EP2243518B1 - Respiratory mask - Google Patents

Respiratory mask Download PDFInfo

- Publication number

- EP2243518B1 EP2243518B1 EP09005783A EP09005783A EP2243518B1 EP 2243518 B1 EP2243518 B1 EP 2243518B1 EP 09005783 A EP09005783 A EP 09005783A EP 09005783 A EP09005783 A EP 09005783A EP 2243518 B1 EP2243518 B1 EP 2243518B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- mask body

- mask

- valve

- condensate

- breathing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000000241 respiratory effect Effects 0.000 title 1

- 230000029058 respiratory gaseous exchange Effects 0.000 claims description 24

- 239000000463 material Substances 0.000 claims description 23

- 238000009792 diffusion process Methods 0.000 claims 1

- 230000000149 penetrating effect Effects 0.000 claims 1

- 230000005494 condensation Effects 0.000 description 7

- 238000009833 condensation Methods 0.000 description 7

- 101100269850 Caenorhabditis elegans mask-1 gene Proteins 0.000 description 4

- 239000004033 plastic Substances 0.000 description 4

- 238000007789 sealing Methods 0.000 description 4

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 239000002244 precipitate Substances 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62B—DEVICES, APPARATUS OR METHODS FOR LIFE-SAVING

- A62B18/00—Breathing masks or helmets, e.g. affording protection against chemical agents or for use at high altitudes or incorporating a pump or compressor for reducing the inhalation effort

- A62B18/08—Component parts for gas-masks or gas-helmets, e.g. windows, straps, speech transmitters, signal-devices

- A62B18/10—Valves

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D13/00—Professional, industrial or sporting protective garments, e.g. surgeons' gowns or garments protecting against blows or punches

- A41D13/05—Professional, industrial or sporting protective garments, e.g. surgeons' gowns or garments protecting against blows or punches protecting only a particular body part

- A41D13/11—Protective face masks, e.g. for surgical use, or for use in foul atmospheres

- A41D13/1107—Protective face masks, e.g. for surgical use, or for use in foul atmospheres characterised by their shape

- A41D13/1138—Protective face masks, e.g. for surgical use, or for use in foul atmospheres characterised by their shape with a cup configuration

- A41D13/1146—Protective face masks, e.g. for surgical use, or for use in foul atmospheres characterised by their shape with a cup configuration obtained by moulding

Definitions

- the invention relates to a breathing mask of the type explained in the preamble of claim 1.

- Such a breathing mask is for example from the EP 267 428 known.

- the known breathing mask includes an exhalation valve integrally formed of a rubber or a rubber-like plastic, which is buttoned into an opening in the mask body.

- the exhalation valve includes an exhalation port disposed on a lip valve that connects outwardly to the insertion site into the mask body. In the normal, closed state, the two walls of the lip valve lie flat on each other in the area of the outlet opening so that no unfiltered air can enter when inhaling.

- the exhalation pressure opens the lip valve and thereby the exhalation port, allowing the air to escape.

- a mask for use outdoors and especially in cold or unfriendly weather.

- the mask contains openings that allow the inhaled air to be preheated by warm, exhaled air.

- the resulting increased amount of condensate is held by chemical hydrogen bonding to the inside of the mask.

- passive air flow cavities and a liquid guide slot are provided which form discharge means for liquid bound to the mask.

- the invention has for its object to provide a breathing mask with improved protection against dripping condensate.

- the inventive design condensate is discharged into the mask body, so that it can neither drain, nor affect the sealing effect of the exhalation valve.

- the arrangement of the condensate receiving area and the condensation surface should be matched to the corresponding construction of the exhalation valve, that the condensation surface is substantially aligned with the mask body is aligned and have a from the outside outward Bogrenzung a valve receiving, so that the condensate preferably by gravity gets into the mask body.

- the exhalation valve has a cover, then it should preferably rest on the mask body and expediently have a guide surface for introducing the condensate.

- the receiving region can be provided at suitable locations in the mask body, for example, a region of the filter material which is permeable to the condensation surface in the direction of the condensation surface or a cavity region of a covering layer of the filter material which is open in the direction of the condensation surface.

- the receiving area is connected to a distribution area for the condensate in the mask body, so that the recorded condensate can be distributed in the mask body, which increases both the tendency to evaporation, as well as the absorption capacity.

- valve receptacle as a Ventithatt für a separate housing and preferably by frictional engagement in the opening provided in the mask body itself, but also by positive engagement or the like can be attached.

