EP1591658A2 - Engine starting system - Google Patents

Engine starting system Download PDFInfo

- Publication number

- EP1591658A2 EP1591658A2 EP05009350A EP05009350A EP1591658A2 EP 1591658 A2 EP1591658 A2 EP 1591658A2 EP 05009350 A EP05009350 A EP 05009350A EP 05009350 A EP05009350 A EP 05009350A EP 1591658 A2 EP1591658 A2 EP 1591658A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- engine

- time

- cylinder

- speed

- stroke

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02N—STARTING OF COMBUSTION ENGINES; STARTING AIDS FOR SUCH ENGINES, NOT OTHERWISE PROVIDED FOR

- F02N99/00—Subject matter not provided for in other groups of this subclass

- F02N99/002—Starting combustion engines by ignition means

- F02N99/004—Generation of the ignition spark

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D35/00—Controlling engines, dependent on conditions exterior or interior to engines, not otherwise provided for

- F02D35/02—Controlling engines, dependent on conditions exterior or interior to engines, not otherwise provided for on interior conditions

- F02D35/025—Controlling engines, dependent on conditions exterior or interior to engines, not otherwise provided for on interior conditions by determining temperatures inside the cylinder, e.g. combustion temperatures

- F02D35/026—Controlling engines, dependent on conditions exterior or interior to engines, not otherwise provided for on interior conditions by determining temperatures inside the cylinder, e.g. combustion temperatures using an estimation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/02—Circuit arrangements for generating control signals

- F02D41/04—Introducing corrections for particular operating conditions

- F02D41/042—Introducing corrections for particular operating conditions for stopping the engine

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02N—STARTING OF COMBUSTION ENGINES; STARTING AIDS FOR SUCH ENGINES, NOT OTHERWISE PROVIDED FOR

- F02N11/00—Starting of engines by means of electric motors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02N—STARTING OF COMBUSTION ENGINES; STARTING AIDS FOR SUCH ENGINES, NOT OTHERWISE PROVIDED FOR

- F02N11/00—Starting of engines by means of electric motors

- F02N11/08—Circuits or control means specially adapted for starting of engines

- F02N11/0851—Circuits or control means specially adapted for starting of engines characterised by means for controlling the engagement or disengagement between engine and starter, e.g. meshing of pinion and engine gear

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/02—Circuit arrangements for generating control signals

- F02D41/021—Introducing corrections for particular conditions exterior to the engine

- F02D41/0235—Introducing corrections for particular conditions exterior to the engine in relation with the state of the exhaust gas treating apparatus

- F02D41/0295—Control according to the amount of oxygen that is stored on the exhaust gas treating apparatus

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02N—STARTING OF COMBUSTION ENGINES; STARTING AIDS FOR SUCH ENGINES, NOT OTHERWISE PROVIDED FOR

- F02N11/00—Starting of engines by means of electric motors

- F02N11/08—Circuits or control means specially adapted for starting of engines

- F02N11/0814—Circuits or control means specially adapted for starting of engines comprising means for controlling automatic idle-start-stop

- F02N11/0818—Conditions for starting or stopping the engine or for deactivating the idle-start-stop mode

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02N—STARTING OF COMBUSTION ENGINES; STARTING AIDS FOR SUCH ENGINES, NOT OTHERWISE PROVIDED FOR

- F02N19/00—Starting aids for combustion engines, not otherwise provided for

- F02N19/005—Aiding engine start by starting from a predetermined position, e.g. pre-positioning or reverse rotation

- F02N2019/007—Aiding engine start by starting from a predetermined position, e.g. pre-positioning or reverse rotation using inertial reverse rotation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02N—STARTING OF COMBUSTION ENGINES; STARTING AIDS FOR SUCH ENGINES, NOT OTHERWISE PROVIDED FOR

- F02N2300/00—Control related aspects of engine starting

- F02N2300/20—Control related aspects of engine starting characterised by the control method

- F02N2300/2002—Control related aspects of engine starting characterised by the control method using different starting modes, methods, or actuators depending on circumstances, e.g. engine temperature or component wear

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02N—STARTING OF COMBUSTION ENGINES; STARTING AIDS FOR SUCH ENGINES, NOT OTHERWISE PROVIDED FOR

- F02N2300/00—Control related aspects of engine starting

- F02N2300/20—Control related aspects of engine starting characterised by the control method

- F02N2300/2011—Control involving a delay; Control involving a waiting period before engine stop or engine start

Definitions

- the present invention relates to an engine starting system, and more particularly to an engine starting system for automatically stopping an engine in an operating state, such as idling state, when a given automatic stop condition is satisfied, and then restarting the engine when a given restart condition is satisfied.

- an operating state such as idling state

- Publication 1 JP 2002-4985 A1 [Hereinafter referred to as Publication 2] As measures for achieving a higher success rate in automatically restarting the automatically stopped engine, the Publication 1 further discloses a technique of controlling an exhaust valve closing timing after an ignition switch is turned off, so as to stop the engine at a given crank angle.

- a starter motor (motor for starting an engine) is additionally driven to provide enhanced reliability of engine starting, as disclosed, for example, In the Publication 2.

- the engine staring system as disclosed in the Publication 2 is designed to unexceptionally drive the starter motor when an engine start condition is satisfied In the state after an engine is completely stopped, as clearly described in the paragraph [0023] of the Publication 2. That is, even if a crankshaft is stopped at a position allowing for the so-called "direct start” (restart based on only combustion in a cylinder) by use of the control technique as disclosed in the Publication 1, the advantage of this control technique cannot be utilized. Thus, it can be hardly said that this system is adapted to sufficiently suppress electric power consumption.

- the system in the Publication 2 is designed such that a fuel is periodically injected into the cylinder in an expansion stroke, to maintain a given engine speed, during the period from the stop of the engine through until the engine start condition is satisfied. This control also leads to consumption of needless fuel.

- an object of the present invention to provide an engine starting system capable of automatically stopping an engine to improve fuel consumption, and quickly restarting the engine in a manner for minimizing the frequency in use of a starter motor and/or needless combustion to facilitate energy saving.

- the present invention provides an engine starting system for use in a vehicle equipped with a 4-stroke engine where one power cycle consisting of intake, compression, expansion and exhaust strokes is produced by two reciprocating motions of a piston.

- the engine includes: fuel supply means for supplying fuel into each of a plurality of cylinders; a plurality of spark plugs provided in the cylinders, respectively; rotational speed detection means for detecting an engine speed; and a start assist device adapted to drive a crankshaft of the engine using a motor.

- the engine starting system comprises: automatic stop control means operable, upon satisfaction of a predetermined automatic engine stop condition, to allow the supply of a fuel for maintaining an operating state of the engine to be interrupted so as to automatically stop the engine; start control means operable, upon satisfaction of a restart condition for restarting the automatically stopped engine, to allow the spark plug of at least the cylinder in the state after being stopped in an expansion stroke to ignite a fuel supplied into the cylinder and induce combustion in the cylinder, so as to automatically restart the engine: start-adequacy evaluation means for evaluating whether the engine start based on the start control means Is adequate; and assist drive control means operable, when the start-adequacy evaluation means determines that the engine start based on the start control means is inadequate, to drive the start assist device.

- the start-adequacy evaluation means Is operable to receive from said engine speed detection means an inspection engine speed defined by an engine speed detected at an inspection time which is set at a time when a given time lapses from initiation of the combustion In the cylinder in the state after being stopped In the compression stroke, and evaluate the adequacy of the engine start in accordance with the inspection engine speed; and the assist drive control means is operable, when the start-adequacy evaluation means determines that the inspection engine speed is less than a given engine speed required for adequately restarting the engine, to drive the start assist device around a zero-speed time when the crankshaft has a transition In rotation direction from a reverse direction occurring after an engine speed is lowered to zero, to a normal direction.

- an engine speed is detected at the inspection time.

