EP3417959B1 - Secondary cooling of a strand in a strand casting assembly - Google Patents

Secondary cooling of a strand in a strand casting assembly Download PDFInfo

- Publication number

- EP3417959B1 EP3417959B1 EP18179585.7A EP18179585A EP3417959B1 EP 3417959 B1 EP3417959 B1 EP 3417959B1 EP 18179585 A EP18179585 A EP 18179585A EP 3417959 B1 EP3417959 B1 EP 3417959B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- coolant

- strand

- nozzle

- line

- switchover valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000001816 cooling Methods 0.000 title claims description 71

- 238000009749 continuous casting Methods 0.000 title claims description 22

- 239000002826 coolant Substances 0.000 claims description 185

- 238000009434 installation Methods 0.000 claims description 4

- 239000012530 fluid Substances 0.000 claims description 3

- 230000008878 coupling Effects 0.000 claims 1

- 238000010168 coupling process Methods 0.000 claims 1

- 238000005859 coupling reaction Methods 0.000 claims 1

- 238000007599 discharging Methods 0.000 claims 1

- 238000001514 detection method Methods 0.000 description 8

- 230000001105 regulatory effect Effects 0.000 description 6

- 230000002123 temporal effect Effects 0.000 description 4

- 230000001419 dependent effect Effects 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 230000010355 oscillation Effects 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- IHQKEDIOMGYHEB-UHFFFAOYSA-M sodium dimethylarsinate Chemical class [Na+].C[As](C)([O-])=O IHQKEDIOMGYHEB-UHFFFAOYSA-M 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/16—Controlling or regulating processes or operations

- B22D11/22—Controlling or regulating processes or operations for cooling cast stock or mould

- B22D11/225—Controlling or regulating processes or operations for cooling cast stock or mould for secondary cooling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B1/00—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means

- B05B1/02—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to produce a jet, spray, or other discharge of particular shape or nature, e.g. in single drops, or having an outlet of particular shape

- B05B1/08—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to produce a jet, spray, or other discharge of particular shape or nature, e.g. in single drops, or having an outlet of particular shape of pulsating nature, e.g. delivering liquid in successive separate quantities ; Fluidic oscillators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/12—Accessories for subsequent treating or working cast stock in situ

- B22D11/124—Accessories for subsequent treating or working cast stock in situ for cooling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/12—Accessories for subsequent treating or working cast stock in situ

- B22D11/124—Accessories for subsequent treating or working cast stock in situ for cooling

- B22D11/1246—Nozzles; Spray heads

Definitions

- the invention relates to a line end segment of a cooling device for secondary cooling of a strand in a strand guide of a continuous casting plant.

- the invention also relates to a cooling device for secondary cooling of a strand in a strand guide of a continuous caster.

- a metallic strand is formed in a mold and then guided in a strand guide and cooled further in the process.

- the cooling of the strand in the strand guide is called secondary cooling, while cooling of the strand in the mold is called primary cooling.

- secondary cooling a coolant, for example water or a water-air mixture, is usually applied to the strand by means of a cooling device.

- a secondary cooling device and a cooling method for secondary cooling of a strand in a continuous casting plant are known, in which the cooling power is set by PWM control of the duty cycle of a switching valve. How the ratio between the maximum and the minimum individual coolant flow is increased and, in addition, the formation of a suitable jet profile (in particular the opening angle of the coolant jet from the coolant outlet) can be achieved even with small individual coolant flows, does not emerge from the document.

- the invention is based on the object of specifying an improved line end segment and an improved cooling device for secondary cooling of a strand in a continuous casting plant.

- a line end segment and a cooling device for secondary cooling of a strand should be specified, with which or which a for Strand cooling particularly suitable jet profile of a coolant jet can be realized.

- the cooling device according to the invention for secondary cooling of a strand in a strand guide of a continuous casting plant comprises at least one line end segment according to the invention.

- a pneumatically or electrically or electromagnetically or hydraulically switchable valve is suitable as the switching valve of the line end segment.

- a switching valve designed in this way is advantageously commercially available and enables an inexpensive implementation of an individual coolant flow that can be switched on and off.

- control line is a pneumatic compressed air line in the case of a pneumatically switchable switching valve, an electrical line in the case of an electrically or electromagnetically switchable switching valve and a hydraulic fluid line in the case of a hydraulically switchable switching valve.

- a further development of the invention provides that the outlet nozzle has an exchangeable nozzle tip.

- An exchangeable nozzle tip advantageously enables a jet profile of a coolant jet emitted by the coolant outlet to be changed, if necessary, in a simple manner by exchanging the nozzle tip.

- the switching valve is screwed onto the segment tube, in particular by a tube-valve screw connection which is formed by an external thread on an outer surface of the segment tube and a corresponding internal thread of the switching valve.

- the outlet nozzle can have a nozzle tip with the coolant outlet and a nozzle base body.

- the The nozzle base body is screwed onto the switching valve, in particular by a valve-nozzle screw connection which is formed by an external thread on an outer surface of the switching valve and a corresponding internal thread of the nozzle base body.

- the nozzle tip can be screwed to the nozzle base body, in particular through an internal thread of the nozzle body and a corresponding external thread of the nozzle tip.

- the connecting flange has a centering bolt arranged between the flange openings.

- cooling device provides at least one longitudinal row of several coolant outlets arranged one behind the other along a transport direction of the strand and / or at least one transverse row of several coolant outlets arranged next to one another transversely to a transport direction of the strand.

- cooling device provides a pressure detection device for detecting a coolant pressure or a flow meter for detecting a coolant flow in a coolant distribution system of the cooling device.

- Such a pressure detection device advantageously enables functions of the cooling device to be analyzed and checked, for example the determination of a degree of blockage of coolant outlets by a Evaluation of the signals detected by the pressure detection device.

- an actual value of a coolant pressure or coolant flow for regulating the coolant pressure or coolant flow in the coolant distribution system can be recorded.

- Figure 1 shows schematically a section of a continuous caster 1 in a side view. Shown are a mold 3, an oscillation device 4 for moving the mold 3 relative to a strand 9, a strand guide 5 downstream of the mold 3 and a cooling device 7 of the continuous casting plant 1.

- the strand guide rollers 13 above the Line 9 and the line segments 17.1 and the coolant outlets 21 below the line 9 are not shown. It is known to the person skilled in the art that after exiting a mold in the secondary cooling, a strand is typically guided by strand guide rollers above and below the strand and the broad sides of the strand lying above and below are cooled.

- a metallic melt is fed to the mold 3, from which the metallic strand 9 is formed with the mold 3, which is guided with the strand guide 5 and transported along a transport direction 11.

- movements of the mold 4, in particular oscillating movements (the direction of movement is shown by an arrow) of the mold 4 are generated, so that the strand 9 does not adhere to an inner surface of the mold.

- the strand guide 5 has several strand guide rollers 13 to support the strand 9.

- the mold 3 has a width adjustment for setting a width of the strand 9, so that strands 9 of different widths can be produced with the mold 3.

- the strand guide 5 has a casting thickness adjustment for setting a thickness of the strand 9, so that strands 9 of different thicknesses can be produced with the strand guide 5.

- the cooling device 7 is used for secondary cooling of the strand 9 in the strand guide 5.

- the cooling device 7 comprises a coolant distribution system 15 with line segments 17.1 to 17.4 for conveying a coolant 19 and several coolant outlets 21 distributed over the strand guide 5 for outputting coolant 19 onto the strand 9.

- the coolant 19 is, for example, water.

- the continuous casting installation 1 shown is designed for what is known as horizontal continuous casting, in which the strand 9 is output horizontally from the mold 3 to the strand guide 5.

- the invention in particular a cooling device 7 according to the invention, is not limited to continuous casting plants 1 for horizontal continuous casting, but in particular also relates to continuous casting plants 1 which are designed for so-called vertical continuous casting, in which the strand 9 emerges vertically through a bottom opening of the mold 3 Mold 3 is issued to the strand guide 5 and the strand guide 5 is designed to be curved, so that the strand 9 is brought along the strand guide 5 from a horizontal to a vertical position.

