EP1452732A1 - Hydraulic buoyant force engine - Google Patents

Hydraulic buoyant force engine Download PDFInfo

- Publication number

- EP1452732A1 EP1452732A1 EP03004535A EP03004535A EP1452732A1 EP 1452732 A1 EP1452732 A1 EP 1452732A1 EP 03004535 A EP03004535 A EP 03004535A EP 03004535 A EP03004535 A EP 03004535A EP 1452732 A1 EP1452732 A1 EP 1452732A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- float

- air

- transmission

- gear

- hydraulic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F03—MACHINES OR ENGINES FOR LIQUIDS; WIND, SPRING, OR WEIGHT MOTORS; PRODUCING MECHANICAL POWER OR A REACTIVE PROPULSIVE THRUST, NOT OTHERWISE PROVIDED FOR

- F03B—MACHINES OR ENGINES FOR LIQUIDS

- F03B17/00—Other machines or engines

- F03B17/02—Other machines or engines using hydrostatic thrust

- F03B17/04—Alleged perpetua mobilia

Definitions

- the present invention relates to hydraulic buoyant force engine, in particular, to a machine which is capable of operating to generate power exclusively driven by buoyancy.

- the conventional power generation can usually be classified into two categories, e,g. power generation by means of force of nature, such as hydraulic power and wind power, the other one is power generation consuming natural resources, such as neuclear power and steam power.

- the hydraulic buoyant force engine of the present invention comprises a plurality of canvas enclosed floats each provided with an air inlet and an air outlet float up and sink down in a water tank along a central transmission bar by expanding and shrinking alternatively in accordance with the action absorbing the air into the float and releasing the air out of the float by means of an air guide unit connected to the float and emerged out of the water surface.

- the pureical power produced by motion of the floats is transmitted to an output shaft trough two sprocket and chain units each provided at one side of the floats so as to produce a continuous and restless mechanical power.

- the expansion and shrinkage of the float are performed by joint action of precisely designed gear mechanism and pivoted lever together with its actuation rod.

- the water tank may be configurated in a L shaped polyhedron, or a regular polyhedron.

- a float 1 the essential component of the present invention, and its expansion and shrinking states are illustrated.

- the component structure of the float 1 includes:

- a tunnel like through hole 153 is opened in the base at a properly offset position beneath the pivoted axle 152, at the end of the through hole 153 near the pivot axle 152, a clogging portion 1531 is formed, while the other end is formed into a threaded portion 1532. Further, a ball 154 is placed in the clogging portion 1531, and a coil spring 155 is set in the through hole 153 with its one end forcibly pressing the ball 154, while the other end thereof is engaged with the threaded portion 152 by screw combination. As shown in figs.

- a bevel gear 16 encircles one end of the transmission bar 11 at the stationary base (15) side, and a gear wheel 17 is provided on it.

- a first joint plate 19 formed above the gear wheel 17 is provided with an end support 191 at its inner side center portion thereof, and two tapped holes are formed on the joint plate 19 each at one side of the end support 191 for engaging with the two stands 18.

- a second joint plate 20 formed under the float 20 also has an end support 201 at is center portion, and are provided with two tapped holes each at one side of the end support 201 to be engaged with staples of a transmission chain (to be described later on).

- the two end supports 191, 201 are for supporting the transmission bar 11.

