EP2316988B1 - Wear-resistant and oxidation-resistant turbine blade - Google Patents

Wear-resistant and oxidation-resistant turbine blade Download PDFInfo

- Publication number

- EP2316988B1 EP2316988B1 EP10188806.3A EP10188806A EP2316988B1 EP 2316988 B1 EP2316988 B1 EP 2316988B1 EP 10188806 A EP10188806 A EP 10188806A EP 2316988 B1 EP2316988 B1 EP 2316988B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- resistant

- oxidation

- turbine blade

- protective coating

- coating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000003647 oxidation Effects 0.000 title claims description 52

- 238000007254 oxidation reaction Methods 0.000 title claims description 52

- 239000010410 layer Substances 0.000 claims description 31

- 238000000034 method Methods 0.000 claims description 29

- 238000000576 coating method Methods 0.000 claims description 25

- 238000004519 manufacturing process Methods 0.000 claims description 23

- 239000012720 thermal barrier coating Substances 0.000 claims description 23

- 239000011248 coating agent Substances 0.000 claims description 19

- 239000000463 material Substances 0.000 claims description 18

- 239000000919 ceramic Substances 0.000 claims description 15

- 239000011230 binding agent Substances 0.000 claims description 14

- 239000003082 abrasive agent Substances 0.000 claims description 10

- 239000002184 metal Substances 0.000 claims description 8

- 229910052751 metal Inorganic materials 0.000 claims description 8

- 239000000126 substance Substances 0.000 claims description 6

- 238000000227 grinding Methods 0.000 claims description 5

- 238000003801 milling Methods 0.000 claims description 4

- 239000000843 powder Substances 0.000 claims description 4

- 239000002356 single layer Substances 0.000 claims description 4

- 229910052582 BN Inorganic materials 0.000 claims description 3

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 claims description 3

- 238000009826 distribution Methods 0.000 claims description 3

- 239000000155 melt Substances 0.000 claims description 3

- 239000000203 mixture Substances 0.000 claims description 3

- 239000011253 protective coating Substances 0.000 claims 21

- 238000003754 machining Methods 0.000 claims 2

- 239000011241 protective layer Substances 0.000 description 49

- 238000003466 welding Methods 0.000 description 12

- 230000008021 deposition Effects 0.000 description 10

- 239000007789 gas Substances 0.000 description 7

- 230000008569 process Effects 0.000 description 6

- 238000013461 design Methods 0.000 description 4

- 238000007750 plasma spraying Methods 0.000 description 4

- 238000005524 ceramic coating Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- 230000002411 adverse Effects 0.000 description 2

- 239000012159 carrier gas Substances 0.000 description 2

- 238000009792 diffusion process Methods 0.000 description 2

- 230000003628 erosive effect Effects 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 230000000873 masking effect Effects 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 238000009420 retrofitting Methods 0.000 description 2

- 240000006829 Ficus sundaica Species 0.000 description 1

- 241001295925 Gegenes Species 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 238000001311 chemical methods and process Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000007712 rapid solidification Methods 0.000 description 1

- 238000009877 rendering Methods 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 238000005488 sandblasting Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000005245 sintering Methods 0.000 description 1

- 238000004901 spalling Methods 0.000 description 1

- 229910000601 superalloy Inorganic materials 0.000 description 1

- 239000002347 wear-protection layer Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C24/00—Coating starting from inorganic powder

- C23C24/08—Coating starting from inorganic powder by application of heat or pressure and heat

- C23C24/10—Coating starting from inorganic powder by application of heat or pressure and heat with intermediate formation of a liquid phase in the layer

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C28/00—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D

- C23C28/02—Coating for obtaining at least two superposed coatings either by methods not provided for in a single one of groups C23C2/00 - C23C26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D only coatings only including layers of metallic material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/08—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator

- F01D11/12—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator using a rubstrip, e.g. erodible. deformable or resiliently-biased part

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

- F01D5/20—Specially-shaped blade tips to seal space between tips and stator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/28—Selecting particular materials; Particular measures relating thereto; Measures against erosion or corrosion

- F01D5/284—Selection of ceramic materials

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/28—Selecting particular materials; Particular measures relating thereto; Measures against erosion or corrosion

- F01D5/288—Protective coatings for blades

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/49336—Blade making

- Y10T29/49337—Composite blade

Definitions

- the invention relates to the field of power plant and materials technology. It relates to a wear and oxidation resistant turbine blade and a manufacturing method for such a wear and oxidation resistant turbine blade.

- the aim of the invention is to avoid the disadvantages of the known prior art.

- the invention has for its object to develop a wear and oxidation resistant turbine blade, which is applicable both for the manufacture of new parts, as well as for reconditioning (retrofit) and for their production of the existing manufacturing process must be minimally adjusted.

- the advantages of the invention are that the main body of the turbine blade is protected against oxidation on all critical surfaces that are exposed to the hot gas and at the same time the blade tip is tolerant to frictional contacts with the heat shield, which is a reduction of the hot gas gap and thus a reduction of leakage losses allowed. In this way, the efficiency of the turbine can be significantly increased.

- the blade according to the invention can be produced by a cost-effective and easily implementable method.

- the turbine blade can be scooped into the rotor of the turbine directly after laser deposition welding (LMF step) without further heat treatment and thus used for turbine operation.

- LMF step laser deposition welding

- the metallic protective layer may be covered by a ceramic thermal barrier coating and the second oxidation and wear resistant protective layer applied by laser deposition welding at least partially overlaps only with the metallic protective layer, but not with the ceramic thermal barrier coating. This achieves optimal oxidation protection and does not adversely affect the integrity of the TBC, i. a spalling of the TBC is prevented.

- the wear-resistant and oxidation-resistant protective layer consists of an abrasive material, which is preferably cubic boron nitride (cBN), and of an oxidation-resistant metallic binder material, in particular having the following chemical composition (in% by weight): 30 Cr, 5-10 Al, 0.3-1.2 Y, 0.1-1.2 Si, 0-2 others, balance Ni, Co.

- cBN cubic boron nitride

- the invention can be used for all blade types of a turbine.

- the abrasive layer is applied to the crown (or part of the crown).

- the method for better wear protection of the shroud web can be used.

- the described realization of the turbine blade is applicable both for the manufacture of new parts, as well as for the reconditioning (retrofit). In doing so, the existing production process has to be adapted only minimally.

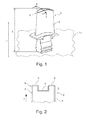

- Fig. 1 shows a perspective view of a turbine blade 1 for a (here only schematically indicated) rotor 13 of a gas turbine, while in Fig. 2 a section along the line II-II in Fig. 1 is shown enlarged.

- the turbine blade 1 has an airfoil 2 which extends in the radial direction r (relative to the rotor) and which is formed on the blade tip 9 as a crown 3 with inner and outer crown edges extending in the radial direction.

- the base material of the airfoil is, for example, a nickel-base superalloy.

- the surface of the airfoil is at least on the crown edges (s. Fig.

- the radially outer blade tip is constructed from a second wear and oxidation resistant protective layer 5 constructed by known laser deposition welding, this second protective layer 5 at least partially on the blade tip 9 along the outer and / or inner crown edge overlaps with the first metallic protective layer 4 arranged there.

