EP2665663B1 - Brewing device - Google Patents

Brewing device Download PDFInfo

- Publication number

- EP2665663B1 EP2665663B1 EP12701366.2A EP12701366A EP2665663B1 EP 2665663 B1 EP2665663 B1 EP 2665663B1 EP 12701366 A EP12701366 A EP 12701366A EP 2665663 B1 EP2665663 B1 EP 2665663B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- actuator

- handle

- brewing device

- frame

- brewing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/70—Containers, packaging elements or packages, specially adapted for particular articles or materials for materials not otherwise provided for

- B65D85/804—Disposable containers or packages with contents which are mixed, infused or dissolved in situ, i.e. without having been previously removed from the package

- B65D85/808—Disposable containers or packages with contents which are mixed, infused or dissolved in situ, i.e. without having been previously removed from the package for immersion in the liquid to release part or all of their contents, e.g. tea bags

- B65D85/812—Disposable containers or packages with contents which are mixed, infused or dissolved in situ, i.e. without having been previously removed from the package for immersion in the liquid to release part or all of their contents, e.g. tea bags with features facilitating their manipulation or suspension

Definitions

- the present invention relates to a brewing device according to the preamble of claim 1, particularly to a brewing device for brewing tea or coffee.

- Tea and coffee are typically prepared by infusion brewing, i.e., by steeping tea leaves or coffee grounds in hot water.

- a variety of devices are available for separating spent coffee grounds or tea leaves from a brewed drink.

- a French press uses a mesh filter fitted to a plunger to extract spent coffee grounds from the brew.

- a commonly-used tea infuser comprises a mesh cage, which separates the tea leaves from the brew during steeping. The press and mesh cage must each be emptied and cleaned after use.

- GB 2420356 which accords with the preamble of claim 1, discloses an infusion bag with a pair of pulling strips secured to a bottom seam and passing through a handle, and used to squeeze a tea bag.

- the present invention seeks to provide a brewing device for brewing tea or coffee by infusion. It is an aim of the present invention to provide a single-use device that is convenient, cost-effective to produce and simple to use.

- the present invention provides a brewing device for brewing tea or coffee comprising a handle, an actuator and a steeping portion, characterised in that said steeping portion comprises a squeezing strip and a resiliently deformable frame for retraining a porous or filter bag, said actuator is arranged to extend through said handle, and said squeezing strip is operative to, on relative motion of said handle and actuator, deform said frame and any said retained bag in a squeezing action.

- the steeping portion comprises a resiliently deformable frame, more preferably a triangular or circular frame.

- the handle is formed as an elongate element, preferably tubular.

- the handle is integral the frame and the actuator is integral the squeezing strip.

- the handle is integral the squeezing strip and the actuator is integral the frame.

- the device further comprises cooperative locking means in the actuator and handle to retain said steeping portion in a squeezed orientation.

- the locking means comprises at least one barb, flap or stud on the actuator for engaging said handle portion.

- the at least one barb has a first, non-locking, configuration, in which it is flush with the actuator and a second, locking, configuration, in which it projects from the actuator.

- the brewing device is made substantially from paper, preferably waxed or water-resistant paper.

- the squeezing means is made from paper, preferably, waxed or water-resistant paper.

- the brewing device is packaged with a porous bag containing loose-leaf tea, broken-leaf tea, fannings or ground coffee.

- the porous bag is retained by the steeping portion.

- the porous bag is secured to the steeping portion by means of an adhesive strip.

- the device comprises at least one compartment for storing powdered milk, sugar, sweetener or a mixture thereof.

- at least one compartment is provided on an exterior wall of the handle portion or within the actuator element.

- Figure 1 illustrates a brewing device having a handle 10, a steeping portion 11 and a squeezer strip 12.

- Handle 10 is a hollow element having a grip end 20 and a stirring end 21. Steeping portion 11 adjoins stirring end 21 of handle 10.

