EP2085560A2 - Vertical or horizontal installation system for netting/fabric/crystal with soldered or sewn zip - Google Patents

Vertical or horizontal installation system for netting/fabric/crystal with soldered or sewn zip Download PDFInfo

- Publication number

- EP2085560A2 EP2085560A2 EP08425773A EP08425773A EP2085560A2 EP 2085560 A2 EP2085560 A2 EP 2085560A2 EP 08425773 A EP08425773 A EP 08425773A EP 08425773 A EP08425773 A EP 08425773A EP 2085560 A2 EP2085560 A2 EP 2085560A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- netting

- fabric

- crystal

- fact

- channel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/02—Shutters, movable grilles, or other safety closing devices, e.g. against burglary

- E06B9/08—Roll-type closures

- E06B9/11—Roller shutters

- E06B9/13—Roller shutters with closing members of one piece, e.g. of corrugated sheet metal

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/02—Shutters, movable grilles, or other safety closing devices, e.g. against burglary

- E06B9/08—Roll-type closures

- E06B9/11—Roller shutters

- E06B9/17—Parts or details of roller shutters, e.g. suspension devices, shutter boxes, wicket doors, ventilation openings

- E06B9/17046—Bottom bars

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/52—Devices affording protection against insects, e.g. fly screens; Mesh windows for other purposes

- E06B9/54—Roller fly screens

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/56—Operating, guiding or securing devices or arrangements for roll-type closures; Spring drums; Tape drums; Counterweighting arrangements therefor

- E06B9/58—Guiding devices

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/56—Operating, guiding or securing devices or arrangements for roll-type closures; Spring drums; Tape drums; Counterweighting arrangements therefor

- E06B9/58—Guiding devices

- E06B2009/587—Mounting of guiding devices to supporting structure

Definitions

- the present invention relates to a system for the installation of netting/fabric/crystal roll-up elements, suitable for both small and large size installations, realized by means of telescopic guides enabling the mounting of said installations even on out-of-square walls, while keeping the netting/fabric/crystal elements always perpendicular.

- the use of a "zip", applied to the netting/fabric/crystal element for the purpose of its relevant mounting, allows for a considerable clamping power in the guide even in adverse weather conditions (i.e.: strong winds, etc.).

- the systems currently in use usually employ rigid guides which allow for a good installation of lengths of material, such as netting or fabrics, when the walls have been erected up to standard.

- the installation of netting or fabrics can be carried out through the employment of different expedients, such as, for instance, a shimming of the guide base until the guide is level, and then, any fissure present is filled with silicone- with subsequent longer installation time.

- the innovation that the present patent intends to claim comprises the use of a telescopic guide, allowing for a correct installation of netting/fabric/crystal even when the relevant walls are out-of-square, a mobile or "end” component and a wind-up roller. Inside the latter a housing for a zip, on which said netting/fabric/crystal has been previously soldered/sewn, is provided.

- the present invention relates to a telescopic guide of extruded aluminium for a roll-up element, comprising a channel to be fixed onto a wall and a guide element, inserted on said channel, housing a zip-holder profile, inside which a netting/fabric/crystal roller element slides; characterized by the fact that it comprises a telescopic system for adjusting the position of said guide element in relation to said channel by adapting said guide element position to any wall found to be out-of-square, and clamping means to mechanically lock said guide element on said channel.

- the present invention also relates to a mobile or "end" component of a netting/fabric/crystal roller element, whose extruded aluminium body shape is basically prismatic and with a flat bottom, characterized by the fact that a housing for the zip of said netting/fabric/crystal element has been obtained directly on its rough cast on its upper section.

- said telescopic system it is possible to adjust the position of said guide element used as a support base for the profile and its closing cover in relation to the channel, adapting it to the out of square wall, and to mechanically lock said guide on said channel by means of screws.

- a PVC feather key is provided on the channel upper section, which slides into the slot specially provided for on said box.

- the mobile or "end” component also made of extruded aluminium,comprises a housing for the insertion of said netting/fabric/crystal, previously fitted with a zip, and is used for stretching out the netting/fabric/crystal material.

- a gaiter acting as a drainer, is provided on said "end” component external area, while, on the lower area of this same section, a closing brush is fitted.

- This invention further relates to a wind-up roller of extruded aluminium, located inside a box, characterized by the fact that a housing for the insertion of a zip of said netting/fabric/crystal element has been obtained directly on blank on its outside diameter.

