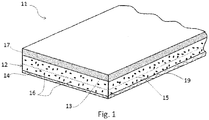

- the asphaltic sheet is or includes a planar body of asphalt material, which may also be referred to as the asphalt component of the sheet or asphalt layer 12.

- asphaltic sheet 11 includes asphalt component 12 having a first planar surface 13 and second planer surface 14.

- Sheet 11 may include an optional textile fabric 15 embedded or impregnated within asphaltic component 12.

- the sheet is devoid of a scrim or fabric.

- Asphaltic component 12 as will be described in greater detail below, may include various constituents such as polymeric modifiers and fillers, as well as expandable graphite 16 and optional complementary flame retardants (not shown) according to the present invention.

- sheet 11 may further include one or more polymeric layers 17 laminated to asphalt component 12 of sheet 11.

- asphaltic sheet 11 may include an asphaltic component 12 laminated to a polypropylene sheet.

- layer 17 may include a layer of release agents, such as silica, sand or talc.

- a release film 19 may be removably secured to at least one of the exposed planar surfaces 13 or 14.

- optional textile fabric 15, which may also be referred to as fabric reinforcement 15, reinforcing member 15, or simply reinforcement 15, may include woven and/or non-woven fabrics.

- fabric reinforcement 15 may be fabricated from fiberglass and/or synthetic yards or filaments.

- Exemplary synthetic yarns include those prepared from polyesters or polyimides.

- the thickness of asphaltic sheet 11 may be at least 10, in other embodiments at least 20, and in other embodiments at least 30 mils. In these or other embodiments, the thickness of asphaltic sheet 11 may be at most 120, in other embodiments at most 100, in other embodiments at most 90, and in other embodiments at most 80 mils. In one or more embodiments, the thickness of asphaltic sheet 11 may be from about 10 to about 100, in other embodiments from about 20 to about 90, and in other embodiments from about 30 to about 80 mils. In other embodiments, especially where the asphaltic sheet is used in a vertical application, the thickness of the asphaltic sheet may be substantially thinner.

- the thickness of the sheet may be less than 20, in other embodiments less than 15, and in other embodiments less than 10 mils, with the thickness ranging from 2 to 20 mils, in other embodiments from 3 to 15 mils, and in other embodiments from 5 to 10 mils.

- the weight of the asphaltic sheet may be at least 5, in other embodiments at least 10 and in other embodiments at least 15 pounds per hundred square feet. In these or other embodiments, the weight of the asphaltic sheet may be at most 90, in other embodiments at most 70, and in other embodiments at most 50 pounds per hundred square feet. In these or other embodiments, the weight of the asphaltic sheet may be from 5 to 100, in other embodiments from 10 to 80, and in other embodiments from 15 to 50 pounds per hundred square feet. In other embodiments, especially where the asphaltic sheet is used in a vertical application, the weight of the asphaltic sheet may be substantially lighter.

- the weight of the sheet may be less than 60, in other embodiments less than 50, and in other embodiments less than 40 pounds per hundred square feet, with the weight ranging from 5 to 60, in other embodiments from 10 to 50, and in other embodiments from 15 to 40 pounds per hundred square feet.

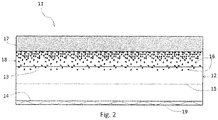

- asphaltic sheet 11 includes asphaltic component 12 having first planer surface 13 and second planar surface 14. Adjacent to asphaltic component 12 is a layer 18 including expandable graphite 16. Layer 18 may be adjacent to asphaltic component 12 as a result of the manner in which asphaltic sheet 11 is fabricated, as will be described in greater detail below.

- Asphaltic sheet 11 may carry optional polymeric layer 17, which may also be referred to as polymeric liner 17.

- layer 17 may include a layer of release agents, such as silica, sand or talc.

- layer 17 may be a glass scrim, polyester mat, metal foil (e.g., aluminum foil), fabric, elastomeric layer, and the like.

- layer 18 includes one or more layers of particles of expandable graphite 16. These particles may be held in place by a matrix of asphalt material present within at least a portion of layer 18. In these or other embodiments, the expandable graphite 16 is held in place by being adhered to the surface of the asphalt.

- asphaltic component 12 may also include expandable graphite dispersed therein. In other words, asphaltic sheet may include expandable graphite dispersed throughout the asphaltic component and layer 18 of expandable graphite adjacent to component 12.

