EP3274271B1 - Paquet d'articles à fumer - Google Patents

Paquet d'articles à fumer Download PDFInfo

- Publication number

- EP3274271B1 EP3274271B1 EP16722369.2A EP16722369A EP3274271B1 EP 3274271 B1 EP3274271 B1 EP 3274271B1 EP 16722369 A EP16722369 A EP 16722369A EP 3274271 B1 EP3274271 B1 EP 3274271B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- panel

- wall

- stiffener

- separating

- package

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000779 smoke Substances 0.000 title claims description 37

- 239000003351 stiffener Substances 0.000 claims description 235

- 230000000284 resting effect Effects 0.000 claims description 116

- 239000000853 adhesive Substances 0.000 claims description 35

- 230000001070 adhesive effect Effects 0.000 claims description 35

- 238000000605 extraction Methods 0.000 claims description 16

- 239000000463 material Substances 0.000 claims description 16

- 238000005192 partition Methods 0.000 claims description 9

- 238000007789 sealing Methods 0.000 claims description 3

- 235000019504 cigarettes Nutrition 0.000 description 145

- 241000208125 Nicotiana Species 0.000 description 9

- 235000002637 Nicotiana tabacum Nutrition 0.000 description 9

- 238000004806 packaging method and process Methods 0.000 description 7

- 238000003466 welding Methods 0.000 description 7

- 238000004026 adhesive bonding Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- NOOLISFMXDJSKH-UTLUCORTSA-N (+)-Neomenthol Chemical compound CC(C)[C@@H]1CC[C@@H](C)C[C@@H]1O NOOLISFMXDJSKH-UTLUCORTSA-N 0.000 description 1

- NOOLISFMXDJSKH-UHFFFAOYSA-N DL-menthol Natural products CC(C)C1CCC(C)CC1O NOOLISFMXDJSKH-UHFFFAOYSA-N 0.000 description 1

- 235000019568 aromas Nutrition 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 229940041616 menthol Drugs 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/07—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles

- B65D85/08—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular

- B65D85/10—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular for cigarettes

- B65D85/1018—Container formed by a flexible material, i.e. soft-packages

- B65D85/1027—Opening devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/07—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles

- B65D85/08—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular

- B65D85/10—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular for cigarettes

- B65D85/1081—Inserts or accessories added or joined to the container, e.g. coins, pens, cards, spacers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/44—Integral, inserted or attached portions forming internal or external fittings

- B65D5/48—Partitions

- B65D5/48024—Partitions inserted

- B65D5/48048—Single partition formed by folding one or more blanks and provided with flaps fixed to or maintained by parts of the container body

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/44—Integral, inserted or attached portions forming internal or external fittings

- B65D5/50—Internal supporting or protecting elements for contents

- B65D5/5028—Elements formed separately from the container body

- B65D5/5035—Paper elements

Definitions

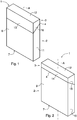

- the lid 3 is cup-shaped, has a parallelpiped shape, and has a top wall 12, parallel to and opposite the bottom wall 7 of the container 2 when the lid 3 is arranged in the closed position, a front wall 13, which is coplanar with the front wall 8 of the container 2 when the lid 3 is arranged in the closed position, a rear wall 14, hinged by the hinge 4 to the rear wall 9 of the container 2 and which is coplanar with the rear wall 9 of the container 2 when the lid 3 is arranged in the closed position, a first lateral wall 15, which is coplanar with the first lateral wall 10 of the container 2 when the lid 3 is arranged in the closed position, and a second lateral wall 16, which is coplanar with the second lateral wall 11 of the container 2 when the lid 3 is arranged in the closed position.

- the separating wall 42 of the separating element 41 finishes higher than the rear walls 38A, 38B of the supporting element 37, "higher” meaning the fact of being further from the bottom wall 18 of the inner package 5.

- the distance between a bottom edge of the separating wall 42 of the separating element 41 and the bottom wall 18 of the inner package 5 is greater than the distance between the bottom edges of the rear walls 38A, 38B of the supporting element 37 and the bottom wall 18 of the inner package 5.

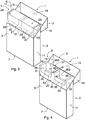

- the supporting element 37 comprises a first supporting appendage 48 which extends from a bottom end of the first separating panel 44 and rests on the bottom wall 33, if present, of the stiffener 29, or on the bottom wall 18 of the inner package 5, and a second supporting appendage 49, connected to the first supporting appendage 48 by the same folding line that connects the first separating panel 44 to the second separating panel 45, which second supporting appendage 49 extends from a bottom end of the second separating panel 45 and rests on the bottom wall 33, if present, of the stiffener 29, or on the bottom wall 18 of the inner package 5.

- the packet 1 of cigarettes further comprises a filling element 50, forming a single body with the supporting element 37 and thus with the separating element 41, which is housed within the cavity 26 inside the inner package 5 so as to retain securely the group of cigarettes in the inner package 5.

- the filling element 50 comprises a resting wall 51 for supporting the group of cigarettes, which extends substantially parallel to the front wall 19 and to the rear wall 20 of the inner package 5 on a "more inner” plane than a plane defined by the rear wall 20 of the inner package 5.

- “more inner” means closer the front wall 19 of the inner package 5.

- a distance between the front wall 19 of the inner package 5 and the resting wall 51 of the filling element 50 is less than a distance between the front wall 19 and the rear wall 20 of the package 5 so as to compensate for the lesser "thickness" of the group of cigarettes with respect to the "thickness" of the inner package 5.

- the blank 56 further comprises a pair of flaps 10', 11' which are arranged on opposite sides of the panel 8', are connected to the panel 8' along the two longitudinal folding lines 57, and constitute part of the lateral walls 10, 11 of the container 2.

- the blank 56 comprises a pair of flaps 10", 11" which are arranged on opposite sides of the panel 9', are connected to the panel 9' along the two longitudinal folding lines 57, constitute part of the lateral walls 10, 11 of the container 2, and are glued to and superimposed on the corresponding flaps 10', 11'.

- Each flap 10", 11” comprises a tab 60 that is folded 90° with respect to the respective flap 10", 11" and is superimposed on and glued to the panel 7'.

- the blank 62 comprises a panel 30' which constitutes the front wall 30 of the stiffener 29 and a panel 33' which constitutes the bottom wall 33 of the stiffener 29 and is directly connected to the panel 30' along a transverse folding line.

