EP2010840B1 - Appareil ménager - Google Patents

Appareil ménager Download PDFInfo

- Publication number

- EP2010840B1 EP2010840B1 EP07727209.4A EP07727209A EP2010840B1 EP 2010840 B1 EP2010840 B1 EP 2010840B1 EP 07727209 A EP07727209 A EP 07727209A EP 2010840 B1 EP2010840 B1 EP 2010840B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- household appliance

- appliance according

- recess

- container

- strut

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000465 moulding Methods 0.000 claims description 12

- 238000009434 installation Methods 0.000 claims 1

- 238000005452 bending Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 235000015243 ice cream Nutrition 0.000 description 2

- 230000000284 resting effect Effects 0.000 description 2

- 229920002430 Fibre-reinforced plastic Polymers 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 239000011151 fibre-reinforced plastic Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000002991 molded plastic Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D23/00—General constructional features

- F25D23/06—Walls

- F25D23/065—Details

- F25D23/067—Supporting elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25C—PRODUCING, WORKING OR HANDLING ICE

- F25C2400/00—Auxiliary features or devices for producing, working or handling ice

- F25C2400/10—Refrigerator units

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25C—PRODUCING, WORKING OR HANDLING ICE

- F25C5/00—Working or handling ice

- F25C5/02—Apparatus for disintegrating, removing or harvesting ice

- F25C5/04—Apparatus for disintegrating, removing or harvesting ice without the use of saws

- F25C5/06—Apparatus for disintegrating, removing or harvesting ice without the use of saws by deforming bodies with which the ice is in contact, e.g. using inflatable members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25C—PRODUCING, WORKING OR HANDLING ICE

- F25C5/00—Working or handling ice

- F25C5/18—Storing ice

- F25C5/182—Ice bins therefor

- F25C5/185—Ice bins therefor with freezing trays

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D23/00—General constructional features

- F25D23/02—Doors; Covers

- F25D23/025—Secondary closures

Definitions

- the present invention relates to a cabinet-like household appliance having a housing surrounding an interior space and at least one strut, which is mounted engaging in a first and a second recess of opposing first and second walls of the interior, wherein at least the first recess part of one in the first wall formed groove.

- Known household appliances of this type are, for example, refrigerators with shelves in the form of a grate, which is formed by two extending in the transverse direction of the housing wire struts and wire struts interconnecting longitudinal wires, the wire struts engage in horizontal grooves in the side walls of the housing.

- a refrigerator is shown, on the inside of the door holding handles of door cabinets are mounted with the help of Befest Trentsstucken.

- These struts, or the shelves to which they belong, may generally be pulled out of the grooves forwards without appreciable resistance, so that they are not suitable for attaching thereto fixtures to which forces parallel to the grooves in use become.

- the object is achieved in that in a household appliance with a housing surrounding an interior and at least one strut, which is mounted engaging in a first and a second recess of opposing first and second walls of the interior, wherein at least the first recess part of a in the first wall formed groove, in the groove engages a flexible latching projection which blocks a movement of a first end of the strut out of the recess along the groove and displaceable by a movement of the first end of this strut along the groove to the recess out of the groove is.

- the strut is thus easy to assemble, but it is in the assembled state by a force opposite to the mounting direction force not easily detached from its mounted position.

- the assembly of the strut can be done by parallel displacement along the grooves.

- the latching projection is displaceable out of the groove by a pivoting movement of the strut, which has the second recess as the center.

- the groove is oriented substantially horizontally.

- the first recess is provided at a closed longitudinal end of the groove, so that a single latching projection is sufficient to have the first end of the strut in the recess substantially immovable.

- the latching projection may be formed by an engaging in the groove flexible tongue with a recess facing the free end.

- the tongue may conveniently be formed by a portion of one of the ribs unconnected to the wall surface.

- At least one of the ribs may have a corrugated course.

- the recesses and the groove may be formed on moldings, which in turn are mounted on walls of the housing.

