EP2017567B1 - Rapid locking system of the trigger plate to the action body of a firearm - Google Patents

Rapid locking system of the trigger plate to the action body of a firearm Download PDFInfo

- Publication number

- EP2017567B1 EP2017567B1 EP08160060A EP08160060A EP2017567B1 EP 2017567 B1 EP2017567 B1 EP 2017567B1 EP 08160060 A EP08160060 A EP 08160060A EP 08160060 A EP08160060 A EP 08160060A EP 2017567 B1 EP2017567 B1 EP 2017567B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- action body

- plunger

- body unit

- holding means

- bush

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A19/00—Firing or trigger mechanisms; Cocking mechanisms

- F41A19/06—Mechanical firing mechanisms, e.g. counterrecoil firing, recoil actuated firing mechanisms

- F41A19/10—Triggers; Trigger mountings

Definitions

- the present invention relates to an action body unit of a firearm having a rapid locking system for locking the trigger plate to the action body of the firearm.

- the invention relates to a rapid locking system destined for a long firearm such as a shotgun or a competition rifle, superimposed or parallel, in general, but not exclusively, swinging.

- the action body unit which represents the central part of the firearm to which the barrels are connected on one side and the stock on the other, can comprise the action body and trigger plate produced as separate assemblable elements.

- the Applicant therefore considered the problem of how to produce an assembly of the trigger plate to the action body of a firearm with a rapid locking which is effective with time.

- the Applicant has solved the above problems by providing a rapid locking system of the trigger plate to the action body of a firearm.

- a main objective of the present invention is to provide an action body unit with a rapid locking system of the trigger plate to the action body of the firearm which recovers the clearances due to wear of the elements to guarantee an effective lockage even after intense and prolonged use of the firearm.

- a firearm 10 presents a action body unit 20 comprising a action body 21 and a trigger plate 22 having a crosspiece 23 destined for the blockage of the trigger plate 22 to the action body 21.

- a stock bolt 24 which extends from the crosspiece 23 to become engaged with the stock of the firearm (not shown) is fixed to the crosspiece 23 by screwing.

- the rapid locking system 30 of the trigger plate 22 to the action body 21 of a firearm comprises a plunger 41 attached to the action body destined for being engaged by the holding means 50 attached to the crosspiece of the trigger plate, said holding means 50 being rotatingly controlled to pass from an unlocked position to an engagement with the plunger 41 in a predefined arc.

- Elastic means 68 are also envisaged, which act on said holding means 50 to keep the coupling between the holding means 50 and the plunger 41 under tension.

- the plunger 41 comprises a hole 48 for the insertion of a transversal pin 44 and a spiral spring 45 to allow the plunger to oscillate to facilitate its insertion into the trigger plate 22 and follow the rotation of the latter to become fixed to the action body 21.

- the action body is equipped with an opening 46 with holes 47 on the walls to house the pin 44 in which the plunger 41 is assembled.

- a lug 25 in the trigger plate close to the opposite end of the crosspiece, for being hinged to a corresponding shoulder 26 of the action body, cooperating to form a hinge around which the trigger plate is rotated to bring it to a locking position.

- the locking is ensured by the engagement of rounded flaps 27 protruding from the top of the crosspiece 23 to be inserted in the corresponding seats 49 symmetrically arranged on the two sides of the action body 21.

- the crosspiece 23 which extends substantially perpendicularly to the trigger plate in the direction of the action body, has two flaps 27 at the end, and between the flaps 27 there is a duct 60 for receiving the spherical portion 43 and the neck 42 of the plunger 41 from above, and, along the rear surface, a cavity 59 for housing the holding means 50 and the elastic means 68.

- Said cavity 59 which is substantially oval and narrowed in the upper portion to receive the elastic means in the form of a crescent 68, is situated in a position above the engagement hole 57 of the stock bolt 24 and has a shaped annular grooving 58 along the outer edge suitable for receiving a ring-shaped stop spacer 55 from which a counterpart 56 extends.