- Squeezer strip 12 engages steeping portion 11 and handle 10.

- squeezer strip 12 engages an edge 14 of steeping portion 11 and is received by an open base of stirring end 21 of handle 10.

- Squeezer strip 12 extends from stirring end 21 to grip end 20.

- Grip end 20 has a sealed top, adjacent which is a slit 36 for engaging squeezer strip 12.

- Steeping portion 11 comprises a generally triangular-shaped frame 22.

- a porous bag 40 containing tea leaves or coffee grounds, is retained in triangular frame 22.

- Bag 40 has an adhesive strip 39 for attaching bag 40 to frame 22.

- Triangular frame 22 has an upper apex 15 and two lower apices 30, 31. Upper apex 15 adjoins stirring end 21 of handle 10. Opposite apex 15 is edge 14.

- a first end of squeezer strip 12 comprises a loop that encircles steeping portion 11.

- the loop encircles edge 14 of triangular frame 22.

- a second end of squeezer strip 12 comprises an actuator element 13 in the form of tab.

- the tab projects from slit 36.

- Locking means in the form of a plurality of barbs 37, is provided on actuator 13 ( Figures 3a and 3b ).

- barbs 37 have a first configuration in which they are flush with actuator 13, and a second configuration, in which they project outwards from actuator 13 ( Figure 3a ).

- the second configuration is obtainable by bending actuator (13).

- Squeezer strip 12 is operated by pulling the actuator tab in a direction that is away from frame 22 and perpendicular to edge 14.

- Triangular frame 22 is resiliently deformable, and in particular, edge 14 can be moved towards, and away-from, apex 15 by operation of squeezer strip 12. Movement of edge 14 towards apex 15 causes compression of bag 40 retained within triangular frame 22. Once the pulling force is removed from tab 13, squeezer strip 12 will relax and frame 22 will return to its original, non-compressed, configuration.

- handle 10 includes one or more storage compartments (not shown) for storing a portion of powdered milk, sugar or artificial sweetener (or mixture thereof). Conveniently, the compartment is formed on an outer wall of handle 10.

- the brewing device of the present invention will be packaged with a porous bag 40, containing either tea leaves or coffee grounds, retained in steeping portion 11.

- steeping portion 11 and bag 40, retained therein

- tab 13 can be pulled (to compress bag 40) and released, in order to speed-up the infusion process.

- the device is removed from the water and tab 13 is pulled to squeeze liquid from bag 40.

- Tab 13 can be pulled and released several times to squeeze additional liquid tea or coffee from bag 40.

- barbs 37 Prior to disposal of the device, barbs 37 are aligned adjacent slit 36 ( Figures 3a and 3b ) by pulling tab 13.

- Tab 13 is held in this final, locked, position by engagement of one of barbs 37 with handle 10.

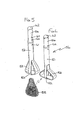

- a second embodiment 50 is illustrated in Figures 5 to 9 .

- This embodiment is arranged to provide a "push to squeeze" operation, but the construction is broadly similar.

- Handle 51 is formed integrally with squeezing strip 52.

- Frame 53 of the steeping portion is formed integrally with squeezing actuator element 54 which passes within handle 51.

- Actuator element 54 and handle 51 are conveniently both tubular.

- pushing down on squeezing actuator 54 causes the lower edge of frame 53 to pull upwards against a bag 55 positioned within the frame, thereby compressing the bag 55 against a lower portion of frame 53, restrained by squeezing strip 52.

- this embodiment of the brewing device also includes locking means into the form of a series of studs 60 formed on squeezing actuator 54 engageable with an aperture 61 formed in corresponding location in handle 51.

- tubular actuator element 54 forms or includes a container to contain sugar or powdered milk or cream; or a mixture of the two, sealed by a cap or seal 62. It will be appreciated that the container will also have a closure at a lower end to retain the powdered materials.