- FIG. 2 shows schematically an exemplary embodiment according to the invention of a cooling device 7 for secondary cooling of a strand 9 in a continuous casting plant 1 in a perspective illustration. Only a section of the strand 9 is shown, which is located in the area of the cooling device 7. Furthermore, of this section of the strand 9 and of the coolant distribution system 15 of the cooling device 7, only one area is shown, which extends over half a width of the strand 9 from a lateral strand edge 9.1 of the strand 9 to a central axis 9.2 running parallel to the transport direction 11 of the strand 9 extends.

- a further area of the coolant distribution system 15 extends, which is designed in the same way as that in FIG Figure 2 area shown, these two areas being mirror-symmetrical with respect to a reflection on a mirror plane which contains the central axis 9.2 and is perpendicular to a strand surface 9.3 of the strand 9.

- the coolant outlets 21 of the coolant distribution system 15 form several longitudinal rows of coolant outlets 21 arranged one behind the other along the transport direction 11 of the strand 9 Form coolant outlets 21.

- the coolant distribution system 15 has eight longitudinal rows of coolant outlets 21 arranged next to one another, each longitudinal row having four coolant outlets 21.

- Alternative exemplary embodiments have one of eight different numbers of longitudinal rows of coolant outlets 21 arranged next to one another and / or at least one longitudinal row with one of four different numbers of coolant outlets 21.

- Each coolant outlet 21 forms an end of a line end segment 17.1 facing the strand 9 and running perpendicular to the strand surface 9.3.

- the coolant distribution system 15 has a line longitudinal segment 17.2 running parallel to the transport direction 11, which connects the line end segments 17.1 having these coolant outlets 21 to one another.

- the coolant distribution system 15 also has a transverse line segment 17.4 running transversely to the transport direction 11, which is connected to each longitudinal line segment 17.2 via an intermediate line segment 17.3 running perpendicular to the strand surface 9.3.

- Each line end segment 17.1 also has an outlet nozzle 33 with the coolant outlet 21 for outputting coolant 19, see in this regard Figure 3 .

- a switching valve 23 is arranged in each line end segment 17.1, with which a coolant supply of coolant 19 to the coolant outlet 21 of this line end segment 17.1 can be interrupted.

- Each switching valve 23 is designed as an on / off valve that has two operating states, the switching valve 23 releasing the coolant supply to the coolant outlet 21 in a first operating state and blocking the coolant supply to the coolant outlet 21 in the second operating state.

- a change in the operating state of a switching valve 23 is referred to here as switching the switching valve 23; Switching from the first to the second operating state is referred to as closing the switching valve 23 and switching from the second to the first operating state is referred to as opening the switching valve 23.

- Precisely one individual coolant flow Q, which is output from a coolant outlet 21, can therefore be switched on and off by each switching valve 23.

- the switching valves 23 are connected to a control unit 27 via control lines 25.1 to 25.4 and can be switched by the control unit 27.

- Each control line 25.1 to 25.4 connects the switching valves 23 of a longitudinal row of coolant outlets 21 with the control unit 27.

- the control lines 25.1 to 25.4 can run at least in sections in pipes of line segments 17.1 to 17.4, see the description of FIG Figure 3 below.

- the switching valves 23 are designed as pneumatically or electrically or electromagnetically or hydraulically switchable valves. Accordingly, the control lines 25.1 to 25.4 in the case of pneumatically switchable switching valves 23 are pneumatic compressed air lines, in the case of electrically or electromagnetically switchable switching valves 23 are electrical lines and in the case of hydraulically switchable switching valves 23 are hydraulic fluid lines.

- the control unit 27 is designed to switch the switching valves 23 in a manner described below.

- the cooling device 7 further comprises a pressure detection device 29 for detecting the coolant pressure P in the coolant distribution system 15.

- the signals detected by the pressure detection device 29 are fed to the control unit 27 via a pressure signal line 31.

- the control unit 27 evaluates these signals to analyze and check functions of the cooling device 7, for example to determine a degree of blockage of the coolant outlets 21.

- Figure 3 shows a perspective view of a line end segment 17.1.

- the line end segment 17.1 comprises a segment tube 35, a connecting flange 37, a switching valve 23 and an outlet nozzle 33.

- the connecting flange 37 is arranged at a first end of the segment tube 35 and can be connected to a line longitudinal segment 17.2.

- the switching valve 23 is arranged, which is attached to this end of the segment tube 35, for example by a pipe-valve screw connection 39, which is formed by an external thread on the outer surface of the segment tube 35 and a corresponding internal thread of the switching valve 23, can be screwed on.

- the outlet nozzle 33 has a nozzle tip 33.1 with a coolant outlet 21 and a nozzle base body 33.2.

- the nozzle body 33.2 is arranged on the switching valve 23 and can be screwed onto the switching valve 23, for example by a valve-nozzle screw connection 41, which is formed by an external thread on the outer surface of the switching valve 23 and a corresponding internal thread of the nozzle body 33.2.

- the nozzle tip 33.1 is arranged on the nozzle base body 33.2.

- the nozzle body 33.2 has an internal thread which corresponds to an external thread of the nozzle tip 33.1, so that the nozzle tip 33.1 can be detachably connected to the nozzle body 33.2.

- a jet profile of a coolant jet emitted by the outlet nozzle 33 can advantageously be changed by changing the nozzle tip 33.1.

- the segment tube 35 is used to guide coolant 19 to the coolant outlet 21 and to guide an end section of a control line 25.1 to 25.4 to the switching valve 23.

- the segment tube 35 has, for example, an outer tube and an inner tube running in the outer tube, with between the outer tube and the inner tube coolant 19 is guided and the inner tube forms or surrounds the end section of a control line 25.1 to 25.4.

- the connecting flange 37 has two flange openings 37.1, 37.2, a first flange opening 37.1 serving to feed coolant 19 into the segment tube 35 and the second flange opening 37.2 for guiding the control line 25.1 to 25.4 in the segment tube 35 is used.

- the connecting flange 37 also has a centering bolt 42 arranged between the flange openings 37.1, 37.2 in order to be able to assemble and align the line end segment 17.1 more easily.

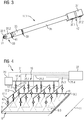

- FIG 4 shows schematically an exemplary embodiment, not according to the invention, of a cooling device 7 for secondary cooling of a strand 9 in a continuous casting plant 1 in a to Figure 2 analog perspective representation.

- This in Figure 4 The illustrated embodiment differs from that in the Figures 2 and 3rd illustrated embodiment in that a switching valve 23 for a coolant outlet 21 is not arranged in each of the line end segments 17.1, but that for each longitudinal row of coolant outlets 21 only one switching valve 23 connected to the control unit 27 via a control line 25.1 to 25.4 is arranged in an intermediate line segment 17.3 is, so that a coolant supply from the line cross segment 17.4 to a line longitudinal segment 17.2 and all the line end segments 17.1 connected to it can be interrupted by each of these switching valves 23.

- a check valve 43 is arranged in order, after a coolant supply to the line end segment 17.1 has been blocked by the corresponding switching valve 23, an output of coolant 19, which is located in line segments 17.1 to 17.3 between the switching valve 23 and check valve 43, to the Strand 9 to prevent.

- the cooling device 7 of the in Figure 4 illustrated embodiment analogous to that in the Figures 2 and 3rd illustrated embodiment formed.

- the switching valves 23 are like the switching valves 23 in the Figures 2 and 3rd illustrated embodiment as on / off valves formed, which can be switched by the control unit 27 in a manner described in more detail below.

- the line end segments 17.1 in turn each have an outlet nozzle 33, the nozzle tip 33.1 of which is preferably designed to be exchangeable.

- the illustrated embodiment requires that in Figure 4

- the illustrated embodiment advantageously has fewer switching valves 23.

