EP1657397B1 - Glazed doorleaf and glazed door with such a doorleaf - Google Patents

Glazed doorleaf and glazed door with such a doorleaf Download PDFInfo

- Publication number

- EP1657397B1 EP1657397B1 EP05025074A EP05025074A EP1657397B1 EP 1657397 B1 EP1657397 B1 EP 1657397B1 EP 05025074 A EP05025074 A EP 05025074A EP 05025074 A EP05025074 A EP 05025074A EP 1657397 B1 EP1657397 B1 EP 1657397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- door leaf

- glass

- door

- framed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B5/00—Doors, windows, or like closures for special purposes; Border constructions therefor

- E06B5/10—Doors, windows, or like closures for special purposes; Border constructions therefor for protection against air-raid or other war-like action; for other protective purposes

- E06B5/16—Fireproof doors or similar closures; Adaptations of fixed constructions therefor

- E06B5/164—Sealing arrangements between the door or window and its frame, e.g. intumescent seals specially adapted therefor

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B5/00—Doors, windows, or like closures for special purposes; Border constructions therefor

- E06B5/10—Doors, windows, or like closures for special purposes; Border constructions therefor for protection against air-raid or other war-like action; for other protective purposes

- E06B5/16—Fireproof doors or similar closures; Adaptations of fixed constructions therefor

- E06B5/162—Fireproof doors having windows or other openings, e.g. for permitting ventilation or escape

Definitions

- the invention relates to a glass frame door leaf according to the preamble of the appended claim 1 and provided therewith a glass frame door, as they are known from EP 0 803 634 A2 are known.

- a door made of self-supporting structural glass which contains a lateral sash made of a material other than glass.

- the sash is glued to the edge portion of at least one side of the glass sheet.

- the sash is made of metal.

- the EP 0 803 634 A2 describes a glass door for fire protection purposes, which has a wooden door leaf frame.

- This door leaf frame has a support structure by means of which the weight of the fire protection pane can be introduced via the door hinges in a frame formed from wood.

- this known support structure of the door leaf frame has a larger-sized upper and a larger-sized lower frame spar, which act as a supporting profiles two frame beams. The weight of the disc is introduced via these two support profiles in the frame. This is to create a glass door with a particularly high glass content.

- the two support profiles are forcibly solid perform, so that in the upper and lower part of the door an undesirably high proportion of wood is visible.

- the present invention takes the opposite route.

- the frame spars are firmly connected to the glass pane so that the glass pane itself serves as a load-bearing element.

- the glass pane is also used as a load-bearing element, one can - but need not - also form the upper and lower frame profiles with much smaller widths. As a result, it is possible to further increase the proportion of glass on the viewing sides of the doors, and this even if the frame of the frame and door leaf are formed essentially or exclusively of wood-based materials.

- the door leaf frame is firmly glued to the glass so that a connection is created along the entire length of the glass pane edge. Bending loads on the disc are thus absorbed by the frame spars. The functional disks are thus hardly loaded in a direction transverse to the disk plane. And against forces in the direction of the disc level also available on the market fire protection windows are sufficiently rigid.

- a glass pane which is formed from a plurality of individual panes, which are preferably made of tempered glass and / or toughened safety glass (ESG). are formed and fixed by means of spacers firmly to each other. The cavity formed between them is filled with fire protection gel.

- ESG toughened safety glass

- all or some or at least one of the frame spars an L-profile with a web and a leg projecting therefrom exhibit.

- the glass pane can then be taken up and then fixed with a arranged on the opposite end of the leg of the L-profile glass bar.

- the glass strip is preferably adapted in shape and dimensions to the leg, so that the glass frame provided with frame rail has a total of a U-profile shape. With a correspondingly firm connection of the glass strip with the L-profile-shaped frame spar, this also a stiffening of the frame Holmes is achieved.

- the door hinge also does not have to be fastened to one of the horizontal frame spars, but can also act on the vertical frame spars.

- the door leaf-side hinge flap of each door leaf is preferably attached to the web of the vertical frame Holmes on its side facing away from the glass with a band fastening device.

- the band fastening device is preferably formed by a plurality of threaded sleeves, which are hammered into openings by clamping. The openings extend in the thickness direction through the frame spar.

- the threaded sleeves are preferably hammered from the glass pane side facing and serve as an abutment for screws with which the door leaf side hinge tab of the Glass pane opposite side are attached from.

- the attachment of the door leaf side hinge flap is preferably carried out in a matched to the hinge flap recess which is milled, for example, from the wood of the frame spar.

- the hinge flap is then preferably flush with the glass pane opposite side in this recess.

- reinforcing strips made of rigid material in the respective frame spars.

- These are preferably metal strips or strips of other suitable material, such as fiber-reinforced strips.

- the strips are profiled for further stiffening, for example as a U-profile, L-profile or T-profile.

- a strip may be attached to the glass pane facing side of the frame Holmes.

- a strip can optionally also be fastened to the edge of the pane. The latter preferably has a U-profile for embracing the disc edge.

- the glass frame door leaf is preferably used in a glass frame door whose frame is formed of Zargenholmen, which are also constructed on the basis of wood materials.

- the spars of the frame and the door leaf frame made of the same material. This results in a similar look for frame and door leaf frame.

- materials for both solid wood or laminated woods are preferably used.

- galvanized woods are preferably used.

- the spars of the frame are preferably also profiled and designed so that they completely cover the frame struts of the door leaf frame in the firing state of the door on the opposite hinge side. This gives on the opposite band side of the door leaf a view without joints.

- the spars of the frame are preferably also formed as L-shaped profiles. With the leg, the just mentioned cover function is achieved.

- the glazing bead can be arranged on the hinge opposite side of the door leaf. There she is from the Frame covered. On the hinge side, there is only a single visible gap.

- a fire protection with a foaming in case of fire material preferably also a cover layer is attached to the intumescent material, which corresponds to the appearance of the wood surface of the corresponding spar.

- Zargen prom the door hinge is preferably received in a tape receiving pocket, which is attached to the thigh-free end of the L-profile of the vertical band-side Zargenstabes on the hinge side.

- the glass frame door can be constructed as single-leaf as well as multi-leaf.

- both the inactive leaf and the active leaf are preferably formed from a corresponding glass frame door leaf.

- the glass pane has a plurality of individual panes of laminated safety glass.

- the laminated safety glass consists - it is already clear from the term - of several interconnected discs. Usually, these discs are bonded together by an adhesive or a double-sided adhesive film. These interconnected panes provide a high strength, so that even from individual panes, which in turn is formed of laminated safety glass, trained fire safety screen can absorb high lateral forces and can fulfill special good carrying functions.

- the lower door leaf frame spar can be completely omitted.

- the two horizontal Schomoshornhornhornholme can be made very narrow. This is because they do not contribute to the support function, as the weight of the disc is transmitted directly to the side frame spars.

- this horizontal door leaf frame rail also made thicker. In such a case, the thicker version is available primarily for optical reasons, a change in the functions of the individual frame members does not result. That is, weight of the disc is also introduced in these embodiments directly from the disc in the side frame spar; the horizontal door leaf frame spars, in particular the lower horizontal Mosblattrahmenholm is preferably not burdened in its thicker version by the weight of the disc.

- FIGS. 16-23 show a total of eight embodiments of glass framed doors 1-4, 101-104 respectively viewed from the hinge side and viewed from the hinge opposite side.

- FIGS. 16 and 17 show a first and a fifth embodiment of a glass frame door 1, 101 in a double-leaf design with a fixed leaf 5 and a moving leaf 6.

- the door leaves 7, of which passive leaf 5 and active leaf 6 are formed, have a four-sided door leaf frame 8.

- second embodiment of a glass frame door 2 and in the in the FIGS. 18 and 19 illustrated sixth embodiment of a glass frame door 102 is also a double-leaf version with fixed leaf 5 and the active leaf 6 to see, with their door leaves 7, however, have a three-sided door leaf frame 9.

- FIGS. 5 and 6 shown third embodiment of a glass frame door 3 and a in the FIGS. 20 and 21 shown seventh embodiment of a glass frame door 103 is formed single-leaf with only one door leaf 7, said door leaf 7 has the four-sided door leaf frame 8.

- FIGS. 7 and 8 show a fourth embodiment of a glass frame door 4 in a single-wing design, wherein the door panel 7 has the three-sided door leaf frame 9, which is in the FIGS. 7 and 8 shown.

- the Fig. 23 and FIG. 24 show an eighth embodiment of a glass frame door 108, which is a modification of the fourth embodiment 4 and is also formed as a single wing with a three-sided door leaf frame 9.

- All doors 1 - 4, 101 - 104 have a frame 10, each having a first vertical Zargenstab 11 and a second vertical Zargenstab 12 and a horizontal Zargenstab 13.