- the blank 63 comprises a pair of panels 38A', 38B' which constitute the rear walls 38A, 38B of the supporting element 37, and two panels 44', 45', which are connected together by a longitudinal folding line (which extends substantially at the central portion of the blank 63) which constitute the first 44 and the second 45 separating panel of the separating element 41, which are interposed between the panels 38A', 38B' and are directly connected to the panels 38A', 38B' along respective longitudinal folding lines.

- the blank 63 further comprises a pair of panels 52', 53' which constitute the first 52 and the second resting panel 53 of the filling element 50, each delimited transversely by a pair of transverse incision lines made on either side respectively of the panels 38A'- 44' and 38B'- 45', and longitudinally by a pair of longitudinal folding lines.

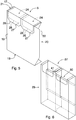

- the blank 63 illustrated in Figure 13 , has a substantially rectangular shape.

- the tabs 46', 47' are obtained in a cantilevered manner from a top edge of the blank 63.

- a bottom edge of the blank 63 has at two supporting appendages 48', 49', respective recesses of a shape which is complementary to the tabs 46', 47'.

- This configuration of the blank 63 is particularly advantageous when the blank 63 is obtained by cutting a continuous web of rigid package material, because it avoids waste being produced.

- first resting panel 52 is staggered, along the longitudinal axis A, with respect to the second resting panel 53, i.e. is further from a bottom edge of the front wall 30 of the stiffener 29, just as the first separating panel 44, is staggered, along the longitudinal axis A, with respect to the second separating panel 45, i.e. is further from a bottom edge of the front wall 30 of the stiffener 29.

- This configuration confers good rigidity to the stiffener 29.

- the chambers 43A, 43B have, in cross section, a rectangular shape, in which the chamber 43A is delimited at the front by an inner surface of the front wall 30 of the stiffener 29, behind by an inner surface of the first resting panel 52, and laterally by an inner surface of the first lateral wall 31 of the stiffener 29 and by an inner surface of the first separating panel 44 of the separating element 41, whereas the chamber 43B is delimited at the front by the inner surface of the front wall 30 of the stiffener 29, behind by an inner surface of the second resting panel 53, and laterally by an inner surface of the second lateral wall 32 of the stiffener 29 and by an inner surface of the second separating panel 45 of the separating element 41.

- the first separating panel 44 has a first abutting appendage 66A for abutting on the rear wall 20 of the inner package 5, which first abutting appendage 66A protrudes from the first separating panel 44 coming out the plane defined by the corresponding first resting panel 52

- the second separating panel 45 has a second abutting appendage 66B for abutting on the rear wall 20 of the inner package 5, which second abutting appendage 66B is staggered, along the longitudinal axis A, with respect to the first abutting appendage 66A, i.e.

- first abutting appendage 66A and the second abutting appendage 66B are coplanar and not superimposed.

- the rear wall 20 of the inner package 5 rests on the longitudinal edges of the first 66A and of the second abutting appendage 66B and on the free longitudinal edges of the first 31 and of the second 32 lateral wall 40 of the stiffener 29.

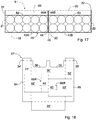

- the packet 1 of cigarettes comprising the stiffener 29 according to the version illustrated in Figures 15 to 17 , comprises a container 2 and a lid 3 obtained by folding around the inner package 5 (inside which the stiffener 29 was previously folded around the group of cigarettes) the blank 56 disclosed above.

- the stiffener 29 according to the version illustrated in Figures 15 to 17 is obtained by folding around the group of cigarettes a blank 67, illustrated in Figure 18 , comprising a plurality of panels that will be marked with accented reference numbers which are the same as the reference numbers which distinguish the corresponding walls of the stiffener 29 according to this version.

- the blank 67 comprises a panel 30' which constitutes the front wall 30 of the stiffener 29 and a panel 33' which constitutes the bottom wall 33 of the stiffener 29 and is directly connected to the panel 30' along a transverse folding line.

- stiffener 29 further comprises a first rear wall 68 connected to the first lateral wall 31 and opposite the front wall 30 of the stiffener 29, and a second rear wall 69 connected to the second lateral wall 32, opposite the front wall 30 of the stiffener 29, and partially superimposed on the first rear wall 68.

- the stiffener 29 according to the version illustrated in Figures 19 to 21 is obtained by folding around the group of cigarettes a blank 70, illustrated in Figure 22 , comprising a plurality of panels that will be marked with accented reference numbers which are the same as the reference numbers which distinguish the corresponding walls of the stiffener 29 according to this version.

- the stiffener 29 according to the version illustrated in Figure 23 , has:

- the filling element 50 comprises a resting wall 51 for supporting the group of smoke articles, which is parallel to and opposite the rear wall 71 of the stiffener 29 and is interposed between the latter and the front wall 30 of the stiffener 29.

- the resting wall 51 is formed by a single resting panel 73, strengthened by longitudinal creases.

- the filling element 50 comprises a first supporting element 76 and a second supporting element 77 for supporting the resting panel 73, obtained by respective "U"-shaped through incisions, made in the resting panel 73.

- the first supporting element 76 comprises a first panel 78, connected to the resting panel 73 and arranged parallel to and opposite the bottom wall 33 of the stiffener 29, and a second panel 79, connected to the first panel 78, arranged perpendicular to the first panel 78 and glued to an inner surface of the rear wall 71 of the stiffener 29.

- the second supporting element 77 comprises a first panel 80, connected to the resting panel 73 and arranged parallel to and opposite the bottom wall 33 of the stiffener 29, and a second panel 81, connected to the first panel 80, arranged perpendicular to the first panel 80 and glued to the inner surface of the rear wall 71 of the stiffener 29.

- the first panel 78 of the first supporting element 76 and the first panel 80 of the second supporting element 77 have the same transverse dimension as the top wall 74 of the filling element 50.

- the separating element 41 comprises a separating wall 42 formed by a single separating panel 82 obtained by a "U"-shaped through incision and is made through the front wall 30 of the stiffener 29.

- the separating panel 82 is arranged perpendicular to the front wall 30 of the stiffener 29.

- the packet 1 of cigarettes comprising the stiffener 29 according to the version illustrated in Figure 23 , comprises a container 2 and a lid 3 obtained by folding around the inner package 5 the blank 56 disclosed above.