- Said stop spacer 55 is then inserted on the terminal portion of the stock bolt 24 to be withheld inside the grooving 58 and in turn to withhold the holding means 50 inside the hole 59 limiting their rotation.

- the holding means 50 are in the form of a bush 51 having a transversal slit 52 extending for most of the circumference of the bush 51.

- the slit 52 has a dimension slightly greater than the diameter of the neck of the plunger 41 and ends with a spherical seat 53 destined for receiving the spherical portion 43 of the plunger 41.

- the internal surface 54 of the spherical seat 53 is in the form of a curvature which is variable with respect to the rotation centre C1 of the bush.

- the plunger 41 in turn pulls the bush which elastically compresses the crescent 68.

- a shaped imprint 67 which is star-shaped or hexagonal or having a similar shape, for receiving the corresponding head of a key 70 for effecting rapid locking by rotating the bush 51, once the plunger 41 has been inserted with the spherical portion 43 in the slit 52 for an arc of about 180°.

- the stop 61 blocks the rotation of the bush in an unlocked position of the system, thus allowing the insertion of the plunger 41.

- the blockage run-end is provided by the contact of the leg 42 of the plunger 41 against the bush 50 ( figure 7a ).

- the elastic means 68 are produced in the form of a crescent made of an elastomeric material for copying a portion of the circular profile of the bush to keep it elastically pressed.

- the crescent 68 has a hole 69 for the passage of the spherical portion 43 and the neck 42 of the plunger 41.

- the system according to the invention can be assembled on a long firearm, such as a rifle, preferably having a swinging barrel(s), i.e. in which the opening of the arm is produced by rotation of the barrel(s) with respect to the action body or on fixed-barrel semiautomatic firearms, without limitations as to the type of firearm which can be of the sports type (for example a superimposed or juxtaposed or single-barrel gun), with a smooth barrel.

- a long firearm such as a rifle, preferably having a swinging barrel(s), i.e. in which the opening of the arm is produced by rotation of the barrel(s) with respect to the action body or on fixed-barrel semiautomatic firearms, without limitations as to the type of firearm which can be of the sports type (for example a superimposed or juxtaposed or single-barrel gun), with a smooth barrel.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Lock And Its Accessories (AREA)

- Vehicle Step Arrangements And Article Storage (AREA)

- Snaps, Bayonet Connections, Set Pins, And Snap Rings (AREA)

- Pivots And Pivotal Connections (AREA)

- Toys (AREA)

- Picture Signal Circuits (AREA)

Abstract

Description

- The present invention relates to an action body unit of a firearm having a rapid locking system for locking the trigger plate to the action body of the firearm.

- In particular, the invention relates to a rapid locking system destined for a long firearm such as a shotgun or a competition rifle, superimposed or parallel, in general, but not exclusively, swinging.

- It is known that in long firearms the action body unit which represents the central part of the firearm to which the barrels are connected on one side and the stock on the other, can comprise the action body and trigger plate produced as separate assemblable elements.

- According to the known art, for example disclosed in the publications of the Applicant "2007-2008 Beretta Annual" and "682 Gold-682 Gold Evolution" this assembly is effected by means of a screw system.

- It consequently occurs that after a certain number of shots and maintenance operations, the blockage is less effective and the trigger plate and action body tensioning must be restored.

- The Applicant therefore considered the problem of how to produce an assembly of the trigger plate to the action body of a firearm with a rapid locking which is effective with time.

- The Applicant has solved the above problems by providing a rapid locking system of the trigger plate to the action body of a firearm.

- A main objective of the present invention is to provide an action body unit with a rapid locking system of the trigger plate to the action body of the firearm which recovers the clearances due to wear of the elements to guarantee an effective lockage even after intense and prolonged use of the firearm.

- These and other objectives according to the present invention are achieved by the action body unit according to claim 1.

- Further characteristics are indicated in the dependent claims.