- the door leaf frames 8, 9 each have a first vertical frame rail 14, a second vertical frame rail 15 and an upper horizontal frame rail 16.

- the four-sided door leaf frame 8 additionally has a lower horizontal frame member 17.

- All Zargenstäbe 11 - 13 and frame members 14 - 17 are constructed of wood materials. Solid wood or laminated wood or finger-jointed wood is used.

- the door leaves 7 are each secured by at least two or more hinges 18, which engage at any point along one of the vertical frame members 14 on the frame 10.

- the door leaf frame 8, 9 of a fire door each comprises a glass pane 20.

- the glass frame door 1 - 4 is designed as a T30 fire door that holds a fire exposure from one side for at least 30 minutes.

- the glass sheet 20, as can be seen in particular from the sectional views of Fig. 9-15 results, designed as a multi-layer firewall 21.

- fire protection discs are selected, which are characterized by particular rigidity and insensitivity to loads.

- An example of this is a fire protection pane, which is offered under the brand name "Contraflam" by the company Vetrotech Saint-Gobain Germany GmbH.

- the individual disks are hardened, for example formed as a single-pane safety glass, and via spacers - not shown - from the outside invisible fixed together. In the illustrated cavities then fire protection gel is filled.

- the spacer in the discs used may but need not be present.

- Another useful fireproof pane has different thicknesses of glass, with a thicker, optionally hardened inner pane surrounded by thinner outer panes.

- disks are used whose maximum permissible bending stress is at least 45 N / mm 2 .

- FIGS. 9 to 15 The in the FIGS. 9 to 15 The subject matter shown is not covered by the appended claims. It is in these embodiments, a prior art that facilitates the understanding of the invention.

- the Zargenstäbe 11-13 are each L-shaped profile with a web 24 and a protruding at one end thereof leg 25 is formed.

- a frame spar 14 - 16 of the door leaf frame 8, 9 is then completely received.

- all frame beams 14 to 16 associated with the frame bars 11 - 13 are completely accommodated, also the respective upper frame rail 16.

- this does not apply to the second vertical frame rails 15 of the two-leaf glass frame doors 1 facing the other wing , 2 and 101, 102.

- the fifth to eighth embodiments each show a modification of the first to fourth embodiments in that the horizontal frame spars 16 and 17 of the door leaf frame 8, 9 are made thicker for purely optical reasons. A change in the function of the horizontal frame spars 16, 17 of the fifth in the eighth embodiment does not arise compared with the function of these frame spars 16, 17 in the first to fourth embodiments.

- the frame members 14-17 of the door leaf frame 8, 9 are L-shaped profile with a web 26 and a leg 27 formed.

- Exemplary dimensions are a total width D z2 of the Zargenstabs of about 64 mm and a thickness D Z1 of Sides-web of about 30 mm, an overall width B T3 of about 30 mm for the frame beams 14 to 17 with width B 27 (T1 and T2 B, each about 15 mm for the frame bridge 26 and the frame-leg please refer Fig. 10 ). These values may differ by ⁇ 5 mm.

- Each of the fire protection liners 30 has a lower layer 31 of intumescent material which intumesces in case of fire, and a cover layer 32 which is identical to the wood of the frame 10 and the door leaf frame 8, 9.

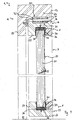

- Fig. 9 - 14 the structure of the glass frame door leaf 7 explained in more detail.

- the edge region of the glass pane 20 is inserted and held on behind blockings 33 - this are, for example, small wooden blocks - at an appropriate distance from the individual frame beams 14 - 17.

- a glass strip 34 is attached.

- the attachment of the glazing bead 34 is made by concealed nailing, by screwing or by gluing.

- the glazing bead 34 preferably has the same dimensions as the limb 27 in terms of thickness and width, so that the combination of glazing bead 34 and frame struts 14 - 17 forms a U-profile of wood-based material which surrounds the edge region of the glass pane 20.

- a sealing material 36 with adhesive function or an adhesive is inserted between the glass pane 20 and the combination of frame members 14-17 and glazing bead 34.

- the glass pane edge is extensively and firmly connected to the U-profile of the door leaf frame 8, 9. In most cases and most sizes, this connection is sufficient for stiffening the door leaf 7 during the entire operation of the door 1 - 4, 101 - 104.

- metal reinforcement strips 38, 40 may optionally be provided.

- a first metal strip 38 is formed in the illustrated embodiments as a T-profile-shaped strip, which is inserted into corresponding recesses on the frame rail 14-17. Additionally or alternatively, also a second metal strip 40 in the form of a U-profile can be provided encompassing the edge of the glass pane 20.

- Fig. 10 an embodiment of the four-sided door leaf frame 9 is shown, in which the lower horizontal frame member 17 is provided in smoke protection and / or sound insulation design with a bottom seal 42.

- the lower horizontal frame member 17 is made slightly wider and in the example approximately of its width comparable to the width of the respective Zargenstabes 11 - 13. This embodiment is not covered by the appended claims.

- a smoke protection and / or soundproofing is shown in the three-sided door leaf frame 9.

- an S-shaped metal profile 44 is attached to the lower glass pane edge, so that the bottom seal 42 can also be used in the three-sided door leaf frame 9. This embodiment is not covered by the appended claims.

- Fig. 12 shows the three-sided door leaf frame 9 with an optional simple conclusion by means of a metal U-profile 45 to protect the lower edge of the glass. This embodiment is not covered by the appended claims.

- Fig. 13 shows a horizontal section through the two double-leaf glass frame doors 1, 2. This embodiment does not fall under the appended claims. Deviating from the illustration in Fig. 13 In the door gap between the inactive leaf 5 and the moving leaf 6, the combinations of fire protection liners 30 shown on the strip-side vertical edges can likewise be present. The fire protection strip 30 may be present on one side or on both sides.

- a drive bolt guide 46 is shown in the inactive leaf 5 a drive bolt guide 46 is shown.

- a lock pocket 48 is shown in the aisle 6 dashed.

- the lock pocket 48 is formed by a on the vertical frame rail 14 on the glass pane 20 facing side mounted lock housing made of wood-based material. During production, the procedure is such that the frame spar and the lock housing are first glued together from solid solid wood and then a lock pocket is milled from the narrow side.

- the L-profile-shaped frame members contribute to a stiffening against transverse forces acting on the glass pane.

- the weight forces acting in the vertical direction and thus in the direction of the plane of the glass pane 20 can also be absorbed by the glass pane and transmitted to it by the large-area and encompassing connection with the door leaf frame. In this way, you can form the door leaf frame overall very narrow.

- the door leaf frame can thus - but not necessarily - less than 40 mm wide - measured along the door level - are formed.

- the width B T2 of the leg 27 is less than about 30 mm.

- the width B T2 leg 27 is only about 15 mm ( ⁇ 10%).

- the thickness B T1 of the web 25 can also be made very narrow, for example less than about 30 mm. In one embodiment, the thickness B T1 is approximately equal to the width B T2 of the leg 27. For example, in one embodiment, the thickness B T1 of the fin 25 is only about 15 mm ( ⁇ 10%). In the mentioned embodiment, this would result in a visible width B T3 of only about 30 mm. Deviations from the values given here purely by way of example are of course possible.

- the formation of the frame spars and bonding to the glass pane is such that in practice in bending the glass frame door leaf with inserted and connected disc, the maximum bending stress (Tensile strength) in the glass sheet is at most 30 N / mm 2 , preferably at most 18 N / mm 2, and most preferably at most 10 N / mm 2 . It can then be used glass sheets with a maximum bending stress or tensile strength of 45 N / mm 2 .

- the glass frame door leaf is bent out with a defined force and the deflection measured on the glass.

- the bending stress in the disk can then be calculated by means of characteristic values of the disks used in each case. Without existing characteristic values, the calculation is carried out according to the finite element method.

- the wooden frame construction becomes thicker frame materials or optionally reinforcing strips or a stronger one and / or larger area bonding reinforced. If the determined maximum flexural stress value is well below the above values, for example, less than about 1/5 or% of the maximum fracture stress, then the frame spar may be made slimmer to obtain a larger visible glass surface. Special tempered glasses, such as TVG, ESG or VSG are suitable for much higher maximum bending stresses or tensile strengths. If a special disc, such as a fire protection disk or with such glasses formed, can be realized using the carrying capacity of the glass narrower frame spars.

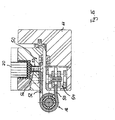

- FIG. 15 is still the attachment of the door hinge 18 between the door panel 7 and the frame 10 shown.

- a belt fastener 50 for securing a door leaf side strap tab 52 has a plurality of threaded sockets 53, which are driven into holes made smaller across the bridge 26, so that they claw into the wood with a corrugated or ribbed outer surface.