- a higher clock frequency of the pulse-width-modulated switching of the switching valves 23 (when using similar switching valves 23 in both embodiments) enables a more flexible control of the cooling with an individual control of the switching valves 23 and reduces the effects of a failure of an individual switching valve 23, since a such failure affects a smaller surface area of the strand 9.

- FIGS Figures 5 to 7 illustrate a cooling method for secondary cooling of a strand 9 in a continuous casting installation 1 with a cooling device 7, which is like one of the in FIGS Figures 2 to 4 illustrated embodiments is formed.

- FIG. 11 shows a diagram for a coolant pressure P as a function of a single coolant flow Q through an outlet nozzle 33 of the cooling device 7, which, like one of the in FIGS Figures 2 and 4th illustrated embodiments is formed.

- the individual coolant flow Q emitted from the outlet nozzle 33 through the coolant outlet 21 is in at least one flow range ⁇ Q for its mean value over time Q switched on and off by a pulse-width-modulated control of a switching valve 23 and thus itself pulse-width-modulated, see Figure 6 .

- this Current range ⁇ Q limited by a threshold current Q S , which corresponds to a threshold pressure P S.

- a maximum pressure P M and a corresponding maximum flow Q M for which the outlet nozzle 33 is designed, are also shown.

- the threshold flow Q S is specified in such a way that the coolant pressure P below the corresponding threshold pressure P S is no longer sufficient to achieve an intended jet profile of a coolant jet emitted by the outlet nozzle 33, in particular an intended opening angle of the coolant jet, to achieve a sufficiently large area to cover the strand surface 9.3 with the coolant jet.

- the individual coolant flows Q are output in the usual way, ie without pulse width modulation.

- the switching valves 23 of the individual coolant flows Q to be generated are opened and the coolant pressure P or a coolant flow in the coolant distribution system 15 is regulated by means of a control circuit 45 to a setpoint dependent on the individual coolant flows Q to be generated, see Figure 9 .

- Figure 6 shows a profile of a pulse-width-modulated individual coolant flow Q of an outlet nozzle 33 as a function of a time t.

- the pulse width modulation has a clock period of the period length T or a clock frequency 1 / T.

- the individual coolant flow Q has a constant, non-zero current pulse value Q P in a first half of each clock period and disappears in the second half of each clock period.

- the time average is accordingly Q of the individual coolant flow Q in this example is half as large as the current pulse value Q P.

- the pulse width modulation allows mean values with a current pulse value Q P that is greater than the threshold current Q S Q a single coolant flow Q can be realized, which is smaller than the threshold current Q S.

- individual coolant flows Q can be realized, their mean values over time Q are smaller than the threshold flow Q S and which nevertheless generate an intended jet profile of a coolant jet emitted by the outlet nozzle 33.

- Figure 7 shows diagrammatically temporal progressions of coolant flows Q 1 to Q 4 and a total coolant flow Q G , which are output by a cooling device 7 for secondary cooling of a strand 9 in a continuous casting plant 1 as a result of a pulse-width-modulated switching of the switching valves 23.

- the cooling device 7 is like one of the in the Figures 2 or 4th illustrated embodiments formed, wherein Figure 7 to simplify the illustration of a cooling device 7 with only four longitudinal rows of coolant outlets 21 instead of as in the exemplary embodiments of FIG Figures 2 and 4th eight longitudinal rows refers to ( Figure 7 can also show temporal progressions of coolant flows Q 1 to Q 4 and a total coolant flow Q G in the Figures 2 or 4th represent the halves of the respective cooling devices 7 shown, the other halves (not shown) being controlled analogously).

- the coolant flows Q 1 to Q 4 are each output from all coolant outlets 21 of a longitudinal row together and are therefore each a sum of the individual coolant flows Q of the coolant outlets 21 of a longitudinal row, the individual coolant flows Q each being analogous to Figure 6 are pulse width modulated.

- the total coolant flow Q G is output from the coolant outlets 21 of all these longitudinal rows together and is the sum of the coolant flows Q 1 to Q 4 .

- the switching valves 23 are switched by the control unit 27 in a pulse width modulated manner with a clock period of the period length T or with a clock frequency 1 / T.

- the switching valves 23 for the various longitudinal rows of Coolant outlets 21 are switched with a time offset to one another, so that the total coolant flow Q G is constant over time.

- the switching valves 23 are switched in such a way that a first coolant flow Q 1 disappears during a second half of each cycle period, a second coolant flow Q 2 disappears during a first and last quarter of each cycle period, and a third coolant flow Q 3 disappears during the first half of each cycle period , a fourth coolant flow Q 4 disappears during a second and third quarter of each cycle period and the coolant flows Q 1 to Q 4 in the remaining times assume a constant, non-zero value for all longitudinal rows, which is half the total coolant flow Q G is.

- the total coolant flow Q G is regulated to a predetermined setpoint during the pulse width modulation.

- an actual value of the total coolant flow Q G is determined and a duty cycle D and the period length T of the pulse width modulation are regulated as a function of a deviation of the determined actual value from the setpoint.

- the duty cycle D of the pulse width modulation is understood to mean the ratio of a pulse duration during a clock period to the period length T. In the in the Figures 6 and 7th In the examples shown, the duty cycle D is, for example, 50% in each case.

- coolant pressures P in line segments 17.1 to 17.4, via which individual coolant flows Q are output are recorded and the individual coolant flows Q output in each case are deduced from this by means of current-pressure characteristics.

- the actual value of the total coolant flow Q G is then formed as the sum of these individual coolant flows Q, each multiplied by the respective duty cycle D of the pulse width modulation.

- Figure 8 shows the duty cycle D of the pulse width modulation of an individual coolant flow Q as a function of the mean value Q of the individual coolant flow Q in the flow range ⁇ Q.

- the duty cycle end value D m assumes the value 1, for example. If the coolant pressure P in the coolant distribution system 15 is set to a higher pressure value, the duty cycle end value D m is correspondingly smaller.

- a selection of coolant outlets 21, through which individual coolant flows Q are output, is also made as a function of a width of the strand 9. Coolant outlets 21, which are not required to cool the strand 9 because they are located next to the strand surface 9.3, for example only release blow-out air in a pulse pause or a short water pulse to prevent these coolant outlets 21 from clogging.

- Figure 9 shows a control circuit 45 for regulating a coolant pressure P or coolant flow in the coolant distribution system 15 in order to generate individual coolant flows Q which are greater than the threshold flow Q S.

- the controlled variable R of the control loop 45 is therefore the coolant pressure P or coolant flow in the coolant distribution system 15.

- a reference variable S of the control loop 45 is accordingly a setpoint value of the coolant pressure P or coolant flow in the which depends on the individual coolant flows Q Coolant distribution system 15.

- the control circuit 45 comprises a controller 47, a controlled system 49 and a measuring element 51.

- the controller 47 is a pump for the direct generation of a coolant pressure P or coolant flow in the coolant distribution system 15, or a pump with a downstream pressure or flow controller for Reduction of a coolant pressure P or coolant flow generated by the pump in the coolant distribution system 15.

- the controlled system 49 is the coolant distribution system 15.

- the measuring element 51 is a pressure detection device 29 for detecting the coolant pressure P or a flow detection device for detecting a coolant flow in the coolant distribution system 15

- Controlled variable R, a system deviation E of the controlled variable R from the reference variable S is formed.

- the controller 47 generates a manipulated variable U that is dependent on the control deviation E in order to reduce the control deviation B.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Continuous Casting (AREA)

Description

Die Erfindung betrifft ein Leitungsendsegment einer Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Strangführung einer Stranggießanlage. Außerdem betrifft die Erfindung eine Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Strangführung einer Stranggießanlage.The invention relates to a line end segment of a cooling device for secondary cooling of a strand in a strand guide of a continuous casting plant. The invention also relates to a cooling device for secondary cooling of a strand in a strand guide of a continuous caster.