- the valve holder can also be formed directly on the mask body.

- the housing itself forms a condensation surface, it is preferably sloping sloping from the inside to the outside and is in flow connection with the condensate receiving region, so that the condensate accumulating here can also be introduced into the mask body.

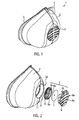

- FIG. 1 shows a first embodiment of a breathing mask 1 according to the invention.

- the breathing mask 1 is a so-called half mask, i. It is worn over the mouth and nose of the wearer and leaves the eyes free.

- the breathing mask 1 contains a mask body 2, which is dimensionally stable in that it does not collapse when inhaled.

- the mask body 2 contains the usual material structure, so it may for example be formed entirely of filter material or contain a filter material between two support layers or a filter material with a cover layer. Both the filter material and the further layers of the mask body 2 must be air permeable, i. be open-pored.

- the mask body 2 contains the usual face seal 3 which flexibly seals against the face of the wearer when the mask body 2 is fastened to the head of the wearer by means of a harness 4.

- the exhalation mask 1 according to the invention is further provided with an exhalation valve 5, which offers a lower resistance to exhalation on exhalation than the wall of the mask body 2, so that exhalation is facilitated.

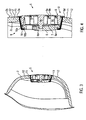

- FIG. 2 shows, in the illustrated embodiment, the exhalation valve 5 of a valve seat 6, a flap 7 and a cover 8.

- the valve seat 6, the flap 7 and the cover 8 are formed substantially circular.

- the valve seat 6 includes a sealing surface 6a, which preferably extends annularly.

- the flap 7 is fastened, preferably unbuttoned, via a fastening 6b, which is connected by means of struts 6c to the annular sealing surface 6a.

- the flap 7 consists of a for Such exhalation valves usual, flexible material, such as rubber or a rubber-like plastic, which is able to stand out when inflating from the interior of the mask body 2 out of the sealing surface 6a and thereby open a Ausströmweg.

- the cover 8 is preferably made of plastic and extends over the entire area occupied by the valve seat 6 and the flap 7.

- the cover 8 includes exhalation ports 8a of suitable design separated by impermeable material regions 8b.

- the cover 8 is kept at a distance from the flap 7, which allows the movement of the flap 7 during exhalation unhindered.

- the exhalation valve 5 is housed in a valve seat 9, which sits in an opening 2 a of the mask body 2.

- a pot-like housing 10 made of plastic or the like, which has a widening from the inside to the outside cross-section.

- the pot-like housing 10 covers the natural cut edges of the material of the mask body 2 in the region of the opening 2 a, terminates substantially with the outer surface 2 b of the mask body 2 and protrudes inwards beyond the inner surface 2 c of the mask body 2.

- the bottom of the cup-shaped housing 10 is formed by the valve member 6, in the central hub 6b a plug 8e of the cover 8 is inserted with the interposition of the flap 7 and the flap 7 attached to the valve member 6b.

- the housing 10 has a substantially keglige conversion 10 a, which is provided on the small diameter side with a radial mounting flange 10 b, on which the valve member 6 is fixed.

- the cover 8 is provided at its peripheral edges with an inwardly angled edge 8d, which engages over the wall 10a on the outside of the mask body 2 and is pressed into the material of the mask body 2.

- a region 11 in which the material of the mask body 2 is receptive to condensate. This means that this area is neither compressed by welding, nor by mechanical contact pressure or the like so that no or only insignificant cavities remain in the material of the mask body 2.

- the region 11 may have the porosity and / or capillarity of the material of the mask body present there, but may also be particularly porous and / or equipped with a particularly high absorbency.

- the configuration of the receiving cavities for the condensate may be formed depending on the material properties of the existing there layer of the material of the mask body 2, for example, in a net-like cover layer relatively large cavities are, while where filter material extends to the outer side 2b of the mask body 2, smaller cavities, but in larger numbers, are available.

- a distribution region 12 can adjoin the condensate receiving region 11, which can in principle extend over the entire mask body 2 and distributes the condensate over the entire mask body 2 over a large area, so that it can evaporate more easily and does not cause any loss of comfort.

- the moisture contained in the exhaled air settles on all parts of the exhalation valve 5, but mainly on the cover 8, down and runs due to gravity both on the cover 8 and the pot-like wall 10a, here due to the sloping from the inside to the outside slope Wall 10a, to the lower point U, where it is introduced by the acting as a guide surface angled edge 8d in the area 11. Even after the mask has been removed or the wearer's head has been tilted, the condensate can collect around the cover 8 and is introduced into the mask body 2.