- the protective layer 5 can be single-layer or multi-layered. In particular, with multilayer overlapping protective layers 5, which are applied by means of LMF, a variation of the length L of the turbine blade 1 can be realized well.

- the protective layer 5 consists of an abrasive material 6, which is preferably cubic boron nitride (cBN), and an oxidation-resistant binder material which preferably has the following chemical composition (in% by weight): 15-30 Cr, 5-10 Al, 0.3- 1.2 Y, 0.1-1.2 Si, 0-2 others, balance Ni, Co.

- cBN cubic boron nitride

- a concretely used suitable binder material is z.

- Fig. 3a and 3b This is especially good on the Fig. 3a and 3b to see the photos of coated according to the invention blade tips.

- the wear-resistant and oxidation-resistant protective layer 5 one can very well recognize the pointed cBN particles as abrasive material 6, which are embedded in the binder material 7.

- This protective layer 5 was by LMF using a fiber-coupled high-power diode laser with max. 1000W output power realized.

- Fig. 3a (left) partially overlaps the new coating with an MCrAIY protective layer 4 previously applied by plasma spraying Fig. 3b the turbine blade 1 on the MCrAIY layer 4 has an additional ceramic thermal barrier coating (TBC) 4a.

- TBC ceramic thermal barrier coating

- Fig. 4 schematically shows a further embodiment of a turbine blade 1 according to the invention with a shroud 11, which is arranged radially outward on the blade tip and a web 12 has.

- a shroud 11 which is arranged radially outward on the blade tip and a web 12 has.

- the special feature of the approach described here is the special design of such a wear-resistant protective layer 5.

- the single-layer or multi-layer 5 is applied so that it at least partially overlaps with other existing protective layers 4.

- a ceramic insulating layer TBC, Thermal Barrier Coating

- TBC Thermal Barrier Coating

- the abrasive layer is applied as the last step in the process chain by laser deposition welding.

- a simple and cost-effective implementation is to remove the radially outwardly located MCrAlY (possibly also TBC) layer (s) by milling or grinding or by chemical process by a defined amount completely.

- the wear-resistant layer is applied by LMF to the now exposed base material.

- the decisive factor here is the locally very limited action of the laser beam, which keeps the effects on the adjacent areas of the blade very low in the case of controlled process control. It is thus possible to apply such a wear-resistant layer in the immediate vicinity of a TBC protective layer without damaging it (see, for example, US Pat Fig. 4b ).

- the surfaces of the turbine blade 1 (eg the blade root) which are not to be coated need not be protected by a masking method.

- the LMF process is a welding process and produces a stable metallurgical bond with the main body of the blade without additional diffusion heat treatment. Due to the low local heat input, the local hardening is kept small despite the rapid solidification process. Thus, the component immediately after the application of the Wear-resistant protective layer can be installed without further subsequent steps.

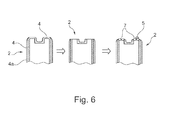

- Fig. 5 shows various implementation options.

- the wear-resistant MCrAlY protective layer 4 is first applied to the blade 1, for example by plasma spraying. Subsequently, this protective layer 4 is locally removed at the blade tip, for example by milling or grinding ( Fig. 5b ).

- the wear and oxidation resistant protective layer 5 is applied by the LMF method. The last applied protective layer 5 overlaps at least partially with the previously applied oxidation-resistant MCrAlY protective layer 4 (FIG. Fig. 5c ). As a result, the entire blade body is protected against oxidation at high operating temperatures.

- the wear-resistant and oxidation-resistant protective layer 5 overlaps with the previously applied MCrAlY protective layer 4 in order to ensure optimum protection of the airfoil 1 against oxidation. Due to the localized and minimized heat input, the LMF method can be performed in close proximity to the ceramic thermal barrier coating 4a, without the TBC flaking off.

- FIG. 6 Another embodiment is in Fig. 6

- This variant can be used, for example, when the crown 3 of the turbine blade 1 is so wide that the wear-resistant and oxidation-resistant protective layer 5 can not be applied with a single welding track.

- initially at least one multilane, overlapping intermediate layer 8 of oxidation-resistant binder material 7 can be applied.

- at least one further track is applied with combined supply of binder material 7 and abrasive material 6 to the first deposited layer (s). It is not necessary that the abrasive particles 6 are distributed over the entire width of the blade tip 9.

- the in Fig. 6 shown variant cost-optimized production of oxidation and wear resistant blade tip.

- Fig. 7 shows by way of example a coating device 14 for carrying out the last step of the inventive method.

- the device 14 is in EP 1 476 272 B1 described in detail, the content of this document is part of the present application.

- abrasive material 6 and oxidation-resistant binder material 7 are mixed in a powder nozzle, transported by means of a carrier gas 15 and then injected concentrically around the laser beam 10 as a focused powder jet into the melt pool 16 produced by the laser beam 10 at the blade tip 9.

- the temperature or temperature distribution in the molten bath is recorded online (optical temperature signal 17) and this information is not recorded with the help of a Fig. 7 used to control the laser power during laser deposition welding and / or to control the relative movement between the laser beam 10 and the turbine blade 1 controlled.

- the invention can be used in many ways for deckless turbine blades, but also for components with shroud. Attention must be paid to the service life of the abrasive coating, which depends on the respective operating conditions (temperature, fuel). By a good distribution and complete embedding of Abrasivteilchen in the oxidation-resistant binder matrix lifetime optimization is achieved. Nevertheless, the main object of the invention is to protect the turbine blade tip, especially during the break-in period. This corresponds to a duration of several tens to several hundred operating hours.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Laser Beam Processing (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Description

Die Erfindung bezieht sich auf das Gebiet der Kraftwerks- und Werkstofftechnik. Sie betrifft eine verschleiss- und oxidationsbeständige Turbinenschaufel sowie ein Herstellungsverfahren für eine derartige verschleiss- und oxidationsbeständige Turbinenschaufel.The invention relates to the field of power plant and materials technology. It relates to a wear and oxidation resistant turbine blade and a manufacturing method for such a wear and oxidation resistant turbine blade.

Die Verringerung von Leckageverlusten in Turbinen ist seit mehreren Jahrzehnten Gegenstand intensiver Entwicklungsarbeiten. Während des Betriebes einer Gasturbine ist eine Relativbewegung zwischen Rotor und Gehäuse unvermeidbar. Der daraus resultierende Verschleiss des Gehäuses bzw. der Schaufeln führt dazu, dass die Dichtwirkung nicht mehr gegeben ist. Als Lösung für dieses Problem wird eine Kombination von dicken abschleifbaren Beschichtungen am Hitzeschild mit abrasiven Schutzschichten an den Schaufelspitzen vorgesehen.The reduction of leakage losses in turbines has been the subject of intensive development work for several decades. During operation of a gas turbine, a relative movement between the rotor and the housing is unavoidable. The resulting wear of the housing or the blades causes the sealing effect is no longer given. The solution to this problem is a combination of thick Abradable coatings on the heat shield provided with abrasive protective layers on the blade tips.