- layer 18 may include a planar region within sheet 11 that includes a higher concentration of expandable graphite relative to any other region of sheet 11.

- layer 18 may include a continuous layer of expandable graphite having a variable or relatively constant thickness across sheet 11.

- the expandable graphite may be discontinuous throughout the region so long as the concentration of expandable graphite within the region is higher than in other areas or regions of sheet 11.

- the discontinuity of the expandable graphite within the layer 18 may result from the asphaltic material which may form a matrix in which the expandable graphite is at least partially dispersed within this region or layer. It should also be appreciated that the concentration of the expandable graphite may not be constant within this layer.

- a concentration gradient may exist whereby the concentration of the expandable graphite moves from a region of maximum concentration to a region of decreased concentration.

- the concentration of expandable graphite 16 furthest from planar surface 13 within layer 18 is the highest, which corresponds to a minimum in asphalt concentration.

- the concentration of expandable graphite 16 proximate to planar surface 13 is a minimum relative to the concentration of expandable graphite within layer 18.

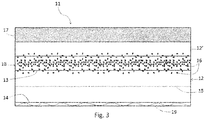

- an additional layer of asphalt 12' is adjacent expandable graphite layer 18 opposite asphaltic component or layer 12.

- Layer 12' may also be referred to as a skin layer 12', and aspects of this embodiment may be described as layer or region 18 being embedded between layers of asphaltic binder or material. Consistent with the other embodiments described above, this layer 12' may include expandable graphite 16 at a concentration lower than layer 18. Nonetheless, in one or more embodiments, layer 12' may include expandable graphite dispersed therein, although the concentration is lower than the concentration of the expandable graphite within region 18. In fact, in one or more embodiments, a concentration gradient may exist between layers 12' and 18 in a similar fashion to the concentration gradient described above.

- the sheet can include multiple discreet regions of the expandable graphite, such as may exist in a pattern where the expandable graphite is applied on the top of the asphaltic sheet in rows or strips in the machine direction of the sheet. This may be advantageous where greater adhesion to a top sheet (e.g. sheet 17) is desired.

- the thickness of layer 18 may be at least 10 ⁇ m, in other embodiments at least 20 ⁇ m, in other embodiments at least 30 ⁇ m, in other embodiments at least 75 ⁇ m, and in other embodiments at least 100 ⁇ m. In these or other embodiments, the thickness of layer 18 may be at most 3 mm, in other embodiments at most 2 mm, and in other embodiments at most 1 mm. In one or more embodiments, the thickness of layer 18 may be from about 10 ⁇ m to about 3 mm, in other embodiments from about 75 ⁇ m to about 2 mm, and in other embodiments from about 100 ⁇ m to about 1 mm.

- the thickness of layer 12' may be at least 2 ⁇ m, in other embodiments at least 5 ⁇ m, and in other embodiments at least 20 ⁇ m. In these or other embodiments, the thickness of layer 12' may be at most 1 mm, in other embodiments at most 0.5 mm, in other embodiments at most 0.25 mm, in other embodiments at most 0.1 mm, and in other embodiments at most 0.050 mm. In one or more embodiments, the thickness of layer 12' may be from about 1 ⁇ m to about 3 mm, in other embodiments from about 2 ⁇ m to about 0.5 mm, and in other embodiments from about 5 ⁇ m to about 0.050 mm.

- the asphaltic sheet of one or more embodiments of the present invention includes an asphaltic component.

- the asphaltic component includes an asphalt binder and expandable graphite dispersed within the binder.

- the asphaltic component may also include, dispersed within the binder, polymeric modifiers, fillers, tackifiers, complementary flame retardants, and other constituents conventionally used in asphaltic-based building materials.

- asphalt binder is used as understood by those skilled in the art and is consistent with the meaning provided by AASHTO M320. As used within this specification, the terms “asphalt” and “asphalt binder” may be used synonymously.

- the asphalt binder material may be derived from any asphalt source, such as natural asphalt, rock asphalt, produced from tar sands, or petroleum asphalt obtained in the process of refining petroleum.

- asphalt binders may include a blend of various asphalts not meeting any specific grade definition. This includes airblown asphalt, vacuum-distilled asphalt, steam-distilled asphalt, cutback asphalt or roofing asphalt. Alternatively, gilsonite, natural or synthetic, used alone or mixed with petroleum asphalt, may be selected.