- the brewing device of the present invention is intended as a single-use product, sold as a factory-assembled unit. Since the device is not intended to brew multiple servings of tea or coffee, the handle and steeping portions can be formed entirely from paper, preferably waxed or water-resistant paper. Consequently, the device is simple and cost-effective to produce, as well as being straightforward to recycle. Furthermore, once a drink has been prepared, the device and bag can be disposed of as a single unit.

Description

- The present invention relates to a brewing device according to the preamble of claim 1, particularly to a brewing device for brewing tea or coffee.

- Tea and coffee are typically prepared by infusion brewing, i.e., by steeping tea leaves or coffee grounds in hot water. A variety of devices are available for separating spent coffee grounds or tea leaves from a brewed drink. For example, a French press uses a mesh filter fitted to a plunger to extract spent coffee grounds from the brew. When brewing loose-leaf tea, it is traditional to use a tea infuser. A commonly-used tea infuser comprises a mesh cage, which separates the tea leaves from the brew during steeping. The press and mesh cage must each be emptied and cleaned after use.

-

GB 2420356 - The present invention seeks to provide a brewing device for brewing tea or coffee by infusion. It is an aim of the present invention to provide a single-use device that is convenient, cost-effective to produce and simple to use.

- In one aspect, the present invention provides a brewing device for brewing tea or coffee comprising a handle, an actuator and a steeping portion, characterised in that said steeping portion comprises a squeezing strip and a resiliently deformable frame for retraining a porous or filter bag, said actuator is arranged to extend through said handle, and said squeezing strip is operative to, on relative motion of said handle and actuator, deform said frame and any said retained bag in a squeezing action.

- The steeping portion comprises a resiliently deformable frame, more preferably a triangular or circular frame.

- Suitably, the handle is formed as an elongate element, preferably tubular.

- In one embodiment, the handle is integral the frame and the actuator is integral the squeezing strip.

- In a further embodiment the handle is integral the squeezing strip and the actuator is integral the frame.

- Preferably the device further comprises cooperative locking means in the actuator and handle to retain said steeping portion in a squeezed orientation.

- Preferably the locking means comprises at least one barb, flap or stud on the actuator for engaging said handle portion.

- Preferably the at least one barb has a first, non-locking, configuration, in which it is flush with the actuator and a second, locking, configuration, in which it projects from the actuator.

- In a preferred embodiment, the brewing device is made substantially from paper, preferably waxed or water-resistant paper.

- In preferred embodiments, the squeezing means is made from paper, preferably, waxed or water-resistant paper.

- In one embodiment, the brewing device is packaged with a porous bag containing loose-leaf tea, broken-leaf tea, fannings or ground coffee. Preferably, the porous bag is retained by the steeping portion. In one embodiment, the porous bag is secured to the steeping portion by means of an adhesive strip.

- Advantageously, the device comprises at least one compartment for storing powdered milk, sugar, sweetener or a mixture thereof. Suitably, at least one compartment is provided on an exterior wall of the handle portion or within the actuator element.

- The above and other aspects of the present invention will now be described in further detail, by way of example only, with reference to the accompanying drawings, in which:

-

Figure 1 illustrates two perspective views of a first embodiment of a brewing device in accordance with the present invention; -

Figure 2 illustrates a porous bag suitable for use with the embodiment ofFigure 1 ; -

Figures 3a and 3b are a series of partial perspective views of the embodiment 1, illustrating locking of the squeezing means; -

Figure 4 illustrates two perspective views of the embodiment ofFigure 1 , showing the apparatus in use; -

Figure 5 is a perspective view of a second embodiment of a brewing device in accordance with the present invention, in a first configuration; -

Figure 6 is a perspective view of the embodiment ofFigure 5 in a second configuration; -

Figure 7 illustrates the operation of the embodiment ofFigure 5 in use; and -

Figure 8 illustrates a storage compartment in the embodiment ofFigure 5 . -

Figure 1 illustrates a brewing device having ahandle 10, asteeping portion 11 and asqueezer strip 12.Handle 10 is a hollow element having agrip end 20 and a stirring end 21. Steepingportion 11 adjoins stirring end 21 ofhandle 10. Squeezerstrip 12 engages steepingportion 11 and handle 10. In particular,squeezer strip 12 engages anedge 14 of steepingportion 11 and is received by an open base of stirring end 21 ofhandle 10. Squeezerstrip 12 extends from stirring end 21 to gripend 20.Grip end 20 has a sealed top, adjacent which is aslit 36 for engagingsqueezer strip 12. - Steeping

portion 11 comprises a generally triangular-shaped frame 22. Aporous bag 40, containing tea leaves or coffee grounds, is retained intriangular frame 22.Bag 40 has anadhesive strip 39 for attachingbag 40 toframe 22.Triangular frame 22 has an upper apex 15 and twolower apices 30, 31. Upper apex 15 adjoins stirring end 21 ofhandle 10. Opposite apex 15 isedge 14. - A first end of

squeezer strip 12 comprises a loop thatencircles steeping portion 11. In particular, theloop encircles edge 14 oftriangular frame 22. A second end ofsqueezer strip 12 comprises anactuator element 13 in the form of tab. The tab projects fromslit 36. Locking means, in the form of a plurality ofbarbs 37, is provided on actuator 13 (Figures 3a and 3b ). In one embodiment,barbs 37 have a first configuration in which they are flush withactuator 13, and a second configuration, in which they project outwards from actuator 13 (Figure 3a ). The second configuration is obtainable by bending actuator (13). - Squeezer

strip 12 is operated by pulling the actuator tab in a direction that is away fromframe 22 and perpendicular toedge 14.Triangular frame 22 is resiliently deformable, and in particular,edge 14 can be moved towards, and away-from, apex 15 by operation ofsqueezer strip 12. Movement ofedge 14 towards apex 15 causes compression ofbag 40 retained withintriangular frame 22. Once the pulling force is removed fromtab 13,squeezer strip 12 will relax andframe 22 will return to its original, non-compressed, configuration. - In certain embodiments,

handle 10 includes one or more storage compartments (not shown) for storing a portion of powdered milk, sugar or artificial sweetener (or mixture thereof). Conveniently, the compartment is formed on an outer wall ofhandle 10. - It is intended that the brewing device of the present invention will be packaged with a

porous bag 40, containing either tea leaves or coffee grounds, retained in steepingportion 11. In use of the brewing device, steeping portion 11 (andbag 40, retained therein) is submerged in a cup of hot water and stirred usinghandle 10. During steeping,tab 13 can be pulled (to compress bag 40) and released, in order to speed-up the infusion process. Once a drink has been prepared, the device is removed from the water andtab 13 is pulled to squeeze liquid frombag 40.Tab 13 can be pulled and released several times to squeeze additional liquid tea or coffee frombag 40. Prior to disposal of the device,barbs 37 are aligned adjacent slit 36 (Figures 3a and 3b ) by pullingtab 13.Tab 13 is held in this final, locked, position by engagement of one ofbarbs 37 withhandle 10. - A second embodiment 50 is illustrated in

Figures 5 to 9 . This embodiment is arranged to provide a "push to squeeze" operation, but the construction is broadly similar.Handle 51 is formed integrally with squeezingstrip 52.Frame 53 of the steeping portion is formed integrally with squeezingactuator element 54 which passes withinhandle 51.Actuator element 54 and handle 51 are conveniently both tubular. As can be seen by a comparison ofFigure 5 and Figure 6 and also fromFigure 7 , pushing down on squeezingactuator 54 causes the lower edge offrame 53 to pull upwards against a bag 55 positioned within the frame, thereby compressing the bag 55 against a lower portion offrame 53, restrained by squeezingstrip 52. - As shown in

Figures 5 to 7 , advantageously, this embodiment of the brewing device also includes locking means into the form of a series ofstuds 60 formed on squeezingactuator 54 engageable with an aperture 61 formed in corresponding location inhandle 51. - As shown in

Figure 8 , suitablytubular actuator element 54 forms or includes a container to contain sugar or powdered milk or cream; or a mixture of the two, sealed by a cap orseal 62. It will be appreciated that the container will also have a closure at a lower end to retain the powdered materials. - The brewing device of the present invention is intended as a single-use product, sold as a factory-assembled unit. Since the device is not intended to brew multiple servings of tea or coffee, the handle and steeping portions can be formed entirely from paper, preferably waxed or water-resistant paper. Consequently, the device is simple and cost-effective to produce, as well as being straightforward to recycle. Furthermore, once a drink has been prepared, the device and bag can be disposed of as a single unit.

Claims (12)

- A brewing device for brewing tea or coffee comprising a handle (10,51), an actuator (13, 54), and a steeping portion, characterised in that

said steeping portion comprises a squeezing strip (12,52) and a resiliently deformable frame (22,53) for retaining a porous or filter bag,

said actuator (13,54) is arranged to extend through said handle (10,51), and said squeezing strip is operative to, on relative motion of said handle (10,51) and actuator, deform said frame (22,53) and any said retained bag in a squeezing action. - A brewing device as claimed in claim 1, wherein the frame (22,53) is triangular or circular.

- A brewing device as claimed in claim 1 or claim 2, wherein the handle (10,52) is formed as an elongate element, preferably tubular.

- A brewing device as claimed in any preceding claim wherein said handle (10) is integral with said frame (22).

- A brewing device as claimed in any preceding claim wherein said actuator (13) is integral with said squeezing strip (12).

- A brewing device as claimed in any of claims 1 to 3, wherein said handle (51) is integral with said squeezing strip (52)

- A brewing device as claimed in any of claims 1 to 3, wherein said actuator (54) is integral with said frame (53).

- A brewing device as claimed in any one of the preceding claims, further comprising cooperative locking means (37,60) in the actuator (13,54) and handle (10,51) to retain said steeping portion in a squeezed orientation.

- A brewing device as claimed in claim 8, wherein the locking means comprises at least one barb (37), flap or stud (60) on the actuator for engaging said handle portion (10,51).

- A brewing device as claimed in claim 9, wherein said at least one barb (37) has a first, non-locking, configuration, in which it is flush with the actuator (13) and a second, locking configuration, in which it projects from the actuator, said second configuration being obtainable by bending the actuator (13).

- A brewing device as claimed in any one of the preceding claims formed substantially from paper, preferably waxed or water-resistant paper.

- A brewing device as claimed in any one of the preceding claims wherein the handle portion comprises a compartment for storing powdered milk, sugar, artificial sweetener, or mixtures thereof.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL12701366T PL2665663T3 (en) | 2011-01-19 | 2012-01-19 | Brewing device |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GBGB1100871.1A GB201100871D0 (en) | 2011-01-19 | 2011-01-19 | A brewing device |

| PCT/GB2012/050113 WO2012098402A1 (en) | 2011-01-19 | 2012-01-19 | Brewing device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2665663A1 EP2665663A1 (en) | 2013-11-27 |

| EP2665663B1 true EP2665663B1 (en) | 2015-07-29 |

Family

ID=43736633

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12701366.2A Not-in-force EP2665663B1 (en) | 2011-01-19 | 2012-01-19 | Brewing device |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US20140030385A1 (en) |

| EP (1) | EP2665663B1 (en) |

| JP (1) | JP5993874B2 (en) |

| CN (1) | CN103596856B (en) |

| CA (1) | CA2861271C (en) |

| ES (1) | ES2550194T3 (en) |

| GB (2) | GB201100871D0 (en) |

| PL (1) | PL2665663T3 (en) |

| WO (1) | WO2012098402A1 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103892707A (en) * | 2012-12-31 | 2014-07-02 | 苏州工业园区咖乐美电器有限公司 | Coffee brewing device |

| DE102014007576B4 (en) * | 2014-05-22 | 2016-10-27 | Sabine Capella | Device for squeezing a tea bag |

| GB201418221D0 (en) * | 2014-10-14 | 2014-11-26 | Sales Alan C | Apparatus for use when making a beverage from a bag containing a beverage concentrate |

| GB2533616B (en) * | 2014-12-23 | 2018-09-05 | Milne Downie Donald | Infusion Device and Method of Making Same |

| GB2545462A (en) * | 2015-12-17 | 2017-06-21 | Milne Downie Donald | Device for infusing an infusionable substance |

| CN109645822A (en) * | 2017-10-11 | 2019-04-19 | 林紫绮 | Non-overflow brews filter and spiral hanger structure |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2678000A (en) * | 1952-05-22 | 1954-05-11 | Scheidt Joseph | Tea bag holder |

| US4991746A (en) * | 1989-07-07 | 1991-02-12 | Emson Research Inc. | Modular pump having a locking rotatable sleeve |

| EE9600122A (en) * | 1993-12-03 | 1997-04-15 | Sidiropolous Perry | Infuser |

| AU696142B2 (en) * | 1996-05-21 | 1998-09-03 | Ross William Bain | Infusion apparatus |

| US5979748A (en) * | 1997-02-06 | 1999-11-09 | Sonoco Development, Inc. | Tubular container with a heat seal having an inner and outer bead and method of manufacturing said container |

| CN100364864C (en) * | 2002-07-17 | 2008-01-30 | 米德韦斯瓦科公司 | Product container with locking end cap |

| US7591219B2 (en) * | 2004-05-26 | 2009-09-22 | Pamela Saha | Disposable combined squeezer/stirrer/dispenser/brewer device |

| GB2420069B (en) * | 2004-11-13 | 2007-07-18 | Martin John Almond | Infusion tool |

| KR20070085329A (en) * | 2004-11-13 | 2007-08-27 | 마틴 존 알몬드 | Infusing device |

| GB2420336B (en) * | 2004-11-23 | 2007-12-12 | Martin John Almond | Infusion package |

| DE102005028618B4 (en) * | 2005-06-20 | 2007-09-06 | Mohammed Bozkurt | Instant coffee spoon |

| WO2007003009A1 (en) * | 2005-07-04 | 2007-01-11 | Steve Segaram | Tea infusion assembly |

| US7704366B2 (en) * | 2005-08-17 | 2010-04-27 | Trevor Pearson | Pretreatment of magnesium substrates for electroplating |

| WO2007102137A2 (en) * | 2006-03-09 | 2007-09-13 | Omer Faruk Ilhan | A stirring tool |

| FR2944688A1 (en) * | 2009-04-22 | 2010-10-29 | Karim Saada | Device for serving e.g. tea in tube, has perforated zone placed with tea and enclosing flexible paper filter, and mobile washer raising and descending when drawn on cord using hook |

-

2011

- 2011-01-19 GB GBGB1100871.1A patent/GB201100871D0/en not_active Ceased

-

2012

- 2012-01-19 PL PL12701366T patent/PL2665663T3/en unknown

- 2012-01-19 CN CN201280014217.7A patent/CN103596856B/en not_active Expired - Fee Related

- 2012-01-19 JP JP2013549890A patent/JP5993874B2/en not_active Expired - Fee Related

- 2012-01-19 GB GB1314065.2A patent/GB2500855B/en not_active Expired - Fee Related

- 2012-01-19 WO PCT/GB2012/050113 patent/WO2012098402A1/en active Application Filing

- 2012-01-19 EP EP12701366.2A patent/EP2665663B1/en not_active Not-in-force

- 2012-01-19 US US13/979,415 patent/US20140030385A1/en not_active Abandoned

- 2012-01-19 ES ES12701366.2T patent/ES2550194T3/en active Active

- 2012-01-19 CA CA2861271A patent/CA2861271C/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| GB2500855B (en) | 2014-10-22 |

| CA2861271A1 (en) | 2012-07-26 |

| GB201100871D0 (en) | 2011-03-02 |

| JP2014504929A (en) | 2014-02-27 |

| CA2861271C (en) | 2019-09-24 |

| CN103596856B (en) | 2016-06-01 |

| ES2550194T3 (en) | 2015-11-05 |

| JP5993874B2 (en) | 2016-09-14 |

| CN103596856A (en) | 2014-02-19 |

| US20140030385A1 (en) | 2014-01-30 |

| PL2665663T3 (en) | 2015-12-31 |

| GB201314065D0 (en) | 2013-09-18 |

| WO2012098402A1 (en) | 2012-07-26 |

| EP2665663A1 (en) | 2013-11-27 |

| GB2500855A (en) | 2013-10-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2665663B1 (en) | Brewing device | |

| RU2223691C2 (en) | Filtering device for coffee and like beverages | |

| US8495951B2 (en) | Disposable combined squeezer/stirrer/dispenser/brewer device | |

| RU2015118032A (en) | METHOD FOR PREPARING A DRINK USING A PORTION CAPSULE | |

| RU2015140922A (en) | PORTION CAPSULE AND METHOD FOR PREPARING A DRINK USING A PORTION CAPSULE | |

| JP2014504929A5 (en) | ||

| US3370524A (en) | High-speed coffee brewer | |

| JP3166151B2 (en) | Drip bag | |

| US20170341855A1 (en) | Disposable means for preparing a beverage | |

| RU46638U1 (en) | DISPOSABLE CAP FOR BREWING LIQUID | |

| RU74054U1 (en) | DISPOSABLE CAPACITY FOR BREWING DRINKS (OPTIONS) | |

| JP3672402B2 (en) | Coffee extraction bag | |

| KR102576031B1 (en) | Drip bag for extracting palatable beverages and packaging container for beverage extraction including the same | |

| JP2008000623A (en) | Drip bag | |

| US1492298A (en) | Tea cartridge | |

| CN209769940U (en) | Container for drinking tea | |

| JP5105565B1 (en) | Simple coffee bag | |

| JP4127173B2 (en) | Drip bag | |

| CN206473200U (en) | Beverage extracting device | |

| RU2687801C1 (en) | Beverage preparation device | |

| EP3075287B1 (en) | Device for diluting solid products in a liquid medium | |

| GB2551572A (en) | Device for infusing an infusionable substance | |

| NL1041544B1 (en) | Coffee brewing means for pre-filled coffee-pods | |

| RU53547U1 (en) | COFFEE BREWER | |

| WO2013015748A2 (en) | Device and method for infusion preparation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130806 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20140624 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20141103 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 739077 Country of ref document: AT Kind code of ref document: T Effective date: 20150815 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012009115 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2550194 Country of ref document: ES Kind code of ref document: T3 Effective date: 20151105 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 739077 Country of ref document: AT Kind code of ref document: T Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151030 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151029 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151129 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151130 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012009115 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160131 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20160502 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160119 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160119 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160131 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: S28 Free format text: APPLICATION FILED |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: S28 Free format text: RESTORATION ALLOWED Effective date: 20161123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20190730 Year of fee payment: 8 Ref country code: TR Payment date: 20190704 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20190705 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20200727 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20200811 Year of fee payment: 9 Ref country code: FR Payment date: 20200724 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200119 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20210201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210201 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210131 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20210714 Year of fee payment: 10 Ref country code: DE Payment date: 20210721 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20220427 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210120 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602012009115 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220119 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220802 |