Bereits seit den 70er Jahren des letzten Jahrhunderts kennt man Methoden, zusätzliche Beschichtungen auf Schaufelspitzen aufzubringen oder durch eine geeignete Modifikation der Schaufelspitze die Verschleissbeständigkeit zu erhöhen. Es sind ebenfalls verschiedene Methoden vorgeschlagen worden, um solche Schutzschichten durch eine Kombination von Abrasivteilchen (Karbiden, Nitriden, etc.) mit oxidationsresistenten Materialien gleichzeitig beständig gegenüber Reibkontakten und durch das Heissgas verursachter Oxidation zu machen. Viele der vorgeschlagenen Methoden sind jedoch in der Herstellung kostenintensiv und komplex, was einen kommerziellen Einsatz erschwert.Already since the 70s of the last century methods are known to apply additional coatings on blade tips or to increase the wear resistance by a suitable modification of the blade tip. Various methods have also been proposed for simultaneously rendering such protective layers resistant to frictional contacts and oxidation caused by the hot gas by a combination of abrasive particles (carbides, nitrides, etc.) with oxidation-resistant materials. However, many of the proposed methods are costly to manufacture and complex, making commercial use difficult.

Eine der populären Strategien besteht deshalb darin, auf den Verschleissschutz der Schaufelspitze ganz zu verzichten und das Hitzeschild mit speziellen, porösen keramischen Einreibschichten zu versehen. Diese können auf Grund ihrer hohen Porosität in gewissem Umfang auch von ungeschützten Schaufelspitzen eingerieben werden. Mit dieser Methode sind jedoch erhebliche technische Risiken verbunden, da die porösen keramischen Einreibschichten nicht die gleiche Erosionsbeständigkeit wie dichte Schichten gewährleisten. Ein weiteres Risiko besteht in betriebsbedingten Veränderungen der porösen keramischen Einreibschichten (Verdichtung durch Sintern), die sich negativ auf die tribologischen Eigenschaften auswirken können. Aus diesem Grund ist bei der Verwendung keramischer Schutzschichten auf Hitzeschildern eine Kombination mit verschleissfesten (abrasiven) Schaufelspitzen ratsam.One of the popular strategies is therefore to dispense with the wear protection of the blade tip completely and to provide the heat shield with special, porous ceramic Einreibschichten. Due to their high porosity, they can also be rubbed to a certain extent by unprotected blade tips. However, this method involves considerable technical risks because the porous ceramic rubbing layers do not ensure the same erosion resistance as dense layers. There is also a risk of operational changes in the porous ceramic rubbing layers (compaction by sintering), which can have a negative effect on the tribological properties. For this reason, when using ceramic protective layers on heat shields, a combination with wear-resistant (abrasive) blade tips is advisable.

In den letzten Jahrzehnten sind mehrere Verfahren zur Erzeugung abrasiver Schaufelspitzen entwickelt und durch zahlreiche Patente geschützt worden, siehe z.B.

Weitere relevante Verfahren sind aus den Anmeldungen

Ziel der Erfindung ist es, die Nachteile des bekannten Standes der Technik zu vermeiden. Der Erfindung liegt die Aufgabe zugrunde, eine verschleiss- und oxidationsbeständige Turbinenschaufel zu entwickeln, welche sowohl für die Neuteilfertigung, als auch für das Rekonditionieren (Retrofit) anwendbar ist und für deren Herstellung der bereits bestehende Fertigungsprozess nur minimal angepasst werden muss.The aim of the invention is to avoid the disadvantages of the known prior art. The invention has for its object to develop a wear and oxidation resistant turbine blade, which is applicable both for the manufacture of new parts, as well as for reconditioning (retrofit) and for their production of the existing manufacturing process must be minimally adjusted.

Die Besonderheit der hier beschriebenen Ausführung eines solchen Bauteils besteht in der bestmöglichen Kompatibilität zu konventionellen Turbinenschaufeln und deren Fertigungsprozessen. Dies erfordert nur einen geringen Aufwand für die Umstellung derzeitiger Fertigungsabläufe und öffnet sehr interessante Perspektiven für Rekonditionierung und Retrofit.The peculiarity of the design of such a component described here consists in the best possible compatibility with conventional turbine blades and their manufacturing processes. This requires only little effort for the conversion of current production processes and opens up very interesting prospects for reconditioning and retrofitting.

Erfindungsgemäss wird diese Aufgabe dadurch gelöst, dass die verschleiss- und oxidationsbeständige Turbinenschaufel gemäss dem Oberbegriff des Patentanspruches 1 durch folgende Merkmale gekennzeichnet ist:

- die mindestens eine erste oxidationsbeständige Schutzschicht ist eine metallische Schicht, insbesondere eine MCrAlY-Schicht (M = Ni, Co oder Kombination beider Elemente)

- diese erste Schutzschicht ist zumindest an der inneren und äusseren Kronenkante bzw. Steg kante angeordnet,

- diese erste Schutzschicht ist an der radial aussen gelegenen Schaufelspitze der Turbinenschaufel nicht vorhanden und

- die radial aussen gelegene Schaufelspitze besteht aus einer mittels bekanntem Laserauftragsschweissen aufgebauten zweiten mindestens einlagigen verschleiss- und oxidationsbeständigen Schutzschicht, wobei diese zweite Schutzschicht auf der Schaufelspitze entlang der äusseren und/oder inneren Kronenkante bzw. Stegkante zumindest teilweise mit der dort angeordneten ersten metallischen Schutzschicht überlappt.

- the at least one first oxidation-resistant protective layer is a metallic layer, in particular an MCrAlY layer (M = Ni, Co or combination of both elements)

- this first protective layer is arranged at least on the inner and outer crown edge or web edge,

- this first protective layer is not present at the radially outer blade tip of the turbine blade and

- the blade tip located radially outward consists of a second at least single-layer wear and oxidation-resistant protective layer constructed by means of known laser deposition welding, this second protective layer resting on the blade tip along the blade tip outer and / or inner crown edge or web edge overlaps at least partially with the first metallic protective layer arranged there.

Das erfindungsgemässe Verfahren zur Herstellung einer Turbinenschaufel gemäss Oberbegriff des Patentanspruches 12 ist durch folgende Merkmale gekennzeichnet:

- die mindestens eine oxidationsbeständige Schutzschicht an der radial aussen gelegenen Schaufelspitze wird durch kontrollierte mechanische Bearbeitung, insbesondere Abschleifen, CNC Fräsen, und/oder chemisches Entschichten, entfernt und

- die verschleiss- und oxidationsbeständige Schutzschicht wird anschliessend mittels bekanntem Laserauftragsschweissen in einer Lage oder in mehreren Lagen auf die Schaufelspitze derart aufgebracht, dass sie entlang der äusseren und/oder inneren Kronenkante bzw. Stegkante zumindest teilweise mit der vorher aufgebrachten ersten metallischen Schutzschicht, aber nicht mit der wahlweise vorher aufgebrachten keramischen Wärmedämmschicht (TBC = Thermal Barrier Coating) überlappt.

- the at least one oxidation-resistant protective layer on the radially outer blade tip is removed by controlled mechanical processing, in particular grinding, CNC milling, and / or chemical stripping, and

- the wear-resistant and oxidation-resistant protective layer is subsequently applied to the blade tip by means of known laser deposition welding in one layer or in several layers such that it at least partially coincides with the previously applied first metallic protective layer along the outer and / or inner crown edge or web edge overlaps the optionally previously applied ceramic thermal barrier coating (TBC = Thermal Barrier Coating).

