EP1592763B2 - Washing product containing bleaching agents and a cellulose derivative which acts on cotton and has a dirt removing capacity - Google Patents

Washing product containing bleaching agents and a cellulose derivative which acts on cotton and has a dirt removing capacity Download PDFInfo

- Publication number

- EP1592763B2 EP1592763B2 EP04707138A EP04707138A EP1592763B2 EP 1592763 B2 EP1592763 B2 EP 1592763B2 EP 04707138 A EP04707138 A EP 04707138A EP 04707138 A EP04707138 A EP 04707138A EP 1592763 B2 EP1592763 B2 EP 1592763B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cellulose

- cellulose derivative

- weight

- acid

- agent

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 229920002678 cellulose Polymers 0.000 title claims abstract description 77

- 239000001913 cellulose Substances 0.000 title claims abstract description 77

- 239000007844 bleaching agent Substances 0.000 title claims abstract description 46

- 229920000742 Cotton Polymers 0.000 title claims abstract description 21

- 238000005406 washing Methods 0.000 title claims description 34

- 239000002689 soil Substances 0.000 claims abstract description 43

- 125000000217 alkyl group Chemical group 0.000 claims abstract description 25

- 239000000178 monomer Substances 0.000 claims abstract description 21

- 239000004753 textile Substances 0.000 claims abstract description 21

- 125000002768 hydroxyalkyl group Chemical group 0.000 claims abstract description 10

- 239000003795 chemical substances by application Substances 0.000 claims description 57

- 229920000642 polymer Polymers 0.000 claims description 27

- 238000000034 method Methods 0.000 claims description 26

- 150000002009 diols Chemical class 0.000 claims description 16

- 150000003839 salts Chemical class 0.000 claims description 11

- OFOBLEOULBTSOW-UHFFFAOYSA-N Malonic acid Chemical compound OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 claims description 10

- 239000012190 activator Substances 0.000 claims description 9

- 239000003945 anionic surfactant Substances 0.000 claims description 9

- 239000002736 nonionic surfactant Substances 0.000 claims description 8

- 238000004140 cleaning Methods 0.000 claims description 6

- 230000002708 enhancing effect Effects 0.000 claims description 6

- 230000029936 alkylation Effects 0.000 claims description 4

- 238000005804 alkylation reaction Methods 0.000 claims description 4

- 230000002152 alkylating effect Effects 0.000 claims 5

- 239000003599 detergent Substances 0.000 abstract description 54

- 239000000463 material Substances 0.000 abstract description 6

- -1 hydroxyalkyl ethers Chemical class 0.000 description 42

- 239000000203 mixture Substances 0.000 description 34

- 125000004432 carbon atom Chemical group C* 0.000 description 27

- 235000014113 dietary fatty acids Nutrition 0.000 description 23

- 239000000194 fatty acid Substances 0.000 description 23

- 229930195729 fatty acid Natural products 0.000 description 23

- LYCAIKOWRPUZTN-UHFFFAOYSA-N ethylene glycol Natural products OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 18

- 229920000728 polyester Polymers 0.000 description 18

- 239000002253 acid Substances 0.000 description 16

- 150000004665 fatty acids Chemical class 0.000 description 15

- 239000004744 fabric Substances 0.000 description 13

- 229910052910 alkali metal silicate Inorganic materials 0.000 description 12

- 239000003925 fat Substances 0.000 description 12

- 235000019197 fats Nutrition 0.000 description 12

- 239000000344 soap Substances 0.000 description 12

- 239000000126 substance Substances 0.000 description 12

- 239000007788 liquid Substances 0.000 description 11

- 230000008569 process Effects 0.000 description 11

- 229920003171 Poly (ethylene oxide) Polymers 0.000 description 10

- 150000007513 acids Chemical class 0.000 description 10

- 150000001875 compounds Chemical class 0.000 description 10

- 239000000428 dust Substances 0.000 description 10

- KKEYFWRCBNTPAC-UHFFFAOYSA-L terephthalate(2-) Chemical compound [O-]C(=O)C1=CC=C(C([O-])=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-L 0.000 description 10

- 229910052783 alkali metal Inorganic materials 0.000 description 9

- 229920001577 copolymer Polymers 0.000 description 9

- 239000004615 ingredient Substances 0.000 description 9

- 239000011734 sodium Substances 0.000 description 9

- 239000004094 surface-active agent Substances 0.000 description 9

- LLLVZDVNHNWSDS-UHFFFAOYSA-N 4-methylidene-3,5-dioxabicyclo[5.2.2]undeca-1(9),7,10-triene-2,6-dione Chemical compound C1(C2=CC=C(C(=O)OC(=C)O1)C=C2)=O LLLVZDVNHNWSDS-UHFFFAOYSA-N 0.000 description 8

- 102000004190 Enzymes Human genes 0.000 description 8

- 108090000790 Enzymes Proteins 0.000 description 8

- 102000004882 Lipase Human genes 0.000 description 8

- 108090001060 Lipase Proteins 0.000 description 8

- 239000004367 Lipase Substances 0.000 description 8

- DNIAPMSPPWPWGF-UHFFFAOYSA-N Propylene glycol Chemical compound CC(O)CO DNIAPMSPPWPWGF-UHFFFAOYSA-N 0.000 description 8

- 150000008051 alkyl sulfates Chemical class 0.000 description 8

- 229940088598 enzyme Drugs 0.000 description 8

- 239000003112 inhibitor Substances 0.000 description 8

- 235000019421 lipase Nutrition 0.000 description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 8

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 7

- IMROMDMJAWUWLK-UHFFFAOYSA-N Ethenol Chemical compound OC=C IMROMDMJAWUWLK-UHFFFAOYSA-N 0.000 description 7

- 239000002202 Polyethylene glycol Substances 0.000 description 7

- 150000001298 alcohols Chemical class 0.000 description 7

- 229910000323 aluminium silicate Inorganic materials 0.000 description 7

- 150000001735 carboxylic acids Chemical class 0.000 description 7

- 229910052739 hydrogen Inorganic materials 0.000 description 7

- 239000001257 hydrogen Substances 0.000 description 7

- 229920005646 polycarboxylate Polymers 0.000 description 7

- 229920001223 polyethylene glycol Polymers 0.000 description 7

- KKEYFWRCBNTPAC-UHFFFAOYSA-N Terephthalic acid Chemical group OC(=O)C1=CC=C(C(O)=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-N 0.000 description 6

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 6

- 150000002148 esters Chemical class 0.000 description 6

- 125000003827 glycol group Chemical group 0.000 description 6

- 229940040461 lipase Drugs 0.000 description 6

- 239000000047 product Substances 0.000 description 6

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 description 6

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 5

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 5

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 description 5

- 230000002378 acidificating effect Effects 0.000 description 5

- 239000003513 alkali Substances 0.000 description 5

- 125000002947 alkylene group Chemical group 0.000 description 5

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 5

- 239000006260 foam Substances 0.000 description 5

- PEDCQBHIVMGVHV-UHFFFAOYSA-N glycerol group Chemical group OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 5

- 229930182470 glycoside Natural products 0.000 description 5

- IPCSVZSSVZVIGE-UHFFFAOYSA-N hexadecanoic acid Chemical compound CCCCCCCCCCCCCCCC(O)=O IPCSVZSSVZVIGE-UHFFFAOYSA-N 0.000 description 5

- 229920013821 hydroxy alkyl cellulose Polymers 0.000 description 5

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 description 5

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 description 5

- 238000002360 preparation method Methods 0.000 description 5

- 150000004760 silicates Chemical class 0.000 description 5

- 229910052708 sodium Inorganic materials 0.000 description 5

- 229920001897 terpolymer Polymers 0.000 description 5

- 229920001634 Copolyester Polymers 0.000 description 4

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical group C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 4

- 229920001479 Hydroxyethyl methyl cellulose Polymers 0.000 description 4

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 4

- ZQPPMHVWECSIRJ-UHFFFAOYSA-N Oleic acid Natural products CCCCCCCCC=CCCCCCCCC(O)=O ZQPPMHVWECSIRJ-UHFFFAOYSA-N 0.000 description 4

- 108091005804 Peptidases Proteins 0.000 description 4

- 239000004365 Protease Substances 0.000 description 4

- 239000004115 Sodium Silicate Substances 0.000 description 4

- BGRWYDHXPHLNKA-UHFFFAOYSA-N Tetraacetylethylenediamine Chemical compound CC(=O)N(C(C)=O)CCN(C(C)=O)C(C)=O BGRWYDHXPHLNKA-UHFFFAOYSA-N 0.000 description 4

- 229910021536 Zeolite Inorganic materials 0.000 description 4

- 239000013543 active substance Substances 0.000 description 4

- WNLRTRBMVRJNCN-UHFFFAOYSA-N adipic acid Chemical compound OC(=O)CCCCC(O)=O WNLRTRBMVRJNCN-UHFFFAOYSA-N 0.000 description 4

- 150000001720 carbohydrates Chemical class 0.000 description 4

- 235000014633 carbohydrates Nutrition 0.000 description 4

- 229920003086 cellulose ether Polymers 0.000 description 4

- POULHZVOKOAJMA-UHFFFAOYSA-N dodecanoic acid Chemical class CCCCCCCCCCCC(O)=O POULHZVOKOAJMA-UHFFFAOYSA-N 0.000 description 4

- ZQPPMHVWECSIRJ-MDZDMXLPSA-N elaidic acid Chemical compound CCCCCCCC\C=C\CCCCCCCC(O)=O ZQPPMHVWECSIRJ-MDZDMXLPSA-N 0.000 description 4

- RTZKZFJDLAIYFH-UHFFFAOYSA-N ether Substances CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 4

- 150000002191 fatty alcohols Chemical class 0.000 description 4

- 150000002338 glycosides Chemical class 0.000 description 4

- FUZZWVXGSFPDMH-UHFFFAOYSA-N hexanoic acid Chemical compound CCCCCC(O)=O FUZZWVXGSFPDMH-UHFFFAOYSA-N 0.000 description 4

- QXJSBBXBKPUZAA-UHFFFAOYSA-N isooleic acid Natural products CCCCCCCC=CCCCCCCCCC(O)=O QXJSBBXBKPUZAA-UHFFFAOYSA-N 0.000 description 4