- the blank 84 further comprises a panel 82' which constitutes the separating panel 82, is connected to the panel 30' by a longitudinal folding line, and is obtained by a "U"-shaped through incision made in the panel 30', a panel 74' which constitutes the top wall 74 of the filling element 50 and is directly connected to the panel 71' along a transverse folding line on an opposite side of the panel 33', a panel 73' which constitutes the resting panel 73 and is directly connected to the panel 74' along a transverse folding line, and a flap 75' which constitutes the bottom wall 75 of the filling element 50 and is directly connected to the panel 73' along a transverse folding line.

- the blank 84 comprises a panel 78' which constitutes the first panel 78 of the first supporting element 76 and is connected, by a transverse folding line, to the panel 73', a panel 79' which constitutes the second panel 79 of the first supporting element 76, is connected to the panel 78' by a transverse folding line and is obtained by a "U"-shaped through incision made in the panel 73', a panel 80' which constitutes the second panel 80 of the second supporting element 77 and is connected, by a transverse folding line to the panel 73', and a panel 81' which constitutes the second panel 81 of the second supporting element 77 , is connected to the panel 80' by a transverse folding line and is obtained by a "U"-shaped through incision made in the panel 73'.

- the supporting element 37 is of rigid type, embraces at the rear the inner package 5, consists of rigid cardboard or card, and is arranged inside the inner package 5 in direct contact with the group of cigarettes.

- the function of the supporting element 37 is to protect the cigarettes during folding and welding of the package sheet 23 of heat-sealable material.

- the separating wall 42 extends parallel to the longitudinal axis A and is arranged transversely, in particular perpendicularly, to the front wall 19 and to the rear wall 20 of the inner package 5, i.e. to the front wall 30 of the stiffener 29 and to the rear walls 38A, 38B of the supporting element 37.

- the separating wall 42 is formed by a first separating panel 44 and by a second separating panel 45 facing one another and connected by a folding line which, in use, faces and contacts a central portion of an inner surface of the front wall 30 of the stiffener 29.

- the first separating panel 44 and the second separating panel 45 originate by folding to the inside of the packet 1 of cigarettes respective adjacent portions of the rear walls 38A, 38B of the supporting element 37 and are each connected and arranged perpendicular to the corresponding rear wall 38A, 38B.

- the supporting element 37 according to the version of Figure 25 comprises two bottom walls 85A, 85B, which are not illustrated in Figure 25 , each connected to a respective bottom edge of a corresponding rear wall 38A, 38B of the supporting element 37 and facing the bottom wall 18 of the inner package 5.

- the filling element 50 further comprises two bottom walls 87A, 87B, which are not illustrated in Figure 25 , each connected to a bottom edge of the respective resting panel 52, 53, and glued to an inner surface of the respective bottom wall 85A, 85B of the supporting element 37 such that respective free edges of the bottom walls 87A, 87B of the filling element 50 and of the bottom walls 85A, 85B of the supporting element 37 are substantially superimposed.

- the filling element 50 comprises two first supporting elements 88 and two second supporting elements 89 for supporting respectively the supporting panels 52, 53, obtained by respective through incisions made on either side of the panels 39-38A, 44-38A, 40-38B and 45-38B.

- the two second supporting elements 89 are positioned symmetrically with respect to a central portion of the second rear wall 38B of the supporting element 37, originate from the second rear wall 38B , have, in cross section, an "L" shape, and are each formed by a first panel 92, connected to the rear wall 38B of the supporting element 37 and arranged perpendicular to the rear wall 38B and by a second panel 93, connected to the respective first panel 92 and to the second lateral wall 40 of the supporting element 37, arranged perpendicular to the first panel 92 and parallel to the second resting panel 53 of the filling element 50.

- the second resting panel 53 of the filling element 50 rests against the second panels 93 of the second supporting elements 89.

- the chambers 43A, 43B have, in cross section, a rectangular shape, in which the chamber 43A is delimited at the front by an inner surface of the front wall 30 of the stiffener 29, behind by an inner surface of the first resting panel 52, and laterally by an inner surface of the first lateral wall 39 of the supporting element 37 and by an inner surface of the first separating panel 44 of the separating element 41, whereas the chamber 43B is delimited at the front by the inner surface of the front wall 30 of the stiffener 29, behind by an inner surface of the second resting panel 53, and laterally by an inner surface of the second lateral wall 40 of the supporting element 37 and by an inner surface of the second separating panel 45 of the separating element 41.

- the supporting element 37 according to the version of Figure 25 is obtained by folding and pre-gluing a blank 96, illustrated in Figure 27 , which has a prevalently longitudinal extent, and comprises a plurality of panels which will be marked with accented reference numbers which are the same as the reference numbers which distinguish the corresponding walls of the supporting element 37 according to this version.

- the blank 96 comprises a pair of panels 38A', 38B' which constitute the rear walls 38A, 38B of the supporting element 37, and two panels 44', 45', which are connected together by a longitudinal folding line (which extends substantially at the central portion of the blank 96) which constitute the first 44 and the second 45 separating panel of the separating element 41, which are interposed between the panels 38A', 38B' and are directly connected to the panels 38A', 38B' along respective longitudinal folding lines.

- the panel 44' is connected to the panel 38A' along a longitudinal folding line and is folded 90° with respect to the panel 38A'

- the panel 45' is connected to the panel 38B' along a longitudinal folding line and is folded 90° with respect to the panel 38B'.

- the panels 44', 45' each comprise a respective tab 46', 47', which constitute respectively the first supporting flap 46 and the second supporting flap 47 of the supporting element 37.

- the tabs 46', 47' are each folded 90° with respect to the corresponding panel 44', 45'.

- the blank 96 further comprises two panels 85A', 85B' which constitute the bottom walls 85A, 85B of the supporting element 37 and are directly connected to the respective panels 38A', 38B' along respective transverse folding lines, two panels 86A', 86B' which constitute the top walls 86A, 86B of the filling element 50 and are directly connected to the panels 38A', 38B' along respective transverse folding lines on the opposite side of the panels 85A', 85B', two panels 52', 53' which constitute the supporting panels 52, 53 of the filling element 50 and are directly connected to the panels 86A', 86B' along respective transverse folding lines, and two panels 87A', 87B' which constitute the bottom walls 87A, 87B of the filling element 50 and are directly connected to the panels 52', 53' along respective transverse folding lines.

- the blank 96 further comprises flaps 39', 40' which extend to the outside of the panels 38A', 38B', are connected to the panels 38A', 38B' along respective longitudinal folding lines, and constitute the first 39 and the second lateral wall 40 of the supporting element 37.

- the blank 96 comprises pairs of panels 90', 91' arranged between the panels 38A'-39' and 38A'- 44', each pair of panels 90', 91' is bounded transversely by a pair of transverse incision lines made on either side of the panels 38A'- 39' and 38A'- 44' and longitudinally by a pair of longitudinal folding lines, which panels 90', 91' constitute the first panels 90 and the second panels 91 of the first supporting elements 88.

- the panels 90' are each folded 90° with respect to the panel 38A'.

- the blank 96 comprises pairs of panels 92', 93' arranged between the panels 38B'-40' and 38B'- 45', each pair of panels 92', 93' is bounded transversely by a pair of transverse incision lines made on either side of the panels 38B'- 40' and 38B'- 45' and longitudinally by a pair of longitudinal folding lines, which panels 92', 93' constitute the first panels 92 and the second panels 93 of the second supporting elements 89.

- the panels 92' are each folded 90° with respect to the panel 38B'.

- the stiffener 29 is made, in particular pre-glued, before being inserted into the packaging machine.

- the stiffener 29 has:

- the filling element 50 comprises a resting wall 71 for supporting the group of smoke articles, which consists of the rear wall of the stiffener 29; the resting wall 71 is interposed between the rear wall 20 of the inner package 5 and the front wall 30 of the stiffener 29. More precisely, in this version, the distance between the front walls 30A, 30B of the stiffener 29 and the rear wall 71 thereof (which, as said, constitutes the resting wall of the filling element 50) is equal to the transverse dimension of the group of cigarettes. Also in this version, the resting wall 71 is formed by a single resting panel 73.

- the separating wall 42 is formed by a first separating panel 44 and by a second separating panel 45 facing one another and glued (as disclosed better below).

- the first separating panel 44 and the second separating panel 45 originate by folding to the inside of the packet 1 of cigarettes respective outer portions respectively of the front walls 30A, 30B of the stiffener 29 and are each connected and arranged perpendicular to the corresponding front wall 30A, 30B.

- the stiffener 29 further comprises a first supporting flap 46, which is not illustrated in Figure 28 , connected to a top end of the first separating panel 44, arranged perpendicular to the first separating panel 44 and facing the top wall 17 of the inner package 5; and a second supporting flap 47, which is not illustrated in Figure 28 , connected to a top end of the second separating panel 45, arranged perpendicular to the second separating panel 45, facing the top wall 17 of the inner package 5, and which is coplanar with the first supporting flap 46.

- the function of the first supporting flap 46 and of the second supporting flap 47 is to protect the cigarettes during folding and welding of the package sheet 23 of heat-sealable material.

- the first separating panel 44 has a first abutting appendage 66A for abutting on the rear wall 20 of the inner package 5, which first abutting appendage 66A protrudes from the first separating panel 44 exiting from the plane defined by the resting panel 73, and a second abutting appendage 66B for abutting on the rear wall 20 of the inner package 5, which second abutting appendage 66B is positioned lower, along the longitudinal axis A, with respect to the first abutting appendage 66A, i.e. is less far away from a bottom edge of the first front wall 30A of the stiffener 29, and protrudes from the first separating panel 44 exiting from the plane defined by the resting panel 73.

- the stiffener 29 comprises a first slot 83A and a second slot 83B, which are not illustrated in Figure 28 , which are obtained in a central portion of the resting panel 73.

- the first slot 83A and the second slot 83B extend parallel to the longitudinal axis A, the second slot 83B being positioned lower, along the longitudinal axis A, with respect to the first slot 83A.

- first abutting appendage 66A and the second abutting appendage 66B engage respectively with the first slot 83A and with the second slot 83B (which thus have the function of maintaining the first separating panel 44, and the second separating panel 45 glued thereto, substantially perpendicular to the front walls 30A, 30B of the stiffener 29) and rest, with respective free edges, on an inner surface of the rear wall 20 of the inner package 5.

- the first lateral wall 31 of the stiffener 29 has two third abutting appendages 97A, 97B for abutting on the rear wall 20 of the inner package 5, which are obtained by respective "U"-shaped through incisions made in the resting panel 73, protrude from the first lateral wall 31 exiting from the plane defined by the resting panel 73, and are positioned in succession parallel to the longitudinal axis A.

- the second lateral wall 32 of the stiffener 29 has two fourth abutting appendages 98A, 98B for abutting on the rear wall 20 of the inner package 5, which are obtained by respective "U"-shaped through incisions made in the resting panel 73, protrude from the second lateral wall 32 exiting from the plane defined by the resting panel 73, and are positioned in succession parallel to the longitudinal axis A.

- the rear wall 20 of the inner package 5 rests on the longitudinal edges of the first abutting appendage 66A, of the second abutting appendage 66B, of the third abutting appendages 97A, 97B and of the fourth abutting appendages 98A, 98B.

- the appendages 66A, 97A and 98A are aligned on one another along a transverse direction, thus like the appendages 66B, 97B and 98B.

- the second separating panel 45 has a connecting appendage 99, which protrudes from a central portion of the second separating panel 45, is folded 180° onto an outer surface of the second separating panel 45 and is glued to an outer surface of the first separating panel 44 so as to fix the latter to the second separating panel 45.

- the chambers 43A, 43B have, in cross section, a rectangular shape, in which the chamber 43A is delimited at the front by an inner surface of the first front wall 30A of the stiffener 29, behind by an inner surface of the resting panel 73, and laterally by an inner surface of the first lateral wall 31 of the stiffener 29 and by an inner surface of the first separating panel 44 of the separating element 41, whereas the chamber 43B is delimited at the front by the inner surface of the second front wall 30B of the stiffener 29, behind by an inner surface of the resting panel 73, and laterally by an inner surface of the second lateral wall 32 of the stiffener 29 and by an inner surface of the second separating panel 45 of the separating element 41.

- the packet 1 of cigarettes comprising the stiffener 29 according to the version illustrated in Figure 28 , comprises a container 2 and a lid 3 obtained by folding around the inner package 5 the blank 56 disclosed above.

- the stiffener 29 according to the version illustrated in Figure 28 is obtained by folding around the group of cigarettes a blank 100, illustrated in Figure 29 , which has a prevalently transverse extent, and comprises a plurality of panels which will be marked with accented reference numbers which are the same as the reference numbers which distinguish the corresponding walls of the stiffener 29 according to this version.

- the blank 100 comprises a panel 73' which constitutes the resting panel 73 of the filling element 50, a panel 33' which constitutes the bottom wall 33 of the stiffener 29 and is directly connected to the panel 73' along a transverse folding line, a pair of panels 31', 32' which are arranged on opposite sides of the panel 73', are connected to the panel 73' along two longitudinal folding lines, and constitute the lateral walls 31, 32 of the stiffener 29; a panel 30A' which is arranged outside the panel 31', is connected to the panel 31' along a longitudinal folding line, and constitutes the first front wall 30A of the stiffener 29; a panel 30B' which is arranged outside the panel 32', is connected to the panel 32' along a longitudinal folding line, and constitutes the second front wall 30B of the stiffener 29; a flap 44' which is arranged outside the panel 30A', is connected to the panel 30A' along a longitudinal folding line, and constitutes the first separating

- the panels 31', 32' (i.e. the lateral walls 31, 32 of the stiffener 29) each comprise a respective tab 34', 35' which constitute respectively the first stiffener flap 34 and the second stiffener flap 35 of the stiffener 29.

- the tabs 34', 35' are each folded 90° with respect to the corresponding panel 31', 32' (i.e. to the corresponding lateral wall 31, 32 of the stiffener 29).

- the flaps 44', 45' (i.e. the separating walls 44, 45 of the separating element 41) each comprise a respective tab 46', 47' which constitute respectively the first supporting flap 46 and the second supporting flap 47.

- the tabs 46', 47' are each folded 90° with respect to the corresponding flap 44', 45'.

- the flap 44' comprises two tabs 66A', 66B' which constitute respectively the first abutting appendage 66A and the second abutting appendage 66B, whereas the flap 45' comprises a tab 99' which constitutes the connecting appendage 99.

- the filling element 50 and the separating element 41 are formed as a single body with the stiffener 29, which is shaped in such a manner as to incorporate also the functions of the supporting element 37.

- the packet of cigarettes containing this version thus differs from the packet 1 of cigarettes disclosed with reference to Figures 4 to 10 by the fact of being devoid of a separate supporting element 37.

- the stiffener 29 is made, in particular pre-glued, before being inserted into the packaging machine.

- the stiffener 29 has a front wall 30 facing the front wall 19 of the inner package 5, a first lateral wall 31 facing the first lateral wall 21 of the inner package 5, and a second lateral wall 32 facing the second lateral wall 22 of the inner package 5. Further, the stiffener 29 comprises a bottom wall 33 which faces the bottom wall 18 of the inner package 5, and a pair of "U"-shaped recesses 36, obtained in the front wall 30 to facilitate extracting of the cigarettes.

- the first resting panel 52 of the resting wall 51 of the filling element 50 is connected to the first lateral wall 101 of the filling element 50 and is arranged perpendicular to the first lateral wall 101

- the second resting panel 53 of the resting wall 51 of the filling element 50 is connected to the second lateral wall 102 of the filling element 50 and is arranged perpendicular to the second lateral wall 102.

- the first separating panel 44 of the separating element 41 has two first abutting appendages 103A, 103B for abutting on the rear wall 20 of the inner package 5, which are obtained by respective "U"-shaped through incisions made in the first resting panel 52, protrude from the first separating panel 44 exiting from the plane defined by the first resting panel 52, and are positioned in succession parallel to the longitudinal axis A.

- the second separating panel 45 of the separating element 41 has two second abutting appendages 104A, 104B for abutting on the rear wall 20 of the inner package 5, which are obtained by respective "U"-shaped through incisions made in the second resting panel 53, protrude from the second separating panel 45 exiting from the plane defined by the second resting panel 53, are positioned in succession parallel to the longitudinal axis A and each face a respective first abutting appendage 103A, 103B.

- the separating element 41 comprises a first connecting wall 105, connected to the first separating panel 44, arranged perpendicular to the first separating panel 44 and glued to an inner surface of the front wall 30 of the stiffener 29, and a second connecting wall 106, connected to the second separating panel 45, arranged perpendicular to the second separating panel 45 and glued to an inner surface of the front wall 30 of the stiffener 29.

- the chambers 43A, 43B have, in cross section, a rectangular shape, in which the chamber 43A is delimited at the front by an inner surface of the first connecting wall 105 of the separating element 41, behind by an inner surface of the first resting panel 52 of the filling element 50, and laterally by an inner surface of the first lateral wall 31 of the stiffener 29 and by an inner surface of the first separating panel 44 of the separating element 41, whereas the chamber 43B is delimited at the front by an inner surface of the second connecting wall 106 of the separating element 41, behind by an inner surface of the second resting panel 53 of the filling element 50, and laterally by an inner surface of the second lateral wall 32 of the stiffener 29 and by an inner surface of the second separating panel 45 of the separating element 41.

- the packet 1 of cigarettes comprising the stiffener 29 according to the version illustrated in Figure 30 , comprises a container 2 and a lid 3 obtained by folding around the inner package 5 the blank 56 disclosed above.

- the stiffener 29 according to the version illustrated in Figure 30 is obtained by folding a blank 107 around the group of cigarettes, illustrated in Figure 31 , which has a prevalently transverse extent, and comprises a plurality of panels which will be marked with accented reference numbers which are the same as the reference numbers which distinguish the corresponding walls of the stiffener 29 according to this version.

- the panels 44', 45' each comprise a pair of tabs 103A', 103B' and 104A', 104B', which constitute respectively the first abutting appendages 103A, 103B and the second abutting appendages 104A, 104B.

- the packet 1 of cigarettes disclosed above uses, with particular reference to the version of Figures 15 to 17 , a relatively small amount of package material, i.e. only slightly more than the amount of package material used in a rigid hinged-lid packet of standard type, with a consequent low impact on the economical and environmental costs of production and disposal, after use, of the packet 1 of cigarettes.