- asphalt includes petroleum derived asphalt and asphaltic residual. These compositions may include asphaltenes, resins, cyclics, and saturates. The percentage of these constituents in the overall asphalt binder composition may vary based on the source of the asphalt.

- Asphaltenes include black amorphous solids containing, in addition to carbon and hydrogen, some nitrogen, sulfur, and oxygen. Trace elements such as nickel and vanadium may also be present. Asphaltenes are generally considered as highly polar aromatic materials of a number average molecular weight of about 2000 to about 5000 g/mol, and may constitute about 5 to about 25% of the weight of asphalt.

- Resins include dark-colored, solid and semi-solid, very adhesive fractions of relatively high molecular weight present in the maltenes. They may include the dispersing agents of peptizers for the asphaltenes, and the proportion of resins to asphaltenes governs, to a degree, the sol-or gel-type character of asphalts. Resins separated from bitumens may have a number average molecular weight of about 0.8 to about 2 kg/mol but there is a wide molecular distribution. This component may constitute about 15 to about 25% of the weight of asphalts.

- Cyclics include the compounds of lowest molecular weight in bitumens and represent the major portion of the dispersion medium for the peptized asphaltenes. They may constitute about 45 to about 60% by weight of the total asphalt binder, and may be dark viscous liquids. They may include compounds with aromatic and naphthenic aromatic nuclei with side chain constituents and may have molecular weights of 0.5 to about 9 kg/mol.

- Saturates include predominantly the straight-and branched-chain aliphatic hydrocarbons present in bitumens, together with alkyl naphthenes and some alkyl aromatics.

- the average molecular weight range may be approximately similar to that of the cyclics, and the components may include the waxy and non-waxy saturates. This fraction may from about 5 to about 20% of the weight of asphalts.

- asphalt binders may include bitumens that occur in nature or may be obtained in petroleum processing.

- Asphalts may contain very high molecular weight hydrocarbons called asphaltenes, which may be soluble in carbon disulfide, pyridine, aromatic hydrocarbons, chlorinated hydrocarbons, and THF.

- Asphalts or bituminous materials may be solids, semi-solids or liquids.

- the asphalt binder includes AC-5, AC-10 and AC-15. These asphalts typically contain about 40 to about 52 parts by weight of aromatic hydrocarbons, about 20 to about 44 parts by weight of a polar organic compound, about 10 to about 15 parts by weight of asphaltene, about 6 to about 8 parts by weight of saturates, and about 4 to about 5 parts by weight of sulfur. Nevertheless, practice of the present invention is not limited by selection of any particular asphalt.

- the molecular weight of the aromatic hydrocarbons present in asphalt may range between about 300 and 2000, while the polar organic compounds, which generally include hydroxylated, carboxylated and heterocyclic compounds, may have a weight average molecular weight of about 500 to 50,000.

- Asphaltenes which are generally known as heavy hydrocarbons, are typically of a high molecular weight and are heptane insoluble. Saturates generally include paraffinic and cycloaliphatic hydrocarbons having about 300 to 2000 molecular weight.

- bitumens may be used.

- Bitumens are naturally occurring solidified hydrocarbons, typically collected as a residue of petroleum distillation. Gilsonite is believed to be the purest naturally formed bitumen, typically having a molecular weight of about 3,000 with about 3 parts by weight complexed nitrogen.

- Expandable graphite may also be referred to as expandable flake graphite, intumescent flake graphite, or expandable flake; and, for the purposes herein, these terms may be used interchangeably.

- expandable graphite includes intercalated graphite in which an intercallant material is included between the graphite layers of graphite crystal or particle.

- intercallant materials include halogens, alkali metals, sulfates, nitrates, various organic acids, aluminum chlorides, ferric chlorides, other metal halides, arsenic sulfides, and thallium sulfides.

- the expandable graphite includes non-halogenated intercallant materials.

- the expandable graphite includes sulfate intercallants, also referred to as graphite bisulfate. As is known in the art, bisulfate intercalation is achieved by treating highly crystalline natural flake graphite with a mixture of sulfuric acid and other oxidizing agents which act to catalyze the sulfate intercalation.