- 239000011976 maleic acid Substances 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- XNGIFLGASWRNHJ-UHFFFAOYSA-N phthalic acid Chemical compound OC(=O)C1=CC=CC=C1C(O)=O XNGIFLGASWRNHJ-UHFFFAOYSA-N 0.000 description 4

- MWNQXXOSWHCCOZ-UHFFFAOYSA-L sodium;oxido carbonate Chemical compound [Na+].[O-]OC([O-])=O MWNQXXOSWHCCOZ-UHFFFAOYSA-L 0.000 description 4

- 239000002904 solvent Substances 0.000 description 4

- BDHFUVZGWQCTTF-UHFFFAOYSA-M sulfonate Chemical compound [O-]S(=O)=O BDHFUVZGWQCTTF-UHFFFAOYSA-M 0.000 description 4

- AKEJUJNQAAGONA-UHFFFAOYSA-N sulfur trioxide Chemical compound O=S(=O)=O AKEJUJNQAAGONA-UHFFFAOYSA-N 0.000 description 4

- 239000010457 zeolite Substances 0.000 description 4

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 3

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 description 3

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 3

- 102000013142 Amylases Human genes 0.000 description 3

- 108010065511 Amylases Proteins 0.000 description 3

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 3

- 108010059892 Cellulase Proteins 0.000 description 3

- SNRUBQQJIBEYMU-UHFFFAOYSA-N Dodecane Natural products CCCCCCCCCCCC SNRUBQQJIBEYMU-UHFFFAOYSA-N 0.000 description 3

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 3

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 3

- 239000004435 Oxo alcohol Substances 0.000 description 3

- 229910019142 PO4 Inorganic materials 0.000 description 3

- 102000035195 Peptidases Human genes 0.000 description 3

- 229910004298 SiO 2 Inorganic materials 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 3

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 description 3

- QAOWNCQODCNURD-UHFFFAOYSA-L Sulfate Chemical compound [O-]S([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 description 3

- GSEJCLTVZPLZKY-UHFFFAOYSA-N Triethanolamine Chemical compound OCCN(CCO)CCO GSEJCLTVZPLZKY-UHFFFAOYSA-N 0.000 description 3

- 239000008186 active pharmaceutical agent Substances 0.000 description 3

- 150000001340 alkali metals Chemical class 0.000 description 3

- 125000003342 alkenyl group Chemical group 0.000 description 3

- 235000019418 amylase Nutrition 0.000 description 3

- 150000001450 anions Chemical class 0.000 description 3

- 239000007864 aqueous solution Substances 0.000 description 3

- BVKZGUZCCUSVTD-UHFFFAOYSA-N carbonic acid Chemical class OC(O)=O BVKZGUZCCUSVTD-UHFFFAOYSA-N 0.000 description 3

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 3

- 229940106157 cellulase Drugs 0.000 description 3

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 description 3

- 239000008139 complexing agent Substances 0.000 description 3

- UKMSUNONTOPOIO-UHFFFAOYSA-N docosanoic acid Chemical compound CCCCCCCCCCCCCCCCCCCCCC(O)=O UKMSUNONTOPOIO-UHFFFAOYSA-N 0.000 description 3

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 3

- 230000032050 esterification Effects 0.000 description 3

- 238000005886 esterification reaction Methods 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 150000004820 halides Chemical class 0.000 description 3

- 229910001385 heavy metal Inorganic materials 0.000 description 3

- 229920000609 methyl cellulose Polymers 0.000 description 3

- 239000001923 methylcellulose Substances 0.000 description 3

- 235000010981 methylcellulose Nutrition 0.000 description 3

- 125000001421 myristyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 3

- WWZKQHOCKIZLMA-UHFFFAOYSA-N octanoic acid Chemical compound CCCCCCCC(O)=O WWZKQHOCKIZLMA-UHFFFAOYSA-N 0.000 description 3

- 238000006384 oligomerization reaction Methods 0.000 description 3

- 230000003287 optical effect Effects 0.000 description 3

- 239000010452 phosphate Substances 0.000 description 3

- 238000006116 polymerization reaction Methods 0.000 description 3

- 235000019351 sodium silicates Nutrition 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000000243 solution Substances 0.000 description 3

- 239000003381 stabilizer Substances 0.000 description 3

- 235000000346 sugar Nutrition 0.000 description 3

- 239000003760 tallow Substances 0.000 description 3

- WRIDQFICGBMAFQ-UHFFFAOYSA-N (E)-8-Octadecenoic acid Natural products CCCCCCCCCC=CCCCCCCC(O)=O WRIDQFICGBMAFQ-UHFFFAOYSA-N 0.000 description 2

- XDOFQFKRPWOURC-UHFFFAOYSA-N 16-methylheptadecanoic acid Chemical compound CC(C)CCCCCCCCCCCCCCC(O)=O XDOFQFKRPWOURC-UHFFFAOYSA-N 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 2

- LQJBNNIYVWPHFW-UHFFFAOYSA-N 20:1omega9c fatty acid Natural products CCCCCCCCCCC=CCCCCCCCC(O)=O LQJBNNIYVWPHFW-UHFFFAOYSA-N 0.000 description 2

- FJKROLUGYXJWQN-UHFFFAOYSA-N 4-hydroxybenzoic acid Chemical compound OC(=O)C1=CC=C(O)C=C1 FJKROLUGYXJWQN-UHFFFAOYSA-N 0.000 description 2

- QSBYPNXLFMSGKH-UHFFFAOYSA-N 9-Heptadecensaeure Natural products CCCCCCCC=CCCCCCCCC(O)=O QSBYPNXLFMSGKH-UHFFFAOYSA-N 0.000 description 2

- 239000004382 Amylase Substances 0.000 description 2

- 241000894006 Bacteria Species 0.000 description 2

- DPUOLQHDNGRHBS-UHFFFAOYSA-N Brassidinsaeure Natural products CCCCCCCCC=CCCCCCCCCCCCC(O)=O DPUOLQHDNGRHBS-UHFFFAOYSA-N 0.000 description 2

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 2

- 235000013162 Cocos nucifera Nutrition 0.000 description 2

- 244000060011 Cocos nucifera Species 0.000 description 2

- SRBFZHDQGSBBOR-IOVATXLUSA-N D-xylopyranose Chemical compound O[C@@H]1COC(O)[C@H](O)[C@H]1O SRBFZHDQGSBBOR-IOVATXLUSA-N 0.000 description 2

- 239000005977 Ethylene Substances 0.000 description 2

- VZCYOOQTPOCHFL-OWOJBTEDSA-N Fumaric acid Chemical compound OC(=O)\C=C\C(O)=O VZCYOOQTPOCHFL-OWOJBTEDSA-N 0.000 description 2

- 241000233866 Fungi Species 0.000 description 2

- WQZGKKKJIJFFOK-GASJEMHNSA-N Glucose Natural products OC[C@H]1OC(O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-GASJEMHNSA-N 0.000 description 2

- MHAJPDPJQMAIIY-UHFFFAOYSA-N Hydrogen peroxide Chemical compound OO MHAJPDPJQMAIIY-UHFFFAOYSA-N 0.000 description 2

- 229920002153 Hydroxypropyl cellulose Polymers 0.000 description 2

- 239000005639 Lauric acid Substances 0.000 description 2

- 239000005642 Oleic acid Substances 0.000 description 2

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 2

- 235000019482 Palm oil Nutrition 0.000 description 2

- 235000021314 Palmitic acid Nutrition 0.000 description 2

- GOOHAUXETOMSMM-UHFFFAOYSA-N Propylene oxide Chemical compound CC1CO1 GOOHAUXETOMSMM-UHFFFAOYSA-N 0.000 description 2

- YGSDEFSMJLZEOE-UHFFFAOYSA-N Salicylic acid Natural products OC(=O)C1=CC=CC=C1O YGSDEFSMJLZEOE-UHFFFAOYSA-N 0.000 description 2

- 229920002125 Sokalan® Polymers 0.000 description 2

- 235000021355 Stearic acid Nutrition 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- 108010056079 Subtilisins Proteins 0.000 description 2

- 102000005158 Subtilisins Human genes 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 239000004480 active ingredient Substances 0.000 description 2

- 239000001361 adipic acid Substances 0.000 description 2

- 235000011037 adipic acid Nutrition 0.000 description 2

- 230000001476 alcoholic effect Effects 0.000 description 2

- 150000003973 alkyl amines Chemical class 0.000 description 2

- 229920013820 alkyl cellulose Polymers 0.000 description 2

- 150000003863 ammonium salts Chemical class 0.000 description 2

- PYMYPHUHKUWMLA-UHFFFAOYSA-N arabinose Natural products OCC(O)C(O)C(O)C=O PYMYPHUHKUWMLA-UHFFFAOYSA-N 0.000 description 2

- 125000003118 aryl group Chemical group 0.000 description 2

- WPYMKLBDIGXBTP-UHFFFAOYSA-N benzoic acid Chemical compound OC(=O)C1=CC=CC=C1 WPYMKLBDIGXBTP-UHFFFAOYSA-N 0.000 description 2

- SRBFZHDQGSBBOR-UHFFFAOYSA-N beta-D-Pyranose-Lyxose Natural products OC1COC(O)C(O)C1O SRBFZHDQGSBBOR-UHFFFAOYSA-N 0.000 description 2

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical compound OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 description 2

- 150000001642 boronic acid derivatives Chemical class 0.000 description 2

- WERYXYBDKMZEQL-UHFFFAOYSA-N butane-1,4-diol Chemical compound OCCCCO WERYXYBDKMZEQL-UHFFFAOYSA-N 0.000 description 2

- 239000001768 carboxy methyl cellulose Substances 0.000 description 2

- 235000010948 carboxy methyl cellulose Nutrition 0.000 description 2

- 239000008112 carboxymethyl-cellulose Substances 0.000 description 2

- 239000003093 cationic surfactant Substances 0.000 description 2

- 239000000470 constituent Substances 0.000 description 2

- GHVNFZFCNZKVNT-UHFFFAOYSA-N decanoic acid Chemical compound CCCCCCCCCC(O)=O GHVNFZFCNZKVNT-UHFFFAOYSA-N 0.000 description 2