- the so-called direct start fails, and then the start assist device is driven and associated with the engine having a relative low engine speed, to assist the restart of the engine.

- the start assets device includes a starter motor having a pinion gear engageable with a ring gear fixed to a flywheel of the engine.

- the starter motor to be used In the present invention is not limited to the type where a driving power is output from the pinion gear, but may be any other suitable type, such as a belt type.

- the assist drive control means is operable to drive the start assist device after the crankshaft has the transition in rotation direction from the reverse direction to the normal direction, and In a time range near to the second zero-speed time.

- the start assist device includes a pinion gear engageable with a ring gear provided in the engine, and the assist drive control means is operable to set around the zero-speed time an engagement time when the pinion gear is brought into' engagement with the ring gear, and drive the start assist device after completion of the engagement between the pinion gear and the ring gear.

- the pinion gear of the start assist device is brought into engagement with the ring gear after the crankshaft has the transition in rotation direction from the reverse direction to the normal direction and in a time range near to the second zero-speed time.

- the engine speed detection means is operable to send to the assist drive control means an assist-control reference time defined by a time when an engine speed is lowered from the inspection engine speed to zero, and the assist drive control means is operable to calculate the zero-speed time in accordance with the assist-control reference time and determine a time range of the engagement between the pinion gear and the ring gear in accordance with the calculated zero-speed time.

- the calculations for the engagement time can be initiated in the stage where the start-adequacy evaluation means determines evaluates the necessity of the start assist device, and quickly determine the engagement time between the pinion gear and the ring gear.

- the assist drive control means is operable to calculate a driving delay time-period in the start assist device, and determine an output time of a drive signal In accordance with the calculated driving delay time-period in such a manner as to allow the drive signal to be output to the start assist device at a time earlier than the zero-speed time.

- the driving delay time-period in the start assist device is included in one of control parameters.

- the start assist device has a time lag between the receiving of the drive signal and the driving of the engine, an intended assist initiation time can be reliably set.

- the start-adequacy evaluation means is operable, when the restart of the engine is successfully initiated, to estimate a time when the cylinder in the state after being stopped in an expansion stroke firstly reaches a top dead center In an exhaust stroke, so as to define the estimated time as the inspection time, and evaluate the adequacy of the engine restart in accordance with the inspection engine speed defined by an engine speed detected at the defined inspection time and received from the rotational speed detection means.

- the inspection time corresponding to the evaluation time for the start-adequacy evaluation means is set at the time when the cylinder in the state after being stopped in an expansion stroke firstly reaches a top dead center in an exhaust stroke, This makes it possible to determine the inspection time in accordance with a phase of the crankshaft corresponding to the inspection time.

- the success/fallure or adequacy of the so-called direct start is determined based on the engine speed at the inspection time.

- the start assist device will not be always driven. This can contributes to energy saving as compared the conventional technique disclosed in the aforementioned Publication 2.

- the start assist device can assist the engine start in the stage where a load to be imposed on the start assist device is minimum.

- the start assist device can have reduced load and enhanced reliability.

- this can contribute to enhancement In durability of the start assist device itself.

- the start assist device includes the pinion gear engageable with the ring gear associated with the engine

- the assist drive control means is operable, after the engine crankshaft has the transition in rotation direction from the reverse direction to the normal direction, to determine the timing of engagement with the pinion gear 36a in the time range near to the zero-speed time, and to allow the assist operation based on the start assist device to be initiated after the engagement between the pinion gear and the ring gear

- the engagement can be achieved without load onto the start assist device even in the type where the pinion gear is brought into engagement with the ring gear, in the state when it is rotated by driving motor In a direction opposite to that in which the ring gear is to be rotated,. This can contribute to enhancement in reliability and durability of the start assist device.

- the rotational speed detection means are operable to send to the assist drive control means an assist-control reference time defined by a time when an engine speed is lowered from the inspection engine speed to zero

- the assist drive control means is operable to calculate the zero-speed time in accordance with the received assist-control reference time and determine the time range of the engagement between the pinion gear and the ring gear in accordance with the calculated zero-speed time

- the assist drive control means is operable to calculate the driving delay time-period in the start assist device, and determine the an output time of the drive signal in accordance with the calculated driving delay time-period

- the driving delay time-period in the start assist device is included in one of control parameters.

- the start-adequacy evaluation means is operable to estimate a time when the cylinder in the state after stopped in an expansion-stroke cylinder first reaches a top dead center in an exhaust stroke, so as to defined the estimated time as the inspection time, and evaluate the adequacy of the engine restart in accordance with an inspection engine speed defined by the engine speed detected at the inspection time and received from the rotational speed detection means, the inspection time can be estimate relatively accurately. This has an advantage of being able to accurately evaluate the adequacy of the inspection engine speed and detect the inspection engine speed readily and accurately so as to achieve enhanced control accuracy.

- FIGS. 1 and 2 schematically show the structure of a four-stroke spark-ignition internal combustion engine having an engine starting system according to one embodiment of the present invention.

- This engine comprises an engine body 1 including a cylinder head 10 and a cylinder block 11, and an engine control ECU (electronic control unit) 2.

- the engine body 1 has four cylinders (a cylinder #1 or 12A, a cylinder #2 or 12B, a cylinder #3 or 12C and a cylinder #4 or 12D), and a piston 13 connected to a crankshaft 3 is slidably fitted In each of the cylinders 12A to 12D to define a combustion chamber 14 thereabove.

- a cylinder which is or was in a compression stroke during an after-mentioned automatic engine stop control, and a cylinder which is or was in an expansion stroke during the automatic engine stop control are referred to, respectively, as “compression-stroke cylinder” and “expansion-stroke cylinder” (in the same way, a cylinder which is or was in an intake position during the automatic engine stop control, and a cylinder which is or was in an exhaust stroke during the automatic engine stop control, are referred to, respectively, as “intake-stroke cylinder” and “exhaust-stroke cylinder”).

- each of these terms does not fixedly mean a specific cylinder, but expediently expresses each cylinder in accordance with the stroke of the cylinder during, or just before the completion of, the automatic engine stop control.

- the combustion chamber 14 in each of the cylinders 12A to 12D has a top wall portion provided with a spark plug 15 whose tip is exposed to the combustion chamber 14.

- Each of the spark plugs 15 is electrically connected to an ignition device 27 for activating the corresponding spark plug 15 to generate an electric spark therein.

- a fuel injection valve 16 is attached to a side wall portion of the combustion chamber 14 in each of the cylinders 12A to 12D to inject fuel directly into the combustion chamber 14,

- This fuel injection valve 16 internally having a needle valve (not shown) and a solenoid (not shown) is designed such that the solenoid is driven for a period of time corresponding to a pulse width of a pulse signal entered therein from a fuel injection control section 41 of the ECU 2, to open the needle valve so as to inject fuel in an amount proportional to the valve open period, toward and around electrodes of the spark plug 15.

- the combustion chamber 14 in each of the cylinders 12A to 12D also has an upper wall portion formed with an intake port 17 and an exhaust ports 18 each extending to open into the combustion chambers 14.

- the Intake port 17 is equipped with an intake valve 19, and each of the exhaust ports 18 is equipped with an exhaust valve 20.

- the intake valve 19 and the exhaust valve 20 are designed to be driven by a valve operating mechanism including a camshaft (not shown), so that respective opening/closing timings of the intake and exhaust valves 19, 20 in the cylinders 12A to 12D are set to allow a four-stroke combustion or power cycle to be performed in the cylinders 12A to 12D with a given phase differences therebetween.

- the intake port 17 and the exhaust port 18 are in fluid communication with an intake passage 21 and an exhaust passage 22, respectively.

- a downstream portion of the intake passage 21 on the side closer to the intake port 17 is formed as an intake manifold with four independent passages 21 a corresponding to the cylinders 12A to 12D, and respective upstream ends of the intake manifold passages 21 a are in fluid communication with a surge tank 21 b.