- expandable graphite examples include HPMS Expandable Graphite (HP Materials Solutions, Inc., Woodland Hills, CA) and Expandable Graphite Grades 1721 (Asbury Carbons, Asbury, NJ).

- HPMS Expandable Graphite HP Materials Solutions, Inc., Woodland Hills, CA

- Expandable Graphite Grades 1721 (Asbury Carbons, Asbury, NJ).

- Other commercial grades contemplated as useful in the present invention include 1722, 3393, 3577, 3626, and 1722HT (Asbury Carbons, Asbury, NJ).

- the expandable graphite may be characterized as having a mean or average size in the range from about 30 ⁇ m to about 1.5 mm, in other embodiments from about 50 ⁇ m to about 1.0 mm, and in other embodiments from about 180 to about 850 ⁇ m. In certain embodiments, the expandable graphite may be characterized as having a mean or average size of at least 30 ⁇ m, in other embodiments at least 44 ⁇ m, in other embodiments at least 180 ⁇ m, and in other embodiments at least 300 ⁇ m.

- expandable graphite may be characterized as having a mean or average size of at most 1.5 mm, in other embodiments at most 1.0 mm, in other embodiments at most 850 ⁇ m, in other embodiments at most 600 ⁇ m, in yet other embodiments at most 500 ⁇ m, and in still other embodiments at most 400 ⁇ m.

- Useful expandable graphite includes Graphite Grade #1721 (Asbury Carbons), which has a nominal size of greater than 300 ⁇ m.

- the expandable graphite may be characterized as having a median size in the range from about 30 ⁇ m to about 1.5 mm, in other embodiments from about 50 ⁇ m to about 1.0 mm, and in other embodiments from about 180 to about 850 ⁇ m. In certain embodiments, the expandable graphite may be characterized as having a median size of at least 30 ⁇ m, in other embodiments at least 44 ⁇ m, in other embodiments at least 180 ⁇ m, and in other embodiments at least 300 ⁇ m.

- expandable graphite may be characterized as having a median size of at most 1.5 mm, in other embodiments at most 1.0 mm, in other embodiments at most 850 ⁇ m, in other embodiments at most 600 ⁇ m, in yet other embodiments at most 500 ⁇ m, and in still other embodiments at most 400 ⁇ m.

- the expandable graphite may be characterized as having a nominal particle size of 20x50 (US sieve). US sieve 20 has an opening equivalent to 0.841 mm and US sieve 50 has an opening equivalent to 0.297 mm. Therefore, a nominal particle size of 20x50 indicates the graphite particles are at least 0.297 mm and at most 0.841 mm.

- the expandable graphite may be characterized as having a carbon content in the range from about 80% to about 99%. In certain embodiments, the expandable graphite may be characterized as having a carbon content of at least 80%, in other embodiments at least 85%, in other embodiments at least 90%, in yet other embodiments at least 95%, in other embodiments at least 98%, and in still other embodiments at least 99% carbon.

- the expandable graphite may be characterized as having a sulfur content in the range from about 0% to about 8%, in other embodiments from about 2.6% to about 5.0%, and in other embodiments from about 3.0% to about 3.5%. In certain embodiments, the expandable graphite may be characterized as having a sulfur content of at least 0%, in other embodiments at least 2.6%, in other embodiments at least 2.9%, in other embodiments at least 3.2%, and in other embodiments 3.5%. In certain embodiments, the expandable graphite may be characterized as having a sulfur content of at most 8%, in other embodiments at most 5%, in other embodiments at most 3.5%.

- the expandable graphite may be characterized as having an expansion ratio (cc/g) in the range from about 10:1 to about 500:1, in other embodiments at least 20:1 to about 450:1, in other embodiments at least 30:1 to about 400:1, in other embodiments from about 50:1 to about 350:1.

- cc/g expansion ratio

- the expandable graphite may be characterized as having an expansion ratio (cc/g) of at least 10:1, in other embodiments at least 20:1, in other embodiments at least 30:1, in other embodiments at least 40:1, in other embodiments at least 50:1, in other embodiments at least 60:1, in other embodiments at least 90:1, in other embodiments at least 160:1, in other embodiments at least 210:1, in other embodiments at least 220:1, in other embodiments at least 230:1, in other embodiments at least 270:1, in other embodiments at least 290:1, and in yet other embodiments at least 300:1.