- this threaded sleeves 24 short-dimensioned countersunk screws 56 are screwed in accordance with the small thickness of the web, which fasten the door leaf-side hinge tabs 52 flush in a corresponding cutout on the glass pane opposite side of the vertical frame spar 14, 15.

- a band receiving pocket 54 is received at the free end of the web 24 in a mating cutout, in which the frame-side hinge tab 55 is attached.

- a large part of the thickness of the likewise narrow trained as the frame-side web 24 is occupied by the tape receiving pocket 54.

- the thickness D Z1 of the frame-side web 24 corresponds in the exemplary embodiment shown approximately to the visible width B T3 of the door leaf frame 8.

- the frame-side leg 25 is dimensioned so wide that it covers the entire door leaf frame 8 with the glass frame door 1-4 closed.

- Exemplary values for the thickness D Z1 of the web 24 and the total thickness D Z2 of the Zargenstabes 11-13 are in ranges between about 50 to 100 mm.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Securing Of Glass Panes Or The Like (AREA)

- Special Wing (AREA)

Abstract

Description

Die Erfindung betrifft ein Glasrahmentürblatt nach dem Oberbegriff des beigefügten Anspruches 1 sowie eine damit versehene Glasrahmentür, wie sie aus der

Aus der

In der

Die

Ausgehend vom Stand der Technik nach der

Diese Aufgabe wird mit einem Glasrahmentürblatt mit den Merkmalen des beigefügten Anspruches 1 bzw. mit einer damit versehenen Glasrahmentür gemäß Anspruche 20 gelöst.This object is achieved with a glass frame door leaf with the features of the attached

Im Stand der Technik nach der

so dass die dort vorgeschlagene Stützkonstruktion mit oberen und unteren Tragprofilen notwendig ist.so that the support structure proposed there with upper and lower support profiles is necessary.

Die vorliegende Erfindung geht den gegenteiligen Weg. Erfindungsgemäß werden die Rahmenholme derart fest mit der Glasscheibe verbunden, dass die Glasscheibe selbst als tragendes Element dient. Versuche haben gezeigt, dass dies überraschenderweise auch mit Funktionsscheiben wie Brandschutzscheiben funktioniert.The present invention takes the opposite route. According to the invention, the frame spars are firmly connected to the glass pane so that the glass pane itself serves as a load-bearing element. Experiments have shown that this works surprisingly well with functional disks such as fire protection.

Dadurch, dass auch die Glasscheibe als tragendes Element mitbenutzt wird, kann man - muss aber nicht - auch die oberen und unteren Rahmenprofile mit wesentlich geringeren Breiten ausbilden. Dadurch kann man den Glasanteil auf den Ansichtsseiten der Türen weiter erhöhen und dies auch dann, wenn der Rahmen von Zarge und Türblatt im wesentlichen oder ausschließlich aus Holzwerkstoffen gebildet sind.Due to the fact that the glass pane is also used as a load-bearing element, one can - but need not - also form the upper and lower frame profiles with much smaller widths. As a result, it is possible to further increase the proportion of glass on the viewing sides of the doors, and this even if the frame of the frame and door leaf are formed essentially or exclusively of wood-based materials.

Vorteilhafte Ausgestaltungen der Erfindung sind Gegenstand der Unteransprüche.Advantageous embodiments of the invention are the subject of the dependent claims.

Mit der erfindungsgemäßen Ausbildung kann man sogar auf einen unteren Rahmenholm verzichten, um den Glasanteil weiter zu erhöhen.With the formation of the invention can even do without a lower frame member to increase the glass content on.

Der Türblattrahmen wird mit der Glasscheibe fest verklebt, so dass auf der gesamten Länge des Glasscheibenrandes eine Verbindung entsteht. Biegebelastungen auf die Scheibe werden so durch die Rahmenholme aufgefangen. Die Funktionsscheiben werden so in einer Richtung quer zur Scheibenebene kaum belastet. Und gegenüber Kräften in Richtung der Scheibenebene sind auch auf dem Markt erhältliche Brandschutzscheiben ausreichend steif ausgebildet.The door leaf frame is firmly glued to the glass so that a connection is created along the entire length of the glass pane edge. Bending loads on the disc are thus absorbed by the frame spars. The functional disks are thus hardly loaded in a direction transverse to the disk plane. And against forces in the direction of the disc level also available on the market fire protection windows are sufficiently rigid.

Um die Steifheit der Glasscheibe weiter zu erhöhen, wird eine Glasscheibe verwendet, die aus mehreren Einzelscheiben gebildet ist, welche vorzugsweise aus gehärtetem Glas und/oder Einscheibensicherheitsglas (ESG) gebildet sind und mittels Abstandshalter fest zueinander fixiert sind. Der dazwischen ausgebildete Hohlraum ist mit Brandschutzgel befüllt.In order to further increase the stiffness of the glass pane, a glass pane is used, which is formed from a plurality of individual panes, which are preferably made of tempered glass and / or toughened safety glass (ESG). are formed and fixed by means of spacers firmly to each other. The cavity formed between them is filled with fire protection gel.

Um auch ein nachträgliches Einsetzen der Glasscheiben nach dem Verbinden der Rahmenholme zu dem Türblattrahmen und damit nach dem Aufbau des Türblattrahmens zu ermöglichen, ist weiter bevorzugt, dass alle oder einige oder wenigstens einer der Rahmenholme ein L-Profil mit einem Steg und einem davon abragenden Schenkel aufweisen. In dem zwischen dem Steg und dem Schenkel gebildeten Hohlraum kann dann die Glasscheibe aufgenommen werden und dann mit einer an dem dem Schenkel gegenüberliegenden Ende des L-Profils angeordneten Glasleiste fixiert werden. Mit dieser Ausbildung sind die Rahmenholme auch bei geringen Ansichtsbreiten aufgrund der Profil-Form ausreichend steif. Dennoch lässt sich die Glasscheibe auch bei eingebautem Türblatt nachträglich noch auswechseln.In order to allow a subsequent insertion of the glass sheets after connecting the frame beams to the door leaf frame and thus after the construction of the door leaf frame, it is further preferred that all or some or at least one of the frame spars an L-profile with a web and a leg projecting therefrom exhibit. In the cavity formed between the web and the leg, the glass pane can then be taken up and then fixed with a arranged on the opposite end of the leg of the L-profile glass bar. With this design, the frame spars are sufficiently rigid even at low view widths due to the profile shape. Nevertheless, the glass pane can be replaced later even with a built-in door leaf.

Aus optischen Gründen ist die Glasleiste bevorzugt in Form und Abmaßen an den Schenkel angepasst, so dass der mit Glasleiste versehene Rahmenholm insgesamt eine U-Profilform aufweist. Bei entsprechend fester Verbindung der Glasleiste mit dem L-profilförmigen Rahmenholm wird hierdurch außerdem eine Versteifung des Rahmenholmes erreicht.For optical reasons, the glass strip is preferably adapted in shape and dimensions to the leg, so that the glass frame provided with frame rail has a total of a U-profile shape. With a correspondingly firm connection of the glass strip with the L-profile-shaped frame spar, this also a stiffening of the frame Holmes is achieved.

Durch die erfindungsgemäße Konstruktion muss das Türband auch nicht an einem der horizontalen Rahmenholme befestigt werden, sondern kann auch an den vertikalen Rahmenholmen angreifen. Hierzu ist der türblattseitige Bandlappen jedes Türblattes vorzugsweise an dem Steg des vertikalen Rahmenholmes auf dessen der Glasscheibe abgewandten Seite mit einer Bandbefestigungseinrichtung befestigt. Die Bandbefestigungseinrichtung ist vorzugsweise durch mehrere Gewindemuffen gebildet, welche in Öffnungen klemmend eingeschlagen sind. Die Öffnungen reichen in Dickenrichtung durch den Rahmenholm. Die Gewindemuffen werden bevorzugt von der der Glasscheibe zugewandten Seite aus eingeschlagen und dienen als Gegenlager für Schrauben, mit denen die türblattseitigen Bandlappen von der der Glasscheibe entgegen gerichteten Seite aus befestigt sind. Die Befestigung des türblattseitigen Bandlappens erfolgt vorzugsweise in einer an den Bandlappen angepassten Aussparung, die beispielsweise aus dem Holz des Rahmenholms ausgefräst ist. Der Bandlappen sitzt dann vorzugsweise flächenbündig mit der der Glasscheibe entgegengerichteten Seite in dieser Ausnehmung.Due to the construction according to the invention, the door hinge also does not have to be fastened to one of the horizontal frame spars, but can also act on the vertical frame spars. For this purpose, the door leaf-side hinge flap of each door leaf is preferably attached to the web of the vertical frame Holmes on its side facing away from the glass with a band fastening device. The band fastening device is preferably formed by a plurality of threaded sleeves, which are hammered into openings by clamping. The openings extend in the thickness direction through the frame spar. The threaded sleeves are preferably hammered from the glass pane side facing and serve as an abutment for screws with which the door leaf side hinge tab of the Glass pane opposite side are attached from. The attachment of the door leaf side hinge flap is preferably carried out in a matched to the hinge flap recess which is milled, for example, from the wood of the frame spar. The hinge flap is then preferably flush with the glass pane opposite side in this recess.