- At least two struts are suitably provided. Recesses for these two struts can be advantageously formed on a same molding.

- the built-in part of the strut it may be provided with a form-fitting embrace the elastic hooks.

- the built-in part may be a frame in which a container is held out.

- the built-in part is an ice maker.

- the container may be a Eis Glaform havinger or a container for ice cubes.

- the collecting container is arranged below the Eis Swissform marginers.

- the latter is preferably between a first position in which mold recesses of Eis Shareform portions are open at the top and can be frozen in the filled in the mold recesses water therein, and a second position rotatable in which the mold recesses down are open.

- the flap expediently has a recess through which the container in the closed position of the flap can be pulled out.

- the frame of the ice maker preferably has a front plate, which is opposite to the flap in the closed position of the flap and thereby covers the recess.

- this is preferably provided with a handle which projects in the assembled position of the container via the front plate of the frame into the recess.

- a knob of the ice maker which serves to rotate the Eis Glaform meetingers, is also expediently by a recess of the flap through closed flap accessible.

- the finished pieces of ice can be removed from the mold without opening the flap.

- This knob preferably engages a first longitudinal end of the ice-cream forming container and the freedom of movement of the rotation caused thereby is limited by a contour cooperating with the opposite second longitudinal end of the ice-cream forming container.

- the latter is preferably elastically deformable by a torque acting on the knob.

- the Eis collaborateform eliminateer is preferably rotatably suspended in a frame which is pulled out of the frame together with the Eis Shareform eliminateer.

- Fig. 1 is a perspective view of a freezer with a body 1 and an open door 2, which enclose a divided into several compartments interior 3.

- Each compartment is closed by a flap 4 and 5, which is pivotable about a respective horizontal axis extending adjacent to its lower edge.

- the flaps 5 of the three lower compartments are closed and are each provided with a grip recess 6 extending over substantially the entire width of the flap.

- the recessed grip 6 is shortened, and in a lateral region of the flap, two recesses are formed, an upper, circular recess 7 and an angular recess 8 open towards the lower edge of the flap.

- the lower, open-edge recess 8 is substantially filled by a handle 9, the (in Fig. 2 not visible) drawer of an arranged behind the flap 5 icemaker 10 belongs. Through the circular recess 7 through a knob 11 of the ice maker 10 is accessible.

- the icemaker 10 has a frame in the form of two closed-walled half-shells 12, which are hooked on its underside pivotally to each other, and of which one on its top elastic strap 13 carries, which are snapped onto locking projections 14 of the other half-shell.

- the bracket 13 By bending up the bracket 13, the half-shells 12 can be unfolded to expose their interior for maintenance or cleaning.

- hooks 24 are formed, the free ends of which face the rear end of the frame.

- the hooks 24 are provided to anchor the frame to two struts 25, in more detail later in a manner described on side walls of the Body 1 are anchored.

- the free ends 26 of the hooks 24 are in the illustration of Fig. 3 bent slightly downward to cause a latching on the positively engaged by the hooks 24 struts 25.

- a bump may be formed on the upper edge of the half-shells 12 in each case opposite the free end of each hook.

- the entire ice maker 10 is accessible and can be removed by simply removing the struts 25.

- the removed ice maker can then be easily disassembled into its individual parts, for example, to clean them in a dishwasher.

- a re-assembly of the ice maker 10 is carried out accordingly by simply snapping onto the struts 25th

- the knob 11 is rotatably mounted on a plate 15 which is pushed onto the upper front corner of the frame 12, 13 from the front.

- a plate 15 On the shield 15 are two in Fig. 5 shown in section arms 16 which extend within the half-shells 12 over its entire depth, and at its opposite end of the plate 15 a vertical plate 17 carry.

- a Eis Sharingform unlikeer 18 of substantially semi-cylindrical shape, which is parallel to the cutting plane of the Fig. 5 extending intermediate walls 19 is divided into a plurality of Eis Glaf kauern 20, resting on concave inner surfaces of the arms 16 and is held in the longitudinal direction between the plate 15 and the plate 17. Through an opening of the plate 15 of Eis Glaform momenter 18 is firmly connected to the knob 11.