Beim Stranggießen in einer Stranggießanlage wird in einer Kokille ein metallischer Strang gebildet und anschließend in einer Strangführung geführt und dabei weiter abgekühlt. Die Abkühlung des Strangs in der Strangführung wird als Sekundärkühlung bezeichnet, während eine Kühlung des Strangs in der Kokille Primärkühlung genannt wird. Bei der Sekundärkühlung wird mittels einer Kühlungsvorrichtung auf den Strang in der Regel ein Kühlmittel, beispielsweise Wasser oder ein Wasser-Luft-Gemisch, aufgebracht.During continuous casting in a continuous caster, a metallic strand is formed in a mold and then guided in a strand guide and cooled further in the process. The cooling of the strand in the strand guide is called secondary cooling, while cooling of the strand in the mold is called primary cooling. In the case of secondary cooling, a coolant, for example water or a water-air mixture, is usually applied to the strand by means of a cooling device.

Aus der

Der Erfindung liegt die Aufgabe zugrunde, ein verbessertes Leitungsendsegment und eine verbesserte Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Stranggießanlage anzugeben. Insbesondere sollen ein Leitungsendsegment und eine Kühlungsvorrichtung zur Sekundärkühlung eines Strangs angegeben werden, mit welchem bzw. welcher ein zur Strangkühlung besonders geeignetes Strahlprofil eines Kühlmittelstrahls realisiert werden kann.The invention is based on the object of specifying an improved line end segment and an improved cooling device for secondary cooling of a strand in a continuous casting plant. In particular, a line end segment and a cooling device for secondary cooling of a strand should be specified, with which or which a for Strand cooling particularly suitable jet profile of a coolant jet can be realized.

Die Aufgabe wird erfindungsgemäß hinsichtlich des Leitungsendsegments durch die Merkmale des Anspruchs 1 und hinsichtlich der Kühlungsvorrichtung durch die Merkmale des Anspruchs 10 gelöst.The object is achieved according to the invention with regard to the line end segment by the features of claim 1 and with regard to the cooling device by the features of claim 10.

Vorteilhafte Ausgestaltungen der Erfindung sind Gegenstand der weiteren Ansprüche.Advantageous embodiments of the invention are the subject of the further claims.

Das erfindungsgemäße Leitungsendsegment einer Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Strangführung einer Stranggießanlage umfasst

- eine Auslassdüse mit einem Kühlmittelauslass zur Ausgabe von Kühlmittel,

- ein Schaltventil zum Ein- und Ausschalten von einem Kühlmitteleinzelstrom,

- ein Segmentrohr zur Führung von dem Kühlmittel zu dem Kühlmittelauslass der Auslassdüse und zur Führung eines Endabschnitts einer Steuerleitung zum Schalten des Schaltventils zu dem Schaltventil,

- einen Verbindungsflansch mit einer ersten Flanschöffnung zur Zuführung des Kühlmittels in das Segmentrohr und einer zweiten Flanschöffnung zur Führung der Steuerleitung in das Segmentrohr,

- der Verbindungsflansch an einem ersten Ende des Segmentrohrs und das Schaltventil an einem zweiten Ende des Segmentrohrs angeordnet ist,

- die Auslassdüse an dem Schaltventil angeordnet ist und

- das Segmentrohr ein Außenrohr und ein in dem Außenrohr verlaufendes Innenrohr aufweist, wobei zwischen dem Außenrohr und dem Innenrohr das Kühlmittel geführt wird und das Innenrohr den Endabschnitt der Steuerleitung bildet oder umgibt.

- an outlet nozzle with a coolant outlet for dispensing coolant,

- a switching valve for switching a single coolant flow on and off,

- a segment tube for guiding the coolant to the coolant outlet of the outlet nozzle and for guiding an end section of a control line for switching the switching valve to the switching valve,

- a connecting flange with a first flange opening for feeding the coolant into the segment tube and a second flange opening for guiding the control line into the segment tube,

- the connecting flange is arranged at a first end of the segment tube and the switching valve is arranged at a second end of the segment tube,

- the outlet nozzle is arranged on the switching valve and

- the segment tube has an outer tube and an inner tube running in the outer tube, the coolant being guided between the outer tube and the inner tube and the inner tube forming or surrounding the end section of the control line.

Die erfindungsgemäße Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Strangführung einer Stranggießanlage umfasst zumindest ein erfindungsgemäßes Leitungsendsegment.The cooling device according to the invention for secondary cooling of a strand in a strand guide of a continuous casting plant comprises at least one line end segment according to the invention.

Als Schaltventile des Leitungsendsegments eignet sich beispielsweise ein pneumatisch oder elektrisch oder elektromagnetisch oder hydraulisch schaltbares Ventile. Ein derartig ausgebildetes Schaltventil ist vorteilhaft kommerziell verfügbar und ermöglicht eine kostengünstige Realisierung eines ein- und abschaltbaren Kühlmitteleinzelstroms.For example, a pneumatically or electrically or electromagnetically or hydraulically switchable valve is suitable as the switching valve of the line end segment. A switching valve designed in this way is advantageously commercially available and enables an inexpensive implementation of an individual coolant flow that can be switched on and off.

Bei einer bevorzugten Ausgestaltung ist vorgesehen, dass die Steuerleitung im Falle eines pneumatisch schaltbaren Schaltventils eine pneumatische Druckluftleitung, im Falle eines elektrisch oder elektromagnetisch schaltbaren Schaltventils eine elektrische Leitung und im Falle eines hydraulisch schaltbaren Schaltventils eine Hydraulikflüssigkeitsleitung ist.In a preferred embodiment, it is provided that the control line is a pneumatic compressed air line in the case of a pneumatically switchable switching valve, an electrical line in the case of an electrically or electromagnetically switchable switching valve and a hydraulic fluid line in the case of a hydraulically switchable switching valve.

Eine Weitergestaltung der Erfindung sieht vor, dass die Auslassdüse eine austauschbare Düsenspitze aufweist.A further development of the invention provides that the outlet nozzle has an exchangeable nozzle tip.

Eine austauschbare Düsenspitze ermöglicht vorteilhaft, ein Strahlprofil eines von dem Kühlmittelauslass abgegebenen Kühlmittelstrahls erforderlichenfalls in einfacher Weise durch den Austausch der Düsenspitze zu verändern.An exchangeable nozzle tip advantageously enables a jet profile of a coolant jet emitted by the coolant outlet to be changed, if necessary, in a simple manner by exchanging the nozzle tip.

Ferner kann vorgesehen sein, dass das Schaltventil auf das Segmentrohr, insbesondere durch eine Rohr-Ventil-Schraubverbindung, die von einem Außengewinde an einer Außenoberfläche des Segmentrohrs und einem korrespondierenden Innengewinde des Schaltventils gebildet wird, aufgeschraubt ist.Furthermore, it can be provided that the switching valve is screwed onto the segment tube, in particular by a tube-valve screw connection which is formed by an external thread on an outer surface of the segment tube and a corresponding internal thread of the switching valve.

Die Auslassdüse kann eine Düsenspitze mit dem Kühlmittelauslass und einen Düsengrundkörper aufweisen. Weiterbildend kann vorgesehen sein, dass der Düsengrundkörper auf das Schaltventil, insbesondere durch eine Ventil-Düse-Schraubverbindung, die von einem Außengewinde an einer Außenoberfläche des Schaltventils und einem korrespondierenden Innengewinde des Düsengrundkörpers gebildet wird, aufgeschraubt ist.The outlet nozzle can have a nozzle tip with the coolant outlet and a nozzle base body. In a further development, it can be provided that the The nozzle base body is screwed onto the switching valve, in particular by a valve-nozzle screw connection which is formed by an external thread on an outer surface of the switching valve and a corresponding internal thread of the nozzle base body.

Die Düsenspitze kann mit dem Düsengrundkörper, insbesondere durch ein Innengewindes des Düsenkörpers und ein korrespondierendes Außengewinde der Düsenspitze, verschraubt sein.The nozzle tip can be screwed to the nozzle base body, in particular through an internal thread of the nozzle body and a corresponding external thread of the nozzle tip.