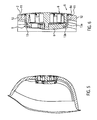

- FIGS. 5 and 6 show a further embodiment of the embodiment according to the invention, which differs from the embodiment of 3 and 4 only differs by a different configuration of the valve seat 9.

- the valve receptacle 9 is formed by turn a pot-like structure, which is here formed by a drawn into the interior of the breathing mask in part 13 from the material of the mask body 2.

- the drawn pot structure 13 in particular the conical wall 13a, contains cavities and / or capillaries, through which the condensate accumulating there or reaching it reaches the region 11, which in this case extends both the area of the area surrounding the opening 2a Material of the mask body 2 and the region of the drawn pot structure 13 includes.

- the distribution region 12 which in turn can extend over the entire surface of the mask body 2, adjoins this receiving region 11.

- the condensate receiving area according to the invention can also be used with differently designed exhalation valves or breathing masks. Depending on the design of the exhalation valve, there will be other exposed areas where condensate precipitates preferentially and in larger quantities. According to the invention, these surfaces are then connected to the material of the mask body in a condensate-absorbing manner directly or via guide surfaces.

Landscapes

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Pulmonology (AREA)

- Business, Economics & Management (AREA)

- Emergency Management (AREA)

- Physical Education & Sports Medicine (AREA)

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Respiratory Apparatuses And Protective Means (AREA)

Description

Die Erfindung bezieht sich auf eine Atemmaske der im Oberbegriff von Anspruch 1 erläuterten Art.The invention relates to a breathing mask of the type explained in the preamble of

Eine derartige Atemmaske ist beispielsweise aus der

Aus der

Der Erfindung liegt die Aufgabe zugrunde, eine Atemmaske mit einem verbesserten Schutz gegen abtropfendes Kondensat zu schaffen.The invention has for its object to provide a breathing mask with improved protection against dripping condensate.

Die Aufgabe wird durch die im Anspruch 1 angegebenen Merkmale gelöst.The object is solved by the features specified in

Durch die erfindungsgemäße Ausgestaltung wird ausgeschiedenes Kondensat in den Maskenkörper geleitet, so dass es weder abtropfen, noch die Dichtwirkung des Ausatemventils beeinträchtigen kann.The inventive design condensate is discharged into the mask body, so that it can neither drain, nor affect the sealing effect of the exhalation valve.

Vorteilhafte Weiterbildungen der Erfindung sind den Unteransprüchen zu entnehmen.Advantageous developments of the invention can be found in the dependent claims.

Die Anordnung des Kondensat-Aufnahmebereichs und der Kondensationsfläche sollte so auf die entsprechende Konstruktion des Ausatemventils abgestimmt werden, dass die Kondensationsfläche im Wesentlichen fluchtend mit dem Maskenkörper ausgerichtet is und eine von innen nach außen alfallenche Bogrenzung einer Ventilaufnahme aufweisen, so dass das Kondensat bevorzugt durch Schwerkraftwirkung in den Maskenkörper gelangt.The arrangement of the condensate receiving area and the condensation surface should be matched to the corresponding construction of the exhalation valve, that the condensation surface is substantially aligned with the mask body is aligned and have a from the outside outward Bogrenzung a valve receiving, so that the condensate preferably by gravity gets into the mask body.

Weist das Ausatemventil eine Abdeckung auf, so sollte diese bevorzugt auf dem Maskenkörper aufliegen und zweckmäßigerweise eine Leitfläche zum Einleiten des Kondensats aufweisen.If the exhalation valve has a cover, then it should preferably rest on the mask body and expediently have a guide surface for introducing the condensate.

Der Aufnahmebereich kann an geeigneten Stellen im Maskenkörper vorgesehen sein, beispielsweise kann als Aufnahmebereich ein in Richtung der Kondensationsfläche diffusionsoffener Bereich des Filtermaterials oder ein in Richtung der Kondensationsfläche offener Hohlraumbereich einer Abdecklage des Filtermaterials sein.The receiving region can be provided at suitable locations in the mask body, for example, a region of the filter material which is permeable to the condensation surface in the direction of the condensation surface or a cavity region of a covering layer of the filter material which is open in the direction of the condensation surface.