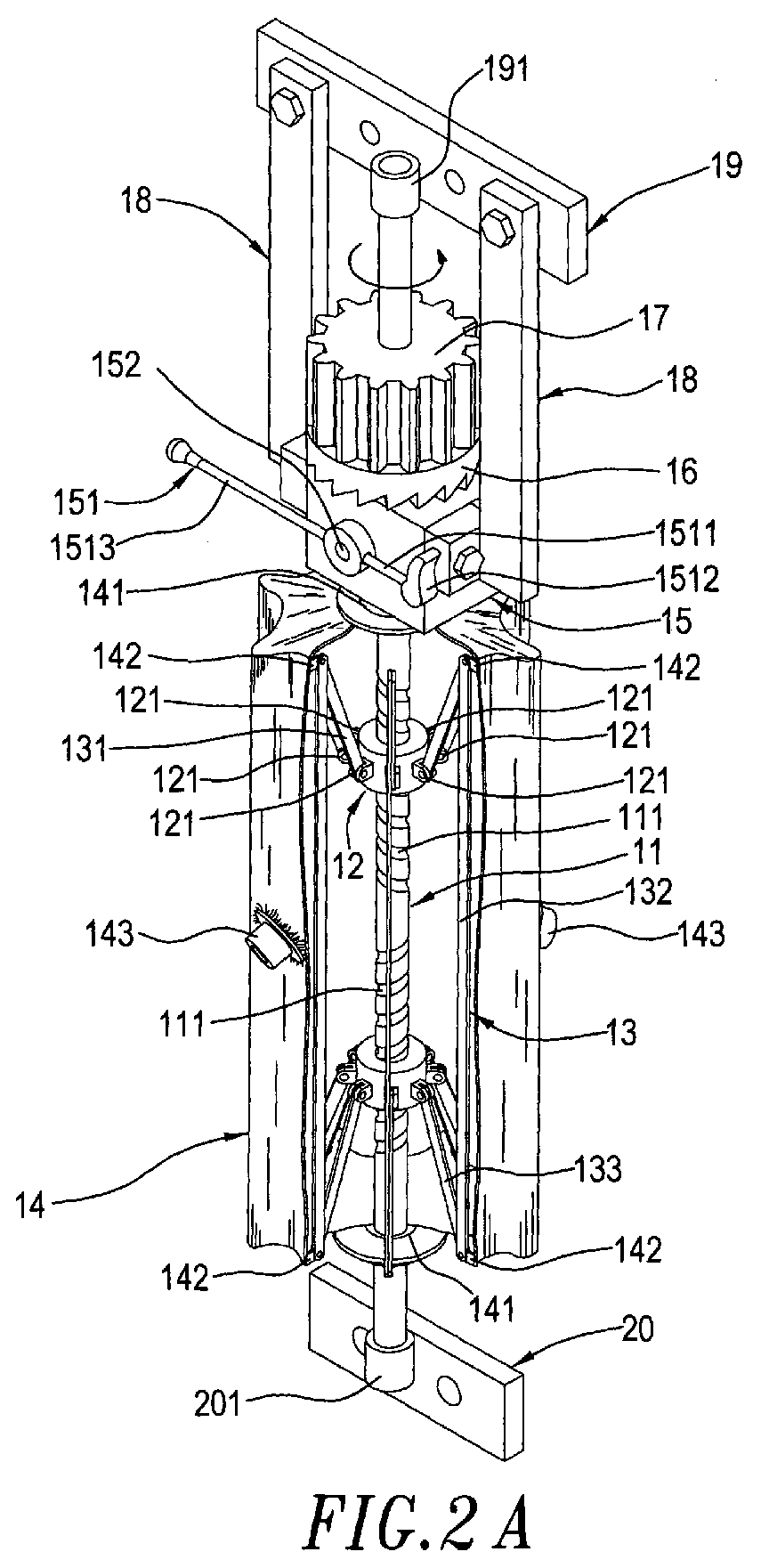

- both bearing blocks 12 are moved relatively close to each other such that the three ribs 131, 132, 133 are retracted inwards thereby the canvas 14 is shrunk (see Fig. 2A).

- both bearing blocks 12 are moved away form each other such the three ribs 131, 132, 133 stretch outwards thereby causing the canvas 14 expanded (see Fig. 2B).

- the float 1 floats up or sinks down in the water.

- the transmission mechanism includes:

- Fig. 5 is a perspective view showing the internal structure of the present invention.

- the first joint plate 19 is engaged with the staple 61 of the first transmission chain 6 by screw combining its tapped hole with the tapped hole 611 of the staple 61, or by welding thereof such that the first joint plate 19 at one end of the float 1 is firmly engaged with the first transmission chain 6; similarly the second joint plate 20 is engaged with the staple 71 of the second transmission chain 7 by screw combining its tapped hole with the tapped hole 711 of the staple 71, or by welding thereof such that the second joint plate 20 at the opposite end of the float 1 is firmly engaged with the second transmission chain 7.

- the float 1 is settled between the two chains 6 an 7 so as to move together with them at a track defined by the two chains 6 and 7.

- Fig. 6 is the side view of Fig. 5, and further refer to Figs. 7A and 7B, several floats 1 can be connected between the first and the second chains 6, 7, in order to make all the floats 1 be communicated with each other, a four-way tube 101 can be provided to an air inlet/outlet 143 installed at the outer side of one of the floats 1, and a three-way tube 102 can be provide at the inner side thereof, and the three-way tubes 102 are provide to both inner/outer air inlet/outlet 143 for rest of the floats 1. Furthermore, a hose 103 is used to interconnect each air inlet/outlet 143 of the floats 1.

- FIG. 7A An embodiment of the present invention is illustrated in Fig. 7A.

- a L shaped water tank 9 constructed according to Torricelli's law is provided, a first electromagnetic valve 91 is installed at the right upper side of the water thank 9, while a second electromagnetic valve 92 is installed at the left lower side thereof. Water is supplied into the water tank 9 from the second electromagnetic valve 92. At this moment the first electromagnetic valve 91 is at closed state so that water can not overflow therefrom. The state of closing the valve 91 and opening the valve 92 is maintained until the water level reaches a height below the output shaft 2. Then the valve 92 is closed, and the valve 91 is opened. At this state, water does not flow out from the valve 92 according to Torricelli's law, and the pressure inside the water tank 9 is reduced so that the floats can move along smoothly.

- the output shaft 2 and transmission shafts 3, 4 are fixed in the water tank 9, and a transmission gear wheel 24 is coupled to the output shaft 2 at one end extended out of the water tank 9 so as to output power.

- a ball bearing block 911 and an annular rubber collar 912 is applied to the tank wall at inner and outer side respectively from where the output shaft 2 goes out so as to prevent air leakage.

