EP1533125B3 - Ink cartridge, ink cartridge unit and ink jet printhead - Google Patents

Ink cartridge, ink cartridge unit and ink jet printhead Download PDFInfo

- Publication number

- EP1533125B3 EP1533125B3 EP03026434A EP03026434A EP1533125B3 EP 1533125 B3 EP1533125 B3 EP 1533125B3 EP 03026434 A EP03026434 A EP 03026434A EP 03026434 A EP03026434 A EP 03026434A EP 1533125 B3 EP1533125 B3 EP 1533125B3

- Authority

- EP

- European Patent Office

- Prior art keywords

- ink cartridge

- ink

- orifice

- housing

- seal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007789 sealing Methods 0.000 claims abstract description 17

- 239000011148 porous material Substances 0.000 claims description 2

- 238000007641 inkjet printing Methods 0.000 claims 5

- 229920001971 elastomer Polymers 0.000 claims 1

- 239000000806 elastomer Substances 0.000 claims 1

- 239000012858 resilient material Substances 0.000 claims 1

- 239000013013 elastic material Substances 0.000 abstract 1

- 238000003780 insertion Methods 0.000 description 7

- 230000037431 insertion Effects 0.000 description 7

- 239000006260 foam Substances 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- 239000004743 Polypropylene Substances 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- -1 polypropylene Polymers 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 238000005086 pumping Methods 0.000 description 2

- 238000009423 ventilation Methods 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000013270 controlled release Methods 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 229920002725 thermoplastic elastomer Polymers 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/17—Ink jet characterised by ink handling

- B41J2/175—Ink supply systems ; Circuit parts therefor

- B41J2/17503—Ink cartridges

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/17—Ink jet characterised by ink handling

- B41J2/175—Ink supply systems ; Circuit parts therefor

- B41J2/17503—Ink cartridges

- B41J2/17553—Outer structure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/17—Ink jet characterised by ink handling

- B41J2/175—Ink supply systems ; Circuit parts therefor

- B41J2/17503—Ink cartridges

- B41J2/17513—Inner structure

Definitions

- the invention relates to an ink cartridge and to an ink cartridge unit and to an inkjet printhead, each comprising such an ink cartridge for use in an inkjet printer.

- the invention is based on the object to provide a generic ink cartridge, which can cooperate with a simple design adapter so that the ink path is reliably sealed so that no disturbing contamination can occur and that it is also easy to use and removable.

- This object is solved by the features in the characterizing part of claim 1.

- the ink cartridge according to the invention can be used in a simple manner by means of straight, substantially friction-free insertion.

- the ink path to the adapter is thus made without further measures. Nevertheless, leakage of ink is reliably prevented.

- the ink cartridge according to the invention can also be removed very easily.

- the invention also provides an ink cartridge unit in which the outlet port is reliably sealed in a very simple manner so that it can be safely and easily transported and stored.

- an inkjet printhead is described which, in addition to the ink cartridge according to the invention, comprises an adapter with nozzle plate to which it can be fastened.

- the adapter is of a very simple construction and cooperates with the ink cartridge according to the invention in such a way that the ink path is reliably sealed and interruption thereof can not occur.

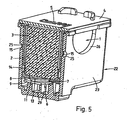

- the ink cartridge 1 has ( Fig.1 . 5 . 6 ) a housing 2, which surrounds a chamber which contains a saturated with ink storage body 3 of open-cell foam and which is closed by a cover 4 with a ventilation opening 5.

- the ventilation opening 5 opens at the top of the lid 4 in a meander-shaped depression, which widens at the end.

- the recess with the exception of the extension at the end, be covered by, for example, an adhesive label and forms an expansion space, which absorbs ink if necessary.

- an ink outlet 6 is provided at the bottom of the housing 2.

- the housing has an opening 7 (FIG. Fig. 5 ), in which a seal 8 is inserted.

- the seal 8 comprises an approximately square contact plate 9, the upper side rests against the underside of the housing 2 and the underside forms an exposed sealing surface 10 and a at the top thereof to the contact plate 9 subsequent, with her einstükkigen ring 11.

- the Contact plate 9 shortened slightly at one corner and abuts there on a projecting from the bottom of the housing 2 cams.

- In the center of the sealing surface 10 there is an outlet opening 12, to which a passage surrounded by the ring 11 connects, which connects it to the chamber in the interior of the housing 2.

- the ring 11 has at the upper end a radially outwardly projecting circumferential collar 13 which projects on the inside of the housing 2 on the slightly depressed edge of the opening 7 and so the seal 8 is snap-locked in the same, so that it is not removable without deformation , At the same time the collar 13 improves the seal between the edge of the opening 7 and the outside of the ring 11.

- a guide element 14 connected to the seal 8, a round plate made of porous material, e.g. made of open-cell foam or of parallel fibers, which lead axially from the interior of the chamber to the outside exists.

- the housing 2 On the side walls, the housing 2 has two opposing spherical cap-shaped flat locking cams 15 and each slightly below it, not far away from the lower edge, rectangular recesses 16.

- the housing 2 and the lid 4 are made of plastic, preferably polypropylene.