- the ice-formed container 18 is elastically deformed, thereby releasing the ice pieces formed therein and falling between the two arms 16 into a push blade 22 connected to the handle 9 in the lower portion of the frame.

- the thrust blade 22 is slightly smaller in cross-section than the open-edged recess 8, so that they can be pulled out by the latter. The release of the pieces of ice and their removal is done so without opening the door 4.

- a modified embodiment of the ice cube maker is in the 6 and 7 shown.

- the shield 15 is omitted here; instead, the knob 11 extends directly through an opening at the front of the half-shells 12, and the ice-maker box 18 is sized to be withdrawn through this opening.

- Fig. 6 shows the Eis Sharingform approachinger 18 resting on two extending in the depth direction arms 16 which are stationary in the frame 12, 13.

- a half shell 12 carries a series of inwardly projecting hooks 23, one for each shape of the ice mold container 18.

- the hooks 23 differ slightly in their dimensions so that upon rotation of the ice mold container 18, one hook after another with a piece of ice in a mold the container 18 comes into contact and pushes it out of the mold.

- the dissolved pieces of ice fall as in the embodiment of FIGS. 3 to 5 in a drawer 22 below the Eis Glaform portions 18, which can be pulled out by means of the handle 9 without the flap 4 to open.

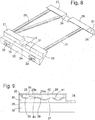

- Fig. 8 is a perspective view showing the already mentioned, parallel between the side walls of the body extending struts 25 and two mold parts 27 which connect the struts 25 with the side walls of the body 1, not shown in the figure.

- the struts 25 are hollow profiles with rounded rectangular cross-section made of aluminum, stainless steel or a bending-resistant, in particular fiber-reinforced plastic.

- the molded parts 27 are injection-molded plastic parts having a front wall 28 and a rear wall each in the form of two triangles overlapping at their corners and the horizontal and vertical wall sections 29 to 32 connecting the catheters of the right-angled triangles. From the outer sides of the vertical wall sections 32 are pins 33 from which are provided to engage positively in not shown recesses of the side walls of the body 1.

- support ribs 35 are arranged for the support of the struts 25, which in Fig. 9 are shown and described in relation to this figure.

- the horizontal wall portions 29 is divided by a notch 34.

- Fig. 9 shows a plan view of the inner sides of the vertical wall portions 30, 32 of a part of the molded parts 27.

- a hook-shaped support rib 35 extends from the horizontal wall portion 29 of arc-shaped downwardly, wherein it terminates in a portion 36 parallel to the wall portion 29.

- the carrier rib 35 is connected in one piece with the vertical wall portion 30 along its entire length.

- a strut 25 is shown positively received between the support rib 35 and the wall portion 29.

- the length of the strut 25 is dimensioned so that their longitudinal ends abut each of the vertical wall portions 30 of the two mold parts 27 or with little play, so that the strut 25 by moving in its longitudinal direction not from the support rib 35 of the two mold parts 27 solvable is.

- a displacement of the strut 25 in the depth direction of the body is locked in one direction by the support rib 35 itself and in the opposite direction by a rib 37, of which a longitudinal end 38 of a narrow side of the strut 25 at a small distance opposite.

- the opposite longitudinal end merges with a crosswind of the notch 34.

- the rib 37 is only on a part of its length, in the perspective of Fig. 9 to the right of a dashed boundary line 39, integrally connected to the wall portion 30.

- the left of the line 39 lying part of the rib 37 thus forms a tongue 40, which, as in the FIG. 9 shown as a dashed outline, flexibly deflected downwards.

- this has a wavy course.

- the struts 25 may occupy a dashed oblique position, in which one end of the strut 25 is held by the carrier rib 25 of the mold parts 27, while the other end of the groove 42 of the other mold part 27th but without intervening. In this position, the strut is easily placed, when the mold parts 27 are inserted with their pins 33 in the corresponding recesses of the side walls.