- 125000001142 dicarboxylic acid group Chemical group 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000008103 glucose Substances 0.000 description 2

- 150000004676 glycans Chemical class 0.000 description 2

- MNWFXJYAOYHMED-UHFFFAOYSA-N heptanoic acid Chemical compound CCCCCCC(O)=O MNWFXJYAOYHMED-UHFFFAOYSA-N 0.000 description 2

- XMHIUKTWLZUKEX-UHFFFAOYSA-N hexacosanoic acid Chemical compound CCCCCCCCCCCCCCCCCCCCCCCCCC(O)=O XMHIUKTWLZUKEX-UHFFFAOYSA-N 0.000 description 2

- 150000002431 hydrogen Chemical class 0.000 description 2

- 239000001863 hydroxypropyl cellulose Substances 0.000 description 2

- 235000010977 hydroxypropyl cellulose Nutrition 0.000 description 2

- VKOBVWXKNCXXDE-UHFFFAOYSA-N icosanoic acid Chemical compound CCCCCCCCCCCCCCCCCCCC(O)=O VKOBVWXKNCXXDE-UHFFFAOYSA-N 0.000 description 2

- IQPQWNKOIGAROB-UHFFFAOYSA-N isocyanate group Chemical group [N-]=C=O IQPQWNKOIGAROB-UHFFFAOYSA-N 0.000 description 2

- QQVIHTHCMHWDBS-UHFFFAOYSA-N isophthalic acid Chemical compound OC(=O)C1=CC=CC(C(O)=O)=C1 QQVIHTHCMHWDBS-UHFFFAOYSA-N 0.000 description 2

- YDSWCNNOKPMOTP-UHFFFAOYSA-N mellitic acid Chemical compound OC(=O)C1=C(C(O)=O)C(C(O)=O)=C(C(O)=O)C(C(O)=O)=C1C(O)=O YDSWCNNOKPMOTP-UHFFFAOYSA-N 0.000 description 2

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 2

- 244000005700 microbiome Species 0.000 description 2

- WQEPLUUGTLDZJY-UHFFFAOYSA-N n-Pentadecanoic acid Natural products CCCCCCCCCCCCCCC(O)=O WQEPLUUGTLDZJY-UHFFFAOYSA-N 0.000 description 2

- 238000006386 neutralization reaction Methods 0.000 description 2

- BDJRBEYXGGNYIS-UHFFFAOYSA-N nonanedioic acid Chemical compound OC(=O)CCCCCCCC(O)=O BDJRBEYXGGNYIS-UHFFFAOYSA-N 0.000 description 2

- QIQXTHQIDYTFRH-UHFFFAOYSA-N octadecanoic acid Chemical compound CCCCCCCCCCCCCCCCCC(O)=O QIQXTHQIDYTFRH-UHFFFAOYSA-N 0.000 description 2

- OQCDKBAXFALNLD-UHFFFAOYSA-N octadecanoic acid Natural products CCCCCCCC(C)CCCCCCCCC(O)=O OQCDKBAXFALNLD-UHFFFAOYSA-N 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 235000019198 oils Nutrition 0.000 description 2

- 150000002482 oligosaccharides Polymers 0.000 description 2

- 125000006353 oxyethylene group Chemical group 0.000 description 2

- 239000002540 palm oil Substances 0.000 description 2

- 125000000913 palmityl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- WLJVNTCWHIRURA-UHFFFAOYSA-N pimelic acid Chemical compound OC(=O)CCCCCC(O)=O WLJVNTCWHIRURA-UHFFFAOYSA-N 0.000 description 2

- 229920001282 polysaccharide Polymers 0.000 description 2

- 239000005017 polysaccharide Substances 0.000 description 2

- 229920001296 polysiloxane Polymers 0.000 description 2

- 150000003138 primary alcohols Chemical class 0.000 description 2

- BDERNNFJNOPAEC-UHFFFAOYSA-N propan-1-ol Chemical compound CCCO BDERNNFJNOPAEC-UHFFFAOYSA-N 0.000 description 2

- YPFDHNVEDLHUCE-UHFFFAOYSA-N propane-1,3-diol Chemical compound OCCCO YPFDHNVEDLHUCE-UHFFFAOYSA-N 0.000 description 2

- 229920006395 saturated elastomer Polymers 0.000 description 2

- CXMXRPHRNRROMY-UHFFFAOYSA-N sebacic acid Chemical compound OC(=O)CCCCCCCCC(O)=O CXMXRPHRNRROMY-UHFFFAOYSA-N 0.000 description 2

- 239000008117 stearic acid Substances 0.000 description 2

- TYFQFVWCELRYAO-UHFFFAOYSA-N suberic acid Chemical compound OC(=O)CCCCCCC(O)=O TYFQFVWCELRYAO-UHFFFAOYSA-N 0.000 description 2

- 125000001424 substituent group Chemical group 0.000 description 2

- 238000006277 sulfonation reaction Methods 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- TUNFSRHWOTWDNC-HKGQFRNVSA-N tetradecanoic acid Chemical class CCCCCCCCCCCCC[14C](O)=O TUNFSRHWOTWDNC-HKGQFRNVSA-N 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- VHOCUJPBKOZGJD-UHFFFAOYSA-N triacontanoic acid Chemical compound CCCCCCCCCCCCCCCCCCCCCCCCCCCCCC(O)=O VHOCUJPBKOZGJD-UHFFFAOYSA-N 0.000 description 2

- ARCGXLSVLAOJQL-UHFFFAOYSA-N trimellitic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C(C(O)=O)=C1 ARCGXLSVLAOJQL-UHFFFAOYSA-N 0.000 description 2

- NQPDZGIKBAWPEJ-UHFFFAOYSA-N valeric acid Chemical compound CCCCC(O)=O NQPDZGIKBAWPEJ-UHFFFAOYSA-N 0.000 description 2

- 125000002030 1,2-phenylene group Chemical group [H]C1=C([H])C([*:1])=C([*:2])C([H])=C1[H] 0.000 description 1

- KEQGZUUPPQEDPF-UHFFFAOYSA-N 1,3-dichloro-5,5-dimethylimidazolidine-2,4-dione Chemical compound CC1(C)N(Cl)C(=O)N(Cl)C1=O KEQGZUUPPQEDPF-UHFFFAOYSA-N 0.000 description 1

- 125000001989 1,3-phenylene group Chemical group [H]C1=C([H])C([*:1])=C([H])C([*:2])=C1[H] 0.000 description 1

- LYPVKWMHGFMDPD-UHFFFAOYSA-N 1,5-diacetyl-1,3,5-triazinane-2,4-dione Chemical compound CC(=O)N1CN(C(C)=O)C(=O)NC1=O LYPVKWMHGFMDPD-UHFFFAOYSA-N 0.000 description 1

- OSSNTDFYBPYIEC-UHFFFAOYSA-N 1-ethenylimidazole Chemical compound C=CN1C=CN=C1 OSSNTDFYBPYIEC-UHFFFAOYSA-N 0.000 description 1

- RTBFRGCFXZNCOE-UHFFFAOYSA-N 1-methylsulfonylpiperidin-4-one Chemical compound CS(=O)(=O)N1CCC(=O)CC1 RTBFRGCFXZNCOE-UHFFFAOYSA-N 0.000 description 1

- ULQISTXYYBZJSJ-UHFFFAOYSA-N 12-hydroxyoctadecanoic acid Chemical compound CCCCCCC(O)CCCCCCCCCCC(O)=O ULQISTXYYBZJSJ-UHFFFAOYSA-N 0.000 description 1

- VOXZDWNPVJITMN-ZBRFXRBCSA-N 17β-estradiol Chemical compound OC1=CC=C2[C@H]3CC[C@](C)([C@H](CC4)O)[C@@H]4[C@@H]3CCC2=C1 VOXZDWNPVJITMN-ZBRFXRBCSA-N 0.000 description 1

- RPZANUYHRMRTTE-UHFFFAOYSA-N 2,3,4-trimethoxy-6-(methoxymethyl)-5-[3,4,5-trimethoxy-6-(methoxymethyl)oxan-2-yl]oxyoxane;1-[[3,4,5-tris(2-hydroxybutoxy)-6-[4,5,6-tris(2-hydroxybutoxy)-2-(2-hydroxybutoxymethyl)oxan-3-yl]oxyoxan-2-yl]methoxy]butan-2-ol Chemical compound COC1C(OC)C(OC)C(COC)OC1OC1C(OC)C(OC)C(OC)OC1COC.CCC(O)COC1C(OCC(O)CC)C(OCC(O)CC)C(COCC(O)CC)OC1OC1C(OCC(O)CC)C(OCC(O)CC)C(OCC(O)CC)OC1COCC(O)CC RPZANUYHRMRTTE-UHFFFAOYSA-N 0.000 description 1

- HIXDQWDOVZUNNA-UHFFFAOYSA-N 2-(3,4-dimethoxyphenyl)-5-hydroxy-7-methoxychromen-4-one Chemical compound C=1C(OC)=CC(O)=C(C(C=2)=O)C=1OC=2C1=CC=C(OC)C(OC)=C1 HIXDQWDOVZUNNA-UHFFFAOYSA-N 0.000 description 1

- KIHBGTRZFAVZRV-UHFFFAOYSA-N 2-Hydroxyoctadecanoic acid Natural products CCCCCCCCCCCCCCCCC(O)C(O)=O KIHBGTRZFAVZRV-UHFFFAOYSA-N 0.000 description 1

- CMWPDPGTNAHDDB-UHFFFAOYSA-N 2-[2-[2-sulfo-4-(2,4,6-triamino-2h-1,3,5-triazin-1-yl)phenyl]ethenyl]-5-(2,4,6-triamino-2h-1,3,5-triazin-1-yl)benzenesulfonic acid Chemical class NC1N=C(N)N=C(N)N1C(C=C1S(O)(=O)=O)=CC=C1C=CC1=CC=C(N2C(=NC(N)=NC2N)N)C=C1S(O)(=O)=O CMWPDPGTNAHDDB-UHFFFAOYSA-N 0.000 description 1