Bei besonders großen Türhöhen in Verbindung mit besonders schmalen Rahmenholmen kann es bei einigen Funktionen, insbesondere bei Feuerschutztüren zur Erhöhung der Stabilität vorteilhaft sein, wahlweise Verstärkungsleisten aus steifem Material in die jeweiligen Rahmenholme einzubringen. Dies sind vorzugsweise Metallleisten oder Leisten aus anderem geeigneten Material, beispielsweise faserverstärkte Leisten. Vorzugsweise sind die Leisten zur weiteren Versteifung profiliert ausgeführt, beispielsweise als U-Profil, L-Profil oder T-Profil. Eine solche Leiste kann an der der Glasscheibe zugewandten Seite des Rahmenholmes befestigt sein. Alternativ oder zusätzlich hierzu kann wahlweise auch an dem Scheibenrand eine Leiste befestigt sein. Letztere hat vorzugsweise ein U-Profil zum Umfassen des Scheibenrandes.For particularly large door heights in connection with particularly narrow frame beams, it may be advantageous in some functions, especially in fire doors to increase the stability, optionally introduce reinforcing strips made of rigid material in the respective frame spars. These are preferably metal strips or strips of other suitable material, such as fiber-reinforced strips. Preferably, the strips are profiled for further stiffening, for example as a U-profile, L-profile or T-profile. Such a strip may be attached to the glass pane facing side of the frame Holmes. Alternatively or in addition to this, a strip can optionally also be fastened to the edge of the pane. The latter preferably has a U-profile for embracing the disc edge.

Das Glasrahmentürblatt wird vorzugsweise in einer Glasrahmentür verwendet, deren Zarge aus Zargenholmen gebildet ist, welche ebenfalls auf der Basis von Holzwerkstoffen aufgebaut sind. Vorzugsweise bestehen die Holme der Zarge und des Türblattrahmens aus dem gleichen Material. Dies ergibt eine gleiche Optik für Zarge und Türblattrahmen. Als Materialien für beide werden vorzugsweise Massivholz oder lamellierte Hölzer eingesetzt. Auch möglich sind keilverzinkte Hölzer. Die Holme der Zarge sind vorzugsweise ebenfalls profiliert und so ausgebildet, dass sie auf der Gegenbandseite die Rahmenholme des Türblattrahmens im Schießzustand der Tür vollständig überdecken. Dies gibt auf der Gegenbandseite des Türblattes eine Ansicht ganz ohne Fugen. Hierzu sind die Holme der Zarge vorzugsweise ebenfalls als L-förmige Profile ausgebildet. Mit dem Schenkel wird die eben erwähnte Deckfunktion erzielt.The glass frame door leaf is preferably used in a glass frame door whose frame is formed of Zargenholmen, which are also constructed on the basis of wood materials. Preferably, the spars of the frame and the door leaf frame made of the same material. This results in a similar look for frame and door leaf frame. As materials for both solid wood or laminated woods are preferably used. Also possible are galvanized woods. The spars of the frame are preferably also profiled and designed so that they completely cover the frame struts of the door leaf frame in the firing state of the door on the opposite hinge side. This gives on the opposite band side of the door leaf a view without joints. For this purpose, the spars of the frame are preferably also formed as L-shaped profiles. With the leg, the just mentioned cover function is achieved.

Zur Reduzierung von im Schließzustand sichtbaren Fugen kann die Glasleiste auf der Bandgegenseite des Türblattes angeordnet sein. Dort wird sie von der Zarge überdeckt. Auf der Bandseite gibt es somit auch nur eine einzelne sichtbare Fuge.To reduce joints that are visible in the closed state, the glazing bead can be arranged on the hinge opposite side of the door leaf. There she is from the Frame covered. On the hinge side, there is only a single visible gap.

An den Holmen von Zarge oder Türblattrahmen kann weiter beidseits oder einseitig ein Brandschutzeinleimer mit aus im Brandfall aufschäumendem Material befestigt sein. Damit dieser die Optik der Tür nicht stört, ist über dem intumeszierenden Material vorzugsweise auch noch eine Deckschicht befestigt, die der Optik der Holzoberfläche des entsprechenden Holmes entspricht. Zargenseitig ist das Türband vorzugsweise in einer Bandaufnahmetasche aufgenommen, welche an dem schenkelfreien Ende des L-Profiles des vertikalen bandseitigen Zargenstabes auf der Bandseite befestigt ist.On the spars of frame or door leaf frame can further be attached on both sides or on one side a fire protection with a foaming in case of fire material. So that this does not disturb the appearance of the door, preferably also a cover layer is attached to the intumescent material, which corresponds to the appearance of the wood surface of the corresponding spar. Zargenseitig the door hinge is preferably received in a tape receiving pocket, which is attached to the thigh-free end of the L-profile of the vertical band-side Zargenstabes on the hinge side.

Die Glasrahmentür kann sowohl einflügelig als auch mehrflügelig aufgebaut sein. Bei einer zweiflügeligen Tür sind vorzugsweise sowohl der Standflügel als auch der Gangflügel aus einem entsprechenden Glasrahmentürblatt gebildet.The glass frame door can be constructed as single-leaf as well as multi-leaf. In a two-leaf door, both the inactive leaf and the active leaf are preferably formed from a corresponding glass frame door leaf.

Besonders bevorzugt ist eine Ausführungsform, bei der die Glasscheibe mehrere Einzelscheiben aus Verbundscheibensicherheitsglas aufweist. Das Verbundsscheibensicherheitsglas besteht - dies geht bereits aus dem Begriff hervor - aus mehreren miteinander verbundenen Scheiben. Üblicherweise sind diese Scheiben durch ein Klebemittel oder eine doppelseitige Klebefolie miteinander verbunden. Diese miteinander verbundenen Scheiben ergeben eine hohe Festigkeit, so dass auch eine aus Einzelscheiben, die wiederum aus Verbundscheibensicherheitsglas gebildet ist, ausgebildete Brandschutzscheibe hohe Querkräfte aufnehmen kann und besondere gute Tragefunktionen erfüllen kann.Particularly preferred is an embodiment in which the glass pane has a plurality of individual panes of laminated safety glass. The laminated safety glass consists - it is already clear from the term - of several interconnected discs. Usually, these discs are bonded together by an adhesive or a double-sided adhesive film. These interconnected panes provide a high strength, so that even from individual panes, which in turn is formed of laminated safety glass, trained fire safety screen can absorb high lateral forces and can fulfill special good carrying functions.

Bevorzugt ist, das für das Türblatt ein möglichst hoher Glasanteil sichtbar ist. Insofern kann der untere Türblattrahmenholm ganz weggelassen werden. Die beiden horizontalen Türblattrahmenblattholme können ganz schmal ausgebildet werden. Dies liegt daran, dass sie nicht zur Tragfunktion beitragen, da die Gewichtskraft der Scheibe unmittelbar auf die seitlichen Rahmenholme übertragen wird. Falls jedoch aus gestalterischen Gründen oder aufgrund des Einpassens in spezielle Räumlichkeiten gewünscht, können selbstverständlich diese horizontalen Türblattrahmenholm auch dicker ausgeführt werden. In einem solchen Fall ist die dickere Ausführung in erster Linie aus optischen Gründen vorhanden, eine Änderung der Funktionen der einzelnen Rahmenholme ergibt sich hierdurch nicht. Das heißt, dass Gewicht der Scheibe wird auch bei diesen Ausführungsformen unmittelbar von der Scheibe in die seitlichen Rahmenholm eingeleitet; die horizontalen Türblattrahmenholme, insbesondere der untere horizontal Türblattrahmenholm wird vorzugsweise auch in seiner dickeren Version durch die Gewichtskraft der Scheibe nicht belastet.It is preferred that the highest possible proportion of glass is visible for the door leaf. In this respect, the lower door leaf frame spar can be completely omitted. The two horizontal Türblattrahmenblattholme can be made very narrow. This is because they do not contribute to the support function, as the weight of the disc is transmitted directly to the side frame spars. However, if desired for design reasons or due to fitting into special premises, of course this horizontal door leaf frame rail also made thicker. In such a case, the thicker version is available primarily for optical reasons, a change in the functions of the individual frame members does not result. That is, weight of the disc is also introduced in these embodiments directly from the disc in the side frame spar; the horizontal door leaf frame spars, in particular the lower horizontal Türblattrahmenholm is preferably not burdened in its thicker version by the weight of the disc.

