EP1982952A1 - Getränkeausgabesystem - Google Patents

Getränkeausgabesystem Download PDFInfo

- Publication number

- EP1982952A1 EP1982952A1 EP07388023A EP07388023A EP1982952A1 EP 1982952 A1 EP1982952 A1 EP 1982952A1 EP 07388023 A EP07388023 A EP 07388023A EP 07388023 A EP07388023 A EP 07388023A EP 1982952 A1 EP1982952 A1 EP 1982952A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- housing part

- dispensing system

- recess

- beverage dispensing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/06—Mountings or arrangements of dispensing apparatus in or on shop or bar counters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/08—Details

Definitions

- This invention relates to a beverage dispensing system.

- DraughtMaster TM a professional draught beer system

- DraughtMaster TM comprising a beverage dispensing system and a chill chamber in which the keg or pack containing carbonate beer is received.

- the keg or pack containing carbonated beer comprises a flexible bottle or bag, which is exposed to an elevated pressure from the outside for dispensing the beer.

- the flexible bottle or bag is connected through a dispensing line to a shut-off valve, which is guided through a channel of the beverage dispensing system and is received within and operated by means of a tap handle for operating the shut-off valve between an open and a closed position.

- the dispensing line is to be mounted properly within the beverage dispensing system. This, however, may be a complicated process since the dispensing line is to be pushed through the inside of the beverage dispensing system. The dispensing line must be guided and retained properly and be correctly connected and fixed to the tap handle.

- a beverage dispensing system comprising:

- the tap handle may like a conventional draught beer system comprise a valve for closing off in a first position the dispensing of beverage from the dispensing line and in a second position allow dispensing of beverage from the dispensing line.

- the valve itself may constitute a separate component as covered by applicant's co-pending European patent applications or, alternatively, constitute an integral component of the dispensing line or further alternatively be implemented by a pinching mechanism causing the dispensing line to be sealed off by the action of an eccentric element or similar component squeezing the dispensing line firmly together and consequently sealing off the dispensing line in the above-mentioned second position in which the dispensing of beverage from the dispensing line is blocked.

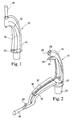

- Figs. 1 and 2 are perspective and schematic views of a first and presently preferred embodiment of a beverage dispensing system designated the reference numeral 10 in its entirety.

- the beverage dispensing system 10 comprises a housing 12 composed of two housing parts 14 and 16.

- the housing 12 is of an overall elongated configuration and defines opposite ends, a first end constituting a tapping end, at which a tap handle 18 is provided and an opposite second end, at which end a fixture 20 is provided for fixating the housing 12 of the beverage dispensing system 10 to a supporting surface such as a supporting table surface, which is not shown in the drawings.

- Fig. 1 the two housing parts 14 and 16 of the housing 12 are joined to one another providing a closed housing, in which a dispensing line shown in Fig. 2 and designated the reference numeral 30 is enclosed, which dispensing line connects a shut-off valve of the tap handle 18 to a keg or pack, in which carbonated beer is contained, which shut-off valve is operated by means of the tap handle 18 for shifting the shut-off valve between an open and a closed state for dispensing and shut-off of dispensing of carbonated beer from the keg or pack, respectively.

- a dispensing line shown in Fig. 2 and designated the reference numeral 30 is enclosed, which dispensing line connects a shut-off valve of the tap handle 18 to a keg or pack, in which carbonated beer is contained, which shut-off valve is operated by means of the tap handle 18 for shifting the shut-off valve between an open and a closed state for dispensing and shut-off of dispensing of carbonated beer from the keg or pack, respectively.

- the beverage dispensing system 10 constitutes a component of a draught beer system also including the dispensing line and as is well known in the art, a refrigerator system for cooling the beer contained within the keg or pack and additional components well known in the art per se. It is to be realised that the present beverage dispensing system may be used in connection with a draught beer system similar to the commercially available DraughtMaster TM system produced and sold by the applicant company, in which a collapsible keg or pack is used, however, the beverage dispensing system according to the present invention may alternatively be used in combination with a conventional draught beer system, in which non-carbonised beer containing metal kegs and carbonising pressurised containers are used.