Bevorzugt ist der Aufnahmebereich mit einem Verteilbereich für das Kondensat im Maskenkörper verbunden, so dass das aufgenommene Kondensat sich im Maskenkörper verteilen kann, was sowohl die Verdunstungsneigung, als auch die Aufnahmekapazität erhöht.Preferably, the receiving area is connected to a distribution area for the condensate in the mask body, so that the recorded condensate can be distributed in the mask body, which increases both the tendency to evaporation, as well as the absorption capacity.

Zum Ausbilden der offenen bzw. diffusionsoffenen Bereiche ist es wichtig, dass der Bereich des Maskenkörpers rund um das Ausatemventil nicht durch Verschweißen oder Verpressen verdichtet wird. Eine besonders bevorzugte Möglichkeit, diese Verdichtung zu vermeiden, besteht darin, dei Ventilaufnahme als Ventithatterung anszuleilden, die entweder ein separates Gehäuse ist und bevorzugt durch Reibschluss in der vorgesehenen Öffnung im Maskenkörper selbst, jedoch auch durch Formschluss oder dergleichen befestigt werden kann. Die Ventilhalterung kann jedoch auch am Maskenkörper direkt angeformt werden.To form the open or vapor-permeable regions, it is important that the area of the mask body around the exhalation valve is not compressed by welding or compression. A particularly preferred way to avoid this compression is to create the valve receptacle as a Ventithatterung, which is either a separate housing and preferably by frictional engagement in the opening provided in the mask body itself, but also by positive engagement or the like can be attached. However, the valve holder can also be formed directly on the mask body.

Sollte das Gehäuse selbst eine Kondensationsfläche bilden, so ist es bevorzugt von innen nach außen abfallend geneigt und steht mit dem Kondensat-Aufnahmebereich in Strömungsverbindung, damit auch das hier anfallende Kondensat in den Maskenkörper eingeleitet werden kann.If the housing itself forms a condensation surface, it is preferably sloping sloping from the inside to the outside and is in flow connection with the condensate receiving region, so that the condensate accumulating here can also be introduced into the mask body.

Ausführungsbeispiele der Erfindung werden nachfolgend anhand der Zeichnungen näher erläutert. Es zeigen:

Figur 1- eine erfindungsgemäße Atemmaske in perspektivischer Darstellung,

Figur 2- die in

Figur 1 Figur 3- einen Vertikalschnitt durch die in

Figur 1 - Figur 4

- eine vergrößerte Darstellung des Ventilbereichs der Atemmaske im Vertikalschnitt,

Figur 5- einen Vertikalschnitt durch ein zweites Ausführungsbeispiel einer Atemmaske, und

Figur 6- eine vergrößerte Darstellung des Ventilbereichs der in

Figur 5

- FIG. 1

- a breathing mask according to the invention in a perspective view,

- FIG. 2

- in the

FIG. 1 shown breathing mask in exploded view, - FIG. 3

- a vertical section through the in

FIG. 1 shown breathing mask, - FIG. 4

- an enlarged view of the valve area of the breathing mask in vertical section,

- FIG. 5

- a vertical section through a second embodiment of a breathing mask, and

- FIG. 6

- an enlarged view of the valve area of in

FIG. 5 shown breathing mask.

Gleiche Komponenten sind in den Figuren durchgängig mit gleichen Bezugszeichen versehen.The same components are provided throughout the figures with the same reference numerals.

Die Atemmaske 1 ist eine sogenannte Halbmaske, d.h. sie wird über Mund und Nase des Trägers getragen und lässt die Augen frei. Die Atemmaske 1 enthält einen Maskenkörper 2, der insoweit formsteif ausgebildet ist, dass er beim Einatmen nicht kollabiert. Der Maskenkörper 2 enthält den üblichen Materialaufbau, kann also beispielsweise vollständig aus Filtermaterial geformt sein oder ein Filtermaterial zwischen zwei Stützschichten oder ein Filtermaterial mit einer Abdeckschicht enthalten. Sowohl das Filtermaterial als auch die weiteren Schichten des Maskenkörpers 2 müssen luftdurchlässig, d.h. offenporig sein. Der Maskenkörper 2 enthält die übliche Gesichtsdichtung 3, die sich flexibel abdichtend an das Gesicht des Trägers anlegt, wenn der Maskenkörper 2 mit Hilfe einer Bebänderung 4 am Kopf des Trägers befestigt ist.The

Die erfindungsgemäße Ausatemmaske 1 ist weiterhin mit einem Ausatemventil 5 versehen, das einen geringeren Durchlasswiderstand beim Ausatmen als die Wandung des Maskenkörpers 2 bietet, so dass das Ausatmen erleichtert wird.The

Wie

Das Ausatemventil 5 ist in einer Ventilaufnahme 9 untergebracht, die in einer Öffnung 2a des Maskenkörpers 2 sitzt. Wie die

Die Abdeckung 8 ist an ihren Umfangsrändern mit einem nach innen abgewinkelten Rand 8d versehen, der die Wandung 10a an der Außenseite des Maskenkörpers 2 übergreift und in das Material des Maskenkörpers 2 eingedrückt wird. An dieser Stelle befindet sich ein Bereich 11, in dem das Material des Maskenkörpers 2 aufnahmefähig für Kondensat ist. Dies bedeutet, dass dieser Bereich weder durch Verschweißen, noch durch mechanischen Anpressdruck oder dergleichen so verdichtet ist, dass keine oder nur unwesentliche Hohlräume im Material des Maskenkörpers 2 verbleiben. Der Bereich 11 kann die Porosität und/oder Kapillarität des dort vorhandenen Materials des Maskenkörpers aufweisen, kann jedoch auch besonders porös und/oder mit besonders hoher Saugfähigkeit ausgestattet sein. Die Ausgestaltung der Aufnahmehohlräume für das Kondensat kann je nach der Materialbeschaffenheit der dort vorhandenen Lage des Materials des Maskenkörpers 2 ausgebildet sein, beispielsweise können sich in einer netzartigen Abdecklage relativ große Hohlräume befinden, während dort, wo Filtermaterial bis zur Außenseite 2b des Maskenkörpers 2 reicht, kleinere Hohlräume, dafür in größerer Anzahl, vorhanden sind. An den Kondensat-Aufnahmebereich 11 kann sich ein Verteilbereich 12 anschließen, der im Prinzip über den gesamten Maskenkörper 2 reichen kann und das Kondensat über den gesamten Maskenkörper 2 großflächig verteilt, so dass es leichter verdunsten kann und keinerlei Komforteinbuße bewirkt.The

Die in der Ausatemluft enthaltene Feuchtigkeit schlägt sich an allen Teilen des Ausatemventils 5, hauptsächlich aber an der Abdeckung 8, nieder und läuft schwerkraftbedingt sowohl an der Abdeckung 8 als auch an der topfartigen Wandung 10a, hier bedingt durch die von innen nach außen abfallende Neigung der Wandung 10a, an die untere Stelle U, wo es durch den als Leitfläche wirkenden abgewinkelten Rand 8d in den Bereich 11 eingeleitet wird. Auch nach dem Ablegen der Maske oder bei geneigter Kopfhaltung des Trägers kann sich das Kondensat auch um die Abdeckung 8 herum sammeln und wird in den Maskenkörper 2 eingeleitet.The moisture contained in the exhaled air settles on all parts of the

Die

In Abwandlung der beschriebenen und gezeichneten Ausführungsbeispiele kann der erfindungsgemäße Kondensat-Aufnahmebereich auch bei anders konstruierten Ausatemventilen oder Atemmasken eingesetzt werden. Je nach Konstruktion des Ausatemventils, werden sich andere exponierte Flächen ergeben, an denen sich bevorzugt und in größeren Mengen Kondensat niederschlägt. Erfindungsgemäß werden dann diese Flächen direkt oder über Leitflächen mit dem Material des Maskenkörpers kondensataufnehmend verbunden.In a modification of the described and illustrated embodiments, the condensate receiving area according to the invention can also be used with differently designed exhalation valves or breathing masks. Depending on the design of the exhalation valve, there will be other exposed areas where condensate precipitates preferentially and in larger quantities. According to the invention, these surfaces are then connected to the material of the mask body in a condensate-absorbing manner directly or via guide surfaces.

Claims (9)

- A breathing mask (1) with a mask body (2) comprising a filter material, and with an exhalation valve (5) penetrating the mask body (2), wherein a condensing surface on the exhalation valve (5) is connected with a condensate receiving area (11) in the mask body (2), wherein the exhalation valve (5) is accommodated in a valve reception (9) which projects over an interior surface (2b) of the mask body (2) into the interior of the mask body (2), and the valve reception (9) comprises a boundary (10a, 13a) inclined from the inside to the outside, which is in a flow connection with the condensate receiving area (11).

- The breathing mask according to claim 1, characterized in that the condensing surface is substantially aligned with the mask body (2).

- The breathing mask according to claims 1 or 2, characterized in that the condensing surface comprises a guide surface (8d) directed to the receiving area (11).

- The breathing mask according to any of claims 1 to 3, characterized in that the condensing surface is provided on a covering (8) of the exhalation valve (5) which overlies the mask body (2).

- The breathing mask according to any of claims 1 to 4, characterized in that the receiving area (11) comprises an area of the material of the mask body (2) which is permeable for diffusion in the direction of the condensing surface.

- The breathing mask according to any of claims 1 to 5, characterized in that the receiving area (11) comprises a cavity area of a covering layer of the mask body (2) which is open in the direction of the condensing surface.

- The breathing mask according to any of claims 1 to 6, characterized in that the receiving area (11) is in connection with a condensate distribution area (12) on the mask body (2).

- The breathing mask according to any of claims 1 to 7, characterized in that the valve reception (9) comprises a housing (10) which is in a friction fit in an opening (2a) in the mask body (2).

- The breathing mask according to any of claims 1 to 7, characterized in that the valve reception (9) comprises a deep-drawn structure (13) from a material of the mask body (2) extending into an opening (2a) on the mask body (2).

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09005783A EP2243518B1 (en) | 2009-04-24 | 2009-04-24 | Respiratory mask |

| US12/661,833 US20100269831A1 (en) | 2009-04-24 | 2010-03-25 | Breathing Mask |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09005783A EP2243518B1 (en) | 2009-04-24 | 2009-04-24 | Respiratory mask |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2243518A1 EP2243518A1 (en) | 2010-10-27 |

| EP2243518B1 true EP2243518B1 (en) | 2013-01-02 |

Family

ID=40874848

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09005783A Active EP2243518B1 (en) | 2009-04-24 | 2009-04-24 | Respiratory mask |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US20100269831A1 (en) |

| EP (1) | EP2243518B1 (en) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2538284B (en) * | 2015-05-14 | 2021-05-05 | Jsp Ltd | Wearable protective device |

| RU2015141569A (en) * | 2015-09-30 | 2017-04-05 | 3М Инновейтив Пропертиз Компани | FOLDING RESPIRATOR WITH FACE MASK AND EXHAUST VALVE |

| CN106723505A (en) * | 2015-11-24 | 2017-05-31 | 苏州乐众能源科技有限公司 | A kind of mouth mask outlet valve |

| CN105536170B (en) * | 2016-01-29 | 2019-02-26 | 陈春松 | A kind of multifunctional protection mask |

| EP3735288A4 (en) * | 2018-05-02 | 2021-11-03 | St Engineering Innosparks Pte. Ltd. | Multi-flap valve for a respiratory device |

| USD885559S1 (en) * | 2019-03-04 | 2020-05-26 | The Smartmask Llc | Respiratory mask |

| USD976389S1 (en) * | 2019-04-16 | 2023-01-24 | Hangzhou Geeshun Sports Equipment Co., Ltd. | Fitness training mask |

| USD1017021S1 (en) * | 2020-04-08 | 2024-03-05 | Conopco, Inc. | Face mask |

| USD956953S1 (en) * | 2020-05-07 | 2022-07-05 | beyondSMART Furniture Co., Ltd. | Filter mask |

| USD954936S1 (en) * | 2020-05-29 | 2022-06-14 | Metal Heart Group of Companies | Mask |

| USD943735S1 (en) * | 2020-06-14 | 2022-02-15 | Dongguan Rentong Silicon Plastic Products Co., Ltd. | Respiratory mask |

| USD955557S1 (en) * | 2020-09-18 | 2022-06-21 | Sillymann Co., Ltd. | Mask frame |

| USD945599S1 (en) * | 2020-09-23 | 2022-03-08 | Grove Biomedical, Llc | Respirator |

| USD961761S1 (en) * | 2020-09-24 | 2022-08-23 | University Of Tennessee Research Foundation | Nose and mouth face mask |

| USD982153S1 (en) * | 2021-06-26 | 2023-03-28 | Global Rise Enterprises Limited | Mask |

| USD982152S1 (en) * | 2021-06-26 | 2023-03-28 | Global Rise Enterprises Limited | Mask |

| USD1022183S1 (en) * | 2021-11-04 | 2024-04-09 | AirBoss Defense Group LLC | Respirator mask |

| CN116077848B (en) * | 2023-02-27 | 2023-10-20 | 江苏海拓科技有限公司 | Double-deck floating filter type respirator |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0266456A1 (en) | 1986-11-06 | 1988-05-11 | Moldex-Metric AG & Co.KG | Respiratory face mask |

| US4873972A (en) * | 1988-02-04 | 1989-10-17 | Moldex/Metric Products, Inc. | Disposable filter respirator with inner molded face flange |

| US6584976B2 (en) * | 1998-07-24 | 2003-07-01 | 3M Innovative Properties Company | Face mask that has a filtered exhalation valve |

| US6047698A (en) * | 1998-08-20 | 2000-04-11 | Moldex-Metric, Inc. | Unidirectional fluid valve |

| JP4144662B2 (en) * | 2001-02-21 | 2008-09-03 | 興研株式会社 | Mask with exhaust holes |

| US8733357B2 (en) * | 2006-12-19 | 2014-05-27 | Talus Outdoor Technologies, Llc | Cold weather exposure mask |

-

2009

- 2009-04-24 EP EP09005783A patent/EP2243518B1/en active Active

-

2010

- 2010-03-25 US US12/661,833 patent/US20100269831A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| EP2243518A1 (en) | 2010-10-27 |

| US20100269831A1 (en) | 2010-10-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2243518B1 (en) | Respiratory mask | |

| DE60133186T2 (en) | SELF-SEALING FILTER CONNECTION AND THEREFORE GAS MASK AND FILTER ASSEMBLY | |

| DE60225015T2 (en) | AEROSOL T ADAPTER ASSEMBLY WITH VALVE | |

| DE102007023959B3 (en) | Filter for respiratory device , comprises anterior and posterior filter mates, flexible frame arranged between the mates, and filter connection at a first end piece of the frame and with a second end piece at opposite end of the frame | |

| DE3783691T2 (en) | ACCESSORIES FOR GAS MASKS AND GAS MASKS THEREFORE. | |

| DE3900183A1 (en) | BREATHING VALVE | |

| WO2010040368A1 (en) | Breathing protection mask | |

| EP0501388A1 (en) | Spray bottle | |

| DE102012111281A1 (en) | Evaporator filler and method for filling an evaporator | |

| DE69822360T2 (en) | Device for dispensing and storing sterile liquids | |

| EP1647310B1 (en) | Breathing mask with exhalation valve | |

| DE2938726A1 (en) | FILTERING RESPIRATORY MASK | |

| DE4138045A1 (en) | BREATHING AID FOR LARYNGOTOMY OR TRACHEOTOMYPATIENTS | |

| AT413978B (en) | AIR VALVE FOR A LID OF A DRINKING CONTAINER | |

| DE3038100A1 (en) | BREATHING MASK | |

| EP1585412A1 (en) | Valve assembly | |

| EP1500341B1 (en) | Shoe with ventilating structure | |

| EP4096461B1 (en) | Respirator mask | |

| DE3304311C2 (en) | Device for venting colostomy bags | |

| DE19754432A1 (en) | Speech valve for the trachea, which is simple to produce and prevents ingress of dust and insects | |

| DE102017011582A1 (en) | Breathing bag for a circuit breathing apparatus and circuit breathing apparatus | |

| DE2012355C3 (en) | Spout mouthpiece for water outlets | |

| DE1914224C3 (en) | Respirator | |

| DE1708075C3 (en) | Respirator | |

| DE2850686C3 (en) | Protective device for breathing apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| 17P | Request for examination filed |

Effective date: 20101203 |

|

| 17Q | First examination report despatched |

Effective date: 20110110 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A62B 18/10 20060101AFI20120613BHEP Ipc: A41D 13/11 20060101ALI20120613BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 591244 Country of ref document: AT Kind code of ref document: T Effective date: 20130115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009005847 Country of ref document: DE Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20130102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130402 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130502 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130402 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130413 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130403 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130502 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 |

|

| BERE | Be: lapsed |

Owner name: MOLDEX-METRIC A.G. & CO. KG Effective date: 20130430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| 26N | No opposition filed |

Effective date: 20131003 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009005847 Country of ref document: DE Effective date: 20131003 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130430 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 591244 Country of ref document: AT Kind code of ref document: T Effective date: 20140424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130102 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130424 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140424 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230822 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240423 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240425 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240423 Year of fee payment: 16 |