EP3199740A2 - Dispositif d'étanchéité comprenant une barre d'étanchéité mobile - Google Patents

Dispositif d'étanchéité comprenant une barre d'étanchéité mobile Download PDFInfo

- Publication number

- EP3199740A2 EP3199740A2 EP17000061.6A EP17000061A EP3199740A2 EP 3199740 A2 EP3199740 A2 EP 3199740A2 EP 17000061 A EP17000061 A EP 17000061A EP 3199740 A2 EP3199740 A2 EP 3199740A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- wing

- movement

- relative

- release

- trigger

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000007789 sealing Methods 0.000 title claims abstract description 126

- 230000033001 locomotion Effects 0.000 claims abstract description 157

- 230000007246 mechanism Effects 0.000 claims abstract description 49

- 238000006073 displacement reaction Methods 0.000 claims description 22

- 230000000903 blocking effect Effects 0.000 claims description 6

- 230000001960 triggered effect Effects 0.000 claims description 4

- 230000000694 effects Effects 0.000 claims description 3

- 238000010276 construction Methods 0.000 description 18

- 238000013016 damping Methods 0.000 description 9

- 239000000758 substrate Substances 0.000 description 6

- 239000006228 supernatant Substances 0.000 description 5

- 241001295925 Gegenes Species 0.000 description 4

- 230000009471 action Effects 0.000 description 4

- 238000000034 method Methods 0.000 description 4

- 230000001151 other effect Effects 0.000 description 3

- 230000004888 barrier function Effects 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 238000013519 translation Methods 0.000 description 2

- 230000001154 acute effect Effects 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 238000009420 retrofitting Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B7/00—Special arrangements or measures in connection with doors or windows

- E06B7/16—Sealing arrangements on wings or parts co-operating with the wings

- E06B7/18—Sealing arrangements on wings or parts co-operating with the wings by means of movable edgings, e.g. draught sealings additionally used for bolting, e.g. by spring force or with operating lever

- E06B7/20—Sealing arrangements on wings or parts co-operating with the wings by means of movable edgings, e.g. draught sealings additionally used for bolting, e.g. by spring force or with operating lever automatically withdrawn when the wing is opened, e.g. by means of magnetic attraction, a pin or an inclined surface, especially for sills

- E06B7/215—Sealing arrangements on wings or parts co-operating with the wings by means of movable edgings, e.g. draught sealings additionally used for bolting, e.g. by spring force or with operating lever automatically withdrawn when the wing is opened, e.g. by means of magnetic attraction, a pin or an inclined surface, especially for sills with sealing strip being moved to a retracted position by elastic means, e.g. springs

Definitions

- the invention relates to a sealing device with a movable sealing strip for the edge region of a movable wing of a door or a window.

- the most common and most typical application for the sealing device relates to the design as a lowerable bottom seal for a hinged door.

- a pivotable wing is equipped at its lower edge region with a vertically guided movable sealing strip, which is lowered as intended with the wing closed and seals the gap between the ground and wing, and which is raised away from the ground with the wing open and thus not pivotal movement of the wing hindered by friction on the ground.

- the sealing strip with the wing open by biased springs, which act between the sealing strip and wing, held in an elevated position. In the most widely used constructions, the downward movement of the sealing strip is driven by the last part of the closing movement of the wing.

- the forced movement of the trigger member is not translated directly into downward movement of the sealing strip, but only a spring tense.

- the spring relaxes via a movement damping element whose guided movable part is movable relative to the wing in the same directional line as the triggering part. Only the movable part of the damping element drives the downward movement of the sealing strip via a drive mechanism. Intended is during the closing process of the wing, the downward movement of the sealing strip against the pivotal movement of the wing delayed so much that the sealing strip touches the ground only when the closing pivotal movement of the wing is already completed.

- the forced movement of the trigger part is not translated directly into downward movement of the sealing strip.

- the trigger part is divided into an inner and an outer trigger part.