- An upstream portion of the intake passage 21 relative to the surge tank 21 b is formed as a common intake passage 21 c which is provided with a throttle valve 23 designed to be driven by an actuator 24.

- an air-flow sensor 25 for detecting an intake-air flow rate and an intake-air temperature sensor 29 for detecting an intake-air temperature are disposed on the upstream side of the throttle valve 23, and an intake pressure sensor 26 for detecting an intake pressure (negative pressure) is disposed on the downstream side of the throttle valve 23.

- a portion of the exhaust passage 22 on the downstream side of an exhaust manifold for collectively receiving exhaust gas from the cylinders 12A to 12D is provided with a catalytic converter 37 for purifying the exhaust gas.

- the catalytic converter 37 contains a three-way catalyst which exhibits a significantly high conversion rate of HC, CO and NOx when an air-fuel ratio of exhaust gas is close to a theoretical value. More specifically, the three-way catalyst has an ability of absorbing and storing oxygen therein in an oxygen-rich atmosphere or when exhaust gas has a relatively high oxygen concentration, and releasing the stored oxygen to induce a reaction with HC, CO, etc. when exhaust gas has a relatively low oxygen concentration.

- the catalyst to be used for the catalytic converter 37 is not limited to the three-way catalyst, but may be any other suitable catalyst having the aforementioned oxygen absorbing/storing ability, for example, the so-called lean NOx catalyst capable of purifying NOx in an oxygen-rich atmosphere.

- An alternator 28 is attached to the engine body 1 and connected to the crankshaft 3 through a timing belt or the like.

- This alternator 28 is internally provided with a regulator circuit 28a for controlling a current to be applied to a field coil (not shown) thereof to regulate an output voltage so as to adjust an output, and designed to be controlled according to a control signal sent from the ECU 2 to the regulator circuit 28a so as to generate an output in proportion, for example, to an electric load of a vehicle and a voltage of a battery mounted on the vehicle.

- the engine is provided with a pair of first and second crank angle sensors 30, 31 for detecting a rotational angle of the crankshaft 3.

- the first crank angle sensor 30 is operable to generate a detection signal for use in detecting an engine speed.

- the first and second crank angle sensors 30, 31 are arranged to generate detection signals having a phase lag, and these detection signals are used to detect a rotation direction and a rotational angle of the crankshaft 3, as described later in more detail.

- the engine body 1 is also provided with a cam angle sensor 32 for detecting a specific rotational position of the camshaft to discriminate the cylinders from each other, and a coolant temperature sensor 33 for detecting an engine coolant temperature.

- a cam angle sensor 32 for detecting a specific rotational position of the camshaft to discriminate the cylinders from each other

- a coolant temperature sensor 33 for detecting an engine coolant temperature.

- an accelerator-pedal angle sensor 34 is associated with an accelerator pedal mounted on the vehicle body to detect an accelerator-pedal angle corresponding to a displacement of the accelerator pedal caused by a driver's operation.

- a flywheel (not shown) and a ring gear 35 fixed to the flywheel are fixedly attached to the crankshaft 3 concentrically with respect to the rotational axis of the crankshaft 3.

- the ring gear 35 is an input member for a starter motor 36 serving as a start assist device, and designed to be engageable with an after-mentioned pinion gear 36d of the starter motor 36.

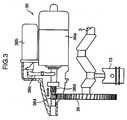

- the starter motor 36 includes a driving motor 36a, an electromagnetically- driven plunger 36b disposed parallel to the driving motor 36a, and a pinion gear 36d which is slidably fitted on an output shaft of the driving motor 36a in a non-rotatable manner relative to the output shaft, and adapted to be reciprocatingly moved along the output shaft by the plunger 36b through a shifting lever 36c.

- the plunger 36b is operable to move the pinion gear 36d from a standby position indicated by the solid lines in FIG. 3 to an engagement position indicated by the two-dot chain lines in FIG. 3 and bring the pinion gear 36d Into engagement with the ring gear 35 so as to rotatively drive the crankshaft 3 to restart the engine.

- the pinion gear 36d of the starter motor 36 employed in this embodiment has helically twisted teeth. Further, in order to facilitate the engagement with the ring gear 35, the starter motor 36 is designed such that, when the ring gear 35 stops, the pinion gear 36d is rotated at a speed of about 60 rpm in a direction opposite to a direction in which the ring gear 35 is to be rotated, and brought into engagement with the ring gear 35.

- the ECU 2 is a control unit for generally controlling operations of the engine.

- the engine starting system is designed to perform a control mode (idling stop mode) for interrupting (cutting) fuel to be injected to the cylinders 12A to 12D upon satisfaction of a predetermined automatic engine stop condition to automatically stop the engine, and then automatically restarting the engine upon satisfaction of a predetermined restart condition, e.g. for example, a driver's operation of the accelerator pedal.

- a control mode for interrupting (cutting) fuel to be injected to the cylinders 12A to 12D upon satisfaction of a predetermined automatic engine stop condition to automatically stop the engine, and then automatically restarting the engine upon satisfaction of a predetermined restart condition, e.g. for example, a driver's operation of the accelerator pedal.

- the ECU 2 In response to receiving respective detection signals from the air-flow sensor 25, the intake pressure sensor 26, the intake-air temperature sensor 29, the crank angle sensors 30, 31, the cam angle sensor 32, the coolant temperature sensor 33 and the accelerator-pedal angle sensor 34, the ECU 2 is operable to generate and send drive signals, respectively, to the fuel injection valves 16, the actuator 24 of the throttle valve 23, the ignition device 27, the regulator circuit 28a of the alternator 28, and the starter motor 36.

- the ECU 2 functionally includes a fuel injection control section 41, an ignition control section 42, an intake-air flow-rate control section 43, an alternator output control section 44, a piston position detection section 45, an in-cylinder temperature estimation section 46, an automatic stop control section 47, a start control section 48, a start-adequacy evaluation section 49, an air-fuel ratio control section 50 and a catalyst temperature estimation section 52.

- the fuel injection control section 41 serves as fuel injection control means for setting a fuel injection timing and a fuel injection amount in each fuel injection timing, and sending a control signal representing them to the fuel injection valves 16. Particularly in this embodiment, a split injection technique is used to supply a fuel for inducing a first combustion in an expansion-stroke cylinder during the engine restart control, as described later in more detail.

- the fuel injection control section 41 is also operable to set split injection timings and a fuel split ratio.

- the ignition control section 42 is operable to set a suitable ignition timing for each of the cylinders 12A to 12D, and send an ignition signal to each of the ignition devices 27.

- the intake-air flow-rate control section 43 is operable to set a suitable intake-air flow rate for each of the cylinders 12A to 12d, and send a throttle opening signal corresponding to the intake-air flow rate to the actuator 24 of the throttle valve 23.

- the opening of the throttle valve 23 is controllably adjusted to allow the piston 13 to be stopped at a position falling within an adequate range for restart of the engine, as described later in more detail.

- the intake-air flow-rate control section 43 is also operable to adjust the opening of the throttle valve 23 for this purpose,.

- the alternator output control section 44 is operable to set a desired target output of the alternator 28, and send a drive signal corresponding to the target output to the regulator circuit 28a. Particularly in this embodiment, during the automatic engine stop control, the output of the alternator 28 is controllably adjusted to change a load onto the crankshaft 3, so as to allow the piston 13 to be stopped at a position falling within an adequate range for restart of the engine, as described later in more detail. Thus, the alternator output control section 44 is also operable to adjust the output of the alternator 28 for this purpose.

- the alternator output control section 44 is operable to allow the alternator 28 to generate a slightly larger output than that in a normal operation so as to increase an engine load to prevent the occurrence of surging (excessively rapid increase in engine speed).

- the piston position detection section 45 is operable to detect a piston position in accordance with respective detection signals of the crank angle sensors 30, 31.