Die Vorteile der Erfindung bestehen darin, dass der Grundkörper der Turbinenschaufel an allen kritischen Oberflächen, die dem Heissgas ausgesetzt sind, gegen Oxidation geschützt wird und gleichzeitig die Schaufelspitze tolerant gegenüber Reibkontakten mit dem Hitzeschild ist, was eine Verkleinerung des Heissgasspaltes und damit eine Verringerung der Leckageverluste erlaubt. Auf diese Weise kann der Wirkungsgrad der Turbine signifikant gesteigert werden.The advantages of the invention are that the main body of the turbine blade is protected against oxidation on all critical surfaces that are exposed to the hot gas and at the same time the blade tip is tolerant to frictional contacts with the heat shield, which is a reduction of the hot gas gap and thus a reduction of leakage losses allowed. In this way, the efficiency of the turbine can be significantly increased.

Die erfindungsgemässe Schaufel kann durch ein kostengünstiges und einfach umsetzbares Verfahren hergestellt werden.The blade according to the invention can be produced by a cost-effective and easily implementable method.

Durch die erhöhte Verschleissbeständigkeit der Turbinenschaufel gegenüber Reibkontakten können relativ dichte keramische Beschichtungen an den Hitzeschildern appliziert werden. Somit kann ein gutes Einreibverhalten mit der erforderlichen Langzeit-Erosionsbeständigkeit der keramischen Beschichtungen auf den Hitzeschildern kombiniert werden.Due to the increased wear resistance of the turbine blade against friction contacts relatively dense ceramic coatings on the Heat shields are applied. Thus, a good rub-in behavior can be combined with the required long-term erosion resistance of the ceramic coatings on the heat shields.

Von besonderem Vorteil ist, dass die Turbinenschaufel direkt nach dem Laserauftragsschweissen (LMF-Schritt) ohne eine weitere Wärmebehandlung in den Rotor der Turbine eingeschaufelt und somit für den Turbinenbetrieb eingesetzt werden kann.It is particularly advantageous that the turbine blade can be scooped into the rotor of the turbine directly after laser deposition welding (LMF step) without further heat treatment and thus used for turbine operation.

Weitere vorteilhafte Ausgestaltungen sind in den Unteransprüchen beschrieben.Further advantageous embodiments are described in the subclaims.

So kann beispielsweise die metallische Schutzschicht von einer keramischen Wärmedämmschicht bedeckt sein und die durch Laserauftragsschweissen aufgebrachte zweite oxidations- und verschleissbeständige Schutzschicht überlappt zumindest teilweise nur mit der metallischen Schutzschicht, nicht aber mit der keramischen Wärmedämmschicht. Dadurch wird ein optimaler Oxidationsschutz erreicht und die Integrität der TBC wird nicht beeinträchtigt, d.h. ein Abplatzen der TBC wird verhindert.Thus, for example, the metallic protective layer may be covered by a ceramic thermal barrier coating and the second oxidation and wear resistant protective layer applied by laser deposition welding at least partially overlaps only with the metallic protective layer, but not with the ceramic thermal barrier coating. This achieves optimal oxidation protection and does not adversely affect the integrity of the TBC, i. a spalling of the TBC is prevented.

Weiterhin ist es vorteilhaft, wenn die verschleiss- und oxidationsbeständige Schutzschicht aus einem Abrasivmaterial, welches vorzugsweise kubisches Bornitrid (cBN) ist, und aus einem oxidationsbeständigen metallischen Bindermaterial besteht, insbesondere mit folgender chemischen Zusammensetzung (Angaben in Gew.- %) aufweist: 15-30 Cr, 5-10 Al, 0.3-1.2 Y, 0.1-1.2 Si, 0-2 andere, Rest Ni, Co.Furthermore, it is advantageous if the wear-resistant and oxidation-resistant protective layer consists of an abrasive material, which is preferably cubic boron nitride (cBN), and of an oxidation-resistant metallic binder material, in particular having the following chemical composition (in% by weight): 30 Cr, 5-10 Al, 0.3-1.2 Y, 0.1-1.2 Si, 0-2 others, balance Ni, Co.

Von Vorteil ist ausserdem, wenn der Anteil an Abrasivmaterial in der verschleiss- und oxidationsbeständigen mehrlagigen Schutzschicht in radialer Richtung nach aussen zunimmt, weil das eine optimale Anpassung an die Beanspruchungsbedingungen gewährleistet.It is also advantageous if the proportion of abrasive material in the wear-resistant and oxidation-resistant multilayer protective layer increases in the radial direction to the outside, because this ensures optimum adaptation to the stress conditions.

Die Erfindung kann für alle Schaufeltypen einer Turbine eingesetzt werden. Bei Schaufeln ohne Deckband (shroud) wird die Abrasivschicht dabei auf die Krone (oder einen Teil der Krone) aufgebracht. Bei Schaufeln mit Deckband kann die Methode zum besseren Verschleissschutz des Deckbandstegs eingesetzt werden.The invention can be used for all blade types of a turbine. For blades without shroud, the abrasive layer is applied to the crown (or part of the crown). For shovels with shroud, the method for better wear protection of the shroud web can be used.

Die beschriebene Realisierung der Turbinenschaufel ist sowohl für die Neuteilfertigung, als auch für das Rekonditionieren (Retrofit) anwendbar. Dabei muss der bestehende Fertigungsprozess nur minimal angepasst werden.The described realization of the turbine blade is applicable both for the manufacture of new parts, as well as for the reconditioning (retrofit). In doing so, the existing production process has to be adapted only minimally.

Ein besonders interessantes kommerzielles Potential besteht im Retrofit bzw. Rekonditionieren bestehender Schaufeln. Derartige Schaufeln können mit dem erfindungsgemässen Verfahren modifiziert werden, um beim Neueinbau geringere Leckageverluste und damit einen verbesserten Wirkungsgrad der Turbine zu erreichen. Für diese Option muss dabei vorher nicht eine eventuell bereits bestehende Schutzschicht auf dem Schaufelblatt entfernt werden, was ein vereinfachtes Herstellungsverfahren ermöglicht.A particularly interesting commercial potential exists in the retrofitting or reconditioning of existing blades. Such blades can be modified with the inventive method to achieve lower leakage losses and thus improved efficiency of the turbine when installing new. For this option, it is not necessary to remove any existing protective layer on the blade, which allows a simplified manufacturing process.