Ausführungsbeispiele der Erfindung werden nachfolgend anhand der beigefügten Zeichnung näher erläutert. Darin zeigen:

- Fig. 1

- eine Ansicht von der Bandseite aus auf eine erste Ausführungsform einer zweiflügeligen Glasrahmentür;

- Fig. 2

- eine Ansicht der Ausführungsform von

Fig. 1 von der Bandgegenseite aus; - Fig. 3

- eine Ansicht auf eine zweite Ausführungsform einer zweiflügeligen Glasrahmentür von der Bandseite aus;

- Fig. 4

- eine Ansicht der zweiten Ausführungsform der Glasrahmentür, jedoch von der Bandgegenseite aus;

- Fig. 5

- eine Ansicht einer dritten Ausführungsform einer Glasrahmentür in einflügeliger Ausführung von der Bandseite aus;

- Fig. 6

- die dritte Ausführungsform der Glasrahmentür von der Bandgegenseite aus;

- Fig. 7

- eine Ansicht einer vierten Ausführungsform einer Glasrahmentür in einflügeliger Ausführung von der Bandseite aus;

- Fig. 8

- die Tür von

Fig. 7 von der Bandgegenseite aus gesehen; - Fig. 9

- einen Vertikalschnitt durch ein Türblatt einer der Türen von

Fig. 1, Fig. 2 ,Fig. 5 oder Fig. 6 in einer Ausführungsform der nicht unter die beigefügte Ansprüche fällt; - Fig. 10

- einen Vertikalschnitt durch ein Türblatt einer der Türen von

Fig. 1, Fig. 2 ,Fig. 5 und Fig. 6 in einer weiteren Ausführungsform der nicht unter die beigefügte Ansprüche fällt; - Fig. 11

- einen Vertikalschnitt durch ein Türblatt einer der Türen von

Fig. 3, Fig. 4 ,Fig. 7 oder Fig. 8 in einer Ausführungsform der nicht unter die beigefügte Ansprüche fällt; - Fig. 12

- einen Vertikalschnitt durch eine Tür gemäß

Fig. 3, Fig. 4 ,Fig. 7 oder Fig. 8 in einer weiteren Ausführungsform der nicht unter die beigefügte Ansprüche fällt; - Fig. 13

- einen Horizontalschnitt durch die zweiflügeligen Türen gemäß

Fig. 1 - Fig. 4 der nicht unter die beigefügte Ansprüche fällt; - Fig. 14

- einen Horizontalschnitt durch die einflügeligen Türen gemäß

Fig. 5 - Fig. 8 der nicht unter die beigefügte Ansprüche fällt; - Fig. 15

- einen Horizontalschnitt durch einen Teilbereich der Türen gemäß

Fig. 1 - Fig. 8 im Bereich eines der Türbänder der nicht unter die beigefügte Ansprüche fällt; - Fig. 16

- eine Ansicht von der Bandseite auf eine fünfte Ausführungsform einer zweiflügeligen Glasrahmentür;

- Fig. 17

- eine Ansicht der Ausführungsform von

Fig. 16 von der Bandgegenseite aus; - Fig. 18

- eine Ansicht auf eine sechste Ausführungsform einer zweiflügeligen Glasrahmentür von der Bandseite aus;

- Fig. 19

- eine Ansicht der sechsten Ausführungsform der Glasrahmentür, jedoch von der Bandgegenseite aus;

- Fig. 20

- eine Ansicht einer siebten Ausführungsform einer Glasrahmentür in einflügeliger Ausführung von der Bandseite aus;

- Fig. 21

- die siebte Ausführungsform der Glasrahmentür von der Bandgegenseite aus;

- Fig. 22

- eine Ansicht einer achten Ausführungsform einer Glasrahmentür in einflügeliger Ausführung von der Bandseite aus; und

- Fig. 23

- die achte Ausführungsform der Glasrahmentür von der Bandgegenseite aus.

- Fig. 1

- a view from the hinge side of a first embodiment of a two-leaf glass frame door;

- Fig. 2

- a view of the embodiment of

Fig. 1 from the tape opposite side; - Fig. 3

- a view of a second embodiment of a two-leaf glass frame door from the hinge side;

- Fig. 4

- a view of the second embodiment of the glass frame door, but from the tape opposite side of;

- Fig. 5

- a view of a third embodiment of a glass frame door in a single-wing design of the band side;

- Fig. 6

- the third embodiment of the glass frame door from the tape opposite side;

- Fig. 7

- a view of a fourth embodiment of a glass frame door in a single-wing design of the band side;

- Fig. 8

- the door of

Fig. 7 seen from the tape opposite side; - Fig. 9

- a vertical section through a door leaf of one of the doors of

Fig. 1, Fig. 2 .Fig. 5 or Fig. 6 in an embodiment not falling under the appended claims; - Fig. 10

- a vertical section through a door leaf of one of the doors of

Fig. 1, Fig. 2 .Fig. 5 and Fig. 6 in a further embodiment not falling under the appended claims; - Fig. 11

- a vertical section through a door leaf of one of the doors of

Fig. 3, Fig. 4 .Fig. 7 or Fig. 8 in an embodiment not falling under the appended claims; - Fig. 12

- a vertical section through a door according to

Fig. 3, Fig. 4 .Fig. 7 or Fig. 8 in a further embodiment not falling under the appended claims; - Fig. 13

- a horizontal section through the two-leaf doors according to

Fig. 1 - Fig. 4 not covered by the attached claims; - Fig. 14

- a horizontal section through the single-leaf doors according to

Fig. 5-8 not covered by the attached claims; - Fig. 15

- a horizontal section through a portion of the doors according to

Fig. 1 - Fig. 8 in the area of one of the hinges not covered by the attached claims; - Fig. 16

- a view from the hinge side to a fifth embodiment of a two-leaf glass frame door;

- Fig. 17

- a view of the embodiment of

Fig. 16 from the tape opposite side; - Fig. 18

- a view of a sixth embodiment of a double-winged glass frame door from the hinge side;

- Fig. 19

- a view of the sixth embodiment of the glass frame door, but from the tape opposite side of;

- Fig. 20

- a view of a seventh embodiment of a glass frame door in a single-wing design of the band side;

- Fig. 21

- the seventh embodiment of the glass frame door from the tape opposite side;

- Fig. 22

- a view of an eighth embodiment of a glass frame door in a single-wing design from the hinge side; and

- Fig. 23

- the eighth embodiment of the glass frame door from the hinge opposite side.

In den

In den

Bei der in

Eine in den

Und eine vierte Ausführungsform einer Glasrahmentür 4 in einflügeliger Ausführung, wobei das Türblatt 7 den dreiseitigen Türblattrahmen 9 aufweist, ist in den

Alle Türen 1 - 4, 101 - 104 weisen eine Zarge 10 mit je einem ersten vertikalen Zargenstab 11 und einem zweiten vertikalen Zargenstab 12 und einem horizontalen Zargenstab 13 auf.All doors 1 - 4, 101 - 104 have a

Die Türblattrahmen 8, 9 weisen jeweils einen ersten vertikalen Rahmenholm 14, einen zweiten vertikalen Rahmenholm 15 und einen oberen horizontalen Rahmenholm 16 auf. Der vierseitige Türblattrahmen 8 weist zusätzlich noch einen unteren horizontalen Rahmenholm 17 auf.The door leaf frames 8, 9 each have a first

Sämtliche Zargenstäbe 11 - 13 und Rahmenholme 14 - 17 sind aus Holzwerkstoffen aufgebaut. Eingesetzt werden Massivholz oder lamelliertes Holz oder keilverzinkte Hölzer.All Zargenstäbe 11 - 13 and frame members 14 - 17 are constructed of wood materials. Solid wood or laminated wood or finger-jointed wood is used.