- strut 25 By turning the strut 25 about its end held on the support rib 35 in a position perpendicular to the sidewalls, its other end gradually engages in the groove 42 and reaches into it an in Fig. 9 as a dashed cross section 25a drawn position in which it touches the tongue 40 and this opposes a further rotation of the strut 25. If the strut 25 is rotated further against the resistance of the tongue 40, it passes through an in Fig. 9 designated 25b position in which the tongue 40 is displaced elastically downwards. The displaced tongue 40 is shown as a dashed outline.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Food-Manufacturing Devices (AREA)

- Production, Working, Storing, Or Distribution Of Ice (AREA)

- Cookers (AREA)

- Table Equipment (AREA)

Claims (21)

- Appareil ménager avec un boîtier englobant un espace intérieur et au moins une entretoise (25) qui peut être montée de façon à pouvoir s'insérer dans un premier et un deuxième évidement de première et deuxième parois se faisant face de l'espace intérieur, dans lequel au moins le premier évidement est une partie d'une rainure (42) constituée dans la première paroi, dans lequel la rainure (42) est dirigée essentiellement horizontalement, dans lequel le premier évidement est prévu en une extrémité longitudinale fermée (35) de la rainure (42), dans lequel l'entretoise (25) est montée avec sa première extrémité dans le premier évidement et avec sa deuxième extrémité dans le deuxième évidement, et dans lequel une saillie d'encliquetage flexible (40) s'insère dans la rainure (42), laquelle saillie bloque un déplacement de la première extrémité de l'entretoise (25) en dehors de l'évidement le long de la rainure (42) et, lors du montage de l'entretoise (25), peut être forcée en dehors de la rainure (42) par un déplacement de la première extrémité le long de la rainure (42) vers l'évidement, caractérisé en ce que l'entretoise (25) peut pivoter lors de son montage autour du deuxième évidement servant de point central et en ce que la saillie d'encliquetage (40) peut être forcée par un déplacement par pivotement de l'entretoise (25) qui a le deuxième évidement comme point central.

- Appareil ménager selon l'une des revendications précédentes, caractérisé en ce que la saillie d'encliquetage est une languette flexible (40) insérée dans la rainure (42) avec une extrémité libre tournée vers l'évidement.

- Appareil ménager selon la revendication 2, caractérisé en ce que la rainure (42) est délimitée par deux nervures essentiellement parallèles (30, 36, 37) espacées d'un panneau vertical (31), et en ce que la languette (40) est constituée par une section (40) non reliée au panneau d'une des nervures (36, 37).

- Appareil ménager selon la revendication 3, caractérisé en ce qu'au moins l'une des nervures (37) possède un profil ondulé.

- Appareil ménager selon l'une des revendications précédentes, caractérisé en ce que les évidements et les rainures (42) sont constitués sur des pièces moulées (27) montées sur des parois du boîtier.

- Appareil ménager selon la revendication 5, caractérisé en ce que des évidements pour deux entretoises (25) sont constitués sur chaque pièce moulée.

- Appareil ménager selon l'une des revendications précédentes, caractérisé en ce qu'une pièce rapportée (10) est suspendue à l'entretoise (25).

- Appareil ménager selon l'une des revendications précédentes, caractérisé en ce que la pièce rapportée (10) comprend un crochet élastique (24) enserrant par concordance de formes l'entretoise (25).

- Appareil ménager selon la revendication 7 ou 8, caractérisé en ce que la pièce rapportée (10) est un châssis dans lequel est maintenu de manière extractible un récipient (18, 22).

- Appareil ménager selon l'une des revendications 7 à 9, caractérisé en ce qu'il s'agit d'un réfrigérateur et en ce que la pièce rapportée (10) est un générateur de glace.

- Appareil ménager selon la revendication 9 et la revendication 10, caractérisé en ce que le récipient est un récipient de formation de glaçons (18).