- DNUYOWCKBJFOGS-UHFFFAOYSA-N 2-[[10-(2,2-dicarboxyethyl)anthracen-9-yl]methyl]propanedioic acid Chemical compound C1=CC=C2C(CC(C(=O)O)C(O)=O)=C(C=CC=C3)C3=C(CC(C(O)=O)C(O)=O)C2=C1 DNUYOWCKBJFOGS-UHFFFAOYSA-N 0.000 description 1

- NYHNVHGFPZAZGA-UHFFFAOYSA-N 2-hydroxyhexanoic acid Chemical compound CCCCC(O)C(O)=O NYHNVHGFPZAZGA-UHFFFAOYSA-N 0.000 description 1

- JRHWHSJDIILJAT-UHFFFAOYSA-N 2-hydroxypentanoic acid Chemical compound CCCC(O)C(O)=O JRHWHSJDIILJAT-UHFFFAOYSA-N 0.000 description 1

- XEEYSDHEOQHCDA-UHFFFAOYSA-N 2-methylprop-2-ene-1-sulfonic acid Chemical compound CC(=C)CS(O)(=O)=O XEEYSDHEOQHCDA-UHFFFAOYSA-N 0.000 description 1

- YZTJKOLMWJNVFH-UHFFFAOYSA-N 2-sulfobenzene-1,3-dicarboxylic acid Chemical class OC(=O)C1=CC=CC(C(O)=O)=C1S(O)(=O)=O YZTJKOLMWJNVFH-UHFFFAOYSA-N 0.000 description 1

- RAADBCJYJHQQBI-UHFFFAOYSA-N 2-sulfoterephthalic acid Chemical class OC(=O)C1=CC=C(C(O)=O)C(S(O)(=O)=O)=C1 RAADBCJYJHQQBI-UHFFFAOYSA-N 0.000 description 1

- ZDFKSZDMHJHQHS-UHFFFAOYSA-N 2-tert-butylbenzoic acid Chemical compound CC(C)(C)C1=CC=CC=C1C(O)=O ZDFKSZDMHJHQHS-UHFFFAOYSA-N 0.000 description 1

- KGIGUEBEKRSTEW-UHFFFAOYSA-N 2-vinylpyridine Chemical compound C=CC1=CC=CC=N1 KGIGUEBEKRSTEW-UHFFFAOYSA-N 0.000 description 1

- ZTGKHKPZSMMHNM-UHFFFAOYSA-N 3-(2-phenylethenyl)benzene-1,2-disulfonic acid Chemical class OS(=O)(=O)C1=CC=CC(C=CC=2C=CC=CC=2)=C1S(O)(=O)=O ZTGKHKPZSMMHNM-UHFFFAOYSA-N 0.000 description 1

- SDGNNLQZAPXALR-UHFFFAOYSA-N 3-sulfophthalic acid Chemical class OC(=O)C1=CC=CC(S(O)(=O)=O)=C1C(O)=O SDGNNLQZAPXALR-UHFFFAOYSA-N 0.000 description 1

- PIFPCDRPHCQLSJ-WYIJOVFWSA-N 4,8,12,15,19-Docosapentaenoic acid Chemical compound CC\C=C\CC\C=C\C\C=C\CC\C=C\CC\C=C\CCC(O)=O PIFPCDRPHCQLSJ-WYIJOVFWSA-N 0.000 description 1

- 229940090248 4-hydroxybenzoic acid Drugs 0.000 description 1

- YGUMVDWOQQJBGA-VAWYXSNFSA-N 5-[(4-anilino-6-morpholin-4-yl-1,3,5-triazin-2-yl)amino]-2-[(e)-2-[4-[(4-anilino-6-morpholin-4-yl-1,3,5-triazin-2-yl)amino]-2-sulfophenyl]ethenyl]benzenesulfonic acid Chemical compound C=1C=C(\C=C\C=2C(=CC(NC=3N=C(N=C(NC=4C=CC=CC=4)N=3)N3CCOCC3)=CC=2)S(O)(=O)=O)C(S(=O)(=O)O)=CC=1NC(N=C(N=1)N2CCOCC2)=NC=1NC1=CC=CC=C1 YGUMVDWOQQJBGA-VAWYXSNFSA-N 0.000 description 1

- SFHBJXIEBWOOFA-UHFFFAOYSA-N 5-methyl-3,6-dioxabicyclo[6.2.2]dodeca-1(10),8,11-triene-2,7-dione Chemical compound O=C1OC(C)COC(=O)C2=CC=C1C=C2 SFHBJXIEBWOOFA-UHFFFAOYSA-N 0.000 description 1

- ZCYVEMRRCGMTRW-UHFFFAOYSA-N 7553-56-2 Chemical compound [I] ZCYVEMRRCGMTRW-UHFFFAOYSA-N 0.000 description 1

- 241000228212 Aspergillus Species 0.000 description 1

- 241000193830 Bacillus <bacterium> Species 0.000 description 1

- 101000740449 Bacillus subtilis (strain 168) Biotin/lipoyl attachment protein Proteins 0.000 description 1

- 235000021357 Behenic acid Nutrition 0.000 description 1

- 239000005711 Benzoic acid Substances 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-M Bicarbonate Chemical compound OC([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-M 0.000 description 1

- 102000005701 Calcium-Binding Proteins Human genes 0.000 description 1

- 108010045403 Calcium-Binding Proteins Proteins 0.000 description 1

- 239000005632 Capric acid (CAS 334-48-5) Substances 0.000 description 1

- 239000005635 Caprylic acid (CAS 124-07-2) Substances 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 description 1

- 108010084185 Cellulases Proteins 0.000 description 1

- 102000005575 Cellulases Human genes 0.000 description 1

- KRKNYBCHXYNGOX-UHFFFAOYSA-K Citrate Chemical compound [O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O KRKNYBCHXYNGOX-UHFFFAOYSA-K 0.000 description 1

- PIFPCDRPHCQLSJ-UHFFFAOYSA-N Clupanodonic acid Natural products CCC=CCCC=CCC=CCCC=CCCC=CCCC(O)=O PIFPCDRPHCQLSJ-UHFFFAOYSA-N 0.000 description 1

- WQZGKKKJIJFFOK-CBPJZXOFSA-N D-Gulose Chemical compound OC[C@H]1OC(O)[C@H](O)[C@H](O)[C@H]1O WQZGKKKJIJFFOK-CBPJZXOFSA-N 0.000 description 1

- WQZGKKKJIJFFOK-WHZQZERISA-N D-aldose Chemical compound OC[C@H]1OC(O)[C@@H](O)[C@@H](O)[C@H]1O WQZGKKKJIJFFOK-WHZQZERISA-N 0.000 description 1

- WQZGKKKJIJFFOK-IVMDWMLBSA-N D-allopyranose Chemical compound OC[C@H]1OC(O)[C@H](O)[C@H](O)[C@@H]1O WQZGKKKJIJFFOK-IVMDWMLBSA-N 0.000 description 1

- WQZGKKKJIJFFOK-QTVWNMPRSA-N D-mannopyranose Chemical compound OC[C@H]1OC(O)[C@@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-QTVWNMPRSA-N 0.000 description 1

- HMFHBZSHGGEWLO-SOOFDHNKSA-N D-ribofuranose Chemical compound OC[C@H]1OC(O)[C@H](O)[C@@H]1O HMFHBZSHGGEWLO-SOOFDHNKSA-N 0.000 description 1

- 108010083608 Durazym Proteins 0.000 description 1

- URXZXNYJPAJJOQ-UHFFFAOYSA-N Erucic acid Natural products CCCCCCC=CCCCCCCCCCCCC(O)=O URXZXNYJPAJJOQ-UHFFFAOYSA-N 0.000 description 1

- 239000001856 Ethyl cellulose Substances 0.000 description 1

- ZZSNKZQZMQGXPY-UHFFFAOYSA-N Ethyl cellulose Chemical compound CCOCC1OC(OC)C(OCC)C(OCC)C1OC1C(O)C(O)C(OC)C(CO)O1 ZZSNKZQZMQGXPY-UHFFFAOYSA-N 0.000 description 1

- 229930091371 Fructose Natural products 0.000 description 1

- 239000005715 Fructose Substances 0.000 description 1

- RFSUNEUAIZKAJO-ARQDHWQXSA-N Fructose Chemical compound OC[C@H]1O[C@](O)(CO)[C@@H](O)[C@@H]1O RFSUNEUAIZKAJO-ARQDHWQXSA-N 0.000 description 1

- 241000223218 Fusarium Species 0.000 description 1

- 229920000663 Hydroxyethyl cellulose Polymers 0.000 description 1

- 239000004354 Hydroxyethyl cellulose Substances 0.000 description 1

- AVXURJPOCDRRFD-UHFFFAOYSA-N Hydroxylamine Chemical compound ON AVXURJPOCDRRFD-UHFFFAOYSA-N 0.000 description 1

- 208000007976 Ketosis Diseases 0.000 description 1

- WQZGKKKJIJFFOK-VSOAQEOCSA-N L-altropyranose Chemical compound OC[C@@H]1OC(O)[C@H](O)[C@@H](O)[C@H]1O WQZGKKKJIJFFOK-VSOAQEOCSA-N 0.000 description 1

- 238000005684 Liebig rearrangement reaction Methods 0.000 description 1

- 235000021353 Lignoceric acid Nutrition 0.000 description 1

- CQXMAMUUWHYSIY-UHFFFAOYSA-N Lignoceric acid Natural products CCCCCCCCCCCCCCCCCCCCCCCC(=O)OCCC1=CC=C(O)C=C1 CQXMAMUUWHYSIY-UHFFFAOYSA-N 0.000 description 1

- 229920003091 Methocel™ Polymers 0.000 description 1

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical class CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 1

- WHNWPMSKXPGLAX-UHFFFAOYSA-N N-Vinyl-2-pyrrolidone Chemical compound C=CN1CCCC1=O WHNWPMSKXPGLAX-UHFFFAOYSA-N 0.000 description 1

- QECVIPBZOPUTRD-UHFFFAOYSA-N N=S(=O)=O Chemical class N=S(=O)=O QECVIPBZOPUTRD-UHFFFAOYSA-N 0.000 description 1