- the storage body 3 may consist of PUR and the guide element 14, if it is designed as a foam body, also, if it is formed as a fiber bundle, made of polyester.

- the contact plate 9 and the ring 11 are made of a material that is elastic and softer than the material of the housing 2, e.g. made of a thermoplastic elastomer.

- the ink cartridge 1 For shipping and storage, the ink cartridge 1 by ( Fig. 3, 4 ) a closure member 17 added to an ink cartridge unit.

- the one-piece closure member 17 comprises a rectangular closure plate 18 and at its opposite ends approximately at right angles protruding parallel retaining wings 19a, b, of which the retaining wing 19a has an obliquely protruding tab 20.

- Die Lasche 20 ist in der Ausbloodung 17 des Geotrouses 19a anorg.

- Each of the retaining wings 19a, b bears against the respectively opposite retaining wing 19b;

- the projection 17 is snap-locked to the housing 2 of the ink cartridge 1 by engaging the projections 21 with the recesses 16.

- the top of the closure plate 18 presses against the sealing surface 10, so that the outlet opening 12 is reliably and tightly closed.

- the closure member 17 consists of a relatively rigid elastic plastic, eg polypropylene.

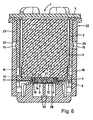

- the ink cartridge 1 forms with an adapter 22 (FIG. Fig. 2 . 5 . 6 ) an ink jet printhead as used in ink jet printers.

- the adapter 22 has a housing 23, which forms a receptacle 24 open at the top, into which the ink cartridge 1 can be inserted.

- the side walls of the housing 23 have mutually opposite round detent holes 25, with which engage the locking cam 15, so that the inserted ink cartridge 1 is locked to the adapter 22.

- At the top they also have semi-circular recesses 26, which facilitate the insertion and removal of the ink cartridge 1.

- the housing 23 carries a nozzle plate (not shown) for the controlled release of ink droplets. Nozzle plates and their control are well known.

- the adapter 22 has a receiving opening 27 surrounded by a stepped frame, in which a sieve-like filter 28 is arranged, which is e.g. formed as a braid of metal wires and the interception of larger particles is used, which could otherwise clog the nozzle of the nozzle plate, with which the receiving opening 27 via a connecting thereto the same cavity 29 and (not shown) lines in communication.

- the effective between the adapter 22 and the ink cartridge 1 latching connection is designed so that the sealing surface 10 presses frontally against the frame of the receiving opening 27, such that of the chamber of the ink cartridge 1 through the outlet opening 12 and the receiving opening 27 to the cavity 29 leading Ink path to the outside, ie is reliably sealed against the surrounding areas of the receiving compartment 24, and the ink is passed from the storage body 3 to the nozzle plate without interrupting the flow of ink through air entering from the surrounding area of the receiving compartment 24 or, conversely, discharging ink into the receiving compartment 24.

- the housing 23 of the adapter 22 is also made of plastic, e.g. glass fiber reinforced PET.

- the ink cartridge 1 is very easy to use by a rectilinear movement in the receiving compartment 24.

- the sealing of the ink path results by itself and without the insertion of the ink cartridge 1 friction between the seal and mating surfaces, with which it cooperates, would arise, which could hinder the insertion. Effortless insertion of a seal on the bottom of the receiving compartment is not required.

- the ink cartridge and the closure part and the adapter can be modified in many ways.

- the ink cartridge may be suitable for color printing and multiple, e.g. have three or four separate chambers, each with a storage body, which is impregnated with an ink of a different color and a Tntenauslass.

- the adapter must then be designed accordingly, with several receiving openings and suitable nozzle plate and control.

- it may be provided with three or four storage compartments each having a receiving opening, each suitable for receiving a single-chamber ink cartridge containing ink of a particular color.

Landscapes

- Ink Jet (AREA)

Abstract

Description

Die Erfindung betrifft eine Tintenpatrone sowie eine Tintenpatroneneinheit und einen Tintenstrahldruckkopf, welche jeweils eine derartige Tintenpatrone umfassen für den Einsatz in einem Tintenstrahldrucker.The invention relates to an ink cartridge and to an ink cartridge unit and to an inkjet printhead, each comprising such an ink cartridge for use in an inkjet printer.

Aus der

Bei einer im übrigen ähnlichen Lösung (

Gemäss

Der Erfindung liegt die Aufgabe zu Grunde, eine gattungsgemässe Tintenpatrone anzugeben, welche mit einem einfach aufgebauten Adapter so zusammenwirken kann, dass der Tintenpfad zuverlässig abgedichtet ist, so dass keine störenden Verschmutzungen auftreten können und dass sie zugleich leicht einsetzbar und entfernbar ist. Diese Aufgabe wird durch die Merkmale im Kennzeichen des Anspruchs 1 gelöst.The invention is based on the object to provide a generic ink cartridge, which can cooperate with a simple design adapter so that the ink path is reliably sealed so that no disturbing contamination can occur and that it is also easy to use and removable. This object is solved by the features in the characterizing part of

Die erfindungsgemässe Tintenpatrone kann durch gerades, im wesentlichen reibungsfreies Einschieben auf einfache Weise eingesetzt werden. Der Tintenpfad zum Adapter ist damit ohne weitere Massnahmen hergestellt. Trotzdem ist ein Austreten von Tinte zuverlässig unterbunden. Die erfindungsgemässe Tintenpatrone kann auch sehr leicht wieder entfernt werden.The ink cartridge according to the invention can be used in a simple manner by means of straight, substantially friction-free insertion. The ink path to the adapter is thus made without further measures. Nevertheless, leakage of ink is reliably prevented. The ink cartridge according to the invention can also be removed very easily.