- the packet 1 of cigarettes disclosed above is, in particular with reference to versions of Figures 10 , 17 , 21 , easy to produce also in a packaging machine of standard type, which has to be subjected to few modifications, which are not invasive.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packaging Of Annular Or Rod-Shaped Articles, Wearing Apparel, Cassettes, Or The Like (AREA)

- Cartons (AREA)

Claims (17)

- Paquet (1) d'articles à fumer, comprenant :un conditionnement souple (5), qui enferme un groupe d'articles à fumer, a une forme de parallélépipède et a une paroi avant (19), une paroi arrière (20), une paroi supérieure (17), une paroi inférieure (18), une première paroi latérale (21), une seconde paroi latérale (22) et au moins une ouverture d'extraction (24) des articles à fumer ;au moins un panneau adhésif refermable (27), qui recouvre la au moins une ouverture d'extraction (24) ;un raidisseur (29), qui est logé à l'intérieur du conditionnement (5) en contact avec le groupe d'articles à fumer et a une paroi avant (30) faisant face à la paroi avant (19) du conditionnement (5), une première paroi latérale (31) faisant face à la première paroi latérale (21) du conditionnement (5) et une seconde paroi latérale (32) faisant face à la seconde paroi latérale (22) du conditionnement (5) ; etun élément de séparation (41), qui est logé à l'intérieur du conditionnement (5) et divise le volume intérieur du conditionnement (5) de manière à former plusieurs partitions du groupe d'articles à fumer ;le paquet (1) est caractérisé en ce que le conditionnement souple (5) a une dimension transversale qui est plus grande que la dimension transversale du groupe d'articles à fumer de manière à former une cavité (26) à l'intérieur du conditionnement (5), et en ce qu'il comprend un élément de remplissage (50) logé à l'intérieur de la cavité (26) pour retenir fermement le groupe d'articles à fumer dans le conditionnement (5).

- Paquet (1) d'articles à fumer selon la revendication 1, dans lequel l'élément de remplissage (50) est formé d'un seul tenant avec l'élément de séparation (41) .

- Paquet (1) d'articles à fumer selon la revendication 1 ou 2, dans lequel l'élément de remplissage (50) comprend une paroi d'appui (51) pour supporter le groupe d'articles à fumer, qui s'étend sensiblement parallèle à la paroi avant (19) et à la paroi arrière (20) du conditionnement (5).

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 1 à 3, dans lequel une distance entre la paroi avant (19) du conditionnement (5) et la paroi d'appui (51) de l'élément de remplissage (50) est inférieure à une distance entre la paroi avant (19) et la paroi arrière (20) du conditionnement (5) de manière à compenser l'épaisseur plus petite du groupe d'articles à fumer par rapport à l'épaisseur du conditionnement (5).

- Paquet (1) d'articles à fumer selon la revendication 3 ou 4, dans lequel :l'élément de séparation (41) divise le volume intérieur du conditionnement en deux partitions ;la paroi d'appui (51) comprend un premier panneau d'appui (52) et un second panneau d'appui (53), dont chacun supporte une partition respective du groupe d'articles à fumer ; etle premier panneau d'appui (52) et le second panneau d'appui (53) sont adjacents et sensiblement coplanaires.

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 1 à 5, dans lequel :l'élément de séparation (41) comprend une paroi de séparation (42) qui sépare le volume intérieur du conditionnement en deux chambres (43A, 43B), chacune contenant une partition respective du groupe d'articles à fumer ; etla paroi de séparation (42) s'étend parallèle à un axe longitudinal d'extension principal du paquet (1) et est agencée transversalement, en particulier perpendiculairement, par rapport à la paroi avant (19) et à la paroi arrière (20) du conditionnement (5).

- Paquet (1) d'articles à fumer selon la revendication 5 ou 6, dans lequel la paroi de séparation (42) comprend un premier panneau de séparation (44) et un second panneau de séparation (45) reliés et se faisant face l'un à l'autre.

- Paquet (1) d'articles à fumer selon la revendication 7, lorsque la revendication 6 est rattachée à la revendication 5, dans lequel :l'élément de remplissage (50) et l'élément de séparation (41) sont formés d'un seul tenant avec le raidisseur (29) ;le premier panneau d'appui (52) provient de la première paroi latérale (31) du raidisseur (29) et est agencé perpendiculairement à la première paroi latérale (31) ;le second panneau d'appui (53) provient de la seconde paroi latérale (32) du raidisseur (29) et est agencé perpendiculairement à la seconde paroi latérale (32) ;le premier panneau de séparation (44) est relié et agencé perpendiculairement au premier panneau d'appui (52), provient de la paroi avant (30) du raidisseur (29) et est agencé perpendiculairement à la paroi avant (30) ; etle second panneau de séparation (45) est relié et agencé perpendiculairement au second panneau d'appui (51), provient de la paroi avant (30) du raidisseur (29) et est agencé perpendiculairement à la paroi avant (30).

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 1 à 8, dans lequel l'élément de remplissage (50) comprend en outre une première partie (64) de la première paroi latérale (31) du raidisseur (29) reliée au premier panneau d'appui (52), et une seconde partie (65) de la seconde paroi latérale (32) du raidisseur (29) reliée au second panneau d'appui (53) .

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 7 à 9, lorsque la revendication 6 est rattachée à la revendication 5, dans lequel :le premier panneau d'appui (52) est décalé, le long d'un axe d'extension principal du paquet (1), par rapport au second panneau d'appui (53) ; etle premier panneau de séparation (44) est décalé, le long de l'axe d'extension principal du paquet (1), par rapport au second panneau de séparation (45).

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 7 à 10, lorsque la revendication 6 est rattachée à la revendication 5, dans lequel :le premier panneau de séparation (44) a un premier appendice de butée (66A) pour venir en butée contre la paroi arrière (20) du conditionnement (5), lequel premier appendice de butée (66A) fait saillie du premier panneau de séparation (44) sortant du plan défini par le premier panneau d'appui (52) correspondant ; etle second panneau de séparation (45) a un second appendice de butée (66B) pour venir en butée contre la paroi arrière (20) du conditionnement (5), lequel second appendice de butée (66B) est décalé, le long d'un axe d'extension principal du paquet (1), par rapport au premier appendice de butée (66A), et fait saillie du second panneau de séparation (45) sortant du plan défini par le second panneau d'appui (53) correspondant.

