EP2229231B1 - Unité de filtre à blocage libérable - Google Patents

Unité de filtre à blocage libérable Download PDFInfo

- Publication number

- EP2229231B1 EP2229231B1 EP08844576.2A EP08844576A EP2229231B1 EP 2229231 B1 EP2229231 B1 EP 2229231B1 EP 08844576 A EP08844576 A EP 08844576A EP 2229231 B1 EP2229231 B1 EP 2229231B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- assembly

- slide assembly

- filter cartridge

- latch

- slide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 230000000717 retained effect Effects 0.000 claims description 3

- 230000007246 mechanism Effects 0.000 description 13

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 9

- 239000000126 substance Substances 0.000 description 8

- 238000000034 method Methods 0.000 description 7

- 239000007788 liquid Substances 0.000 description 6

- 238000001914 filtration Methods 0.000 description 5

- 230000015572 biosynthetic process Effects 0.000 description 4

- 238000005755 formation reaction Methods 0.000 description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 230000013011 mating Effects 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 229920000388 Polyphosphate Polymers 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 239000000706 filtrate Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- -1 for example Substances 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 239000012466 permeate Substances 0.000 description 1

- 239000001205 polyphosphate Substances 0.000 description 1

- 235000011176 polyphosphates Nutrition 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000001223 reverse osmosis Methods 0.000 description 1

- 239000013049 sediment Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D35/00—Filtering devices having features not specifically covered by groups B01D24/00 - B01D33/00, or for applications not specifically covered by groups B01D24/00 - B01D33/00; Auxiliary devices for filtration; Filter housing constructions

- B01D35/30—Filter housing constructions

- B01D35/306—Filter mounting adapter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D35/00—Filtering devices having features not specifically covered by groups B01D24/00 - B01D33/00, or for applications not specifically covered by groups B01D24/00 - B01D33/00; Auxiliary devices for filtration; Filter housing constructions

- B01D35/30—Filter housing constructions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2201/00—Details relating to filtering apparatus

- B01D2201/30—Filter housing constructions

- B01D2201/301—Details of removable closures, lids, caps, filter heads

- B01D2201/302—Details of removable closures, lids, caps, filter heads having inlet or outlet ports

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2201/00—Details relating to filtering apparatus

- B01D2201/40—Special measures for connecting different parts of the filter

- B01D2201/4007—Use of cam or ramp systems

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2201/00—Details relating to filtering apparatus

- B01D2201/40—Special measures for connecting different parts of the filter

- B01D2201/4015—Bayonet connecting means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2201/00—Details relating to filtering apparatus

- B01D2201/40—Special measures for connecting different parts of the filter

- B01D2201/4046—Means for avoiding false mounting of different parts

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2201/00—Apparatus for treatment of water, waste water or sewage

- C02F2201/002—Construction details of the apparatus

- C02F2201/006—Cartridges

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49815—Disassembling

Definitions

- the present disclosure generally relates to filtering systems and more particularly relates to attachment features of a filtering system.

- Filter systems designed for residential and commercial use have become increasingly popular. The popularity arises from the need to remove unwanted substances from input water to make output water safer for consumption in various end uses. Filter systems may also be used to add substances to the output liquid, for example, minerals for taste enhancement.

- the filter unit includes a slide assembly comprising an actuator and spring.

- the slide assembly is moveably attached and contained within a collar assembly.

- the collar assembly is configured to receive an end portion of a filter cartridge in releasable engagement.

- the slide assembly is movable between a first position in which the slide assembly prevents disengagement of the filter cartridge from the collar assembly, and a second position in which the filter cartridge can be disengaged from the collar assembly. In the second position, the slide assembly engages the collar assembly in a way that the second position is maintained until an external force is applied. The external force can result from engagement of a portion of the slide assembly with a portion of the filter cartridge as the filter cartridge is being disengaged from the collar assembly.

- filter unit for example, a filter unit for filtering water for residential and commercial uses.

- the structure, creation, and use of some example filter units and methods are described hereinafter.

- filter cartridge includes any device effective for separating a feed (input) liquid-containing substance into a product (output) liquid-containing substance of less undissolved solids and/or dissolved solids content than the feed liquid-containing substance and a filtrate or concentrate or permeate.

- filter cartridge includes a device that can add a substance to a feed (input) liquid-containing substance in the form of a modified product (output) liquid-containing substance.

- filter means include activated carbon filters, permeable sediment filters, water softeners, filters that add polyphosphates for scale control, and reverse osmosis modules.

- Some types of filter cartridges are maintained in an installed orientation relative to a mounting manifold or head assembly with some type of engagement mechanism.

- Such engagement mechanisms resist rotation and/or axial movement of the filter cartridge relative to the manifold unless the engagement mechanism is intentionally released.

- This resistance feature of such an engagement mechanism prevents the unintended release or removal of a filter, for example, under water line pressure.

- the amount of force required to remove a filter cartridge from the head assembly even when such an engagement mechanism is released can be best applied when an operator can grasp the filter cartridge with two hands.