- When closing the wing of the outer trigger member is displaced by contact with the door frame relative to the wing and thereby biases a spring which presses against the inner trigger part, the mobility of the wing is initially locked but. Only by the displacement of the outer trigger part over a certain minimum distance addition, the lock of the mobility of the inner trigger part is released.

- the inner trigger member drives the drive mechanism for moving the bottom seal so that it moves the bottom seal in the lowered position.

- the supernatant of the outer trigger part of the wing is adjustable, which is adjustable, starting from which angular position of the wing when closing movement of the outer trigger member relative to the wing begins and thus at which angular position of the wing movement of the inner trigger member is released.

- the sealing strip only then comes into contact with the ground when the wing is already completely in the closed position, whereby the abovementioned disadvantages should be avoided.

- the construction has not prevailed. The probable reason is that it is only in the very rare cases - and there too often only temporarily - was possible to avoid both the grinding of the seal on the ground when closing and opening the wing well, so also to achieve that the movable seal actually seals with the wing closed.

- the object underlying the invention is to provide a provided for attachment to the edge region of a movable wing of a door or a window sealing device with movable sealing strip, wherein movement of the sealing strip from the open to the sealing position by linear displacement movement belonging to the sealing device Triggering part is driven and wherein the movement of the sealing device can be started later than the driving displacement movement of the triggering part.

- the invention has been consistently recognized the finding that two parameters are to be set when setting a movable seal, and not - as often assumed - only one.

- the first parameter concerns the path around which the sealing strip is ideally moved.

- the second parameter relates to the position of the wing, in which during the closing movement of the wing, the movement of the sealing strip is started in the sealing position - that is, the lock of the mobility of the inner trigger part is canceled.

- the first parameter is adjustable, namely, how far the outer trigger member is moved relative to the wing during the closing movement of the wing.

- the width of this movement is linked in a strictly monotonously increasing function with how far the sealing strip would be moved, if it would not previously rest on the ground and thus springs, which press the sealing strip to the ground, are stretched.

- the supernatant of the outer release part is adjusted so that the sealing strip is just moved by the closing of the wing just in the sealing position, but is not strongly pressed by tensioned springs to the ground. In the case of a very large gap between the wing and the base, therefore, a greater movement of the outer triggering part is desirable as with a very small gap between the wing and the ground. If the first parameter is well set, the sealing strip is sealed when the wing is closed, but when the wing is opened it is raised as early as possible when the outer trigger part slides out of the wing.

- the feature according to the invention is independent of the first parameter in addition the second parameter adjustable at which position of the wing during the closing movement of the wing, the movement of the sealing strip is started from the non-sealing to the sealing position. This is - regardless of how far the outer trip part actually moves a total - always adjustable that the lock on the mobility of the inner release part is always canceled only at the very last moment of the closing movement of the wing.

- the locking release part is adjustable relative to the outer triggering part and also with respect to the abutment part driving the same in its position.

- the wing has not one, but two stopper parts on the closing of the wing come into contact with an outer object and are thereby displaced relative to the wing.

- the "usual" stop member which moves the outer trigger member

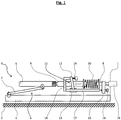

- wing 1 which may be a hinged or laterally movable door or window sash, indicated only by a vertical dotted line, which symbolizes a vertical end face of the wing 1 in side view.

- the wing 1 is equipped with an exemplary sealing device 3 according to the invention, the essential part of which is a sealing strip 4 which, with the wing 1 closed, is displaced parallel to the wing surface from the latter onto the substrate 2, so that it rests against the base 2 is applied.

- the sealing strip 4 is connected by a drive mechanism 5.

- indicated drive mechanism 5 has a longitudinally displaceable, parallel to the sealing strip 4 oriented rod 6 and thereto with one end pivotally mounted, mutually parallel lever 7. With the respective second end, the lever 7 are pivotally connected to the sealing strip 4.

- the lever 7 take with the longitudinal direction of the rod 6 a very acute angle.