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 7 à 10, lorsque la revendication 6 est rattachée à la revendication 5, dans lequel :le raidisseur (29) comprend une première paroi arrière (68) reliée à la première paroi latérale (31) et opposée à la paroi avant (30) du raidisseur (29), et une seconde paroi arrière (69) reliée à la seconde paroi latérale (32), opposée à la paroi avant (30) du raidisseur (29), et chevauchant partiellement la première paroi arrière (68) ;le premier panneau de séparation (44) a un premier appendice de butée (66A) pour venir en butée contre la première paroi arrière (68) du raidisseur (29), lequel premier appendice de butée (66A) fait saillie du premier panneau de séparation (45) sortant du plan défini par le premier panneau d'appui (52) correspondant ; etle second panneau de séparation (45) a un second appendice de butée (66B) pour venir en butée contre la première paroi arrière (68) du raidisseur (29), lequel second appendice de butée (66B) est décalé, le long d'un axe d'extension principal du paquet (1), par rapport au premier appendice de butée (66A), et fait saillie du second panneau de séparation (45) sortant du plan défini par le second panneau d'appui (53) correspondant.

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 1 à 7, et comprenant en outre un élément de support (37), qui est logé à l'intérieur du conditionnement (5) en contact avec le groupe d'articles à fumer et a une paroi arrière (38A, 38B) faisant face à la paroi arrière (20) du conditionnement (5), une première paroi latérale (39) faisant face à la première paroi latérale (31) du raidisseur (29), et une seconde paroi latérale (40) faisant face à la seconde paroi latérale (32) du raidisseur (29).

- Paquet (1) d'articles à fumer selon la revendication 13, lorsque la revendication 6 est rattachée à la revendication 5, dans lequel :la paroi arrière (38A, 38B) de l'élément de support (37) comprend une première paroi arrière (38A) et une seconde paroi (38B) agencées côte à côte et sensiblement coplanaires ;le premier panneau de séparation (44) provient de la première paroi arrière (38A) de l'élément de support (37) et est agencé perpendiculairement à la première paroi arrière (38A) ;le second panneau de séparation (45) provient de la seconde paroi arrière (38B) de l'élément de support (37) et est agencé perpendiculairement à la seconde paroi arrière (38B) ;une ligne de pliage reliant le premier panneau de séparation (44) au second panneau de séparation (45) fait face à une surface intérieure de la paroi avant (30) du raidisseur (29) et vient en contact avec celle-ci ;le premier panneau d'appui (52) provient du premier panneau de séparation (44) et est agencé perpendiculairement au premier panneau de séparation (44) et parallèle à la première paroi arrière (38A) de l'élément de support (37) ; etle second panneau d'appui (53) provient du second panneau de séparation (45) et est agencé perpendiculairement au second panneau de séparation (45) et parallèle à la seconde paroi arrière (38B) de l'élément de support (37).

- Paquet (1) d'articles à fumer selon la revendication 13 ou 14, lorsque la revendication 6 est rattachée à la revendication 5, dans lequel l'élément de remplissage (50) comprend en outre :une première partie (54) de la première paroi arrière (66A) de l'élément de support (37), laquelle première partie (54) est reliée au premier panneau d'appui (52) et à la première paroi latérale (39) de l'élément de support (37), fait face à la première paroi latérale (39) de l'élément de support (37) et est agencée perpendiculairement au premier panneau d'appui (52) ; etune seconde partie (55) de la seconde paroi arrière (66B) de l'élément de support (37), laquelle seconde partie (55) est reliée au second panneau d'appui (53) et à la seconde paroi latérale (40) de l'élément de support (37), fait face à la seconde paroi latérale (40) de l'élément de support (37), et est agencée perpendiculairement au second panneau d'appui (53).

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 13 à 15, dans lequel l'élément de support (37) comprend :un premier rabat de support (46) relié à une extrémité supérieure du premier panneau de séparation (44), agencé perpendiculairement au premier panneau de séparation (44) et faisant face à la paroi supérieure (17) du conditionnement (5) ; et/ouun second rabat de support (47) relié à une extrémité supérieure du second panneau de séparation (45), agencé perpendiculairement au second panneau de séparation (45) et faisant face à la paroi supérieure (17) du conditionnement (5) ; et/ouun premier appendice de support (48) faisant saillie d'une extrémité inférieure du premier panneau de séparation (44) et en appui sur la paroi inférieure (18) du conditionnement (5), ou sur une paroi inférieure (33) du raidisseur (29) ; et/ouun second appendice de support (49), relié au premier appendice de support (48), faisant saillie d'une extrémité inférieure du second panneau de séparation (45) et en appui sur la paroi inférieure (18) du conditionne-ment (5), ou sur la paroi inférieure (33) du raidisseur (29) .

- Paquet (1) d'articles à fumer selon l'une quelconque des revendications 1 à 16, dans lequel :le raidisseur (29) comprend une paroi inférieure (33) qui fait face à la paroi inférieure (18) du conditionnement (5), et/ou un premier rabat de raidisseur (34) relié à une extrémité supérieure de la première paroi latérale (31) du raidisseur (29), agencé perpendiculairement à la première paroi latérale (31) du raidisseur (29) et opposé à la paroi inférieure (33) du raidisseur (29), et/ou un second rabat de raidisseur (35) relié à une extrémité supérieure de la seconde paroi latérale (32) du raidisseur (29), agencé perpendiculairement à la seconde paroi latérale (32) du raidisseur (29) et opposé à la paroi inférieure (33) du raidisseur (29) ; et/oule paquet (1) comprend un conteneur (9), qui a une forme de parallélépipède, a une extrémité supérieure ouverte (6), une paroi inférieure (7), une paroi avant (8), une paroi arrière (9), une première paroi latérale (10) et une seconde paroi latérale (11), et loge le conditionnement souple (5) ; et/ouun couvercle (3), qui est articulé sur le conteneur (2), a une forme de parallélépipède et a une paroi supérieure (12), une paroi avant (13), une paroi arrière (14), une première paroi latérale (15) et une seconde paroi latérale (16) ; et/oule conditionnement (5) est formé par un matériau de conditionnement souple thermocollable plié directement autour du groupe d'articles à fumer de manière à être en contact direct avec les articles à fumer et stabilisé par un thermocollage ; et/oule conditionnement (5) a deux ouvertures d'extraction (24) ; et/oule paquet (1) comprend deux panneaux adhésifs refermables (27), dont chacun recouvre une ouverture d'extraction (24) respective, dans lequel les deux panneaux adhésifs refermables (27) sont partiellement reliés l'un à l'autre, ou dans lequel les deux panneaux adhésifs refermables (27) sont espacés l'un de l'autre ; et/ouune languette de prise (28) est reliée au au moins un panneau adhésif refermable (27), dans lequel la languette de prise (28) est dépourvue d'adhésif pour faciliter la manipulation du au moins un panneau adhésif refermable (27) et fait face à une surface extérieure de la paroi avant (19) du conditionnement (5).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL16722369T PL3274271T3 (pl) | 2015-03-25 | 2016-03-24 | Opakowanie na wyroby do palenia |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITBO20150145 | 2015-03-25 | ||