- the housing components 14 and 16 are separated from one another exposing the interior of the housing 12, and consequently exposing the beverage dispensing line 30 for allowing easy access to the beverage dispensing line when shifting the beverage dispensing line 30.

- the two housing parts 14 and 16 are hinged to one another, as is illustrated in Fig. 2 by means of a hinge provided at the bottom of the housing 12 above the fixture 20.

- the hinge interconnecting the housing parts 14 and 16 is dislosed and designates the reference numeral 22.

- the housing part 14 is provided with an inwardly protruding pin 24 having an V-shaped recessed end 26 serving to catch around the freely exposed dispensing line 30 when the housing is pivoted relative to the hinge 22 for joining the housing part 16 to the housing part 14 for providing the closed state as is illustrated in Fig. 1 .

- the housing parts 14 and 16 are provided with cooperating locking elements 28 and 29, the locking element 28 being provided at the upper end of the housing part 14 and serving to catch with and lock to the locking element 29 of the housing part 16.

- the locking element 29 may be disengaged from the locking elements 28 of the housing part 14.

- the housing part 16 is provided with an internal recess 32, in which the dispensing line 30 is received, which recess preferably further comprises catching elements for arresting and fixating the dispensing line 30 in its intentional position relative to the housing part 16.

- the catching elements are shown in greater details in Figs. 5 and 6 illustrating two alternative variants of the catching elements, the one variant comprising inwardly protruding fins 36 shown in Fig. 5 , whereas in Fig.

- the catching elements are constituted by pivotally journalled flanges, one of which is designated the reference numeral 36', which is pivotally journalled for allowing the flange to be moved from an open position shown in dotted line to a closed position shown in solid line, in which closed position the dispensing line 30 is arrested in its intentional position shown in Fig. 6 and received in the recess 32.

- the tap handle and consequently the shut-off valve operated by means of the tap handle 18 are joined to the housing part 16, which is pivotally journalled relative to the stationary housing part 14. It is contemplated that the provision of the tap handle 18 and the shut-off valve operated by the tap handle 18 at the movable part 16 is the most advantageous since, provided the tap handle 18 is connected to the movable part, as is illustrated in Fig. 2 , the proper mounting and positioning of the dispensing line 30 is most easily accomplished.

- the tap handle 18 and the shut-off valve operated by the tap handle 18 are supported by the stationary housing part 14, in which a recess similar to the recess 32 of the housing part 16 shown in Fig. 2 is provided, in which embodiment the movable housing part 16 simply constitutes a front closure.

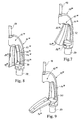

- Fig. 3 is a perspective and schematic view of a second embodiment of a beverage dispensing system in an open position.

- the first embodiment of Figs. 1 and 2 is modified into the second embodiment in that the two housing parts 12' and 14' are pivotally joined by means of the hinge 22', which hinge is mounted along a longitudinal edge 15 between the housing parts 14' and 16'.

- the tap handle 18 is mounted at the tapping end of the housing part 16' and swings with the housing part 16', when the housing part 16' is moved from and away from the housing part 14', which constitutes a stationary housing part in the open position shown in Fig.

- the recess is provided in the housing part 14' and provides the same function.

- the housing parts 14' and 16' are each provided with locking and arresting elements 28' and 29', respectively.

- Fig. 4 is a perspective and schematic view of a third embodiment of a beverage dispensing system 10".

- the housing part 16" is pivotally connected to the stationary housing part 16" by means of a hinge 22" at the top end of the housing 12".

- Fig. 7 is a perspective and schematic view of a fourth embodiment of a beverage dispensing system 10''' is shown in an open position.

- the housing part 16"' is pivotally connected by means of a hinge 22''' below the top end of the housing 12"' to the other housing part 14"'.