- The characteristics and advantages of an action body unit with rapid locking system locking the trigger plate to the action body of a firearm according to the present invention will appear more evident from the following illustrative and nonlimiting description, referring to the enclosed schematic drawings in which:

-

figure 1 is an exploded perspective view of the action body unit comprising a locking system according to the invention; -

figure 2 is a raised sectional schematic side view of a action body of a long firearm provided with the locking system according to the invention in an unlocked position; -

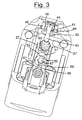

figure 3 is a front section of the receiver chamber according to the line III-III offigure 2 ; -

figure 4 is a partially sectional raised side view of a action body unit of a long firearm provided with the locking system according to the invention in a locked position; -

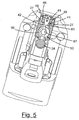

figure 5 is a front section of the action body unit according to the line V-V offigure 4 ; -

figure 6a illustrates in a partial front section from behind according to the line N-N offigure 6b , a crosspiece of the action body unit with holding means in an open position; -

figure 6b illustrates in a side section, a crosspiece of the action body unit with holding means in an open position; -

figure 7a illustrates in a partial front section from behind according to the line R-R offigure 7b , a crosspiece of the action body unit with holding means in a locked position; -

figure 7b illustrates in a side section a crosspiece of the action body unit with holding means in a locked position. - With reference to the figures, a

firearm 10 presents aaction body unit 20 comprising aaction body 21 and atrigger plate 22 having acrosspiece 23 destined for the blockage of thetrigger plate 22 to theaction body 21. - A

stock bolt 24 which extends from thecrosspiece 23 to become engaged with the stock of the firearm (not shown) is fixed to thecrosspiece 23 by screwing. - The

rapid locking system 30 of thetrigger plate 22 to theaction body 21 of a firearm according to the invention, comprises aplunger 41 attached to the action body destined for being engaged by theholding means 50 attached to the crosspiece of the trigger plate, said holdingmeans 50 being rotatingly controlled to pass from an unlocked position to an engagement with theplunger 41 in a predefined arc. -

Elastic means 68 are also envisaged, which act on saidholding means 50 to keep the coupling between theholding means 50 and theplunger 41 under tension. - The

plunger 41 comprises ahole 48 for the insertion of atransversal pin 44 and aspiral spring 45 to allow the plunger to oscillate to facilitate its insertion into thetrigger plate 22 and follow the rotation of the latter to become fixed to theaction body 21. - In this respect, the action body is equipped with an opening 46 with

holes 47 on the walls to house thepin 44 in which theplunger 41 is assembled. - For the assembly of the

trigger plate 22 onto theaction body 21, there is alug 25, in the trigger plate close to the opposite end of the crosspiece, for being hinged to acorresponding shoulder 26 of the action body, cooperating to form a hinge around which the trigger plate is rotated to bring it to a locking position. - The locking is ensured by the engagement of

rounded flaps 27 protruding from the top of thecrosspiece 23 to be inserted in thecorresponding seats 49 symmetrically arranged on the two sides of theaction body 21. - A

neck 42 terminating in aspherical portion 43 destined for being engaged with theholding means 50, extends from theplunger 41. - The

crosspiece 23, which extends substantially perpendicularly to the trigger plate in the direction of the action body, has twoflaps 27 at the end, and between theflaps 27 there is aduct 60 for receiving thespherical portion 43 and theneck 42 of theplunger 41 from above, and, along the rear surface, acavity 59 for housing theholding means 50 and the elastic means 68. - Said

cavity 59 which is substantially oval and narrowed in the upper portion to receive the elastic means in the form of a crescent 68, is situated in a position above the engagement hole 57 of thestock bolt 24 and has a shapedannular grooving 58 along the outer edge suitable for receiving a ring-shaped stop spacer 55 from which acounterpart 56 extends. - Said

stop spacer 55 is then inserted on the terminal portion of thestock bolt 24 to be withheld inside the grooving 58 and in turn to withhold theholding means 50 inside thehole 59 limiting their rotation. - The holding means 50 are in the form of a