- the other end of the output shaft 2 and the fixed ends of both transmission shafts 3, 4 are all set at the wall surface of the water tank 4, and the annular rubber collar 912 is made of a friction resist and heat withstanding material.

- a miniature water tank 93 is equipped abut on the outer wall of the water tank 9 and is similarly pierced through by the output shaft 2.

- the wall of the water tank 9 where the output shaft 2 pierced through is provided with the ball bearing 911 and the annular rubber collar 912, whereas for the miniature tank 93, only an annular rubber collar 913 is provided.

- the first and the second transmission chains 6, 7 are set in the tank 9 and the air guide unit 21 on the output shaft 2 is emerged above the water level so as to let the air in.

- a first actuating rod 94 is provided at the rear upper inner wall of the tank 9, and a second actuating rod 95 is provided on the bottom of the tank 9 nearby the first chain 6.

- the two actuating rods 94, 95 are essentially for actuating the lever of the pivoted block 151 so as to cause the float 1 shrink or expand.

- the lever of the pivoted block 151 is apart from the surface of the bevel gear 16, before the float 1 approaches the driving gear wheel 41 of the transmission shaft 4 the second actuating rod 95 will tap the lever 151 in advance such that the lever 151 swings to the left and is blocked on the surface of the bevel gear 16.

- the pinion 17 is in mesh with the driving gear 42 and rotates. Meanwhile, by reason that the pivoted block 151 has an inlaid tension spring provided at its blocking terminal 1512 of the blocking rod 1511 (see Fig.

- the blocking terminal 1512 can not strongly trammel the bevel gear 16, but can only pressing it lightly.

- the two bearing blocks 12 of the float 1 is displaced gradually outward and extended so as to introduce external air into the float 1 via the air guide unit 21 thereby the float 1 is expanded.

- the first and the second chains 6, 7 are driven to move along and drive the other floats conjoined with the first and the second transmission chains 6, 7, and the output shaft 2 together with the transmission shaft 3, 4.

- the first actuating rod 94 taps the lever of the pivoted block 151 in advance so that the lever swings to the left and leaves away from the surface of the bevel gear 16 and the gear wheel 17 comes to, in mesh with the annular gear 8 and rotates. Then, the two bearing blocks 12 of the float 1 are gradually displaced inwards and the float 1 is shrunk to discharge the contained air into the other float which is gradually expanding.

- the float 1 which entirely lost its air sinks down in the water by its own weight and by driving force of the first and the second chains 6, 7. Each float repeats expansion and shrinkage restlessly so as to cause the first and the second chains 6, 7 also continuously to drive the output shaft 2 thereby a continuous mechanical power output can be obtained.

- the water tank 10 may be constructed poly hedrical as shown in Fig. 10.

- annular flange 213 is provided between the air outlet 211 and air inlet 212, and a check damper 214 is rockingly hinged abut on the annular flange 213 with a pivot axle 215.

- the required air may be absorbed from the air inlet 212 whereas the check damper 214 works to prohibit counter flow of air in the float.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Other Liquid Machine Or Engine Such As Wave Power Use (AREA)

Abstract

Disclosed herein is a hydraulic buoyant force engine whose essential

component is a plurality of floats (1) engaged to two transmission

chains (6,7) of two sprocket and chain combination units each disposed

at either side of the floats. The float (1) is wrapped with a canvas

(14) supported by several rib units (13). When the float (1) is expanded

by air its buoyancy overcomes its own weight, floats up and drives the

chains (6,7) to move up. When the float comes up to a gear (8) above it,

a gear (17) will mate an annular gear rack (8) to act as an internal

spur gear unit so as to retract the rib units (13) thereby squeezing the

float (1) to discharge the contained air. The shrunk float sinks into

the water together with the two chains.

Description

- The present invention relates to hydraulic buoyant force engine, in particular, to a machine which is capable of operating to generate power exclusively driven by buoyancy.

- The conventional power generation can usually be classified into two categories, e,g. power generation by means of force of nature, such as hydraulic power and wind power, the other one is power generation consuming natural resources, such as neuclear power and steam power.

- However, there are some disadvantages inherent to the aforesaid modes of power generation.

- 1.Reliability of force of nature can not be expected up to 100%, abrupt variation of annual rainfall and frequency of typhoon cause the production of water power, and wind power can not be eagily controlled.

- 2.The production and maintenance cost for a neuclear or a steam power plant is usually quite expensive, and the rapid fading of natural resources in addition to loosing ecological balance applies a brake force to unlimited and unvironment unconscious exploitation of natural reforces that causes further development of neuclear power and steam power impossible.

- It is what the reason the inventor has endeavored for years by continuous research and experimentation attempting to find out an ingeniously unlimited and clean environment conscious power generating technique, and finally has come out with the hydraulic buoyant force engine of the present invention.

- It is an object of the present invention to provide a hydraulic buoyant force engine which can generate mechanical power without consuming any other resurces.