Die Erfindung gibt ausserdem eine Tintenpatroneneinheit an, bei welcher die Auslassöffnung auf sehr einfache Weise zuverlässig verschlossen ist, so dass sie sicher und problemlos transportiert und gelagert werden kann. Zudem wird ein Tintenstrahldruckkopf beschrieben, welcher neben der erfindungsgemässen Tintenpatrone einen Adapter mit Düsenplatte umfasst, an welchem dieselbe befestigbar ist. Der Adapter ist sehr einfach aufgebaut und wirkt so mit der erfindungsgemässen Tintenpatrone zusammen, dass derTintenpfad zuverlässig abgedichtet ist und eine Unterbrechung desselben nicht eintreten kann.The invention also provides an ink cartridge unit in which the outlet port is reliably sealed in a very simple manner so that it can be safely and easily transported and stored. In addition, an inkjet printhead is described which, in addition to the ink cartridge according to the invention, comprises an adapter with nozzle plate to which it can be fastened. The adapter is of a very simple construction and cooperates with the ink cartridge according to the invention in such a way that the ink path is reliably sealed and interruption thereof can not occur.

Im folgenden wird die Erfindung anhand von Figuren, welche lediglich ein Ausführungsbeispiel darstellen, näher erläutert. Es zeigen

- Fig. 1

- eine Explosionsdarstellung einer erfindungsgemässen Tintenpatrone,

- Fig. 2

- einen Adapter eines erfindungsgemässen Tintenstrahldruckkopfs,

- Fig.3 3

- eine erfindungsgemässe Tintenpatroneneinheit,

- Fig.4 4

- ein Verschlussteil der Tintenpatroneneinheit nach

Fig. 3 , - Fig. 5

- einen erfindungsgemässen Tintenstrahldruckkopf, teilweise geschnitten und

- Fig. 6

- einen Schnitt durch den Tintenstrahldruckkopf nach

Fig. 5 .

- Fig. 1

- an exploded view of an inventive ink cartridge,

- Fig. 2

- an adapter of an inventive inkjet printhead,

- 3

- an ink cartridge unit according to the invention,

- Fig.4 4

- a closure part of the ink cartridge unit

Fig. 3 . - Fig. 5

- an inventive ink jet print head, partially cut and

- Fig. 6

- a section through the inkjet printhead after

Fig. 5 ,

Die erfindungsgemässe Tintenpatrone 1 weist (

Die Dichtung 8 umfasst eine etwa quadratische Kontaktplatte 9, deren Oberseite an der Unterseite des Gehäuses 2 anliegt und deren Unterseite eine freiliegende Dichtfläche 10 bildet sowie einen an deren Oberseite an die Kontaktplatte 9 anschliessenden, mit ihr einstükkigen Ring 11. Zur Sicherung gegen Verdrehung ist die Kontaktplatte 9 an einer Ecke etwas verkürzt und stösst dort an einen von der Unterseite des Gehäuse 2 abstehenden Nocken. Im Zentrum der Dichtfläche 10 liegt eine Auslassöffnung 12, an die ein vom Ring 11 umgebener Durchlass anschliesst, der sie mit der Kammer im Inneren des Gehäuses 2 verbindet. Der Ring 11 weist am oberen Ende einen radial nach aussen vorstehenden umlaufenden Kragen 13 auf, welcher an der Innenseite des Gehäuses 2 über den etwas eingesenkten Rand der Oeffnung 7 ragt und so die Dichtung 8 in derselben schnappverriegelt, so dass sie nicht ohne Deformation entfernbar ist. Zugleich verbessert der Kragen 13 die Abdichtung zwischen dem Rand der Oeffnung 7 und der Aussenseite des Ringes 11. In der Auslassöffnung 12 liegt ein mit der Dichtung 8 verbundenes Leitelement 14, ein rundes Plättchen, das aus porösem Material, z.B. aus offenporigem Schaumstoff oder aus parallelen Fasern, die axial vom Inneren der Kammer nach aussen führen, besteht.The

An den Seitenwänden weist das Gehäuse 2 zwei einander gegenüberliegende kugelkalottenförmige flache Rastnocken 15 auf sowie jeweils etwas unterhalb davon, nicht weit von der Unterkante entfernt, rechteckige Vertiefungen 16. Das Gehäuse 2 und der Deckel 4 bestehen aus Kunststoff, vorzugsweise aus Polypropylen. Der Speicherkörper 3 kann aus PUR bestehen und das Leitelement 14, falls es als Schaumstoffkörper ausgebildet ist, ebenfalls, falls es als Faserbündel ausgebildet ist, aus Polyester. Die Kontaktplatte 9 und der Ring 11 bestehen aus einem Material, das elastisch ist und weicher als das Material des Gehäuses 2, z.B. aus einem thermoplastischen Elastomer.On the side walls, the

