EP2803839B1 - Scroll structure of turbine housing - Google Patents

Scroll structure of turbine housing Download PDFInfo

- Publication number

- EP2803839B1 EP2803839B1 EP12864916.7A EP12864916A EP2803839B1 EP 2803839 B1 EP2803839 B1 EP 2803839B1 EP 12864916 A EP12864916 A EP 12864916A EP 2803839 B1 EP2803839 B1 EP 2803839B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tongue

- side passage

- exhaust gas

- side tongue

- turbine housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005192 partition Methods 0.000 claims description 29

- 230000002093 peripheral effect Effects 0.000 claims description 23

- 210000002105 tongue Anatomy 0.000 description 74

- 239000007789 gas Substances 0.000 description 64

- 230000000052 comparative effect Effects 0.000 description 10

- 238000000638 solvent extraction Methods 0.000 description 4

- 230000008646 thermal stress Effects 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 238000005266 casting Methods 0.000 description 2

- 239000012141 concentrate Substances 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 230000009977 dual effect Effects 0.000 description 2

- 238000003754 machining Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/40—Casings; Connections of working fluid

- F04D29/403—Casings; Connections of working fluid especially adapted for elastic fluid pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D9/00—Stators

- F01D9/02—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles

- F01D9/026—Scrolls for radial machines or engines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C6/00—Plural gas-turbine plants; Combinations of gas-turbine plants with other apparatus; Adaptations of gas-turbine plants for special use

- F02C6/04—Gas-turbine plants providing heated or pressurised working fluid for other apparatus, e.g. without mechanical power output

- F02C6/10—Gas-turbine plants providing heated or pressurised working fluid for other apparatus, e.g. without mechanical power output supplying working fluid to a user, e.g. a chemical process, which returns working fluid to a turbine of the plant

- F02C6/12—Turbochargers, i.e. plants for augmenting mechanical power output of internal-combustion piston engines by increase of charge pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B37/00—Engines characterised by provision of pumps driven at least for part of the time by exhaust

- F02B37/02—Gas passages between engine outlet and pump drive, e.g. reservoirs

- F02B37/025—Multiple scrolls or multiple gas passages guiding the gas to the pump drive

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/40—Application in turbochargers

Definitions

- the present invention relates to a scroll structure of a turbine housing, and more particularly, to a scroll structure of a turbine housing of a twin scroll turbocharger that includes a dual exhaust gas passage introducing exhaust gas to a turbine rotor.

- a twin scroll turbocharger which avoids the exhaust interference caused by a plurality of cylinders of an engine and improves the rotation efficiency of a turbine rotor by effectively using a pulse effect of an exhaust pulse, is known as a turbocharger that is mounted on a vehicle.

- Conventional twin scroll turbochargers are e.g. known from documents JP S63 140 U and JP Hoi 66433U .

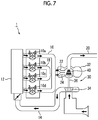

- FIG. 7 is a schematic view of an engine including such a twin scroll turbocharger.

- an engine 1 including a twin scroll turbocharger 30 includes, for example, four cylinders 10a, 10b, 10c, and 10d and phases of crank angles of these cylinders 10a to 10d are shifted from each other by, for example, 180°.

- the cylinders 10a and 10d are connected to a first exhaust manifold 16 and the cylinders 10b and 10c are connected to a second exhaust manifold 18.

- the phases of the crank angles of the cylinders 10a and 10d are shifted from each other by, for example, 360°, so that the respective exhaust pulses of the cylinders 10a and 10d do not interfere with each other.

- the phases of the crank angles of the cylinders 10b and 10c are shifted from each other by, for example, 360°, so that the respective exhaust pulses of the cylinders 10b and 10c do not interfere with each other.

- the first exhaust manifold 16 is connected to an exhaust gas passage (front-side passage 22) formed in a turbine housing 32, so that exhaust gas discharged from the cylinders 10a and 10d is introduced to a turbine rotor 40 accommodated in the turbine housing 32 through the front-side passage 22.

- the second exhaust manifold 18 is connected to an exhaust gas passage (rear-side passage 24) formed in the turbine housing 32, so that exhaust gas discharged from the cylinders 10b and 10c is introduced to the turbine rotor 40 accommodated in the turbine housing 32 through the rear-side passage 24.

- the twin scroll turbocharger 30 needs to be designed so that the flow-through abilities of the two exhaust gas passages 22 and 24 are equal to each other. That is, if there is a difference between the flow-through abilities of the front-side passage 22 and the rear-side passage 24, a pressure difference between the exhaust gas flowing in the front-side passage 22 and the exhaust gas flowing in the rear-side passage 24 is generated.

- the pressure difference between the exhaust gases causes an exhaust resistance difference between the exhaust gas discharged from the cylinders 10a and 10d and the exhaust gas discharged from the cylinders 10b and 10c, so that the operating states of the cylinders 10a and 10d are different from those of the cylinders 10b and 10c.

- twin scroll turbocharger in the related art, two exhaust gas passages are formed to be symmetrical with respect to a partition wall perpendicular to a turbine shaft as shown in, for example, Fig. 4 of PTL 1 so that the flow-through abilities of the two exhaust gas passages are equal to each other.

- a turbine housing 32 in which a scroll portion 26 is inclined forward may be employed as a whole due to a joint relationship that is generated when the turbine housing 32 and a bearing housing 33 are connected to each other by a coupling member 35 as shown in Fig. 8 .

- the invention has been made in consideration of the task in the related art, and an object of the invention is to provide a scroll structure of a turbine housing that is formed so that the flow-through abilities of two exhaust gas passages are equal to each other in a turbine housing of a twin scroll turbocharger in which a partition wall partitioning a scroll portion into the two exhaust gas passages is inclined with respect to a central axis of a turbine shaft.

- the invention has been made to achieve the above-mentioned task and object in the related art.

- a scroll structure of a turbine housing of a twin scroll turbocharger according to claim 1 is provided.

- the invention is an invention relating to a turbine housing of a twin scroll turbocharger in which the partition wall partitioning the scroll portion into two exhaust gas passages, that is, the front-side passage and the rear-side passage, is inclined with respect to the turbine shaft.

- the tongue which partitions the scroll portion into the outer peripheral portion and the inner peripheral portion in the longitudinal section parallel to the flow direction of the exhaust gas, is formed at the turbine housing of the invention.