Bei einer bevorzugten Ausführungsvariante weist der Verbindungsflansch einen zwischen den Flanschöffnungen angeordneten Zentrierungsbolzen auf.In a preferred embodiment variant, the connecting flange has a centering bolt arranged between the flange openings.

Weitere Ausgestaltungen der Kühlungsvorrichtung sehen wenigstens eine Längsreihe mehrerer entlang einer Transportrichtung des Strangs hintereinander angeordneter Kühlmittelauslässe und/oder wenigstens eine Querreihe mehrerer quer zu einer Transportrichtung des Strangs nebeneinander angeordneter Kühlmittelauslässe vor.Further refinements of the cooling device provide at least one longitudinal row of several coolant outlets arranged one behind the other along a transport direction of the strand and / or at least one transverse row of several coolant outlets arranged next to one another transversely to a transport direction of the strand.

Diese Ausgestaltungen ermöglichen vorteilhaft eine über einen Abschnitt einer Strangführung gleichmäßig verteilte Sekundärkühlung eines Strangs, insbesondere wenn die Kühlungsvorrichtung jeweils mehrere Längs- und Querreihen von Kühlmittelauslässen aufweist.These configurations advantageously enable secondary cooling of a strand that is uniformly distributed over a section of a strand guide, in particular when the cooling device has a plurality of longitudinal and transverse rows of coolant outlets.

Eine weitere Ausgestaltung der Kühlungsvorrichtung sieht eine Druckerfassungsvorrichtung zur Erfassung eines Kühlmitteldrucks oder einen Durchflussmesser zur Erfassung eines Kühlmittelstroms in einem Kühlmittelverteilungssystem der Kühlungsvorrichtung vor.Another embodiment of the cooling device provides a pressure detection device for detecting a coolant pressure or a flow meter for detecting a coolant flow in a coolant distribution system of the cooling device.

Eine derartige Druckerfassungsvorrichtung ermöglicht vorteilhaft eine Analyse und Überprüfung von Funktionen der Kühlungsvorrichtung, beispielsweise die Ermittlung eines Verstopfungsgrades von Kühlmittelauslässen, durch eine Auswertung der von der Druckerfassungsvorrichtung erfassten Signale. Außerdem kann ein Ist-Wert eines Kühlmitteldrucks oder Kühlmittelstroms zur Regelung des Kühlmitteldrucks oder Kühlmittelstroms im Kühlmittelverteilungssystem erfasst werden.Such a pressure detection device advantageously enables functions of the cooling device to be analyzed and checked, for example the determination of a degree of blockage of coolant outlets by a Evaluation of the signals detected by the pressure detection device. In addition, an actual value of a coolant pressure or coolant flow for regulating the coolant pressure or coolant flow in the coolant distribution system can be recorded.

Die oben beschriebenen Eigenschaften, Merkmale und Vorteile dieser Erfindung sowie die Art und Weise, wie diese erreicht werden, werden klarer und deutlicher verständlich im Zusammenhang mit der folgenden Beschreibung eines erfindungsgemäßen Ausführungsbeispiels sowie eines nicht erfindungsgemäßen Ausführungsbeispiels, die im Zusammenhang mit den Zeichnungen näher erläutert werden. Dabei zeigen:

-

FIG 1 schematisch einen Ausschnitt einer Stranggießanlage in einer Seitenansicht, -

FIG 2 schematisch ein erfindungsgemäßes Ausführungsbeispiel einer Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Stranggießanlage in einer perspektivischen Darstellung, -

FIG 3 eine perspektivische Darstellung eines Leitungsendsegments einer Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Stranggießanlage, -

FIG 4 schematisch ein nicht erfindungsgemäßes Ausführungsbeispiel einer Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Stranggießanlage in einer perspektivischen Darstellung, -

FIG 5 ein Diagramm eines Kühlmitteldrucks in Abhängigkeit von einem Kühlmitteleinzelstrom einer Auslassdüse, -

FIG 6 ein Diagramm eines zeitlichen Verlaufs eines pulsweitenmodulierten Kühlmitteleinzelstroms einer Auslassdüse, -

FIG 7 diagrammatisch zeitliche Verläufe von pulsweitenmodulierten Kühlmittelströmen, die von einer Kühlungsvorrichtung zur Sekundärkühlung eines Strangs in einer Stranggießanlage ausgegeben werden, -

FIG 8 einen Tastgrad D einer Pulsweitenmodulation eines Kühlmitteleinzelstroms in Abhängigkeit von dem Mittelwert des Kühlmitteleinzelstroms, und -

FIG 9 einen Regelkreis zur Regelung eines Kühlmitteldrucks oder Kühlmittelstroms in einem Kühlmittelverteilungssystem.

-

FIG 1 schematically a section of a continuous caster in a side view, -

FIG 2 schematically an embodiment of the invention of a cooling device for secondary cooling of a strand in a continuous casting plant in a perspective view, -

FIG 3 a perspective view of a line end segment of a cooling device for secondary cooling of a strand in a continuous caster, -

FIG 4 schematically an embodiment of a cooling device not according to the invention for secondary cooling of a strand in a continuous casting plant in a perspective view, -

FIG 5 a diagram of a coolant pressure as a function of a single coolant flow from an outlet nozzle, -

FIG 6 a diagram of a time profile of a pulse-width-modulated individual coolant flow from an outlet nozzle, -

FIG 7 diagrammatic temporal progressions of pulse-width-modulated coolant flows that are output by a cooling device for secondary cooling of a strand in a continuous caster, -

FIG 8 a duty cycle D of a pulse width modulation of an individual coolant flow as a function of the mean value of the individual coolant flow, and -

FIG 9 a control loop for regulating a coolant pressure or coolant flow in a coolant distribution system.

Einander entsprechende Teile sind in allen Figuren mit den gleichen Bezugszeichen versehen.Corresponding parts are provided with the same reference symbols in all figures.

Der Kokille 3 wird eine metallische Schmelze zugeführt, aus der mit der Kokille 3 der metallische Strang 9 gebildet wird, der mit der Strangführung 5 geführt und entlang einer Transportrichtung 11 transportiert wird. Mit der Osszilationseinrichtung 4 werden Bewegungen der Kokille 4, insbesondere oszillierende Bewegungen (die Bewegungsrichtung ist durch einen Pfeil dargestellt) der Kokille 4, erzeugt, damit der Strang 9 nicht an einer Innenoberfläche der Kokille anhaftet. Die Strangführung 5 weist mehrere Strangführungsrollen 13 zur Stützung des Strangs 9 auf.A metallic melt is fed to the

Die Kokille 3 weist eine Breitenverstellung zur Einstellung einer Breite des Strangs 9 aufweist, so dass mit der Kokille 3 Stränge 9 unterschiedlicher Breiten erzeugbar sind. Die Strangführung 5 weist eine Gießdickenverstellung zur Einstellung einer Dicke des Strangs 9 auf, so dass mit der Strangführung 5 Stränge 9 verschiedener Dicken erzeugbar sind.The

Die Kühlungsvorrichtung 7 dient der Sekundärkühlung des Strangs 9 in der Strangführung 5. Die Kühlungsvorrichtung 7 umfasst ein Kühlmittelverteilungssystem 15 mit Leitungssegmenten 17.1 bis 17.4 zur Leitung eines Kühlmittels 19 und mehreren über die Strangführung 5 verteilten Kühlmittelauslässen 21 zur Ausgabe von Kühlmittel 19 auf den Strang 9. Anhand der

Die in

Die Kühlmittelauslässe 21 des Kühlmittelverteilungssystems 15 bilden mehrere Längsreihen entlang der Transportrichtung 11 des Strangs 9 hintereinander angeordneter Kühlmittelauslässe 21. Dabei sind die Längsreihen quer zu der Transportrichtung 11 des Strangs 9 nebeneinander angeordnet, so dass Kühlmittelauslässe 21 verschiedener Längsreihen Querreihen quer zu der Transportrichtung 11 nebeneinander angeordneter Kühlmittelauslässe 21 bilden.The