- the expandable graphite may be characterized as having an expansion ratio (cc/g) of at most 350:1, and in yet other embodiments at most 300:1.

- the expandable graphite as it exists with the asphaltic component of the asphaltic sheet of the present invention, is partially expanded. In one or more embodiments, the expandable graphite is not expanded, however, to a deleterious degree, which includes that amount or more of expansion that will deleteriously the ability to form the sheet product and the ability of the graphite to serve as flame retardant at desirable levels, which include those levels that allow proper formation of the sheet. In one or more embodiments, the expandable graphite is expanded to at most 60%, in other embodiments at most 50%, in other embodiments at most 40%, in other embodiments at most 30%, in other embodiments at most 20%, and in other embodiments at most 10% beyond its original unexpanded size.

- the expandable graphite may be characterized as having a pH in the range from about 1 to about 10; in other embodiments from about 1 to about 6; and in yet other embodiments from about 5 to about 10. In certain embodiments, the expandable graphite may be characterized as having a pH in the range from about 4 to about 7. In one or more embodiments, the expandable graphite may be characterized as having a pH of at least 1, in other embodiments at least 4, and in other embodiments at least 5. In certain embodiments, the expandable graphite may be characterized as having a pH of at most 10, in other embodiments at most 7, and in other embodiments at most 6.

- the expandable graphite may be characterized by an onset temperature ranging from about 100 oC to about 250 oC; in other embodiments from about 160 oC to about 225 oC; and in other embodiments from about 180 oC to about 200 oC. In one or more embodiments, the expandable graphite may be characterized by an onset temperature of at least 100 oC, in other embodiments at least 130 oC, in other embodiments at least 160 oC, and in other embodiments at least 180 oC. In one or more embodiments, the expandable graphite may be characterized by an onset temperature of at most 250 oC, in other embodiments at most 225 oC, and in other embodiments at most 200 oC. Onset temperature may also be interchangeably referred to as expansion temperature and also alternatively referred to as the temperature at which expansion of the graphite starts.

- the polymeric modifier which may simply be referred to as polymer, includes thermoplastic polymers, thermosetting elastomers, thermoplastic elastomers, and/or mixtures thereof. Each of these polymers have been used, either alone or in combination with each other to modify asphalt binders, and practice of the present invention is not necessarily limited by the selection of any particular polymeric modifier.

- the polymers may be characterized by a glass transition temperature (Tg), as measured by DSC analysis, of less than 150°C, in other embodiment less than 125°C, in other embodiment less than 100°C, in other embodimetns less than 20°C, in other embodiments less than 0°C, in other embodiments less than -20°C, in other embodiments less than -35°C, and in other embodiments from about -90°C to about -20°C.

- Tg glass transition temperature

- the polymers may be characterized by a glass transition temperature (Tg), as measured by DSC analysis, of more than -20°C, in other embodiments more than 0°C, in other embodiments more than 20°C, in other embodiments more than 50°C, and in other embodiments more than 100°C.

- Tg glass transition temperature

- the polymeric modifier may be characterized by a melt index (ASTM D-1238;2.16 kg load @ 190°C) of less than 1,000 dg/min, in other embodiments less than 500 dg/min, in other embodiments less than 50 dg/min, in other embodiments less than 20 dg/min, in other embodiments less than 10 dg/min, and in other embodiments less than 1 dg/min.

- the unsaturated polymers may have a melt index of between 3 and 15 dg/min, and other embodiments between 4 and 12 dg/min.

- the polymeric modifier may be characterized by a number average molecular weight (M n ) of from about 10 to about 1,000 kg/mol, in other embodiments from about 40 to about 500 kg/mol, and in other embodiments from about 80 to about 200 kg/mol.

- M n number average molecular weight

- the polymeric modifier may also be characterized by a weight average molecular weight (M w ) of from about 10 to about 4,000 kg/mol, in other embodiments from about 40 to about 2,000 kg/mol, and in other embodiments from about 80 to about 800 kg/mol.

- the polymeric modifier may be characterized by a molecular weight distribution of from about 1.1 to about 5, in other embodiments from about 1.5 to about 4.5, and in other embodiments from about 1.8 to about 4.0.

- Molecular weight can be determined by gel permeation chromatography (GPC) calibrated with polystyrene standards and adjusted for the Mark-Houwink constants for the polymer in question.