- the object of the present invention ( fig. 1 ) is a system for a vertical or horizontal installation of roll-up elements of netting/fabric/crystal, etc.

- Said system comprises at least one telescopic guide (1) extended in a longitudinal direction, a mobile or "end” component (2) basically set transverse to said telescopic guide (1) with a housing for hooking up a leading edge of a netting/fabric/crystal roll-up element (18), and a box (3) acting as container for a wind-up roller (21) of said roll-up element (18).

- Said roll-up element (18) is a flexible element realized, for instance, in netting/fabric/crystal, and so on.

- the side edges, end edge and upper edge of said element (18) are provided with a zip (8).

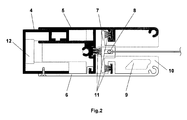

- Said telescopic guide (1) fundamentally comprises three extruded aluminium sections ( fig. 2 ) extended longitudinally and parallel to each other:

- Said guide element (5) is slot mounted on said channel (4); said closing cover (6), slot mounted on said guide element (5) and on the relevant stoppers (9) provided for on the plastic closing caps (10) fitted on both ends of said guide element (5), allows to hold in position a PVC profile (7).

- Said profile (7) houses a slot, where a sliding zip (8), with said netting/fabric/crystal element (18)soldered/sewn on, is inserted.

- Said channel (7) retaining housing is free to slide transversally on said channel (4) allowing for any final adjustment, in presence of out of square walls.

- a closing lid (12) is mounted, provided with a PVC key that may be inserted by sliding it into a special slot obtained on the box (3) therefore easing, improving and holding in alignment said telescopic guide (1) installation.

- a mobile or "end” component ( Fig. 3 ), consisting of, for example, a body of extruded aluminium, is fitted for the purpose of stretching said netting/fabric/crystal element (18).

- Said "end” component (2) shape is fundamentally prismatic, with a flat bottom, and it is transversally partitioned into an upper and lower section; inside the upper section of said "end” component (2) a slot (13) for the insertion of said netting/fabric/crystal element(18), previously

- a fastening system of said soldered/sewn netting/fabric/crystal element (18) is fitted on the ends of said "end” component (2) ( fig. 4 ), said system has been realized by using special plastic plates (19) and relative plastic clamping inserts (20), also used for said "end” component (2) sliding motion inside the relevant housing obtained in said telescopic guide (1).

- a brush (17) is provided enabling to locate against any end face noiselessly, while guaranteeing a proper hold.

- a box (3) acting as a container for a wind-up roller (21), is located inside said box (3).

- Said wind-up roller (21) is of extruded aluminium and is provided, on the outside, with a relevant rough cast slot (22) for the insertion of a zip (8) with said netting/fabric/crystal element (18) soldered/sewn on.

- Said wind-up roller (21) guarantees a saving in the relevant production time or replacement time of said netting/fabric/crystal element (18) and a greater resistance of said netting/fabric/crystal element (18) even in adverse weather conditions (strong wind, etc.)

Abstract

Description

- The present invention relates to a system for the installation of netting/fabric/crystal roll-up elements, suitable for both small and large size installations, realized by means of telescopic guides enabling the mounting of said installations even on out-of-square walls, while keeping the netting/fabric/crystal elements always perpendicular. The use of a "zip", applied to the netting/fabric/crystal element for the purpose of its relevant mounting, allows for a considerable clamping power in the guide even in adverse weather conditions (i.e.: strong winds, etc.).

- The systems currently in use usually employ rigid guides which allow for a good installation of lengths of material, such as netting or fabrics, when the walls have been erected up to standard.

- When the walls are out-of-square, the installation of netting or fabrics can be carried out through the employment of different expedients, such as, for instance, a shimming of the guide base until the guide is level, and then, any fissure present is filled with silicone- with subsequent longer installation time.

- It should be taken into consideration, however, that the silicone may change colour through time, therefore spoiling the overall effect of the installation.

- Vice versa , installations carried out on out-of-square walls do not guarantee a proper tensioning of said netting or fabric, compromising their relevant operation and working life, beside spoiling their overall effect.

- As regards the netting/fabric/crystal fastening onto the mobile or "end" component of said wind-up roller, the system currently in use foresee hooking said netting/fabric/crystal by means of a spinner or a double sided tape.

