EP2155567B1 - Boite d'emballage pour flacons et decoupes correspondantes - Google Patents

Boite d'emballage pour flacons et decoupes correspondantes Download PDFInfo

- Publication number

- EP2155567B1 EP2155567B1 EP08805561.1A EP08805561A EP2155567B1 EP 2155567 B1 EP2155567 B1 EP 2155567B1 EP 08805561 A EP08805561 A EP 08805561A EP 2155567 B1 EP2155567 B1 EP 2155567B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- products

- side walls

- forming

- boat

- blank

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/06—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers

- B65D71/38—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding and interconnecting two or more blanks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/32—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper having bodies formed by folding and interconnecting two or more blanks

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47F—SPECIAL FURNITURE, FITTINGS, OR ACCESSORIES FOR SHOPS, STOREHOUSES, BARS, RESTAURANTS OR THE LIKE; PAYING COUNTERS

- A47F7/00—Show stands, hangers, or shelves, adapted for particular articles or materials

- A47F7/28—Show stands, hangers, or shelves, adapted for particular articles or materials for containers, e.g. flasks, bottles, tins, milk packs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/44—Integral, inserted or attached portions forming internal or external fittings

- B65D5/50—Internal supporting or protecting elements for contents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/06—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers

- B65D71/12—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank

- B65D71/14—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank having the shape of a tube, without, or not being characterised by, end walls

- B65D71/34—Packaging elements holding or encircling completely or almost completely the bundle of articles, e.g. wrappers the packaging elements, e.g. wrappers being formed by folding a single blank having the shape of a tube, without, or not being characterised by, end walls characterised by weakened lines or other opening devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00129—Wrapper locking means

- B65D2571/00135—Wrapper locking means integral with the wrapper

- B65D2571/00141—Wrapper locking means integral with the wrapper glued

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00129—Wrapper locking means

- B65D2571/00135—Wrapper locking means integral with the wrapper

- B65D2571/00154—Wrapper locking means integral with the wrapper interlocked

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00246—Locating elements for the contents

- B65D2571/00253—Locating elements for the contents integral with the wrapper

- B65D2571/00283—Openings in at least a side wall

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00246—Locating elements for the contents

- B65D2571/00253—Locating elements for the contents integral with the wrapper

- B65D2571/0029—Openings in top or bottom walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00246—Locating elements for the contents

- B65D2571/00253—Locating elements for the contents integral with the wrapper

- B65D2571/00302—Locating elements for the contents integral with the wrapper consisting of an inward deformation of at least a wall, e.g. embossed, keels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00555—Wrapper opening devices

- B65D2571/00561—Lines of weakness

- B65D2571/00567—Lines of weakness defining a narrow removable strip

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00648—Elements used to form the wrapper

- B65D2571/00654—Blanks

- B65D2571/00666—Blanks formed from two or more sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00709—Shape of the formed wrapper, i.e. shape of each formed element if the wrapper is made from more than one element

- B65D2571/0079—U-shaped

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2571/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans, pop bottles; Bales of material

- B65D2571/00123—Bundling wrappers or trays

- B65D2571/00709—Shape of the formed wrapper, i.e. shape of each formed element if the wrapper is made from more than one element

- B65D2571/00796—Shape of the formed wrapper, i.e. shape of each formed element if the wrapper is made from more than one element cross-like

Definitions

- the present invention relates to a packaging box for substantially oblong products such as bottles or bottles of glass or plastic, each product having an intermediate portion of overall width greater than that of its ends, the box comprising a bottom and a cap in cardboard sheet material or corrugated cardboard.

- It also relates to a blank or a set of blanks for obtaining such a packaging box.

- Such packaging makes it possible to limit the width of the package, which in fact corresponds substantially to that of the bottles themselves, the plastic film being of a very thin thickness.

- the plastic film must be torn for the shelving of the products and their placement one by one in the shelves. This leads to loss of time related to the many manipulations to which are added the difficulties to store the products in an aligned manner.