In den Zeichnungen sind Ausführungsbeispiele der Erfindung dargestellt. Es zeigen:

- Fig. 1

- eine Turbinenschaufel für den Rotor einer Gasturbine mit einer als Krone ausgebildeten Schaufelspitze gemäss einem ersten Ausführungsbeispiel der Erfindung;

- Fig. 2

- einen schematischen Schnitt entlang der Linie II-II in

Fig. 1 ; - Fig. 3

- fotographische Aufnahmen von mit dem LMF-Verfahren erzeugten verschleiss- und oxidationsbeständigen Panzerungen von Turbinenschaufelspitzen in zwei erfindungsgemässen Varianten;

- Fig. 4

- eine schematische Darstellung eines weiteren Ausführungsbeispieles der Erfindung anhand einer Turbinenschaufel mit Deckband;

- Fig. 5

- die Fertigungsabfolge bei der Herstellung einer Turbinenschaufel gemäss der Erfindung in zwei Varianten;

- Fig. 6

- die Fertigungsabfolge bei der Herstellung einer Turbinenschaufel gemäss der Erfindung in einer weiteren Variante und

- Fig. 7

- eine beispielhafte Beschichtungsvorrichtung für das LMF Verfahren.

- Fig. 1

- a turbine blade for the rotor of a gas turbine with a trained as a crown blade tip according to a first embodiment of the invention;

- Fig. 2

- a schematic section along the line II-II in

Fig. 1 ; - Fig. 3

- Photographs of LMF-produced wear and oxidation-resistant armor plating of turbine blade tips in two variants according to the invention;

- Fig. 4

- a schematic representation of another embodiment of the invention with reference to a turbine blade with shroud;

- Fig. 5

- the manufacturing sequence in the manufacture of a turbine blade according to the invention in two variants;

- Fig. 6

- the production sequence in the manufacture of a turbine blade according to the invention in a further variant and

- Fig. 7

- an exemplary coating device for the LMF process.

Nachfolgend wird die Erfindung anhand von Ausführungsbeispielen und der

Die Schutzschicht 5 besteht aus einem Abrasivmaterial 6, welches vorzugsweise kubisches Bornitrid (cBN) ist, und einem oxidationsbeständigen Bindermaterial, welches vorzugsweise folgende chemische Zusammensetzung (Angaben in Gew.- %) aufweist: 15-30 Cr, 5-10 Al, 0.3-1.2 Y, 0.1-1.2 Si, 0-2 andere, Rest Ni, Co. Ein konkret angewendetes gut geeignetes Bindermaterial ist z. B. die kommerzielle Legierung Amdry995.The

Besonders gut ist das an den

Das Besondere des hier beschriebenen Ansatzes besteht in der speziellen Auslegung einer solchen verschleissfesten Schutzschicht 5. Die ein- oder mehrlagige Schicht 5 wird so appliziert, dass sie zumindest teilweise mit anderen bestehenden Schutzschichten 4 überlappt. Bei den bereits bestehenden Schutzschichten 4 handelt es sich z.B. um aus dem Stand der Technik bekannte MCrAlY-Schichten (M= Ni, Co, oder eine Kombination beider Elemente), die bei den meisten hochbelasteten Turbinenschaufeln die Oberflächen des Schaufelblattes gegen Oxidation und Korrosion schützen. Weiterhin kann auf dieser MCrAlY-Schicht zusätzlich auf dem Schaufelblatt eine keramische Dämmschicht (TBC, Thermal Barrier Coating) aufgebracht sein, deren Integrität durch die vorgeschlagene Methode nicht beeinträchtigt wird.The special feature of the approach described here is the special design of such a wear-resistant

Die vorgeschlagene Ausführung einer oxidationsbeständigen Abrasivschicht auf der Schaufelspitze gewährleistet durch die Überlappung mit den bereits bestehenden Schutzschichten einen effizienten Schutz der gegenüber dem Heissgas exponierten Flächen der Schaufelspitze. Eine Applikation dieser Verschleissschutzschicht durch das LMF-Verfahren ermöglicht es zudem, diese Beschichtungsoperation als letzten Fertigungsschritt im Herstellungsprozess anzusetzen. Damit werden die folgenden technischen Probleme umgangen:

- Bei der MCrAlY-Beschichtung muss die Oberfläche durch Sandstrahlen und/oder Reinigung mit übertragenem Lichtbogen vorgängig von Oxiden befreit werden, um eine optimale Anbindung zu gewährleisten. Eine mit herkömmlichen (z.B galvanischen) Verfahren aufgebrachte Abrasivschicht, müsste während der Vorbereitung zur MCrAIY-Beschichtung durch eine entsprechende Maskierung gegen Schädigung geschützt werden, was Zusatzaufwand und Zusatzkosten verursachen würde.

- MCrAlY-Beschichtungen werden meist durch Plasmaspritzen hergestellt. Im Anschluss an das Aufbringen der Beschichtung ist ein Diffusions-Wärmebehandlungsschritt bei Temperaturen im Bereich >1050°C erforderlich. Bei diesem Prozessschritt können durch die hohen Temperaturen die Eigenschaften von vorher aufgebrachten Abrasivbeschichtungen negativ beeinflusst werden.

- For the MCrAlY coating, sandblasting and / or transferred-arc cleaning must be used to remove oxides from the surface to ensure optimum bonding. An applied with conventional (eg galvanic) abrasive layer, would have during preparation for MCrAIY coating by an appropriate masking against Be protected damage, which would cause additional expense and additional costs.

- MCrAlY coatings are mostly produced by plasma spraying. Subsequent to application of the coating, a diffusion annealing step at temperatures in the range> 1050 ° C is required. In this process step, the high temperatures can adversely affect the properties of previously applied abrasive coatings.

O.g. Probleme werden umgangen, wenn wie hier beschrieben, die Abrasivschicht als letzter Schritt in der Prozesskette durch das Laserauftragsschweissen aufgebracht wird. Eine einfache und kosteneffiziente Umsetzung besteht darin, die in radialer Richtung aussen gelegenen MCrAlY- (ggf. auch TBC-) Schicht(en) durch Abfräsen oder Abschleifen bzw. durch chemische Prozesses um einen definierten Betrag komplett zu entfernen. Auf das nun exponierte Grundmaterial wird anschliessend die Verschleissschutzschicht durch LMF aufgebracht. Entscheidend ist dabei die lokal sehr begrenzte Einwirkung des Laserstrahls, die bei kontrollierter Prozessführung die Einwirkungen auf die benachbarten Bereiche der Schaufel sehr gering hält. Es wird damit möglich, eine solche verschleissfeste Schicht in unmittelbarer Nähe zu einer TBC-Schutzschicht aufzubringen, ohne diese zu beschädigen (siehe z.B.

Im Gegensatz zu konventionellen (z.B. galvanischen) Beschichtungsmethoden, müssen die nicht zu beschichtenden Flächen der Turbinenschaufel 1 (z.B. der Schaufelfuss) nicht durch ein Maskierungsverfahren geschützt werden. Der LMF-Prozess ist ein Schweissverfahren und erzeugt ohne zusätzliche Diffusions-Wärmebehandlung eine stabile metallurgische Verbindung mit dem Grundkörper der Schaufel. Durch die geringe lokale Wärmeeinbringung wird die lokale Aufhärtung trotz des schnellen Erstarrungsprozesses klein gehalten. Damit kann die Komponente unmittelbar nach dem Applizieren der verschleissbeständigen Schutzschicht ohne weitere nachfolgende Schritte eingebaut werden.In contrast to conventional (eg galvanic) coating methods, the surfaces of the turbine blade 1 (eg the blade root) which are not to be coated need not be protected by a masking method. The LMF process is a welding process and produces a stable metallurgical bond with the main body of the blade without additional diffusion heat treatment. Due to the low local heat input, the local hardening is kept small despite the rapid solidification process. Thus, the component immediately after the application of the Wear-resistant protective layer can be installed without further subsequent steps.