- the housing parts 14''' constitutes, as is evident from Fig. 7 , a main housing part of the housing 12''' relative to which main housing part the housing part 16" can be pivoted between a closed position and the open position.

- a longitudinal recess 42 is provided in which the dispensing line not shown can be positioned and retained.

- a longitudinal recess may be provided in the housing part 16"'.

- the longitudinal recess 42 is exposed, when the housing parts 14''' and 16''' are in the open position. Conversely, the longitudinal recess 42 is concealed when the housing parts 14''' and 16''' are in the closed position.

- the housing parts 14"' and 16"' are provided with locking and arresting elements 28"'.

- a fifth and a sixth embodiment, respectively, of the beverage dispensing system is shown designated the reference numerals 10 iv and 10 v , respectively.

- the fifth and sixth embodiments shown in Figs. 8 and 9 respectively, basically differs from the fourth embodiment shown in Fig. 7 in that the movable housing part 16 iv is in Fig. 8 hinged relative to the stationary or ain housing part 14 iv along a longitudinal edge of the two housing parts 14 iv and 16 iv similar to the second embodiment shown in Fig. 3 , whereas in the sixth embodiment 10 V shown in Fig.

- the movable housing part 16 v is hinged to the bottom of the housing part 14 V of the housing 12 V similar to the first embodiment shown in Figs. 1 and 2 .

- No further detailed description of the fifth and sixth embodiments is contemplated to be needed in view of the above description of the first, second, third and fourth embodiments.

Landscapes

- Devices For Dispensing Beverages (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07388023A EP1982952A1 (de) | 2007-04-16 | 2007-04-16 | Getränkeausgabesystem |

| EP08758205A EP2148834B1 (de) | 2007-04-16 | 2008-04-16 | Zapfständer |

| AT08758205T ATE521569T1 (de) | 2007-04-16 | 2008-04-16 | Zapfständer |

| DK08758205.2T DK2148834T3 (da) | 2007-04-16 | 2008-04-16 | Drikkevareaftapningssystem |

| PCT/DK2008/000138 WO2008125113A2 (en) | 2007-04-16 | 2008-04-16 | A tapping stanchion |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07388023A EP1982952A1 (de) | 2007-04-16 | 2007-04-16 | Getränkeausgabesystem |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1982952A1 true EP1982952A1 (de) | 2008-10-22 |

Family

ID=38585121

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07388023A Withdrawn EP1982952A1 (de) | 2007-04-16 | 2007-04-16 | Getränkeausgabesystem |

| EP08758205A Active EP2148834B1 (de) | 2007-04-16 | 2008-04-16 | Zapfständer |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08758205A Active EP2148834B1 (de) | 2007-04-16 | 2008-04-16 | Zapfständer |

Country Status (4)

| Country | Link |

|---|---|

| EP (2) | EP1982952A1 (de) |

| AT (1) | ATE521569T1 (de) |

| DK (1) | DK2148834T3 (de) |

| WO (1) | WO2008125113A2 (de) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009115928A2 (en) | 2008-03-20 | 2009-09-24 | Lancer Gb Llp | Beverage dispenser with removable flexible line |

| ITRN20090044A1 (it) * | 2009-10-19 | 2011-04-20 | Celli Spa | Colonna di dispensazione di almeno una bevanda |

| EP2562129A1 (de) | 2011-08-23 | 2013-02-27 | Anheuser-Busch InBev S.A. | Reihenausschankvorrichtung für Getränke |

| EP2660185A1 (de) | 2012-05-02 | 2013-11-06 | Anheuser-Busch InBev S.A. | Kompakte Ausschankvorrichtung für Getränke |

| EP2660188A1 (de) | 2012-05-02 | 2013-11-06 | Anheuser-Busch InBev S.A. | Getränkeausschankeinheit mit öffenbarem Klemmventil |