Im in

Jeder Kühlmittelauslass 21 bildet ein dem Strang 9 zugewandtes Ende eines Leitungsendsegments 17.1, das senkrecht zu der Strangoberfläche 9.3 verläuft. Für jede Längsreihe von Kühlmittelauslässen 21 weist das Kühlmittelverteilungssystem 15 ein parallel zur Transportrichtung 11 verlaufendes Leitungslängssegment 17.2 auf, das die diese Kühlmittelauslässe 21 aufweisenden Leitungsendsegmente 17.1 miteinander verbindet. Das Kühlmittelverteilungssystem 15 weist ferner ein quer zur Transportrichtung 11 verlaufendes Leitungsquersegment 17.4 auf, das mit jedem Leitungslängssegment 17.2 über jeweils ein senkrecht zur Strangoberfläche 9.3 verlaufendes Leitungszwischensegment 17.3 verbunden ist. Jedes Leitungsendsegment 17.1 weist ferner zur Ausgabe von Kühlmittel 19 eine Auslassdüse 33 mit dem Kühlmittelauslass 21 auf, siehe dazu

In jedem Leitungsendsegment 17.1 ist ein Schaltventil 23 angeordnet, mit dem eine Kühlmittelzufuhr von Kühlmittel 19 zu dem Kühlmittelauslass 21 dieses Leitungsendsegments 17.1 unterbrechbar ist. Jedes Schaltventil 23 ist dabei als ein Auf-/Zu-Ventil ausgebildet, das zwei Betriebszustände aufweist, wobei das Schaltventil 23 in einem ersten Betriebszustand die Kühlmittelzufuhr zu dem Kühlmittelauslass 21 freigibt und in dem zweiten Betriebszustand die Kühlmittelzufuhr zu dem Kühlmittelauslass 21 sperrt. Eine Veränderung des Betriebszustands eines Schaltventils 23 wird hier als Schalten des Schaltventils 23 bezeichnet; ein Schalten von dem ersten in den zweiten Betriebszustand wird als Schließen des Schaltventils 23 bezeichnet und ein Schalten von dem zweiten in den ersten Betriebszustand wird als Öffnen des Schaltventils 23 bezeichnet. Durch jedes Schaltventil 23 ist also genau ein Kühlmitteleinzelstrom Q ein- und abschaltbar, der von einem Kühlmittelauslass 21 ausgegeben wird.A switching

Die Schaltventile 23 sind über Steuerleitungen 25.1 bis 25.4 mit einer Steuereinheit 27 verbunden und durch die Steuereinheit 27 schaltbar. Dabei verbindet jede Steuerleitung 25.1 bis 25.4 die Schaltventile 23 einer Längsreihe von Kühlmittelauslässen 21 mit der Steuereinheit 27. Die Steuerleitungen 25.1 bis 25.4 können zumindest abschnittsweise in Rohren von Leitungssegmenten 17.1 bis 17.4 verlaufen, vgl. die Beschreibung von

Die Schaltventile 23 sind als pneumatisch oder elektrisch oder elektromagnetisch oder hydraulisch schaltbare Ventile ausgebildet. Entsprechend sind die Steuerleitungen 25.1 bis 25.4 im Falle pneumatisch schaltbarer Schaltventile 23 pneumatische Druckluftleitungen, im Falle elektrisch oder elektromagnetisch schaltbarer Schaltventile 23 elektrische Leitungen und im Falle hydraulisch schaltbarer Schaltventile 23 Hydraulikflüssigkeitsleitungen.The switching

Die Steuereinheit 27 ist dazu ausgebildet, die Schaltventile 23 in einer unten beschriebenen Weise zu schalten.The

Die Kühlungsvorrichtung 7 umfasst ferner eine Druckerfassungsvorrichtung 29 zur Erfassung des Kühlmitteldrucks P in dem Kühlmittelverteilungssystem 15. Die von der Druckerfassungsvorrichtung 29 erfassten Signale werden über eine Drucksignalleitung 31 der Steuereinheit 27 zugeführt. Die Steuereinheit 27 wertet diese Signale zu einer Analyse und Überprüfung von Funktionen der Kühlungsvorrichtung 7, beispielsweise zur Ermittlung eines Verstopfungsgrades der Kühlmittelauslässe 21, aus.The

Der Verbindungsflansch 37 ist an einem ersten Ende des Segmentrohrs 35 angeordnet und mit einem Leitungslängssegment 17.2 verbindbar. An dem zweiten Ende des Segmentrohrs 35 ist das Schaltventil 23 angeordnet, das auf dieses Ende des Segmentrohrs 35 beispielsweise durch eine Rohr-Ventil-Schraubverbindung 39, die von einem Außengewinde an der Außenoberfläche des Segmentrohrs 35 und einem korrespondierenden Innengewinde des Schaltventils 23 gebildet wird, aufschraubbar ist.The connecting

Die Auslassdüse 33 weist eine Düsenspitze 33.1 mit einem Kühlmittelauslass 21 und einen Düsengrundkörper 33.2 auf. Der Düsengrundkörper 33.2 ist an dem Schaltventil 23 angeordnet und auf das Schaltventil 23 beispielsweise durch eine Ventil-Düse-Schraubverbindung 41, die von einem Außengewinde an der Außenoberfläche des Schaltventils 23 und einem korrespondierenden Innengewinde des Düsengrundkörpers 33.2 gebildet wird, aufschraubbar. Die Düsenspitze 33.1 ist an dem Düsengrundkörper 33.2 angeordnet. Beispielsweise weist der Düsenkörper 33.2 ein Innengewinde auf, das zu einem Außengewinde der Düsenspitze 33.1 korrespondiert, so dass die Düsenspitze 33.1 lösbar mit dem Düsenkörper 33.2 verbindbar ist. Dadurch kann durch einen Wechsel der Düsenspitze 33.1 vorteilhaft ein Strahlprofil eines von der Auslassdüse 33 ausgegebenen Kühlmittelstrahls verändert werden.The

Das Segmentrohr 35 dient der Führung von Kühlmittel 19 zu dem Kühlmittelauslass 21 und der Führung eines Endabschnitts einer Steuerleitung 25.1 bis 25.4 zu dem Schaltventil 23. Dazu weist das Segmentrohr 35 beispielsweise ein Außenrohr und ein in dem Außenrohr verlaufendes Innenrohr auf, wobei zwischen dem Außenrohr und dem Innenrohr Kühlmittel 19 geführt wird und das Innenrohr den Endabschnitt einer Steuerleitung 25.1 bis 25.4 bildet oder umgibt. Der Verbindungsflansch 37 weist zwei Flanschöffnungen 37.1, 37.2 auf, wobei eine erste Flanschöffnung 37.1 der Zuführung von Kühlmittel 19 in das Segmentrohr 35 dient und die zweite Flanschöffnung 37.2 der Führung der Steuerleitung 25.1 bis 25.4 in das Segmentrohr 35 dient. Der Verbindungsflansch 37 weist ferner einen zwischen den Flanschöffnungen 37.1, 37.2 angeordneten Zentrierungsbolzen 42 auf, um das Leitungsendsegment 17.1 einfacher montieren und ausrichten zu können.The

Abgesehen von diesen Unterschieden ist die Kühlungsvorrichtung 7 des in

Gegenüber dem in den

Die

Der Schwellenstrom QS wird dabei derart vorgegeben, dass der Kühlmitteldruck P unterhalb des korrespondierenden Schwellendrucks PS nicht mehr ausreicht, um ein vorgesehenes Strahlprofil eines von der Auslassdüse 33 ausgegebenen Kühlmittelstrahls, insbesondere einen vorgesehenen Öffnungswinkel des Kühlmittelstrahls, zu realisieren, um einen ausreichend großen Bereich der Strangoberfläche 9.3 mit dem Kühlmittelstrahl abzudecken.The threshold flow Q S is specified in such a way that the coolant pressure P below the corresponding threshold pressure P S is no longer sufficient to achieve an intended jet profile of a coolant jet emitted by the

