EP2139792B1 - Capsule for hot drink machines - Google Patents

Capsule for hot drink machines Download PDFInfo

- Publication number

- EP2139792B1 EP2139792B1 EP08751521A EP08751521A EP2139792B1 EP 2139792 B1 EP2139792 B1 EP 2139792B1 EP 08751521 A EP08751521 A EP 08751521A EP 08751521 A EP08751521 A EP 08751521A EP 2139792 B1 EP2139792 B1 EP 2139792B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- capsule

- holder

- hot drink

- indentation

- top surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/70—Containers, packaging elements or packages, specially adapted for particular articles or materials for materials not otherwise provided for

- B65D85/804—Disposable containers or packages with contents which are mixed, infused or dissolved in situ, i.e. without having been previously removed from the package

- B65D85/8043—Packages adapted to allow liquid to pass through the contents

- B65D85/8061—Filters

Definitions

- the top (8) of the capsule is made of filter paper and is perfectly flat

- the flat filter-paper surface (8) when the capsule is placed inside the holder and the holder introduced into the housing in the machine, comes into close contact with the filter, which is integral with the water heating block, through which the hot water is made to pass, under pressure, by means of a pump and is then forced through the top surface (8) of the capsule to make the drink.

- the flat top surface (8) of the capsule fits perfectly against the flat surface of the filter integral with the water heating block, which determines the uniform distribution and penetration of the water through the top surface (8) of the capsule and into the capsule itself, where it mixes with the drink product contained therein; the resulting hot drink then filters through the holes on the bottom surface (7), and after having passed through the lower filter paper (3) is collected inside the filter holder and poured through the spout in the machine.

- both the indentation and the protuberance may be of any shape and size, and serve the function of immediately and properly fitting the capsule into its holder.

- the position of the indentation and protuberance may be inverted, so that the capsule (1) features a protuberance in any point of its surface (1), while the filter holder has the indentation; in this case also the indentation and the protuberance may be of any shape and size.

- the solutions may be adopted independently of one another.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Apparatus For Making Beverages (AREA)

- Tea And Coffee (AREA)

- Beverage Vending Machines With Cups, And Gas Or Electricity Vending Machines (AREA)

- Non-Alcoholic Beverages (AREA)

- Feeding, Discharge, Calcimining, Fusing, And Gas-Generation Devices (AREA)

- Feeding And Watering For Cattle Raising And Animal Husbandry (AREA)

Abstract

Description

- Hot drink machines using capsule systems have been on the market for many years now.

- Present-day machines use either single-dose rigid cylindrical capsules, which are perforated by the machine when the water is forced through, or single/multiple-dose disc capsules, made of filter paper, which come in different shapes and sizes according to the type of machine they're used in. The disc capsules feature a convex top/bottom and contain the drink product, such as coffee for example. Such a shape, however, can be inconvenient, because when the hot water under pressure is forced through the filter, from the water heating block, it spreads and penetrates irregularly through the capsule shell and tends to "slide" along the convex surface, thus impairing the quality of the drink.

- A further inconvenience consists in that, like all disc-shaped objects, in order to provide a best quality drink they must preferably be placed with a specific side against the hot water supply, and according to a specific orientation with respect to the filter holder; as regards the disc capsules currently on the market these preferential positions are generally indicated on the capsule shell with a small coloured text, which, however, in most cases is hard to find and to read by the user.

- Document

GB 2411106 GB 2411106 - The present invention relates to a hot-drink capsule in accordance with appended claim 1, capable of remedying the above mentioned inconveniences.

- According to this invention the capsule features a flat top that fits perfectly against the filter, so that the hot water forced through from the heating block spreads in a uniform manner.

- The flat top is made of filter paper and is sealed around the edges onto a polypropylene container, of suitable shape and size, the bottom of which features a series of microscopic holes in the middle, covered by filter paper, through which the brewed beverage can pass and be poured through a spout into the cup or other container.

- In a preferred embodiment of this invention the edge of the capsule features a notch or indentation that matches a protuberance on the capsule holder, of any shape or size, to help the user immediately and properly fit the capsule into its holder, also thanks to the above mentioned flat top side.

- A specific embodiment of the invention will now be described by way of example with reference to the accompanying drawings in which:

-

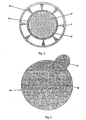

figure 1 shows a cross-section of the polypropylene container; -

figure 2 shows a cross-section of the polypropylene container complete with the filter paper at the top; -

figure 3 shows a view from above of the container without the filter paper top; -

figure 4 shows a view from above of the capsule; -

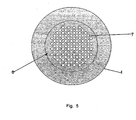

figure 5 shows a plan view of the lower part of the container. - Referring to the drawings, the capsule consists of a rigid disc-shaped container (1), made of PP (polypropylene) suitable for food use applications, or other like material, containing the drink product, such as milk powder, in the centre (6); the edge (4) features a tab (5), of the preferred shape, for easily extracting the capsule from its holder after use.

- The middle bottom part (6) of the container (1) features small or very small holes (7), through which the brewed drink leaves the container (1) when hot water is forced through, after having passed through a layer of filter paper beneath (3).