- 108090000854 Oxidoreductases Proteins 0.000 description 1

- 102000004316 Oxidoreductases Human genes 0.000 description 1

- ALQSHHUCVQOPAS-UHFFFAOYSA-N Pentane-1,5-diol Chemical compound OCCCCCO ALQSHHUCVQOPAS-UHFFFAOYSA-N 0.000 description 1

- 102000003992 Peroxidases Human genes 0.000 description 1

- LGRFSURHDFAFJT-UHFFFAOYSA-N Phthalic anhydride Natural products C1=CC=C2C(=O)OC(=O)C2=C1 LGRFSURHDFAFJT-UHFFFAOYSA-N 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 241000589516 Pseudomonas Species 0.000 description 1

- 102100037486 Reverse transcriptase/ribonuclease H Human genes 0.000 description 1

- 241000235527 Rhizopus Species 0.000 description 1

- PYMYPHUHKUWMLA-LMVFSUKVSA-N Ribose Natural products OC[C@@H](O)[C@@H](O)[C@@H](O)C=O PYMYPHUHKUWMLA-LMVFSUKVSA-N 0.000 description 1

- KDYFGRWQOYBRFD-UHFFFAOYSA-N Succinic acid Natural products OC(=O)CCC(O)=O KDYFGRWQOYBRFD-UHFFFAOYSA-N 0.000 description 1

- 229930006000 Sucrose Natural products 0.000 description 1

- CZMRCDWAGMRECN-UGDNZRGBSA-N Sucrose Chemical compound O[C@H]1[C@H](O)[C@@H](CO)O[C@@]1(CO)O[C@@H]1[C@H](O)[C@@H](O)[C@H](O)[C@@H](CO)O1 CZMRCDWAGMRECN-UGDNZRGBSA-N 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- 241000223258 Thermomyces lanuginosus Species 0.000 description 1

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 1

- QYKIQEUNHZKYBP-UHFFFAOYSA-N Vinyl ether Chemical class C=COC=C QYKIQEUNHZKYBP-UHFFFAOYSA-N 0.000 description 1

- UAOKXEHOENRFMP-ZJIFWQFVSA-N [(2r,3r,4s,5r)-2,3,4,5-tetraacetyloxy-6-oxohexyl] acetate Chemical class CC(=O)OC[C@@H](OC(C)=O)[C@@H](OC(C)=O)[C@H](OC(C)=O)[C@@H](OC(C)=O)C=O UAOKXEHOENRFMP-ZJIFWQFVSA-N 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 150000001253 acrylic acids Chemical class 0.000 description 1

- 239000002671 adjuvant Substances 0.000 description 1

- 150000001323 aldoses Chemical class 0.000 description 1

- 229910000288 alkali metal carbonate Inorganic materials 0.000 description 1

- 150000008041 alkali metal carbonates Chemical class 0.000 description 1

- 229910000272 alkali metal oxide Inorganic materials 0.000 description 1

- 229910052936 alkali metal sulfate Inorganic materials 0.000 description 1

- 150000001447 alkali salts Chemical class 0.000 description 1

- 150000005215 alkyl ethers Chemical class 0.000 description 1

- 150000001350 alkyl halides Chemical class 0.000 description 1

- 239000002168 alkylating agent Substances 0.000 description 1

- 229940100198 alkylating agent Drugs 0.000 description 1

- 125000005263 alkylenediamine group Polymers 0.000 description 1

- HMFHBZSHGGEWLO-UHFFFAOYSA-N alpha-D-Furanose-Ribose Natural products OCC1OC(O)C(O)C1O HMFHBZSHGGEWLO-UHFFFAOYSA-N 0.000 description 1

- WQZGKKKJIJFFOK-PHYPRBDBSA-N alpha-D-galactose Chemical compound OC[C@H]1O[C@H](O)[C@H](O)[C@@H](O)[C@H]1O WQZGKKKJIJFFOK-PHYPRBDBSA-N 0.000 description 1

- SRBFZHDQGSBBOR-STGXQOJASA-N alpha-D-lyxopyranose Chemical compound O[C@@H]1CO[C@H](O)[C@@H](O)[C@H]1O SRBFZHDQGSBBOR-STGXQOJASA-N 0.000 description 1

- 150000001414 amino alcohols Chemical class 0.000 description 1

- 229940025131 amylases Drugs 0.000 description 1

- JFCQEDHGNNZCLN-UHFFFAOYSA-N anhydrous glutaric acid Natural products OC(=O)CCCC(O)=O JFCQEDHGNNZCLN-UHFFFAOYSA-N 0.000 description 1

- 229920006321 anionic cellulose Polymers 0.000 description 1

- PYMYPHUHKUWMLA-WDCZJNDASA-N arabinose Chemical compound OC[C@@H](O)[C@@H](O)[C@H](O)C=O PYMYPHUHKUWMLA-WDCZJNDASA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000002585 base Substances 0.000 description 1

- 229940116226 behenic acid Drugs 0.000 description 1

- 150000001555 benzenes Chemical class 0.000 description 1

- 235000010233 benzoic acid Nutrition 0.000 description 1

- WQZGKKKJIJFFOK-VFUOTHLCSA-N beta-D-glucose Chemical compound OC[C@H]1O[C@@H](O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-VFUOTHLCSA-N 0.000 description 1

- 239000004327 boric acid Substances 0.000 description 1

- KDYFGRWQOYBRFD-NUQCWPJISA-N butanedioic acid Chemical compound O[14C](=O)CC[14C](O)=O KDYFGRWQOYBRFD-NUQCWPJISA-N 0.000 description 1

- JHIWVOJDXOSYLW-UHFFFAOYSA-N butyl 2,2-difluorocyclopropane-1-carboxylate Chemical compound CCCCOC(=O)C1CC1(F)F JHIWVOJDXOSYLW-UHFFFAOYSA-N 0.000 description 1

- 159000000007 calcium salts Chemical class 0.000 description 1

- 150000003857 carboxamides Chemical group 0.000 description 1

- 150000001244 carboxylic acid anhydrides Chemical class 0.000 description 1

- 150000001733 carboxylic acid esters Chemical class 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000003153 chemical reaction reagent Substances 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- XTHPWXDJESJLNJ-UHFFFAOYSA-N chlorosulfonic acid Substances OS(Cl)(=O)=O XTHPWXDJESJLNJ-UHFFFAOYSA-N 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 239000002537 cosmetic Substances 0.000 description 1

- 150000007973 cyanuric acids Chemical class 0.000 description 1

- YSRSBDQINUMTIF-UHFFFAOYSA-N decane-1,2-diol Chemical compound CCCCCCCCC(O)CO YSRSBDQINUMTIF-UHFFFAOYSA-N 0.000 description 1

- 125000002704 decyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 150000001991 dicarboxylic acids Chemical class 0.000 description 1

- 150000005690 diesters Chemical class 0.000 description 1

- 125000005442 diisocyanate group Chemical group 0.000 description 1

- VAYGXNSJCAHWJZ-UHFFFAOYSA-N dimethyl sulfate Chemical compound COS(=O)(=O)OC VAYGXNSJCAHWJZ-UHFFFAOYSA-N 0.000 description 1

- VTIIJXUACCWYHX-UHFFFAOYSA-L disodium;carboxylatooxy carbonate Chemical compound [Na+].[Na+].[O-]C(=O)OOC([O-])=O VTIIJXUACCWYHX-UHFFFAOYSA-L 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- ZITKDVFRMRXIJQ-UHFFFAOYSA-N dodecane-1,2-diol Chemical compound CCCCCCCCCCC(O)CO ZITKDVFRMRXIJQ-UHFFFAOYSA-N 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 230000002255 enzymatic effect Effects 0.000 description 1

- DPUOLQHDNGRHBS-KTKRTIGZSA-N erucic acid Chemical compound CCCCCCCC\C=C/CCCCCCCCCCCC(O)=O DPUOLQHDNGRHBS-KTKRTIGZSA-N 0.000 description 1

- 125000004185 ester group Chemical group 0.000 description 1

- 125000001033 ether group Chemical group 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- 238000007046 ethoxylation reaction Methods 0.000 description 1

- FARYTWBWLZAXNK-WAYWQWQTSA-N ethyl (z)-3-(methylamino)but-2-enoate Chemical compound CCOC(=O)\C=C(\C)NC FARYTWBWLZAXNK-WAYWQWQTSA-N 0.000 description 1

- 229920001249 ethyl cellulose Polymers 0.000 description 1

- 235000019325 ethyl cellulose Nutrition 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 238000005562 fading Methods 0.000 description 1

- 238000000855 fermentation Methods 0.000 description 1

- 230000004151 fermentation Effects 0.000 description 1

- BDAGIHXWWSANSR-UHFFFAOYSA-N formic acid Substances OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 description 1

- 239000001530 fumaric acid Substances 0.000 description 1

- 229930182830 galactose Natural products 0.000 description 1

- 125000002791 glucosyl group Chemical group C1([C@H](O)[C@@H](O)[C@H](O)[C@H](O1)CO)* 0.000 description 1

- 150000002334 glycols Chemical class 0.000 description 1

- 125000001046 glycoluril group Chemical group [H]C12N(*)C(=O)N(*)C1([H])N(*)C(=O)N2* 0.000 description 1

- 239000004519 grease Substances 0.000 description 1

- 108010002430 hemicellulase Proteins 0.000 description 1

- 229940059442 hemicellulase Drugs 0.000 description 1

- XXMIOPMDWAUFGU-UHFFFAOYSA-N hexane-1,6-diol Chemical compound OCCCCCCO XXMIOPMDWAUFGU-UHFFFAOYSA-N 0.000 description 1

- 229920001519 homopolymer Polymers 0.000 description 1

- 150000001469 hydantoins Chemical class 0.000 description 1

- 229940042795 hydrazides for tuberculosis treatment Drugs 0.000 description 1

- 238000005984 hydrogenation reaction Methods 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 235000019447 hydroxyethyl cellulose Nutrition 0.000 description 1

- 239000001866 hydroxypropyl methyl cellulose Substances 0.000 description 1

- 229920003088 hydroxypropyl methyl cellulose Polymers 0.000 description 1

- 235000010979 hydroxypropyl methyl cellulose Nutrition 0.000 description 1

- UFVKGYZPFZQRLF-UHFFFAOYSA-N hydroxypropyl methyl cellulose Chemical compound OC1C(O)C(OC)OC(CO)C1OC1C(O)C(O)C(OC2C(C(O)C(OC3C(C(O)C(O)C(CO)O3)O)C(CO)O2)O)C(CO)O1 UFVKGYZPFZQRLF-UHFFFAOYSA-N 0.000 description 1

- 125000002951 idosyl group Chemical class C1([C@@H](O)[C@H](O)[C@@H](O)[C@H](O1)CO)* 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 229910052740 iodine Inorganic materials 0.000 description 1

- 239000011630 iodine Substances 0.000 description 1

- 150000002584 ketoses Chemical class 0.000 description 1

- 238000004900 laundering Methods 0.000 description 1

- 159000000003 magnesium salts Chemical class 0.000 description 1

- 150000002689 maleic acids Chemical class 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 108010003855 mesentericopeptidase Proteins 0.000 description 1

- IJFXRHURBJZNAO-UHFFFAOYSA-N meta--hydroxybenzoic acid Natural products OC(=O)C1=CC=CC(O)=C1 IJFXRHURBJZNAO-UHFFFAOYSA-N 0.000 description 1

- 125000005395 methacrylic acid group Chemical class 0.000 description 1

- YLGXILFCIXHCMC-JHGZEJCSSA-N methyl cellulose Chemical compound COC1C(OC)C(OC)C(COC)O[C@H]1O[C@H]1C(OC)C(OC)C(OC)OC1COC YLGXILFCIXHCMC-JHGZEJCSSA-N 0.000 description 1

- 125000005527 methyl sulfate group Chemical group 0.000 description 1

- XJRBAMWJDBPFIM-UHFFFAOYSA-N methyl vinyl ether Chemical class COC=C XJRBAMWJDBPFIM-UHFFFAOYSA-N 0.000 description 1

- 108010020132 microbial serine proteinases Proteins 0.000 description 1

- 239000004200 microcrystalline wax Substances 0.000 description 1

- 235000019808 microcrystalline wax Nutrition 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 150000002763 monocarboxylic acids Chemical class 0.000 description 1

- 150000004682 monohydrates Chemical class 0.000 description 1

- 235000021290 n-3 DPA Nutrition 0.000 description 1

- SLCVBVWXLSEKPL-UHFFFAOYSA-N neopentyl glycol Chemical compound OCC(C)(C)CO SLCVBVWXLSEKPL-UHFFFAOYSA-N 0.000 description 1

- OEIJHBUUFURJLI-UHFFFAOYSA-N octane-1,8-diol Chemical compound OCCCCCCCCO OEIJHBUUFURJLI-UHFFFAOYSA-N 0.000 description 1

- 229960002446 octanoic acid Drugs 0.000 description 1

- 125000002347 octyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- ZQPPMHVWECSIRJ-KTKRTIGZSA-N oleic acid group Chemical group C(CCCCCCC\C=C/CCCCCCCC)(=O)O ZQPPMHVWECSIRJ-KTKRTIGZSA-N 0.000 description 1

- 229920001542 oligosaccharide Polymers 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 235000011837 pasties Nutrition 0.000 description 1

- 239000002304 perfume Substances 0.000 description 1

- 108040007629 peroxidase activity proteins Proteins 0.000 description 1

- ACVYVLVWPXVTIT-UHFFFAOYSA-N phosphinic acid Chemical compound O[PH2]=O ACVYVLVWPXVTIT-UHFFFAOYSA-N 0.000 description 1

- UEZVMMHDMIWARA-UHFFFAOYSA-M phosphonate Chemical compound [O-]P(=O)=O UEZVMMHDMIWARA-UHFFFAOYSA-M 0.000 description 1

- 229910052615 phyllosilicate Inorganic materials 0.000 description 1

- 239000006187 pill Substances 0.000 description 1

- 229920001515 polyalkylene glycol Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 229920001451 polypropylene glycol Polymers 0.000 description 1

- 230000008092 positive effect Effects 0.000 description 1

- 159000000001 potassium salts Chemical class 0.000 description 1

- UIIIBRHUICCMAI-UHFFFAOYSA-N prop-2-ene-1-sulfonic acid Chemical compound OS(=O)(=O)CC=C UIIIBRHUICCMAI-UHFFFAOYSA-N 0.000 description 1

- 235000019419 proteases Nutrition 0.000 description 1

- 238000005956 quaternization reaction Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000005871 repellent Substances 0.000 description 1

- 230000002940 repellent Effects 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 238000000518 rheometry Methods 0.000 description 1

- WBHHMMIMDMUBKC-XLNAKTSKSA-N ricinelaidic acid Chemical compound CCCCCC[C@@H](O)C\C=C\CCCCCCCC(O)=O WBHHMMIMDMUBKC-XLNAKTSKSA-N 0.000 description 1

- 229960003656 ricinoleic acid Drugs 0.000 description 1

- FEUQNCSVHBHROZ-UHFFFAOYSA-N ricinoleic acid Natural products CCCCCCC(O[Si](C)(C)C)CC=CCCCCCCCC(=O)OC FEUQNCSVHBHROZ-UHFFFAOYSA-N 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 238000007127 saponification reaction Methods 0.000 description 1

- 150000004671 saturated fatty acids Chemical class 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- RYMZZMVNJRMUDD-HGQWONQESA-N simvastatin Chemical compound C([C@H]1[C@@H](C)C=CC2=C[C@H](C)C[C@@H]([C@H]12)OC(=O)C(C)(C)CC)C[C@@H]1C[C@@H](O)CC(=O)O1 RYMZZMVNJRMUDD-HGQWONQESA-N 0.000 description 1

- 239000001509 sodium citrate Substances 0.000 description 1

- NLJMYIDDQXHKNR-UHFFFAOYSA-K sodium citrate Chemical compound O.O.[Na+].[Na+].[Na+].[O-]C(=O)CC(O)(CC([O-])=O)C([O-])=O NLJMYIDDQXHKNR-UHFFFAOYSA-K 0.000 description 1

- 229940045872 sodium percarbonate Drugs 0.000 description 1

- 159000000000 sodium salts Chemical class 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 239000005720 sucrose Substances 0.000 description 1

- 150000008163 sugars Chemical class 0.000 description 1

- 230000001180 sulfating effect Effects 0.000 description 1

- 125000000542 sulfonic acid group Chemical group 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 239000012209 synthetic fiber Substances 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 108010075550 termamyl Proteins 0.000 description 1

- 150000004685 tetrahydrates Chemical class 0.000 description 1

- 238000009988 textile finishing Methods 0.000 description 1

- DPUOLQHDNGRHBS-MDZDMXLPSA-N trans-Brassidic acid Chemical compound CCCCCCCC\C=C\CCCCCCCCCCCC(O)=O DPUOLQHDNGRHBS-MDZDMXLPSA-N 0.000 description 1

- 125000005208 trialkylammonium group Chemical group 0.000 description 1

- 150000003852 triazoles Chemical class 0.000 description 1

- 150000005691 triesters Chemical class 0.000 description 1

- 229940005605 valeric acid Drugs 0.000 description 1

- 229920001567 vinyl ester resin Polymers 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 239000001993 wax Substances 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/0005—Other compounding ingredients characterised by their effect

- C11D3/0036—Soil deposition preventing compositions; Antiredeposition agents

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D11/00—Special methods for preparing compositions containing mixtures of detergents ; Methods for using cleaning compositions

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D17/00—Detergent materials or soaps characterised by their shape or physical properties

- C11D17/0039—Coated compositions or coated components in the compositions, (micro)capsules

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/16—Organic compounds

- C11D3/20—Organic compounds containing oxygen

- C11D3/22—Carbohydrates or derivatives thereof

- C11D3/222—Natural or synthetic polysaccharides, e.g. cellulose, starch, gum, alginic acid or cyclodextrin

- C11D3/225—Natural or synthetic polysaccharides, e.g. cellulose, starch, gum, alginic acid or cyclodextrin etherified, e.g. CMC

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/39—Organic or inorganic per-compounds

- C11D3/3942—Inorganic per-compounds

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/01—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with natural macromolecular compounds or derivatives thereof

- D06M15/03—Polysaccharides or derivatives thereof

- D06M15/05—Cellulose or derivatives thereof

- D06M15/09—Cellulose ethers

-

- C11D2111/12—

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M2200/00—Functionality of the treatment composition and/or properties imparted to the textile material

Definitions

- the present invention relates to the use of certain soil release cellulose derivatives for enhancing the cleaning performance of bleach-containing detergents in the washing of textiles made of cotton or containing cotton, as well as bleach-containing detergents and cleaners containing such soil release-capable cellulose derivatives.

- Detergents contain in addition to the indispensable for the washing process ingredients such as surfactants and builder materials usually further ingredients that can be summarized under the term washing aids and include as different drug groups such as foam regulators, grayness inhibitors, bleach, bleach activators and dye transfer inhibitors.

- Such adjuvants also include substances which impart soil repellency properties to the laundry fiber and, if present during the wash, aid the soil release properties of the remaining detergent ingredients. The same applies mutatis mutandis to cleaners for hard surfaces.

- soil release agents are often referred to as “soil release” agents or because of their ability to impart soil repellency to the treated surface, such as the fiber, as “soil repellents". For example, from the US Pat. No.

- 4,000,093 discloses detergents containing from 0.1% to 3% by weight of alkyl cellulose, hydroxyalkyl cellulose or alkyl hydroxyalkyl cellulose and from 5% to 50% by weight surfactant, wherein the surfactant component is substantially consists of C 10 - to C 13 alkyl sulfate and up to 5% by weight of C 14 alkyl sulfate and less than 5 wt .-% alkyl sulfate having alkyl radicals of C 15 and higher.

- the surfactant component is substantially consists of C 10 - to C 13 alkyl sulfate and up to 5% by weight of C 14 alkyl sulfate and less than 5 wt .-% alkyl sulfate having alkyl radicals of C 15 and higher.