- the tongue includes the front-side tongue and the rear-side tongue that respectively close the front-side passage and the rear-side passage in the cross-section perpendicular to the flow direction of the exhaust gas.

- the respective inner sides of the front-side tongue and the rear-side tongue and the respective minimal outflow width portions of the front-side passage and the rear-side passage are formed substantially parallel to each other in the cross-section at the downstream end of the outer peripheral portion of the scroll portion.

- the flow rate of the exhaust gas flowing out from the front-side passage is substantially equal to the flow rate of the exhaust gas flowing out from the rear-side passage. That is, the inner sides of the tongues are aligned parallel to the minimal outflow width portions in the exhaust gas passages. Accordingly, the flow direction of the exhaust gas flowing along the inner side of the tongue in the outer peripheral portion is changed to a direction perpendicular to the inner side in the inner peripheral portion exceeding the tongue, and the exhaust gas forms a flow perpendicular to the minimal outflow width portion and flows to the rotor blade.

- the velocity component of the exhaust gas which is perpendicular to the minimal outflow width portion, becomes the flow rate of the exhaust gas passing through the minimal outflow width portion (that is, flowing in the exhaust gas passage). Accordingly, it is possible to prevent an eccentric flow near the tongue and to make vortex characteristics uniform by making the respective inner sides of the front-side tongue and the rear-side tongue parallel to the minimal outflow width portions.

- a fact that the respective inner sides of the front-side tongue and the rear-side tongue and the respective minimal outflow width portions of the front-side passage and the rear-side passage are "substantially" parallel to each other means a case in which angles, which are formed between the inner sides of the front-side tongue and the rear-side tongue and the minimal outflow width portions of the front-side passage and the rear-side passage, are in the range of -10° to +10°.

- the angle formed between the inner side of the front-side tongue and the minimal outflow width portion of the front-side passage does not necessarily need to be equal to the angle formed between the inner side of the rear-side tongue and the minimal outflow width portion of the rear-side passage, and the angles may be angles different from each other.

- the front-side passage and the rear-side passage are formed to be substantially symmetrical with respect to a central axis of the partition wall in the cross-section at the downstream end of the outer peripheral portion, it is possible to make the flow-through abilities of the two exhaust gas passages more accurately equal to each other.

- the turbine housing is generally manufactured by casting. Accordingly, an extra thick portion is cut from the inner peripheral portion (shroud portion) of the turbine housing near the rotor blade by machining, so that the inner peripheral portion is machined in a desired shape corresponding to the shape of the rotor blade.

- a part of the front-side tongue may be cut from the outer side of the front-side tongue in a step of cutting the extra thick portion.

- the front-side tongue is a portion exposed to a high-temperature exhaust gas. Accordingly, if a thin portion is locally formed at the front-side tongue, there is a concern that cracks caused by thermal stress may be generated at the thin portion.

- a portion of the front-side tongue which is formed on the back of the outer side and is close to the inner side, is formed to be thicker by at least the thickness of a portion of the outer side to be cut, it is possible to avoid the generation of cracks that are caused by local thermal stress.

- a portion of the rear-side tongue close to a rear wall surface extend downstream more than a portion of the rear-side tongue close to a partition wall surface at a downstream end of the rear-side tongue of the invention.

- a portion of the front-side tongue close to a front wall surface extend downstream more than a portion of the front-side tongue close to the partition wall surface even at a downstream end of the front-side tongue of the invention.

- a partition wall partitioning a scroll portion into two exhaust gas passages that is, a front-side passage and a rear-side passage

- respective minimal outflow width portions of the front-side passage and the rear-side passage are formed so as to have substantially the same passage width, and respective inner sides of the front-side tongue and the rear-side tongue and the respective minimal outflow width portions of the front-side passage and the rear-side passage are formed substantially parallel to each other. Accordingly, it is possible to provide a scroll structure of a turbine housing that is formed so that the flow-through abilities of the two exhaust gas passages are equal to each other.

- a turbine housing 32 of the invention is a turbine housing 32 of a twin scroll turbocharger 30 which accommodates a turbine rotor 40 and at which two exhaust gas passages 22 and 24 introducing exhaust gases to the turbine rotor 40 are formed.

- a central axis 28' of a partition wall 28 of the turbine housing 32 is inclined with respect to a central axis 36' of a turbine shaft 36 and the turbine housing 32 is connected to a bearing housing 33 by a coupling member 35.

- a scroll structure of the turbine housing 32 of the invention in a longitudinal section parallel to the flow direction of an exhaust gas e, includes a spiral scroll portion 26 and a tongue 44 that partitions the scroll portion 26 into an outer peripheral portion 26a and an inner peripheral portion 26b.

- the scroll portion 26 in a cross-section perpendicular to the flow direction of the exhaust gas e, is partitioned into a front-side passage 22 and a rear-side passage 24 by the partition wall 28.

- the above-mentioned tongue 44 includes a front-side tongue 46 and a rear-side tongue 48 that close the front-side passage 22 and the rear-side passage 24 at the outer peripheral portion 26a in the cross-section, respectively.

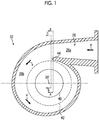

- Fig. 2(a) is a cross-sectional view taken along line a-a of Fig. 1

- Fig. 2(b) is a cross-sectional view taken along line b-b of Fig. 1 .

- respective inner sides 46a and 48b of the front-side tongue 46 and the rear-side tongue 48 are formed substantially parallel to minimal outflow width portions 56a and 58a shown in Fig. 2(b) as described below.

- the "minimal outflow width portions" in the invention means portions, of which the passage widths are the minimum, of outflow portions of the front-side passage 22 and the rear-side passage 24 in the cross-sections at the downstream end of the above-mentioned outer peripheral portion 26a (the cross-sections taken along line a-a and b-b of Fig. 1 ).

- the front-side passage 22 and the rear-side passage 24 are formed to be substantially symmetrical with respect to the central axis 28' of the partition wall 28 in the cross-section at the downstream end of the outer peripheral portion 26a.

- Fig. 3(a) is a cross-sectional view of the embodiment

- Fig. 3(b) is a cross-sectional view of a comparative example

- Fig. 4(a) is a cross-sectional view illustrating a relationship between the inner sides and the minimal outflow width portions of the embodiment

- Fig. 4(b) is a cross-sectional view illustrating a relationship between inner sides and minimal outflow width portions of the comparative example.

- the embodiments or examples shown in Figures 3(a), 3(b) , 4(a), 4(b) do not fall within the scope of the claims.