- Appareil ménager selon la revendication 9 et la revendication 10, caractérisé en ce que le récipient est un récipient collecteur (22) pour des glaçons.

- Appareil ménager selon la revendication 12, caractérisé en ce que le récipient collecteur (22) est disposé au-dessous d'un récipient de formation de glaçons (18).

- Appareil ménager selon la revendication 11 ou 13, caractérisé en ce que le récipient de formation de glaçons (18) peut tourner entre une première position dans laquelle des évidements de formage (20) du récipient de formation de glaçons (18) s'ouvrent vers le haut et une deuxième position dans laquelle ils s'ouvrent vers le bas.

- Appareil ménager selon la revendication 9 ou l'une des revendications 11 à 14, caractérisé en ce que le châssis (12, 12) est contenu dans un compartiment pouvant être fermé par un volet (4) de l'espace intérieur (3), et en ce que le volet (4) comprend un évidement (7, 8) par lequel peut être extrait le récipient (18, 22) lorsque le volet (4) est en position fermée.

- Appareil ménager selon la revendication 15, caractérisé en ce que le châssis (12, 12) comprend une plaque frontale (15) qui, lorsque le volet (4) est en position fermée, repose sur celui-ci en recouvrant l'évidement (7).

- Appareil ménager selon la revendication 16, caractérisé en ce que le récipient (18, 22) comprend une poignée (9, 11) qui en position de montage vient en saillie par-dessus la plaque frontale dans l'évidement (7, 8).

- Appareil ménager selon la revendication 14 et l'une des revendications 15 à 17, caractérisé en ce qu'un bouton rotatif (11) du générateur de glace, qui sert à faire tourner le récipient de formation de glaçons (18), est accessible en traversant un évidement (7) du volet (4) lorsque le volet (4) est fermé.

- Appareil ménager selon la revendication 18, caractérisé en ce que le bouton rotatif (11) vient en prise avec une première extrémité longitudinale du récipient de formation de glaçons (18), et en ce que la liberté de déplacement par rotation est limitée par un contour (21) coopérant avec la deuxième extrémité longitudinale opposée du récipient de formation de glaçons (18).

- Appareil ménager selon la revendication 18 ou 19, caractérisé en ce que le récipient de formation de glaçons (18) est élastiquement déformable par un couple de rotation agissant sur le bouton rotatif (11).

- Appareil ménager selon la revendication 14 ou l'une des revendications 18 à 20, caractérisé en ce que le récipient de formation de glaçons (18) est suspendu de façon rotative dans un cadre (15, 16, 17) qui est extractible hors du châssis (12, 13) conjointement avec le récipient de formation de glaçons (18).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL07727209T PL2010840T3 (pl) | 2006-04-18 | 2007-03-22 | Urządzenie gospodarstwa domowego |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006017804A DE102006017804A1 (de) | 2006-04-18 | 2006-04-18 | Haushaltsgerät |

| PCT/EP2007/052733 WO2007122048A1 (fr) | 2006-04-18 | 2007-03-22 | Appareil ménager |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2010840A1 EP2010840A1 (fr) | 2009-01-07 |

| EP2010840B1 true EP2010840B1 (fr) | 2017-01-25 |

Family

ID=38328441

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07727209.4A Active EP2010840B1 (fr) | 2006-04-18 | 2007-03-22 | Appareil ménager |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP2010840B1 (fr) |

| CN (1) | CN101421570B (fr) |

| DE (1) | DE102006017804A1 (fr) |

| PL (1) | PL2010840T3 (fr) |

| RU (1) | RU2420698C2 (fr) |

| WO (1) | WO2007122048A1 (fr) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2159523B1 (fr) | 2008-08-29 | 2018-08-01 | Electrolux Home Products Corporation N.V. | Équipement de réfrigération et système de console pour l'utiliser |

| DE102009026999A1 (de) * | 2009-06-17 | 2010-12-23 | BSH Bosch und Siemens Hausgeräte GmbH | Schrankartiges Haushaltsgerät mit Fachboden |