- 4,174,305 discloses detergents containing from 0.1% to 3% by weight of alkyl cellulose, hydroxyalkyl cellulose or alkyl hydroxyalkyl cellulose and from 5% to 50% by weight surfactant, wherein the surfactant component is substantially consists of C 10 - to C 12 -alkylbenzenesulfonate and less than 5 wt .-% alkylbenzenesulfonate having alkyl radicals of C 13 and higher.

- the European Patent EP 0 271 312 relates to soil release agents, among these cellulose alkyl ethers and cellulose hydroxyalkyl ethers (having DS 1.5 to 2.7 and molecular weights of 2,000 to 100,000) such as methylcellulose and ethylcellulose, with weight ratio of peroxygen bleach (based on the active oxygen content of the bleach) of 10: 1 to 1 : 10 should be used.

- the European Patent Application EP 0 634 481 relates to a detergent containing alkali metal percarbonate and one or more nonionic cellulose derivatives.

- the latter expressly disclose only hydroxyethylcellulose, hydroxypropylcellulose and methylcellulose and, in the examples, the methylhydroxyethylcellulose Tylose® MH50, the hydroxypropylmethylcellulose Methocel® F4M and hydroxybutylmethylcellulose.

- a laundry detergent in liquid or granular form which imparts textile appearance benefits such as pill / lint reduction, anti-color fading, improved abrasion resistance and / or enhanced softness to fabrics and textiles washed therewith, and from 1 to 80 weight percent surfactant, 1 to 80 wt .-% organic or inorganic builder, 0.1 to 80 wt .-% of a hydrophobically modified nonionic cellulose ether having a molecular weight of 10,000 to 2,000,000, wherein the modification in the presence of optionally oligomerized (degree of oligomerization up to 20 ) Ethyleneoxy or 2-propyleneoxy ether units and C 8-24 alkyl substituents and the alkyl substituents must be present in amounts of 0.1-5 wt .-%, based on the cellulose ether material.

- German Offenlegungsschrift DT 16 17 141 describes a washing process using polyethylene terephthalate-polyoxyethylene glycol copolymers.

- German laid-open specification DT 22 00 911 relates to detergents which contain nonionic surfactant and a copolymer of polyoxyethylene glycol and polyethylene terephthalate.

- acidic textile finishing agents which contain a copolymer of a dibasic carboxylic acid and an alkylene or Cycloalkylenpolyglykol and optionally an alkylene or cycloalkylene glycol.

- Polymers of ethylene terephthalate and polyethylene oxide terephthalate in which the polyethylene glycol units have molecular weights of 750 to 5000 and the molar ratio of ethylene terephthalate to polyethylene oxide terephthalate 50:50 to 90:10, and their use in detergents are in the German patent DE 28 57,292.

- the European patent EP 066 944 relates to textile treatment compositions comprising a copolyester of ethylene glycol, polyethylene glycol, aromatic dicarboxylic acid and sulfonated aromatic dicarboxylic acid in certain molar ratios.

- a copolyester of ethylene glycol, polyethylene glycol, aromatic dicarboxylic acid and sulfonated aromatic dicarboxylic acid in certain molar ratios From the European patent EP 185 427 For example, methyl or ethyl group-end capped polyesters having ethylene and / or propylene terephthalate and polyethylene oxide terephthalate units and detergents containing such soil release polymer are known.

- the European patent EP 241 984 relates to a polyester which in addition to oxyethylene groups and terephthalic acid units also contains substituted ethylene units and glycerol units.

- polyester containing in addition to oxyethylene groups and terephthalic acid units 1,2-propylene, 1,2-butylene and / or 3-methoxy-1,2-propylene and glycerol units and end phenomenon with C 1 - to C 4 alkyl groups are.

- the European patent EP 253 567 concerns. Soil-release polymers having a molecular weight of 900 to 9000 of ethylene terephthalate and polyethylene oxide terephthalate, wherein the polyethylene glycol units have molecular weights of 300 to 3000 and the molar ratio of ethylene terephthalate to polyethylene oxide terephthalate is 0.6 to 0.95.

- EP 272 033 are at least partially by C 1-4 alkyl or acyl radicals end-capped polyester with poly-propylene terephthalate and polyoxyethylene terephthalate units known.

- the European patent EP 274 907 describes sulfoethyl end-capped terephthalate-containing soil release polyesters.

- EP 357,280 are prepared by sulfonation of unsaturated end groups soil release polyester with terephthalate, alkylene glycol and Foly C 2-4 glycol units.

- the German patent application DE 26 55 551 describes the reaction of such polyesters with isocyanate group-containing polymers and the use of the polymers thus prepared against the repulping of dirt during the washing of synthetic fibers.

- the invention relates to the use of a combination of soil release cellulose derivative obtainable by alkylation and hydroxyalkylation of cellulose, and bleaching agent for enhancing the cleaning performance of detergents in the washing of textiles made of cotton or containing cotton.

- Another object of the invention is a process for laundering textiles using a bleach-containing detergent and a soil release cellulose derivative obtainable by alkylation and hydroxyalkylation of cellulose.

- This method can be carried out manually or preferably by means of a conventional household washing machine. It is possible to use the bleach-containing detergent and the soil release-capable cellulose derivative simultaneously or successively. The simultaneous application can be particularly advantageous by the use of a bleach-containing detergent, which contains the soil release wealthy cellulose derivative perform.

- the washing performance-enhancing effect of the cellulose derivatives to be used according to the invention with repeated use, that is to say in particular for removing soiling of corresponding textiles which had already been washed and / or post-treated in the presence of the cellulose derivative before being provided with the soil.

- the positive aspect referred to can also be realized by a washing process in which the textile after the actual washing process, with the help of a bleach-containing detergent - which may contain a called cellulose derivative, but in this case also can be free of this - is carried out, with an aftertreatment agent, for example in the context of a fabric softening step, which contains a cellulose derivative to be used according to the invention, is brought into contact. Also in this procedure occurs during the next washing process, although again if desired, although a bleach-containing detergent, but no detergent is used with a cellulose derivative mentioned, the washing performance enhancing effect of the present invention to be used cellulose derivatives.

- Preferred cellulose derivatives are those which are alkylated with C 1 to C 10 groups, in particular C 1 to C 3 groups, and additionally carry C 2 to C 10 hydroxyalkyl groups, in particular C 2 to C 3 hydroxyalkyl groups.

- C 1 to C 10 groups in particular C 1 to C 3 groups

- C 2 to C 10 hydroxyalkyl groups in particular C 2 to C 3 hydroxyalkyl groups.

- alkylating agents for example alkyl halides or alkyl sulfates

- alkylene oxides such as Ethylene oxide and / or propylene oxide.

- a mean of 0.5 to 2.5, in particular 1 to 2, alkyl groups and 0.02 to 0.5, in particular 0.05 to 0.3, hydroxyalkyl groups per anhydroglycosemonomer unit are contained in the cellulose derivative.

- the average molar mass of the cellulose derivatives used according to the invention is preferably in the range from 10,000 D to 150,000 D, in particular from 40,000 D to 120,000 D and particularly preferably in the range from 80,000 D to 110,000 D.

- the determination of the degree of polymerization or of the molecular weight of the soil release-capable cellulose derivative is based on the determination of the limiting viscosity number of sufficiently dilute aqueous solutions by means of an Ubbelohde capillary viscometer (capillary 0c). Using a constant [H. Staudinger and F. Reinecke, “On Molecular Weight Determination on Cellulose Ethers", Liebigs Annalen der Chemie 535, 47 (1938)] and a Correction Factor [F.

- Rodriguez and LAGoettler, "The Flow of Moderately Concentrated Polymer Solutions in Water", Transactions of the Society of Rheology VIII, 3 17 (1964)] can be calculated from the degree of polymerization and taking into account the degrees of substitution (DS and MS), the corresponding molecular weight.

- the cellulose derivatives used according to the invention can be prepared in a simple manner and are ecologically and toxicologically harmless. They lead to a significantly better detachment of, in particular, grease and cosmetic stains on cotton or cotton-containing fabrics than is the case with the use of compounds previously known for this purpose. Alternatively, significant amounts of surfactants can be saved while maintaining fat removal capability.

- the use according to the invention can be carried out as part of a washing process by adding a bleaching agent and the cellulose derivative of a detergent-containing liquor, adding the cellulose derivative of a bleach-containing and detergent-containing liquor separately, or preferably introducing the cellulose derivative as a constituent of a lead-containing detergent into the liquor.

- Another object of the invention is therefore a bleach-containing detergent containing a cellulose derivative described above.

- a laundry aftertreatment process can be carried out in such a way that the cellulose derivative is added separately to the rinse liquor which is used after the wash cycle using a bleach-containing detergent or it is incorporated as a component of the laundry aftertreatment agent, in particular a softener.

- said bleach-containing detergent may also contain, but may be free from, a cellulose derivative to be used in accordance with the invention.

- said laundry aftertreatment agent may also contain a bleach, but may be free of it.

- An agent which contains a cellulose derivative to be used according to the invention or is used together or is used in the process according to the invention contains bleaching agents, preferably peroxygen-based, in particular in amounts ranging from 5% by weight to 70% by weight optionally bleach activator, especially in amounts ranging from 2% to 10% by weight.

- the bleaches which may be used are preferably the peroxygen compounds generally used in detergents, such as percarboxylic acids, for example dodecanediperic acid or phthaloylaminoperoxicaproic acid, hydrogen peroxide, alkali metal perborate, which may be present as tetra- or monohydrate, percarbonate, perpyrophosphate and persilicate, which are generally used as alkali metal salts, in particular as sodium salts.

- percarboxylic acids for example dodecanediperic acid or phthaloylaminoperoxicaproic acid

- hydrogen peroxide alkali metal perborate

- percarbonate percarbonate

- perpyrophosphate and persilicate which are generally used as alkali metal salts, in particular as sodium salts.

- Such bleaching agents are in detergents which contain a cellulose derivative used according to the invention, preferably in amounts of up to 25 wt .-%, in particular up to 15 wt .-% and particularly preferably from 5 wt .-% to 15 wt .-%, respectively on total agent, present, in particular percarbonate is used.