- It is another object of the present invention to provide a hydraulic buoyant force engine which can be fabricated with a low production cost and operate with hydraulic buoyant force only without need for other expensive natural resources.

- To achieve the above objects, the hydraulic buoyant force engine of the present invention comprises a plurality of canvas enclosed floats each provided with an air inlet and an air outlet float up and sink down in a water tank along a central transmission bar by expanding and shrinking alternatively in accordance with the action absorbing the air into the float and releasing the air out of the float by means of an air guide unit connected to the float and emerged out of the water surface. The machenical power produced by motion of the floats is transmitted to an output shaft trough two sprocket and chain units each provided at one side of the floats so as to produce a continuous and restless mechanical power. The expansion and shrinkage of the float are performed by joint action of precisely designed gear mechanism and pivoted lever together with its actuation rod. Meanwhile, the water tank may be configurated in a L shaped polyhedron, or a regular polyhedron.

- For fuller understanding of the nature and objects of the invention, reference should be made to the following detailed description taken in conjunction with the accompanying drawings in which:

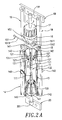

- Fig. 1 is a three dimensional view of the float which is an essential component of the present invention;

- Fig. 2A and 2B are sectional views showing the float are in expanded and shrunk states respectively;

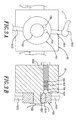

- Fig. 3A to 3D are the drawings illustrating the function of the pivoted block on a stationary base;

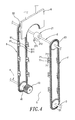

- Fig. 4 is a schematic view showing the transmission mechanism of the present invention;

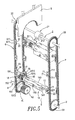

- Fig. 5 is a perspective view showing the internal structure of the hydraulic buoyant force engine of the present invention;

- Fig. 6 is the side view of Fig. 5;

- Figs. 7A and 7B are schematic views showing an embodiment of the present invention;

- Figs. 8A and 8B are cross sectional view of the air guide unit according to the present invention;

- Fig. 9 is a schematic view in another embodiment of the present invention; and

- Fig. 10 is a schematic view in further embodiment of the present invention.

-

- Referring to Figs. 1, 2A and 2B simultaneously, in which a

float 1, the essential component of the present invention, and its expansion and shrinking states are illustrated. The component structure of thefloat 1 includes: -

transmission bar 11 erecting and piercing through the center of thefloat 1 and having two sections ofscrew threads 111 spiraled in opposite direction with respect to each other formed on the upper and lower portions respectively thereof; - two ball bearing

blocks 12 sleeved onto the upper and lower threadedportions 111 of thetransmission bar 11 and having a plurality of drilledholes 121 formed in equal spacing around their outer surfaces thereof; - a

rib unit 13 composed of a first, a second, and athird ribs ribs holes 121 of bothbearing blocks 121, while the via holes at the other end of theribs second rib 132; - a

canvas 14 wrapping theentire rib unit 13 and having afixed axle 141 engaged with thecanvas 14 at upper and lower ends thereof by high frequency bonding for achieving water tight effect and keeping flexibility of thecanvas 14, wherein thecanvas 14 is enclosed over thetransmission bar 11, furthermore,several holding rings 142 made of similar material as that of thecanvas 13 and bonded to thecanvas 14 by high frequency bonding are provided in order to tie the end position of each rib, besides, an air inlet/outlet 143 is respectively formed at each side of thecanvas 14 opposite to each other, wherein thefixed axle 141 is provided with a ball bearing; and - a

stationary base 15 conjoined with the canvas fixedaxle 141 and being sleeved over thetransmission bar 11 for firmly holding thecanvas 14, wherein at its side thereof is a cylindrically shapedpivoted block 151 turnable around apivoted axle 152 on thebase 15, theblock 151 has anengaging arm 1511 etended out from one side, thearm 1511 has ahook 1512 at its front end, and a pushingrod 1513 extended from the other side thereof, and arecess 1514 is formed inside of thepivoted block 151, and a lever is extended from thepivoted block 151. -

- The action of the

pivoted block 151 are described in Figs. 3A-3D. A tunnel like throughhole 153 is opened in the base at a properly offset position beneath thepivoted axle 152, at the end of the throughhole 153 near thepivot axle 152, aclogging portion 1531 is formed, while the other end is formed into a threadedportion 1532. Further, aball 154 is placed in theclogging portion 1531, and acoil spring 155 is set in the throughhole 153 with its one end forcibly pressing theball 154, while the other end thereof is engaged with the threadedportion 152 by screw combination. As shown in figs. 3A-3D, when thepivoted block 151 has not yet actuated by a external force, therecess 1514 is engaged with theball 154, when thepivoted block 151 is actuated by an external force, theball 154 is exerted a downward force so as to leave away from therecess 1514. In case thepivoted block 151 is displaced a certain angle, therecess 1514 now comes down to trap anotherball 156 so as to assist thepivoted block 151 to operate effectively. - A

bevel gear 16 encircles one end of thetransmission bar 11 at the stationary base (15) side, and agear wheel 17 is provided on it. - Two

stand 18 are engaged with a firstjoint plate 19 by screws, and the other end of eachstand 18 is bolted with thestationary base 15 by means of a protruded block. - A