- respective inner sides 146a and 148a of a front-side tongue 146 and a rear-side tongue 148 are horizontally formed so as to be parallel to a central axis 136' of a turbine shaft as shown in Fig. 3(b) , unlike in the above-mentioned turbine housing 32 of the invention that is the embodiment.

- the flow-through ability of the exhaust gas passage depends on the velocity component of an exhaust gas that is perpendicular to the minimal outflow width portion. Further, in the embodiment, the respective inner sides 46a and 48a of the front-side tongue 46 and the rear-side tongue 48 and the respective minimal outflow width portions 56a and 58a of the front-side passage 22 and the rear-side passage 24 are formed substantially parallel to each other as shown in Fig. 4(a) .

- exhaust gases e and e which pass through the respective minimal outflow width portions 56a and 58a of the front-side passage 22 and the rear-side passage 24, flow in directions perpendicular to the respective minimal outflow width portions 56a and 58a; the flow velocities of both of the exhaust gases are also substantially equal to each other; and the flow rates of the exhaust gases flowing out from the front-side passage 22 and the rear-side passage 24 are also substantially equal to each other.

- the respective inner sides 146a and 148a of the front-side tongue 146 and the rear-side tongue 148 are formed together in a flat shape and the inner side 148a and a minimal outflow width portion 158a are formed substantially parallel to each other, but the inner side 146a and a minimal outflow width portion 156a are not formed substantially parallel to each other.

- the flow of an exhaust gas e' which flows out from a front-side passage 122, is biased and the exhaust gas e' flows at a flow velocity different from the flow velocity of an exhaust gas e' that flows out from a rear-side passage 124. Therefore, the flow rates of the exhaust gases, which flow out from the front-side passage 122 and the rear-side passage 124, are different from each other.

- the respective inner sides 46a and 48a of the front-side tongue 46 and the rear-side tongue 48 and the respective minimal outflow width portions 56a and 58a of the front-side passage 22 and the rear-side passage 24 are formed substantially parallel to each other. Accordingly, a difference between the flow-through abilities of the two exhaust gas passages, which is caused by the inclination of the partition wall 28 with respect to the central axis 36' of the turbine shaft, is corrected, so that it is possible to make the flow-through abilities of the front-side passage 22 and the rear-side passage 24 equal to each other.

- front-side passage 22 and the rear-side passage 24 are formed to be substantially symmetrical with respect to the central axis 28' of the partition wall 28 in the cross-section at the downstream end of the outer peripheral portion 26a as described above, it is possible to make the flow-through abilities of the front-side passage 22 and the rear-side passage 24 more accurately equal to each other.

- the above-mentioned turbine housing 32 of the invention is manufactured by casting.

- an extra thick portion 38a is formed on an inner peripheral portion (shroud portion 38) of the turbine housing 32 near a rotor blade 42 and is cut by a cutting tool 37 for a lathe, so that the inner peripheral portion is formed in a desired shape corresponding to the shape of the rotor blade 42.

- the front-side tongue 146 is not cut even when an extra thick portion 138a is cut by a cutting tool 137 for a lathe. Even if a part of an outer side 146b of the front-side tongue 146 is cut, there is no particular problem since the front-side tongue 146 of the comparative example is formed to be sufficiently thick.

- the front-side tongue 46 is a portion exposed to a high-temperature exhaust gas. Accordingly, if a part of the outer side 46b of the front-side tongue 46 is cut and a thin portion is locally formed at the front-side tongue 46, there is a concern that cracks caused by thermal stress may be generated at the thin portion.

- a build-up portion 49 corresponding to a cut portion 47 is formed on the inner side 46a and a portion of the front-side tongue 46, which is formed on the back of the outer side 46b and is close to the inner side 46a, is formed to be thicker by at least the thickness of a portion of the outer side 46b to be cut, it is possible to avoid the generation of cracks that are caused by local thermal stress.

- Fig. 6 is a view illustrating the flows of exhaust gases at the respective minimal outflow width portions of the front-side passage 22 and the rear-side passage 24, Fig. 6(a) is a cross-sectional view, and Figs. 6(b) to 6(d) are plan views of the respective tongues as seen from above.

- a portion of the rear-side tongue 48 close to a rear wall surface 24a extends downstream more than a portion of the rear-side tongue 48 close to a partition wall surface 28a, at the downstream end of the rear-side tongue 48.

- a portion of the front-side tongue 46 close to a front wall surface 22a extends downstream more than a portion of the front-side tongue 46 close to a partition wall surface 28a even at the downstream end of the front-side tongue 46.

- a radial component of a flow velocity vector of each of the exhaust gases, which flow near the partition wall surfaces 28a, the rear wall surface 24a, and the front wall surface 22a, is predominant with respect to a circumferential component thereof due to the resistance of the wall surfaces. That is, the exhaust gases, which flow near the partition wall surfaces 28a, the rear wall surface 24a, and the front wall surface 22a, early and easily flow to the turbine rotor 40 as compared to the exhaust gases that flow near intermediate positions between the partition wall surface 28a and the rear wall surface 24a and between the partition wall surface 28a and the front wall surface 22a.

- the invention can be suitably used as a scroll structure of a turbine housing of a twin scroll turbocharger that includes a dual exhaust gas passage introducing exhaust gases to a turbine rotor.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Supercharger (AREA)

Description

- The present invention relates to a scroll structure of a turbine housing, and more particularly, to a scroll structure of a turbine housing of a twin scroll turbocharger that includes a dual exhaust gas passage introducing exhaust gas to a turbine rotor.