- the palatability of filmed products is more unstable, the film tends to relax over time. It may also have been poorly manufactured and / or poorly put in place during the formation of the packaging, given the sometimes random conditions of shrinkage related to the temperature of the furnace upstream, to untimely differences in the speed of movement of plastic films during their continuous installation, or even the quality of the plastic used, often poorly controlled.

- the total width of a packaging layer is greater than with plastic films.

- the present invention therefore aims first of all to overcome the disadvantages mentioned above of the types of packaging of the prior art, whether in the form of plastic film or cardboard, while having their advantages.

- It also aims to improve the holding of the products on said pallets and to produce a package whose overall width does not exceed that of the products.

- the present invention essentially provides a packaging box for substantially oblong products, each product having an intermediate portion of overall width greater than those of its ends, comprising a bottom and a cap made of cardboard sheet or corrugated material , characterized in that the cap comprises two side walls interconnected by an upper wall, the bottom and the upper wall being of width less than or equal to said overall width and the side walls being perforated by openings regularly distributed in screws to screws arranged to allow the embedding of the respective intermediate parts of said products.

- the invention proposes a packaging box whose cap covers the products and keeps them grouped rigidly, being perforated in various places so that the shoulders of products at the level in their greatest width pass through perforated areas.

- a package comprising on the one hand products as described, and on the other hand a box with perforated walls in which said products are embedded as indicated above.

- the bottom is in the form of a base with vertical or substantially vertical walls.

- a packaging box for several substantially oblong products comprising a bottom and a cap, characterized in that the bottom is in the form of a base with vertical walls to a given height, to wrap at least partly a first end of the products, and having a first predetermined width, in that the cap comprises two side walls interconnected by an upper wall provided with locking means regularly distributed for the respective second end of each of the products and having a second determined equal width or substantially equal to the first determined width, said side walls being perforated by openings regularly distributed to the right of the corresponding blocking means, to allow lateral embedding of said products.

- the invention also proposes a blank or a set of blanks made of cardboard or corrugated board materials for the constitution of a packaging box as described above.

- a blank or a set of blanks made of cardboard or corrugated cardboard material for the constitution of a packaging box provided with a bottom and a cap for substantially oblong products, each product having an intermediate portion of overall width greater than that of its ends, comprising a shutter suitable for forming the bottom and a series of three shutters adapted to form the cap, characterized in that the following comprises two lateral flaps adapted to form the side walls of said cap interconnected by an upper flap adapted to form the upper wall of said cap, the shutter clean to form the bottom and the upper flap being of width less than or equal to said overall width and the side flaps being perforated by regularly distributed openings arranged to be opposite and allow the embedding of the respective intermediate portions of said products when the box is formed.

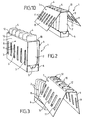

- FIGS. 1A to 1D and 2 show in perspective a packaging box 1 (cf. figure 2 ) for products 2 substantially oblong, each product 2 having an intermediate portion 3 of overall width greater than that of its ends 4 and 5, for example constituted by the bottom of the product and its cap 5.

- the box 1 comprises a bottom 6 of a first predetermined width and a cap 7 made of cardboard sheet material for example flat cardboard or corrugated cardboard with a thickness of 2 mm or 3 mm.

- the cap 7 comprises two identical rectangular lateral walls 8 and 9 interconnected by a rectangular upper wall 10 of a second determined width equal to or substantially equal to the first width, for example equal to said first width plus two thicknesses of cardboard, the bottom 6 forming a base of determined height, for example on 1/5 th of the height of the cap and / or the box.

- the determined height is for example comprised between 1/10 and 1/3 of the total height of the cap and / or the box.

- the first and the second width are of width less than the overall width of the product in its intermediate portion 3.

- the side walls 8 and 9 are perforated by oval, oblong, rectangular or substantially rectangular openings 11, regularly distributed facing each other and arranged to allow the embedding of the respective intermediate portions 3 of the products.

- these openings 11 are for example constituted by perforated strips of slightly trapezoidal shape of one to two centimeters in width, depending on the intermediate part to be embedded in the product.