Für Versand und Lagerung ist die Tintenpatrone 1 durch (

Die Tintenpatrone 1 bildet mit einem Adapter 22 (

An der Unterseite trägt das Gehäuse 23 eine Düsenplatte (nicht dargestellt) zur gesteuerten Abgabe von Tintentropfen. Düsenplatten und ihre Steuerung sind wohlbekannt. Am Grund des Aufnahmefaches 24 weist der Adapter 22 eine von einem abgesetzten Rahmen umgebene Aufnahmeöffnung 27 auf, in welcher ein siebartiger Filter 28 angeordnet ist, der z.B. als Geflecht aus Metalldrähten ausgebildet ist und dem Abfangen grösserer Partikel dient, die sonst die Düsen der Düsenplatte verstopfen könnten, mit denen die Aufnahmeöffnung 27 über einen an dieselbe anschliessenden Hohlraum 29 und (nicht dargestellte) Leitungen in Verbindung steht.At the bottom, the

Die zwischen dem Adapter 22 und der Tintenpatrone 1 wirksame Rastverbindung ist so angelegt, dass die Dichtfläche 10 frontal gegen den Rahmen der Aufnahmeöffnung 27 drückt, derart, dass der von der Kammer der Tintenpatrone 1 durch die Auslassöffnung 12 und die Aufnahmeöffnung 27 zum Hohlraum 29 führende Tintenpfad gegen aussen, d.h. gegen die umgebenden Bereiche des Aufnahmefachs 24, zuverlässig abgedichtet ist und die Tinte vom Speicherkörper 3 zur Düsenplatte geleitet wird, ohne dass der Tintenfluss durch aus dem umgebenden Bereich des Aufnahmefachs 24 eindringende Luft unterbrochen werden oder umgekehrt Tinte ins Aufnahmefach 24 austreten könnte. Das Gehäuse 23 des Adapters 22 besteht ebenfalls aus Kunststoff, z.B. glasfaserverstärktem PET.The effective between the

Die Tintenpatrone 1 ist sehr einfach durch eine geradlinige Bewegung in das Aufnahmefach 24 einsetzbar. Die Abdichtung des Tintenpfades ergibt sich dabei von selbst und ohne dass beim Einsetzen der Tintenpatrone 1 Reibung zwischen der Dichtung und Gegenflächen, mit denen sie zusammenwirkt, entstünde, welche das Einsetzen behindern könnte. Mühsames Einsetzen einer Dichtung auf dem Grund des Aufnahmefachs ist nicht erforderlich.The

Die beschriebene Tintenpatrone sowie das Verschlussteil und der Adapter können vielfach abgewandelt werden. Insbesondere kann die Tintenpatrone für Farbdruck geeignet sein und mehrere, z.B. drei oder vier getrennte Kammern aufweisen, jede mit einem Speicherkörper, der mit einer Tinte einer anderen Farbe getränkt ist und einem Tntenauslass. Der Adapter muss dann entsprechend ausgebildet sein, mit mehreren Aufnahmeöffnungen und geeigneter Düsenplatte und Steuerung. Alternativ kann er mit drei oder vier Aufnahmefächern mit jeweils einer Aufnahmeöffnung versehen sein, die jeweils zur Aufnahme einer Tintenpatrone mit einer einzigen Kammer, welche Tinte einer bestimmten Farbe enthält, geeignet sind.The described ink cartridge and the closure part and the adapter can be modified in many ways. In particular, the ink cartridge may be suitable for color printing and multiple, e.g. have three or four separate chambers, each with a storage body, which is impregnated with an ink of a different color and a Tntenauslass. The adapter must then be designed accordingly, with several receiving openings and suitable nozzle plate and control. Alternatively, it may be provided with three or four storage compartments each having a receiving opening, each suitable for receiving a single-chamber ink cartridge containing ink of a particular color.

- 11

- Tintenpatroneink cartridge

- 22

- Gehäusecasing

- 33

- Speicherkörperstorage body

- 44

- Deckelcover

- 55

- Lüftungsöffnungvent

- 66

- Tintenauslassink outlet

- 77

- OeffnungOpening

- 88th

- Dichtungpoetry

- 99

- Kontaktplattecontact plate

- 1010

- Dichtflächesealing surface

- 1111

- Ringring

- 1212

- Auslassöffnungoutlet

- 1313

- Kragencollar

- 14.14th

- Leitelementvane

- 1515

- Rastnockenlocking cams

- 1616

- Vertiefungdeepening

- 1717

- Verschlussteilclosing part

- 1818

- Verschlussplatteclosing plate

- 19a,b19a, b

- Halteflügelretaining wings

- 2020

- Lascheflap

- 2121

- Nasenose

- 2222

- Adapteradapter

- 2323

- Gehäusecasing

- 2424

- Aufnahmefachreceiving compartment

- 2525

- Rastlochcatch hole

- 2626

- Ausnehmungrecess

- 2727

- Aufnahmeöffnung.Receiving opening.