Die Türblätter 7 sind jeweils durch wenigstens zwei oder mehrere Türbänder 18, die an beliebigen Stellen entlang eines der vertikalen Rahmenholme 14 angreifen, an der Zarge 10 befestigt.The door leaves 7 are each secured by at least two or more hinges 18, which engage at any point along one of the

Der Türblattrahmen 8, 9 einer erfindungsgemäßen Feuerschutztür umfasst jeweils eine Glasscheibe 20. In bevorzugter Ausführung ist die Glasrahmentür 1 - 4 als T30-Feuerschutztür ausgebildet, die einer Feuerbeaufschlagung von einer Seite aus mindestens 30 Minuten Stand hält. Hierzu ist die Glasscheibe 20, wie sich insbesondere aus den Schnittdarstellungen der

Die in den

Wie sich aus den Vertikalschnitten gemäß den

Auch die Rahmenholme 14 - 17 des Türblattrahmens 8, 9 sind L-profilförmig mit einem Steg 26 und einem Schenkel 27 ausgebildet. Beispielhafte Ausmaße sind eine Gesamtbreite Dz2 des Zargenstabs von ca. 64 mm und eine Dicke DZ1 des Zargen-Stegs von ca. 30 mm, eine Gesamtbreite BT3 von ca. 30 mm für die Rahmenholme 14 - 17 mit Breiten BT1 und BT2 von je ca. 15 mm für den Rahmen-Steg 26 und den Rahmen-Schenkel 27 (siehe

An den sich gegenüberliegenden Seiten der Stege 24, 26 von Zarge 10 und Türblattrahmen 8, 9 sind wahlweise Brandschutzeinleimer 30 in eine entsprechende Ausnehmung flächenbündig eingebracht. Der Brandschutzeinleimer 30 hat jeweils eine untere Schicht 31 aus im Brandfall aufschäumendem (intumeszierenden) Material und eine Deckschicht 32, welche ansichtsgleich zu dem Holz der Zarge 10 und des Türblattrahmens 8, 9 ist.On the opposite sides of the

Im folgenden wird nun anhand der Darstellung gemäß

Im gesamten Umgreifungsbereich und auf der gesamten Länge des Glasscheibenrandes ist zwischen der Glasscheibe 20 und der Kombination aus Rahmenholme 14 - 17 und Glasleiste 34 ein Dichtungsmaterial 36 mit Kleberfunktion oder ein Kleber eingesetzt. Hierdurch wird der Glasscheibenrand großflächig und fest mit dem U-Profil des Türblattrahmens 8, 9 verbunden. In den meisten Fällen und den meisten Größen reicht diese Verbindung zur Versteifung des Türblattes 7 während des gesamten Betriebes der Tür 1 - 4, 101 - 104 aus. Bei besonders hohen und breiten Türen können wahlweise auch Metallverstärkungsleisten 38, 40 vorgesehen sein. Ein erste Metallleiste 38 ist in den dargestellten Ausführungsbeispielen als T-profilförmige Leiste ausgebildet, welche in entsprechende Ausnehmungen an dem Rahmenholm 14 - 17 eingesetzt ist. Zusätzlich oder alternativ kann auch noch eine zweite Metallleiste 40 in Form eines U-Profils den Rand der Glasscheibe 20 umgreifend vorgesehen sein.In the entire encompassing region and on the entire length of the glass pane edge, a sealing

In

In

Aufgrund der Befestigung des Türblattrahmens 8, 9 mittels Verklebung mit dem Glasscheibenrand tragen die L-profilförmige Rahmenholme zu einer Versteifung gegenüber auf die Glasscheibe wirkenden Querkräften bei. Die in vertikaler Richtung und damit in Richtung der Ebene der Glasscheibe 20 wirkenden Gewichtskräfte können auch durch die Glasscheibe mit aufgenommen werden und durch die großflächige und umgreifende Verbindung mit dem Türblattrahmen auf diesen übertragen werden. Auf diese Weise kann man den Türblattrahmen insgesamt sehr schmal ausbilden. Der Türblattrahmen kann so - muss aber nicht - auch weniger als 40 mm breit - gemessen entlang der Türebene - ausgebildet werden. Beispielsweise beträgt die Breite BT2 des Schenkel 27 weniger als etwa 30 mm. Die Breite BT2 Schenkels 27 beträgt in einer Ausführungsform beispielsweise nur etwa 15 mm (±10%). Auch die Dicke BT1 des Steges 25 kann sehr schmal, beispielsweise weniger als etwa 30 mm ausgebildet sein. In einem Ausführungsbeispiel ist die Dicke BT1 ungefähr gleich der Breite BT2 des Schenkels 27. Beispielsweise beträgt die Dicke BT1 Steges 25 in einer Ausführungsform nur etwa 15 mm (±10%). Bei der genannten Ausführungsform ergäbe dies eine sichtbare Breite BT3 von nur etwa 30 mm. Abweichungen von den hier lediglich rein beispielhaft genannten Werten sind selbstverständlich möglich.Due to the attachment of the

Das vorgesagte gilt auch für die fünfte bis achte Ausführungsform, bei der die beiden vertikalen Rahmenholme 14 und 15 genauso wie bei der ersten und vierten Ausführungsform ausgeführt sind. Bei dieser fünften bis achten Ausführungsform ist lediglich aus optischen Gründen eine größere Friesbreite, also eine größere Rahmenholmbreite durch Vergrößerung der Dicke des Steges der L-förmigen Rahmenholme vorgesehen.The above also applies to the fifth to eighth embodiments, in which the two vertical frame beams 14 and 15 are made the same as in the first and fourth embodiments. In this fifth to eighth embodiment, a larger frieze width, ie a larger frame width by enlarging the thickness of the web of the L-shaped frame members is provided only for optical reasons.

So geringe Rahmenholmdicken werden insbesondere durch die folgende Verfahrensweise bei der Herstellung der Glasrahmentürblätter erreicht:Such low frame thicknesses are achieved in particular by the following procedure in the production of the glass frame door leaves:

Die Ausbildung der Rahmenholme und Verklebung mit der Glasscheibe erfolgt derart, dass in der Praxis bei Verbiegung des Glasrahmentürblattes mit eingesetzter und verbundener Scheibe die maximale Biegespannung (Zugfestigkeit) in der Glasscheibe höchstens 30 N/mm2, vorzugsweise höchstens 18 N/mm2 und am meisten bevorzugt höchstens 10 N/mm2 beträgt. Damit können dann Glasscheiben mit einer maximalen Biegespannung oder Zugfestigkeit von 45 N/mm2 verwendet werden. Hierzu wird das Glasrahmentürblatt mit einer definierten Kraft ausgebogen und die Auslenkung am Glas gemessen. Über Kennwerte der jeweils eingesetzten Scheiben lässt sich dann die Biegespannung in der Scheibe berechnen. Ohne vorliegende Kennwerte erfolgt die Berechnung nach der Methode der finiten Elementen. Liegt der so ermittelte maximale Biegespannungswert oberhalb der genannten Werte oder, bei spezielleren Scheiben, die größere mechanische Spannungen aushalten, oberhalb von etwa 2/3 bis 4/5 der maximal zulässigen Biegespannung, dann wird die Holzrahmenkonstruktion durch dickere Rahmenmaterialien oder wahlweise Verstärkungsleisten oder eine stärkere und/oder großflächigere Verklebung verstärkt. Liegt der ermittelte maximale Biegespannungswert weit unterhalb der oben genannten Werte, zum Beispiel weniger als etwa 1/5 oder % der maximalen Bruchspannung, dann kann der Rahmenholm schlanker ausgeführt werden, um eine größere sichtbare Glasfläche zu erhalten. Spezielle gehärtete Gläser, wie TVG, ESG oder VSG sind für weitaus höhere maximale Biegespannungen oder Zugfestigkeiten geeignet. Wird eine Spezialscheibe, wie zum Beispiel eine Brandschutzscheibe aus oder mit solchen Gläsern gebildet, können unter Verwendung der Tragfähigkeit des Glases schmalere Rahmenholme realisiert werden.The formation of the frame spars and bonding to the glass pane is such that in practice in bending the glass frame door leaf with inserted and connected disc, the maximum bending stress (Tensile strength) in the glass sheet is at most 30 N / mm 2 , preferably at most 18 N / mm 2, and most preferably at most 10 N / mm 2 . It can then be used glass sheets with a maximum bending stress or tensile strength of 45 N / mm 2 . For this purpose, the glass frame door leaf is bent out with a defined force and the deflection measured on the glass. The bending stress in the disk can then be calculated by means of characteristic values of the disks used in each case. Without existing characteristic values, the calculation is carried out according to the finite element method. If the maximum flexural strength value determined in this way is above the stated values or, for more specific disks that withstand greater mechanical stresses, above approximately 2/3 to 4/5 of the maximum permissible bending stress, then the wooden frame construction becomes thicker frame materials or optionally reinforcing strips or a stronger one and / or larger area bonding reinforced. If the determined maximum flexural stress value is well below the above values, for example, less than about 1/5 or% of the maximum fracture stress, then the frame spar may be made slimmer to obtain a larger visible glass surface. Special tempered glasses, such as TVG, ESG or VSG are suitable for much higher maximum bending stresses or tensile strengths. If a special disc, such as a fire protection disk or with such glasses formed, can be realized using the carrying capacity of the glass narrower frame spars.