- Even if widely in use, this solution cannot always guarantee a proper tensioning of said netting/fabric/crystal, often resulting in unaesthetic bulges.

- Moreover, by employing the above solution the overall effect is further compromised as the netting/fabric/crystal soldering/sewing is always in full view.

- On the other hand, the use of double sided tape could, in time, lead to a weakening of the netting/fabric/crystal original anchoring onto the mobile section when, for instance, strong winds blow.

- The innovation that the present patent intends to claim comprises the use of a telescopic guide, allowing for a correct installation of netting/fabric/crystal even when the relevant walls are out-of-square, a mobile or "end" component and a wind-up roller. Inside the latter a housing for a zip, on which said netting/fabric/crystal has been previously soldered/sewn, is provided.

- The present invention relates to a telescopic guide of extruded aluminium for a roll-up element, comprising a channel to be fixed onto a wall and a guide element, inserted on said channel, housing a zip-holder profile, inside which a netting/fabric/crystal roller element slides; characterized by the fact that it comprises a telescopic system for adjusting the position of said guide element in relation to said channel by adapting said guide element position to any wall found to be out-of-square, and clamping means to mechanically lock said guide element on said channel.

- Furthermore, the present invention also relates to a mobile or "end" component of a netting/fabric/crystal roller element, whose extruded aluminium body shape is basically prismatic and with a flat bottom, characterized by the fact that a housing for the zip of said netting/fabric/crystal element has been obtained directly on its rough cast on its upper section.

- With said telescopic system, it is possible to adjust the position of said guide element used as a support base for the profile and its closing cover in relation to the channel, adapting it to the out of square wall, and to mechanically lock said guide on said channel by means of screws.

- For the purpose of easing the coupling of said adjustable guide to said box, a PVC feather key is provided on the channel upper section, which slides into the slot specially provided for on said box.

- The mobile or "end" component, also made of extruded aluminium,comprises a housing for the insertion of said netting/fabric/crystal, previously fitted with a zip, and is used for stretching out the netting/fabric/crystal material. A gaiter, acting as a drainer, is provided on said "end" component external area, while, on the lower area of this same section, a closing brush is fitted.

- This invention further relates to a wind-up roller of extruded aluminium, located inside a box, characterized by the fact that a housing for the insertion of a zip of said netting/fabric/crystal element has been obtained directly on blank on its outside diameter.

- The present invention is herein further described by way of non-limitative examples of realization, with reference to the figures on the accompanying drawings wherein:

-

Fig. 1 is a perspective overall view of the installation system according to the present invention; -

Fig. 2 is a view of section A-A offig. 1 ; -

Fig. 3 is a view of section B-B offig. 1 ; -

Fig. 4 is a view of section C offig. 1 ; -

Fig. 5 is a view of section D-D offigure 1 . - The object of the present invention (

fig. 1 ) is a system for a vertical or horizontal installation of roll-up elements of netting/fabric/crystal, etc. - Said system comprises at least one telescopic guide (1) extended in a longitudinal direction, a mobile or "end" component (2) basically set transverse to said telescopic guide (1) with a housing for hooking up a leading edge of a netting/fabric/crystal roll-up element (18), and a box (3) acting as container for a wind-up roller (21) of said roll-up element (18).

- Said roll-up element (18) is a flexible element realized, for instance, in netting/fabric/crystal, and so on. The side edges, end edge and upper edge of said element (18) are provided with a zip (8).

- Said telescopic guide (1) fundamentally comprises three extruded aluminium sections (

fig. 2 ) extended longitudinally and parallel to each other: - a channel (4) extendable in a longitudinal direction, to be fixed onto the relevant wall for any final adjustments when said wall is out of square;

- a guide element (5) used as a support base and/or as a container for a zip-holder profile (7), made of, for instance, PVC, inside which a zip (8), with the netting/fabric/crystal element(18) soldered/sewn on, slides;

- a closing cover (6) interlocking said guide element (5) and said channel (4).

Said telescopic guide (1) is characterized by the fact that it represents a telescopic system enabling to adjust the position of said guide element (5) in relation to said channel (4) in a transverse direction to said channel (4), and to mechanically lock said guide element (5) onto said channel (4) by means of a clamping device. - Said guide element (5) is slot mounted on said channel (4); said closing cover (6), slot mounted on said guide element (5) and on the relevant stoppers (9) provided for on the plastic closing caps (10) fitted on both ends of said guide element (5), allows to hold in position a PVC profile (7). Said profile (7) houses a slot, where a sliding zip (8), with said netting/fabric/crystal element (18)soldered/sewn on, is inserted.