- break out torque The applied rotational torque required to remove a filter cartridge from the manifold is sometimes referred to as the "break out torque." If the engagement mechanism must be held in an actuated (disengaged) position in order to release the cartridge, it can be difficult for the operator to maintain one hand releasing the engagement mechanism while using the other hand to apply the necessary break out torque (e.g., rotating/twisting forces) to the filter cartridge necessary to remove the filter cartridge from the head assembly.

- the various filter unit examples described herein include a slide assembly that defines an engagement mechanism.

- the filter unit permits securing of the slide assembly in a latched configuration thereby permitting the operator to use two hands to grasp the filter cartridge when removing the filter cartridge from the manifold.

- Other aspects of the disclosed example filter units provides for automatic resetting of the slide assembly back into an unlatched position as part of the process of removing the filter cartridge from the manifold such that the head assembly is not occupied by a filter cartridge and the head assembly is prepared to receive a replacement filter cartridge.

- the disclosed examples illustrate a filter unit that includes a plurality of engagement features on each of the filter cartridge, a collar assembly, and a slide assembly supported in the collar assembly.

- Some of the slide assembly features are movable relative to the collar assembly and the filter cartridge in a rotation direction, a radially inward direction, and an axial direction relative to a central axis of the filter unit.

- the slide assembly can be positioned in unlatched orientations as well as latched orientations. In each of the unlatched and latched orientations, the slide assembly features are arranged to engage different portions of the collar assembly and filter cartridge and or other components to provide the desired engagement functionality.

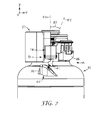

- the filter unit 5 includes a head assembly 11, a collar assembly 12, a slide assembly 14, and a filter cartridge housing 16 (see Figure 1 ).

- the slide assembly 14 is adjustably retained by the collar assembly 12.

- the slide assembly 14 can be removed from the collar assembly 12 by separating first and second collar members 20, 22 of the collar assembly 12.

- the head assembly 11 can be attached to a structural support, for example, a wall or pipe.

- the head assembly 11 typically includes an input 8 and an output 7.

- the input 8 and output 7 can be coupled in fluid communication to a water input line, a water output line, and an interior of the filter cartridge 16.

- An example filter assembly that includes a filter housing and collar assembly is described in US 4,915,831 (Taylor ), which patent is incorporated herein by reference.

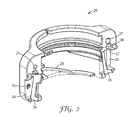

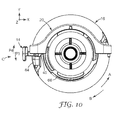

- the collar assembly 12 includes first and second collar members 20, 22, a slide recess 24 and a spring recess 27 that are defined in each of the first and second collar members 20, 22 (see Figures 2 and 3 ), a first latch protrusion 28, first and second fasteners 30, 32 and a slide pivot recess 34.

- the recesses 24, 26, 34 and protrusion 28 are configured to house or engage features of the slide assembly 14 as will be described in further detail below.

- the collar assembly 12 further includes key ring engagement track feature 36 adapted for engagement with key ring 74 and head track engagement feature 37 for engagement with the head assembly 11.

- the collar assembly 12 is maintained in a fixed position relative to the head assembly 11.

- the filter cartridge 16 is secured to the collar assembly 12 via the engagement of the filter cartridge 16 with the ramp features 29

- the first and second collar members 20, 22 include recess features 24, 34 and protrusion features 26, 28 at one end thereof, and a mating set of recess features 25, 35 and 27 at an on opposite end thereof.

- the recess features 24, 34 of the first collar member 20 and the recess features 25, 35 of the second collar member 22 define a cavity within which the slide assembly 14 is retained.

- the examples illustrated herein include a single slide assembly 14 mounted to the collar assembly 12. Other example configurations may include multiple slide assemblies 14 for each filter unit 5, depending upon the size and spatial need of the particular filter unit 5.

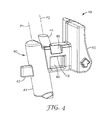

- the slide assembly 14 includes a pivot member 40 having an engagement extension 41, a reset latch protrusion 42 extending from the pivot member 40, a spring retaining member 44, a latch recess 46, an engagement surface 49, and a ramp surface 48 (see Figure 4 ).

- the slide assembly 14 further includes an actuator 50 and a spring 52.

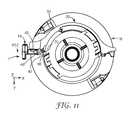

- the slide assembly 14 pivots about a pivot axis P1 that passes through the pivot member 40 in a pivot unlatch direction P3 (see Figure 11 ) and pivot latch direction P4 (see Figure 12 ).

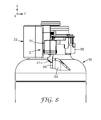

- the pivot axis P1 is arranged at an angle ⁇ 1 relative to the XY plane as shown in Figure 6 .

- the pivot axis P1 is also arranged parallel with the XZ plane (see Figure 7 ).

- the filter cartridge 16 includes a shoulder portion 60, a neck portion 62, a first ramp member 64 positioned on the shoulder portion 60, and a lug member 66 positioned on the neck portion 62 (see Figure 5 ).

- the first ramp member 64 includes a shoulder portion 68.

- the lug member 66 includes a neck stop surface 70.

- a plurality of keyed surface formations 75 are also positioned on the neck portion 62.

- the key ring 74 is configured to engage the key ring engagement track feature 36 of the collar assembly 12 to provide engagement of the filter cartridge 16 with the collar assembly 12 via the mating keyed surface formations 75.