| FR2998286A1 (fr) * | 2012-11-19 | 2014-05-23 | Cryl | Boitier comprenant un capot dont l'articulation est controlee magnetiquement |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9862589B2 (en) | 2016-05-31 | 2018-01-09 | Starbucks Corporation | Chilled beverage dispenser |

| CN110461762B (zh) | 2017-03-27 | 2021-09-21 | 嘉士伯酿酒有限公司 | 用于分配碳酸饮料的饮料分配系统和分配碳酸饮料的方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2286818A (en) * | 1994-01-13 | 1995-08-30 | Microflow Uk Limited | Liquid dispenser head |

| GB2358854A (en) * | 1999-12-02 | 2001-08-08 | Porter Lancastrian Ltd | A font for serving alcoholic beverages |

| WO2006103566A2 (en) * | 2005-03-31 | 2006-10-05 | Celli S.P.A. | Device for dispensing liquids |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004018733A1 (de) * | 2004-04-17 | 2005-11-10 | Miller, Hans-Peter, Dipl.-Ing. | Getränke-Abgabe-Vorrichtung |

-

2007

- 2007-04-16 EP EP07388023A patent/EP1982952A1/de not_active Withdrawn

-

2008

- 2008-04-16 WO PCT/DK2008/000138 patent/WO2008125113A2/en active Application Filing

- 2008-04-16 EP EP08758205A patent/EP2148834B1/de active Active

- 2008-04-16 AT AT08758205T patent/ATE521569T1/de not_active IP Right Cessation

- 2008-04-16 DK DK08758205.2T patent/DK2148834T3/da active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2286818A (en) * | 1994-01-13 | 1995-08-30 | Microflow Uk Limited | Liquid dispenser head |

| GB2358854A (en) * | 1999-12-02 | 2001-08-08 | Porter Lancastrian Ltd | A font for serving alcoholic beverages |

| WO2006103566A2 (en) * | 2005-03-31 | 2006-10-05 | Celli S.P.A. | Device for dispensing liquids |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009115928A2 (en) | 2008-03-20 | 2009-09-24 | Lancer Gb Llp | Beverage dispenser with removable flexible line |

| WO2009115928A3 (en) * | 2008-03-20 | 2010-07-29 | Lancer Gb Llp | Beverage dispenser with removable flexible line |

| GB2458713B (en) * | 2008-03-20 | 2013-10-09 | Lancer Corp | Beverage dispense apparatus |

| ITRN20090044A1 (it) * | 2009-10-19 | 2011-04-20 | Celli Spa | Colonna di dispensazione di almeno una bevanda |

| EP2562129A1 (de) | 2011-08-23 | 2013-02-27 | Anheuser-Busch InBev S.A. | Reihenausschankvorrichtung für Getränke |

| WO2013026703A1 (en) | 2011-08-23 | 2013-02-28 | Anheuser-Busch Inbev S.A. | Roving beverage dispensing unit |

| US11753290B2 (en) | 2011-08-23 | 2023-09-12 | Anheuser-Busch Inbev S.A. | Roving beverage dispensing unit |

| RU2621377C2 (ru) * | 2012-05-02 | 2017-06-02 | Анхойзер-Буш ИнБев СА | Приспособление для разлива напитков с открываемым запорным клапаном |

| US9580289B2 (en) | 2012-05-02 | 2017-02-28 | Anheuser-Busch Inbev S.A. | Beverage dispensing unit with openable pinch valve |

| WO2013164259A1 (en) | 2012-05-02 | 2013-11-07 | Anheuser-Busch Inbev Sa | Compact beverage dispensing unit |

| EP2660185A1 (de) | 2012-05-02 | 2013-11-06 | Anheuser-Busch InBev S.A. | Kompakte Ausschankvorrichtung für Getränke |

| CN104379494A (zh) * | 2012-05-02 | 2015-02-25 | 安海斯-布希英博股份有限公司 | 具有可打开夹紧阀的饮料分配单元 |

| CN104379493A (zh) * | 2012-05-02 | 2015-02-25 | 安海斯-布希英博股份有限公司 | 紧凑型饮料分配单元 |

| AU2013255941B2 (en) * | 2012-05-02 | 2016-09-15 | Anheuser-Busch Inbev Sa | Beverage dispensing unit with openable pinch valve |

| WO2013164258A1 (en) | 2012-05-02 | 2013-11-07 | Anheuser-Busch Inbev Sa | Beverage dispensing unit with openable pinch valve |

| EP2660188A1 (de) | 2012-05-02 | 2013-11-06 | Anheuser-Busch InBev S.A. | Getränkeausschankeinheit mit öffenbarem Klemmventil |

| CN104379494B (zh) * | 2012-05-02 | 2017-06-09 | 安海斯-布希英博股份有限公司 | 具有可打开夹紧阀的饮料分配单元 |

| US10280059B2 (en) | 2012-05-02 | 2019-05-07 | Anheuser-Busch Inbev S.A. | Compact beverage dispensing unit |

| CN112723292A (zh) * | 2012-05-02 | 2021-04-30 | 安海斯-布希英博股份有限公司 | 紧凑型饮料分配单元 |

| CN112723292B (zh) * | 2012-05-02 | 2023-09-05 | 安海斯-布希英博股份有限公司 | 紧凑型饮料分配单元 |

| FR2998286A1 (fr) * | 2012-11-19 | 2014-05-23 | Cryl | Boitier comprenant un capot dont l'articulation est controlee magnetiquement |

Also Published As

| Publication number | Publication date |

|---|---|

| DK2148834T3 (da) | 2011-12-19 |

| EP2148834B1 (de) | 2011-08-24 |

| EP2148834A2 (de) | 2010-02-03 |

| ATE521569T1 (de) | 2011-09-15 |

| WO2008125113A3 (en) | 2009-01-29 |

| WO2008125113A2 (en) | 2008-10-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1982952A1 (de) | Getränkeausgabesystem | |

| US10064506B2 (en) | Sealing mechanism for beverage container | |

| EP1721863B1 (de) | Vorrichtung mit einem Getränkebehälter | |

| GB2397501B (en) | Machine for the preparation of beverages | |

| US9936830B2 (en) | Sealing pitcher assembly | |

| HK1090017A1 (en) | Drink dispenser with dispensing line that can be hinged open | |

| WO2004064582A3 (en) | Machine for the preparation of beverages | |

| EP1982951A1 (de) | Getränkeausgabeanordnung | |

| RU2001122372A (ru) | Головка для емкостей, содержащих напитки под давлением | |

| ES2195176T3 (es) | Recipiente, especialmente lata de bebida, asi como una tapa para un recipiente de este tipo. | |

| JP5567370B2 (ja) | 容器、蓋 | |

| JP2007197091A (ja) | 飲料用容器 | |

| WO2006133201A3 (en) | An improved disposable beverage container with lid | |

| JP4796679B2 (ja) | 飲料用容器 | |

| EP1746040A8 (de) | Verschluss für einen Behälter | |

| WO2006007418A3 (en) | Bottle top and valve apparatus | |

| CN216494697U (zh) | 直饮杯盖 | |

| KR200454700Y1 (ko) | 원터치 손잡이와 회전 개폐구 어셈블리를 가지는 알루미늄 캔 | |

| US20230040658A1 (en) | Water Bottle | |

| WO2005000683A3 (en) | Drinks container and closure member therefor | |

| WO2007145514A3 (en) | Device for cooling and cooled storage of packages with drink | |

| KR970059994A (ko) | 자동판매기의 음료 배출장치 | |

| KR20070057735A (ko) | 알루미늄(철) 음료수 캔 개폐장치 | |

| ES1050628U (es) | Dispositivo de cierre para envases contenedores de bebidas gasificadas | |

| RU2006129290A (ru) | Устройство для укупоривания контейнеров для пищевых продуктов и контейнер для пищевых продуктов, снабженный таким устройством |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20090423 |