- 2828

- Filterfilter

- 2929

- Hohlraumcavity

Claims (15)

- Ink cartridge (1) for an inkjet printer, comprising a housing (2) which encloses at least one chamber which has, at a bottom, an ink outlet (6) having an orifice (7) and, on a top, a vent orifice (5) and which is filled by a porous storage body (3) for taking up ink, characterized in that the ink outlet (6) comprises an annular seal (8) of soft resilient material, which seal is inserted into the orifice (7) and forms a sealing surface (10) lying on the outside of the housing (2) and surrounding an outlet orifice (12), wherein the seal (8) comprises a contact plate (9) whose upper side rests against the lower side of the housing (2) and whose lower side forms the exposed sealing surface (10).

- Ink cartridge according to Claim 1, characterized in that the seal (8) comprises a ring (11) which is adjacent to the side facing the housing (2) and which surrounds a passage connected to the outlet orifice (12) and whose outside rests against the edge of the orifice (7), while it has, at its end facing away from the contact plate (9) a projection which projects outwards, is preferably in the form of an all-round collar (13) and, on the inside of the housing (2), projects over the edge of the orifice (7) so that the seal (8) is snapped in in the orifice (7).

- Ink cartridge according to Claim 1 or 2, characterized in that the contact plate (9) is substantially rectangular, in particular square.

- Inkcartridge according to any of Claims 1 to 3, characterized in that the seal (8) consists of an elastomer.

- Inkcartridge according to any of Claims 1 to 4, characterized in that a guide element (14) of porous material is present in the outlet orifice (12).

- Ink cartridge according to Claim 5, characterized in that the guide element (14) is connected to the seal (8).

- Ink cartridge according to Claim 5 or 6, characterized in that the guide element (14) substantially comprises parallel fibres oriented outwards from the interior of the chamber.

- Ink cartridge unit comprising an ink cartridge according to any of Claims 1 to 7, characterized in that it additionally comprises a closure part (17) which is removably fastened to the ink cartridge (1) in such a way that it closes the outlet orifice (12) and rests against the sealing surface (10).

- Ink cartridge unit according to Claim 8, characterized in that the closure part (17) is resilient and is fastened to the ink cartridge (1) by means of a snap-in lock.

- Ink cartridge unit according to Claim 9, characterized in that the closure part (17) is in the form of a clamp, comprising a closure plate (18) closing the outlet orifice (12) and two retaining wings (19a,19b) which project approximately parallel therefrom and rest against opposite sides of the housing (2) of the ink cartridge (1).

- Inkjet printing head comprising at least one ink cartridge (1) according to any of Claims 1 to 7, characterized in that it comprises an adapter (22) to which the ink cartridge (1) can be fastened, having, on its underside, a nozzle plate provided with nozzle orifices and having a receiving orifice (27) for ink, which is connected to at least a part of the nozzle orifices and which is surrounded by a frame which, when the ink cartridge (1) is fastened, surrounds the outlet orifice (12) and rests against the sealing surface (10) thereof.

- Inkjet printing head according to Claim 11, characterized in that the adapter (22) has a receptacle (24) into which the ink cartridge (1) can be inserted and on the bottom of which the receiving orifice (27) is arranged.

- Inkjet printing head according to Claim 11 or 12, characterized in that a filter (28), in particular a screen-like one, is present in the adapter (22), between the receiving orifice (27) and the nozzle plate.

- Inkjet printing head according to Claim 13, characterized in that the filter (28) is arranged in the receiving orifice (27).

- Inkjet printing head according to any of Claims 11 to 14, characterized in that the ink cartridge (1) is snapped in to the adapter (22).

Priority Applications (14)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES03026434T ES2268261T7 (en) | 2003-11-19 | 2003-11-19 | INK CARTRIDGE, INK CARTRIDGE GROUP AND PRINT HEAD BY INK JET. |

| DE50304298T DE50304298D1 (en) | 2003-11-19 | 2003-11-19 | Ink cartridge, ink cartridge unit and inkjet printhead |

| EP03026434A EP1533125B3 (en) | 2003-11-19 | 2003-11-19 | Ink cartridge, ink cartridge unit and ink jet printhead |

| AT03026434T ATE333371T1 (en) | 2003-11-19 | 2003-11-19 | INK CARTRIDGE, INK CARTRIDGE UNIT AND INKJET PRINTHEAD |

| US10/985,952 US7625078B2 (en) | 2003-11-19 | 2004-11-12 | Ink cartridge, ink cartridge unit and inkjet printing head |

| AU2004229077A AU2004229077B2 (en) | 2003-11-19 | 2004-11-12 | Ink cartridge, ink cartridge unit and inkjet printing head |

| TW093134912A TWI255234B (en) | 2003-11-19 | 2004-11-15 | Ink cartridge, ink cartridge unit and inkjet printing head |

| ZA200409188A ZA200409188B (en) | 2003-11-19 | 2004-11-18 | Ink cartridge, ink cartridge unit and inkjet printing head. |

| JP2004334271A JP2005145074A (en) | 2003-11-19 | 2004-11-18 | Ink cartridge, ink cartridge unit and ink jet printing head |

| BR0405103-3A BRPI0405103A (en) | 2003-11-19 | 2004-11-19 | Ink cartridge, ink cartridge unit, and inkjet printhead |

| MYPI20044797A MY129388A (en) | 2003-11-19 | 2004-11-19 | Ink catridge, ink cartridge unit and inkjet printing head |

| KR1020040095332A KR100730505B1 (en) | 2003-11-19 | 2004-11-19 | Ink cartridge, ink cartridge unit and inkjet printing head |

| CNB2004100949802A CN100346977C (en) | 2003-11-19 | 2004-11-19 | Ink cartridge, ink cartridge unit and ink jet printhead |

| MXPA04011541A MXPA04011541A (en) | 2003-11-19 | 2004-11-19 | Ink cartridge, ink cartridge unit and ink jet printhead. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03026434A EP1533125B3 (en) | 2003-11-19 | 2003-11-19 | Ink cartridge, ink cartridge unit and ink jet printhead |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1533125A1 EP1533125A1 (en) | 2005-05-25 |

| EP1533125B1 EP1533125B1 (en) | 2006-07-19 |

| EP1533125B3 true EP1533125B3 (en) | 2008-12-17 |

Family

ID=34429384

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03026434A Expired - Lifetime EP1533125B3 (en) | 2003-11-19 | 2003-11-19 | Ink cartridge, ink cartridge unit and ink jet printhead |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US7625078B2 (en) |

| EP (1) | EP1533125B3 (en) |

| JP (1) | JP2005145074A (en) |

| KR (1) | KR100730505B1 (en) |

| CN (1) | CN100346977C (en) |

| AT (1) | ATE333371T1 (en) |

| AU (1) | AU2004229077B2 (en) |

| BR (1) | BRPI0405103A (en) |

| DE (1) | DE50304298D1 (en) |

| ES (1) | ES2268261T7 (en) |

| MX (1) | MXPA04011541A (en) |

| MY (1) | MY129388A (en) |

| TW (1) | TWI255234B (en) |

| ZA (1) | ZA200409188B (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006036716B3 (en) * | 2006-06-02 | 2007-09-27 | Artech Gmbh Design + Production In Plastic | Printer e.g. inkjet printer, retrofitting device, has cartridge retaining device to retain replaceable original ink cartridges, and locking pin to lock fastener in fastening position when insert-ink cartridge is attached in retaining device |

| CN200954714Y (en) * | 2006-09-30 | 2007-10-03 | 聂瑞权 | Head-box-split type printing head ink box |

| CN200984864Y (en) * | 2006-12-18 | 2007-12-05 | 刘春云 | Regenerating cartridge with printing head |

| CN200995522Y (en) * | 2007-01-09 | 2007-12-26 | 聂瑞权 | Fixed press cap for printing head ink box |

| JP2010012608A (en) * | 2008-06-30 | 2010-01-21 | Brother Ind Ltd | Adaptor for ink cartridge |

| CN102161278B (en) * | 2008-06-30 | 2014-03-05 | 兄弟工业株式会社 | Adaptor for ink cartridge |

| JP5724398B2 (en) * | 2011-01-14 | 2015-05-27 | セイコーエプソン株式会社 | Container unit and liquid jet system |

| AU2015100932B4 (en) * | 2015-07-14 | 2015-11-26 | The Trustee For Rihac Trading Trust | Improved Ink Refill Cartridge for all-in-one Printhead-ink Cartridge |

| CN105034600A (en) * | 2015-08-27 | 2015-11-11 | 石立公 | Random marking head without rigid inner core |

| CN110027324A (en) | 2019-05-06 | 2019-07-19 | 珠海艾派克微电子有限公司 | Nozzle print cartridge, inkjet component and circuit substrate |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1232551B (en) | 1989-07-13 | 1992-02-19 | Olivetti & Co Spa | PRINT HEAD FOR A INK-JET THERMAL PRINTER |

| US5790158A (en) * | 1992-01-28 | 1998-08-04 | Seiko Epson Corporation | Ink-jet recording apparatus and ink tank cartridge therefor |

| DE9203206U1 (en) * | 1992-03-10 | 1992-05-21 | Franz Büttner AG, Egg | Ink cartridge for a print head of an ink jet printer |

| US5359356A (en) * | 1992-09-30 | 1994-10-25 | Ecklund Joel E | Collapsible jet-ink container assembly and method |

| JP3199092B2 (en) * | 1993-11-05 | 2001-08-13 | セイコーエプソン株式会社 | Ink cartridge for printer |

| ES2112951T3 (en) * | 1993-07-20 | 1998-04-16 | Canon Kk | APPARATUS FOR INK JET PRINTING USING AN INK CARTRIDGE PRINTING UNIT WHICH HAS AN INDUCTION ELEMENT OF THE INK PASS. |

| US6188417B1 (en) * | 1994-10-31 | 2001-02-13 | Hewlett-Packard Company | Fluidic adapter for use with an inkjet print cartridge having an internal pressure regulator |

| US5745139A (en) * | 1994-12-12 | 1998-04-28 | Brother Kogyo Kabushiki Kaisha | Ink feed connecting member |

| US5793396A (en) * | 1994-12-12 | 1998-08-11 | Brother Kogyo Kabushiki Kaisha | Ink-supply connecting member and ink ejection system |