- guide is the sealing strip 4 on the wing 1 normal to its longitudinal direction and thus kept guided to the longitudinal direction of the rod 6 movable.

- the sealing strip 4 in the absence of others Forces from the ground 2 away raised to an end position near the rod 6. Longitudinal displacement of the rod 6 of the in Fig. 1 dotted indicated end face of the wing 1 away causes strong displacement of the sealing strip 4 to the ground 2 out.

- the longitudinal displacement of the rod 6 of the drive mechanism 5, which leads to moving the sealing strip 4 in the sealing position, is driven causally by the outer trigger part 8 and directly by the inner trigger part 9.

- the two release parts 8, 9 are elongated, on the wing 1 in its longitudinal direction at a distance from one another and a linearly displaceably guided in this direction held parts.

- the orientation in this direction, in which the release parts 8, 9 must move relative to the wing 1 in order to cause movement of the sealing strip 4 in the sealing position, is in Fig. 1 symbolized by an arrow shown in dotted lines.

- the two release parts 8, 9 are connected by an elastic spring 10 whose bias changes when the distance between the release parts 8, 9 changes.

- the lock can be released by the over the wing 1 projecting outer trigger part 8 is moved over an adjustable minimum way out in the wing 1 into it.

- a retaining tab 15 is rigidly fixed, which has a nuts-through hole.

- the screw forming the lock-release member 16 abuts with its end face to one end of a wing 1 longitudinally displaceably guided, belonging to the locking mechanism 11 rod 17, which with its second end to an arm of a two-sided, pivotally held on the wing 1 lever 18 of the locking mechanism abuts, causing it presses with its second arm of the, the spring 14 opposite side of the clamping plate 12 and it pivots in a non-clamping position.

- the movement of the drive mechanism 5 is thus started later than the movement of the outer release part 8 started during the closing of the wing.

- the position of the rod 17 relative to the outer release part 8 is adjustable , This is finely adjustable, after which previous displacement of the outer trigger part 8 in the wing 1 in the displacement of the inner release part 9 and thus movement of the drive mechanism 5 and thus the sealing strip 4 is started in the sealing position.

- the stop member 19 projects from the wing 1. According to the rules he comes when closing the wing 1 with a part not belonging to the wing 1 - in the case of a hinged wing with the hinge side frame - in contact and is moved in the course of the closing movement of the wing 1 to the wing 1 out, bringing the outer trigger part 8 is moved further into the wing 1 inside.

- the connection of the stop member 19 with the outer trigger member 8 is a threaded connection. By adjusting this connection is adjustable, how much the stop member projecting at fully open wing 1 of this. If he continues to project, he pushes when closing the wing 1 earlier to the frame and is moved over the entire wing as if he protrudes less far. By adjusting the connection between stop member 19 and outer trigger part 8 is thus adjustable, how far the outer trigger member 8 is moved relative to the entire wing 1 during the closing movement of the wing 1.

- outer and inner trigger part 8, 9 are in their direction of succession, they can very easily be installed to improve retrofitting to a door, which previously had a conventional one-piece trigger part, which has translated sliding movement of the door wing projecting part without delay in movement of the sealing strip , To adjust the length, only the longitudinally displaceable rod 6, which is the connection part of the drive mechanism 5, needs to be shortened slightly.

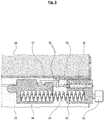

- Fig. 2 . Fig. 3 and Fig. 4 show, by way of example, three further possible and useful construction methods of two-part release parts according to the invention, each including the associated spring and locking mechanism.

- Fig. 2 the outer trigger member 20 and the inner trigger member 21 along a wing 22 rigidly mounted profile 23 in the manner of sliding blocks held longitudinally displaceably held and held by a voltage applied to both elastic spring 24 at a distance from each other.

- the inner trigger part 21 is in turn connected to a drive mechanism for moving a sealing strip (drive mechanism and sealing strip are in Fig. 2 not shown).

- Central parts of the locking mechanism 25 of Fig. 2 are a locking ball 26 and a spool 27, which are both held linearly displaceable on the inner trigger member 21, wherein the possible displacement direction of the locking ball 26 is normal to the possible possible direction of displacement of the inner trigger member 21 and the displacement direction of the spool 27 parallel thereto.

- spool 27 By an acting between spool 27 and inner trigger part 21 elastic spring 28 -. executed as an arcuate or sinusoidal pre-curved leaf spring - the spool 27 is displaced relative to the inner trigger member 21 and held so that it limits the mobility of the locking ball 26 in its guide formed by a bore so that the locking ball 26 via a lateral surface of the inner release part 21st protrudes, and in a normal to the possible possible direction of displacement of the inner trigger member 21 aligned bore 29 of a relative to the wing 22 fixed mounting bracket 30 protrudes into it.

- the locking ball 26 is fixed both against the wing 22 and against the inner trigger member 21 against movement in the direction of the profile 23, and thus the inner trigger member 21 against relative movement to the profile 23 and thus locked to the wing 22.

- a screw 34 For the purpose of adjustability relative to the outer release part 20 of the locking release part 33 is part of a screw 34, which is screwed into a parallel to the direction of displacement of the outer release part 20 threaded bore in the outer release part 20.

- By adjusting the screw-in depth of the screw 34 can in turn be set arbitrarily, after which displacement of the outer release part 20 mobility of the inner release part 21 is released and thus movement of the sealing strip is triggered in the sealing position.

- the at the closing movement of the blade 22 to an outer object (typically frame) abutting stop member 31 is in turn connected to the outer trigger member 20 via a threaded connection, so that its supernatant on the wing 22 by adjusting the threaded connection is adjustable.

- the blocking ball 26 can be understood as a special case of a guided on the inner trigger part 21 movable blocking body, in which the guideway of the movement is not parallel, preferably normal, to the trajectory of the inner trigger member 21 itself, and which depending on the position on its guideway on a with respect to the wing 22 stationary recess snaps or not.

- the spool 27 need not necessarily be kept movably guided on the inner trigger part 21, in particular when inner trigger part 21 and outer trigger part 20 are movable on mutually parallel trajectories or even one behind the other on the same trajectory, it can be rigid as with the outer trigger member 20 but be formed adjustable connected part and thus form the locking release part.

- Fig. 3 The construction according to Fig. 3 is different from that of Fig. 2 by the nature of the locking mechanism 35 and the appropriate inner triggering part 36th

- the central part of the locking mechanism 35 is a relative to the wing 22 rotatably mounted two-armed lever 37.

- the hook-shaped end of an arm of the lever 37 is hooked to the inner trigger member 36 so that this against movement to the drive mechanism for the sealing strip out (both in Fig. 3 not shown) is blocked.

- the outer trigger member 20 is moved to the lever 37, abuts with the bolt-formed locking release part 33 at the second lever arm and pivots the lever 37 so that the entanglement is solved with the inner trigger member 36.

- the inner trigger member 36 is then displaced by the action of the spring 24, which is biased between the two release members 20, 36 to pressure in the wing 22 and thus actuates the drive mechanism for moving the sealing strip in the sealing position.

- Fig. 4 shows a particularly advantageous construction for the locking mechanism 38 and the adjacent parts of a sealing device according to the invention.

- the construction is both particularly economical to produce and particularly slim formable and yet very robust working.

- Fig. 4 shows the locking mechanism 38 in the state at wide-open wing. 1

- Outer trigger member 39 and inner trigger member 40 are again in the direction of movement of the outer trigger member 39 when closing the wing 1 in succession, between the two trigger parts 39, 40 in their direction of movement, an elastic spring 41 is biased to pressure.

- a stop member 42 is fixed, which projects beyond the wing 1 and its connection to the outer trigger member 39 is a threaded connection whose screwing is adjustable, so that thus the supernatant of the stop member 42 via the wing 1 is adjustable.

- the inner trigger part 40 is essentially a guided in its longitudinal direction relative to the wing 1 movably guided rod.

- the central part of the locking mechanism 38 is as well as in the construction of Fig. 1 a relative to the wing 1 only very limited movable clamping plate 43, which in turn with a through hole, the cross-sectional area of the inner trigger member 40 in a clearance fit, and is aligned with its plane approximately normal to the longitudinal direction of the inner trigger member 40, and depending on its angular position the longitudinal direction of the inner trigger member 40 and the direction of movement of the inner trigger member 40 at this jammed or not.

- the locking mechanism 38 has a relative to the wing 1 held stationary base member 44 through which the rod-shaped inner trigger member 40 is guided, wherein the clamping plate 43 is located in the interior of the base member 44.

- the inner base part 44 has two projections 45, 46, which protrude next to the inner trigger part 40 from opposite sides close to the surface of the clamping plate 43.

- a spring 47 presses against the clamping plate 43 and, in the absence of other forces, displaces it against the projection 46 in the base part, which is located on the side of the clamping plate 43 facing the outer triggering part 39. Since this projection 46 and the spring 47 on the surface of the clamping plate 43 does not attack exactly opposite, the clamping plate 43 is pivoted so far by the force of the spring 47 until the clamping plate 43 has jammed with the inner trigger member 40.

- the inner triggering part 40 shifts away from the projection 46 together with the clamping plate 43 (in FIG Fig. 4 ie to the left) until the clamping plate 43 abuts the opposite projection 45.

- the inner trigger part 40 can then no longer be moved; Upon further movement of the outer release part 39, the elastic spring 41 is biased.

- a slide 48 is mounted longitudinally displaceably along the inner release part 40 between the base part 44 and the outer release part 39.

- elastic compression spring 49 of the carriage 48 is kept at a distance from the base member 44 in order to obtain the necessary pivoting of the clamping plate 43.

- a parallel to the direction of movement of the trip parts 39, 40 aligned threaded bolt is mounted as locking release part 50, which with its side facing away from the outer trigger part 39 in the base member 44 into close to the outer trigger member 39 facing side of the clamping plate 43rd zoom extends.

- the setting of the maximum displacement of the sealing strip is again by adjusting the screwing of the threaded connection, with which the stop member 42 with the outer Trigger part 39 is connected. Adjusting the position of the wing 1, in which the movement of the sealing strip is triggered in the sealing position, so the lock of the mobility of the inner trigger member 40 is canceled, done by the depth of engagement of formed as a threaded bolt locking release member 50 on the carriage 48 changed becomes.

- the locking release member 50 is not directly connected to the outer trigger member 39 in this case, but also changes its position relative to the outer trigger member 39 by changing the screwing on the carriage 48 and is thus adjustable according to which displacement of the outer trigger member 39 at Close the wing 1, the lock of the mobility of the inner release part 40 is released.

- the outer trigger member 39 if necessary, presses against the carriage 48 via the spring 51 and not directly, causes an overload protection. It is thus achieved that nothing is destroyed at the locking mechanism 38 when the outer trigger part is displaced too much in the wing 1 into it.

- the spring 51 prevents too much pivoting of the clamping plate 43 when unlocking, to prevent a locking action of the inner trigger member 40 when opening the wing 1 (direction of movement in Fig. 4 so to the right). This can be important, for example, if the door hinges tire during the service life of a door leaf, thus narrowing the gap between the sash and the sash.

- the basic operating principle implies that an outer and an inner trigger member are connected together by a resilient spring, the state of stress changes with the distance of the release parts, wherein during the movement of the outer trigger member according to the closing of the wing of the inner trigger member so long is locked against movement until the outer trigger part is an adjustable (!) Movement amount of path is moved and thereby releasably connected to the outer trigger part associated locking release part releases the lock.

- Fig. 1 to Fig. 4 correspond to the above-mentioned first of two categories, wherein the lock releasing part 16, 33, 50 is fastened in each case either directly on the outer triggering part 8, 20, 39 or on a co-moving part 15, 48, so that the locking release part 16 , 33, 50 ultimately by those abutment part 19, 31, 42 relative to the wing 1, 22 is moved, which also moves the outer trigger part 8, 20, 39 relative to the wing 1, 22.

- FIG. 5 to Fig. 8 that is not true; these figures show constructions according to the above-mentioned second category, according to which the locking release part is movable in each case by movement of a separate, second stop member 56, 70 relative to the wing.

- Fig. 5 shows a pivotable on a frame 52 about a vertical axis 53 wings 54th

- Both stop members 55, 56 each protrude from a vertical end face of the wing 54. Both are held on the wing 54 horizontally guided parallel to the plane of the wing 54 slidably, beat in the closing movement of the wing 54 on the frame 52 and the rigidly connected to this and thus "zargenfesten” casserole part 57 and are by this concern in the remaining Closing movement of the wing 54 in the volume of the wing 54 into shifted.

- stop member 55 which on the outer triggering part 60 ( Fig. 7 ), arranged on the hinge-side vertical end face of the wing 54 and that stop member 56, which on the lock release part 66 (FIG. Fig. 7 ) acts on the lock-side vertical end face of the wing 54th

- the ramp part 57 may be made in two parts, wherein a part of the surface 58 is fixed "unchangeable" and the second part is displaceable on the first part by turning a screw.

- Fig. 7 is in an elongated housing 59 which is rigidly connected to the wing 54 and the horizontal outer contour can be formed flush with the horizontal outer contour of the wing 54, the stop member 55 horizontally, parallel to the plane of the wing 54 and thus to the longitudinal direction of the housing 59 slidably.

- the housing 59 of the bolt-shaped stop member 55 is rigidly connected to an end face of the stop member 55 coaxially arranged sleeve-shaped outer trigger member 60 which encloses the pressure to be loaded spring 61.

- the inner triggering part 62 designed as a rod protrudes into the outer triggering part 60 and bears against the spring 61 at the end face.

- Inner trigger part 62 and outer trigger part 60 are mutually displaceable in their two longitudinal direction.

- the outer trigger member 62 is horizontally aligned parallel to the plane of the wing 54 and slidably guided in this direction guided on the housing 59 and pressed in the absence of other effects by a tensioning device (not shown, typically elastic spring) in a compliant manner to the spring 61.

- Trained as a rod inner release part 62 is guided through a through hole in a clamping plate 63 through which is arranged fixed in the housing 59 except for a small pivoting.

- the through hole and the rod cross section form a clearance fit when the plane of the clamping plate 63 is aligned approximately normal to the rod longitudinal direction.

- clamping plate 63 and inner triggering part 62 jam against each other.

- the clamping plate 63 is pivotally mounted on a fixedly arranged bearing block 64, wherein the pivot axis is normal to the formed as a rod inner trigger member 62 adjacent thereto.

- the clamping plate 63 pivots away from the side of the stop member 55 in the absence of other effects until it rests with the edge of its through hole on the lateral surface of the formed as a rod inner release part 62. In this position, movement of the inner release part 62 is blocked away from the stop member 55 by jamming. Movement of the inner trigger member 62 in the opposite direction, however, is not blocked by the clamping plate 63.

- the abutment member 55 abuts against the frame 52 and is displaced into the housing 59 upon further closing movement of the vane 54. Since movement of the inner trigger member 62 from the stop member 55 and the outer trigger member 60 away - for the time being - as described by the clamping plate 63 is blocked is the spring 61, which is located between inner trigger member 62 and outer trigger member 60, compressed, so elastically tensioned on pressure.

- the second stop member 56 passes to the casserole fixed ramp part 57.

- the stop member 56 is moved into the housing 59 into it.

- the stop member 56 is rigidly connected to the rod-shaped locking release member 66 which is held longitudinally displaceably mounted in the housing 59 and the clamping plate 63 opposite to the direction in which the clamping plate 63 is pivoted by the spring 65.

- the locking release member 66 is again by a biased between locking release member 66 and housing 59 return spring 68 to the side of the stop member 56 back shifted and thus the stop member 56 again increased from the housing 59 also moved out.

- a tensioning device typically elastic spring

- the blocking and releasing movement of the inner triggering part 62 designed as a rod does not necessarily have to take place with the aid of a clamping plate 63. In the context of expert action, there are a variety of possibilities.

- the inner trigger member 62 may include detent recesses and a latch lever movable by movement of the latch release member 66 may engage or disengage depending on the position of the latch release member 66 and thereby block or release movement of the inner trigger member 62.

- energy-storing elements may be used, such as permanent magnets, enveloped gas volumes, weights that are moved up and down.

- energy-storing elements such as permanent magnets, enveloped gas volumes, weights that are moved up and down.

- Fig. 8 illustrates the functional principle of a sealing device according to the invention, in turn, a clamping plate 63 is applied, but wherein the two adjustable by means of threaded connection in position stop members 69, 70 from the same end face 71 of the wing (in Fig. 8 indicated by a dotted line) protrude. Movement of the stop member 70 into the wing is translated by means of a two-armed pivotal lever 72 in oppositely directed movement, by which the clamping plate 63 is moved out of the position in which it locks the inner trigger member 62.

- Fig. 8 further illustrates an exemplary mechanism known per se for translating the horizontal movement of the formed as a rod inner trigger member 62 in a vertical movement of the sealing strip 67.

- the sealing strip 67 is held vertically displaceably guided on the wing.

- the sealing strip 67 is connected via a plurality of mutually parallel aligned, both sides pivotally mounted arms 73.

- the arms 73 are only slightly inclined from the horizontal, so that for geometric reasons, the horizontal movement of the inner release part 62 causes a much larger vertical movement of the sealing strip 67.

- the lowering movement of the sealing strip 67 may be slowed down by a damping element.

- the most significant advantage thereof is the avoidance of loud noise.

- stop members are movably mounted in the wing and abut when closing the wing to the frame and thereby moved relative to the wing

- other drive means are used, which are triggered in response to the closing movement of the wing and thereby movement of the outer release part and / or the lock release part.

- a transmission can translate pivotal movement of the wing continuously in motion of parts in the wing, these parts in turn driving the outer release part and / or the lock release part.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ATA13/2016A AT517964B1 (de) | 2016-01-18 | 2016-01-18 | Dichtungsvorrichtung für den unteren Randbereich eines schwenkbaren Türflügels |

| ATA395/2016A AT518198B1 (de) | 2016-01-18 | 2016-08-25 | Dichtungsvorrichtung für den Randbereich eines bewegbaren Tür- oder Fensterflügels mit einer relativ zum Flügel bewegbaren Dichtleiste |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3199740A2 true EP3199740A2 (fr) | 2017-08-02 |

| EP3199740A3 EP3199740A3 (fr) | 2017-08-16 |

| EP3199740B1 EP3199740B1 (fr) | 2018-12-05 |

Family

ID=57850872

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17000061.6A Active EP3199740B1 (fr) | 2016-01-18 | 2017-01-15 | Dispositif d'étanchéité comprenant une barre d'étanchéité mobile |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP3199740B1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102017121993A1 (de) * | 2017-09-22 | 2019-03-28 | Athmer Ohg | Türspaltdichtung |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3943526C2 (de) * | 1989-10-27 | 1994-03-03 | Hahn Gmbh & Co Kg Dr | Schubstange einer automatischen Bodendichtung für eine Tür |

| JPH084445A (ja) * | 1994-06-20 | 1996-01-09 | Sumitomo Forestry Co Ltd | ドアの気密保持装置 |

| US8745924B2 (en) * | 2007-09-26 | 2014-06-10 | Zero International, Inc. | Automatic door bottom with release mechanism |

-

2017

- 2017-01-15 EP EP17000061.6A patent/EP3199740B1/fr active Active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102017121993A1 (de) * | 2017-09-22 | 2019-03-28 | Athmer Ohg | Türspaltdichtung |

| DE102017121993B4 (de) * | 2017-09-22 | 2021-06-02 | Athmer Ohg | Türspaltdichtung |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3199740A3 (fr) | 2017-08-16 |

| EP3199740B1 (fr) | 2018-12-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0356728B1 (fr) | Dispositif de commande de la séquence de fermeture de portes à doubles battants | |

| EP3502384A1 (fr) | Serrure de véhicule automobile | |

| EP2474698A2 (fr) | Dispositif d'étanchéité doté d'un profil d'étanchéité et d'un mécanisme destiné au déplacement du profil d'étanchéité lors de l'actionnement du mécanisme | |

| DE202010018031U1 (de) | Vorrichtung für das Steuern der Schließfolge von zweiflügeligen Schwenktüren | |

| WO2016174129A1 (fr) | Entraînement de porte comportant un entraînement principal et un entraînement auxiliaire | |

| AT504314B1 (de) | Vorrichtung zur regelung der öffnungsfolge von zweiflügeligen schwenktüren | |

| EP3034728B1 (fr) | Dispositif limiteur d'ouverture | |

| EP3199740B1 (fr) | Dispositif d'étanchéité comprenant une barre d'étanchéité mobile | |

| EP3417134B1 (fr) | Ensemble ferrure pour le raccordement d'un battant coulissant et basculant | |

| DE3334298C3 (de) | Verschluß für Fenster, Türen oder dergleichen | |

| AT518198B1 (de) | Dichtungsvorrichtung für den Randbereich eines bewegbaren Tür- oder Fensterflügels mit einer relativ zum Flügel bewegbaren Dichtleiste | |

| WO2016116526A1 (fr) | Entraînement de porte comprenant un entraînement principal et un entraînement auxiliaire et éléments fonctionnels supplémentaires | |

| EP0554671B1 (fr) | Dispositif d'aération pour locaux | |

| WO2021198185A1 (fr) | Dispositif d'aide à la fermeture et à l'ouverture d'un élément de levage et de coulissement, et élément de levage et de coulissement équipé d'un tel dispositif | |

| EP3301249B1 (fr) | Dispositif d'étanchéité doté d'une barre d'étanchéité mobile | |

| AT519385B1 (de) | Schiebetür | |

| EP1247931B1 (fr) | Commande de séquence de fermeture | |

| DE102012107443B4 (de) | Vorrichtung für das Steuern der Schließfolge von zweiflügeligen Schwenktüren, welche mit Gleitschienenschließern ausgestattet sind | |

| DE69205695T2 (de) | Flügelgelenkband für eine Tür, ein Fenster oder dergleichen von dem der Flügel nach aussen und um eine senkrechte Achse schwenkt gegenüber einem Fensterrahmen. | |

| EP3626918B1 (fr) | Ferrure pour une fenêtre, fenêtre | |

| DE3008043A1 (de) | Zusatzverriegelung fuer fenster, tueren o.dgl. | |

| DE7419171U (de) | Verschlussvorrichtung fuer fenster tueren od.dgl. | |

| EP4265879A1 (fr) | Agencement de porte | |

| AT504334B1 (de) | Anordnung zur ver- und entriegelung von gedichteten schwenktüren | |

| EP4265878A1 (fr) | Agencement de porte |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E06B 7/215 20060101AFI20170712BHEP |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180213 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20180627 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1073295 Country of ref document: AT Kind code of ref document: T Effective date: 20181215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017000431 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20181205 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190305 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190306 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190405 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190405 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502017000431 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190115 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190131 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190205 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| 26N | No opposition filed |

Effective date: 20190906 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20170115 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181205 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20230131 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240123 Year of fee payment: 8 Ref country code: CH Payment date: 20240201 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1073295 Country of ref document: AT Kind code of ref document: T Effective date: 20240115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240115 |