| PCT/IB2016/051671 WO2016151522A1 (fr) | 2015-03-25 | 2016-03-24 | Paquet d'articles à fumer |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3274271A1 EP3274271A1 (fr) | 2018-01-31 |

| EP3274271B1 true EP3274271B1 (fr) | 2019-02-13 |

Family

ID=53442823

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16722369.2A Active EP3274271B1 (fr) | 2015-03-25 | 2016-03-24 | Paquet d'articles à fumer |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP3274271B1 (fr) |

| PL (1) | PL3274271T3 (fr) |

| WO (1) | WO2016151522A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018005626A1 (de) * | 2018-07-17 | 2020-01-23 | Focke & Co. (Gmbh & Co. Kg) | Packung für Produkte der Zigarettenindustrie |

| IT201900001125A1 (it) * | 2019-01-25 | 2020-07-25 | Gd Spa | Pacchetto rigido di articoli da fumo e sbozzato per realizzare detto pacchetto rigido di articoli da fumo |

| DE102019108824A1 (de) * | 2019-04-04 | 2020-10-08 | Focke & Co. (Gmbh & Co. Kg) | Packung für Produkte der Tabakindustrie und Verfahren zur Herstellung derselben |

| DE102021130274A1 (de) | 2021-11-19 | 2023-05-25 | Focke & Co. (Gmbh & Co. Kg) | Packung für Produkte der Zigarettenindustrie |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4771882A (en) * | 1987-06-24 | 1988-09-20 | Brown & Williamson Tobacco Corporation | Cigarette package with spacer |

| DE4005443A1 (de) * | 1990-02-21 | 1991-08-22 | Focke & Co | Quaderfoermige verpackung, insbesondere klappschachtel fuer zigaretten |

| CN100584710C (zh) * | 2004-10-19 | 2010-01-27 | 日本烟草产业株式会社 | 香烟包装 |

| GB0815948D0 (en) * | 2008-09-02 | 2008-10-08 | British American Tobacco Co | Packaging for smoking articles |

-

2016

- 2016-03-24 EP EP16722369.2A patent/EP3274271B1/fr active Active

- 2016-03-24 PL PL16722369T patent/PL3274271T3/pl unknown

- 2016-03-24 WO PCT/IB2016/051671 patent/WO2016151522A1/fr active Application Filing

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| PL3274271T3 (pl) | 2019-09-30 |

| WO2016151522A1 (fr) | 2016-09-29 |

| EP3274271A1 (fr) | 2018-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2155568B1 (fr) | Emballage d'articles a base de tabac comprenant un emballage interieur pourvu d'un rabat fixe sur un couvercle a charniere | |

| EP3283397B1 (fr) | Paquet d'articles à fumer | |

| EP2138411B1 (fr) | Ensemble d'articles à forme allongée | |

| EP2250103B1 (fr) | Emballage de cigarettes muni d un emballage intérieur à renfort | |

| JP5986582B2 (ja) | 気密密封を有するヒンジ蓋付き容器 | |

| DK2814763T3 (en) | Container with self-adhesive label with area without adhesive | |

| CN101628651B (zh) | 具有带盖片的内包装的烟草制品包装 | |

| EP3274271B1 (fr) | Paquet d'articles à fumer | |

| KR101323501B1 (ko) | 흡연물품의 계단식 힌지-뚜껑 팩 | |

| KR20180090991A (ko) | 용기용 재밀봉 가능한 내부 패키지 | |

| CN113329954B (zh) | 具有双铰接盖的用于抽吸物品的硬包装和制造该用于抽吸物品的硬包装的坯件 | |

| EP1829799B1 (fr) | Emballage rigide pour articles de tabac, avec couvercle articulé collé | |

| WO2013131620A1 (fr) | Récipient comportant un couvercle à étiquette pour une ouverture d'emballage | |

| KR101142750B1 (ko) | 담뱃갑 용지 | |

| CN114616190B (zh) | 设置有铰接盖的用于抽吸制品的硬质包装 | |

| EP3180269B1 (fr) | Conteneur pour articles de consommation avec cadre interne et procédé pour la formation d'un conteneur pour articles de consommation | |

| IT201900001125A1 (it) | Pacchetto rigido di articoli da fumo e sbozzato per realizzare detto pacchetto rigido di articoli da fumo | |

| WO2017109712A1 (fr) | Paquet d'articles à fumer | |

| ITUB20153917A1 (it) | Pacchetto di articoli da fumo rigido con coperchio incernierato. | |

| ITBO20150186A1 (it) | Pacchetto di articoli da fumo. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20171025 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: FEDERICI, LUCA Inventor name: POLLONI, ROBERTO Inventor name: PARADISO, LUCA Inventor name: MARCHITTO, GIUSEPPE |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20180823 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 1096071 Country of ref document: AT Kind code of ref document: T Effective date: 20190215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602016009951 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20190213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190513 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190613 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190513 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190514 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190613 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1096071 Country of ref document: AT Kind code of ref document: T Effective date: 20190213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602016009951 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190324 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190331 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 |

|

| 26N | No opposition filed |

Effective date: 20191114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190324 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190413 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190324 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20160324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190213 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230519 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240327 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20240305 Year of fee payment: 9 |