- the upper wall 10 is itself also perforated by openings 12 oval or circular, horizontal, regularly distributed, located in line with the openings 11, that is to say axes centered in the same vertical plane and / or symmetrically centered identical way (in other words the center or the vertical axis of the horizontal openings is parallel to the vertical axis of symmetry of the openings 11) arranged to allow the embedding of the upper ends 4 of the products, for example formed by the bottom of these.

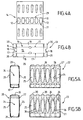

- the bottom and the cap are formed by two cutouts represented on the Figures 4A and 4B .

- This is a first cut 13 suitable for forming the tray-shaped bottom and a second cutout 14 suitable for forming the cap.

- the first cutout 13 arranged to form the display tray 6 comprises a rectangular central flap 15 connected on each of its edges 16 by first fold lines 17 with four lateral flaps opposite two by two, namely two small transverse flaps 18 and two large longitudinal flaps 19, the small flaps 18 being provided with rectangular or trapezoidal end flaps located on either side, connected to the lateral edges of these transverse flaps 18 by second perpendicular fold lines or in the extension or substantially in the extension of the first fold lines.

- the second cutout 14 capable of forming the cap 7, for its part comprises a series of three parts, namely a central flap (upper wall) 10 rectangular perforated by the oblong holes 12 intended to receive the bottom and / or plug portions 4 or 5 of the products 2 and two lateral flaps (side walls) 8 and 9, connected to the central flap 10 by parallel fold lines 21, the two lateral flaps 8 and 9 being themselves also perforated by the holes 11 adapted to receive the wider intermediate parts of the products, for example in the form of an elongate opening of substantially rectangular or slightly trapezoidal type.

- Products can be arranged upside down in the tray ( Figure 5A ) or head up ( Figure 5B ), the ends 29 or 30 then protruding from the cap by orifices provided for this purpose.

- FIGS. 6A and 6B show a set 31 of cuts according to one embodiment of the invention showing a first cutout 13 for trays of the type described with reference to the Figure 4B and a second cutout 14 for a cap provided on either side outwardly of each of the lateral flaps 32, at the outer periphery and connected by a fold line 33, with a substantially rectangular tongue 34 adapted to be fixed on the bottom of the tray after coating the products by the cap for example by gluing.

- Each of the side flaps 32 comprises for example in the lower part a frangible tab 35 for disengaging the tray / cap pulling in a manner known per se.

- FIGS 7A and 7B show another set 36 of two cutouts 37 and 38 according to the invention, again for six aligned products.

- first cutout 37 and the second cutout 38 comprise fastening means 39 of one of the cutouts with the other snap-fastening at their overlap. More precisely the first cutout comprises, regularly distributed longitudinally along the main side flaps 19 one, two, three or more parts 40 formed of small squares partially frangible or pre-cut on the Y-shaped middle, to form a wedge settable, arranged to come snap in force with spacing in pre-established holes 41 of complementary shape made in the lower part 42 of the flaps of the cap, to allow snapping in a manner known per se.

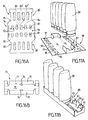

- FIGS. 8A and 8B, 9A and 9B give two other embodiments of an assembly, respectively 43,44, cuts according to the invention, for six aligned products, having first cutouts 45 whose central flap 46 is provided with cut corners 47 giving the tray thus formed a generally octagonal shape, the end flaps 48 of the transverse flaps 49 on the side of the cut corners, being provided on each side with a small complementary rectangular end flap 50, which will make it possible to glue said flap on the outer face or internal part of the adjacent flap, so as to form the octagonal configuration tray.

- the second cutouts 51 comprise, for their part, tear strips 52 as specified with reference to FIG. Figure 6A ( Figure 9A ) with gluing tab or locking means 53, 54 as indicated with reference to FIG. Figure 7A ( figure 8A ).

- the second cutouts 51 comprise lateral flaps 55 provided with lateral edges presenting recesses 56, for example forming lines. rectilinear discontinuous, to replace the openwork part allowing the embedding of end products.

- FIGS 10, 11A and 11B respectively give a package 57 for six products 58 in two rows of three, and the corresponding cuts 59, 60 to form them of the type described with reference to Figures 8 and 9 .