- a spring axis P2 passes through the spring retaining member 44 (see Figures 4 , 6 and 7 ).

- Spring axis P2 is arranged at an angle ⁇ 2 relative to the XY plane (see Figure 6 ), and at an angle ⁇ 3 relative to the XZ plane (see Figure 7 ).

- the spring 52 is captured between the spring retaining member 44 and structure defining the spring recess 26 in the collar assembly 12.

- the spring 52 is oriented along the axis P2, thereby applying a biasing force to the slide assembly in a direction defined by angles ⁇ 2, ⁇ 3.

- the direction of the applied biasing force helps retain the slide assembly 14 in the first unlatched position C shown in Figure 6 prior to the first latch protrusion 28 engaging the latch recess 46 of the slide assembly 14.

- the angle ⁇ 1 is typically less than about 80°, more preferably about 40° to about 80°, and more preferably about 60° to about 80°. In some arrangements, the angle ⁇ 1 could be a negative angle in the range of about 0° to about -80°.

- the angle ⁇ 2 is typically less than about 90°, more preferably about 40° to about 90°, and more preferably about 60° to about 80°. In some arrangements, the angle ⁇ 2 could be a negative angle in the range of about 0° to about -90°. In some arrangements, the angle ⁇ 2 is equal with ⁇ 1.

- the inherent flexibility of spring 52 permits unequal values for angles ⁇ 1, ⁇ 2 while still providing the desired biasing force to maintain engagement between the latch recess 46 and first latch protrusion 28.

- the angle ⁇ 3 is typically at least 15°. In some arrangements, the angle ⁇ 3 is in the range of about 0° to about 80°, and more preferably about 15° to about 45°. In some arrangements, the angle ⁇ 3 could be a negative angle in the range of about 0° to about -90°.

- Movement of the slide assembly 14 along the axis P1 between the first unlatched position C shown in Figures 6 , 8 , and 12 and the second latched position shown in Figures 9 and 11 results in movement of the slide assembly 14 in each of the X, Y and Z directions relative to the collar assembly 12. Movement of the slide assembly 14 along the axis P1 changes a position of the reset protrusion 42 relative to engagement features of the filter cartridge 16 and changes a position of the latch recess 46 relative to the latch protrusion 28 of the collar assembly 12.

- the slide pivot recess 34 is arranged coaxial with the pivot axis PI that passes through pivot member 40.

- the pivot member 40 moves within the slide pivot recess 34, thus moving the slide assembly 14 in both the X and Z directions as the slide assembly 14 is moved between the first unlatched position C and the second latched position F.

- the slide assembly 14 moves along the pivot axis P1

- the slide assembly 14 must also rotate in the pivot release direction P3 and pivot latch direction P4 about the pivot axis P1 due to engagement between the first latch protrusion 28 (see Figure 2 ) and the engagement surface 49 (see Figure 4 ).

- the operator continues to apply this force in the X, Y and Z directions until the first latch protrusion 28 is engaged within the latch recess 46.

- the operator must apply a rotational force in the P4 pivot direction when the slide assembly 14 has engaged a top surface of the latch recess 24 to ensure engagement of the first latch protrusion 28 in the latch recess 46 even though the biasing force of the spring 52 tends to bias the slide assembly 14 in the pivot latch direction P4.

- the neck portion 62 of the filter cartridge 16 is inserted in an axial direction into collar assembly 12 to initiate engagement between the key ring 74, the plurality of keyed surface formations 75 and ramp feature 29.

- Rotation of the filter cartridge 16 in the engagement direction A advances the filter cartridge 16 in the Z direction relative to the collar assembly 12.

- FIG. 6 illustrates the reset protrusion 42 of the slide assembly 14 spaced radially outward from engagement with the lug member 66 of the filter cartridge 16.

- the first latch protrusion 28 is positioned vertically above (in the Z direction) the ramp surface 48 and is not in engagement with the latch recess 46.

- the filter cartridge 16 is rotated in the engagement direction A until the latch extension 41 of the pivot member 40 of the slide assembly 14 engages the first ramp member 64 of the filter cartridge 16.

- Engagement between the latch extension 41 and first ramp member 64 moves the slide assembly 14 in the XZ direction along the axis P1 into the second unlatched position D.

- the first latch protrusion 28 engages with the ramp surface 48, thus rotating the slide assembly 14 in the direction P3 about the pivot axis P1.

- the slide assembly 14 is not moved vertically in the Z direction far enough for the first latch protrusion 28 to engage within the latch recess 46.

- the second latch protrusion 42 can freely move in the X direction without engaging the lug member 66 while the latch extension 41 moves over the first ramp member 64 and into engagement with the shoulder 68.

- the filter cartridge 16 cannot be rotated in a disengagement direction B (see Figure 10 ) to disengage the key rings 74 from the plurality of keyed surface formations 75 and to disengage the filter cartridge 16 from the collar assembly 12.

- FIG. 10 is a top view illustrating the latched orientation shown in Figure 8 , wherein the slide assembly 14 is in the first unlatched position C with the latch extension 41 is in engagement with the first ramp member 64 of the filter cartridge 16.

- Removing the filter cartridge 16 from the collar assembly 12 is initiated by manually moving the slide assembly 14 along the pivot axis P1 in the XZ direction until reaching the third unlatched position E, wherein the slide assembly 14 is at the top end of the latch recess 24 (see Figure 9 ) and the first latch protrusion 28 is not engaged in the latch recess 46.

- the third unlatched position can be maintained by one hand of the operator while a second hand of the operator is used to rotate the filter cartridge 16 in the direction B to disengage the key rings 74 from the key ring engagement track features 36 until the filter cartridge 16 is removed from the collar assembly 12.

- the slide assembly 14 can be moved in the pivot direction P4 shown in Figure 10 while the slide assembly 14 is in the third unlatched position E to engage the first latch protrusion 28 within the latch recess 46 to establish the first latched position F shown in Figure 9 .

- the latch extension 41 is positioned vertically above the first ramp member 64 in the Z direction thereby permitting rotation of the filter cartridge 16 relative to the collar assembly 12 in the direction B.

- the slide assembly 14 can maintain the first latched position F until the operator manually rotates the slide assembly 14 in the pivot release direction P3 to disengage the first latch protrusion 28 from the latch recess 46.

- the second reset protrusion 42 is provided on the slide assembly 14 to initiate an automatic release of the slide assembly 14 from the first latched position F back into the first unlatched position C.

- the second reset protrusion 42 is positioned further radially inward in the X direction towards the filter cartridge 16 neck portion 62 as compared to the position of second latch protrusion 42 when in the first unlatched position C shown in Figure 6 .

- the second reset protrusion 42 engages the neck surface 70 of the lug member 66.

- Still further rotation of the filter cartridge 16 in the direction B applies a force to the second reset protrusion 42 that rotates the slide assembly 14 about the pivot axis P1. This action causes the latch recess 46 to rotate away from latch protrusion 28.

- Movement of the slide assembly 14 along the axis P1 can be considered translational movement. Movement about axis P1 (e.g., movement from the third unlatched position E to the latched position F) can be considered rotational movement.

- the slide assembly 14, having been automatically reset into the first unlatched position C, is now prepared for receiving a replacement filter cartridge 16. If the slide assembly 14 were to remain in the latched position F, the second reset protrusion 42 would interfere with the neck stop surface 70 (see Figure 9 ) when installing the replacement filter housing thereby preventing installation of the replacement filter cartridge 16.

- the automatic reset features of the slide assembly 14 can better ensure that the consumer is able to properly install the replacement filter housing. If the consumer inadvertently actuates slide assembly 14 into the latched position F after the filter cartridge 16 has been removed, the second reset protrusion 42 would interfere with the neck stop surface 70 (see Figure 9 ). However, when the consumer removes the filter cartridge 16 in direction B the automatic reset features of the slide assembly are actuated and proper installation of the filter cartridge 16 is permitted.

- the slide assembly 14 is configured to move primarily within the XZ plane between the first unlatched position C and the latched position F.

- the slide assembly 14 can be arranged to move primarily in the YZ plane, in the XY plane, or any plane arranged at angles relative to the XZ, YZ, and XY planes.

- the illustrated example provides for movement of the slide assembly 14 into the latched position F by moving generally in the Z direction along the axis P1 generally away from the filter cartridge 16.

- the slide assembly 14 can be arranged to move in an opposite direction generally towards the filter cartridge 16 to attain the latched position F.

- the slide assembly 14 is shown in the Figures mounted primarily to the collar assembly 12 of the head assembly 11. In other arrangements, the slide assembly 14 can be mounted to other features of the head assembly 11. Although the two-piece construction of the collar assembly 12 provides some advantages in capturing the slide assembly 14 in a mounted position in the head assembly 11, other constructions and arrangement are possible for the slide assembly 14 and head assembly 11 to permit mounting of the slide assembly 14 in different ways while providing the desired latching functions. In still further arrangements, at least some aspects of the slide assembly 14 can be mounted to the filter cartridge 16. In still further arrangements some aspects of the first ramp member 64 (such as the shoulder stop portion 68) can be alternatively mounted on the key ring 74 while maintaining essentially the similar locking function of the filter cartridge 16.

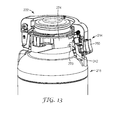

- the example filter unit assembly illustrated in Figures 1 - 12 has the stop surface 70 on lug member 66.

- Figure 13 illustrates another embodiment whereby a stop surface 270 is on a key ring 274, replacing the stop surface 70 described in the previous embodiment in Figures 1-12 .

- the stop surface 270 functions similar to the stop surface 70, wherein rotation of a filter cartridge 216 results in a second reset protrusion 242 of a slide assembly 214 engaging the stop surface 270.

- a primary difference between the stop surfaces 70, 270 is the location of the stop surface 270 compared to the location of the stop surface 70.

- filter units having stop surfaces, reset protrusions, and other features described herein used in conjunction with rotary valves, other valve members, and further filter unit features that rotate with or without the filter cartridge when mounting a filter cartridge to a head assembly, such as those features described in U.S Pat. No 6,458,269 (Bassett et al. ), which is incorporated herein by reference in its entirety.