first joint plate 19 formed above thegear wheel 17 is provided with anend support 191 at its inner side center portion thereof, and two tapped holes are formed on thejoint plate 19 each at one side of theend support 191 for engaging with the twostands 18. A secondjoint plate 20 formed under thefloat 20 also has anend support 201 at is center portion, and are provided with two tapped holes each at one side of theend support 201 to be engaged with staples of a transmission chain (to be described later on). The two end supports 191, 201 are for supporting thetransmission bar 11. - As soon as the

gear wheel 17 above thefloat 1 is driven to rotate clockwise, both bearingblocks 12 are moved relatively close to each other such that the threeribs canvas 14 is shrunk (see Fig. 2A). On the other hand, when thegear wheel 17 is driven to rotate counterclockwise, both bearingblocks 12 are moved away form each other such the threeribs canvas 14 expanded (see Fig. 2B). In this version, thefloat 1 floats up or sinks down in the water. - For understanding the structure of the transmission mechanism of the present invention, reference should be made to Fig. 4. The transmission mechanism includes:

- an

output shaft 2 having anair guide unit 21 sleeved onto a proper middle position of theoutput shaft 2, wherein the front end thereof is formed into anair outlet 211, while anair inlet 212 is formed at its side, a first and asecond sprockets output shaft 2 respectively, wherein theair guide unit 21 is provided with a ball bearing: - two

transmission shafts fourth sprockets first sprocket 22 is coupled with thefourth sprocket 41 by afirst transmission chain 6, while thesecond sprocket 23 is coupled with thethird sprocket 31 by asecond transmission chain 7, further, thefourth sprocket 41 is coupled with adriving gear 42 nearby by means for thetransmission shaft 4, afixing plate 43 with twoposts 44 tightened on its upper portion is engaged with thedriving gear 42 with screws, and bothposts 44 are fastened to the wall of thewater tank 9 to be described latter, aclear space 5 is formed between the twotransmission shafts driving gear 42 is provided with a ball bearing, at least onestaple 61, (71) is provided for the first and thesecond sprockets - a semi-circular

annular gear 8 to be coupled with thepinion gear 17 for driving the same so as to serve as an internal gear unit, wherein working of thepinion gear 17 causes the two bearingblocks 12 to move towards each other thereby making thefloat 1 shrink and loose buoyancy by discharging the inner air, and thefloat 1 sinks following the motion of the first and thesecond sprockets -

- Fig. 5 is a perspective view showing the internal structure of the present invention. The first

joint plate 19 is engaged with thestaple 61 of thefirst transmission chain 6 by screw combining its tapped hole with the tappedhole 611 of the staple 61, or by welding thereof such that the firstjoint plate 19 at one end of thefloat 1 is firmly engaged with thefirst transmission chain 6; similarly the secondjoint plate 20 is engaged with thestaple 71 of thesecond transmission chain 7 by screw combining its tapped hole with the tappedhole 711 of the staple 71, or by welding thereof such that the secondjoint plate 20 at the opposite end of thefloat 1 is firmly engaged with thesecond transmission chain 7. By doing so , thefloat 1 is settled between the twochains 6 an 7 so as to move together with them at a track defined by the twochains - Fig. 6 is the side view of Fig. 5, and further refer to Figs. 7A and 7B,

several floats 1 can be connected between the first and thesecond chains floats 1 be communicated with each other, a four-way tube 101 can be provided to an air inlet/outlet 143 installed at the outer side of one of thefloats 1, and a three-way tube 102 can be provide at the inner side thereof, and the three-way tubes 102 are provide to both inner/outer air inlet/outlet 143 for rest of thefloats 1. Furthermore, ahose 103 is used to interconnect each air inlet/outlet 143 of thefloats 1. Finally, external air is introduced into thefloats 1 viaair guide unit 21 by connecting the output end of thehose 103 with theair guide unit 21. Meanwhile, in order to prevent twisting of thehose 103 during operation of the present invention, thehose 103 laid under the first and thesecond chains clear spacing 5 reserved between the twotransmission shafts supporter 1021 is provided at one side of the three-way tube 102 (see Fig. 7B) installed on the air inlet/outlet 143 at outer side of thefloat 1 so as to trap thehose 103 thereat, and cause thefloat 1 along with its four-way tube 101 to locate thereby preventing the twisting of thehose 103 during movement of thefloat 1. - An embodiment of the present invention is illustrated in Fig. 7A.