Bei der Konstruktion und dem Aufbau der hier beschriebenen Glasrahmentürblätter wird die maximale Dicke der Holz-Rahmenholme an die maximale Biegespannung der benutzten Scheibe angepasst und so minimiert. Versuche haben gezeigt, dass hier bei einer Vielzahl einsetzbarer unterschiedlicher Scheiben eine erstaunlich geringe Rahmenholmdicke vorgesehen werden kann, und dies auch bei Verwirklichung einer Brandschutz- oder Rauchschutzfunktion.In the design and construction of the glass frame door leaves described herein, the maximum thickness of the wood frame spars is adjusted to the maximum bending stress of the disk used and thus minimized. Experiments have shown that an astonishingly low frame beam thickness can be provided here with a multiplicity of usable different panes, and this is also the case when a fire protection or smoke protection function is implemented.

In

An der Zarge 10 ist an dem freien Ende des Steges 24 in eine passende Ausfräsung eine Bandaufnahmetasche 54 aufgenommen, in welcher der zargenseitige Bandlappen 55 befestigt ist. Hier wird ein Großteil der Dicke des ebenfalls möglichst schmal ausgebildeten zargenseitigen Steges 24 durch die Bandaufnahmetasche 54 besetzt.On the

Die Dicke DZ1 des zargenseitigen Steges 24 entspricht in dem gezeigten Ausführungsbeispiel in etwa der sichtbaren Breite BT3 des Türblattrahmens 8. Insbesondere ist der zargenseitige Schenkel 25 so breit bemessen, dass er den gesamten Türblattrahmen 8 bei geschlossener Glasrahmentür 1-4 überdeckt. Beispielhafte Werte für die Dicke DZ1 des Steges 24 und die Gesamtdicke DZ2 des Zargenstabes 11-13 liegen in Bereichen zwischen etwa 50 bis 100 mm.The thickness D Z1 of the frame-

- 11

- GlasrahmentürGlass frame door

- 22

- GlasrahmentürGlass frame door

- 33

- GlasrahmentürGlass frame door

- 44

- GlasrahmentürGlass frame door

- 55

- StandflügelFixed leaf

- 66

- Gangflügelleaf

- 77

- Türblattdoor leaf

- 88th

- vierseitiger Türblattrahmenfour-sided door leaf frame

- 99

- dreiseitiger Türblattrahmenthree-sided door leaf frame

- 1010

- Zargeframe

- 1111

- erster vertikaler Zargenstabfirst vertical frame rod

- 1212

- zweiter vertikaler Zargenstabsecond vertical Zargenstab

- 1313

- horizontaler Zargenstabhorizontal frame rod

- 1414

- erster vertikaler Rahmenholmfirst vertical frame spar

- 1515

- zweiter vertikaler Rahmenholmsecond vertical frame spar

- 1616

- oberer horizontaler RahmenholmUpper horizontal frame spar

- 1717

- unterer horizontaler Rahmenholmlower horizontal frame spar

- 1818

- Türbänderdoor hinges

- 2020

- Glasscheibepane

- 2121

- BrandschutzscheibeFireproof panel

- 2222

- EinzelscheibenSingle discs

- 2424

- Steg (Zarge)Bridge (frame)

- 2525

- Schenkel (Zarge)Thigh (frame)

- 2626

- Steg (Türblatt)Bridge (door leaf)

- 2727

- Schenkel (Türblatt)Leg (door leaf)

- 3030

- BrandschutzeinleimerBrandschutzeinleimer

- 3131

- BrandaufschäumerBrandaufschäumer

- 3232

- Deckschichttopcoat

- 3333

- HinterklotzungenHinterklotzungen

- 3434

- Glasleisteglazing bead

- 3636

- Dichtungsmaterial mit Klebefunktion oder KleberSeal material with adhesive function or adhesive

- 3838

- Metallleistemetal bar

- 4040

- U-ProfilU-profile

- 4242

- Bodendichtungfloor seal

- 4444

- S-förmiges MetallprofilS-shaped metal profile

- 4545

- U-ProfilU-profile

- 4646

- TreibriegelführungShoot bolt guide

- 4848

- Schlosstaschemortice

- 5050

- BandbefestigungseinrichtungBelt attachment means

- 5252

- türblattseitiger BandlappenDoor leaf side hinge flap

- 5353

- Gewindemuffethreaded socket

- 5454

- BandaufnahmetascheBand receiving pocket

- 5555

- zargenseitiger Bandlappenframe-side hinge flap

- 5656

- Senkkopfschraubencountersunk

- 101101

- GlasrahmentürGlass frame door

- 102102

- GlasrahmentürGlass frame door

- 103103

- GlasrahmentürGlass frame door

- 104104

- GlasrahmentürGlass frame door

Claims (29)

- Framed glass door leaf (7) for a fire door (1-4, 101-104), having a door leaf frame (8,9) made of frame capping beams (14-17) based on wooden material and having a glass panel (20, 21) accommodated in the door leaf frame (8, 9), wherein door hinges (18) are to be arranged on the door leaf frame (8, 9) for directing the weight of the door leaf (7) into a door box (10), wherein the frame capping beams (14-17) are each firmly bonded to the glass panel edge and wherein the glass panel (20, 21) is composed of a plurality of individual panels (22) being firmly secured to each other by spacers and/or having different thicknesses and/or being hardened and/or being composed of single-panel safety glass or multi-panel safety glass,

characterized in that,

the frame capping beams (14-17) and the glass panel (20, 21) are fastened in such a way that the glass panel (20, 21) serves as a carrying element and wherein a hollow space between the individual panels is filled with fire-protection gel. - Framed glass door leaf according to claim 1,

characterized in that,

the bonding is present throughout the entire length of the glass panel edge. - Framed glass door leaf according to one of the preceding claims,

characterized in that,

the bonding is additionally carried out on the boundary area of the wide sides of the glass panel (20, 21) which are overlapped by the frame capping beams (14-17) and/or by a glass strip (34) of the same. - Framed glass door leaf according to one of the preceding claims,

characterized in that,

all or some or at least one of the frame capping beams (14-17) comprise an L-shaped profile having a web (26) and a bar (27) protruding therefrom. - Framed glass door leaf according to claim 4,

characterized in that,

a glass strip (34) is arranged on the side of the L-shaped profile which is opposed to the bar (27). - Framed glass door leaf according to claim 5,

characterized in that,

the glass strip (34) is fitted to the bat (27) with regard to shape and size, such that the frame capping beam (14, 17) provided with the glass strip (34) has a U-profile shape overall. - Framed glass door leaf according to any one of the claims 4 to 6,

characterized in that,

a hinge band (52) of a door hinge (18) being arranged on the side of the door leaf is secured to the web of a vertical frame capping beam (14) on its side which is distant from the glass panel (20) by means of a hinge fastening device (50). - Framed glass door leaf according to any one of the claims 1 to 6,

characterized in that,

a hinge band (52) of a door hinge (18) being arranged on the side of the door leaf is secured to the side of a vertical frame capping beam (14) which is distant from the glass panel (20) by means of a hinge fastening device (50). - Framed glass door leaf according to one of the preceding claims 7 or 8,

characterized in that,

the hinge band (52) being arranged on the side of the door leaf is accommodated in flush with the side remote from the glass panel (20). - Framed glass door leaf according to any one of the preceding claims 7 to 9,

characterized in that,

the hinge fastening device (50) comprises at least one threaded sleeve (53) that is tucked in a locking fashion from a side of the frame capping beam (14) facing the glass panel (20) into an opening in a pinching fashion, and at least one screw, preferably a counter-sunk screw (56), that is screwed in from the side distant of the glass panel (20) into the threaded sleeve (53) for securing the door hinge (18). - Framed glass door leaf according to one of the preceding claims,

characterized in that,

two lateral vertical frame capping beams (14, 15) and one upper horizontal frame capping beam (16) are provided and that no frame capping beam is present on the lower side of the framed glass door leaf. - Framed glass door leaf according to any one of the claims 1 to 10,

characterized in that,

the door leaf frame (8) comprises a total of four frame capping beams (14-17) that frame the window panel (20) from all sides. - Framed glass door leaf according to any one of the preceding claims,

characterized in that,

the door leaf frame (8) is shaped and coupled to the glass panel (20) such that a maximum bending stress of 30 N/mm2 for the glass panel, preferably 18 N/mm2, further preferably 10 N/mm2 is not surpassed when the entire structure is laterally buckled due to a load applied in use. - Framed glass door leaf according to one of the claims 7 or 8,

characterized in that,

the door leaf frame (8) is shaped and secured to the glass panel (20) such that approximately ½ to ¼ of the maximally allowed tensile strength of the employed glass panel is not surpassed when the entire structure is laterally buckled under the application of forces occurring during fire tests. - Framed glass door leaf according to any one of the preceding claims,

characterized in that,

a reinforcement bead (38, 40) made of non-wooden material, which is more rigid compared to wooden material, preferably made of a fire resistant material such as metal is provided between the glass panel (20) and a frame capping beam (14-17). - Framed glass door leaf according to claim 15,

characterized in that,

a profiled metal rail (38) is attached to the side of the frame capping beam (14-17) facing the window panel (20) for reinforcing. - Framed glass door leaf according to claim 15 or 16,

characterized in that,

a metal rail (40) framing the edge of the window panel (20) is provided. - Framed glass door leaf according to any one of the preceding claims,

characterized in that,

a fire-protective concealed edge band (30) having a strip (31) of material which is foaming in the case of a fire and a coating (32) adapted to the frame capping beam with regard to appearance, is secured to the side of the frame capping beam (14-17) distant from the glass panel (20). - Framed glass door leaf according to any one of the preceding claims,

characterized in that,

the frame capping beams (14-17) are made of solid wood, laminated wood and/or finger-jointed wood. - Framed glass door leaf according to any one of the preceding claims,

characterized in that,

each of the frame capping beams (14-17) viewed from a broad visible face have a total width of at most 50 to 40 mm. - Framed glass door (1-4) having a door box (10) and at least one framed glass door leaf (7) according to any one of the preceding claims.