- the optionally present component of the bleach activators comprises the commonly used N- or O-acyl compounds, for example polyacylated alkylenediamines, in particular tetraacetylethylenediamine, acylated glycolurils, in particular tetraacetylglycoluril, N-acylated hydantoins, hydrazides, triazoles, urazoles, diketopiperazines, sulphurylamides and cyanurates, and also carboxylic acid anhydrides , in particular phthalic anhydride, carboxylic acid esters, especially sodium isononanoyl-pienolsulfonat, and acylated sugar derivatives, in particular pentaacetylglucose, as well as cationic nitrile derivatives such as trimethylammoniumacetonitrile salts.

- N- or O-acyl compounds for example polyacylated alkylenediamines, in particular tetraace

- the bleach activators may have been coated or granulated in a known manner with coating substances in order to avoid the interaction with the per compounds, with the aid of carboxymethylcellulose granulated tetraacetylethylenediamine having average particle sizes of 0.01 mm to 0.8 mm, as for example according to in the European patent specification EP 37 026 granulated 1,5-diacetyl-2,4-dioxohexahydro-1,3,5-triazine, as described in the German Patent DD 255,884 described method can be prepared, and / or according to those in the international Patent Applications WO 00/50553 . WO 00/50556 . WO 02/12425 .

- WO 02/12426 or WO 02/26927 Particularly preferred is the trialkylammonium acetonitrile formulated in particulate form.

- Such bleach activators are preferably contained in detergents in amounts of up to 8% by weight, in particular from 2% by weight to 6% by weight, based in each case on the total agent.

- Bleach-containing detergents which contain a cellulose derivative to be used according to the invention or used together with it or used in the process according to the invention may contain all customary other constituents of such agents which are not undesirable with the interact with the cellulose derivative of the invention.

- the cellulose derivative is preferably incorporated in amounts of from 0.1% by weight to 5% by weight, in particular from 0.5% by weight to 2.5% by weight, in bleach-containing detergents.

- an agent used according to the invention or used in the process according to the invention comprises nonionic surfactant selected from fatty alkyl polyglycosides, fatty alkyl polyalkoxylates, in particular ethoxylates and / or propoxylates, fatty acid polyhydroxyamides and / or ethoxylation and / or propoxylation products of fatty alkylamines, vicinal diols, Fatty acid alkyl esters and / or fatty acid amides and mixtures thereof, in particular in an amount in the range of 2 wt .-% to 25 wt .-%.

- Such agents comprises the presence of sulfate and / or sulfonate synthetic anionic surfactant, in particular fatty alkyl sulfate, fatty alkyl ether sulfate, sulfo fatty acid ester and / or sulfo fatty acid salt, in particular in an amount in the range from 2% to 25% by weight.

- the anionic surfactant is preferably selected from the alkyl or alkenyl sulfates and / or the alkyl or alkenyl ether sulfates in which the alkyl or alkenyl group has 8 to 22, in particular 12 to 18, carbon atoms. These are usually not individual substances, but cuts or mixtures. Of these, preference is given to those whose content of compounds having longer-chain radicals in the range from 16 to 18 carbon atoms is more than 20% by weight.

- Suitable nonionic surfactants include the alkoxylates, in particular the ethoxylates and / or propoxylates of saturated or mono- to polyunsaturated linear or branched-chain alcohols having 10 to 22 C atoms, preferably 12 to 18 C atoms.

- the degree of alkoxylation of the alcohols is generally between 1 and 20, preferably between 3 and 10. They can be prepared in a known manner by reacting the corresponding alcohols with the corresponding alkylene oxides.

- Particularly suitable are the derivatives of fatty alcohols, although their branched-chain isomers, in particular so-called oxo alcohols, can be used for the preparation of usable alkoxylates.

- alkoxylates in particular the ethoxylates, primary alcohols with linear, in particular dodecyl, tetradecyl, hexadecyl or octadecyl radicals and mixtures thereof.

- suitable alkoxylation products of alkylamines, vicinal diols and carboxamides, which correspond to the said alcohols with respect to the alkyl part usable.

- the ethylene oxide and / or propylene oxide insertion products of fatty acid alkyl esters as described in the international Patent Application WO 90/13533 as well as fatty acid polyhydroxyamides, as prepared according to the methods of U.S. Pat. Nos. 1,985,424 .

- alkylpolyglycosides which are suitable for incorporation in the compositions according to the invention are compounds of the general formula (G) n -OR 12 , in which R 12 is an alkyl or alkenyl radical having 8 to 22 C atoms, G is a glycose unit and n is a number between 1 and 10 mean.

- R 12 is an alkyl or alkenyl radical having 8 to 22 C atoms

- G is a glycose unit

- n is a number between 1 and 10 mean.

- the glycoside component (G) n are oligomers or polymers of naturally occurring aldose or ketose monomers, in particular glucose, mannose, fructose, galactose, talose, gulose, altrose, allose, idose, ribose, arabinose, Include xylose and lyxose.

- the oligomers consisting of such glycosidically linked monomers are characterized not only by the nature of the sugars contained in them by their number, the so-called Oligomermaschinesgrad.

- the degree of oligomerization n assumes as the value to be determined analytically generally broken numerical values; it is between 1 and 10, with the glycosides preferably used below a value of 1.5, in particular between 1.2 and 1.4.

- Preferred monomer building block is glucose because of its good availability.

- Nonionic surfactant is used according to the invention in agents containing a soil-release agent used according to the invention, or used in the process according to the invention, preferably in amounts from 1 wt% to 30 wt%, especially from 1 wt% to 25 wt%, with amounts in the upper part of this range being more likely to be found in liquid detergents and particulate detergents preferably being smaller amounts up to to 5 wt .-% contained.

- the agents may instead or additionally contain other surfactants, preferably synthetic anionic surfactants of the sulfate or sulfonate type, such as, for example, alkylbenzenesulfonates, in amounts of preferably not more than 20% by weight, in particular from 0.1% by weight to 18% by weight. %, in each case based on total resources.

- Suitable synthetic anionic surfactants which are particularly suitable for use in such compositions are the alkyl and / or alkenyl sulfates having 8 to 22 C atoms which carry an alkali, ammonium or alkyl or hydroxyalkyl-substituted ammonium ion as counter cation.

- alkyl and alkenyl sulfates can be prepared in a known manner by reaction of the corresponding alcohol component with a conventional sulfating reagent, in particular sulfur trioxide or chlorosulfonic acid, and subsequent neutralization with alkali metal, ammonium or alkyl or hydroxyalkyl-substituted ammonium bases.

- Sulfur-type surfactants which can be used also include the sulfated alkoxylation products of the alcohols mentioned, known as ether sulfates.

- Such ether sulfates preferably contain from 2 to 30, in particular from 4 to 10, ethylene glycol groups per molecule.

- Suitable anionic surfactants of the sulfonate type include the ⁇ -sulfoesters obtainable by reaction of fatty acid esters with sulfur trioxide and subsequent neutralization, in particular those of fatty acids having 8 to 22 C atoms, preferably 12 to 18 C atoms, and linear alcohols having 1 to 6 carbon atoms, preferably 1 to 4 carbon atoms, derivative sulfonation, as well as the formal saponification resulting from these sulfo fatty acids.

- soaps suitable being saturated fatty acid soaps, such as the salts of lauric acid, myristic acid, palmitic acid or stearic acid, and soaps derived from natural fatty acid mixtures, for example coconut, palm kernel or tallow fatty acids.

- those soap mixtures are preferred which are composed of 50% by weight to 100% by weight of saturated C 12 -C 18 fatty acid soaps and up to 50% by weight of oleic acid soap.

- soap is included in amounts of from 0.1% to 5% by weight.

- higher amounts of soap as a rule up to 20% by weight, can also be present.

- compositions may also contain betaines and / or cationic surfactants, which, if present, are preferably used in amounts of from 0.5% by weight to 7% by weight.

- betaines and / or cationic surfactants which, if present, are preferably used in amounts of from 0.5% by weight to 7% by weight.

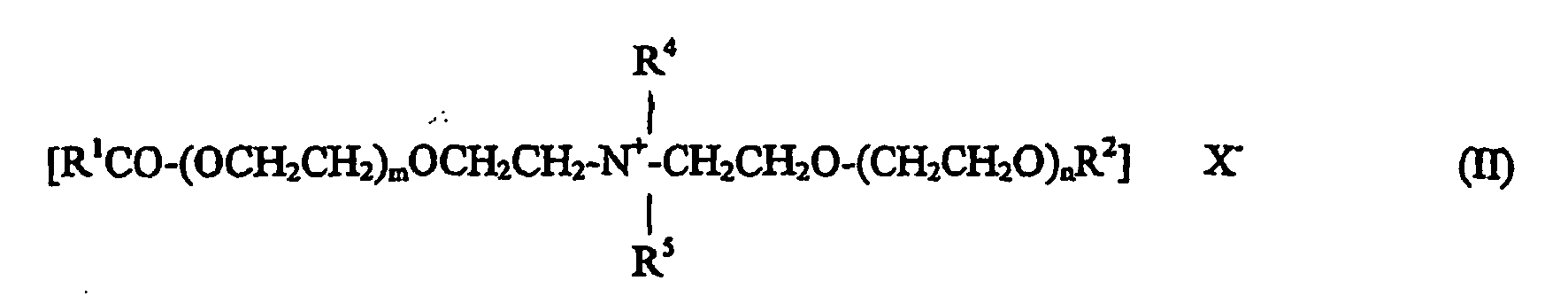

- esterquats discussed below are particularly preferred.

- the composition contains water-soluble and / or water-insoluble builder, in particular selected from alkali metal aluminosilicate, crystalline alkali metal silicate with modulus above 1, monomeric polycarboxylate, polymeric polycarboxylate and mixtures thereof, in particular in amounts ranging from 2.5 wt .-% to 60 wt .-%.

- water-soluble and / or water-insoluble builder in particular selected from alkali metal aluminosilicate, crystalline alkali metal silicate with modulus above 1, monomeric polycarboxylate, polymeric polycarboxylate and mixtures thereof, in particular in amounts ranging from 2.5 wt .-% to 60 wt .-%.