| JPH08192518A (en) | 1995-01-18 | 1996-07-30 | Matsushita Electric Ind Co Ltd | Ink tank and ink jet recording apparatus |

| DE29507743U1 (en) * | 1995-05-10 | 1996-09-12 | Pelikan Produktions Ag, Egg | Printhead for an ink jet printer |

| ES2143141T3 (en) * | 1995-05-16 | 2000-05-01 | Dynamic Cassette Int | INK CARTRIDGE FOR PRINTER FOR INK JETS. |

| US5793356A (en) * | 1995-07-31 | 1998-08-11 | Microsoft Corporation | System and method for the software emulation of a computer joystick |

| US5917525A (en) * | 1995-10-30 | 1999-06-29 | Pelikan Produktions Ag | Ink cartridge for a print head of an ink-jet printer |

| JP3687706B2 (en) | 1996-09-13 | 2005-08-24 | 富士ゼロックス株式会社 | Printer and ink tank |

| JPH10250104A (en) * | 1997-03-12 | 1998-09-22 | Seiko Epson Corp | Ink cartridge for ink-jet type recording apparatus, and its manufacture |

| JPH10272782A (en) * | 1997-03-31 | 1998-10-13 | Brother Ind Ltd | Ink jet recording apparatus |

| JPH10329329A (en) | 1997-06-03 | 1998-12-15 | S T Sangyo Kk | Ink cartridge for ink jet recorder |

| JP3823588B2 (en) * | 1998-08-05 | 2006-09-20 | ブラザー工業株式会社 | Inkjet recording device |

| JP2000062259A (en) * | 1998-08-19 | 2000-02-29 | Ricoh Co Ltd | Ink-jet recording apparatus |

| JP3897490B2 (en) * | 1999-08-24 | 2007-03-22 | キヤノン株式会社 | Coated rubber member, recording head, storage box, and ink jet recording apparatus |

| JP2001260172A (en) | 2000-03-17 | 2001-09-25 | Canon Inc | Molded article comprising a plurality of resin materials, and storing container, method for recovering material of molded article, method for separating molded article, method for utilizing molded article, method for molding molded article, and cap member for storing container for recording material |

| US6935730B2 (en) * | 2000-04-03 | 2005-08-30 | Unicorn Image Products Co. Ltd. Of Zhuhai | One-way valve, valve unit assembly, and ink cartridge using the same |

| TW503183B (en) * | 2000-06-19 | 2002-09-21 | Ind Tech Res Inst | Ink cartridge |

| CN1165432C (en) * | 2000-07-31 | 2004-09-08 | 珠海飞马耗材有限公司 | Ink cartridge with sealing part at its ink outlet |

| US20020075366A1 (en) * | 2000-12-20 | 2002-06-20 | Xerox Corporation. | Liquid ink tank with integral capillary |

| US6854836B2 (en) * | 2001-10-05 | 2005-02-15 | Canon Kabushiki Kaisha | Liquid container, liquid supply system, liquid using apparatus, ink tank, ink supply system, inkjet print head and print apparatus |

| US7128380B2 (en) * | 2002-04-10 | 2006-10-31 | Canon Kabushiki Kaisha | Recording liquid container, ink jet recording apparatus, and cartridge collecting apparatus |

| US6648458B2 (en) * | 2002-04-23 | 2003-11-18 | Hewlett-Packard Development Company, L.P. | Pinch seal providing fluid interconnects between fluid delivery system components |

-

2003

- 2003-11-19 AT AT03026434T patent/ATE333371T1/en active

- 2003-11-19 EP EP03026434A patent/EP1533125B3/en not_active Expired - Lifetime

- 2003-11-19 ES ES03026434T patent/ES2268261T7/en active Active

- 2003-11-19 DE DE50304298T patent/DE50304298D1/en not_active Expired - Lifetime

-

2004

- 2004-11-12 AU AU2004229077A patent/AU2004229077B2/en not_active Ceased

- 2004-11-12 US US10/985,952 patent/US7625078B2/en not_active Expired - Fee Related

- 2004-11-15 TW TW093134912A patent/TWI255234B/en not_active IP Right Cessation

- 2004-11-18 JP JP2004334271A patent/JP2005145074A/en active Pending

- 2004-11-18 ZA ZA200409188A patent/ZA200409188B/en unknown

- 2004-11-19 BR BR0405103-3A patent/BRPI0405103A/en not_active IP Right Cessation

- 2004-11-19 MY MYPI20044797A patent/MY129388A/en unknown

- 2004-11-19 CN CNB2004100949802A patent/CN100346977C/en not_active Expired - Fee Related

- 2004-11-19 KR KR1020040095332A patent/KR100730505B1/en not_active IP Right Cessation