- a filter unit that includes a filter cartridge, a slide assembly, a collar assembly and a head assembly.

- the slide assembly includes, a spring, and a first latching member.

- the collar assembly includes a latch recess and a second latching member and is configured to receive a filter cartridge in releasable engagement.

- the latch recess is configured to receive at least a portion of the slide assembly, and the second latching member is configured to releaseably engage the first latching member.

- the slide assembly is movable by translational and rotational movement between a latched position in which the first and second latching members are engaged and the filter cartridge is permitted to rotate relative to the head assembly, and a unlatched position wherein the first and second latching members are disengaged and the slide assembly engages the filter cartridge to limit rotational movement of the filter cartridge relative to the head assembly.

- the latch assembly can further include a third reset member. The third latching member is arranged and configured to engage the filter cartridge during rotation of the filter cartridge when the slide assembly is in the latched position. Engagement of the third latching member with the filter cartridge disengages the first and second latching members.

- a filter unit that includes a filter cartridge, a head assembly, a collar assembly and a slide assembly.

- the head assembly includes a first latching member.

- the slide assembly includes a second latching member.

- the filter cartridge is releaseably mounted to the collar assembly.

- the slide assembly is configured to move between a first position in which the filter cartridge is held in a fixed axial and rotational position relative to the head assembly, and a second position in which the filter cartridge is moveable axially and rotationally relative to the head assembly.

- the slide assembly is also configured to maintain the second position by engagement of the first and second latching members until the slide assembly engages the filter cartridge at a predetermined rotated position of the filter cartridge relative to the head assembly to disengage the first and second latching members prior to removing the filter cartridge from engagement with the head assembly.

- a further aspect of the present disclosure relates to a method of detaching a filter cartridge from a filter cartridge head assembly.

- the collar assembly includes a slide assembly and is movable between a latched position and an unlatched position.

- the filter cartridge includes first and second stop members. The method includes moving the slide assembly from the unlatched position wherein the slide assembly engages the first stop member to restrict rotation of the filter cartridge relative to the filter cartridge head assembly, into the latched position in which the slide assembly is disengaged from the first stop member to permit rotation of the filter cartridge relative to the head assembly.

- the method also includes engaging a first latch member of the slide assembly with a second latch member of the head assembly to retain the latch assembly in the latched position, rotating the filter cartridge in a release direction relative to the head assembly until the second stop member engages the slide assembly to disengage the first and second latch member to provide movement of the latch assembly from the latched position to the unlatched position, and further rotating the filter cartridge in the release direction until the filter cartridge is removed from the head assembly.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Separation Using Semi-Permeable Membranes (AREA)

- Casting Support Devices, Ladles, And Melt Control Thereby (AREA)

- Lock And Its Accessories (AREA)

- Quick-Acting Or Multi-Walled Pipe Joints (AREA)

- Snaps, Bayonet Connections, Set Pins, And Snap Rings (AREA)

- Lubrication Details And Ventilation Of Internal Combustion Engines (AREA)

Claims (5)

- Une unité filtre (5), comprenant :un ensemble tête (11) ;un ensemble col (12) ; etun ensemble coulissant (14) retenu par l'ensemble col (12), l'ensemble coulissant (14) contenant un évidement de verrou (46) et un élément pivot (40) ; etl'ensemble col (11) contenant un évidement coulissant (24) et une saillie de verrou (28), l'ensemble col (12) étant configuré pour recevoir une cartouche de filtre (16) en prise détachable, l'évidement coulissant (24) étant configuré pour recevoir au moins une partie de l'ensemble coulissant (14) et la saillie de verrou (28) étant configurée pour mettre en prise détachable l'évidement de verrou (46) ;dans laquelle l'ensemble coulissant (14) est mobile par mouvement pivotant autour de l'élément pivot (40) et un mouvement de translation entre :(i) une position verrouillée, dans laquelle l'évidement de verrou (46) et la saillie de verrou (28) sont en prise et la cartouche de filtre (16) peut tourner par rapport à l'ensemble tête (11) et(ii) une position déverrouillée, dans laquelle l'évidement de verrou (46) et la saillie de verrou (28) ne sont pas en prise et l'ensemble coulissant (14) est en prise avec la cartouche de filtre (16) pour limiter le mouvement de rotation de la cartouche de filtre par rapport à l'ensemble tête

dans laquelle l'ensemble coulissant (14) comprend en outre un ressort (52) agencé pour solliciter l'ensemble coulissant (14) dans la position déverrouillée et pour solliciter l'évidement de verrou (46) et la saillie de verrou (28) en prise l'un avec l'autre lorsque l'ensemble coulissant (14) est dans la position verrouillée. - L'unité de filtre selon la revendication 1, dans laquelle l'ensemble coulissant (14) comprend en outre un élément de réinitialisation (42) agencé et configuré pour mettre en prise une saillie de réinitialisation (66) pendant la rotation de la cartouche de filtre (16) lorsque l'ensemble coulissant (14) est dans la position verrouillée, dans laquelle la mise en prise de l'élément de réinitialisation (42) avec la saillie de réinitialisation (66) désolidarise l'évidement de verrou (46) et la saillie de verrou (28).

- L'unité de filtre de la revendication 1, dans laquelle l'ensemble coulissant (14) est mobile en mouvement de translation le long d'un premier axe (P1) et le ressort (52) est agencé afin de former un angle par rapport au premier axe (P1).

- L'unité de filtre de la revendication 1, dans laquelle le premier élément de verrouillage (46) est un évidement et le second élément de verrouillage (28) est une saillie.

- L'unité de filtre de la revendication 2, dans laquelle l'élément de réinitialisation (42) est une saillie.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US98346907P | 2007-10-29 | 2007-10-29 | |

| PCT/US2008/079031 WO2009058520A2 (fr) | 2007-10-29 | 2008-10-07 | Unité de filtre à blocage libérable |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2229231A2 EP2229231A2 (fr) | 2010-09-22 |

| EP2229231A4 EP2229231A4 (fr) | 2011-06-29 |

| EP2229231B1 true EP2229231B1 (fr) | 2014-12-24 |

Family

ID=40591708

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08844576.2A Not-in-force EP2229231B1 (fr) | 2007-10-29 | 2008-10-07 | Unité de filtre à blocage libérable |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US20100264078A1 (fr) |

| EP (1) | EP2229231B1 (fr) |

| JP (1) | JP5260668B2 (fr) |

| CN (1) | CN101835520B (fr) |

| WO (1) | WO2009058520A2 (fr) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8580109B2 (en) | 2011-09-15 | 2013-11-12 | Whirlpool Corporation | Electronic interface for water filter system |

| US8950052B2 (en) | 2011-09-15 | 2015-02-10 | Whirlpool Corporation | Method of installing a filter unit |

| US8845896B2 (en) | 2011-09-15 | 2014-09-30 | Whirlpool Corporation | Water filter system |

| US20130068684A1 (en) | 2011-09-15 | 2013-03-21 | Whirlpool Corporation | Filter unit |

| US10525387B2 (en) | 2017-04-06 | 2020-01-07 | Whirlpool Corporation | Filter cartridge |

| CN108721994A (zh) * | 2017-04-25 | 2018-11-02 | 佛山市顺德区美的饮水机制造有限公司 | 净水器滤芯及净水器 |

| CN109319961B (zh) * | 2017-08-01 | 2024-05-28 | 佛山市顺德区美的饮水机制造有限公司 | 净水机 |

| DE102017007497A1 (de) | 2017-08-08 | 2019-02-14 | Daimler Ag | Filterelement für einen Luftfilter eines Kraftwagens und Luftfilter |

| US10584040B2 (en) | 2017-10-06 | 2020-03-10 | Whirlpool Corporation | Filter cartridge |

| GB2568249B (en) * | 2017-11-08 | 2022-07-06 | Kohler Mira Ltd | Cartridge retention and removal means |

| CN118788032A (zh) * | 2018-04-10 | 2024-10-18 | 艾欧史密斯(中国)热水器有限公司 | 净水器 |

| US10807025B2 (en) | 2018-08-06 | 2020-10-20 | Whirlpool Corporation | Blind attachment interface for filter housing assembly |

| TWI692372B (zh) * | 2018-10-12 | 2020-05-01 | 旭然國際股份有限公司 | 鑰部結構以及具有前述鑰部結構之過濾裝置 |

| DE102018009187A1 (de) * | 2018-11-23 | 2020-05-28 | Hydac Filtertechnik Gmbh | Filtervorrichtung |

| EP3969151B1 (fr) | 2019-05-17 | 2024-09-11 | KX Technologies LLC | Interconnexion de filtre utilisant un actionnement magnétique corrélé pour fonction de système en aval |

| US11931679B2 (en) | 2019-05-17 | 2024-03-19 | Kx Technologies Llc | Filter interconnect utilizing a magnetic repulsion force |

| WO2021041900A1 (fr) | 2019-08-28 | 2021-03-04 | Kx Technologies, Llc | Interconnexions de filtre utilisant une force de cisaillement magnétique générée par des aimants programmés (polymagnets) codés |

| USD969964S1 (en) | 2020-03-06 | 2022-11-15 | Pentair Residential Filtration, Llc | Filtration system |

| EP4096805A4 (fr) | 2020-04-21 | 2023-12-20 | KX Technologies LLC | Interconnexion de filtre alimenté par gravité utilisant des aimants programmés (polymagnets) codés |

| WO2021222177A1 (fr) | 2020-04-27 | 2021-11-04 | Kx Technologies Llc | Interconnexion de filtre utilisant une force de cisaillement magnétique |

| IL297422A (en) * | 2020-05-12 | 2022-12-01 | Kx Technologies Llc | Connecting a filter that uses a magnetic repulsion force |

Family Cites Families (43)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2955712A (en) * | 1958-05-08 | 1960-10-11 | Parmatic Engineering Ltd | High pressure oil filter unit having threaded bowl assembly valve actuating means |

| DE1910165C3 (de) * | 1969-02-28 | 1980-02-28 | Preh, Elektrofeinmechanische Werke, Jakob Preh, Nachf. Gmbh & Co, 8740 Bad Neustadt | Zweipoliger Schiebeschalter |

| US3900401A (en) * | 1974-11-04 | 1975-08-19 | Us Navy | Dual filter for lubricating oil |

| US4419234A (en) * | 1981-09-24 | 1983-12-06 | Pall Corporation | Multiple cartridge filter assembly with removable filter cartridge array |

| US4504389A (en) * | 1983-01-17 | 1985-03-12 | Associated Mills, Inc. | Water filter |

| US4522717A (en) * | 1983-06-24 | 1985-06-11 | Brust John E | Filter apparatus |

| US4898670A (en) * | 1985-06-17 | 1990-02-06 | A/G Technology Corporation | Cartridge bonding |

| US4725354A (en) * | 1986-03-07 | 1988-02-16 | Everpure, Inc. | Filtering system |

| US4882049A (en) * | 1988-03-15 | 1989-11-21 | Baker Hughes, Incorporated | Apparatus for shifting and washing filter plates in a filter press |

| US4857189A (en) * | 1988-10-13 | 1989-08-15 | Everpure, Inc. | Filter cartridge with a lugged concentric closure portion |

| US4915831A (en) | 1989-01-23 | 1990-04-10 | Cuno, Incorporated | Filter assembly featuring displaceable filter head plunger for locking into filter cartridge detent |

| US5132009A (en) * | 1990-02-26 | 1992-07-21 | Allied-Signal Inc. | Filter for a fuel system |

| US5336406A (en) * | 1993-01-26 | 1994-08-09 | Elkay Manufacturing Company | Replaceable filter cartridge and head assembly with safety shut-off valve |

| FR2726483B1 (fr) * | 1994-11-09 | 1997-01-24 | Siebec Sa | Cartouche filtrante a couronne mobile de maintien |

| US5591332A (en) * | 1995-05-25 | 1997-01-07 | Omnipure Filter Co. | Filter assembly with automatic shut-off and quick-connect filter cartridge |

| US5738785A (en) * | 1995-12-20 | 1998-04-14 | Baldwin Filters, Inc. | Oil filter housing |

| US5771885A (en) * | 1996-02-22 | 1998-06-30 | Tri-Pact Enterprises, Inc. | Exercise filter |

| US20020036162A1 (en) * | 1996-08-08 | 2002-03-28 | Magnusson Jan H. | Appliance with iodinated water source |

| DE19633896A1 (de) * | 1996-08-22 | 1998-02-26 | Mann & Hummel Filter | Gehäusefilter |

| US6001249A (en) * | 1997-11-06 | 1999-12-14 | Dart Industries Inc. | Multi-stage water filter system |

| PL348456A1 (en) * | 1998-01-21 | 2002-05-20 | Clorox Co | Faucet mounted water filter |

| US5976362A (en) * | 1998-04-01 | 1999-11-02 | The Clorox Company | Faucet mounted water filter |

| US6372132B1 (en) * | 1998-07-10 | 2002-04-16 | Richard T. Williams | Purifier for filtering and purifying a fluid |

| US6245229B1 (en) * | 1998-07-31 | 2001-06-12 | Amway Corporation | Point-of-use water treatment system |

| DE19917567A1 (de) * | 1999-04-19 | 2000-11-02 | Brueninghaus Hydromatik Gmbh | Filtervorrichtung mit einem lösbaren Fitergehäuse |

| US6299661B1 (en) * | 1999-05-12 | 2001-10-09 | Siemens Canada Limited | Twist fit connection for air cleaners |

| EP1128060A3 (fr) * | 2000-02-16 | 2002-05-02 | Stanadyne Automotive Corp. | Base de filtre avec dispositif autoserrant de retenue de cartouche |

| US6458269B1 (en) * | 2000-04-20 | 2002-10-01 | Cuno Incorporated | Keyed filter assembly |

| US6554140B2 (en) * | 2000-12-19 | 2003-04-29 | Fleetguard, Inc. | Spin-on filter assembly |

| US20020125188A1 (en) * | 2001-03-06 | 2002-09-12 | Hacker John R. | Liquid filter having interchangeable spin-on canister filter and cartridge filter, and methods |

| WO2002089949A1 (fr) * | 2001-05-02 | 2002-11-14 | Parker-Hannifin Corporation | Element filtrant a visser et tete de filtrage correspondante |

| US20040159600A1 (en) * | 2002-06-10 | 2004-08-19 | Stankowski Ralph J | Filtration module including unitary filter cartridge-bowl construction |

| US6793818B1 (en) * | 2002-06-19 | 2004-09-21 | Brunswick Corporation | Support and locking structure for a fuel filter |

| EP1594586A2 (fr) * | 2003-01-28 | 2005-11-16 | Donaldson Company, Inc. | Ensemble de filtre et procedes |

| WO2004069367A2 (fr) * | 2003-01-28 | 2004-08-19 | Donaldson Company, Inc. | Assemblage de filtres dote de filtres amovibles et methodes associees |

| BRPI0412609A (pt) * | 2003-07-29 | 2006-09-26 | Cuno Inc | adaptador de filtro; método de adaptação de um tubo de filtro; conjunto de filtragem e seu dispositivo; conjunto de filtro |

| US20060006124A1 (en) * | 2004-07-12 | 2006-01-12 | Yates Brian G | Filter cartridge and method and apparatus for replacing same |

| US20060021925A1 (en) * | 2004-08-02 | 2006-02-02 | Jack Stifelman | Re-usable structure which attaches to the same filter head as originally intended to receive a throw-away spin-on |

| JP4847526B2 (ja) * | 2005-07-20 | 2011-12-28 | スリーエム イノベイティブ プロパティズ カンパニー | 流体濾過システム |

| DE102005042714A1 (de) * | 2005-09-02 | 2007-03-22 | Joma-Polytec Kunststofftechnik Gmbh | Ölfilteranordnung |

| US7261815B2 (en) * | 2005-10-12 | 2007-08-28 | Whirlpool Corporation | Water filter for refrigerator water dispenser |

| EP3381534B1 (fr) * | 2005-11-15 | 2021-05-05 | Donaldson Company, Inc. | Ensemble filtre a liquides |

| KR100646182B1 (ko) * | 2006-07-10 | 2006-11-15 | 정휘동 | 정수기 필터 어셈블리 |

-

2008

- 2008-10-07 US US12/739,530 patent/US20100264078A1/en not_active Abandoned

- 2008-10-07 EP EP08844576.2A patent/EP2229231B1/fr not_active Not-in-force

- 2008-10-07 JP JP2010532109A patent/JP5260668B2/ja not_active Expired - Fee Related

- 2008-10-07 WO PCT/US2008/079031 patent/WO2009058520A2/fr active Application Filing

- 2008-10-07 CN CN2008801132903A patent/CN101835520B/zh active Active

-

2015

- 2015-11-05 US US14/933,687 patent/US11185804B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US20160059165A1 (en) | 2016-03-03 |

| US20100264078A1 (en) | 2010-10-21 |

| WO2009058520A2 (fr) | 2009-05-07 |

| JP2011502044A (ja) | 2011-01-20 |

| CN101835520A (zh) | 2010-09-15 |

| US11185804B2 (en) | 2021-11-30 |

| CN101835520B (zh) | 2012-11-21 |

| WO2009058520A3 (fr) | 2009-07-02 |

| EP2229231A4 (fr) | 2011-06-29 |

| EP2229231A2 (fr) | 2010-09-22 |

| JP5260668B2 (ja) | 2013-08-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2229231B1 (fr) | Unité de filtre à blocage libérable | |

| EP0818228B1 (fr) | Système comprenant un module jetable de séparation de fluide et support avec aptitude à connexion rapide | |

| EP3013446B1 (fr) | Cartouche de filtration et système de filtration d'eau | |

| US6635175B2 (en) | Filter housing | |

| US20220258082A1 (en) | Torsional No Filter No Run System and Method | |

| KR20180041239A (ko) | 매니폴드의 병진 삽입 및 회전 맞물림을 위한 필터 카트리지 | |

| US9289704B2 (en) | Filter assembly | |

| US10213719B2 (en) | Cam lock system for reciprocating air compressor inlet filter | |

| CN1724108A (zh) | 过滤筒及其更换方法和设备 | |

| EP2640497A1 (fr) | Système de filtration | |

| SG191123A1 (en) | Filtration system and assembly thereof | |

| CN107207302B (zh) | 用于水净化药筒的连接机构 | |

| NO332395B1 (no) | Undervannsventilsammenstilling med uttagbart last blenderelement | |

| US20100089472A1 (en) | Faucet with Integral Filter and Method of Installation | |

| WO2016106170A2 (fr) | Système de filtration sans filtre et sans écoulement pouvant être installé sur un dispositif existant | |

| JP7316783B2 (ja) | 押出し可能な物質を表面上に堆積させるための装置及び方法 | |

| JP3061344B2 (ja) | 遠隔操作用脱着コネクタ | |

| EP4104914B1 (fr) | Mécanisme de rétention de cuve de filtre | |

| US7024956B2 (en) | Sensor ball valve safety interlock | |

| US11873744B2 (en) | Thread locking mechanism | |

| US12121836B2 (en) | Filter bowl retention mechanism | |

| WO2018197842A1 (fr) | Moyen de fixation de cuve de filtre | |

| EP4400195A1 (fr) | Ensemble filtre et élément de demi-accouplement comprenant un ensemble filtre | |

| CN116951143B (zh) | 一种螺纹式安全阀 | |

| WO2024194650A1 (fr) | Appareil de canalisation amélioré |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20100527 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20110526 |

|

| 17Q | First examination report despatched |

Effective date: 20120329 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602008036055 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: B01D0027080000 Ipc: B01D0035300000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B01D 35/30 20060101AFI20140710BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20140812 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 702841 Country of ref document: AT Kind code of ref document: T Effective date: 20150115 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008036055 Country of ref document: DE Effective date: 20150219 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20141224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150324 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150325 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 702841 Country of ref document: AT Kind code of ref document: T Effective date: 20141224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150424 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602008036055 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20150925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602008036055 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151007 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20151007 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151031 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160503 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151031 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151007 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20160630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151007 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20081007 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141224 |