- A twin scroll turbocharger, which avoids the exhaust interference caused by a plurality of cylinders of an engine and improves the rotation efficiency of a turbine rotor by effectively using a pulse effect of an exhaust pulse, is known as a turbocharger that is mounted on a vehicle. Conventional twin scroll turbochargers are e.g. known from documents

JP S63 140 U JP Hoi 66433U -

Fig. 7 is a schematic view of an engine including such a twin scroll turbocharger. As shown inFig. 7 , anengine 1 including atwin scroll turbocharger 30 includes, for example, fourcylinders cylinders 10a to 10d are shifted from each other by, for example, 180°. Among these four cylinders, thecylinders first exhaust manifold 16 and thecylinders second exhaust manifold 18. The phases of the crank angles of thecylinders cylinders cylinders cylinders - The

first exhaust manifold 16 is connected to an exhaust gas passage (front-side passage 22) formed in aturbine housing 32, so that exhaust gas discharged from thecylinders turbine rotor 40 accommodated in theturbine housing 32 through the front-side passage 22. Likewise, thesecond exhaust manifold 18 is connected to an exhaust gas passage (rear-side passage 24) formed in theturbine housing 32, so that exhaust gas discharged from thecylinders turbine rotor 40 accommodated in theturbine housing 32 through the rear-side passage 24. When arotor blade 42 is rotated by the introduced exhaust gas, theturbine rotor 40 and aturbine shaft 36 supporting theturbine rotor 40 are rotated and acompressor rotor 34 supported by theturbine shaft 36 is rotated. Accordingly, compressed air is supplied to each of thecylinders 10a to 10d through anintake pipe 14 and anintake manifold 12. The exhaust gas, which has rotated theturbine rotor 40, is discharged to the outside of theengine 1 from anexhaust pipe 20. - The

twin scroll turbocharger 30 needs to be designed so that the flow-through abilities of the twoexhaust gas passages side passage 22 and the rear-side passage 24, a pressure difference between the exhaust gas flowing in the front-side passage 22 and the exhaust gas flowing in the rear-side passage 24 is generated. The pressure difference between the exhaust gases causes an exhaust resistance difference between the exhaust gas discharged from thecylinders cylinders cylinders cylinders engine 1 may deteriorate. Accordingly, it is necessary to make the flow-through abilities of the front-side passage 22 and the rear-side passage 24 equal to each other in thetwin scroll turbocharger 30. - For this reason, in the twin scroll turbocharger in the related art, two exhaust gas passages are formed to be symmetrical with respect to a partition wall perpendicular to a turbine shaft as shown in, for example,

Fig. 4 ofPTL 1 so that the flow-through abilities of the two exhaust gas passages are equal to each other. - [PTL 1] Japanese Unexamined Patent Application Publication No.

2008-101589 - Incidentally, when the size of the

twin scroll turbocharger 30 is reduced due to a problem such as mountability on a vehicle, aturbine housing 32 in which ascroll portion 26 is inclined forward may be employed as a whole due to a joint relationship that is generated when the turbine housing 32 and a bearinghousing 33 are connected to each other by acoupling member 35 as shown inFig. 8 . In theturbine housing 32 in which thescroll portion 26 is inclined forward as described above and a central axis 28' of apartition wall 28 partitioning the front-side passage 22 and the rear-side passage 24 is inclined forward with respect to a central axis 36' of theturbine shaft 36, a difference between the flow-through abilities of both of the exhaust gas passages is generated, for example, even though the front-side passage 22 and the rear-side passage 24 are formed to be symmetrical with respect to the central axis 28'. - The invention has been made in consideration of the task in the related art, and an object of the invention is to provide a scroll structure of a turbine housing that is formed so that the flow-through abilities of two exhaust gas passages are equal to each other in a turbine housing of a twin scroll turbocharger in which a partition wall partitioning a scroll portion into the two exhaust gas passages is inclined with respect to a central axis of a turbine shaft.

- The invention has been made to achieve the above-mentioned task and object in the related art.

- A scroll structure of a turbine housing of a twin scroll turbocharger according to

claim 1 is provided. - The invention is an invention relating to a turbine housing of a twin scroll turbocharger in which the partition wall partitioning the scroll portion into two exhaust gas passages, that is, the front-side passage and the rear-side passage, is inclined with respect to the turbine shaft. The tongue, which partitions the scroll portion into the outer peripheral portion and the inner peripheral portion in the longitudinal section parallel to the flow direction of the exhaust gas, is formed at the turbine housing of the invention. The tongue includes the front-side tongue and the rear-side tongue that respectively close the front-side passage and the rear-side passage in the cross-section perpendicular to the flow direction of the exhaust gas. Further, the respective inner sides of the front-side tongue and the rear-side tongue and the respective minimal outflow width portions of the front-side passage and the rear-side passage are formed substantially parallel to each other in the cross-section at the downstream end of the outer peripheral portion of the scroll portion.

- Since the respective inner sides of the front-side tongue and the rear-side tongue and the respective minimal outflow width portions of the front-side passage and the rear-side passage are formed substantially parallel to each other in the invention, the flow rate of the exhaust gas flowing out from the front-side passage is substantially equal to the flow rate of the exhaust gas flowing out from the rear-side passage. That is, the inner sides of the tongues are aligned parallel to the minimal outflow width portions in the exhaust gas passages. Accordingly, the flow direction of the exhaust gas flowing along the inner side of the tongue in the outer peripheral portion is changed to a direction perpendicular to the inner side in the inner peripheral portion exceeding the tongue, and the exhaust gas forms a flow perpendicular to the minimal outflow width portion and flows to the rotor blade. In this case, the velocity component of the exhaust gas, which is perpendicular to the minimal outflow width portion, becomes the flow rate of the exhaust gas passing through the minimal outflow width portion (that is, flowing in the exhaust gas passage). Accordingly, it is possible to prevent an eccentric flow near the tongue and to make vortex characteristics uniform by making the respective inner sides of the front-side tongue and the rear-side tongue parallel to the minimal outflow width portions.

- Therefore, it is possible to make the flow-through abilities of the two exhaust gas passages equal to each other by making the invention in this way.

- In the invention, a fact that the respective inner sides of the front-side tongue and the rear-side tongue and the respective minimal outflow width portions of the front-side passage and the rear-side passage are "substantially" parallel to each other means a case in which angles, which are formed between the inner sides of the front-side tongue and the rear-side tongue and the minimal outflow width portions of the front-side passage and the rear-side passage, are in the range of -10° to +10°. In this case, the angle formed between the inner side of the front-side tongue and the minimal outflow width portion of the front-side passage does not necessarily need to be equal to the angle formed between the inner side of the rear-side tongue and the minimal outflow width portion of the rear-side passage, and the angles may be angles different from each other.

- In the invention, if the front-side passage and the rear-side passage are formed to be substantially symmetrical with respect to a central axis of the partition wall in the cross-section at the downstream end of the outer peripheral portion, it is possible to make the flow-through abilities of the two exhaust gas passages more accurately equal to each other.

- Further, when a part of the front-side tongue of the invention is to be cut from an outer side, it is preferable that a portion of the front-side tongue, which is formed on the back of the outer side and is close to the inner side, be formed to be thicker by at least the thickness of the part of the outer side to be cut.