- FIGS. 12A, 12B, 13A, 13B provide further embodiments of set of cutouts 61, 62 and 63, 64 according to the invention with rectangular end tabs 61 ', 63', to be glued to the underside of the tray.

- Figures 12A and 12B corresponding to a package for six products (2x3) of the type described with reference to figures 6 , without pull tab and the Figures 13A and 13B correspond to Figures 11A and 11B .

- the figure 14A shows the formation of a package 65 around products whose lower tray 66 has an octagonal bottom making it possible to better fit the end, for example of the product cap, of the same type as that described with reference to FIG. Figure 9B .

- the outer edge 67 of the flaps of the cap is in turn recess, as described with reference to FIGS. 8A or 9A , which allows a better visibility of the products 68 while allowing a bulk overall identical to them.

- locking means 69 formed by a part 70 precut on horseback on the upper edge 71 of the cap formed by the junction fold line between the upper flap 72 and the side flap 73 of the cap and which, when pressed inwardly of the cap, takes a shaped configuration orthogonal angle for blocking, as shown in FIG. figure 15 .

- the Figures 16A and 16B give the cutouts 74 and 75 for forming the packaging of the Figures 14A to 15 .

- the cutout 75 is for example substantially identical to the cutout 45 of the Figure 9B with an orifice, for example substantially oval or circular, central 76 straddling the fold line 77 connecting the central flap 78 and the longitudinal side flap 79 for detaching the fixed tray bonding point easily peelable by lateral traction, as for most trays usable with the invention.

- the cutout 74 is for its break-off 80 in the form of broken line and provided with rectangular frangible portions 81 to form the angles 69, comprises two cut edges 82 and three fold lines 83, 83 ', 83 ", parallel to the line. 84, namely two lines in the lateral flap 85 and a line in the central flap 86.

- FIGS. 17A and 17B show other embodiments of locking means 87 this time at the tray 88 and not the product cap 89 in the package.

- oblong holes 90 regularly precut, in the form of inverted arches in a longitudinal flap 91, it itself connected to an outer flap 92.

- a portion 93 pre-cut on two sides and connected to the flap 92 without folding is provided to fit into the oblong hole to form blocking at each cap, once the flap 91 folded towards the inside of the tray and the outer flap 92 bent perpendicularly and plated on the bottom of the tray.

- the Figures 18A and 18B give in top view the blanks or cutouts 94 and 95 to make the tray of the Figure 17B and the packaging of Figures 19A, and 19B .

- the figure 20 gives another embodiment of the first blank 98 forming a tray with a locking device 71 of the type described with reference to FIG. Figure 14B for the headdress.

- the packages 99, 100 and 101 respectively comprise trays 102, 103, 104 respectively of the type of the blank 98 (tray 102), or the blank 94 (trays 100 and 101).

- the caps are, for their part, either of the conventional type (105) as described with reference to the figure 2 , of the type enveloping (106, 107) with cut sides 108 conforming laterally to the shape of the bottom or the cap.

- the figure 23 is a blank according to another embodiment of the invention comprising a series of four rectangular flaps, 109, 110, 111, 112, attached to each other, where appropriate, by parallel fold lines, namely a flap main 111 forming the bottom provided laterally on its two free flap edges 111 'with end tab 113 on either side, two side flaps 110 and 112 perforated according to the invention, respectively attached to both sides to main flap 111, forming the perforated side walls, and an end flap 109 attached to one of the side flaps forming the perforated upper wall, this flap 110 comprising on its outer edge a tab 114 of bonding, as the flap 112 .

- the products 2 (for example six in number) are placed in a row in a known manner in itself, plugs 5 plated on the central flap.

- the cap 7 is then fed over, the parts 4 of the products 2 being inserted into the holes 12 vis-à-vis the upper flap, then the side walls 8 and 9 of the cap, here again also previously glued internally are folded down , the lower ends being vis-à-vis vertical walls of the tray with which they come to cooperate by gluing, the intermediate portions 3 of the products then returning to be inserted into the lateral orifices 11, to obtain the packaging 1 of the figure 2 , which can then be stored and transported.

- the lower parts of the walls are removed, by separating them in a manner known per se, by manual lateral pulling towards the outside, then the cap is lifted and removed (cf. figure 3 ) to release the tray and products that can be placed in a block radius.

- the present invention is not limited to the embodiments more particularly described. On the contrary, it embraces all the variants and in particular those where the products are different from those shown and / or those where the cap and the tray are reversed, or those where the tray is stuck externally on the lower edges of the cap, the games being compensated by clamping / plating the tray on said edges of the cap.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cartons (AREA)

- Packages (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0703437A FR2915973B1 (fr) | 2007-05-11 | 2007-05-11 | Boite d'emballage pour flacons et decoupes correspondantes. |

| PCT/FR2008/000657 WO2008155482A1 (fr) | 2007-05-11 | 2008-05-13 | Boite d'emballage pour flacons et decoupes correspondantes |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2155567A1 EP2155567A1 (fr) | 2010-02-24 |

| EP2155567B1 true EP2155567B1 (fr) | 2013-12-25 |

Family

ID=38716486

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08805561.1A Not-in-force EP2155567B1 (fr) | 2007-05-11 | 2008-05-13 | Boite d'emballage pour flacons et decoupes correspondantes |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US8955682B2 (enExample) |

| EP (1) | EP2155567B1 (enExample) |

| JP (1) | JP5490681B2 (enExample) |

| KR (1) | KR20100031499A (enExample) |

| CA (1) | CA2686552A1 (enExample) |

| ES (1) | ES2450753T3 (enExample) |

| FR (1) | FR2915973B1 (enExample) |

| WO (1) | WO2008155482A1 (enExample) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104284841B (zh) | 2012-05-18 | 2016-10-12 | 印刷包装国际公司 | 具有检查特征部的纸箱 |

| USD839089S1 (en) * | 2014-07-18 | 2019-01-29 | Colormatrix Europe Limited | Display box with bottles |

| WO2017062542A1 (en) | 2015-10-09 | 2017-04-13 | Graphic Packaging International, Inc. | Carton with display feature |

| USD962078S1 (en) * | 2018-07-03 | 2022-08-30 | Curaden Ag | Blister package with toothbrush and toothpaste tubes |

| EP3849919B1 (en) * | 2018-09-11 | 2023-08-30 | Soffieria Bertolini S.p.A. | Packaging for the scratchproof transportation of pharmaceutical bottles |

| US11117704B2 (en) | 2019-11-11 | 2021-09-14 | Pratt Corrugated Holdings, Inc. | Beverage box |

| WO2021121616A1 (de) * | 2019-12-20 | 2021-06-24 | Hipp & Co | Verpackungseinrichtung, system aus verpackungseinrichtung und verpackungsartikeln, und verfahren |

| US12162662B2 (en) * | 2020-03-23 | 2024-12-10 | Westrock Mwv, Llc | Product package, carrier, and blank therefor |

| US11472596B2 (en) | 2020-06-17 | 2022-10-18 | Pratt Corrugated Holdings, Inc. | One- and two-pack beverage box |

| USD997741S1 (en) | 2020-09-30 | 2023-09-05 | Pratt Corrugated Holdings, Inc. | Six-cell beverage box |

| USD997739S1 (en) * | 2020-09-30 | 2023-09-05 | Pratt Corrugated Holdings, Inc. | Six-cell beverage box with top flaps |

| USD1026667S1 (en) | 2020-09-30 | 2024-05-14 | Pratt Corrugated Holdings, Inc. | One-cell beverage box |

| USD997740S1 (en) | 2020-09-30 | 2023-09-05 | Pratt Corrugated Holdings, Inc. | Three-cell beverage box |

| USD1007300S1 (en) | 2020-09-30 | 2023-12-12 | Pratt Corrugated Holdings, Inc. | Two-cell beverage box |

| WO2022232097A1 (en) * | 2021-04-27 | 2022-11-03 | Graphic Packaging International, Llc | Cover for tray with containers |

| USD1060050S1 (en) | 2021-12-30 | 2025-02-04 | Graphic Packaging International, Llc | Tray cover |

| USD1018298S1 (en) | 2022-01-21 | 2024-03-19 | Graphic Packaging International, Llc | Tray cover |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2334638A (en) * | 1940-10-05 | 1943-11-16 | Fort Orange Paper Company | Bottle carrier |

| US2563065A (en) * | 1946-06-22 | 1951-08-07 | Reynolds Metals Co | Bottle carrier |

| US2690839A (en) * | 1950-06-10 | 1954-10-05 | Armour & Co | Package |

| US2881914A (en) * | 1954-04-28 | 1959-04-14 | Forsum Company | Shipping and display cartons |

| US2877894A (en) * | 1958-02-13 | 1959-03-17 | Mead Atlanta Paper Company | Wrapper carton incorporating center partitioning means |

| US3552082A (en) * | 1968-04-01 | 1971-01-05 | Mead Corp | Method for displaying an assembly of like articles |

| US3570663A (en) * | 1968-08-16 | 1971-03-16 | Illinois Tool Works | Container carrier package |

| FR2215354B1 (enExample) * | 1973-01-26 | 1977-07-29 | Oreal | |

| JPS5467187U (enExample) * | 1977-10-20 | 1979-05-12 | ||

| US4174779A (en) * | 1978-07-18 | 1979-11-20 | Schenley Industries, Inc. | Carrying case for bottles |

| US4262814A (en) * | 1979-06-18 | 1981-04-21 | Champion International Corporation | Device for detecting tampering with a capped container and blank therefor |

| FR2525184A1 (fr) * | 1982-04-14 | 1983-10-21 | Allard Sarl | Panier a bouteilles obtenu par pliage et assemblage, manuel ou mecanique, d'un flan en matiere semi-rigide telle que du carton ondule |

| GB8425882D0 (en) * | 1984-10-12 | 1984-11-21 | Procter & Gamble | Container |

| US4696402A (en) * | 1985-03-19 | 1987-09-29 | Rayovac Corporation | Easy-open, individual unit dispensing package |

| DE3914915A1 (de) * | 1989-05-06 | 1990-11-08 | Unilever Nv | Verpackung aus karton od.dgl. |

| US5060804A (en) * | 1991-03-25 | 1991-10-29 | International Paper Company | Gable top carton wrapper |

| US5437363A (en) * | 1994-05-27 | 1995-08-01 | Crown Packaging Ltd. | Wrap-around carrier sleeve with article retaining means |

| US5655705A (en) * | 1996-02-07 | 1997-08-12 | The Mead Corporation | Multi-ply handle for wrap-around carton |

| GB0207090D0 (en) * | 2002-03-26 | 2002-05-08 | Mead Corp | Article carrier with integral bottle label |

-

2007

- 2007-05-11 FR FR0703437A patent/FR2915973B1/fr not_active Expired - Fee Related

-

2008

- 2008-05-13 JP JP2010506968A patent/JP5490681B2/ja not_active Expired - Fee Related

- 2008-05-13 WO PCT/FR2008/000657 patent/WO2008155482A1/fr not_active Ceased

- 2008-05-13 KR KR1020097023398A patent/KR20100031499A/ko not_active Withdrawn

- 2008-05-13 EP EP08805561.1A patent/EP2155567B1/fr not_active Not-in-force

- 2008-05-13 CA CA002686552A patent/CA2686552A1/fr not_active Abandoned

- 2008-05-13 ES ES08805561.1T patent/ES2450753T3/es active Active

- 2008-05-13 US US12/594,886 patent/US8955682B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US20100065618A1 (en) | 2010-03-18 |

| WO2008155482A1 (fr) | 2008-12-24 |

| FR2915973B1 (fr) | 2012-12-28 |

| US8955682B2 (en) | 2015-02-17 |

| KR20100031499A (ko) | 2010-03-22 |

| EP2155567A1 (fr) | 2010-02-24 |

| JP2010526730A (ja) | 2010-08-05 |

| ES2450753T3 (es) | 2014-03-25 |

| FR2915973A1 (fr) | 2008-11-14 |

| JP5490681B2 (ja) | 2014-05-14 |

| CA2686552A1 (fr) | 2008-12-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2155567B1 (fr) | Boite d'emballage pour flacons et decoupes correspondantes | |

| EP0403482B1 (fr) | Boite a verrouillage | |

| EP3548394B1 (fr) | Decoupes pour emballage primaire et/ou secondaire et/ou tertiaire et emballage obtenu avec de telles decoupes | |

| CA2268024A1 (fr) | Emballage, procede et dispositif pour le conditionnement de lots d'articles de volume indetermine | |

| EP3620402B1 (fr) | Élément intercalaire, pack de pots comprenant cet élément intercalaire et procédé de constitution dudit pack | |

| EP1787915B1 (fr) | Emballage pour bouteille | |

| EP3063078A1 (fr) | Ensemble de présentation avec plateau de groupage et articles à fond rond tels que des pots de yaourt | |

| EP1623934B1 (fr) | Plateau intercalaire de manutention pour empiler des conditionnements en couches | |

| FR2792290A1 (fr) | Ensemble de decoupes, caisse, procede et machine pour la fabrication de caisse a partir d'un tel ensemble | |

| EP1963197A1 (fr) | Paquet d'articles comprenant un flanc le recouvrant partiellement et un film enveloppant le tout | |

| WO2016083710A1 (fr) | Systeme de caisse de transport thermiquement isolante livrable en kit | |

| WO2020025777A1 (fr) | Flan et conditionnement pour pack de pots comprenant au moins une partie d'espacement/calage | |

| FR2936232A1 (fr) | Emballage universel, systeme et procede de fabrication d'emballage universel | |

| EP0277079A1 (fr) | Pièce longitudinale de calage et de renfort pour emballage de groupement | |

| FR2683207A1 (fr) | Emballage de transport et de distribution. | |

| FR2658787A1 (fr) | Barquette pour le conditionnement de produits fragiles. | |

| EP3049336A1 (fr) | Plateau en matiere en feuille de carton, flan, dispositif et procede pour la realisation d'un tel plateau | |

| EP2723645B1 (fr) | Emballage d'objets disposes en une ou plusieurs couches | |

| EP1593611B1 (fr) | Emballage en matière plastique pour le beurre | |

| EP1838586A2 (fr) | Emballage alimentaire et systeme d'emballage alimentaire comprenant au moins deux emballages de ce type | |

| BE1001359A6 (fr) | Recipient empilable, flan pour la fabrication d'un tel recipient et presentoir forme de tels recipients empiles. | |

| EP0541762A1 (fr) | Emballage du type comprenant une poche interne souple et une enveloppe externe rigide et son procede de fabrication | |

| FR2733740A1 (fr) | Emballage ferme pour le groupage d'un ensemble d'objets tels que des contenants de boissons | |

| FR3029182A1 (fr) | Emballage refermable pour le conditionnement d'œufs obtenu par pliage d'une unique feuille plane | |

| FR3123055A3 (fr) | Emballage à double coque |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20091006 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20100726 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602008029552 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: B65D0005320000 Ipc: B65D0071380000 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B65D 71/38 20060101AFI20130708BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20130822 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 646491 Country of ref document: AT Kind code of ref document: T Effective date: 20140115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008029552 Country of ref document: DE Effective date: 20140213 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2450753 Country of ref document: ES Kind code of ref document: T3 Effective date: 20140325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140325 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20131225 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 646491 Country of ref document: AT Kind code of ref document: T Effective date: 20131225 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140428 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140424 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602008029552 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20140926 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140513 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602008029552 Country of ref document: DE Effective date: 20140926 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140531 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140531 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140513 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602008029552 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140326 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131225 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140531 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20080513 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20180601 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180423 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CA Effective date: 20181105 Ref country code: FR Ref legal event code: CD Owner name: DS SMITH PACKAGING FRANCE, FR Effective date: 20181105 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: DS SMITH PACKAGING FRANCE Effective date: 20190301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190514 |