| DE102009046029A1 (de) | 2009-10-27 | 2011-05-05 | BSH Bosch und Siemens Hausgeräte GmbH | Kältegerät mit Eisbereiter |

| DE102009046034A1 (de) | 2009-10-27 | 2011-05-05 | BSH Bosch und Siemens Hausgeräte GmbH | Kältegerät mit Eisbereiter |

| DE102009046031A1 (de) | 2009-10-27 | 2011-04-28 | BSH Bosch und Siemens Hausgeräte GmbH | Kältegerät mit Eisbereiter |

| DE102009046026A1 (de) | 2009-10-27 | 2011-05-05 | BSH Bosch und Siemens Hausgeräte GmbH | Kältegerät und Eisbereiter dafür |

| CN102679661B (zh) * | 2012-06-12 | 2014-04-16 | 合肥华凌股份有限公司 | 冰箱 |

| KR101696850B1 (ko) * | 2015-06-17 | 2017-01-16 | 동부대우전자 주식회사 | 아이스버킷 록킹장치를 갖는 냉장고 및 아이스버킷 록킹장치의 설치 방법 |

| KR101696817B1 (ko) * | 2015-06-17 | 2017-01-16 | 동부대우전자 주식회사 | 아이스버킷 록킹장치를 갖는 냉장고 및 아이스버킷 록킹장치의 설치 방법 |

| KR101732168B1 (ko) * | 2015-06-17 | 2017-05-11 | 동부대우전자 주식회사 | 아이스버킷 록킹장치를 갖는 냉장고 및 아이스버킷 록킹장치의 설치 방법 |

| DE102015224795A1 (de) | 2015-12-10 | 2017-06-14 | BSH Hausgeräte GmbH | Kältegerät mit Eisvorratsbehälter |

| CN111895697A (zh) * | 2019-05-06 | 2020-11-06 | 青岛海尔电冰箱有限公司 | 制冰机及冰箱 |

| CN116928919A (zh) * | 2022-04-07 | 2023-10-24 | 青岛海尔电冰箱有限公司 | 制冷电器 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2040634A (en) * | 1934-09-10 | 1936-05-12 | Kelvinator Corp | Refrigerating apparatus |

| US3666228A (en) * | 1970-11-09 | 1972-05-30 | Owens Illinois Inc | Refrigerator clip |

| DE3544446C1 (en) * | 1985-12-16 | 1987-01-08 | Bosch Siemens Hausgeraete | Cooling device, in particular domestic refrigerator |

| AT391253B (de) * | 1986-05-14 | 1990-09-10 | Blum Gmbh Julius | Beschlagbausatz fuer eine aus mehreren teilen zusammensetzbare schublade |

| IT242214Y1 (it) * | 1996-07-10 | 2001-06-04 | Whirlpool Europ S R L | Frigorifero domestico con ripiani amovibili |

| KR100389389B1 (ko) * | 2000-08-07 | 2003-06-27 | 주식회사 엘지이아이 | 냉장고의 제빙부 |

| CN1220017C (zh) * | 2002-08-13 | 2005-09-21 | 乐金电子(天津)电器有限公司 | 电冰箱用制冰装置 |

| CN100397008C (zh) * | 2003-12-15 | 2008-06-25 | 乐金电子(天津)电器有限公司 | 电冰箱用制冰器 |

| DE202004016966U1 (de) * | 2004-11-03 | 2006-03-16 | Liebherr-Hausgeräte Lienz Gmbh | Kühl- und/oder Gefriergutbehältnis |

-

2006

- 2006-04-18 DE DE102006017804A patent/DE102006017804A1/de not_active Withdrawn

-

2007

- 2007-03-22 RU RU2008143652/21A patent/RU2420698C2/ru not_active IP Right Cessation

- 2007-03-22 WO PCT/EP2007/052733 patent/WO2007122048A1/fr active Application Filing