- the polymeric modifier may be linear, branched, or coupled polymers.

- Types of polymers may include both natural and synthetic polymers.

- Useful synthetic polymers may include polydienes or polydiene copolymers with non-diene comonomer (e.g., styrene).

- the copolymers may include block and random copolymers.

- the coupled polymers may include linearly coupled polymers (e.g. di-coupled polymers) or raidally coupled polymers (e.g. tri-coupled or, tetra-coupled penta-coupled, hexa-coupled etc.).

- Exemplary polydienes include polybutadiene and polyisoprene.

- Exemplary copolymers may include random styrene-butadiene rubber, styrene-butadiene block copolymer, styrene-butadiene-styrene block copolymer, random styrene-isoprene, styrene-isoprene block copolymer, styrene-isoprene-butadiene block copolymer, random styrene-isoprene-butadiene, styrene-isoprene-styrene block copolymer, and chloroprene rubber.

- the polymeric modifier include linear or radial block copolymers wherein the block copolymers include terminal styrene blocks.

- the styrene content of these block copolymers may be from 10% to 50% by weight, in other embodiments from 15% to 45% by weight, and in other embodiments from 20% to 40% by weight.

- the polymeric modifier is an SBS block copolymer (i.e. poly(styrene-b-butadiene-b-styrene).

- SBS block copolymer i.e. poly(styrene-b-butadiene-b-styrene).

- these block copolymers may be characterized by a weight average molecular weight of from about 90,000 to about 750,000, or in other embodiments from about 150,000 to about 250,000.

- these polymers may be characterized by a polydispersity of up to about 1.1 or in other embodiments up to about 1.05.

- the SBS block copolymers have from about 27 to about 43 parts by weight of styrene.

- SBS block copolymer useful for practice of the present invention is that sold under the tradename Kraton D (Kraton Polymer Group), including, for example, D1118, D1101, and D1184. Included among these polymers are SBS block linear and radial block copolymers. In particular embodiments, two block copolymers, linear and radial, can be mixed to achieve the desired results. In certain embodiments, the weight ratio of linear to radial SBS copolymers may be from about 0 to about 7 parts by weight of radial and from about 7 to about 15 parts by weight of linear SBS block copolymer.

- useful thermoplastic polymers that may used as the polymeric modifier include polyolefins.

- polypropylenes include polypropylenes.

- polypropylenes may have a weight average molecular weight of from about 50,000 to about 250,000, or in other embodiments from about 150,000 to about 170,000.

- the polydispersity may be from about 2.5 to about 3.5.

- the polypropylene may be further characterized by a melt temperature of from about 160° C to about 175 ° C, and may have a cold crystallization temperature above 120° C.

- the polymeric modifier is isotactic polypropylene (IPP).

- IPP isotactic polypropylene

- the IPP has at least 45 percent by weight crystallinity, or in other embodiments from about 46 to about 50 percent by weight crystallinity.

- Blends of atactic polypropylene and isotactic polypropylene may be used.

- atactic polyalpha olefins APAOs

- the expandable graphite may be used in conjunction with a complementary flame retardant.

- Flame retardants may include any compound that increases the burn resistivity, particularly flame spread such as tested by UL 94 and/or UL 790, in the polymeric compositions of the present invention.

- useful flame retardants include those that operate by forming a char-layer across the surface of a specimen when exposed to a flame.

- Other flame retardants include those that operate by releasing water upon thermal decomposition of the flame retardant compound.

- Useful flame retardants may also be categorized as halogenated flame retardants or non-halogenated flame retardants.

- Exemplary non-halogenated flame retardants include magnesium hydroxide, aluminum trihydrate, zinc borate, ammonium polyphosphate, melamine polyphosphate, and antimony oxide (Sb 2 O 3 ).

- Magnesium hydroxide (Mg(OH) 2 ) is commercially available under the tradename VertexTM 60

- ammonium polyphosphate is commercially available under the tradename ExoliteTM AP 760 (Clarian), which is sold together as a polyol masterbatch

- melamine polyphosphate is available under the tradename BuditTM 3141 (Budenheim)

- antimony oxide (Sb 2 O 3 ) is commercially available under the tradename FireshieldTM.

- the complementary flame retardant includes colemanite, which is a borate mineral that is believed to include about 50-80% calcium borate.