Wie oben bereits beschrieben, ist es möglich, in einem weiteren vorangehenden Herstellungsschritt die Schaufelspitze mit einer zusätzlichen Wärmedämmschicht 4a zu versehen. In der in

Ein weiteres Ausführungsbeispiel ist in

Die Erfindung kann auf vielfältige Weise für deckbandlose Turbinenschaufeln, aber auch für Komponenten mit Deckband eingesetzt werden. Zu beachten ist die von den jeweiligen Betriebsbedingungen (Temperatur, Brennstoff) abhängige Lebensdauer der Abrasivbeschichtung. Durch eine gute Verteilung und komplette Einbettung der Abrasivteilchen in die oxidationsbeständige Bindermatrix wird eine Lebensdaueroptimierung erreicht. Dennoch ist das Hauptziel der Erfindung, die Turbinenschaufelspitze vor allem während der Einlaufphase zu schützen. Dies entspricht einer Dauer von mehreren Dutzend bis mehreren Hundert Betriebsstunden.The invention can be used in many ways for deckless turbine blades, but also for components with shroud. Attention must be paid to the service life of the abrasive coating, which depends on the respective operating conditions (temperature, fuel). By a good distribution and complete embedding of Abrasivteilchen in the oxidation-resistant binder matrix lifetime optimization is achieved. Nevertheless, the main object of the invention is to protect the turbine blade tip, especially during the break-in period. This corresponds to a duration of several tens to several hundred operating hours.

Selbstverständlich ist die Erfindung nicht auf die beschriebenen Ausführungsbeispiele beschränkt.Of course, the invention is not limited to the described embodiments.

- 11

- Turbinenschaufelturbine blade

- 22

- Schaufelblattairfoil

- 33

- KroneCrown

- 4, 4a4, 4a

- erste oxidationsbeständige Schutzschicht (4 metallische Schicht, 4a keramische Wärmedämmschicht)first oxidation-resistant protective layer (4 metallic layer, 4a ceramic thermal barrier layer)

- 55

- zweite verschleiss- und oxidationsbeständige Schutzschichtsecond wear and oxidation resistant protective layer

- 66

- Abrasivmaterialabrasive

- 77

- Bindermaterialbinder material

- 88th

- Zwischenschicht aus oxidationsbeständigem BindermaterialIntermediate layer of oxidation-resistant binder material

- 99

- Schaufelspitzeblade tip

- 1010

- Laserstrahllaser beam

- 1111

- Deckbandshroud

- 1212

- Stegweb

- 1313

- Rotorrotor

- 1414

- Beschichtungsvorrichtungcoater

- 1515

- Trägergascarrier gas

- 1616

- Schmelzbadmelting bath

- 1717

- optisches Temperatursignaloptical temperature signal

- rr

- radiale Richtungradial direction

- LL

- Länge der TurbinenschaufelLength of the turbine blade

Claims (15)

- Turbine blade (1) for the rotor (13) of a turbine, having a main blade section (2), which has a blade tip (9), extends in the radial direction (r) and is formed at the blade tip (9) either as a crown (3) with an inner and outer crown edge extending in the radial direction (r) or as a shroud (11) with a web (12), which extends in the radial direction and has lateral edges, wherein at least certain zones on the surface of the main blade section (2) are provided with at least one first protective coating (4, 4a) consisting of oxidation-resistant material, characterized in that- the at least one first, oxidation-resistant protective coating (4) is a metallic coating, namely an MCrAlY coating,- said first protective coating (4) is arranged at least at the inner and/or outer crown edge or at the web edges,- said first protective coating (4) is not present at the radially outer blade tip (9) of the turbine blade (1), and- the radially outer blade tip (9) consists of a second, at least single-layer wear-resistant and oxidation-resistant protective coating (5) which is built up by known laser metal forming, wherein said second protective coating (5) on the blade tip (9) overlaps along the outer and/or inner crown edge or the web edges at least partially with the first, metallic protective coating (4) arranged there.

- Turbine blade (1) according to Claim 1, characterized in that the at least one metallic protective coating (4) is covered by a ceramic thermal barrier coating (4a), and wherein the second, oxidation-resistant and wear-resistant protective coating (5) which is applied by laser metal forming overlaps at least partially only with the metallic protective coating (4), but not with the ceramic thermal barrier coating (4a).

- Turbine blade (1) according to Claim 1 or 2, characterized in that the wear-resistant and oxidation-resistant protective coating (5) consists of an abrasive material (6) and an oxidation-resistant metallic binder material (7).

- Turbine blade (1) according to Claim 3, characterized in that the abrasive material (6) is cubic boron nitride (cBN).

- Turbine blade (1) according to Claim 3, characterized in that the oxidation-resistant binder material (7) has the following chemical composition (amounts in % by weight): 15-30 Cr, 5-10 Al, 0.3-1.2 Y, 0.1-1.2 Si, 0-2 others, remainder Ni, Co.

- Turbine blade (1) according to Claim 3, characterized in that the proportion of abrasive material (6) in the protective coating (5), if said coating has a multi-layer form, increases outward in the radial direction (r).

- Turbine blade (1) according to Claim 1 or 2, characterized in that an intermediate coating (8), which consists exclusively of oxidation-resistant binder material (7), is additionally arranged between the first, metallic protective coating (4) and the second, wear-resistant and oxidation-resistant protective coating (5), wherein the intermediate coating (8) at least partially overlaps the first protective coating (4) and wherein the second protective coating (5) in turn at least partially overlaps the intermediate coating (8).

- Turbine blade (1) according to one of Claims 1 to 7, characterized in that the turbine blade (1) is a reconditioned turbine blade.

- Turbine blade (1) according to Claim 8, characterized in that the turbine blade was used in a preceding service interval of the turbine without an abrasive blade tip (9).

- Turbine blade (1) according to one of Claims 1 to 9, characterized in that the turbine blade (1) is a new component.

- Turbine blade (1) according to one of Claims 1 to 10 having a length (L), characterized in that the length (L) can be varied by the coatings (5) built up by laser metal forming.

- Method for producing a turbine blade (1) according to one of Claims 1 to 11, wherein, in a preceding production step, at least certain zones on the surface of the main blade section (2) of the turbine blade (1) are coated with the oxidation-resistant, metallic protective coating (4), namely the MCrAlY coating, and an oxidation-resistant, ceramic thermal barrier coating (4a) is optionally applied to said protective coating (4), characterized in that- the at least one oxidation-resistant protective coating (4, 4a) on the radially outer blade tip (9) is removed by controlled machining and/or chemical coating removal, and then- the wear-resistant and oxidation-resistant protective coating (5) is applied to the blade tip (9) in one layer or in a plurality of layers by known laser metal forming, such that said coating overlaps along the outer and/or inner crown edge or the web edges at least partially with the first, metallic protective coating (4) applied beforehand, but not with the ceramic thermal barrier coating (4a) optionally applied beforehand.

- Method according to Claim 12, characterized in that the controlled machining is carried out by grinding away or CNC milling.