- The top (8) of the capsule is made of filter paper and is perfectly flat

- The flat filter-paper surface (8), when the capsule is placed inside the holder and the holder introduced into the housing in the machine, comes into close contact with the filter, which is integral with the water heating block, through which the hot water is made to pass, under pressure, by means of a pump and is then forced through the top surface (8) of the capsule to make the drink. The flat top surface (8) of the capsule fits perfectly against the flat surface of the filter integral with the water heating block, which determines the uniform distribution and penetration of the water through the top surface (8) of the capsule and into the capsule itself, where it mixes with the drink product contained therein; the resulting hot drink then filters through the holes on the bottom surface (7), and after having passed through the lower filter paper (3) is collected inside the filter holder and poured through the spout in the machine.

- In another embodiment there is an indentation in the top surface (8) of the container (1), in any position, which matches a protuberance in the filter holder; both the indentation and the protuberance may be of any shape and size, and serve the function of immediately and properly fitting the capsule into its holder.

- Obviously, the position of the indentation and protuberance may be inverted, so that the capsule (1) features a protuberance in any point of its surface (1), while the filter holder has the indentation; in this case also the indentation and the protuberance may be of any shape and size.

- The solutions may be adopted independently of one another.

- Based on tests carried out, it has been found that a capsule with a flat surface (6) and a diameter of 50 mm offers the best dose-quantity and drink-quality ratio.

Claims (6)

- Capsule for hot drink machines comprising a rigid polypropylene container (1) without a top surface and containing the basic drink product, in which the top surface (8) of the polypropylene container is closed by means of filter paper sealed at the edges, characterised in that

a middle bottom part (6) or bottom of the above mentioned rigid polypropylene container (1) features an area with a series of holes (7) and a lower layer of filter paper (3) is arranged beneath the middle bottom part (6) or bottom of the said rigid polypropylene container. - Capsule for hot drink machines according to claim 1, wherein the top surface (8) is flat.

- Capsule for hot drink machines according to claim 1, wherein the series of holes (7) consists of a micro-perforations.

- Capsule for hot drink machines according to claim 1, wherein the top surface (8) features a tab (5) for the easy extraction of the capsule from the capsule holder.

- Capsule for hot drink machines according to claim 1, wherein the capsule (1) features an indentation in the top surface (8), in any position, which matches a protuberance in the filter holder, both the indentation and the protuberance may be of any shape and size, and serve the function of immediately and properly fitting the capsule into its holder.

- Capsule for hot drink machines according to claim 1, wherein the capsule (1) features a protuberance in the top surface (8), in any position, which matches an indentation in the filter holder; both the indentation and the protuberance may be of any shape and size, and serve the function of immediately and properly fitting the capsule into its holder.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT000074U ITRM20070074U1 (en) | 2007-03-27 | 2007-03-27 | IMPROVEMENT TO PODS FOR FEEDING MACHINES FOR EXPRESS DRINKS |

| PCT/IT2008/000197 WO2008117329A1 (en) | 2007-03-27 | 2008-03-25 | Capsule for hot drink machines |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2139792A1 EP2139792A1 (en) | 2010-01-06 |

| EP2139792B1 true EP2139792B1 (en) | 2011-03-23 |

Family

ID=39591657

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08751521A Not-in-force EP2139792B1 (en) | 2007-03-27 | 2008-03-25 | Capsule for hot drink machines |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP2139792B1 (en) |

| AT (1) | ATE502879T1 (en) |

| DE (1) | DE602008005726D1 (en) |

| IT (1) | ITRM20070074U1 (en) |

| WO (1) | WO2008117329A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2015138296A1 (en) * | 2014-03-11 | 2015-09-17 | Starbucks Corporation D/B/A Starbucks Coffee Company | Single-serve beverage cartridge comprising a restricting orifice |

| US9783361B2 (en) | 2013-03-14 | 2017-10-10 | Starbucks Corporation | Stretchable beverage cartridges and methods |

| US9877495B2 (en) | 2015-01-09 | 2018-01-30 | Starbucks Corporation | Method of making a sweetened soluble beverage product |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2566319C2 (en) * | 2009-06-17 | 2015-10-20 | Конинклейке Дауве Егбертс Б.В. | Capsule and system for beverage preparation containing soluble substance |

| DK2307288T3 (en) * | 2009-06-17 | 2015-02-23 | Koninkl Douwe Egberts Bv | System, method and capsule for producing a beverage |

| RS53192B (en) * | 2009-06-17 | 2014-06-30 | Koninklijke Douwe Egberts B.V. | SYSTEM, CAPSULE AND BEVERAGE PREPARATION PROCEDURE |

| KR20120027537A (en) * | 2009-06-17 | 2012-03-21 | 사라 리/디이 비.브이. | System, method and capsule for preparing a beverage |

| JP5719356B2 (en) | 2009-06-17 | 2015-05-20 | コーニンクラケ ダウ エグバート ビー.ブイ. | System, capsule and method for making a predetermined amount of beverage |

| JP2012530529A (en) * | 2009-06-17 | 2012-12-06 | コーニンクラケ ダウ エグバート ビー.ブイ. | Capsule for containing beverage ingredients |

| US20160185519A1 (en) | 2013-08-14 | 2016-06-30 | Merck Patent Gmbh | High pressure extraction capsule |

| BR112020009353A2 (en) * | 2017-12-20 | 2020-10-27 | Société des Produits Nestlé S.A. | optimized coffee container for beverage preparation |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2411106B (en) | 2004-02-17 | 2006-11-22 | Kraft Foods R & D Inc | Cartridge for the preparation of beverages |

| PL1784344T3 (en) * | 2004-08-23 | 2009-08-31 | Nestec Sa | Capsule for preparing and delivering a drink by injecting a pressurized fluid into the capsule |

| ITRM20040186U1 (en) * | 2004-11-25 | 2005-02-25 | Espressaroma S P A | IMPROVEMENT TO PODS FOR THE SUPPLY OF MACHINES FOR EXPRESS DRINKS. |

| ITBO20060723A1 (en) * | 2006-10-20 | 2008-04-21 | Aroma System Srl | CAPSULES CONTAINING HYDRO-SOLUBLE PRODUCTS OR INFUSION PRODUCTS TO OBTAIN HOT DRINKS |

-

2007

- 2007-03-27 IT IT000074U patent/ITRM20070074U1/en unknown

-

2008

- 2008-03-25 WO PCT/IT2008/000197 patent/WO2008117329A1/en not_active Ceased

- 2008-03-25 AT AT08751521T patent/ATE502879T1/en not_active IP Right Cessation

- 2008-03-25 DE DE602008005726T patent/DE602008005726D1/en active Active

- 2008-03-25 EP EP08751521A patent/EP2139792B1/en not_active Not-in-force

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9783361B2 (en) | 2013-03-14 | 2017-10-10 | Starbucks Corporation | Stretchable beverage cartridges and methods |

| WO2015138296A1 (en) * | 2014-03-11 | 2015-09-17 | Starbucks Corporation D/B/A Starbucks Coffee Company | Single-serve beverage cartridge comprising a restricting orifice |

| US9877495B2 (en) | 2015-01-09 | 2018-01-30 | Starbucks Corporation | Method of making a sweetened soluble beverage product |

| US10820607B2 (en) | 2015-01-09 | 2020-11-03 | Starbucks Corporation | Soluble beverages with enhanced flavors and aromas |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2008117329A1 (en) | 2008-10-02 |

| DE602008005726D1 (en) | 2011-05-05 |

| EP2139792A1 (en) | 2010-01-06 |

| ITRM20070074U1 (en) | 2008-09-28 |

| ATE502879T1 (en) | 2011-04-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2139792B1 (en) | Capsule for hot drink machines | |

| CA2496416C (en) | Form-retaining pad for preparing a beverage suitable for consumption | |

| US8361527B2 (en) | Beverage cartridge | |

| EP0006175B1 (en) | Coffee machine which brews coffee beverages from pods of ground coffee | |

| EP2442697B1 (en) | System, apparatus and method for preparing a beverage | |

| EP2594170B1 (en) | Beverage extraction filter | |

| CA2839290C (en) | Compositions, systems and method for portion-packaged soups and meals | |

| EP1961676B1 (en) | Rigid capsule for coffee or other soluble products with improved lower seal | |

| EP1398279A2 (en) | Form-retaining pad for preparing a beverage suitable for consumption | |

| EP1786298A2 (en) | System for making a beverage, as well as a restriction-element and a pad evidently intended for such a system, as well as a method for making a beverage and use of he system for making a beverage | |

| JP2005261921A (en) | Filtering drink pack used in coffee maker and improvement of filter basket | |

| EP2773577B1 (en) | Form-retaining pad for preparing a beverage, assembly of a beverage preparation machine comprising a pad holder and such a form-retaining pad and related methods | |

| EP2179943B1 (en) | Capsule for infusion products | |

| RU118619U1 (en) | CAPSULE FOR PREPARING A DRINK OR LIQUID FOOD PRODUCT IN A DEVICE FOR PREPARING A BEVERAGE | |

| KR200488895Y1 (en) | drink manufacturing apparatus | |

| CN202287818U (en) | Improved Structure of Particulate Material Filter Container for Extracting Beverages | |

| KR200452779Y1 (en) | Capsules Containing Powdered Compositions for Beverages | |

| CN202723587U (en) | Particulate material filter container for extracting beverages | |

| KR102226622B1 (en) | Disposable Cup of Leaching Tea for Sleeping |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20090916 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20100217 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 602008005726 Country of ref document: DE Date of ref document: 20110505 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008005726 Country of ref document: DE Effective date: 20110505 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20110323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110624 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20110323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110623 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110623 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110725 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110723 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110325 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111001 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602008005726 Country of ref document: DE Effective date: 20111001 |

|

| 26N | No opposition filed |

Effective date: 20111227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110523 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120331 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120325 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110323 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20150330 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160325 |