- Between said profile (7) and its relevant retaining housing, formed by said guide element (5) and said closing cover (6), special brushes (11) are mounted, making said coupling specially noiseless.

- He position if said guide element (5) in relation to said channel (4) is adjustable in a transverse direction so to compensate for any out of square sections of the wall said channel (4) is mounted on. Once the cross position between said guide element (5) and said channel (4) is adjusted, said guide element (5) is locked to said channel (4) by means of suitable clamping means, such as, for example, a closing cover (6), screwed into said channel (4), engaging said guide element (5) by slotting it.

- Said channel (7) retaining housing is free to slide transversally on said channel (4) allowing for any final adjustment, in presence of out of square walls.

- On the upper end section of said channel (4) a closing lid (12) is mounted, provided with a PVC key that may be inserted by sliding it into a special slot obtained on the box (3) therefore easing, improving and holding in alignment said telescopic guide (1) installation.

- A mobile or "end" component (

Fig. 3 ), consisting of, for example, a body of extruded aluminium, is fitted for the purpose of stretching said netting/fabric/crystal element (18). - Said "end" component (2) shape is fundamentally prismatic, with a flat bottom, and it is transversally partitioned into an upper and lower section; inside the upper section of said "end" component (2) a slot (13) for the insertion of said netting/fabric/crystal element(18), previously

- fitted with a "zip" (8), has been obtained from its rough cast. Inside the lower section of said "end" component (2) a relevant space (14), where a ballast ( not depicted) may be introduced for ballasting said profile according to requirements , and a slot (15) for the introduction of a gaiter (16), acting as a drainer, have been obtained, respectively.

- A fastening system of said soldered/sewn netting/fabric/crystal element (18) is fitted on the ends of said "end" component (2) (

fig. 4 ), said system has been realized by using special plastic plates (19) and relative plastic clamping inserts (20), also used for said "end" component (2) sliding motion inside the relevant housing obtained in said telescopic guide (1). - On the outside base of said "end" component (2) a brush (17) is provided enabling to locate against any end face noiselessly, while guaranteeing a proper hold.

- A box (3) (

fig. 5 ) acting as a container for a wind-up roller (21), is located inside said box (3). - Said wind-up roller (21) is of extruded aluminium and is provided, on the outside, with a relevant rough cast slot (22) for the insertion of a zip (8) with said netting/fabric/crystal element (18) soldered/sewn on.

- Inside said wind-up roller (21), different ribs (23) are positioned, also realized on the rough cast, providing to said roller structure a high flexural strength so as to make it also suitable for large size installations.

- Said wind-up roller (21) guarantees a saving in the relevant production time or replacement time of said netting/fabric/crystal element (18) and a greater resistance of said netting/fabric/crystal element (18) even in adverse weather conditions (strong wind, etc.)

- Lastly, it is clear that said telescopic guide, said mobile or "end" component and wind-up roller herein described and depicted may be further modified without straying from the scope of the claims hereof.

Claims (11)

- A telescopic guide (1) of extruded aluminium for a roll-up element, comprising a channel (4) to be fixed onto a wall and a guide element (5), slot mounted on said channel (4) housing a zip-holder profile (7) inside which slides a roll-up element (18) of netting/fabric/crystal;

characterized by the fact that it comprises a telescopic system to adjust the position of said guide element (5) in relation to said channel (4) adapting the position of said guide element (5) to any out of square on the wall, and clamping means to mechanically lock said guide element (5) onto said channel (4); - A telescopic guide according to claim 1 characterized by the fact that said channel (4) is fitted with a plastic feather key that may be inserted by sliding it into a relevant slot specially provided for in a rolling shutter box (3) for said netting/fabric/crystal element;

- A telescopic guide according to claim 1 characterized by the fact that said telescopic guide enables to adjust the position of said guide element (5) in relation to said channel (4) in a transverse direction to said channel (4);