- 2004-11-19 MX MXPA04011541A patent/MXPA04011541A/en active IP Right Grant

Also Published As

| Publication number | Publication date |

|---|---|

| CN1618613A (en) | 2005-05-25 |

| ATE333371T1 (en) | 2006-08-15 |

| CN100346977C (en) | 2007-11-07 |

| TW200531844A (en) | 2005-10-01 |

| MXPA04011541A (en) | 2005-05-23 |

| TWI255234B (en) | 2006-05-21 |

| BRPI0405103A (en) | 2005-07-19 |

| MY129388A (en) | 2007-03-30 |

| EP1533125A1 (en) | 2005-05-25 |

| KR100730505B1 (en) | 2007-06-22 |

| KR20050048533A (en) | 2005-05-24 |

| JP2005145074A (en) | 2005-06-09 |

| AU2004229077B2 (en) | 2006-11-23 |

| US7625078B2 (en) | 2009-12-01 |

| AU2004229077A1 (en) | 2005-06-02 |

| DE50304298D1 (en) | 2006-08-31 |

| US20060001709A1 (en) | 2006-01-05 |

| ES2268261T7 (en) | 2009-06-18 |

| ZA200409188B (en) | 2005-07-12 |

| ES2268261T3 (en) | 2007-03-16 |

| EP1533125B1 (en) | 2006-07-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE602004011978T2 (en) | Valve, ink cartridge with this valve and ink supply method | |

| EP0800869B1 (en) | Fluid discharge device | |

| DE69031541T2 (en) | Ink jet device and cartridge with ink reservoir can be set up on this device | |

| EP1609643B1 (en) | Air improving apparatus for use in motor vehicles and cartridge for the air improving apparatus | |

| EP1533125B3 (en) | Ink cartridge, ink cartridge unit and ink jet printhead | |

| DE60030662T2 (en) | Ink jet recording apparatus | |

| DE102009006430A1 (en) | discharge | |

| EP2361599A1 (en) | Device for supplying or removing a liquid into or out of a container | |

| EP2697131B1 (en) | Closure with valve for a pliable tubular container | |

| DE8411409U1 (en) | DEGASSING VALVE FOR STORAGE AND / OR TRANSPORT CONTAINERS | |

| EP0780234B1 (en) | Ink cartridge and printhead for an inkjet printer | |

| DE102007040108A1 (en) | Apparatus for refilling an ink cartridge for an inkjet printer | |

| WO2012104351A1 (en) | Functional head for a fragrance container | |

| EP2918939B1 (en) | Filter cartridge for a safety workbench and safety workbench with at least one filter cartridge | |

| EP2110606A2 (en) | Commercial cooking device, in particular hot air steamer | |

| DE10324059B4 (en) | ink cartridge | |

| EP2121331A1 (en) | Apparatus for refilling an ink cartridge for an inkjet printer | |

| DE29507743U1 (en) | Printhead for an ink jet printer | |

| EP0966331B1 (en) | Piston for inserting into a filled cartouche | |

| EP3311928B1 (en) | Cartridge piston with venting valve | |

| EP0173939A1 (en) | Cover for the nozzles of a depression ink print head | |

| DE19934426C2 (en) | Ink printer with a cleaning station for a nozzle head | |

| DE212020000431U1 (en) | Pressure control unit and ink cartridge with the same | |

| DE10261391B4 (en) | ink cartridge | |

| DE10206696B4 (en) | Ink cartridge with valve |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050922 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060719 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50304298 Country of ref document: DE Date of ref document: 20060831 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ZIMMERLI, WAGNER & PARTNER AG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061019 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061019 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061019 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061219 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2268261 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| 26N | No opposition filed |

Effective date: 20070420 |

|

| BERE | Be: lapsed |

Owner name: 3T SUPPLIES A.G. Effective date: 20061130 |

|

| PLCP | Request for limitation filed |

Free format text: ORIGINAL CODE: EPIDOSNLIM1 |

|

| PLCQ | Request for limitation of patent found admissible |

Free format text: ORIGINAL CODE: 0009231 |

|

| LIM1 | Request for limitation found admissible |

Free format text: SEQUENCE NO: 1; FILED AFTER OPPOSITION PERIOD Filing date: 20080225 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061020 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| PLCR | Communication despatched that request for limitation of patent was allowed |

Free format text: ORIGINAL CODE: 0009245 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061119 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070120 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| PLCN | Payment of fee for limitation of patent |

Free format text: ORIGINAL CODE: EPIDOSNRAL3 |

|

| PUAM | (expected) publication of b3 document |

Free format text: ORIGINAL CODE: 0009410 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN LIMITED |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: BESCHRAENKUNGANTRAG GUTGEHEISSEN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: 3T SUPPLIES AG Free format text: 3T SUPPLIES AG#CHALTENBODENSTRASSE 6#8834 SCHINDELLEGI (CH) -TRANSFER TO- 3T SUPPLIES AG#CHALTENBODENSTRASSE 6#8834 SCHINDELLEGI (CH) |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: WAGNER PATENT AG, CH |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20141120 Year of fee payment: 12 Ref country code: ES Payment date: 20141120 Year of fee payment: 12 Ref country code: CZ Payment date: 20141110 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20141120 Year of fee payment: 12 Ref country code: AT Payment date: 20141119 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20141124 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 333371 Country of ref document: AT Kind code of ref document: T Effective date: 20151119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151119 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151119 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151130 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20151201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20161228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151120 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20191114 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20201119 Year of fee payment: 18 Ref country code: GB Payment date: 20201123 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50304298 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20211119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20211130 |