- the asphaltic component may include tackifier resins. These resins include, but are not limited to, petroleum resins, synthetic polyterpenes, resin esters and natural terpenes, and combinations thereof.

- the resin modifiers soften or become liquid at temperatures of about 40o C to about 150o C.

- the resin modifiers have number average molecular weights, as measured by vapor phase osmometry, below that of the polymeric material included in the polymeric film. In certain embodiments, the number average molecular weights of the resin modifiers are less than about 5,000. In other embodiments, the number average molecular weights of the resin modifiers are less than about 1,000. In additional embodiments, the number average molecular weights of the resin modifiers are from about 500 to about 1000.

- the resin modifiers have ring and ball softening point of about 20o C to about 160o C. In additional embodiments, resin modifiers have ring and ball softening points of about 40o C to about 160o C. In still other embodiments, resin modifiers have ring and ball softening points of about 50o C to about 160o C.

- Suitable resins include, but are not limited to, natural rosins and rosin esters, hydrogenated rosins and hydrogenated rosin esters, coumarone-indene resins, petroleum resins, polyterpene resins, and terpene-phenolic resins.

- suitable petroleum resins include, but are not limited to, aliphatic hydrocarbon resins, hydrogenated aliphatic hydrocarbon resins, mixed aliphatic and aromatic hydrocarbon resins, hydrogenated mixed aliphatic and aromatic hydrocarbon resins, cycloaliphatic hydrocarbon resins, hydrogenated cycloaliphatic resins, mixed cycloaliphatic and aromatic hydrocarbon resins, hydrogenated mixed cycloaliphatic and aromatic hydrocarbon resins, aromatic hydrocarbon resins, substituted aromatic hydrocarbons, and hydrogenated aromatic hydrocarbon resins.

- hydrogenated includes fully, substantially and at least partially hydrogenated resins.

- Suitable aromatic resins include aromatic modified aliphatic resins, aromatic modified cycloaliphatic resin, and hydrogenated aromatic hydrocarbon resins.

- any of the above resins may be grafted with an unsaturated ester or anhydride to provide enhanced properties to the resin.

- resin modifiers e.g., Hydrocarbon Resins, Kirk-Othmer, Encyclopedia of Chemical Technology, 4th Ed. v.13, pp. 717-743 (J. Wiley & Sons, 1995 ).

- the tackifier resins include phenol-based resins. Included among the phenol-based resins are phenolic resins. These resins may include reactive phenol resins (also referred to as functionalized phenol resins), as well as unreactive resins.

- the phenolic resin is a resole resin, which can be made by the condensation of alkyl, substituted phenols, or unsubstituted phenols with aldehydes such as formaldehyde in an alkaline medium or by condensation of bi-functional phenoldialcohols. In one or more embodiments, this condensation reaction occurs in the excess or molar equivalent of formaldehyde. In other embodiments, the phenolic resin may be formed by an acid-catalyzed reaction.

- the tackifier resin is a polybutene polymer or oligomer.

- polybutene oils are employed.

- Useful polybutene oils include high-viscosity oils that may be characterized by a viscosity at 100 °C of at least 80 cst, in other embodiments at least 100 cst, or in other embodiments at least 120 cst up to, for example, about 700 or 800 cst.

- the high viscosity polybutene oils may be characterized by a molecular weight of at least 1000 g/mole, in other embodiments at least 1200 g/mole, or in other embodiments at least 1300 g/mole up to, for example, 1400 or 1500 g/mole.

- An exemplary high-viscosity polybutene oil is available under the tradename Indapol H300 (Ineos) or PB32 (Soltex).

- the asphaltic component may include oil, which may also be referred to as processing oil or extender oil.

- these extenders may include high-boiling hydrocarbons.

- these oils include paraffinic oils, aromatic oils, naphthenic oils, vegetable oils, and low PCA oils including MES, TDAE, and SRAE, and heavy naphthenic oils, and various synthetic oils such as, but not limited, polybutene oils.

- the oil employed is selected based upon its compatibility with the rubber, as well as its ability to provide advantageous properties to the final composition (e.g., green strength or tack).

- the asphaltic component may also include fillers, extenders, antioxidants, waxes, antiozonants, and the like.

- Useful fillers include, but are not limited to, inorganic fillers such as calcium carbonate (i.e. limestone) and glass, such as glass beads.