- The turbine housing is generally manufactured by casting. Accordingly, an extra thick portion is cut from the inner peripheral portion (shroud portion) of the turbine housing near the rotor blade by machining, so that the inner peripheral portion is machined in a desired shape corresponding to the shape of the rotor blade. In the invention including the above-mentioned front-side tongue, a part of the front-side tongue may be cut from the outer side of the front-side tongue in a step of cutting the extra thick portion. The front-side tongue is a portion exposed to a high-temperature exhaust gas. Accordingly, if a thin portion is locally formed at the front-side tongue, there is a concern that cracks caused by thermal stress may be generated at the thin portion. Therefore, in this case, if a portion of the front-side tongue, which is formed on the back of the outer side and is close to the inner side, is formed to be thicker by at least the thickness of a portion of the outer side to be cut, it is possible to avoid the generation of cracks that are caused by local thermal stress.

- Further, it is preferable that a portion of the rear-side tongue close to a rear wall surface extend downstream more than a portion of the rear-side tongue close to a partition wall surface at a downstream end of the rear-side tongue of the invention.

- Furthermore, it is preferable that a portion of the front-side tongue close to a front wall surface extend downstream more than a portion of the front-side tongue close to the partition wall surface even at a downstream end of the front-side tongue of the invention.

- According to this structure, exhaust gases flowing close to the partition wall surfaces early and easily flow to the turbine rotor in both the rear-side passage and the front-side passage. That is, the exhaust gases easily flow so as to concentrate on the center of the rotor blade in the cross-section, so that it is possible to efficiently rotate the turbine rotor.

- According to the invention, in a turbine housing of a twin scroll turbocharger in which a partition wall partitioning a scroll portion into two exhaust gas passages, that is, a front-side passage and a rear-side passage, is inclined with respect to a turbine shaft, respective minimal outflow width portions of the front-side passage and the rear-side passage are formed so as to have substantially the same passage width, and respective inner sides of the front-side tongue and the rear-side tongue and the respective minimal outflow width portions of the front-side passage and the rear-side passage are formed substantially parallel to each other. Accordingly, it is possible to provide a scroll structure of a turbine housing that is formed so that the flow-through abilities of the two exhaust gas passages are equal to each other.

-

-

Fig. 1 is a longitudinal sectional view of a turbine housing of a twin scroll turbocharger not falling within the scope of the claims. -

Fig. 2(a) is a cross-sectional view taken along line a-a ofFig. 1 , andFig. 2(b) is a cross-sectional view taken along line b-b ofFig. 1 . -

Fig. 3(a) is a cross-sectional view of an embodiment not falling within the scope of the claims, andFig. 3(b) is a cross-sectional view of a comparative example. -

Fig. 4(a) is a cross-sectional view illustrating a relationship between inner sides and minimal outflow width portions of the embodiment not falling within the scope of the claims, andFig. 4(b) is a cross-sectional view illustrating a relationship between inner sides and minimal outflow width portions of the comparative example not falling within the scope of the claims. -

Fig. 5(a) is an enlarged view of an "a" portion ofFig. 3(a) and is a cross-sectional view of the embodiment according to the invention showing a case in which an extra thick portion of a shroud portion is cut, andFig. 5(b) is an enlarged view of a "b" portion ofFig. 3(b) and is a cross-sectional view of the comparative example, not falling within the scope of the claims, showing a case in which an extra thick portion of a shroud portion is cut. -

Fig. 6 is a view illustrating the flows of exhaust gases at the respective minimal outflow width portions of a front-side passage and a rear-side passage,Fig. 6(a) is a cross-sectional view, andFigs. 6(b) to 6(d) are plan views of respective tongues as seen from above. -

Fig. 7 is a schematic view of an engine including a twin scroll turbocharger. -

Fig. 8 is a longitudinal sectional view of the twin scroll turbocharger. - An embodiment of the invention will be described in detail below with reference to the drawings.

- However, the scope of the invention is not limited to the following embodiment. As long as not particularly described, the dimensions, materials, shapes, relative arrangement, and the like of components described in the following embodiment are not to limit the scope of the invention to the following embodiment and are merely exemplified.

- As shown in the above-mentioned

Fig. 7 , aturbine housing 32 of the invention is aturbine housing 32 of atwin scroll turbocharger 30 which accommodates aturbine rotor 40 and at which twoexhaust gas passages turbine rotor 40 are formed. As shown in the above-mentionedFig. 8 , a central axis 28' of apartition wall 28 of theturbine housing 32 is inclined with respect to a central axis 36' of aturbine shaft 36 and theturbine housing 32 is connected to a bearinghousing 33 by acoupling member 35. - As shown in

Fig. 1 , in a longitudinal section parallel to the flow direction of an exhaust gas e, a scroll structure of theturbine housing 32 of the invention includes aspiral scroll portion 26 and atongue 44 that partitions thescroll portion 26 into an outerperipheral portion 26a and an innerperipheral portion 26b. As shown inFig. 2 , in a cross-section perpendicular to the flow direction of the exhaust gas e, thescroll portion 26 is partitioned into a front-side passage 22 and a rear-side passage 24 by thepartition wall 28. As shown inFig. 2(a) , the above-mentionedtongue 44 includes a front-side tongue 46 and a rear-side tongue 48 that close the front-side passage 22 and the rear-side passage 24 at the outerperipheral portion 26a in the cross-section, respectively.Fig. 2(a) is a cross-sectional view taken along line a-a ofFig. 1 , andFig. 2(b) is a cross-sectional view taken along line b-b ofFig. 1 . - In the invention, respective

inner sides side tongue 46 and the rear-side tongue 48 are formed substantially parallel to minimaloutflow width portions Fig. 2(b) as described below. Meanwhile, the "minimal outflow width portions" in the invention means portions, of which the passage widths are the minimum, of outflow portions of the front-side passage 22 and the rear-side passage 24 in the cross-sections at the downstream end of the above-mentioned outerperipheral portion 26a (the cross-sections taken along line a-a and b-b ofFig. 1 ). - In the invention, the front-

side passage 22 and the rear-side passage 24 are formed to be substantially symmetrical with respect to the central axis 28' of thepartition wall 28 in the cross-section at the downstream end of the outerperipheral portion 26a. - The effect of the scroll structure of the

turbine housing 32 of the invention in which the respectiveinner sides side tongue 46 and the rear-side tongue 48 and the respective minimaloutflow width portions side passage 22 and the rear-side passage 24 are formed substantially parallel to each other in the cross-section at the downstream end of the outerperipheral portion 26a as described above will be described with reference toFigs. 3 and4 while the embodiment and a comparative example are compared with each other. -