- a crank position and a crank angle (°CA) correspond one-to-one with one another.

- a piston position is indicated by a crank angle as in a common practice.

- an air quantity in each of the expansion-stroke and compression-stroke cylinders is calculated based on each piston position of the cylinders during the automatic engine stop control to control combustion in each cylinder in accordance with the calculated air quantity, as described later In more detail.

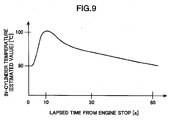

- the in-cylinder temperature estimation section 46 serves as in-cylinder temperature estimation means for estimating an in-cylinder air temperature in each of the cylinders 12A to 12D in accordance with an engine-coolant temperature detected by the coolant temperature sensor 33, an intake-air temperature detected by the intake-air temperature sensor 29 or the like and by use of a map experimentally prepared in advance or the like. Particularly In this embodiment, during the engine restart control, an in-cylinder temperature is estimated in consideration of an engine stop time, or a lapsed time after stop of the engine, to perform the combustion control in accordance with the estimated value, as described later in more detail.

- the automatic stop control section 47 serves as automatic stop control means for allowing the fuel injection to be interrupted upon satisfaction of a given engine stop condition during idling, so as to automatically stop the engine, as described later in more detail.

- the start control section 48 serves as start control means for allowing the automatically stopped engine to be automatically restarted upon satisfaction of an engine restart condition.

- the engine restart control if the stop position of each piston 13 falls within an after-mentioned specific range (adequate range), a certain amount of fuel is injected to at least an expansion-stroke cylinder In the state after stop of the engine, and ignited to induce combustion therein.

- an initial combustion is induced in a compression-stroke cylinder in the state after stop of the engine to move the piston 13 of the compression-stroke cylinder downward, whereby the piston of an expansion-stroke cylinder is moved upward to provide an increased in-cylinder pressure therein.

- the start control section 48 also serves as assist drive control means.

- the start-adequacy evaluation section 49 serves as start-adequacy evaluation means for evaluating the adequacy of engine restart by receiving Inputs from the piston position detection section 45 and the sensors 30, 31 serving as an engine speed detection section, and using an inspection engine speed defined by an engine speed detected at Inspection Time t12 (see FIG. 11) set after the lapse of a given time from initiation of the combustion in the expansion-stroke cylinder.

- the air-fuel ratio control section 50 serves as air-fuel ratio control means for calculating an air-fuel ratio, and determine a fuel amount to be distributed by the fuel injection control section 41 and an intake-air flow-rate to be controlled by the intake-air flow-rate control section 43.

- the catalyst temperature estimation section 52 serves as catalyst temperature estimation means for estimating a temperature of the catalytic converter 37 in accordance with an intake-air temperature detected by the intake-air temperature sensor 29 or the like and by use of a map experimentally prepared in advance or the like. Particularly in this embodiment, during the engine restart control, the catalyst temperature estimation section 52 is operable to estimate a temperature of the catalytic converter 37 so as to allow the fuel injection and the combustion control to be performed in accordance with the estimated value, as described later In more detail.

- the engine restart control is performed as follows. Initially, combustion is induced in the compression-stroke cylinder to move the piston 13 of the compression-stroke cylinder downward so as to reversely rotate the crankshaft 3. Thus, the piston 13 of the expansion-stroke cylinder is moved upward (closer to a top dead center (TDC)) to compress air (air-fuel mixture after the fuel injection) in the expansion-stroke cylinder. In this state, the air-fuel mixture is ignited and burnt to give a driving torque in a normal rotation direction to the crankshaft 3 so as to restart the engine.

- TDC top dead center

- the expansion-stroke cylinder can have an increased air quantity to obtain sufficient combustion energy, as shown in FIG. 4(b).

- BDC bottom dead center

- the ECU 2 (automatic stop control section 47) performs the following control to allow the piston 13 to be stopped at a position falling within the adequate stop range R.

- FIG. 5 is a time chart showing an engine speed Ne, a boost pressure Bt (intake pressure) and an opening K of the throttle valve 23, during an automatic stop control based on the automatic stop control section 47.

- FIG. 6 is an enlarged diagram of a portion of FIG. 5 just before and after Time t1, wherein changes in crank angle CA and transitions of the strokes in each of the cylinders are additionally illustrated.

- the following description will be made on the assumption that the cylinders #1 or 12A, #2 or 128, #3 or 12C, #4 or 12D are expansion-stroke, exhaust-stroke, compression-stroke and intake stroke cylinders, respectively.

- a target engine speed (idling engine speed when the automatic stop condition is satisfied) is stabilized at a value slightly greater than a normal idling engine speed in engine operations without the automatic engine stop control (hereinafter referred to as "normal idling engine speed). For example, if the engine has the normal idling engine speed set at 650 rpm (when an automatic transmission is operated in a drive (D) state), the target engine speed will be set at about 850 rpm (when the automatic transmission is operated in a neutral (N) range). Further, the opening K of the throttle valve 23 is adjusted to allow the boost pressure Bt to be stabilized at a relatively high given value (about - 400 mmHg).

- the fuel injection is interrupted to lower the engine speed Ne. Further, at Time t1 when the fuel injection is interrupted or in the initial stage of the automatic engine stop control, the opening K of the throttle valve 23 is increased to allow the intake-air quantity to be greater than that in an idling operation under the condition that an in-cylinder air-fuel ratio is set to have an excess air ratio ⁇ of 1 (a minimum intake-air quantity required for maintaining an engine operation).

- the opening K of the throttle valve 23 will be increased (for example, up to about 30 %). If the engine is operated in stratified combustion just before Time t1 by use of an air-fuel mixture set to have a lean in-cylinder air-fuel ratio, the opening K of the throttle valve 23 will be maintained as is (at a relatively large opening in the stratified combustion).

- FIGS. 5 and 6 show the former case.

- the boost pressure Bt starts increasing slightly after Time t1 (if the engine is operated in homogeneous combustion just before Time t1), or keeps at a relatively high value (if the engine is operated in stratified combustion just before Time t1), to facilitate scavenging in the combustion chamber.

- the air is introduced Into the cylinder #4 or 12D, the cylinder #2 or 12B, the cylinder #1 or 12A and the cylinder #1 or 12C in this order, as seen in FIG. 6.

- the cylinder #1 or 12A expansion-stroke cylinder

- the cylinder #1 or 12A compression-stroke cylinder

- the solid line indicates a crank angle under the condition that TDCs of the first and third cylinders 12A, 12C are set at 0 (zero)°CA

- the one-dot chain line indicates a crank angle under the condition that TDCs of the second and fourth cylinders 12B, 12D are set at 0 (zero)°CA.

- the solid line and the one-dot chain line become opposite in phase on the basis of 90°CA.

- a time when each piston of the cylinders reaches a compression TDC corresponds to a time when each of the rise-fall waves of the engine speed Ne has a bottom. This means that the engine speed Ne is gradually lowered in such manner as to it temporarily falls off every time each piston of the cylinders reaches a compression TDC and then rises at the time when the piston passes through the compression TDC to form the jiggly rise-fall waves.

- each stop position of the pistons 13 is almost determined by the balance between the respective compressive reaction forces in the compression-stroke cylinder 12C and the expansion-stroke cylinder 12A. Further, the piston stop positions are affected by an air-intake resistance in the suction-stroke cylinder 12D and a frictional resistance of the engine, and varied depending on a rotational inertia force of the engine or the level of the engine speed Ne at Time t4 when the piston of the cylinder 12A passes through the last compression TDC.

- the ECU 2 in this embodiment performs a control for allowing a given TDC engine speed Ne (particularly, the 2nd TDC (Time t3) to the last compression TDC just before stop of the engine is important) during the process of lowering in the engine speed Ne, to fall within a given speed range so as to more reliably stop the piston 13 of the expansion-stroke cylinder 12A at a position falling within the adequate stop range R.