- A L shaped

water tank 9 constructed according to Torricelli's law is provided, a firstelectromagnetic valve 91 is installed at the right upper side of the water thank 9, while a secondelectromagnetic valve 92 is installed at the left lower side thereof. Water is supplied into thewater tank 9 from the secondelectromagnetic valve 92. At this moment the firstelectromagnetic valve 91 is at closed state so that water can not overflow therefrom. The state of closing thevalve 91 and opening thevalve 92 is maintained until the water level reaches a height below theoutput shaft 2. Then thevalve 92 is closed, and thevalve 91 is opened. At this state, water does not flow out from thevalve 92 according to Torricelli's law, and the pressure inside thewater tank 9 is reduced so that the floats can move along smoothly. Meanwhile, theoutput shaft 2 andtransmission shafts water tank 9, and atransmission gear wheel 24 is coupled to theoutput shaft 2 at one end extended out of thewater tank 9 so as to output power. A ball bearing block 911 and anannular rubber collar 912 is applied to the tank wall at inner and outer side respectively from where theoutput shaft 2 goes out so as to prevent air leakage. The other end of theoutput shaft 2 and the fixed ends of bothtransmission shafts water tank 4, and theannular rubber collar 912 is made of a friction resist and heat withstanding material. - In another embodiment shown in Fig. 9, a

miniature water tank 93 is equipped abut on the outer wall of thewater tank 9 and is similarly pierced through by theoutput shaft 2. The wall of thewater tank 9 where theoutput shaft 2 pierced through is provided with theball bearing 911 and theannular rubber collar 912, whereas for theminiature tank 93, only anannular rubber collar 913 is provided. With this structure, the first and thesecond transmission chains tank 9 and theair guide unit 21 on theoutput shaft 2 is emerged above the water level so as to let the air in. Meanwhile, afirst actuating rod 94 is provided at the rear upper inner wall of thetank 9, and asecond actuating rod 95 is provided on the bottom of thetank 9 nearby thefirst chain 6. The twoactuating rods block 151 so as to cause thefloat 1 shrink or expand. When thefloat 1 is under the water level, the lever of the pivotedblock 151 is apart from the surface of thebevel gear 16, before thefloat 1 approaches thedriving gear wheel 41 of thetransmission shaft 4 thesecond actuating rod 95 will tap thelever 151 in advance such that thelever 151 swings to the left and is blocked on the surface of thebevel gear 16. On the other hand, thepinion 17 is in mesh with thedriving gear 42 and rotates. Meanwhile, by reason that the pivotedblock 151 has an inlaid tension spring provided at itsblocking terminal 1512 of the blocking rod 1511 (see Fig. 3C), the blocking terminal 1512 can not strongly trammel thebevel gear 16, but can only pressing it lightly. At this moment the two bearing blocks 12 of thefloat 1 is displaced gradually outward and extended so as to introduce external air into thefloat 1 via theair guide unit 21 thereby thefloat 1 is expanded. As soon as the buoyancy of thefloat 1 has overcome its own weight and floats up, the first and thesecond chains second transmission chains output shaft 2 together with thetransmission shaft float 1 approaches theannular gear 8, thefirst actuating rod 94 taps the lever of the pivotedblock 151 in advance so that the lever swings to the left and leaves away from the surface of thebevel gear 16 and thegear wheel 17 comes to, in mesh with theannular gear 8 and rotates. Then, the two bearing blocks 12 of thefloat 1 are gradually displaced inwards and thefloat 1 is shrunk to discharge the contained air into the other float which is gradually expanding. Thefloat 1 which entirely lost its air sinks down in the water by its own weight and by driving force of the first and thesecond chains second chains output shaft 2 thereby a continuous mechanical power output can be obtained. - Incidentally, the

water tank 10 may be constructed poly hedrical as shown in Fig. 10. - Returning to Figs. 8A and 8B which show the cross sectional view of the

air guide unit 21, anannular flange 213 is provided between theair outlet 211 andair inlet 212, and acheck damper 214 is rockingly hinged abut on theannular flange 213 with apivot axle 215. During the expanding and shrinking operation of the float, the required air may be absorbed from theair inlet 212 whereas thecheck damper 214 works to prohibit counter flow of air in the float. - It emerges from the above description that the hydraulic buoyanct force engine of the present invention has several noteworthy merits namely:

- 1. The mechanical power is obtained from the buoyant force only without need for help of other cources.

- 2.No sophisiticated structure is involved in the present invention which helps to reduce the production cost.

-

- Other embodiment of the present invention will become obvious to those skilled in the art in light of above disclosure. It is of course also understood that the scope of the present invention is not to be determined by the foregoing description, but only by the following claims.

Claims (10)

- A hydraulic buoyant force engine comprising:a float capable of shrinking and expanding, wherein said float is provided with more than one air inlet/outlet, a transmission bar is piercing through the center portion thereof with its both ends emerged out of said float, and engaged with a joint plate at each side, a fixed axle for a canvas enclosing said float is fixed at each float end, one of said fixed axle is engaged with a stationary base and a bevel gear accompanying a gear wheel at is side is installed at one side of said stationary base, said joint plate is conjoined to said stationary base by two stands:a water tank equipped with two electromagnetic valves each of them being set at its upper and lower sides for storing water, wherein an annular gear is provided near the top portion of said water tank, a first and a second actuating rods are each provided at the upper rear side and the inner bottom of said water tank respectively;an output shaft equipped with an air guide unit on it, wherein one end of said air guide unit is an air outlet, while an air inlet is formed at its side thereof, a first and a second sprockets are each respectively coupled with its one end, one end of said output shaft is extended out of the wall of said water tank, and a transmission gear is fitted to this end;two transmission shafts each coupled with a third and a fourth sprockets respectively, wherein the first and the fourth sprockets, and the second and the third sprockets are aligned with each other, one end of said fourth sprocket is coupled with a driving gear by mean of said transmission shaft, a fixing plate is provided in the manner engaging its lower portion with said driving gear, while its upper portion is fastened to the wall of the water tank, and a clear space is formed between said two transmission shafts; anda first and a second transmission chains each provided with several staples, wherein said first transmission chain is in mesh with said first and said fourth sprockets, while said second transmission chain is in mesh with said second and said third sprockets;with this structure, said joint plates at two sides of said float are engaged with said staples provided on said first and said second transmission chains so as to settle said float between said two transmission chains, and connect said air inlet/outlet for each float in cascade with a hose, and one of the output terminal of said hose is connected with the air outlet of said air guide unit, when said float sinks nearby said driving gear for said transmission shaft, the float is in a shrunk state, said gear wheel located above will be mated with said driving gear to rotate so as to expand said float, as soon as the buoyancy of said float becomes larger than its own weight, it floats up so as to drive said first and said second chains, the float, conjoined with the first and third, the second and fourth sprockets, said output shaft, and two transmission shafts, besides, when said float approaches said annular gear, the gear above said float is mated with said annular gear and rotate so that said float shrinks thereby discharging its air to other float which is going to expand, said shrunk float lost its inner air entirely sinks down by its own weight along with the rotation of said first and said second chains, in this manner, each float repeats expansion and shrinkage action restlessly so as to cause said first and said second chains also continuously drive said output shaft therefore a continuous mechanical power output is obtained.

- The hydraulic buoyant force engine of claim 1, wherein said float is composed of said transmission bar, several rib units, and said canvas, wherein said canvas is used to enclose said rib units so as to achieve a water tight effect and cause said float to expand or shrink.

- The hydraulic buoyant force engine of claims 1 to 2, wherein two ball bearing blocks are sleeved onto said transmission bar, and several said rib units are engaged therebetween, when both bearing blocks are moved relatively close together to each other, said rib units are retracted inwards thereby said canvas shrank, on the other hand, when both bearing blocks are moved away from each other, said rib units are extended outwards thereby causing said canvas to expand.

- The hydraulic buoyancy force engine of claim 1, wherein in order to avoid twisting of said hose during operation of said engine, a clear -space is always provided between said two transmission shafts and is able to revolve together with the motion of said float.

- The hydraulic buoyancy force engine of claim 1, wherein a four-way tube is provided to an air inlet/outlet installed at the outer side of one of said floats, and a three-way tube is provided at the inner side thereof, and said three-way tubes are provided to both outer and inner sides of the air inlet/outlet for rest of said floats, said hose is used to interconnect each air inlet/outlet of said floats, finally, outside air is introduced into said floats 1 via air guide unit by connecting the output end of said hose with said air guide unit.

- The hydraulic buoyant force engine of claim 1, wherein a pivoted lever is provided at the side of said stationary base to act to press on said bevel surface of said expanded float so as to set said float in expanded state without back turning or shrinking.

- The hydraulic buoyant force engine of claim 6, wherein a first and a second actuating rods are used to actuate said pivoted lever of said float.

- The hydraulic buoyant force engine of claim 1, wherein an annular flange is provided between the air outlet and air inlet of said air guide unit, and a check damper is rockingly hinged abut on said annular flange with a pivot axle.

- The hydraulic buoyancy force engine of claim 8, wherein expansion speed of said float is accelerated by introducing outside air form said air guide unit.

- The hydraulic buoyancy force engine of claim 8, wherein said air guide unit is emerged out of the water level for inputting air.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03004535A EP1452732A1 (en) | 2003-02-28 | 2003-02-28 | Hydraulic buoyant force engine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03004535A EP1452732A1 (en) | 2003-02-28 | 2003-02-28 | Hydraulic buoyant force engine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1452732A1 true EP1452732A1 (en) | 2004-09-01 |

Family

ID=32748833

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03004535A Withdrawn EP1452732A1 (en) | 2003-02-28 | 2003-02-28 | Hydraulic buoyant force engine |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1452732A1 (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006122558A1 (en) * | 2005-05-17 | 2006-11-23 | Lindhagen Joergen | A gravity driven water pxmp with a water energy producing module |

| GB2430471A (en) * | 2005-09-26 | 2007-03-28 | Blaise Coonan | Variable volume buoyancy engine |

| WO2007076719A1 (en) * | 2005-12-31 | 2007-07-12 | Solar City Limited | A power output device and a generating device using the same |

| EP2235362A1 (en) * | 2007-12-19 | 2010-10-06 | James Kwok | Hydrodynamic energy generation system |

| GR1007323B (en) * | 2010-03-29 | 2011-06-22 | Γεμιστος, Παντελης Μιχαηλ | Power generation system provided with submarine folding cisterns |

| WO2011091493A1 (en) * | 2010-01-28 | 2011-08-04 | Cavalheiro Mario Teixeira | Hydraulic power generator with a circular movement for generating electric energy at two different generation points and mechanic power generator with a circular movement for generating electric energy |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2260001A1 (en) * | 1974-01-31 | 1975-08-29 | Gomila Charles | Motor driven by hydrostatic thrust - has driving chambers with cyclically varying volumes |

| EP0452601A1 (en) * | 1990-04-20 | 1991-10-23 | Alexandre Fabry | Buoyancy motor |

| GB2326916A (en) * | 1997-07-01 | 1999-01-06 | Ghem Sheng Whan | Buoyancy motor |

-

2003

- 2003-02-28 EP EP03004535A patent/EP1452732A1/en not_active Withdrawn

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2260001A1 (en) * | 1974-01-31 | 1975-08-29 | Gomila Charles | Motor driven by hydrostatic thrust - has driving chambers with cyclically varying volumes |

| EP0452601A1 (en) * | 1990-04-20 | 1991-10-23 | Alexandre Fabry | Buoyancy motor |

| GB2326916A (en) * | 1997-07-01 | 1999-01-06 | Ghem Sheng Whan | Buoyancy motor |

Non-Patent Citations (1)

| Title |

|---|

| ORD-HUME A W J G: "PERPETUAL MOTION", PERPETUAL MOTION. HISTORY OF AN OBSESSION, NEW YORK, ST. MARTIN'S PRESS, US, PAGE(S) 100-103, XP002067445 * |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006122558A1 (en) * | 2005-05-17 | 2006-11-23 | Lindhagen Joergen | A gravity driven water pxmp with a water energy producing module |

| GB2430471A (en) * | 2005-09-26 | 2007-03-28 | Blaise Coonan | Variable volume buoyancy engine |

| WO2007076719A1 (en) * | 2005-12-31 | 2007-07-12 | Solar City Limited | A power output device and a generating device using the same |

| EP2235362A1 (en) * | 2007-12-19 | 2010-10-06 | James Kwok | Hydrodynamic energy generation system |

| EP2235362A4 (en) * | 2007-12-19 | 2013-07-10 | James Kwok | Hydrodynamic energy generation system |

| WO2011091493A1 (en) * | 2010-01-28 | 2011-08-04 | Cavalheiro Mario Teixeira | Hydraulic power generator with a circular movement for generating electric energy at two different generation points and mechanic power generator with a circular movement for generating electric energy |

| GR1007323B (en) * | 2010-03-29 | 2011-06-22 | Γεμιστος, Παντελης Μιχαηλ | Power generation system provided with submarine folding cisterns |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11125204B2 (en) | System for conversion of wave energy into electrical energy | |

| CA2696502C (en) | System and method for conversion of wave energy into electrical energy | |

| CN102272442B (en) | For water wave energy being converted to the system of electric energy | |

| US20070080540A1 (en) | Hydraulic buoyancy kinetic energy apparatus | |

| EP1452732A1 (en) | Hydraulic buoyant force engine | |

| CN107200104B (en) | A kind of hull surface cleaning climbing robot | |

| US20080092535A1 (en) | Systems and methods using gravity and buoyancy for producing energy | |

| CN110165989B (en) | Tower type tracking sunlight catcher | |

| KR101398292B1 (en) | Tracking Type floating Photovoltaic system | |

| WO2008074214A1 (en) | Wind power generation device | |

| KR20090034290A (en) | Power generating apparatus using fluid | |

| AU2016210776A1 (en) | Wave-driven power generation system | |

| US20040093863A1 (en) | Hydraulic buoyant force engine | |

| EP3622171A1 (en) | Wave power plant and method for generating electricity | |

| DE19832232A1 (en) | Conversion method for solar energy | |

| JP2003139037A (en) | Wave-power pump | |

| CN201554060U (en) | Wind-powered water supply system for afforestation | |

| JP2018526582A (en) | Damless hydroelectric generator | |

| US20010024038A1 (en) | Pendulum pump | |

| FR2919685A1 (en) | Energy recovering device for e.g. bank of sea, has hollow structure formed with opening and fixations to fix pedestal for being ballasted at bottom part, and gear box connected to generator for gearing down movement of sea | |

| EP1426615A1 (en) | Hydraulic buoyancy motor | |

| JP6397513B2 (en) | Buoyancy-driven kinetic energy generator and kinetic energy generation method thereof | |

| DE102010046135A1 (en) | Roessler gravitation manipulator for converting e.g. natural energy of motors into kinetic energy utilized to produce mechanical energy, has energy converter, where sum of working paths of converter and load is divided into partial paths | |

| JP2004270502A (en) | Dynamic power machine using buoyancy | |

| FR2860270A1 (en) | Sea water raising device for dam, has boat moving up and down to allow water to pass into cylinder and to close cylinder, depending on waves, and cage lowering into cylinder by pushing water from cylinder to aqueous pipe leading to dam |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20050302 |