bush 51 having atransversal slit 52 extending for most of the circumference of thebush 51. - The

slit 52 has a dimension slightly greater than the diameter of the neck of theplunger 41 and ends with aspherical seat 53 destined for receiving thespherical portion 43 of theplunger 41. - With particular reference to

figures 6a, 6b ,7a, 7b , it should be noted that theinternal surface 54 of thespherical seat 53 is in the form of a curvature which is variable with respect to the rotation centre C1 of the bush. - In this way, by passing from an opened position to a closed position, the traction is obtained of the

spherical portion 43 on the part of thebush 51. - The

plunger 41 in turn pulls the bush which elastically compresses the crescent 68. - Upon passing from a position of complete opening, i.e. the plunger unlocked, to a completely locked position, the rotation axis A1 of the

bush 51 which is situated underneath the axis A2 of thespherical seat 54, passes above the latter effecting a translation of about 0.4 mm which correspond to the locking deformation exerted during the rapid locking traction. - In this way, the trigger plate and action body are rapidly and integrally assembled.

- On the front of the

bush 51, there is ashaped imprint 67 which is star-shaped or hexagonal or having a similar shape, for receiving the corresponding head of akey 70 for effecting rapid locking by rotating thebush 51, once theplunger 41 has been inserted with thespherical portion 43 in theslit 52 for an arc of about 180°. - Along the external edge of the

bush 51, there is anannular throat 67 for receiving thecounterpart 56 and terminating in astop 61 suitable for coming into contact with thecounterpart 56. - In particular, the

stop 61 blocks the rotation of the bush in an unlocked position of the system, thus allowing the insertion of theplunger 41. The blockage run-end is provided by the contact of theleg 42 of theplunger 41 against the bush 50 (figure 7a ). - The

elastic means 68 are produced in the form of a crescent made of an elastomeric material for copying a portion of the circular profile of the bush to keep it elastically pressed. - The crescent 68 has a

hole 69 for the passage of thespherical portion 43 and theneck 42 of theplunger 41. - The system according to the invention can be assembled on a long firearm, such as a rifle, preferably having a swinging barrel(s), i.e. in which the opening of the arm is produced by rotation of the barrel(s) with respect to the action body or on fixed-barrel semiautomatic firearms, without limitations as to the type of firearm which can be of the sports type (for example a superimposed or juxtaposed or single-barrel gun), with a smooth barrel.

Claims (12)

- An action body unit (20) of a firearm having a trigger plate (22) with a crosspiece (23), an action body (21) and a rapid locking system (30), characterized in that the locking system (30) comprises:- a plunger (41) being attached to action body;- holding means (50) being attached to the crosspiece (23) of the trigger plate and destined for engaging said plunger (41), said holding means (50) being rotatingly controlled to pass from an unlocked position to an engagement with the plunger (41) in a predefined arc;- elastic means (68) acting on said holding means (50) to keep the coupling between the holding means (50) and the plunger (41) under tension.

- An action body unit of a firearm according to claim 1, wherein said plunger (41) comprises a hole (48) from which a neck (42) extends, terminating in a spherical portion (43) destined for engagement with the holding means (50).

- An action body unit of a firearm according to claim 2, wherein said holding means (50) are in the form of a bush (51) provided with a transversal slit (52) which extends for most of the circumference of the bush (51), said slit having a dimension slightly greater than the diameter of the neck of the plunger (41) and terminating with a spherical seat (53) destined for receiving the spherical portion (43) of the plunger (41).

- An action body unit of a firearm according to claim 3, wherein said spherical seat (53) has an internal surface (54) in the form of a curvature which is variable with respect to the rotation centre (C1) of the bush so that by rotating the bush, the plunger is drawn by this.

- An action body unit of a firearm according to claim 3, wherein on the front of the bush (51) there is a shaped imprint (67) which is star-shaped or hexagonal or having a similar shape, for receiving the corresponding head of a locking key (70).