Oberhalb des Schwellenstroms QS werden die Kühlmitteleinzelströme Q in der üblichen Weise, d. h. ohne Pulsweitenmodulation ausgegeben. Dazu werden die Schaltventile 23 der zu erzeugenden Kühlmitteleinzelströme Q geöffnet und der Kühlmitteldruck P oder ein Kühlmittelstrom in dem Kühlmittelverteilungssystem 15 wird mittels eines Regelkreises 45 auf einen von den zu erzeugenden Kühlmitteleinzelströmen Q abhängigen Sollwert geregelt, siehe dazu

Durch die Pulsweitenmodulation können mit einem Strompulswert QP, der größer als der Schwellenstrom QS ist, Mittelwerte

Die Kühlmittelströme Q1 bis Q4 werden jeweils von allen Kühlmittelauslässen 21 einer Längsreihe zusammen ausgegeben und sind daher jeweils eine Summe der Kühlmitteleinzelströme Q der Kühlmittelauslässe 21 einer Längsreihe, wobei die Kühlmitteleinzelströme Q jeweils analog zu

Die Schaltventile 23 werden von der Steuereinheit 27 pulsweitenmoduliert mit einer Taktperiode der Periodenlänge T bzw. mit einer Taktfrequenz 1/T geschaltet. Dabei werden die Schaltventile 23 für die verschiedenen Längsreihen von Kühlmittelauslässen 21 zeitversetzt zueinander geschaltet, so dass der Kühlmittelgesamtstrom QG zeitlich konstant ist. In dem in

Der Kühlmittelgesamtstrom QG wird dabei bei der Pulsweitenmodulation auf einen vorgegebenen Sollwert geregelt. Dazu wird ein Istwert des Kühlmittelgesamtstroms QG ermittelt und ein Tastgrad D und die Periodenlänge T der Pulsweitenmodulation werden in Abhängigkeit von einer Abweichung des ermittelten Istwertes von dem Sollwert geregelt. Unter dem Tastgrad D der Pulsweitenmodulation wird wie üblich das Verhältnis einer Pulsdauer während einer Taktperiode zu der Periodenlänge T verstanden. In den in den

Bei dem Kühlungsverfahren wird ferner eine Auswahl von Kühlmittelauslässen 21, durch die Kühlmitteleinzelströme Q ausgegeben werden, in Abhängigkeit von einer Breite des Strangs 9 getroffen. Dabei werden durch Kühlmittelauslässe 21, die zur Kühlung des Strangs 9 nicht benötigt werden, da sie sich neben der Strangoberfläche 9.3 befinden, beispielsweise nur jeweils Ausblasluft in einer Pulspause oder ein kurzer Wasserpuls abgegeben, um ein Verstopfen dieser Kühlmittelauslässe 21 zu verhindern.In the cooling method, a selection of

Obwohl die Erfindung im Detail durch ein bevorzugtes Ausführungsbeispiel (vgl.

- 11

- StranggießanlageContinuous caster

- 33

- KokilleMold

- 44th

- OszillationseinrichtungOscillation device

- 55

- StrangführungStrand guide

- 77th

- KühlungsvorrichtungCooling device

- 99

- Strangstrand

- 9.19.1

- StrangrandStrand edge

- 9.29.2

- MittelachseCentral axis

- 9.39.3

- StrangoberflächeStrand surface

- 1111

- TransportrichtungTransport direction

- 1313th

- StrangführungsrolleStrand guide roller

- 1515th

- KühlmittelverteilungssystemCoolant distribution system

- 17.117.1

- LeitungsendsegmentLine end segment

- 17.217.2

- LeitungslängssegmentLine length segment

- 17.317.3

- LeitungszwischensegmentLine intermediate segment

- 17.417.4

- LeitungsquersegmentLine cross segment

- 1919th

- KühlmittelCoolant

- 2121

- KühlmittelauslassCoolant outlet

- 2323

- SchaltventilSwitching valve

- 25.1 bis 25.425.1 to 25.4

- SteuerleitungControl line

- 2727

- SteuereinheitControl unit

- 2929

- DruckerfassungsvorrichtungPressure detection device

- 3131

- DrucksignalleitungPressure signal line

- 3333

- AuslassdüseOutlet nozzle

- 33.133.1

- DüsenspitzeNozzle tip

- 33.233.2

- DüsenkörperNozzle body

- 3535

- SegmentrohrSegment tube

- 3737

- VerbindungsflanschConnecting flange

- 37.1, 37.237.1, 37.2

- FlanschöffnungFlange opening

- 3939

- Rohr-Ventil-SchraubverbindungPipe-valve screw connection

- 4141

- Ventil-Düse-SchraubverbindungValve-nozzle screw connection

- 4242

- ZentrierungsbolzenCentering bolt

- 4343

- Rückschlagventilcheck valve

- 4545

- RegelkreisControl loop

- 4747

- ReglerRegulator

- 4949

- RegelstreckeControlled system

- 5151

- MessgliedMeasuring element

- DD.

- TastgradDuty cycle

- DmDm

- TastgradendwertDuty cycle end value

- EE.

- RegelabweichungControl deviation

- PP

- KühlmitteldruckCoolant pressure

- PSPS

- SchwellendruckThreshold pressure

- PMPM

- MaximaldruckMaximum pressure

- RR.

- RegelgrößeControlled variable

- KühlmitteleinzelstromIndividual coolant flow

- QPQP

- StrompulswertCurrent pulse value

- Q1 bis Q4Q1 to Q4

- KühlmittelstromCoolant flow

- QGQG

- KühlmittelgesamtstromTotal coolant flow

- QSQS

- SchwellenstromThreshold current

- QMQM

- MaximalstromMaximum current

- ΔQΔQ

- StrombereichCurrent range

- MittelwertAverage

- SS.

- FührungsgrößeReference variable

- tt

- Zeittime

- TT

- PeriodenlängePeriod length

- UU

- StellgrößeManipulated variable

Claims (10)

- Line end segment (17.1) of a coupling device (7) for the secondary cooling of a strand (9) in a strand guide (5) of a continuous casting installation (1), the line end segment (17.1) comprising- an outlet nozzle (33) with a coolant outlet (21) for discharging coolant (19),- a switchover valve (23) for switching an individual coolant stream (Q) on and off,- a segmented pipe (35) for guiding the coolant (19) to the coolant outlet (21) of the outlet nozzle (33) and for guiding an end portion of a control line (25.1 to 25.4) for switching the switchover valve (23) to the switchover valve (23),- a connecting flange (37) with a first flange opening (37.1) for feeding the coolant (19) into the segmented pipe (35) and a second flange opening (37.2) for guiding the control line (25.1 to 25.4) into the segmented pipe (35), wherein- the connecting flange (37) is arranged at a first end of the segmented pipe (35) and the switchover valve (23) is arranged at a second end of the segmented pipe (35),the outlet nozzle (33) is arranged at the switchover valve (23) and- the segmented pipe (35) has an outer pipe and an inner pipe running in the outer pipe, wherein the coolant (19) is guided between the outer pipe and the inner pipe and the inner pipe forms or surrounds the end portion of the control line (25.1 to 25.4).

- Line end segment (17.1) according to Claim 1, characterized in that the switchover valve (23) is a pneumatically or electrically or electromagnetically or hydraulically switchable switchover valve (23).

- Line end segment (17.1) according to Claim 2, characterized in that the control line (25.1 to 25.4) in the case of a pneumatically switchable switchover valve (23) is a pneumatic compressed air line, in the case of an electrically or electromagnetically switchable switchover valve (23) is an electrical line and in the case of a hydraulically switchable switchover valve (23) is a hydraulic fluid line.

- Line end segment (17.1) according to one of the preceding claims, characterized in that the outlet nozzle (33) has an exchangeable nozzle tip (33.1).

- Line end segment (17.1) according to one of the preceding claims, characterized in that the switchover valve (23) is screwed onto the segmented pipe (35), in particular by a pipe-valve screw connection (39), which is formed by an external thread on an outer surface of the segmented pipe (35) and a corresponding internal thread of the switchover valve (23).