- the output of the alternator 28 is increased or reduced to adjust the load of the crank shaft 3 (engine load) so as to allow the 2nd TDC engine speed Ne (Time t3) to the last TDC engine speed Ne just before stop of the engine to be set in the range of 350 ⁇ 50 rpm.

- the air-intake resistance acting on the piston 13 of the intake-stroke cylinder 12D is increased when the piston 13 of the intake-stroke cylinder 12D is moved toward the BDC, so that the piston 13 of the intake-stroke cylinder 12D is apt to be stopped on the side of the TDC relative to a target position.

- the respective pistons 13 of the intake-stroke and expansion-stroke cylinders 12D, 12A are moved in the same phase.

- the piston 13 of the expansion-stroke cylinder 12A is liable to be stopped at an undesirable position on the side of the TDC relative to the target position.

- K1 about 40 %

- the ECU 2 is operable to determine a time of the passing of the last compression TDC. Specifically, ECU 2 compares the engine speed detected at a time of the passing of each TDC with a given engine speed (e.g.

- the balance of respective intake-air flow rates of the expansion-stroke and compression-stroke cylinders 12A, 12C just before stop of the engine is also affected by the boost pressure Bt.

- the time (Time t3 in FIG. 6) of the passing of the 2nd compression TDC to the last compression TDC just before stop of the engine corresponds to the initial point of the last intake stroke in the compression-stroke cylinder 12C, and thereby a value of the boost pressure Bt at Time t3 has a great impact.

- the conditions allowing the piston 13 of the expansion-stroke cylinder 12A to be stopped at a position on the side of the last phase of the stroke are overlapped to provide higher possibility of being stopped at the target position (100 to 120°CA after the TDC).

- the control for increasing the opening of the throttle valve 23 up to K1 at Time t3 the piston stop position will be located closer to the last phase of the stroke to cause the risk of deviating from the target stop position.

- the opening of the throttle valve 23 at Time t3 is set at the opening K2 (see FIG. 6) less than K1 (or zero opening) to suppress increase in intake-air flow rate so as to prevent the piston stop position of the expansion-stroke position from being excessively moved toward the BDC.

- FIG. 7 is a flowchart showing the process of detecting the piston stop position.

- a first crank angle signal CA1 from the crank angle sensor 30

- a second crank angle signal CA2 from the crank angle sensor 31

- it is determined whether the second crank angle signal CA2 is "High" at the up edge of the first crank angle signal CA1 (Step S41). According to this determination, it is determined which of relationships illustrated in FIG. 8(a) and 8(b) each of the phases of the signals CA1, CA2 has. Then, based on this determination, it is determined whether the engine crankshaft is rotated in the normal direction.

- the second crank angle signal CA2 when the engine crankshaft is rotated in the normal direction, the second crank angle signal CA2 is generated with a phase delay of about half pulse width relative to the first crank angle signal CA1, as shown in FIG. 8(a). Thus, the second crank angle signal CA2 becomes “Low” at the up edge of the first crank angle signal CA1, and becomes “High” at the down edge of the first crank angle signal CA1.

- the second crank angle signal CA2 when the engine crankshaft is rotated in the reverse direction, the second crank angle signal CA2 is generated with a phase advance of about half pulse width relative to the first crank angle signal CA1, as shown in FIG. 8(b).

- the second crank angle signal CA2 in contradiction to the case where the engine crankshaft is rotated in the normal direction, the second crank angle signal CA2 becomes “High” at the up edge of the first crank angle signal CA1, and becomes “Low” at the down edge of the first crank angle signal CA1.

- Step S41 a CA counter for measuring changes in crank angle in a direction corresponding to the normal rotation direction of the engine crankshaft will be incremented (Step S42). If the determination at Step S41 is made as NO, the CA counter will be decremented (Step S43). Then, after stop of the engine, the measured value is checked to determine the piston stop positions (Step S44).

- FIG. 9 is a graph showing the relationship between a lapsed time from the stop of the engine and the in-cylinder temperature, specifically, estimated values of in-cylinder temperature change wherein the in-cylinder temperature at the time when the engine is stopped (Time 5) is 80°C.

- the in-cylinder temperature estimation section 46 stores data of these characteristics in the form of a map.

- the opening K of the throttle valve 23 may be increased to provide enhanced scavenging so as to allow a sufficient amount of flesh air to be supplied to the catalytic converter 37.

- the catalyst in the catalytic converter 37 has a sufficient amount of absorbed oxygen during the engine stop.

- TDC compression top dead center in each of the cylinders 12A to 12d

- B the periods before and after the piston is moved beyond are indicated by "B” and "A”, respectively.

- combustion is initially induced In the compression-stroke cylinder 12C to reversely rotate the engine crankshaft (reverse rotation operation), and then the combustion is induced in the expansion-stroke cylinder 12A to rotate the engine crankshaft in the normal direction again (normal rotation operation), as mentioned above. That is, the piston 13 of the expansion-stroke cylinder 12A is firstly moved upward to increase the compression pressure therein by reversely rotating the engine crankshaft, and then combustion is induced in the expansion-stroke cylinder 12A.

- the piston stop position in the expansion-stroke cylinder 12A stopped at a position falling within the adequate range with a sufficient air quantity therein, and the air compressed by the reverse rotation, can provide large combustion energy. This makes it possible to reliably rotate the engine crankshaft in the normal direction and assure a smooth transition to a subsequent continuous engine operation.

- the presence of the sufficient air in the expansion-stroke cylinder 12A hinders the air from strongly compressed. This is caused by the compressive reaction force from the compressed air which acts as a force pushing back the piston 13 of the expansion-stroke cylinder 12A.

- the ECU 2 performs a control for delaying the timing of fuel injection for the expansion-stroke cylinder 12A to allow the compression rate (density) of air in the expansion-stroke cylinder 12A to be increased.

- the fuel injection timing is delayed, the fuel is injected into the cylinder having the in-cylinder air compressed to some extent, and the compression pressure is reduced by the latent heat of vaporization of the injected fuel.

- the piston 13 can be moved to a position closer to the TDC (increase in piston stroke or moving distance) to provide further increased density of compressed air.

- FIG. 10 is a graph showing the relationship between a fuel injection timing for the expansion-stroke cylinder 12A and a reachable piston position (piston position closest to the TDC without ignition) based on the fuel injection timing, or showing an effect of fuel injection delay.

- the horizontal axis represents a crank angle (after top dead center: ATDC) corresponding to a fuel injection timing for the Initial combustion in the expansion-stroke cylinder 12A

- the vertical axis represent a crank angle (after top dead center: ATDC) corresponding to a reachable piston position in the expansion-stroke cylinder 12A based on the fuel injection timing.

- the in-cylinder volume at a maximum compression becomes smaller (higher air density) to provide larger combustion energy.

- the characteristic in FIG. 10 is obtained when the piston stop position of the expansion-stroke cylinder 12A is 110°C (ATDC).

- the reachable piston position is about 36.5°CA (ATDC).

- the reachable piston position can be changed to 33.5°CA (ATDC) to obtain an increased density of compressed air coresponding to about 3°CA.

- the fuel injection timing is preferably set in the range of the intermediate phase to the beginning of last phase in the compression stroke of the expansion-stroke cylinder 12A.

- the delay of fuel injection timing means a shortened period between fuel injection and ignition which is likely to cause the risk of insufficiently vaporized fuel at the ignition timing.

- the fuel injection is preferably initiated at early phase (e.g. the initial phase of the reverse rotation operation. That is, the increase in air density and the facilitation in fuel vaporization at the ignition timing have contradictory requirements for fuel injection timing.

- a split fuel injection technique (half-split) is employed. Specifically, a first fuel injection is performed In the initial phase of the reverse rotation operation, and a second fuel injection is performed during the reverse rotation operation (preferably, at the timing corresponding to a crank angle closer to 90°CA (ATDC) or the midpoint of the stroke: the timing corresponding to 70°CA (ATDC) in FIG. 10).

- ATDC 90°CA

- ATDC 70°CA

- the fuel injection control section 41 of the ECU 2 is operable to correct the ratio (split ratio) between respective fuel amounts in the first and second fuel injections, and the timing of the second fuel injection, in accordance with the piston stop position of the expansion-stroke cylinder 12A, and the in-cylinder air temperature (estimated value) at the initiation of the reverse rotation operation, so as to ensure a desired vaporization performance and maximize combustion energy. Specifically, if the piston stop position In the expansion-stroke cylinder 12A is located relatively close to the BDC (in-cylinder air quantity is relatively large), the percentage of the second fuel injection amount will be increased as compared to the case where the piston stop position in the expansion-stroke cylinder 12A is located relatively close to the TDC (in-cylinder air quantity is relatively small).

- the relatively large in-cylinder air quantity causes a high compressive reaction force.

- the second fuel injection amount is increased to effectively provide a reduced compression force so as to achieve an increased density of compressed air.

- the percentage of the second fuel injection amount is also Increased when the in-cylinder air temperature is relatively high. The reason is that the high in-cylinder air temperature provides an enhanced fuel vaporization performance, and thereby relaxes the requirements of increasing the first fuel Injection amount.

- the timing of the second fuel injection it is delayed when the in-cylinder temperature is relatively high (wherein the upper limit is set at the timing corresponding to the injection timing 70°CA in FIG. 10).

- the high in-cylinder air temperature provides an enhanced fuel vaporization performance, and thereby the vaporization of the injected fuel can be facilitated before the ignition even if the second fuel injection timing is delayed.

- the delayed fuel injection timing can facilitate increase in compressed air density.

- an Inspection Time t12 is set at a time where the piston of the intake-stroke cylinder 12D reaches the 2TDC, and the engine speed Ne at the inspection Time t2 is detected as an inspection engine speed. Then, based on the detected inspection engine speed, the start, the start-adequacy evaluation section 49 of the ECU 2 is operable to evaluate whether the direct start is successively achieved.

- Step S101 it is determined whether a given restart condition is satisfied (for example, whether an accelerator pedal operation for starting a stopped vehicle is performed; whether a battery voltage is less than a predetermined value; or whether an air conditioner is activated) (Step S101). If the determination in Step S101 is NO, or it is determined that the engine restart condition is not satisfied, the ECU 2 will be kept in a standby state.

- a given restart condition for example, whether an accelerator pedal operation for starting a stopped vehicle is performed; whether a battery voltage is less than a predetermined value; or whether an air conditioner is activated

- Step S101 determines whether the in-cylinder temperature estimation section 46 is based on the stop position of each piston 13 detected by the piston position detection section 45.

- respective air quantities in the compression-stroke cylinder 12C and the expansion-stroke cylinder 12A are calculated (Step S103). Specifically, a volume of the combustion chamber in each of the compression-stroke and expansion-stroke cylinders 12C, 12A can be calculated from the stop position of the corresponding piston 13.

- a flesh air quantity can be derived from the calculated combustion chamber volume, because the engine has several cycles in the period from the interruption of the fuel injection to the engine stop to allow the cylinders including the expansion-stroke cylinder 12A to be filled with flesh air, and an in-cylinder pressure in each of the compression-stroke and expansion-stroke cylinders 12C, 12A becomes approximately equal to atmosphere pressure after the engine stop.

- Step S104 it is determined whether the piston stop position in the compression-stroke cylinder 12C is located at a position falling within the adequate stop range (of 60 to 80°CA before TDC or BTDC 60 to 80°CA) and relatively close to the bottom dead center (BDC) In the compression-stroke cylinder 12C (Step S104),

- Step S104 determines whether the compression-stroke cylinder 12C contains a relatively large air quantity. If the determination in Step S104 is YES, and it Is determined that the compression-stroke cylinder 12C contains a relatively large air quantity, the process will advance to Step S105.

- Step 105 a given amount of fuel is injected into the compression-stroke cylinder 12C containing the air quantity calculated in Step S103 to form therein an air-fuel mixture with an air-fuel ratio having ⁇ (excess air ratio) > 1 (e.g. air-fuel ratio: about 20) (initial or primary fuel injection).

- This air-fuel ratio is determined using a first air-fuel ratio map M1 for the primary fuel injection in a compression-stroke cylinder, which is predetermined with respect to each piston stop position.

- the lean air-fuel ratio having A > 1 can prevent combustion energy for the reverse rotation operation from being excessively produced, so as to avoid the risk of excessive movement in the reverse rotation direction (the piston 13 of the compression-stroke cylinder 12C moved in the reverse rotation toward the BDC direction passes through the BDC and reached an intake stroke), even if the compression-stroke cylinder 12C contains a relatively large air quantity.

- This air-fuel ratio is determined using a second air-fuel ratio map M2 for the primary fuel injection in a compression-stroke cylinder.

- Step S107 the process advances to Step S107, at a time (Time t10 in FIG. 11) after the lapse of a given time predetermined in consideration of a period of time required for vaporization of the fuel injected into the compression-stroke cylinder 2C through the primary fuel injection, the obtained air-fuel mixture in the cylinder 12C is ignited. Subsequently, it is determined whether the pistons 13 are moved, based on whether at least one edge (rising (up) or falling (down) edge) of detection signals from the crank angle sensors 30, 31 is detected within a given time after the ignition (Step S108).

- Step S109 If the determination in Step S108 is NO or it is determined that the pistons 13 are not moved due to misfire, an additional ignition will be performed for the compression-stroke cylinder 12C (Step S109).

- a split ratio [the ratio between a first (initial) injection and a second (last) injection] In a split fuel injection for the expansion-stroke cylinder 12A is calculated based on and the in-cylinder temperature estimated in Step S102 and the piston stop position (Step S121).

- the percentage of the last injection is set at a larger value as the piston stop position in the expansion-stroke cylinder 12A is located closer to the BDC, and the in-cylinder temperature is higher.

- This total air-fuel ratio is determined using an air-fuel ratio map M3 for the expansion-stroke cylinder 12A, predetermined with respect to each stop position of the piston 13.

- an initial (first) fuel injection amount for the expansion-stroke cylinder 12A is calculated based on the total fuel injection amount calculated in Step S122 and the split ratio calculated in Step S121, and the calculated amount of fuel is injected (Step S123).

- a last (second) fuel injection timing for the expansion-stroke cylinder 12A is calculated based on the in-cylinder temperature estimated in Step S102 (Step S124).

- This second injection timing is set to be in a period where the in-cylinder air is being compressed after the piston 13 starts moving toward the TDC (reverse rotation of the engine crankshaft), so as allow latent heat of vaporization of the injected fuel to effectively reduce a compression pressure (or allow the piston 13 to be moved toward the TDC as close as possible.

- the second injection timing is also set to maximize a period of time for allowing the fuel in the second injection to be vaporized before an ignition timing therefor.

- a last (second) fuel injection amount for the expansion-stroke cylinder 12A is calculated based on the total fuel injection amount for the expansion-stroke cylinder 12A calculated in Step S122 and the split ratio calculated in Step S121 (Step S125), and this fuel is injected at the second injection timing calculated in Step S124 (Step 126).

- Step S127 After the second fuel injection to the expansion-stroke cylinder 12A, the obtained air-fuel mixture is ignited after the lapse of a given delay time-period (at Time t11 in FIG. 11) (Step S127).

- This delay time-period is determined using an ignition map M4 for the expansion-stroke cylinder 12A, predetermined with respect to each stop position of the piston 13.

- the rotation direction of the engine crankshaft is changed from the reverie rotation to the normal rotation.

- the piston 13 of the compression-stroke cylinder 12C is moved toward the TDC to start compressing in-cylinder gas (burnt gas through the combustion induced by the ignition in Step S107).

- a secondary fuel injection is performed for the compression-stroke cylinder 12C (Step S128).

- the amount of fuel in the secondary fuel injection is determined to allow a total air-fuel ratio based the sum of respective fuel injection amounts in the primary and secondary fuel injections to be richer (e.g. about 6) than a combustible air-fuel ratio (lower limit: 7 to 8), by use of an air-fuel ratio map M5 for the secondary fuel injection, predetermined with respect to each stop position of the piston 13.

- a compression pressure around 1TDC in the compression-stroke cylinder 12C can be reduced to allow the piston 13 to readily pass through this 1TDC.

- the secondary fuel injection to the compression-stroke cylinder 12C is intended only to reduce the in-cylinder compression pressure. That is, no ignition for inducing combustion is executed (the obtained air-fuel mixture richer than a combustible air-fuel ratio causes no self-ignition).

- the resulting unburnt fuel will be purified through the reaction with oxygen stored in the catalyst of the catalytic converter 37 in the exhaust passage 22.

- the fuel injected by the secondary fuel injection for the compression-stroke cylinder 12C Is not burnt.

- combustion subsequent to the first combustion in the expansion-stroke cylinder 12A is induced in the intake-stroke cylinder 12D.

- Energy of the first combustion in the expansion-stroke cylinder 12A is partly used as energy required for the piston 13 of the intake-stroke cylinder 12D to pass through 2TDC. That is, the energy of the first combustion in the expansion-stroke cylinder 12A is used as both energy required for the piston 13 of the compression-stroke cylinder 12C to pass through the 1TDC and energy required for the piston 13 of the intake-stroke cylinder 12D to pass through the 2TDC.

- Step S140 an air density in the intake-stroke cylinder 12D is estimated to calculate an air quantity therein In accordance with the estimated value. Then, in Step S102, based on the in-cylinder temperature estimated in Step S102, an air-fuel ratio correction value for preventing self-Ignition is calculated (Step S141). Specifically, the occurrence of self-ignition leads to combustion generating an undesirable force (counter torque) pushing back the piston 13 toward the BDC before reaching the 2TDC. This undesirably causes additional consumption of the energy for passing through the 2TDC. Thus, the air-fuel ratio is corrected to a leaner value to prevent the occurrence of self-ignition.

- Step S142 based on the air quantity in the intake-stroke cylinder 12D calculated in Step S140, and an air-fuel ratio corrected by the air-fuel ratio correction value calculated in Step S141, a fuel injection amount for the intake-stroke cylinder 12D is calculated (Step S142).

- Step S143 the calculated amount of fuel is injected into the intake-stroke cylinder 12D.

- This fuel injection is executed at a delayed timing set in the last phase of a compression stroke to allow latent heat of vaporization of the fuel to effectively reduce a compression pressure (or allow the energy require for passing through the 2TDC to be reduced) (Step S143).

- This delay time-period is calculated based on the lapsed time after completion of the automatic engine stop control (automatic stop period of the engine), the intake temperature, the engine coolant temperature, etc.

- the start-adequacy evaluation section 49 of the ECU 2 calculates the inspection time on the basis of a reference time defined by the time when the edge of the detection signals from the crank angle sensors 30, 31 in Step S108 (Step S145).

- Step S146 it is determined whether the engine speed (inspection engine speed) Ne at Time t12 in FIG. 11 is less than a given required engine speed (e.g. 200 rpm) (Step S146).

- the inspection engine speed is equal to or greater than the required engine speed in this determination, as in the characteristic curve indicated by the broken line in FIG. 11, it can be considered that the piston of the Intake-stroke cylinder will be moved beyond the 2TDC.

- the ignition timing in the intake-stroke cylinder Is retarded or delayed after the 2TDC (Step S148).

- the above process makes it possible to reduce the compression pressure in the intake-stroke cylinder 12D before the 2TDC so as to allow the piston of the intake-stroke cylinder 12D to be reliably moved beyond the 2TDC, and to Induce combustion in the intake-stroke cylinder 12D after passing of the 2TDC so as to generate a torque in the normal rotation direction.

- Step S146 if the inspection engine speed is less than the required engine speed, as in the characteristic curve indicated by the solid line in FIG. 11, the process will advance to a simultaneous starter-motor drive subroutine, and Step S148 will be skipped.

- the start control section 48 waits until Time t13 when the engine speed Ne becomes lower and initially reaches 0 (zero) is detected by the crank angle sensor 30 (Step S1471).

- the start-adequacy evaluation section 49 defines this Time t13 as an assist-control reference time for performing a calculation related to an assist control on the basis thereof (Step S1472).

- Step S1473 a period of time between Time t13 and a zero-speed Time tp when the engine speed Ne becomes 0 (zero) by a transition in rotation direction of the engine crankshaft 3 from the reverse direction occurring at Time t13 to the normal direction is calculated. Further, based on the calculated zero-speed Time tp an engagement time range Ts for the engagement with the starter motor 36 is calculated (Step S1474).

- This engagement time range Ts is determined based on data of product specifications of the starter motor 36 employed in this embodiment. The data is pre-stored in a storage area of the ECU 2.

- the engine starting system is designed such that, when the ring gear 35 is stopped, the pinion gear 36b is driven by driving motor 36a at about 60 rpm in a direction opposite to that in which the ring gear 35 is to be rotated, and brought into engagement with the ring gear 35.

- the engagement time range is set in a range where the engine speed Ne is increased from 0 (zero) to 60 rpm.

- a driving delay time-period Tdy in the starter motor 36 is calculated based on the buttery voltage (Step S1475).

- the engine starting system according to this embodiment is designed such that the pinion gear 36b is brought into engagement with the ring gear 35, in the state when it is rotated by driving motor 36a in a direction opposite to that in which the ring gear 35 is to be rotated.

- a certain time lag i.e. driving delay time-period Tdy

- Step S1475 Time t out is calculated in consideration of the driving delay time-period Tdy.

- the start control section 48 determines whether a lapsed time from Time t13 reaches Time t out (Step S1477). Upon reaching t out , the drive signal is entered into the driving motor 36a of the starter motor 36 (Step S1478). Thus, the pinion gear 36b of the starter motor 36 is driven by the driving motor 36a, and bought Into engagement with the ring gear 35. Then, the crankshaft 3 is assisted by a driving force from the starter motor 36, and the process returns to the main routine.

- the start control section 48 is designed to define the Time t13 when the engine speed Ne becomes lower and initiatiy reaches 0 (zero), in accordance with the engine speed Ne signal detected by the crank angle censor 30, the Time t13 may be defined based on a time of a transition in rotation direction of the crankshaft 3 to be detected by the pair of crank angle sensors 30, 31, or a signal representing a time when the engine crankshaft has a transition in rotation direction from the normal direction to the reverse direction, which can be obtained from respective detection signals of the pair of crank angle sensors 30, 31.

- engine restart control may be shifted to a normal engine control after the passing of 2TDC by means of the direct start control or the combination of the direct start control and the starter motor, an additional control for suppressing engine speed surging is performed in this embodiment.

- engine speed surging herein means a phenomenon that an engine speed is increased excessively and rapidly after the first combustion in the intake-stroke cylinder 12D. The sharp increase in engine speed due to the engine speed surging undesirably causes acceleration shock and driver's uncomfortable feel.

- the intake pressure (pressure on the downstream side of the throttle valve 23) is approximately equal to atmosphere pressure during the automatic stop period, and thereby combustion energy in each of the cylinders 12A to 12D just after engine start (after the first combustion in the intake-stroke cylinder 12D) temporarily becomes greater than that in normal idling to cause the engine speed surging.

- a control for setting an air-fuel ratio at a lean value ( ⁇ > 1) and/or delaying an ignition timing depending on the temperature of the catalytic converter 37 to suppress the engine speed surging is performed In the subsequent Steps S149 to S159.

- the alternator 28 is firstly activated to generate power (Step S149). Under the control of the alternator output control section 44 of the ECU 2, a target output current in this power generation Is set at a value slightly greater than a normal value. This power generation of the alternator 28 provides an increased load onto the crankshaft 3 (engine load) to suppress engine speed surging.

- Step S150 it is determined whether the intake pressure detected by the Intake pressure sensor 26 is greater than that during a normal idling without the automatic engine stop control. If the determination in Step S150 is YES, or the current condition is liable to cause engine speed surging, the opening of the throttle valve 23 will be reduced to be less than that during the normal idling (Step S151) to suppress the amount of combustion energy to be produced.

- Step S152 it is determined whether the catalyst of the catalytic converter 37 in the exhaust passage 22 has a temperature equal to or less than an activation temperature thereof (Step S152).

- the amount of combustion energy to be produced can be further suppresses by the delayed ignition timing.

- Step S152 If the determination in Step S152 is made as NO, the target air-fuel ratio is set at a lean value or ⁇ > 1 and fuel is injected (Step S158). In this case, the fuel is burnt without delaying the ignition timing (Step S159). This lean combustion makes it possible to achieve reduced fuel consumption and suppress the amount of combustion energy to be produced.

- Step S154 or S159 the process returns to Step S150, the process will be repeated until the determination at Step S150 is made as NO. If the determination at Step S150 is made as NO, or the current condition has no risk of causing engine speed surging, the engine control including the alternator output control will return to the normal control (Step S160).

- the success/failure or adequacy of the so-called direct start is determined based on the engine speed Ne at Inspection Time t12.

- the starter motor 36 will not be always driven. This can contributes to energy saving as compared the conventional technique disclosed in the aforementioned Publication 2.

- the starter motor 36 is driven after the engine crankshaft has the transition in rotation direction from the reverse direction to the normal direction and in a time range near to the zero-speed Time tp. This makes it possible to assist the engine start in the stage where a load to be imposed on the starter motor 36 is minimum.

- the starter motor 36 can have reduced load and enhanced reliability. In addition, this can contribute to enhancement in durability of the starter motor 36 itself.

- the starter motor 36 includes the pinion gear 36d engageable with the ring gear 35 associated with the engine, and the start control section 48 is operable, after the engine crankshaft has the transition in rotation direction from the reverse direction to the normal direction, to determine the timing of engagement with the pinion gear 36a in the time range near to the zero-speed Time tp, and to allow the assist operation based on the starter motor 36 to be initiated after the engagement between the pinion gear 36d and the ring gear 35.

- the crank angle sensors 30, 31 serving as the rotational speed detection means are operable to send to the start control section 48 an assist-control reference Time t13 defined by a time when the engine speed is lowered from the inspection engine speed Ne to zero, and the start control section 48 is operable to calculate the zero-speed Time tp in accordance with the received assist-control reference Time t13 and determine the time range of the engagement between the pinion gear 36d and the ring gear 35 in accordance with the calculated zero-speed Time tp.

- the start control section 48 is operable to calculate the driving delay time-period Tdy in the starter motor 36, and determine the an output time of the drive signal in accordance with the calculated driving delay time-period Tdy in such a manner as to allow the drive signal to be output at a time earlier than the zero-speed Time tp. That is, the driving delay time-period Tdy in the starter motor 36 Is Included in one of control parameters.

- the starter motor 36 has a time lag between the receiving of the drive signal and the driving of the engine, an intended assist initiation time can be reliably set. This makes it possible to allow tolerance of the driving delay time-period in the starter motor 36 to be relaxed so as to provide applicability of various types of alternators and contribute to cost reduction.

- the start-adequacy evaluation means may be operable to estimate a time when the expansion-stroke cylinder 12A first reaches a top dead center in an exhaust stroke, so as to defined the estimated time as Inspection Time t12, and evaluate the adequacy of the engine restart in accordance with an inspection engine speed Ne defined by the engine speed detected at the inspection Time t12 and received from the rotational speed detection means.

- the inspection time t12 can be estimate relatively accurately. This has an advantage of being able to accurately evaluate the adequacy of the inspection engine speed Ne and detect the inspection engine speed Ne readily and accurately so as to achieve enhanced control accuracy.

- the control In combination with the assist operation using the starter motor 36 may also be performed, but not shown in the above embodiment, when a given condition is not satisfied (for example, when the piston stop position is not in the adequate range), and/or when the engine speed does not reach a given value within a given period of time after the initiation of the engine restart control.

- the start assets device While it is preferable to use the starter motor 36 having the pinion gear engageable with the ring gear fixed to the flywheel of the engine, the start assets device to be used in the present invention is not limited to this type designed to output a driving power from the pinion gear, but may be any other suitable type, such as a belt type.

- the automatic engine stop control to be used in the present invention is not limited to the control described in the above embodiment, but may be appropriately arranged. However, in order to achieve an enhanced engine restart performance, it is desirable to control in such a manner that the piston 12 of the expansion-stroke cylinder 12A is stopped at a position slightly close to the BDC relative to the midpoint of the stroke (in the compression-stroke cylinder 12C: a position slightly close to the TDC relative to the midpoint of the stroke).

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Control Of Vehicle Engines Or Engines For Specific Uses (AREA)

- Combined Controls Of Internal Combustion Engines (AREA)

- Output Control And Ontrol Of Special Type Engine (AREA)

Abstract

Disclosed is an engine starting system for restarting an automatically stopped engine in

such a manner as to rotate a crankshaft in a reverse rotation direction and then to rotate the

crankshaft In a reverse rotation direction. The engine starting system comprises

start-adequacy evaluation means operable to evaluate the adequacy of the engine start in

accordance with an inspection engine speed defined by an engine speed Ne at an inspection

time t12 which is set at a time when a given time lapses from initiation of the combustion in a

cylinder in the state after being stopped in a compression stroke. The engine restart system is

designed such that, when the start-adequacy evaluation means determines that the inspection

engine speed is less than an engine speed required for normally restarting the engine, a start

assist device is driven at a given timing. The engine starting system of the present invention

can automatically stop an engine to improve fuel consumption, and quickly restart the engine in

a manner for minimizing the frequency in use of a starter motor and/or needless combustion to

facilitate energy saving.

Description

The present invention relates to an engine starting system, and more particularly to an

engine starting system for automatically stopping an engine in an operating state, such as idling

state, when a given automatic stop condition is satisfied, and then restarting the engine when a

given restart condition is satisfied.

In late years, as part of measures for reductions In fuel consumption and CO2 emissions,

efforts have been made to develop an engine staring system intended to automatically stop an

engine in an operating state, such as an idling state, and then automatically restart the engine

upon satisfaction of a restart condition, e.g. a driver's action for vehicle start. From a technical

standpoint, there has been known one technique of supplying fuel to a cylinder which is in an

expansion stroke position after an engine is stopped, and inducing combustion In the cylinder to

start the engine by means of the resulting combustion energy, as disclosed, for example, in the

following Publications 1 and 2.

WO 01/44636 A2 [Hereinafter referred to as Publication 1]

JP 2002-4985 A1 [Hereinafter referred to as Publication 2]

As measures for achieving a higher success rate in automatically restarting the automatically stopped engine, thePublication 1 further discloses a technique of controlling an exhaust valve

closing timing after an ignition switch is turned off, so as to stop the engine at a given crank

angle.

WO 01/44636 A2 [Hereinafter referred to as Publication 1]

JP 2002-4985 A1 [Hereinafter referred to as Publication 2]

As measures for achieving a higher success rate in automatically restarting the automatically stopped engine, the

It is also known that, when an engine cannot be adequately started only by combustion in a

cylinder which is in an expansion stroke position after the engine is stopped, a starter motor

(motor for starting an engine) is additionally driven to provide enhanced reliability of engine