- An action body unit of a firearm according to claim 5, wherein said bush (51) has, along a circumferential edge, an annular throat (66) terminating in a stop (61), suitable for coming into contact with the counterpart (56), the stop (61) being destined for blocking the rotation of the bush in an unlocked position of the system to allow the insertion of the plunger (41).

- An action body unit of a firearm according to claim 1, wherein said elastic means (68) are produced in the form of a crescent made of an elastomeric material destined for copying a portion of the circular profile of the bush for keeping it elastically pressed, the crescent (68) having a hole (69) for the passage of the spherical portion (43) and the neck (42) of the plunger (41).

- An action body unit of a firearm according to claim 2, wherein said plunger (41) has a hole (48) for the insertion of a transversal pin (44) and a spiral spring (45) to allow the plunger to oscillate to facilitate its insertion into said trigger plate (22) and follow the rotation which the latter must effect to become fixed to the action body (21), said action body (21) having an opening (46) with holes (47) on the walls to house the pin (44) carrying the plunger (41).

- An action body unit of a fiream according to claim 8, wherein said action body (21) is provided with an opening (46) with holes (47) on the walls to house the pin (44) carrying the plunger (41).

- An action body unit of a fiream according to claim 9, wherein said crosspiece (23), which extends substantially perpendicularly with respect to the trigger plate in the direction of the action body, has at the upper end, a duct (60) for receiving the spherical portion (43) and the neck (42) of the plunger (41) from above, and, along the rear surface, a cavity (59) for housing the holding means (50) and the elastic means (68).

- An action body unit of a firearm according to claim 10, wherein said cavity (59) which is substantially oval and narrowed is situated in a position above the engagement hole (57) of a tie-rod (24) of the stock which can be fixed to said plate, said cavity (59) having a shaped annular grooving (58) along the outer edge, suitable for receiving a ring-shaped stop plate (55) from which a counterpart (56) extends, said stop plate (55) being destined for being inserted on the terminal portion of the tie-rod (24) of the stock to be withheld inside the grooving (58) and in turn to withhold the holding means (50) inside the hole (59) limiting their rotation.

- An action body unit of a firearm according to claim 1, wherein for the assembly of the trigger plate (22) onto the action body (21), there is a lug (25) in the trigger plate close to the opposite end of the crosspiece (23), for being hinged to a corresponding shoulder (26) of the action body and a pair of rounded flaps (27) protruding from the top of the crosspiece (23) to be inserted in the corresponding seats (49) symmetrically arranged on the two sides of the action body (21).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT001467A ITMI20071467A1 (en) | 2007-07-20 | 2007-07-20 | RAPID LOCKING SYSTEM OF THE SUB-GARDEN TO THE BASCULA OF A FIRE WEAPON |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2017567A1 EP2017567A1 (en) | 2009-01-21 |

| EP2017567B1 true EP2017567B1 (en) | 2012-02-08 |

Family

ID=39798225

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08160060A Not-in-force EP2017567B1 (en) | 2007-07-20 | 2008-07-10 | Rapid locking system of the trigger plate to the action body of a firearm |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20090019756A1 (en) |

| EP (1) | EP2017567B1 (en) |

| JP (1) | JP2009024995A (en) |

| AT (1) | ATE544999T1 (en) |

| IT (1) | ITMI20071467A1 (en) |

| RU (1) | RU2008129344A (en) |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US326986A (en) * | 1885-09-29 | Fire-arm | ||

| US810046A (en) * | 1905-08-12 | 1906-01-16 | Ansley H Fox | Barrel-locking device for breakdown guns. |

| GB337997A (en) * | 1929-11-15 | 1930-11-13 | Ernst Scholz | Means for jointing parts of furniture |

| FR1519013A (en) * | 1967-03-02 | 1968-03-29 | M A P Manifattura Armi Perazzi | Device for quick locking and unlocking of the group carrying the battery of the dogs of hunting rifles on the rocker of the rifles themselves |

| DE202004016800U1 (en) * | 2004-10-29 | 2005-09-22 | Merkel Jagd- Und Sportwaffen Gmbh | Lock case for a repeater rifle |