- A mobile or "end" component (2) for said netting/fabric/crystal roll-up element (18), whose body is of extruded aluminium and whose shape is fundamentally prismatic with a flat bottom and

characterized by the fact that on its upper section a slot (13) for the insertion of a zip (8) of said netting/fabric/crystal roll-up element has been directly obtained from its rough cast; - A mobile or "end" component according to claim 4, characterized by the fact that it is transversally partitioned in two sections and in its lower section a special space (14) has been obtained suitable for housing any ballast eventually required;

- A mobile or "end" component according to claim 3 characterized by the fact that it presents on its side a relevant slot (15) for the insertion of a gaiter (16) acting as a drainer;

- A mobile or "end" component according to claim 3 characterized by the fact that on its base a special housing has been obtained for the application of a brush (17) enabling said mobile component to locate against any end face noiselessly while guaranteeing a proper hold ;

- A mobile or "end" component according to claim 3 characterized by the fact that plastic closing plates (19) are fitted on both of its side ends, provided with a clamping system for said netting/fabric/crystal (18) carried out by means of plastic inserts (20), ensuring said netting/fabric/crystal clamping throughout its length;

- A mobile or "end" component according to claims 3 and 7

characterized by the fact that said plastic plates (19) are also used for the sliding of said netting/fabric/crystal (18) inside said telescopic guide (1). - A wind-up roller (21) , located inside a box (3) of extruded aluminium, and characterized by the fact that on its outside diameter, it is provided with a relevant rough cast slot (22) for the insertion of a zip (8) of a roll-up element (18) of netting/fabric/crystal;

- A wind-up roller according to claim 10 characterized by the fact that ribs (23) have been rough cast obtained in its inside diameter, conferring to said roller structure a high flexural strength so as to make it also suitable for installations of large size.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT000039A ITPS20070039A1 (en) | 2007-12-07 | 2007-12-07 | SYSTEM FOR VERTICAL OR HORIZONTAL NETWORK / FABRIC / CRYSTAL INSTALLATION WITH WELDED OR SEWED ZIP |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2085560A2 true EP2085560A2 (en) | 2009-08-05 |

| EP2085560A3 EP2085560A3 (en) | 2015-01-14 |

| EP2085560B1 EP2085560B1 (en) | 2017-11-29 |

Family

ID=40315788

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08425773.2A Not-in-force EP2085560B1 (en) | 2007-12-07 | 2008-12-03 | A telescopic guide for a roll-up element |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2085560B1 (en) |

| IT (1) | ITPS20070039A1 (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012050518A1 (en) * | 2010-10-15 | 2012-04-19 | Erco Systems Ab | Window screen device |

| US20150240551A1 (en) * | 2014-02-27 | 2015-08-27 | Michael Murray | Tension Adjustable Retractable Screen Assembly |

| ITUA20162498A1 (en) * | 2016-03-23 | 2017-09-23 | Marco Giuseppe Di | INSTALLATION SYSTEM FOR MOSQUITO NETS WITHOUT ADDITIONAL CHASSIS, HANDLED FROM THE INSIDE |

| EP3130742A4 (en) * | 2014-04-30 | 2018-02-28 | Hayashiguchi MFG Co., Ltd. | Screen device |

| WO2019016688A1 (en) | 2017-07-18 | 2019-01-24 | Renson Sunprotection-Screens Nv | Screen device |

| IT202000015940A1 (en) * | 2020-07-02 | 2022-01-02 | Pratic F Lli Orioli S P A | ADJUSTABLE GUIDE GROUP FOR ROLL-UP CURTAINS, AND RELATIVE ASSEMBLY METHOD |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3721921C1 (en) * | 1987-07-02 | 1989-02-16 | Seizo Hayashiguchi | Screening device |

-

2007

- 2007-12-07 IT IT000039A patent/ITPS20070039A1/en unknown

-

2008

- 2008-12-03 EP EP08425773.2A patent/EP2085560B1/en not_active Not-in-force

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3721921C1 (en) * | 1987-07-02 | 1989-02-16 | Seizo Hayashiguchi | Screening device |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012050518A1 (en) * | 2010-10-15 | 2012-04-19 | Erco Systems Ab | Window screen device |

| US20150240551A1 (en) * | 2014-02-27 | 2015-08-27 | Michael Murray | Tension Adjustable Retractable Screen Assembly |

| US9458666B2 (en) * | 2014-02-27 | 2016-10-04 | Michael Murray | Tension adjustable retractable screen assembly |