- Method according to Claim 12, characterized in that, during the laser metal forming step of the blade tip (9), abrasive material (6) and oxidation-resistant binder material (7) are mixed in a powder nozzle and then injected concentrically about the laser beam (10) as a focused jet of powder into the melt pool produced by the laser beam (10) on the blade tip (9).

- Method according to Claim 12 or 14, characterized in that the temperature or temperature distribution in the melt pool is additionally recorded online during the laser metal forming, and in that this information is used, with the aid of a control system, to control the laser power during the laser metal forming and/or to change the relative movement between the laser beam (10) and the turbine blade (1) in a controlled manner.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009051661 | 2009-11-02 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2316988A1 EP2316988A1 (en) | 2011-05-04 |

| EP2316988B1 true EP2316988B1 (en) | 2015-07-08 |

Family

ID=43402110

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10188806.3A Active EP2316988B1 (en) | 2009-11-02 | 2010-10-26 | Wear-resistant and oxidation-resistant turbine blade |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8740572B2 (en) |

| EP (1) | EP2316988B1 (en) |

| JP (1) | JP5693149B2 (en) |

| CA (1) | CA2719273C (en) |

| DE (1) | DE102010049398A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2645631C1 (en) * | 2016-12-07 | 2018-02-26 | Федеральное государственное бюджетное образовательное учреждение высшего образования "Казанский национальный исследовательский технический университет им. А.Н. Туполева-КАИ" (КНИТУ-КАИ) | Method of applying the coating on the sample (variants) and the device for its implementation (variants) |

| CN110899695A (en) * | 2019-12-09 | 2020-03-24 | 浙江翰德圣智能再制造技术有限公司 | Method for manufacturing micro-arc spark MCrAlY electrode by laser additive manufacturing |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2978931B1 (en) * | 2011-08-10 | 2014-05-09 | Snecma | METHOD FOR PRODUCING A PROTECTIVE REINFORCEMENT ON THE EDGE OF A BLADE |

| EP2604797B1 (en) * | 2011-12-13 | 2020-01-22 | MTU Aero Engines GmbH | Rotor blade with a rib assembly with an abrasive coating |

| US20140010663A1 (en) * | 2012-06-28 | 2014-01-09 | Joseph Parkos, JR. | Gas turbine engine fan blade tip treatment |

| US8858873B2 (en) | 2012-11-13 | 2014-10-14 | Honeywell International Inc. | Nickel-based superalloys for use on turbine blades |

| EP2932046A1 (en) * | 2012-12-17 | 2015-10-21 | General Electric Company | Robust turbine blades |

| US9909428B2 (en) | 2013-11-26 | 2018-03-06 | General Electric Company | Turbine buckets with high hot hardness shroud-cutting deposits |

| CN103659024B (en) * | 2013-12-31 | 2016-03-30 | 无锡透平叶片有限公司 | For the divided edge structure of turbine blade leading edge laser melting coating |

| DE102014202457A1 (en) * | 2014-02-11 | 2015-08-13 | Siemens Aktiengesellschaft | Improved wear resistance of a high-temperature component through cobalt coating |

| US9358663B2 (en) | 2014-04-16 | 2016-06-07 | General Electric Company | System and methods of removing a multi-layer coating from a substrate |

| US20160237832A1 (en) * | 2015-02-12 | 2016-08-18 | United Technologies Corporation | Abrasive blade tip with improved wear at high interaction rate |

| DE102015208781A1 (en) | 2015-05-12 | 2016-11-17 | MTU Aero Engines AG | Combination of blade tip armor and erosion control layer and method of making the same |

| DE102015208783A1 (en) | 2015-05-12 | 2016-11-17 | MTU Aero Engines AG | Covering method for producing a combination of blade tip armor and erosion protection layer |

| US10415579B2 (en) | 2016-09-28 | 2019-09-17 | General Electric Company | Ceramic coating compositions for compressor blade and methods for forming the same |

| EP3301260A1 (en) * | 2016-09-30 | 2018-04-04 | Siemens Aktiengesellschaft | Turbine blade with increase tip lifetime and a method for manufacturing said turbine blade |

| DE102017201645A1 (en) * | 2017-02-02 | 2018-08-02 | MTU Aero Engines AG | A method and apparatus for repairing a damaged blade tip of an armored and blade-coated turbine blade |

| US10533429B2 (en) | 2017-02-27 | 2020-01-14 | Rolls-Royce Corporation | Tip structure for a turbine blade with pressure side and suction side rails |

| EP3546703A1 (en) | 2018-03-29 | 2019-10-02 | Siemens Aktiengesellschaft | Turbine blade for a gas turbine |

| EP3546702A1 (en) * | 2018-03-29 | 2019-10-02 | Siemens Aktiengesellschaft | Turbine blade for a gas turbine |

| US11346232B2 (en) * | 2018-04-23 | 2022-05-31 | Rolls-Royce Corporation | Turbine blade with abradable tip |

| US10933469B2 (en) | 2018-09-10 | 2021-03-02 | Honeywell International Inc. | Method of forming an abrasive nickel-based alloy on a turbine blade tip |

| US20200157953A1 (en) * | 2018-11-20 | 2020-05-21 | General Electric Company | Composite fan blade with abrasive tip |

| CN109249120B (en) * | 2018-11-23 | 2020-10-23 | 佛山市固高自动化技术有限公司 | Multi-station full-automatic welding method for machining fan impeller |

| CN109628921A (en) * | 2018-12-31 | 2019-04-16 | 中北大学 | The method for preparing CoCrAlY coating based on laser melting coating and pulsed electron beam |

| CN110747377B (en) * | 2019-11-15 | 2020-11-10 | 清华大学 | High-chromium-nickel-based high-temperature alloy and preparation method and application thereof |

| DE102020206202A1 (en) | 2020-05-18 | 2021-11-18 | MTU Aero Engines AG | Blade for a turbomachine with blade tip armor and anti-erosion layer and method for producing the same |

| DE202020107410U1 (en) | 2020-12-18 | 2022-03-21 | Liebherr-Aerospace Lindenberg Gmbh | metallic component |

| US11486263B1 (en) | 2021-06-28 | 2022-11-01 | General Electric Company | System for addressing turbine blade tip rail wear in rubbing and cooling |

| DE102023100617A1 (en) | 2023-01-12 | 2024-07-18 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung eingetragener Verein | Processes for coating and machining components |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4169020A (en) * | 1977-12-21 | 1979-09-25 | General Electric Company | Method for making an improved gas seal |

| US4390320A (en) * | 1980-05-01 | 1983-06-28 | General Electric Company | Tip cap for a rotor blade and method of replacement |

| US5794338A (en) * | 1997-04-04 | 1998-08-18 | General Electric Company | Method for repairing a turbine engine member damaged tip |

| US5935407A (en) | 1997-11-06 | 1999-08-10 | Chromalloy Gas Turbine Corporation | Method for producing abrasive tips for gas turbine blades |

| JP3801452B2 (en) * | 2001-02-28 | 2006-07-26 | 三菱重工業株式会社 | Abrasion resistant coating and its construction method |