- 2007-03-22 CN CN2007800137036A patent/CN101421570B/zh not_active Expired - Fee Related

- 2007-03-22 PL PL07727209T patent/PL2010840T3/pl unknown

- 2007-03-22 EP EP07727209.4A patent/EP2010840B1/fr active Active

Also Published As

| Publication number | Publication date |

|---|---|

| RU2420698C2 (ru) | 2011-06-10 |

| RU2008143652A (ru) | 2010-05-27 |

| DE102006017804A1 (de) | 2007-10-25 |

| CN101421570B (zh) | 2012-09-26 |

| PL2010840T3 (pl) | 2017-05-31 |

| WO2007122048A1 (fr) | 2007-11-01 |

| EP2010840A1 (fr) | 2009-01-07 |

| CN101421570A (zh) | 2009-04-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2010840B1 (fr) | Appareil ménager | |

| EP1857750B1 (fr) | Dispositif frigorifique avec préparateur de glace | |

| WO2008095780A2 (fr) | Appareil frigorifique pourvu de fonds de compartiments suspendus à un rail | |

| EP2499445B1 (fr) | Appareil frigorifique muni d'un balconnet de porte et d'un dispositif d'arrêt à montage flottant | |

| EP2626656B1 (fr) | Dispositif de production de glace avec un levier à actionnement manuel et appareil ménager réfrigérant avec un tel dispositif de production de glace | |

| DE10107646A1 (de) | Auszugskasten für ein Kältegerät | |

| EP2694892B1 (fr) | Système de machine à glaçons et appareil de froid équipé d'un système de machine à glaçons de ce type | |

| EP1984685B1 (fr) | Appareil frigorifique | |

| EP2746706B1 (fr) | Appareil de réfrigération avec butée de porte pouvant être modifiée | |

| EP2010834A2 (fr) | Appareil de réfrigération doté d'un élément rapporté | |

| DE202006007722U1 (de) | Kältegerät | |

| EP2443405B1 (fr) | Appareil ménager de type armoire, pourvu d'un rayon | |

| EP0611931A1 (fr) | Conteneur, en particulier en forme de tiroir | |

| EP3136027A1 (fr) | Appareil menager frigorifique avec une paroi frontale pour un compartiment de stockage | |

| EP2244043B1 (fr) | Appareil frigorifique et récipient intérieur correspondant | |

| EP0611929B1 (fr) | Appareil de refroidissement ou de congélation avec une enceinte isolée thermiquement | |

| EP2420780B1 (fr) | Unité de stockage pour produit surgelé dotée d'un support de produit surgelé | |

| EP2145143A1 (fr) | Appareil électroménager | |

| EP3809079B1 (fr) | Récipient collecteur alimentaire doté d'un rabat pivotant sur la barquette, ainsi que appareil de froid électroménager | |

| EP2156122B1 (fr) | Fond de rayonnage pour un appareil frigorifique | |

| EP2265875B1 (fr) | Appareil de réfrigération et système d'encliquetage en une seule pièce associé | |

| EP3193111B1 (fr) | Récipient de stockage pour produit alimentaire et réfrigérateur comprenant un récipient de stockage pour produit alimentaire | |

| DE102024200804A1 (de) | Kältegerät | |

| DE102019219739A1 (de) | Haushaltsgerät mit einer Tür und einem Griff mit spezifischen Rückstellelement | |

| WO2002081985A1 (fr) | Bac a glaçons |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20081118 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17Q | First examination report despatched |

Effective date: 20090327 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BSH HAUSGERAETE GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160317 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 864386 Country of ref document: AT Kind code of ref document: T Effective date: 20170215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007015408 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170525 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170426 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170525 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170425 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007015408 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170425 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20171130 |

|

| 26N | No opposition filed |

Effective date: 20171026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170425 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170322 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170331 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 864386 Country of ref document: AT Kind code of ref document: T Effective date: 20170322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170125 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20190620 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20070322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170125 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20220331 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200322 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20230313 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502007015408 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231003 |