- Line end segment (17.1) according to one of the preceding claims, characterized in that the outlet nozzle (33) has a nozzle tip (33.1) with the coolant outlet (21) and a nozzle main body (33.2).

- Line end segment (17.1) according to the preceding claims, characterized in that the nozzle main body (33.2) is screwed onto the switchover valve (23), in particular by a valve-nozzle screw connection (41), which is formed by an external thread on an outer surface of the switchover valve (23) and a corresponding internal thread of the nozzle main body (33.2).

- Line end segment (17.1) according to one of the preceding Claims 6 or 7, characterized in that the nozzle tip (33.1) is screwed to the nozzle main body (33.2), in particular by an internal thread of the nozzle body (33.2) and a corresponding external thread of the nozzle tip (33.1).

- Line end segment (17.1) according to one of the preceding claims, characterized in that the connecting flange (37) has a centring bolt (42) arranged between the flange openings (37.1, 37.2) .

- Coiling device (7) for the secondary cooling of a strand (9) in a strand guide (5) of a continuous casting installation (1), the cooling device (7) comprising at least one line end segment (17.1) according to at least one of the preceding claims.

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT507672015 | 2015-09-07 | ||

| ATA50985/2015A AT517772B1 (en) | 2015-09-07 | 2015-11-19 | Secondary cooling of a strand in a continuous casting plant |

| EP16757916.8A EP3347151B1 (en) | 2015-09-07 | 2016-08-31 | Secondary cooling of a strand in a strand casting system |

| PCT/EP2016/070441 WO2017042059A1 (en) | 2015-09-07 | 2016-08-31 | Secondary cooling of a strand in a strand casting system |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16757916.8A Division EP3347151B1 (en) | 2015-09-07 | 2016-08-31 | Secondary cooling of a strand in a strand casting system |

| EP16757916.8A Division-Into EP3347151B1 (en) | 2015-09-07 | 2016-08-31 | Secondary cooling of a strand in a strand casting system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3417959A1 EP3417959A1 (en) | 2018-12-26 |

| EP3417959B1 true EP3417959B1 (en) | 2021-05-26 |

Family

ID=58504997

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP18179585.7A Active EP3417959B1 (en) | 2015-09-07 | 2016-08-31 | Secondary cooling of a strand in a strand casting assembly |

| EP16757916.8A Active EP3347151B1 (en) | 2015-09-07 | 2016-08-31 | Secondary cooling of a strand in a strand casting system |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16757916.8A Active EP3347151B1 (en) | 2015-09-07 | 2016-08-31 | Secondary cooling of a strand in a strand casting system |

Country Status (3)

| Country | Link |

|---|---|

| EP (2) | EP3417959B1 (en) |

| AT (1) | AT517772B1 (en) |

| BR (1) | BR112018004427B1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT520006B1 (en) | 2017-06-07 | 2021-08-15 | Primetals Technologies Austria GmbH | COOLANT NOZZLE FOR COOLING A METALLIC STRAND IN A CONTINUOUS CASTING PLANT |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT409940B (en) * | 2001-02-20 | 2002-12-27 | Voest Alpine Ind Anlagen | TWO-MATERIAL SHAFT NOZZLE AND CONTINUOUS CASTING SYSTEM WITH AN ARRANGEMENT OF TWO-FABRIC SHAFT NOZZLES |

| AT503526B1 (en) * | 2006-04-25 | 2008-07-15 | Voest Alpine Ind Anlagen | SPRAY NOZZLE ADJUSTMENT |

| EP2583772B1 (en) * | 2010-05-19 | 2015-10-21 | SMS group GmbH | Strand guiding device |

| EP2527061A1 (en) * | 2011-05-27 | 2012-11-28 | Siemens VAI Metals Technologies GmbH | Method for cooling a metallic strand and switching valve for intermittent opening and closing of a volume flow of a coolant medium |

| DE202011110064U1 (en) * | 2011-06-07 | 2012-11-16 | Sms Siemag Ag | Nozzle device and strand guiding device with the nozzle device |

-

2015

- 2015-11-19 AT ATA50985/2015A patent/AT517772B1/en active

-

2016

- 2016-08-31 BR BR112018004427-0A patent/BR112018004427B1/en active IP Right Grant

- 2016-08-31 EP EP18179585.7A patent/EP3417959B1/en active Active

- 2016-08-31 EP EP16757916.8A patent/EP3347151B1/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| AT517772A1 (en) | 2017-04-15 |

| BR112018004427A2 (en) | 2018-10-02 |

| EP3347151A1 (en) | 2018-07-18 |

| EP3347151B1 (en) | 2021-05-19 |

| EP3417959A1 (en) | 2018-12-26 |

| AT517772B1 (en) | 2018-12-15 |

| BR112018004427B1 (en) | 2022-08-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2017042059A1 (en) | Secondary cooling of a strand in a strand casting system | |

| DE4211291C3 (en) | Mixing device and method for mixing two liquids at a constant mixture volume flow to supply the headbox of a paper machine | |

| EP2714304B1 (en) | Method for cooling a metallic strand, and switching valve for intermittently permitting and shutting off a volume flow of a cooling medium | |

| AT516075B1 (en) | Cooling of a metallic strand section | |

| DE102017214450B3 (en) | Spray gun and method for cooling a metallic strand in a continuous casting machine | |

| WO1997011833A1 (en) | Process for the variable limitation of a flat flow channel and process for extracting a mass channel of variable geometry | |

| EP1900449B1 (en) | Spray header of a hydraulic descaling facility and method for operating such a spray header | |

| EP3417959B1 (en) | Secondary cooling of a strand in a strand casting assembly | |

| AT506673B1 (en) | METHOD FOR LIQUID HOLDING ON A CAST METAL STRUCTURE IN A CONTINUOUS CASTING SYSTEM AND CONTINUOUS CASTING SYSTEM THEREFOR | |

| DE60312107T2 (en) | Air supply device for jet loom | |

| EP1393817A2 (en) | Device for applying coating material | |

| EP2712691B1 (en) | Device and method for secondary cooling in a casting machine | |

| EP3774099B1 (en) | Cooling device and method for operating the same | |

| EP3056957B1 (en) | Diagnostic device and method for monitoring the operation of a closed loop | |

| DE102013214809A1 (en) | Apparatus and method for controlled multi-material secondary cooling of a cast metal strand | |

| DE102017105614A1 (en) | Method and cooling device for cooling a metallic strand | |

| DE102012014665A1 (en) | Electric arc spraying burner for coating surfaces of cylinder of engine, has deflecting element to deflect process gas from gas supply direction into main gas direction for atomization and transport of molten material | |

| DE69028850T2 (en) | DRIP IRRIGATION PIPE AND METHOD FOR THE PRODUCTION THEREOF | |

| DE2657986A1 (en) | LEVELING MACHINE FOR LEVELING PLATES AND FLAT MATERIALS | |

| EP0403035B1 (en) | Method for attaining a temperature in a metal bath | |

| EP3877142A1 (en) | Switching device and method for switching a flat film machine from an input product to a subsequent product | |

| EP3934823B1 (en) | Apparatus for cooling a strip-shaped product, and method for operating such an apparatus | |

| DE4133501C2 (en) | Device for applying coating color on a fibrous web | |

| DE102023005409A1 (en) | Control device for controlling a pressure of a fluid | |

| WO2011082893A1 (en) | Nozzle device and strand guiding device having said nozzle device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 3347151 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17P | Request for examination filed |

Effective date: 20190626 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| 17Q | First examination report despatched |

Effective date: 20190725 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20210205 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 3347151 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1395707 Country of ref document: AT Kind code of ref document: T Effective date: 20210615 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502016013120 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210826 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20210526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210927 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210826 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210827 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210926 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502016013120 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20210831 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210831 |

|

| 26N | No opposition filed |

Effective date: 20220301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |