EP2401552B1 - Method for autolytic combustion of sludge - Google Patents

Method for autolytic combustion of sludge Download PDFInfo

- Publication number

- EP2401552B1 EP2401552B1 EP10706501A EP10706501A EP2401552B1 EP 2401552 B1 EP2401552 B1 EP 2401552B1 EP 10706501 A EP10706501 A EP 10706501A EP 10706501 A EP10706501 A EP 10706501A EP 2401552 B1 EP2401552 B1 EP 2401552B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- heat exchanger

- sludge

- slurry

- combustion

- flue gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000002485 combustion reaction Methods 0.000 title claims description 61

- 238000000034 method Methods 0.000 title claims description 28

- 239000010802 sludge Substances 0.000 title description 65

- 230000002358 autolytic effect Effects 0.000 title 1

- 239000003546 flue gas Substances 0.000 claims description 52

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 claims description 51

- 239000010801 sewage sludge Substances 0.000 claims description 40

- 238000010438 heat treatment Methods 0.000 claims description 23

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 17

- 239000007787 solid Substances 0.000 claims description 9

- 239000007791 liquid phase Substances 0.000 claims description 5

- 239000002002 slurry Substances 0.000 claims 12

- 238000011144 upstream manufacturing Methods 0.000 claims 1

- 238000010586 diagram Methods 0.000 description 11

- 239000003292 glue Substances 0.000 description 7

- 239000012071 phase Substances 0.000 description 7

- 239000007789 gas Substances 0.000 description 6

- 239000000203 mixture Substances 0.000 description 5

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 4

- 206010053615 Thermal burn Diseases 0.000 description 3

- 238000001035 drying Methods 0.000 description 3

- 239000000470 constituent Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 239000002910 solid waste Substances 0.000 description 2

- 230000002269 spontaneous effect Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000018044 dehydration Effects 0.000 description 1

- 238000006297 dehydration reaction Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000010813 municipal solid waste Substances 0.000 description 1

- 235000019645 odor Nutrition 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 102000004169 proteins and genes Human genes 0.000 description 1

- 108090000623 proteins and genes Proteins 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G7/00—Incinerators or other apparatus for consuming industrial waste, e.g. chemicals

- F23G7/001—Incinerators or other apparatus for consuming industrial waste, e.g. chemicals for sludges or waste products from water treatment installations

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2206/00—Waste heat recuperation

- F23G2206/10—Waste heat recuperation reintroducing the heat in the same process, e.g. for predrying

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2209/00—Specific waste

- F23G2209/12—Sludge, slurries or mixtures of liquids

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2900/00—Special features of, or arrangements for incinerators

- F23G2900/00001—Exhaust gas recirculation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2900/00—Special features of, or arrangements for incinerators

- F23G2900/50213—Preheating processes other than drying or pyrolysis

Definitions

- the invention relates to a method for the automatic combustion of sludge.

- sludges for their disposal are self-contained, that burned without external thermal energy.

- Such sludges can be formed in particular by sewage sludge.

- the mechanically dewatered sludge is fed to a dryer, for example a drum, disc or stacker dryer, by methods known in the art.

- the sludge dried there is then fed to a combustion unit, for example a fluidized bed furnace, where it is incinerated.

- the running of the combustion unit, hot flue gas is used in these methods as a heating medium in the dryer.

- a major disadvantage here is that the design effort and thus the cost of implementing the method is undesirably large.

- a further disadvantage is that during drying of the sludge in the dryer, in particular when the sludge is sewage sludge, exhaust gases with organic constituents are formed which have to be filtered out with an exhaust system such as activated carbon filters. This represents another significant cost factor.

- sewage sludge but also other protein-containing sludges change their physical properties at a solids content of about 30-70% in the way that they go through the so-called glue phase.

- the viscosity of the sludge increases significantly and there are problems in conveying the sludge.

- the sludge is heated to a temperature of, for example, greater than 180 ° C, the long-chain molecules contained in the sludge break up and the sludge hydrolyzes, and thus no glue phase is produced when the dry matter increases and the sludge has a much lower viscosity.

- the DE 31 03 417 A1 relates to a process for the oxidation of solids and aqueous sludges, in particular solid waste such as waste and sewage sludge in an oven.

- aqueous sludges, especially sewage sludge in a predetermined amount with solids, especially crushed combustible solid waste (garbage), mixed intensively, fed without dewatering in the oven and burned under pressure, strigwelt or gasified.

- the EP 0 304 783 A1 relates to a process for burning aqueous sewage sludge in fluidized bed, wherein aqueous mixtures of sewage sludge and TDI residues having a solids content of 25 to 98 wt .-% and their content of TDI residue 25 to 95 wt .-%, based on The solids content is burned without further input of energy carrier.

- the invention has for its object to provide a method of the type mentioned, by means of which a cost-effective and efficient combustion of sludge is made possible without additional thermal energy supply.

- the inventive method is used for the automatic combustion of sludge with a high water content.

- the sludge is heated under pressure before being fed to a combustion unit in a heat exchanger, so that the water contained in the sludge does not evaporate but remains in a liquid phase.

- the sludge to be incinerated has a high water content because prior mechanical dehydration typically can not lower the water content of the sludge to below about 75%.

- the feed of this hydrous sludge to the incineration unit takes place in conduits through which the sludge is pumped at high pressures, typically at least 40 bar. In these lines, the sludge is heated by means of the heat exchanger. Due to the high pressure, the sludge can absorb large amounts of heat without the water evaporating in the sludge. The sludge water thus remains in the liquid phase and the sludge thus remains pumpable.

- the sludge When the sludge is heated under pressure, it hydrolyzes, ie large organic molecules are broken up and the viscosity of the sludge decreases considerably. This is an essential prerequisite for a controlled supply of sludge to the combustion unit and a compact design of the system components. There, the pre-heated sludge can be burned energy-efficient.

- the pumpability of the sludge to be supplied to the heat exchanger is considerably improved by recycling a portion of the sludge heated in the heat exchanger and mixing it with fresh sludge forming sludge before being fed to the heat exchanger under pressure.

- the temperature of the raw sludge mixed with the recycled sludge is increased so that in this case the formation of a glue phase in the heat exchanger

- Shape of a tough mud avoided or at least partially reduced.

- this raw sludge is preheated before entering the heat exchanger.

- the raw sludge is heated to such an extent by the mixture with sludge already passed through the heat exchanger that the mixture thus obtained is at such a high temperature that it no longer passes through any glue phase in the heat exchanger.

- the mixture is made so that it passes through the glue phase only very short and incomplete in the heat exchanger. In any case, achieved by the sludge recirculation avoidance of the glue phase is achieved, that the sludge remains well pumpable when passing through the heat exchanger and thus can pass well this.

- Essential for an automatic combustion of the sludge without external thermal energy supply in this case is that the heat exchanger for heating the sludge, the flue gas is supplied as a heat exchange medium.

- the heat exchanger for heating the sludge is designed as a thermal oil heat exchanger, wherein the thermal oil is heated by means of the flue gas.

- a heat exchanger with high-pressure steam or high-pressure hot water can be used as a heat exchange medium.

- thermal oil as a heat carrier between the flue gas and the sludge is an alternative embodiment of the method. It is particularly advantageous, however, that the heat exchanger for heating the Sludge the flue gas is supplied as a heat exchange medium. Coils are expediently installed for heating the sludge under pressure in the flue gas duct behind a fluidized bed combustion as a combustion unit. This could also be realized by immersion heating surfaces built into the fluidized-bed combustion or by radiant heating surfaces in the combustion chamber.

- This method has as an additional advantage that the sludge can be heated directly by the exhaust gas stream, so that it is possible to dispense with thermal oil heat exchangers or a corresponding unit.

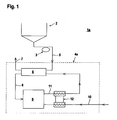

- FIG. 1 shows schematically the structure of a known from the prior art plant 1a for the spontaneous combustion of sludge.

- sewage sludge is always mentioned as an example of a sludge to be disposed of.

- the sewage sludge is first supplied from a reservoir 2 of a mechanical drainage 3, which is formed by a press or the like. There, the water content of sewage sludge is reduced by mechanical means to about 75%. From the mechanical dewatering the sewage sludge is fed to a system 4a for self-combustion to burn the sewage sludge without additional thermal energy supply.

- the sewage sludge is first fed via a line 5 to a dryer 6, which is typically designed as a tube dryer. In the dryer 6, the sewage sludge is dried. In order to filter the resulting exhaust gases, the dryer 6 is associated with a filter system, not shown, such as an activated carbon filter.

- the exhaust air of the dryer 6 is discharged from the system 4a via a line 7.

- the sewage sludge dried in the drier 6 is fed via a line 8 to a combustion unit, which is formed, for example, by a fluidized-bed furnace 9.

- the combustion unit is supplied via a line 10 combustion air.

- the resulting in the fluidized bed combustion 9 hot flue gas is carried out via a line 11 from the fluidized bed furnace 9 and fed to the dryer 6 as a heating medium.

- the combustion air is heated by using the heat of the noise gas.

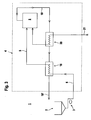

- the Figures 2 and 3 show embodiments of the system 1 according to the invention for the spontaneous combustion of sludge, which is again exemplified as sewage sludge.

- the sewage sludge is supplied from a reservoir 2 to a mechanical drainage 3 such as a press. There, the mechanical content of the water content sewage sludge is reduced to about 75%.

- the sewage sludge is fed to a system 4 for automatic combustion.

- the sewage sludge Due to the high pressure prevailing in the line 5, the sewage sludge remains liquid when heated and can thus be supplied with compact plant components, in particular lines 5 of the combustion unit.

- the emerging from the combustion unit hot flue gases are used to heat the sewage sludge, whereby a closed system 4 is obtained without external thermal energy supply.

- the sludge is fed in the line 5 a combustion unit in the form of a fluidized bed 9.

- the combustion unit (as in the following embodiment according to FIG. 3 ) be formed by a cyclone furnace or a rotary kiln.

- the sewage sludge in the line 5 is heated by means of a heat exchanger system in the form of a thermal oil heat exchanger 13.

- the heating of the sludge is carried out under high pressure, so that the water contained in the sludge remains in the liquid phase until it is released during combustion.

- the flue gas generated in the fluidized bed combustion 9 during the combustion of the sewage sludge is fed via a line 14 to an air preheater 15 to heat there via a line 16 to the system 4 supplied combustion air which is fed to the fluidized bed 9.

- the flue gas stream in the line 14 ' is supplied to the thermal oil heat exchanger 13 for heating the thermal oil.

- the flue gas stream is fed via line 14 "to another air preheater 17 for a first heating of the combustion air and then via line 14"'out of the system executed.

- the air preheaters 15, 17 for heating the combustion air form further heat exchanger systems.

- FIG. 3 points to the embodiment according to FIG. 2 an even more simplified and therefore more cost-effective construction.

- the sewage sludge is in turn supplied from the reservoir 2 to a mechanical drainage 3 and then fed via the line 5 of the fluidized bed furnace 9.

- no thermal oil heat exchanger 13 is required for heating the sewage sludge in the line 5, but only a simple heat exchanger 18.

- This heat exchanger 18, the flue gas generated in the fluidized bed 9, and performed via a line 19 is supplied as a heat exchange medium.

- the heat exchanger 18 is preceded by an air preheater 20 in the flue gas flow as another heat exchanger system, wherein in the air preheater 20 via a line 21 of the fluidized bed combustion 9 supplied combustion air is heated.

- the flue gas stream at the outlet of the heat exchanger 18 is discharged from the system 4 via a line 19 '.

- the heat exchangers for sludge heating and air preheating are usefully installed in the flue gas duct behind the combustion.

- FIG. 4 shows a TQ diagram, that is, a temperature-heat diagram for the system 1 according to FIG. 2 ,

- I the temperature-heat curve of the discharged from the fluidized bed 9 flue gas.

- the direct outlet of the flue gas from the fluidized bed furnace 9 is designated by a.

- the temperature of the flue gas at the exit from the fluidized bed combustion 9 is about 800 ° C, as shown FIG. 4 is apparent.

- the temperature-heat curve forms a monotonically decreasing straight line up to the point b, which forms the exit of the flue gas from the system 4.

- the outlet temperature of the flue gas is about 270 ° C.

- the flue gas is supplied within the system 4 the two air preheaters 15, 17 and the thermal oil heat exchanger 13, where the flue gas emits heat to the local heat exchanger media.

- FIG. 4 is denoted by II the temperature-heat curve of heated in the air preheater 15, the fluidized bed combustion 9 supplied combustion air.

- FIG. 4 III denotes the temperature-heat curve of the thermal oil of the thermal oil heat exchanger 13.

- FIG. 4 IV denotes the temperature-heat curve of the heated in the air preheater 17, introduced into the system 4 cold air.

- the slope of the curve II is greater than the slope of the curve I, since the amount of air in the air preheater 15 is considerably less than the amount of flue gas.

- the flue gas After heating the air in the air preheater 15, the flue gas is fed to the thermal oil heat exchanger 13. The flue gas releases heat to the thermal oil so that the flue gas cools from the temperature of 654 ° C (point c on curve I) to a temperature of about 375 ° C (point d on curve I).

- the flue gas is supplied from the outlet of the thermal oil heat exchanger 13 to the further air preheater 17, where the introduced into the system 4 cold air is heated.

- FIG. 4 can be seen by the heat emission of the flue gas, the air in the air preheater 17 from the temperature 375 ° C (point d on the curve I) to the outlet temperature 270 ° C (point b cooled on the curve I).

- the air in the air preheater 17 is heated from the inlet temperature 20 ° C (right end of the curve IV) to about 319 ° C (left end of the curve IV).

- Appendix 1 are to be interpreted as meaning that the exit temperature of the flue gas at exit from the system 4 is as low as possible, so that much heat of the flue gas is transferred to the components of the system 1, namely the thermal oil heat exchanger 13 and the air preheaters 15, 17.

- This requirement is in accordance with Appendix 1a FIG. 2 relatively well fulfilled, since the starting temperature of the flue gas (point b on the curve I) is about 270 ° C.

- Another requirement is that the distances between the curves II, III, IV to the temperature-heat curve of the flue gas are as large as possible, since then large temperature differences are realized in the system components, whereby the sizes of the system components can be selected small. Also this requirement is how out FIG. 4 can be seen in Appendix 1 according to FIG. 2 relatively well met.

- FIG. 5 shows a TQ diagram for the system 1 according to FIG. 3 , Analogous to FIG. 4 is also referred to in the TQ diagram with I the temperature-heat curve of the flue gas.

- a is the direct exit of the flue gas from the fluidized bed 9, where the temperature of the flue gas is about 800 ° C.

- the temperature of the flue gas decreases until it leaves the system 4 to an outlet temperature of 182 ° C (point b of the curve I).

- FIG. 5 II denotes the temperature-heat curve of the combustion air in the air preheater 20.

- FIG. 5 III denotes the temperature of the sewage sludge, denoted by d (right end of curve III) the entry of the sewage sludge in the heat exchanger 18, and e designates the exit of the sewage sludge from the heat exchanger 18 or the inlet of sewage sludge in the fluidized bed 9 is.

- the flue gas is cooled from 800 ° C (point a of the curve I) to a temperature of about 615 ° C (point c of curve I).

- the combustion air for the fluidized bed combustion 9 in the air preheater 20 from a starting temperature of 20 ° C when entering the system 4 (right end of the curve II) is heated to a temperature of 548 ° C (left end of the curve II). Since the amount of flue gas is considerably larger than the amount of combustion air, the slope of the curve I for the flue gas is smaller than the slope of the curve II for the combustion air.

- the flue gas is cooled from the temperature 615 ° C (point c on the curve I) to the outlet temperature of the system 4 of 182 ° C (point b on the curve I).

- the sewage sludge is heated from a temperature of 20 ° C (point d on curve III) to a temperature of about 288 ° C (point e on curve III). Since the sewage sludge is under pressure, the water of the sludge remains in the liquid phase.

- the invention is not limited to the specific designs of the systems according to the FIGS. 4 and 5 limited.

- Plant designs are possible in which an exit temperature of the flue gas is obtained from the system 4, which is at 80 ° C or even lower.

Landscapes

- Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Water Supply & Treatment (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fluidized-Bed Combustion And Resonant Combustion (AREA)

- Treatment Of Sludge (AREA)

- Air Supply (AREA)

Description

Die Erfindung betrifft ein Verfahren zur selbstgängigen Verbrennung von Schlamm.The invention relates to a method for the automatic combustion of sludge.

Bei dem in Rede stehenden Verfahren werden Schlämme zu deren Entsorgung selbstgängig, das heißt ohne äußere thermische Energiezufuhr verbrannt. Derartige Schlämme können insbesondere von Klärschlämmen gebildet sein.In the process in question, sludges for their disposal are self-contained, that burned without external thermal energy. Such sludges can be formed in particular by sewage sludge.

Nach einer mechanischen Entwässerung mittels Pressen, Dekanter oder dergleichen weisen diese typischerweise einen Feststoffgehalt von etwa 18 bis 30 Prozent auf. Um diese Schlämme zu Zwecken der Entsorgung weiter zu behandeln wird nach aus dem Stand der Technik bekannten Verfahren der mechanisch entwässerte Schlamm einem Trockner, zum Beispiel einem Trommel-, Scheiben- oder Etagentrockner zugeführt. Der dort getrocknete Schlamm wird dann einer Verbrennungseinheit, beispielsweise einer Wirbelschichtfeuerung, zugeführt und dort verbrannt. Das aus der Verbrennungseinheit ausgeführte, heiße Rauchgas wird bei diesen Verfahren als Heizmedium im Trockner genutzt.After mechanical dewatering by means of presses, decanters or the like, these typically have a solids content of about 18 to 30 percent. To further treat these sludges for disposal purposes, the mechanically dewatered sludge is fed to a dryer, for example a drum, disc or stacker dryer, by methods known in the art. The sludge dried there is then fed to a combustion unit, for example a fluidized bed furnace, where it is incinerated. The running of the combustion unit, hot flue gas is used in these methods as a heating medium in the dryer.

Ein wesentlicher Nachteil hierbei ist, dass der konstruktive Aufwand und damit auch der Kostenaufwand zur Durchführung des Verfahrens unerwünscht groß ist. Weiterhin ist nachteilig, dass bei der Trocknung des Schlamms im Trockner, insbesondere dann, wenn es sich bei dem Schlamm um Klärschlamm handelt, Abgase mit organischen Bestandteilen entstehen, die mit einer Abgasanlage wie Aktivkohlefiltern ausgefiltert werden müssen. Dies stellt einen weiteren wesentlichen Kostenfaktor dar.A major disadvantage here is that the design effort and thus the cost of implementing the method is undesirably large. A further disadvantage is that during drying of the sludge in the dryer, in particular when the sludge is sewage sludge, exhaust gases with organic constituents are formed which have to be filtered out with an exhaust system such as activated carbon filters. This represents another significant cost factor.

Insbesondere Klärschlämme, aber auch andere eiweißhaltige Schlämme verändern Ihre Stoffwerte bei einem Feststoffgehalt von ca. 30 - 70 % in der Art, dass sie die sogenannte Leimphase durchlaufen. Hierbei erhöht sich die Viskosität des Schlamms erheblich und es treten Probleme beim Fördern des Schlamms auf. Wird der Schlamm jedoch auf eine Temperatur von zum Beispiel größer 180 °C erhitzt so brechen die im Schlamm enthaltenen langkettigen Moleküle auf, der Schlamm hydrolisiert, und somit entsteht bei Erhöhung der Trockensubstanz keine Leimphase und der Schlamm hat eine wesentlich geringere Viskosität.In particular sewage sludge, but also other protein-containing sludges change their physical properties at a solids content of about 30-70% in the way that they go through the so-called glue phase. Here, the viscosity of the sludge increases significantly and there are problems in conveying the sludge. However, if the sludge is heated to a temperature of, for example, greater than 180 ° C, the long-chain molecules contained in the sludge break up and the sludge hydrolyzes, and thus no glue phase is produced when the dry matter increases and the sludge has a much lower viscosity.

Die

Die

Der Erfindung liegt die Aufgabe zugrunde, ein Verfahren der eingangs genannten Art bereitzustellen, mittels dessen eine kostengünstige und effiziente Verbrennung von Schlämmen ohne zusätzliche thermische Energiezufuhr ermöglicht wird.The invention has for its object to provide a method of the type mentioned, by means of which a cost-effective and efficient combustion of sludge is made possible without additional thermal energy supply.

Zur Lösung dieser Aufgabe sind die Merkmale des Anspruchs 1 vorgesehen. Vorteilhafte Ausführungsformen und zweckmäßige Weiterbildungen der Erfindung sind in den Unteransprüchen beschrieben.To solve this problem, the features of

Das erfindungsgemäße Verfahren dient zur selbstgängigen Verbrennung von Schlamm mit hohem Wassergehalt. Der Schlamm wird vor Zuführung zu einer Verbrennungseinheit in einem Wärmetauscher unter Druck erhitzt, so dass das im Schlamm enthaltene Wasser nicht verdampft, sondern in einer flüssigen Phase bleibt.The inventive method is used for the automatic combustion of sludge with a high water content. The sludge is heated under pressure before being fed to a combustion unit in a heat exchanger, so that the water contained in the sludge does not evaporate but remains in a liquid phase.

Durch die erfindungsgemäße Erhitzung des Schlamms in einem Wärmetauscher vor der Zuführung zur Verbrennungseinheit kann eine signifikante Reduzierung des Kostenaufwands bei der selbstgängigen Verbrennung von Schlämmen erzielt werden. Dies beruht im Wesentlichen darauf, dass bei dem Verfahren kein kostenaufwendiger Trockner zum Trocknen von Schlamm mehr eingesetzt werden muss. Der Umstand, dass bei dem erfindungsgemäßen Verfahren kein Trockner mehr benötigt wird, ist insbesondere bei der Verbrennung von Klärschlamm vorteilhaft. Die in einem Trockner beim Trocknen von Klärschlamm auffallenden Abgase entfallen nun, so dass auch hierfür keine entsprechende Abgasbehandlung, insbesondere zur Abscheidung von organischen Bestandteilen und auch Geruchsstoffen mehr vorgesehen werden muss, da diese bei der Verbrennung vollkommen zersetzt werden.By heating the sludge in a heat exchanger according to the invention before it is fed to the combustion unit, a significant reduction in the cost of self-contained sludge incineration can be achieved. This is essentially due to the fact that in the process no costly dryer for drying sludge must be used more. The fact that in the method according to the invention no more dryer is needed, is particularly advantageous in the combustion of sewage sludge. The in a dryer when drying sewage sludge striking exhaust gases are now eliminated, so that there is no corresponding Exhaust gas treatment, especially for the separation of organic constituents and odors must be provided more, since they are completely decomposed during combustion.

Außerdem werden die Probleme, welche in Verbindung mit der Leimphase bei der Erhöhung des Feststoffgehalts auftreten, gelöst.In addition, the problems associated with the glue phase in increasing the solids content are solved.

Der zu verbrennende Schlamm weist einen hohen Wassergehalt auf, da durch eine vorab durchzuführende mechanische Entwässerung der Wassergehalt des Schlammes typischerweise nicht unter etwa 75 % gesenkt werden kann. Die Zufuhr dieses wasserhaltigen Schlamms zur Verbrennungseinheit erfolgt in Leitungen, durch welche der Schlamm mit hohen Drücken, die typischerweise bei mindestens 40 bar liegen, gepumpt werden. In diesen Leitungen wird der Schlamm mittels des Wärmetauschers erhitzt. Aufgrund des hohen Drucks kann der Schlamm hohe Wärmemengen aufnehmen, ohne dass hierbei das Wasser im Schlamm verdampft. Das Schlammwasser verbleibt somit in der flüssigen Phase und der Schlamm bleibt somit weiter pumpfähig. Bei der Erhitzung des Schlamms unter Druck, hydrolisiert dieser, das heißt große organische Moleküle werden aufgebrochen und die Viskosität des Schlammes verringert sich erheblich. Dies ist eine wesentliche Voraussetzung für eine kontrollierte Zufuhr des Schlamms zur Verbrennungseinheit und eine kompakte Auslegung der Anlagenkomponenten. Dort kann der vorab erhitzte Schlamm energieeffizient verbrannt werden.The sludge to be incinerated has a high water content because prior mechanical dehydration typically can not lower the water content of the sludge to below about 75%. The feed of this hydrous sludge to the incineration unit takes place in conduits through which the sludge is pumped at high pressures, typically at least 40 bar. In these lines, the sludge is heated by means of the heat exchanger. Due to the high pressure, the sludge can absorb large amounts of heat without the water evaporating in the sludge. The sludge water thus remains in the liquid phase and the sludge thus remains pumpable. When the sludge is heated under pressure, it hydrolyzes, ie large organic molecules are broken up and the viscosity of the sludge decreases considerably. This is an essential prerequisite for a controlled supply of sludge to the combustion unit and a compact design of the system components. There, the pre-heated sludge can be burned energy-efficient.

Erfindungsgemäß wird die Pumpfähigkeit des dem Wärmetauscher zuzuführenden Schlamms dadurch noch erheblich verbessert, dass ein Teil des im Wärmetauscher erhitzten Schlamms rückgeführt und neuem, Rohschlamm bildenden Schlamm vor Zuführung zum Wärmetauscher unter Druck zugemischt wird. Dadurch wird die Temperatur des mit dem rückgeführten Schlamm gemischten Rohschlamms so erhöht, dass bei diesem im Wärmetauscher die Bildung einer Leimphase inAccording to the invention, the pumpability of the sludge to be supplied to the heat exchanger is considerably improved by recycling a portion of the sludge heated in the heat exchanger and mixing it with fresh sludge forming sludge before being fed to the heat exchanger under pressure. As a result, the temperature of the raw sludge mixed with the recycled sludge is increased so that in this case the formation of a glue phase in the heat exchanger

Form eines zähen Schlamms vermieden oder zumindest teilweise reduziert wird.Shape of a tough mud avoided or at least partially reduced.

Durch die Rückführung eines Teils des im Wärmetauscher erhitzten Schlamms und dessen Mischung mit Rohschlamm, das heißt neuem, erstmalig dem Wärmetauscher zugeführten Schlamm, wird dieser Rohschlamm bereits vor Eintritt in den Wärmetauscher vorerhitzt. Vorzugsweise wird der Rohschlamm durch die Mischung mit bereits durch den Wärmetauscher gelaufenen Schlamm so stark erhitzt, dass die so erhaltene Mischung bei so hoher Temperatur liegt, dass sie im Wärmetauscher überhaupt keine Leimphase mehr durchläuft. Alternativ erfolgt die Mischung so, dass diese dann im Wärmetauscher nur sehr kurz und unvollständig die Leimphase durchläuft. In jedem Fall wird die durch die Schlammrückführung erzielte Vermeidung der Leimphase erreicht, dass der Schlamm bei Durchgang durch den Wärmetauscher gut pumpfähig bleibt und diesen somit gut passieren kann.By returning a portion of the heated in the heat exchanger sludge and its mixture with raw sludge, that is new, the first time the heat exchanger supplied sludge, this raw sludge is preheated before entering the heat exchanger. Preferably, the raw sludge is heated to such an extent by the mixture with sludge already passed through the heat exchanger that the mixture thus obtained is at such a high temperature that it no longer passes through any glue phase in the heat exchanger. Alternatively, the mixture is made so that it passes through the glue phase only very short and incomplete in the heat exchanger. In any case, achieved by the sludge recirculation avoidance of the glue phase is achieved, that the sludge remains well pumpable when passing through the heat exchanger and thus can pass well this.

Wesentlich für eine selbstgängige Verbrennung des Schlamms ohne äußere thermische Energiezufuhr ist hierbei, dass dem Wärmetauscher zum Erhitzen des Schlamms das Rauchgas als Wärmetauschermedium zugeführt wird.Essential for an automatic combustion of the sludge without external thermal energy supply in this case is that the heat exchanger for heating the sludge, the flue gas is supplied as a heat exchange medium.

Gemäß einer weiteren Variante der Erfindung ist der Wärmetauscher zum Erhitzen des Schlamms als Thermalöl-Wärmetauscher ausgebildet, wobei mittels des Rauchgases das Thermalöl erhitzt wird. Anstelle des Thermalöl-Wärmetauschers kann auch ein Wärmetauscher mit Hochdruckdampf oder Hochdruckheißwasser als Wärmetauschermedium verwendet werden.According to a further variant of the invention, the heat exchanger for heating the sludge is designed as a thermal oil heat exchanger, wherein the thermal oil is heated by means of the flue gas. Instead of the thermal oil heat exchanger and a heat exchanger with high-pressure steam or high-pressure hot water can be used as a heat exchange medium.

Bereits mit dieser Variante wird eine effiziente und kostengünstige Verbrennung des Schlamms ermöglicht.Already with this variant, an efficient and cost-effective combustion of the sludge is possible.

Die Verwendung von Thermalöl als Wärmeträger zwischen dem Rauchgas und dem Schlamm stellt eine alternative Ausführungsart des Verfahrens dar. Besonders vorteilhaft ist jedoch, dass dem Wärmetauscher zum Erhitzen des Schlamms das Rauchgas als Wärmetauschermedium zugeführt wird. Rohrschlangen sind dabei zum Erhitzen des Schlamms unter Druck zweckmäßig in den Rauchgaskanal hinter einer Wirbelschichtverbrennung als Verbrennungseinheit eingebaut. Diese könnte auch durch in die Wirbelschichtverbrennung eingebaute Tauchheizflächen oder durch Strahlungsheizflächen im Feuerraum verwirklicht werden.The use of thermal oil as a heat carrier between the flue gas and the sludge is an alternative embodiment of the method. It is particularly advantageous, however, that the heat exchanger for heating the Sludge the flue gas is supplied as a heat exchange medium. Coils are expediently installed for heating the sludge under pressure in the flue gas duct behind a fluidized bed combustion as a combustion unit. This could also be realized by immersion heating surfaces built into the fluidized-bed combustion or by radiant heating surfaces in the combustion chamber.

Dieses Verfahren weist als zusätzlichen Vorteil auf, dass der Schlamm unmittelbar durch den Abgasstrom erhitzt werden kann, so dass auf Thermalöl Wärmetauscher oder eine entsprechende Einheit verzichtet werden kann.This method has as an additional advantage that the sludge can be heated directly by the exhaust gas stream, so that it is possible to dispense with thermal oil heat exchangers or a corresponding unit.

Damit weist die Anlage zur Durchführung dieser Verfahrensvariante einen besonders kompakten und kostengünstigen Aufbau auf, wobei insbesondere auch die Baugrößen und Gewichte der Anlagenkomponenten gegenüber der Variante mit einem zwischengeschalteten Wärmeträger noch weiter signifikant reduziert sind.Thus, the system for implementing this method variant on a particularly compact and inexpensive construction, in particular, the sizes and weights of the system components compared to the variant with an intermediate heat transfer medium are further significantly reduced.

Die Erfindung wird im Folgenden anhand der Zeichnungen erläutert. Es zeigen:

- Figur 1:

- Anlage zur selbstgängigen Verbrennung von Schlamm gemäß dem Stand der Technik.

- Figur 2:

- Erstes Ausführungsbeispiel einer erfindungsgemäßen Anlage zur selbstgängigen Verbrennung von Schlamm.

- Figur 3:

- Zweites Ausführungsbeispiel einer erfindungsgemäßen Anlage zur selbstgängigen Verbrennung von Schlamm.

- Figur 4:

- T-Q-Diagramm für die Anlage gemäß

Figur 2 - Figur 5:

- T-Q-Diagramm für die Anlage gemäß

Figur 3

- FIG. 1:

- Plant for the automatic incineration of sludge according to the prior art.

- FIG. 2:

- First embodiment of a plant according to the invention for the automatic combustion of sludge.

- FIG. 3:

- Second embodiment of a plant according to the invention for the automatic combustion of sludge.

- FIG. 4:

- TQ diagram for the system according to

FIG. 2 , - FIG. 5:

- TQ diagram for the system according to

FIG. 3 ,

Der Klärschlamm wird zunächst aus einem Reservoir 2 einer mechanischen Entwässerung 3 zugeführt, die von einer Presse oder dergleichen gebildet ist. Dort wird auf mechanischem Weg der Wassergehalt des Klärschlamms auf etwa 75 % reduziert. Von der mechanischen Entwässerung wird der Klärschlamm einem System 4a zur selbstgängigen Verbrennung zugeführt um den Klärschlamm ohne zusätzliche thermische Energiezufuhr zu verbrennen. Dabei wird der Klärschlamm zuerst über eine Leitung 5 einem Trockner 6 zugeführt, der typischerweise als Röhrentrockner ausgebildet ist. In dem Trockner 6 wird der Klärschlamm getrocknet. Um dabei entstehende Abgase zu filtern ist dem Trockner 6 eine nicht dargestellte Filteranlage wie zum Beispiel ein Aktivkohlefilter zugeordnet. Die Abluft des Trockners 6 wird aus dem System 4a über eine Leitung 7 ausgeleitet.The sewage sludge is first supplied from a

Der im Trockner 6 getrocknete Klärschlamm wird über eine Leitung 8 einer Verbrennungseinheit zugeführt, die zum Beispiel von einer Wirbelschichtfeuerung 9 gebildet ist. Ebenso wird der Verbrennungseinheit über eine Leitung 10 Verbrennungsluft zugeführt. Das in der Wirbelschichtfeuerung 9 entstehende heiße Rauchgas wird über eine Leitung 11 aus der Wirbelschichtfeuerung 9 ausgeführt und dem Trockner 6 als Heizmedium zugeführt. Mittels einer Wärmetauschereinheit 12 wird die Verbrennungsluft unter Verwendung der Wärme des Rauschgases erhitzt.The sewage sludge dried in the drier 6 is fed via a

Die

Bei dem Ausführungsbeispiel gemäß

Das in der Wirbelschichtfeuerung 9 bei der Verbrennung des Klärschlamms generierte Rauchgas wird über eine Leitung 14 einem Luftvorwärmer 15 zugeführt, um dort über eine Leitung 16 dem System 4 zugeführte Verbrennungsluft, die der Wirbelschichtfeuerung 9 zugeführt wird, zu erhitzen. Dann wird der Rauchgasstrom in der Leitung 14' dem Thermalöl-Wärmetauscher 13 zur Erhitzung des Thermalöls zugeführt. Schließlich wird der Rauchgasstrom über die Leitung 14" einem weiteren Luftvorwärmer 17 zu einer ersten Erhitzung der Verbrennungsluft zugeführt und dann über die Leitung 14"' aus dem System ausgeführt. Die Luftvorwärmer 15, 17 zur Erhitzung der Verbrennungsluft bilden weitere Wärmetauschersysteme.The flue gas generated in the

Das Ausführungsbeispiel gemäß

Der Klärschlamm wird wiederum aus dem Reservoir 2 einer mechanischen Entwässerung 3 zugeführt und dann über die Leitung 5 der Wirbelschichtfeuerung 9 zugeführt. Im Unterschied zur Ausführungsform gemäß

Das Rauchgas wird innerhalb des Systems 4 den beiden Luftvorwärmern 15, 17 und dem Thermalöl-Wärmetauscher 13 zugeführt, wo das Rauchgas jeweils Wärme an die dortigen Wärmetauschermedien abgibt. In

Durch die Wärmezufuhr des Rauchgases wird im Luftvorwärmer 15 die der Wirbelschichtfeuerung 9 zuzuführende, bereits im Luftvorwärmer 17 vorerhitzte Verbrennungsluft weiter erhitzt und zwar von einer Temperatur von etwa 320°C (unteres Ende der Kurve II) bis auf eine Temperatur von etwa 734°C (oberes Ende der Kurve II). Dementsprechend kühlt sich dabei das Rauchgas von der Ausgangstemperatur von 800°C (Punkt a der Kurve I) bis auf eine Temperatur von etwa 654°C als (Punkt c auf der Kurve I) ab.Due to the heat input of the flue gas, the combustion air to be supplied to the

Dabei ist die Steigung der Kurve II größer als die Steigung der Kurve I, da die Luftmenge im Luftvorwärmer 15 erheblich geringer ist als die Rauchgasmenge.The slope of the curve II is greater than the slope of the curve I, since the amount of air in the

Nach der Erhitzung der Luft im Luftvorwärmer 15 wird das Rauchgas dem Thermalöl-Wärmetauscher 13 zugeführt. Dabei gibt das Rauchgas Wärme an das Thermalöl ab, so dass sich das Rauchgas von der Temperatur vom 654°C (Punkt c auf der Kurve I) auf eine Temperatur von etwa 375°C (Punkt d auf der Kurve I) abkühlt.After heating the air in the

Schließlich wird das Rauchgas vom Ausgang des Thermalöl-Wärmetauschers 13 dem weiteren Luftvorwärmer 17 zugeführt, wo die in das System 4 eingeleitete kalte Luft erhitzt wird. Wie aus

Die Komponenten der Anlage 1 sind auszulegen, dass die Ausgangstemperatur des Rauchgases bei Austritt aus dem System 4 möglichst gering ist, damit viel Wärme des Rauchgases auf die Komponenten der Anlage 1, nämlich den Thermalöl-Wärmetauscher 13 und die Luftvorwärmer 15, 17 übertragen wird. Diese Anforderung ist bei der Anlage 1a gemäß

In

Durch die Erhitzung des Klärschlamms im Wärmetauscher 18 mittels des Rauchgases wird das Rauchgas von der Temperatur 615°C (Punkt c auf der Kurve I) bis auf die Austrittstemperatur aus dem System 4 von 182°C (Punkt b auf der Kurve I) abgekühlt. Dabei wird der Klärschlamm ausgehend von der Temperatur 20°C (Punkt d auf der Kurve III) bis auf eine Temperatur von etwa 288°C (Punkt e auf der Kurve III) erhitzt. Da der Klärschlamm unter Druck steht verbleibt das Wasser des Schlamms in der flüssigen Phase.By heating the sewage sludge in the

Wie aus dem Vergleich der

Die Erfindung ist nicht auf die konkreten Auslegungen der Anlagen gemäß den

Insbesondere für die Ausführungsform gemäß

- (1)(1)

- Anlageinvestment

- (1a)(1a)

- Anlageinvestment

- (2)(2)

- Reservoirreservoir

- (3)(3)

- Entwässerungdrainage

- (4)(4)

- Systemsystem

- (4')(4 ')

- Systemsystem

- (5)(5)

- Leitungmanagement

- (6)(6)

- Trocknerdryer

- (7)(7)

- Leitungmanagement

- (8)(8th)

- Leitungmanagement

- (9)(9)

- Wirbelschichtfeuerungfluidised bed combustion

- (10)(10)

- Leitungmanagement

- (11)(11)

- Leitungmanagement

- (12)(12)

- Wärmetauscherheat exchangers

- (13)(13)

- Thermalöl-WärmetauscherThermal oil heat exchanger

- (14)(14)

- Leitungmanagement

- (14')(14 ')

- Leitungmanagement

- (14")(14 ")

- Leitungmanagement

- (15)(15)

- Luftvorwärmerair preheater

- (16)(16)

- Leitungmanagement

- (17)(17)

- Luftvorwärmerair preheater

- (18)(18)

- Wärmetauscherheat exchangers

- (19)(19)

- Leitungmanagement

- (19')(19 ')

- Leitungmanagement

- (20)(20)

- Luftvorwärmerair preheater

- (21)(21)

- Leitungmanagement

Claims (12)

- Method for self-feeding combustion of slurry with high water content, wherein the slurry prior to supply to a combustion unit is heated in a heat exchanger (18) under pressure so that the water contained in the slurry is not evaporated, but remains in liquid phase, characterised in that a part of the slurry heated in the heat exchanger (18) is fed back and new raw slurry is admixed under pressure prior to supply to the heat exchanger (18), wherein the temperature of the raw slurry mixed with the slurry fed back is increased to such an extent that prior to entry into the heat exchanger this hydrolises and thus the viscosity of the slurry is substantially reduced.

- Method according to claim 1, characterised in that heat present in flue gas conducted out of the combustion unit is used for heating the slurry.

- Method according to claim 2, characterised in that the flue gas is fed as heat exchange medium to the heat exchanger (18) for heating the slurry.

- Method according to claim 3, characterised in that the heat exchanger (18) for heating the slurry is constructed as a thermal oil heat exchanger (13).

- Method according to claim 4, characterised in that the thermal oil is heated by means of the flue gas.

- Method according to one of claims 4 and 5, characterised in that a heat exchanger (18) with high-pressure steam or high-pressure hot water as heat exchange medium is used instead of the thermal oil heat exchanger (13).

- Method according to any one of claims 2 to 6, characterised in that an air preheater (15, 20) for heating air fed to the combustion unit is arranged in the flue gas flow upstream and/or downstream of the heat exchanger (18) for heating slurry.

- Method according to any one of claims 1 to 7, characterised in that a fluidised bed furnace (9), a cyclonic furnace or a drum furnace is used as combustion unit.

- Method according to any one of claims 1 to 8, characterised in that a self-feeding combustion of sewage sludge is performed by that.

- Method according to claim 9, characterised in that the sewage sludge is subjected to mechanical removal of water prior to the combustion.

- Method according to claim 10, characterised in that the sewage sludge after the mechanical removal of water has a solids content in the range of 18 to 30%.

- Method according to claim 11, characterised in that the sewage sludge after the mechanical removal of water has a solids content of approximately 25%.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL10706501T PL2401552T3 (en) | 2009-02-24 | 2010-02-06 | Method for autolytic combustion of sludge |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009010118A DE102009010118B4 (en) | 2009-02-24 | 2009-02-24 | Process for the automatic incineration of sewage sludge |

| PCT/EP2010/000749 WO2010097162A1 (en) | 2009-02-24 | 2010-02-06 | Method for autolytic combustion of sludge |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2401552A1 EP2401552A1 (en) | 2012-01-04 |

| EP2401552B1 true EP2401552B1 (en) | 2012-11-21 |

Family

ID=42211934

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10706501A Not-in-force EP2401552B1 (en) | 2009-02-24 | 2010-02-06 | Method for autolytic combustion of sludge |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP2401552B1 (en) |

| DE (1) | DE102009010118B4 (en) |

| DK (1) | DK2401552T3 (en) |

| ES (1) | ES2395531T3 (en) |

| PL (1) | PL2401552T3 (en) |

| WO (1) | WO2010097162A1 (en) |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4215637A (en) * | 1979-04-02 | 1980-08-05 | Envirotech Corporation | System for combustion of wet waste materials |

| DE3103417A1 (en) * | 1981-02-02 | 1982-08-12 | Saarberg-Fernwärme GmbH, 6600 Saarbrücken | Process and apparatus for the oxidation of solid substances and aqueous sludges |

| DE3728398A1 (en) * | 1987-08-26 | 1989-03-09 | Bayer Ag | BURNING OF SEVERAL CLAUSE FLUIDS THROUGH THE SWITCHING PROCESS |

| ES2042869T3 (en) * | 1988-05-24 | 1993-12-16 | Siemens Ag | PROCEDURE AND DEVICE FOR THE DRYING OF ACTIVATED SLUDGE. |

| DD294684A5 (en) * | 1990-05-30 | 1991-10-10 | Petrolchemisches Kominat Schwedt,De | PROCESS FOR PROCESSING WATER-CONTAINING OIL SLUDGE |

| DE4217729A1 (en) * | 1992-05-29 | 1993-12-02 | Dessau Zement Maschbau Gmbh | Process and technical circuit for drying and burning waste materials |

| DE4431564A1 (en) * | 1994-07-13 | 1996-01-18 | Kloeckner Humboldt Deutz Ag | Process and technical circuit for drying and burning sewage sludge |

| ATE196000T1 (en) * | 1994-12-06 | 2000-09-15 | Steinmueller Gmbh L & C | METHOD FOR COMBUSTING SEWAGE SLUDGE AND SYSTEM FOR IMPLEMENTING THE METHOD |

| DE19604506C2 (en) * | 1995-02-23 | 1999-09-02 | Julia Innotec Gmbh | Process for the use of residual heat energy resulting from the combustion and / or gasification of sewage sludge and device for using this residual heat energy |

| FR2758100B1 (en) * | 1997-01-06 | 1999-02-12 | Youssef Bouchalat | OPTIMIZED PROCESSING AND ENERGY RECOVERY OF SLUDGE FROM URBAN AND INDUSTRIAL PURIFICATION PLANTS |

| DE19859052C2 (en) * | 1998-12-21 | 2001-01-25 | Dieter Steinbrecht | Process and device for thermal waste recycling and waste disposal of solid, liquid and pumpable inhomogeneous flammable mixtures and thermal cleaning of contaminated materials in a fluidized bed furnace |

| WO2001038818A1 (en) * | 1999-11-19 | 2001-05-31 | Munehiro Tokashiki | Scale with variable gauge |

| DE19956562A1 (en) * | 1999-11-24 | 2001-06-13 | Bbp Environment Gmbh | Process for cleaning a heat exchanger surface and solid blowing medium for carrying out the process |

-

2009

- 2009-02-24 DE DE102009010118A patent/DE102009010118B4/en not_active Expired - Fee Related

-

2010

- 2010-02-06 ES ES10706501T patent/ES2395531T3/en active Active

- 2010-02-06 DK DK10706501.3T patent/DK2401552T3/en active

- 2010-02-06 PL PL10706501T patent/PL2401552T3/en unknown

- 2010-02-06 EP EP10706501A patent/EP2401552B1/en not_active Not-in-force

- 2010-02-06 WO PCT/EP2010/000749 patent/WO2010097162A1/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| ES2395531T3 (en) | 2013-02-13 |

| DE102009010118B4 (en) | 2011-03-31 |

| WO2010097162A1 (en) | 2010-09-02 |

| DK2401552T3 (en) | 2013-01-21 |

| PL2401552T3 (en) | 2013-04-30 |

| EP2401552A1 (en) | 2012-01-04 |

| DE102009010118A1 (en) | 2010-09-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2609330C3 (en) | Process for converting solid waste materials initially containing water into economically usable or environmentally harmless products and device for carrying out the process | |

| EP2230477B1 (en) | Wood chips drying plant for drying wood chips and method for drying wood chips | |

| DE2901723C2 (en) | Method and apparatus for drying a solid material | |

| EP0343431B1 (en) | Process and apparatus for sewage sludge drying | |

| EP2424955B1 (en) | Device and method for drying and torrefying at least one carbon-containing substance stream in a multiple-hearth furnace | |

| DE2940164C2 (en) | Process for heat recovery when drying solid fuels from hydrous organic materials | |

| EP2508494B1 (en) | Method and device for manufacturing cement clinker | |

| DE102012013877B4 (en) | Process for the treatment of biomass in a plant for the production of cement and the corresponding plant | |

| EP0465479B1 (en) | A method of reprocessing sewage sludge | |

| WO2008095524A2 (en) | Method and system for drying fuels in the form of dust, particularly to be fed to a gasification process | |

| EP0716264B1 (en) | Method and installation for sludge combustion | |

| EP0851194A2 (en) | Dryer with exhaust gas purification by thermal afterburning | |

| EP1921375A2 (en) | Method and assembly for combustion of biomass and/or organic waste as secondary fuel in pulverised coal fuel firing | |

| DE2902323A1 (en) | METHOD AND DEVICE FOR DRYING AND TREATMENT OF MOISTURE CONTAINING SOLID PARTICLES WITH ORGANIC AND / OR MINERAL INORGANIC COMPONENTS | |

| DE2810479C2 (en) | Process for drying raw lignite in a feed suspension produced with liquid hydrocarbons | |

| DE4434447A1 (en) | Method and device for reducing the water content of carbon-containing solid materials | |

| DE19531379C1 (en) | Process for the incineration of sewage sludge and plant for carrying out the process | |

| EP2401552B1 (en) | Method for autolytic combustion of sludge | |

| DE2726157B2 (en) | Kiln plant for solid goods | |

| EP0692679A2 (en) | Method and plant layout for drying and incinerating sewage sludge | |

| DE2535683A1 (en) | METHOD AND DEVICE FOR INCINERATION OF SLUDGE WITH THE HELP OF RECUPERATIVE SLUDGE DRYING | |

| DE19501736C1 (en) | Process for the incineration of sewage sludge and plant for carrying out the process | |

| EP3859207B1 (en) | Combustion installation with heat accumulator | |

| EP0571722A2 (en) | Process and plant layout for drying and burning waste materials | |

| DE29918945U1 (en) | Mobile drainage device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20110729 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: FRODENO, CHRISTA JOSEFINE |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: MICHAEL KADEN |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: ROTTMANN, ZIMMERMANN + PARTNER AG, CH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 585286 Country of ref document: AT Kind code of ref document: T Effective date: 20121215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010001698 Country of ref document: DE Effective date: 20130117 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2395531 Country of ref document: ES Kind code of ref document: T3 Effective date: 20130213 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20121121 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20130221 Year of fee payment: 4 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20130219 Year of fee payment: 4 Ref country code: CZ Payment date: 20130130 Year of fee payment: 4 Ref country code: FR Payment date: 20130301 Year of fee payment: 4 Ref country code: NO Payment date: 20130214 Year of fee payment: 4 Ref country code: IE Payment date: 20130219 Year of fee payment: 4 Ref country code: ES Payment date: 20130227 Year of fee payment: 4 Ref country code: FI Payment date: 20130213 Year of fee payment: 4 Ref country code: MC Payment date: 20130213 Year of fee payment: 4 Ref country code: DK Payment date: 20130218 Year of fee payment: 4 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130222 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130321 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LV Payment date: 20130213 Year of fee payment: 4 Ref country code: PL Payment date: 20130123 Year of fee payment: 4 Ref country code: NL Payment date: 20130219 Year of fee payment: 4 Ref country code: BE Payment date: 20130220 Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130221 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20130822 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010001698 Country of ref document: DE Effective date: 20130822 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: MT Payment date: 20130129 Year of fee payment: 4 |

|

| BERE | Be: lapsed |

Owner name: FRODENO, CHRISTA JOSEFINE Effective date: 20140228 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20140901 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20140228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 Ref country code: NO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20141031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140207 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20150218 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20150527 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20150219 Year of fee payment: 6 Ref country code: TR Payment date: 20150204 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: LAPE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20100206 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140207 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121121 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502010001698 Country of ref document: DE Ref country code: DE Ref legal event code: R409 Ref document number: 502010001698 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 585286 Country of ref document: AT Kind code of ref document: T Effective date: 20160206 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R409 Ref document number: 502010001698 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160229 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160206 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160709 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502010001698 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160206 |