| US6461107B1 (en) * | 2001-03-27 | 2002-10-08 | General Electric Company | Turbine blade tip having thermal barrier coating-formed micro cooling channels |

| EP1340583A1 (en) | 2002-02-20 | 2003-09-03 | ALSTOM (Switzerland) Ltd | Method of controlled remelting of or laser metal forming on the surface of an article |

| DE102004059904A1 (en) | 2004-12-13 | 2006-06-14 | Alstom Technology Ltd | Moving blade e.g. for turbo machine, has blade point which faces stator in turbo machine and contacts into channel of stator with blade point provided in such way that blade contacts channel at its edges and into rotor |

| US7510370B2 (en) * | 2005-02-01 | 2009-03-31 | Honeywell International Inc. | Turbine blade tip and shroud clearance control coating system |

| US7473072B2 (en) * | 2005-02-01 | 2009-01-06 | Honeywell International Inc. | Turbine blade tip and shroud clearance control coating system |

| EP1715140A1 (en) * | 2005-04-21 | 2006-10-25 | Siemens Aktiengesellschaft | Turbine blade with a cover plate and a protective layer on the cover plate |

| US7140952B1 (en) * | 2005-09-22 | 2006-11-28 | Pratt & Whitney Canada Corp. | Oxidation protected blade and method of manufacturing |

| JP4535059B2 (en) * | 2006-11-30 | 2010-09-01 | 株式会社日立製作所 | Aluminum diffusion coating construction method |

| DE102008003100A1 (en) * | 2008-01-03 | 2009-07-16 | Mtu Aero Engines Gmbh | Solder coating, method for coating a component, component and adhesive tape with a solder coating |

-

2010

- 2010-10-26 EP EP10188806.3A patent/EP2316988B1/en active Active

- 2010-10-26 DE DE102010049398A patent/DE102010049398A1/en not_active Withdrawn

- 2010-10-26 CA CA2719273A patent/CA2719273C/en not_active Expired - Fee Related

- 2010-11-01 JP JP2010245232A patent/JP5693149B2/en not_active Expired - Fee Related

- 2010-11-01 US US12/917,114 patent/US8740572B2/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2645631C1 (en) * | 2016-12-07 | 2018-02-26 | Федеральное государственное бюджетное образовательное учреждение высшего образования "Казанский национальный исследовательский технический университет им. А.Н. Туполева-КАИ" (КНИТУ-КАИ) | Method of applying the coating on the sample (variants) and the device for its implementation (variants) |

| CN110899695A (en) * | 2019-12-09 | 2020-03-24 | 浙江翰德圣智能再制造技术有限公司 | Method for manufacturing micro-arc spark MCrAlY electrode by laser additive manufacturing |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2719273C (en) | 2017-03-28 |

| US20110103968A1 (en) | 2011-05-05 |

| DE102010049398A1 (en) | 2011-05-05 |

| JP2011099437A (en) | 2011-05-19 |

| JP5693149B2 (en) | 2015-04-01 |

| US8740572B2 (en) | 2014-06-03 |

| CA2719273A1 (en) | 2011-05-02 |

| EP2316988A1 (en) | 2011-05-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2316988B1 (en) | Wear-resistant and oxidation-resistant turbine blade | |

| EP2317078B2 (en) | Abrasive single-crystal turbine blade | |

| EP3191244B1 (en) | Method for manufacturing a rotor blade and blade obtained thereby | |

| WO2006061267A1 (en) | Layered system, use thereof and method for producing a layered system | |

| CH704833A1 (en) | Component for a turbo machine and a method of manufacturing such a component. | |

| WO2005072884A1 (en) | Method for removing a layer | |

| EP2780552B1 (en) | Armoring sealing fins of tial vanes by induction brazing hard-material particles | |

| EP1808508A1 (en) | Component located in the flow channel of a turbomachine and spraying process for generating a coating. | |

| EP1707301B1 (en) | Process for applying fibre mats on the surface or a recess of a component | |

| EP1867423A1 (en) | Process for repairing a workpiece through soldering with a sheet coated with solder | |

| DE102007005755A1 (en) | Device for the protection of components with combustible titanium alloy from titanium fire and process for their production | |

| EP2809826B1 (en) | Method for applying a protective layer to a turbine component | |

| EP1835045A1 (en) | Process for obtaining a coated part | |

| EP3093372A2 (en) | Coating method for producing a combination of armor plating for a blade tip and erosion resistant coating | |

| DE69818769T2 (en) | Multi-layer components of a combustion device close to the final dimensions, according to the vacuum plasma spraying process and process for its production | |

| EP1522604A1 (en) | Layer system and process for its production | |

| EP1382707A1 (en) | Layer system | |

| WO2006040221A1 (en) | Method for producing a layer system | |

| EP1707651A1 (en) | Coating system and process of manufacturing a coating system | |

| EP2230041A2 (en) | Process for the fabrication of a hole | |

| EP1808236A1 (en) | Process of masking cooling holes, espacially of turbine blades | |

| EP2661541B1 (en) | Method for producing a protective layer for a rotor blade | |

| WO2018024759A1 (en) | Method for producing a channel structure and component | |

| EP1867749A1 (en) | Method to deposit a material on to a workpiece | |

| EP1811055A1 (en) | Method for manufacturing a component with holes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20111025 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150224 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 735502 Country of ref document: AT Kind code of ref document: T Effective date: 20150715 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010009813 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151008 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151108 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151109 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010009813 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151026 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| 26N | No opposition filed |

Effective date: 20160411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: GENERAL ELECTRIC TECHNOLOGY GMBH, CH Free format text: FORMER OWNER: ALSTOM TECHNOLOGY LTD, CH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502010009813 Country of ref document: DE Owner name: GENERAL ELECTRIC TECHNOLOGY GMBH, CH Free format text: FORMER OWNER: ALSTOM TECHNOLOGY LTD., BADEN, CH Ref country code: DE Ref legal event code: R081 Ref document number: 502010009813 Country of ref document: DE Owner name: ANSALDO ENERGIA IP UK LIMITED, GB Free format text: FORMER OWNER: ALSTOM TECHNOLOGY LTD., BADEN, CH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151026 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: HC Owner name: GENERAL ELECTRIC TECHNOLOGY GMBH; CH Free format text: DETAILS ASSIGNMENT: VERANDERING VAN EIGENAAR(S), VERANDERING VAN NAAM VAN DE EIGENAAR(S); FORMER OWNER NAME: ALSTOM TECHNOLOGY LTD Effective date: 20161006 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 735502 Country of ref document: AT Kind code of ref document: T Effective date: 20151026 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: ALSTOM TECHNOLOGY LTD, CH Effective date: 20161110 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20161020 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151026 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: ANSALDO ENERGIA IP UK LIMITED, GB Free format text: FORMER OWNER: GENERAL ELECTRIC TECHNOLOGY GMBH, CH |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: PD Owner name: ANSALDO ENERGIA IP UK LIMITED; GB Free format text: DETAILS ASSIGNMENT: CHANGE OF OWNER(S), ASSIGNMENT; FORMER OWNER NAME: GENERAL ELECTRIC TECHNOLOGY GMBH Effective date: 20170301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20101026 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150708 |

|

| REG | Reference to a national code |