Fig. 3(a) is a cross-sectional view of the embodiment, andFig. 3(b) is a cross-sectional view of a comparative example. Further,Fig. 4(a) is a cross-sectional view illustrating a relationship between the inner sides and the minimal outflow width portions of the embodiment, andFig. 4(b) is a cross-sectional view illustrating a relationship between inner sides and minimal outflow width portions of the comparative example. The embodiments or examples shown inFigures 3(a), 3(b) ,4(a), 4(b) do not fall within the scope of the claims. In aturbine housing 132 in the related art that is the comparative example, respectiveinner sides side tongue 146 and a rear-side tongue 148 are horizontally formed so as to be parallel to a central axis 136' of a turbine shaft as shown inFig. 3(b) , unlike in the above-mentionedturbine housing 32 of the invention that is the embodiment. - The flow-through ability of the exhaust gas passage depends on the velocity component of an exhaust gas that is perpendicular to the minimal outflow width portion. Further, in the embodiment, the respective

inner sides side tongue 46 and the rear-side tongue 48 and the respective minimaloutflow width portions side passage 22 and the rear-side passage 24 are formed substantially parallel to each other as shown inFig. 4(a) . For this reason, exhaust gases e and e, which pass through the respective minimaloutflow width portions side passage 22 and the rear-side passage 24, flow in directions perpendicular to the respective minimaloutflow width portions side passage 22 and the rear-side passage 24 are also substantially equal to each other. - In contrast, in the comparative example, as shown in

Fig. 4(b) , the respectiveinner sides side tongue 146 and the rear-side tongue 148 are formed together in a flat shape and theinner side 148a and a minimaloutflow width portion 158a are formed substantially parallel to each other, but theinner side 146a and a minimaloutflow width portion 156a are not formed substantially parallel to each other. Accordingly, as shown inFig. 4(b) , the flow of an exhaust gas e', which flows out from a front-side passage 122, is biased and the exhaust gas e' flows at a flow velocity different from the flow velocity of an exhaust gas e' that flows out from a rear-side passage 124. Therefore, the flow rates of the exhaust gases, which flow out from the front-side passage 122 and the rear-side passage 124, are different from each other. - As described above, in the scroll structure of the

turbine housing 32 of the invention, the respectiveinner sides side tongue 46 and the rear-side tongue 48 and the respective minimaloutflow width portions side passage 22 and the rear-side passage 24 are formed substantially parallel to each other. Accordingly, a difference between the flow-through abilities of the two exhaust gas passages, which is caused by the inclination of thepartition wall 28 with respect to the central axis 36' of the turbine shaft, is corrected, so that it is possible to make the flow-through abilities of the front-side passage 22 and the rear-side passage 24 equal to each other. Further, in this case, if the front-side passage 22 and the rear-side passage 24 are formed to be substantially symmetrical with respect to the central axis 28' of thepartition wall 28 in the cross-section at the downstream end of the outerperipheral portion 26a as described above, it is possible to make the flow-through abilities of the front-side passage 22 and the rear-side passage 24 more accurately equal to each other. - Incidentally, the above-mentioned

turbine housing 32 of the invention is manufactured by casting. For this reason, as shown inFig. 5(a) , an extrathick portion 38a is formed on an inner peripheral portion (shroud portion 38) of theturbine housing 32 near arotor blade 42 and is cut by acutting tool 37 for a lathe, so that the inner peripheral portion is formed in a desired shape corresponding to the shape of therotor blade 42. - In the above-mentioned comparative example not falling within the scope of the claims, as shown in

Fig. 5(b) , the front-side tongue 146 is not cut even when an extrathick portion 138a is cut by a cutting tool 137 for a lathe. Even if a part of anouter side 146b of the front-side tongue 146 is cut, there is no particular problem since the front-side tongue 146 of the comparative example is formed to be sufficiently thick. - In contrast, if a part of an

outer side 46b of the front-side tongue 46 is cut as shown inFig. 5(a) in the embodiment according to the invention, there is the following problem. That is, the front-side tongue 46 is a portion exposed to a high-temperature exhaust gas. Accordingly, if a part of theouter side 46b of the front-side tongue 46 is cut and a thin portion is locally formed at the front-side tongue 46, there is a concern that cracks caused by thermal stress may be generated at the thin portion. Therefore, in this case, if a build-upportion 49 corresponding to acut portion 47 is formed on theinner side 46a and a portion of the front-side tongue 46, which is formed on the back of theouter side 46b and is close to theinner side 46a, is formed to be thicker by at least the thickness of a portion of theouter side 46b to be cut, it is possible to avoid the generation of cracks that are caused by local thermal stress. -

Fig. 6 is a view illustrating the flows of exhaust gases at the respective minimal outflow width portions of the front-side passage 22 and the rear-side passage 24,Fig. 6(a) is a cross-sectional view, andFigs. 6(b) to 6(d) are plan views of the respective tongues as seen from above. As shown inFig. 6(b) , a portion of the rear-side tongue 48 close to arear wall surface 24a extends downstream more than a portion of the rear-side tongue 48 close to apartition wall surface 28a, at the downstream end of the rear-side tongue 48. Likewise, as shown inFig. 6(c) , a portion of the front-side tongue 46 close to afront wall surface 22a extends downstream more than a portion of the front-side tongue 46 close to apartition wall surface 28a even at the downstream end of the front-side tongue 46. - A radial component of a flow velocity vector of each of the exhaust gases, which flow near the

partition wall surfaces 28a, therear wall surface 24a, and thefront wall surface 22a, is predominant with respect to a circumferential component thereof due to the resistance of the wall surfaces. That is, the exhaust gases, which flow near thepartition wall surfaces 28a, therear wall surface 24a, and thefront wall surface 22a, early and easily flow to theturbine rotor 40 as compared to the exhaust gases that flow near intermediate positions between thepartition wall surface 28a and therear wall surface 24a and between thepartition wall surface 28a and thefront wall surface 22a. - Accordingly, if the rear-

side tongue 48 and the front-side tongue 46 are formed as shown inFigs. 6(b) and 6(c) , exhaust gases ea flowing close to the partition wall surfaces 28a more early and easily flow to theturbine rotor 40 than exhaust gases eb flowing close to therear wall surface 24a and thefront wall surface 22a in both the rear-side passage 24 and the front-side passage 22. Accordingly, the exhaust gases flow so as to concentrate on the center of therotor blade 42 in the cross-section, so that it is possible to efficiently rotate theturbine rotor 40. Further, if the width of the front-side tongue 46 extending downward is increased and the length of the front-side tongue 46 is also increased as shown inFig. 6(d) instead ofFig. 6(c) , it is possible to further increase the flow rate of the exhaust gases ea in the front-side passage 22. That is, it is possible to adjust a flow rate ratio between the above-mentioned exhaust gases ea and eb to a desired ratio by adjusting the width and length of the front-side tongue 46 or the rear-side tongue 48 that extends downward. - A preferred embodiment of the invention has been described above. However, the invention is not limited to the above-mentioned embodiment, and may have various modifications without departing from the purpose of the invention.

- According to the invention, the invention can be suitably used as a scroll structure of a turbine housing of a twin scroll turbocharger that includes a dual exhaust gas passage introducing exhaust gases to a turbine rotor.

Claims (5)

- A scroll structure of a turbine housing (32) of a twin scroll turbocharger (30) comprising:a scroll portion (26) that introduces an exhaust gas (e) to a turbine rotor (40), wherein the scroll portion (26) includes two exhaust gas passages (22, 24), that is, a front-side passage (22) and a rear-side passage (24), which are partitioned by a partition wall (28) in a cross-section perpendicular to a flow direction of the exhaust gas (e),the partition wall (28) is inclined with respect to a turbine shaft (36),a tongue (44), which partitions the scroll portion (26) into an outer peripheral portion (26a) and an inner peripheral portion (26b) in a longitudinal section parallel to the flow direction of the exhaust gas (e), is formed at the turbine housing (32),the tongue (44) includes a front-side tongue (46) and a rear-side tongue (48) that respectively close the two exhaust gas passages (22, 24) at the outer peripheral portion (26a) in the cross-section,respective inner sides (46a, 48a) of the front-side tongue (46) and the rear-side tongue (48) and respective minimal outflow width portions (56a, 58a) of the front-side passage (22) and the rear-side passage (28) are formed substantially parallel to each other in the cross-section at a downstream end of the outer peripheral portion (26a),characterized in that a part of an outer side (46b) of the front-side tongue (46) is cut to form a cut portion (47), andwherein a build-up portion (49), corresponding to the cut portion (47) is formed on the inner side (46a) of the front-side tongue (46).

- The scroll structure of the turbine housing (32) according to claim 1,

wherein angles, which are formed between the inner sides (46a, 48a) of the front-side tongue (46) and the rear-side tongue (48) and the minimal outflow width portions (56a, 58a) of the front-side passage (22) and the rear-side passage (24) in the cross-section at the downstream end of the outer peripheral portion (26a), are in the range of -10° to +10°. - The scroll structure of the turbine housing (32) according to claim 1 or 2,

wherein the front-side passage (22) and the rear-side passage (24) are formed to be substantially symmetrical with respect to a central axis (28') of the partition wall (28) in the cross-section at the downstream end of the outer peripheral portion (26a). - The scroll structure of the turbine housing (32) according to any one of claims 1 to 3,

wherein a portion of the rear-side tongue (48) close to a rear wall surface (24a) extends downstream more than a portion of the rear-side tongue (48) close to a partition wall surface (28a) at a downstream end of the rear-side tongue (48). - The scroll structure of the turbine housing (32) according to any one of claims 1 to 4,

wherein a portion of the front-side tongue (46) close to a front wall surface (22a) extends downstream more than a portion of the front-side tongue (46) close to the partition wall surface (28a), at a downstream end of the front-side tongue (46).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012002756A JP5964056B2 (en) | 2012-01-11 | 2012-01-11 | Scroll structure of turbine housing |

| PCT/JP2012/076173 WO2013105316A1 (en) | 2012-01-11 | 2012-10-10 | Scroll structure of turbine housing |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2803839A1 EP2803839A1 (en) | 2014-11-19 |

| EP2803839A4 EP2803839A4 (en) | 2015-09-02 |

| EP2803839B1 true EP2803839B1 (en) | 2020-01-15 |

Family

ID=48781280

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12864916.7A Active EP2803839B1 (en) | 2012-01-11 | 2012-10-10 | Scroll structure of turbine housing |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US9874222B2 (en) |

| EP (1) | EP2803839B1 (en) |

| JP (1) | JP5964056B2 (en) |

| CN (1) | CN103874835B (en) |

| WO (1) | WO2013105316A1 (en) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB201322206D0 (en) * | 2013-12-16 | 2014-01-29 | Cummins Ltd | Turbine housing |

| DE102015205329A1 (en) * | 2015-03-24 | 2016-09-29 | Bosch Mahle Turbo Systems Gmbh & Co. Kg | Turbine housing and associated exhaust gas turbocharger |

| DE102015205998A1 (en) | 2015-04-02 | 2016-10-06 | Ford Global Technologies, Llc | Charged internal combustion engine with double-flow turbine and grouped cylinders |

| DE102016008273A1 (en) * | 2016-03-15 | 2017-09-21 | Daimler Ag | Turbine housing for a turbine of an exhaust gas turbocharger |

| DE102016013346A1 (en) * | 2016-11-09 | 2018-05-09 | Daimler Ag | Turbine housing for a turbine of an exhaust gas turbocharger |

| DE112018000945B4 (en) * | 2017-02-22 | 2022-12-08 | Ihi Corporation | turbocharger |

| GB2561837A (en) * | 2017-04-24 | 2018-10-31 | Hieta Tech Limited | Turbine rotor, turbine, apparatus and method |

| US10570822B2 (en) * | 2017-06-26 | 2020-02-25 | Garrett Transportation I Inc. | Exhaust manifold system for turbocharger device with plural volute members |

| GB201712182D0 (en) | 2017-07-28 | 2017-09-13 | Cummins Ltd | Diffuser space for a turbine of a turbomachine |

| GB2568732B (en) * | 2017-11-24 | 2021-05-05 | Cummins Ltd | Turbine |

| JP6947304B2 (en) * | 2018-06-29 | 2021-10-13 | 株式会社Ihi | Turbines and turbochargers |

| US11085311B2 (en) * | 2019-03-12 | 2021-08-10 | Garrett Transportation I Inc. | Turbocharger with twin-scroll turbine housing and twin vaned nozzle ring for directing exhaust gases from each scroll onto turbine wheel in interleaved fashion |

| JPWO2020209146A1 (en) | 2019-04-10 | 2020-10-15 | ||

| WO2023085178A1 (en) * | 2021-11-09 | 2023-05-19 | 株式会社Ihi | Turbine and supercharger |

| WO2024105784A1 (en) * | 2022-11-15 | 2024-05-23 | 株式会社Ihi | Turbine and supercharger |

| WO2024116411A1 (en) * | 2022-12-02 | 2024-06-06 | 三菱重工エンジン&ターボチャージャ株式会社 | Turbine housing, turbine, and turbo charger |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63140U (en) * | 1986-06-18 | 1988-01-05 | ||

| JPS63141836U (en) * | 1987-03-11 | 1988-09-19 | ||

| JPH0166433U (en) * | 1987-10-22 | 1989-04-27 | ||

| JP3253978B2 (en) | 1990-12-10 | 2002-02-04 | 雅弘 井上 | Turbine scroll |

| JP3104381B2 (en) * | 1992-03-26 | 2000-10-30 | 石川島播磨重工業株式会社 | Turbocharger turbine housing |

| JP2586822Y2 (en) * | 1992-03-27 | 1998-12-14 | 段谷産業株式会社 | Accessory storage box |

| US6742989B2 (en) | 2001-10-19 | 2004-06-01 | Mitsubishi Heavy Industries, Ltd. | Structures of turbine scroll and blades |

| JP3534728B2 (en) | 2001-10-19 | 2004-06-07 | 三菱重工業株式会社 | Scroll structure of radial turbine |

| JP4548237B2 (en) | 2005-06-17 | 2010-09-22 | トヨタ自動車株式会社 | Turbocharger twin scroll turbine housing |

| JP5106818B2 (en) | 2006-10-20 | 2012-12-26 | 三菱重工業株式会社 | Exhaust turbocharger structure with wastegate valve |

| JP2009281197A (en) * | 2008-05-20 | 2009-12-03 | Mitsubishi Heavy Ind Ltd | Mixed flow turbine |

| EP2249002B1 (en) | 2008-10-20 | 2018-10-03 | Mitsubishi Heavy Industries, Ltd. | Radial turbine scroll structure |

-

2012

- 2012-01-11 JP JP2012002756A patent/JP5964056B2/en active Active

- 2012-10-10 CN CN201280049585.5A patent/CN103874835B/en active Active

- 2012-10-10 WO PCT/JP2012/076173 patent/WO2013105316A1/en active Application Filing

- 2012-10-10 EP EP12864916.7A patent/EP2803839B1/en active Active

- 2012-10-10 US US14/350,494 patent/US9874222B2/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2803839A4 (en) | 2015-09-02 |

| CN103874835A (en) | 2014-06-18 |

| US9874222B2 (en) | 2018-01-23 |

| JP5964056B2 (en) | 2016-08-03 |

| JP2013142324A (en) | 2013-07-22 |

| CN103874835B (en) | 2016-03-30 |

| EP2803839A1 (en) | 2014-11-19 |

| WO2013105316A1 (en) | 2013-07-18 |

| US20140294577A1 (en) | 2014-10-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2803839B1 (en) | Scroll structure of turbine housing | |

| EP2948641B1 (en) | Seal assembly in a gas turbine engine including grooves in a radially outwardly facing side of a platform and in a inwardly facing side of an inner shroud | |

| EP2249002B1 (en) | Radial turbine scroll structure | |

| EP3163023B1 (en) | Turbine bucket with cooling passage in the shroud | |

| US8757965B2 (en) | Gas turbine compression system and compressor structure | |

| EP2692994B1 (en) | Turbine of a turbocharger | |

| EP2948639B1 (en) | Seal assembly including grooves in an inner shroud in a gas turbine engine | |

| JP5611379B2 (en) | Impeller for turbocharger, method for manufacturing impeller for turbocharger, turbocharger, and turbo unit | |

| JP6351049B2 (en) | Turbine housing and method for manufacturing turbine housing | |

| US20150064020A1 (en) | Turbine blade or vane with separate endwall | |

| CN107989657B (en) | Turbine blade with trailing edge cooling circuit | |

| JP2009047043A (en) | Axial flow turbine | |

| US11078797B2 (en) | Turbine bucket having outlet path in shroud | |

| WO2000071873A1 (en) | Variable displacement turbo supercharger | |

| WO2008060195A1 (en) | Vane assembly configured for turning a flow ina a gas turbine engine, a stator component comprising the vane assembly, a gas turbine and an aircraft jet engine | |

| JP5374563B2 (en) | Axial flow turbine | |

| EP2799689A1 (en) | Twin-scroll turbocharger | |

| EP3336318B1 (en) | Struts for exhaust frames of turbine systems | |

| US20190010819A1 (en) | Turbomachine sealing element | |

| EP3153674A1 (en) | Integrated turbine exhaust case mixer design | |

| SE528183C2 (en) | Gas turbine compressor system for aircraft engine, has compression structure held directly downstream last rotor in low pressure compression section and has several struts having cambered shape | |

| EP3693551A1 (en) | Diffuser assemblies for compression systems | |

| WO2024048211A1 (en) | Gas turbine stationary blade and gas turbine | |

| CN209818121U (en) | Twin scroll turbine housing | |

| JP2017057779A (en) | Turbo charger |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140331 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RA4 | Supplementary search report drawn up and despatched (corrected) |

Effective date: 20150804 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F01D 9/02 20060101AFI20150729BHEP Ipc: F02B 37/02 20060101ALI20150729BHEP Ipc: F02C 6/12 20060101ALI20150729BHEP |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: MITSUBISHI HEAVY INDUSTRIES ENGINE & TURBOCHARGER, |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20190806 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012067325 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1225315 Country of ref document: AT Kind code of ref document: T Effective date: 20200215 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200607 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200415 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200515 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200416 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012067325 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20200914 Year of fee payment: 9 Ref country code: NL Payment date: 20200915 Year of fee payment: 9 Ref country code: GB Payment date: 20200930 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1225315 Country of ref document: AT Kind code of ref document: T Effective date: 20200115 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20201016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201010 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20201031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201031 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201010 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20211101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20211010 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211101 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211010 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211031 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230830 Year of fee payment: 12 |