| EP3130742A4 (en) * | 2014-04-30 | 2018-02-28 | Hayashiguchi MFG Co., Ltd. | Screen device |

| US9982483B2 (en) | 2014-04-30 | 2018-05-29 | Hayashiguchi Mfg Co., Ltd. | Screen device |

| ITUA20162498A1 (en) * | 2016-03-23 | 2017-09-23 | Marco Giuseppe Di | INSTALLATION SYSTEM FOR MOSQUITO NETS WITHOUT ADDITIONAL CHASSIS, HANDLED FROM THE INSIDE |

| WO2019016688A1 (en) | 2017-07-18 | 2019-01-24 | Renson Sunprotection-Screens Nv | Screen device |

| BE1025407B1 (en) * | 2017-07-18 | 2019-02-18 | Renson Sunprotection Screens Nv | SCREEN DEVICE |

| IT202000015940A1 (en) * | 2020-07-02 | 2022-01-02 | Pratic F Lli Orioli S P A | ADJUSTABLE GUIDE GROUP FOR ROLL-UP CURTAINS, AND RELATIVE ASSEMBLY METHOD |

Also Published As

| Publication number | Publication date |

|---|---|

| ITPS20070039A1 (en) | 2009-06-08 |

| EP2085560B1 (en) | 2017-11-29 |

| EP2085560A3 (en) | 2015-01-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2085560A2 (en) | Vertical or horizontal installation system for netting/fabric/crystal with soldered or sewn zip | |

| ES2650788T3 (en) | A compensation system for pleated screens, such as mosquito nets and blinds | |

| GB2498330A (en) | A flood barrier | |

| JP4823608B2 (en) | Roll screen door | |

| US4781235A (en) | Combined sun screen and storm window | |

| JP2001220971A (en) | Shutter | |

| ITUB20159493A1 (en) | CURTAIN SUPPORT DEVICE | |

| CN212186099U (en) | Fixing device of composite curtain | |

| CN214615267U (en) | Be used for outer window to cornice outer plastering binding off instrument | |

| CN210439941U (en) | Upper rail mechanism and blind window curtain provided with same | |

| JP4749883B2 (en) | Fixture frame mounting structure | |

| EP2474702A1 (en) | Screening arrangement with releasable decorative cover on top rail | |

| CN214147715U (en) | Adjustable lamp post for solar street lamp | |

| CN213838228U (en) | Novel waterproof wing window section bar | |

| CN211950108U (en) | Combined anti-theft door frame structure | |

| KR200494228Y1 (en) | fixing device of roll blind | |

| JP3867244B2 (en) | shutter | |

| US20020129554A1 (en) | Flange-shaped fitting frame | |

| KR200373398Y1 (en) | Connecting structure of bracket used in blind | |

| CN206681653U (en) | A kind of aluminium alloy extrusions for shutter | |

| JP2009030386A (en) | Device for preventing screen door from falling | |

| JP5393088B2 (en) | Shutter panel removal prevention tool, sash with shutter | |

| JP2012087456A (en) | Waterproof structure of shutter attached to external wall | |

| ES2374877T3 (en) | KIT FOR THE ASSEMBLY OF TWO SLIDING LEAVES MADE WITH GLASS OR OTHER MATERIAL IN A SYSTEM OF SLIDING DOORS. | |

| JP2010001635A (en) | Sash |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E06B 9/54 20060101ALI20141210BHEP Ipc: E06B 9/13 20060101AFI20141210BHEP Ipc: E06B 9/17 20060101ALI20141210BHEP Ipc: E06B 9/58 20060101ALI20141210BHEP |

|

| 17P | Request for examination filed |

Effective date: 20150713 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AXX | Extension fees paid |

Extension state: AL Extension state: BA Extension state: MK Extension state: RS |

|

| 17Q | First examination report despatched |

Effective date: 20160805 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170622 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 950557 Country of ref document: AT Kind code of ref document: T Effective date: 20171215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008053144 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20171129 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 950557 Country of ref document: AT Kind code of ref document: T Effective date: 20171129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180228 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180228 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180301 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602008053144 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171203 Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171203 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20171231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180703 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171203 |

|

| 26N | No opposition filed |

Effective date: 20180830 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171231 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171231 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171231 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20181221 Year of fee payment: 11 Ref country code: FR Payment date: 20181231 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20181220 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20081203 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180329 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20191203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191203 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191231 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191203 |