-

2007

- 2007-07-20 IT IT001467A patent/ITMI20071467A1/en unknown

-

2008

- 2008-07-10 AT AT08160060T patent/ATE544999T1/en active

- 2008-07-10 EP EP08160060A patent/EP2017567B1/en not_active Not-in-force

- 2008-07-11 US US12/218,193 patent/US20090019756A1/en not_active Abandoned

- 2008-07-18 JP JP2008209363A patent/JP2009024995A/en not_active Withdrawn

- 2008-07-18 RU RU2008129344/02A patent/RU2008129344A/en not_active Application Discontinuation

Also Published As

| Publication number | Publication date |

|---|---|

| ITMI20071467A1 (en) | 2009-01-21 |

| ATE544999T1 (en) | 2012-02-15 |

| JP2009024995A (en) | 2009-02-05 |

| US20090019756A1 (en) | 2009-01-22 |

| RU2008129344A (en) | 2010-01-27 |

| EP2017567A1 (en) | 2009-01-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8443536B1 (en) | Adjustable dual stage trigger mechanism for semi-automatic weapons | |

| US9904073B2 (en) | Hinge device for spectacle frames | |

| EP1732414B1 (en) | Slide and snap clamp | |

| US5370102A (en) | Caliper bow string release with mountable sear elements | |

| US4519156A (en) | Firearm with interchangeable barrels | |

| US7698848B1 (en) | Folding gunstock | |

| US10126078B1 (en) | Retractable takedown pin for firearm | |

| JP2008111655A (en) | Mechanism for locking and regulating tension assembly of gunstock to receiver of small firearm | |

| EP3800429A1 (en) | Magazine holder for a firearm | |

| US11029125B2 (en) | Break open system having an adjustable, releasable forend stock | |

| US20020056218A1 (en) | Device for hinging a barrel in an air-powered carbine of gun having a tiltable barrel | |

| EP1090324A1 (en) | Elastic hinge for eyeglasses with safety locking | |

| EP2017567B1 (en) | Rapid locking system of the trigger plate to the action body of a firearm | |

| US6705035B2 (en) | Barrel balancing device for collapsible firearms | |

| JP3774213B2 (en) | Break action gun | |

| US11105580B2 (en) | Pivoting limb pad assembly for an archery bow | |

| JP5709116B1 (en) | Hinge structure | |

| EP3555549B1 (en) | Articulated stock for shoulder-fired weapon | |

| US4063379A (en) | Fore end assembly for a firearm | |

| US4614051A (en) | Firearm construction | |

| US20080168693A1 (en) | Buckle gun | |

| US2567879A (en) | Spectacle frame hinge | |

| FR2757264A1 (en) | SHORT RIFLE WITH CANON IN THE EXTENSION OF THE SOCKET | |

| US2887810A (en) | Firearm barrel latch | |

| WO2020120418A1 (en) | Gun heel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| 17P | Request for examination filed |

Effective date: 20090713 |

|

| 17Q | First examination report despatched |

Effective date: 20090806 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 544999 Country of ref document: AT Kind code of ref document: T Effective date: 20120215 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008013204 Country of ref document: DE Effective date: 20120412 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20120208 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20120208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120508 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120509 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120608 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 544999 Country of ref document: AT Kind code of ref document: T Effective date: 20120208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20121109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120731 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602008013204 Country of ref document: DE Effective date: 20121109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120731 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120519 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120731 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120710 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120508 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080710 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180612 Year of fee payment: 11 Ref country code: BE Payment date: 20180614 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20180706 Year of fee payment: 11 Ref country code: DE Payment date: 20180626 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20180709 Year of fee payment: 11 Ref country code: GB Payment date: 20180704 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602008013204 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190710 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200201 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190710 |