- Framed glass door according to claim 21,

characterized in that,

the door box (10) entirely covers at least one of the frame capping beams (14-17) on the side of the opposing hinge in a closed state of the door (1-4). - Framed glass door according to claim 21 or 22,

characterized in that,

the door box (10) has door box posts (11-13) based on wooden material. - Framed glass door according to claim 23,

characterized in that,

the door box posts (11-13) are made of solid wood, laminated wood and/or finger-jointed wood. - Framed glass door according to any one of the claims 21 to 24,

characterized in that,

the door box (10) comprises at least one door box post (11-13) having an L-profile shape and comprising a web (24) and a bar (25). - Framed glass door according to claim 25,

characterized in that,

the bar (25) of the door box post (11-13) covers the directly neighbouring frame capping beam (14-17) of the framed glass door leaf (7). - Framed glass door according to any one of the claims 25 to 26,

characterized in that,

a hinge accommodation pocket (54) configured to fixedly accommodate the hinge band (55) of a door hinge (18) being arranged on the door box side is provided on the bar-free end of the door box posts web (24) on the fire-side. - Framed glass door according to any one of the claims 21 to 27,

characterized in that,

a fire-protective concealed edge band (30) having a strip (31) of material which is foaming in the case of a fire and a coating (32) adapted to the frame capping beam with regard to appearance, is secured to the side of a door box post (11-13) which is facing the framed glass door leaf (7). - Method of manufacturing a framed glass door leaf or rather a framed glass door according to one of the preceding claims,

characterized in that,

the maximum pending stress of the glass panel is determined under normal conditions in a bend test by bending an assembled testing door leaf, and such a small thickness of the door leaf frame is chosen in such a way that bending stresses of 8 to 30 N/mm2 are reached during the bend test.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004055214 | 2004-11-16 | ||

| DE102004057218A DE102004057218B4 (en) | 2004-11-16 | 2004-11-26 | Glass frame door leaf and glass frame door provided therewith |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1657397A2 EP1657397A2 (en) | 2006-05-17 |

| EP1657397A3 EP1657397A3 (en) | 2007-01-24 |

| EP1657397B1 true EP1657397B1 (en) | 2011-06-01 |

Family

ID=35788058

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05025074A Not-in-force EP1657397B1 (en) | 2004-11-16 | 2005-11-16 | Glazed doorleaf and glazed door with such a doorleaf |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1657397B1 (en) |

| AT (1) | ATE511590T1 (en) |

| DE (1) | DE102004057218B4 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2922583A1 (en) * | 2007-10-19 | 2009-04-24 | Sarl Portes Ellipse Sarl | DOOR BLOCK COMPRISING FIREFIGHTING MEANS |

| CN102561900B (en) * | 2012-01-15 | 2013-12-25 | 深圳市方大自动化系统有限公司 | Shielding door with glass capable of being rapidly replaced |

| EP3173567B1 (en) | 2012-10-25 | 2018-05-09 | Carminati Serramenti S.r.l. | Door, window or french window assembly |

| GB2546328B (en) * | 2016-01-18 | 2018-09-12 | Newmor Group Ltd | Door frame assembly |

| DE202018105092U1 (en) * | 2018-06-08 | 2019-09-10 | Holzbau Schmid Gmbh & Co. Kg | Door frame or door |

| RU210523U1 (en) * | 2022-02-01 | 2022-04-19 | Общество с ограниченной ответственностью "СКС-Штакузит" | PLUG FOR GLASS CLAMP |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE726588A (en) * | 1968-01-09 | 1969-06-16 | ||

| DE3625367A1 (en) * | 1986-07-26 | 1988-02-04 | Schuermann & Co Heinz | FIRE RESISTANT GLAZING FOR WINDOWS, DOORS AND WALLS |

| FR2719334B1 (en) * | 1994-04-28 | 1996-06-07 | Saint Gobain Vitrage | Building glass door. |

| DE19615902A1 (en) * | 1996-04-22 | 1997-10-23 | Promat Gmbh | Glass door for fire protection purposes |

| EP0900906A1 (en) * | 1997-09-09 | 1999-03-10 | Emmerich Hohl | Dividing element such as a door or the like |

| EP1209314B1 (en) * | 2000-11-23 | 2004-06-09 | Schörghuber Spezialtüren GmbH & Co. Betriebs-KG | Wooden fireproof T90-door with glazing panels |

| ITPD20030033U1 (en) * | 2003-04-15 | 2004-10-16 | Panto Spa | FRAME STRUCTURE FOR FRAMES, WINDOWS AND SIMILAR, AND PROCEDURE FOR THE CREATION OF FRAME STRUCTURES FOR FRAMES, WINDOWS AND SIMILAR |

| DE202004012651U1 (en) * | 2004-08-12 | 2004-10-07 | Holzbau Schmid Gmbh & Co. Kg | Flat fireproof finish |

-

2004

- 2004-11-26 DE DE102004057218A patent/DE102004057218B4/en not_active Expired - Fee Related

-

2005

- 2005-11-16 EP EP05025074A patent/EP1657397B1/en not_active Not-in-force

- 2005-11-16 AT AT05025074T patent/ATE511590T1/en active

Also Published As

| Publication number | Publication date |

|---|---|

| DE102004057218B4 (en) | 2012-04-05 |

| ATE511590T1 (en) | 2011-06-15 |

| EP1657397A3 (en) | 2007-01-24 |

| EP1657397A2 (en) | 2006-05-17 |

| DE102004057218A1 (en) | 2006-05-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1657397B1 (en) | Glazed doorleaf and glazed door with such a doorleaf | |

| DE19933406A1 (en) | Fire door with a comprehensive door frame | |

| EP2581515A1 (en) | Fireproof frameless glas partition with door | |

| EP2581538A1 (en) | Profile-free flame-retardant glazing with pivoting door | |

| EP0803634B1 (en) | Glazed fire door | |

| EP3216966A1 (en) | Device for closing an opening for fire protection purposes | |

| EP2657012B1 (en) | Frame-free fire protection all-glass door | |

| EP2803807A1 (en) | Door | |

| DE19633001B4 (en) | Burglar-proof window | |

| EP1863999A2 (en) | Leaf for a door or window | |

| DE3604433C1 (en) | Door leaf or window sash and frame configured in a bulletproof manner | |

| EP2581534A1 (en) | Clamp holder | |

| CH674541A5 (en) | ||

| DE19615518C2 (en) | French casement window | |

| EP3974612A1 (en) | Burglar-inhibiting assembly | |

| EP0828913B1 (en) | Burglar-proof system | |

| DE19929664A1 (en) | Frame strut especially middle strut has wooden core with reinforcement strip, and glass pane | |

| CH697255B1 (en) | Door, in particular doorstep. | |

| DE20304020U1 (en) | Panel-shaped closing element for a building opening | |

| DE19617730C2 (en) | Bullet-resistant window made using solid wood or wood-like material | |

| DE20208152U1 (en) | Rahmenkonkstruktion | |

| EP3741947A1 (en) | Partition wall for forming a fire section in rooms of buildings | |

| EP2845982B1 (en) | Post for a swinging door and fire-resistant glazing with such a post | |

| EP0834640A1 (en) | Panels for doors, balustrades or similar | |

| AT502154B1 (en) | FITTING AND FIXING SYSTEM FOR GLASS ELEMENTS |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| 17P | Request for examination filed |

Effective date: 20070720 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070912 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BRAUNPAT BRAUN EDER AG |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502005011451 Country of ref document: DE Effective date: 20110714 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20110601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110601 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110601 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110601 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110902 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110601 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110912 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110601 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |