EP1428935A2 - Improvements relating to the construction of playing surfaces - Google Patents

Improvements relating to the construction of playing surfaces Download PDFInfo

- Publication number

- EP1428935A2 EP1428935A2 EP03257849A EP03257849A EP1428935A2 EP 1428935 A2 EP1428935 A2 EP 1428935A2 EP 03257849 A EP03257849 A EP 03257849A EP 03257849 A EP03257849 A EP 03257849A EP 1428935 A2 EP1428935 A2 EP 1428935A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- layer

- playing surface

- surface according

- grain sizes

- preparing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C13/00—Pavings or foundations specially adapted for playgrounds or sports grounds; Drainage, irrigation or heating of sports grounds

- E01C13/08—Surfaces simulating grass ; Grass-grown sports grounds

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C13/00—Pavings or foundations specially adapted for playgrounds or sports grounds; Drainage, irrigation or heating of sports grounds

- E01C13/02—Foundations, e.g. with drainage or heating arrangements

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C13/00—Pavings or foundations specially adapted for playgrounds or sports grounds; Drainage, irrigation or heating of sports grounds

- E01C13/04—Pavings made of prefabricated single units

- E01C13/045—Pavings made of prefabricated single units the prefabricated single units consisting of or including bitumen, rubber or plastics

Definitions

- This invention relates to the construction of playing surfaces, in particular games playing surfaces, and the invention has particular, but not exclusive, reference to surfaces for playing outdoor games and sports or other recreational activities, and for children's playgrounds.

- Sand as a particulate infill whilst being very 'natural' has some unpredictability due to moisture or compaction, along with variations in grading of different sands. This variability has proven satisfactory, with careful selection of the sand, for general multi-purpose use, though it is not predictable enough for better quality sports grounds such as for hockey at higher levels.

- shock pad layers have a degree of elasticity.

- We produce a shock pad layer by introducing loose rubber granules into a fibre shock pad, inside an envelope. This is very effective, but it is costly to construct, as it is done by hand and is labour intensive.

- More rubber and larger particles could be used within the envelope rather than in a fibre shock pad. Problems with larger loose rubber crumb are that if it is disturbed, it does not self-level the in same way as sand or finer crumb. The use of finer rubber in greater depths for greater level stability, can result in too much elasticity so that the surface becomes less stable to play on. This can increase the chance of ankles turning over and other twisting injuries.

- a playing surface for sports or other recreational activities which comprises a water permeable textile envelope containing a layer of mineral particles, an upper layer of the textile envelope bearing a resin bound, adherent, subjacent layer of discrete rubber particles.

- the invention affords a number of advantages. It is very simple to unroll a rolled textile web and thereby rapidly cover even rather extensive playing areas, for example for forming football or hockey pitches.

- the invention accordingly affords considerable advantages in reducing the amount of time required to lay a playing surface incorporating a layer of rubber particles adhered to a textile web. Also, the requirement for lengthy employment of highly skilled labour on site when laying the playing surface is reduced.

- the layer of rubber particles may be applied to the textile web under factory conditions, and accordingly a much greater degree of precision and reproducibility can be obtained than would be possible by applying the rubber particles to form the layer under field conditions. We have also found that it is simpler to form consistent joints between successive textile webs than it is between successive areas of rubber mat.

- the invention includes a method of preparing a playing surface for sports or other recreational activities which comprises laying a first water permeable textile layer to ground, applying thereto a layer of mineral particles, and applying an upper water permeable textile layer bearing a resin bound, adherent, subjacent layer of discrete rubber particles over the mineral layer to form, with the first textile layer, an envelope containing the mineral particles.

- the use of a water-permeable envelope is confers particularly important advantages.

- the adoption of this feature has the further advantage of allowing reconditioning of the playing surface. If the layer of mineral particles, particularly sand or finer particles, is drenched so that it is effectively put into suspension, it may be allowed to drain and rolled, to impart desired playing characteristics.

- a textile web 1 is carried by a conveyor 2 beneath an applicator 3 where a fluid layer 4 of rubber particles in a resin binder is applied.

- the web passes beneath a doctor blade 5 where this fluid layer is levelled and its thickness regulated, and thence beneath an appropriate curing device 6 where the fluid layer is cured to become an adherent resin bound rubber of rubber particles 7.

- an undersheet 8 of a suitable geotextile material is laid down over a prepared area of ground.

- a layer 9 of sand or other fine particulate mineral is screeded over the undersheet 8, and a textile web 1 bearing an adherent layer 7 of rubber particles is applied to the layer of sand 9 with the rubber layer 7 facing downwards to form an envelope.

- the undersheet 8 and the textile web 1 may be bonded together at their margins 10.

- a layer 11 of artificial sports surface such as an artificial turf is then applied.

- the layer of sand 9 is replaced by a layer of angular stone 12, and a protective layer 13 of a suitable geotextile material is incorporated into the envelope between the layer of stones 12 and the rubber-containing layer 7.

- the mineral particles are fine, as in Figure 2, so that interstices between them are small in relation to the rubber particles adhered to the upper textile layer 1, then, if the rubber-containing layer should break down during the course of time it is found that the rubber particles tend to remain as a stable layer between that textile web and the mineral layer.

- the purpose of the protective layer 13 is firstly to delay and breakdown of the rubber containing layer 7, and secondly, to ensure that any rubber particles which become separated remain in a shock-absorbing layer rather than falling through interstices between the stones.

- the textile web used for preparing any of the textile layers of the envelope is suitably a non-woven, needle-punched synthetic fibre mat, for example of polyester, polypropylene or polyamide material.

- a resin binder for any of the textile webs may be chosen to confer appropriate properties, such as a desired stiffness, on the web.

- Example 1 2 3 4 Upper textile layer thickness 1-2mm 200-350g/mm 2 Rubber particle density (kg/m 2 ) 1.5-2.3 2.0-3.0 0.5-3.0 0.5-1.2 Rubber layer thickness (mm) 4-6 4-8 1-8 1-3 Mineral Stone Sand or stone Sand or Stone stone Mineral layer thickness (mm) 50-75 50-100 50-100 50-75 Bottom textile layer thickness 1-3mm Lower textile layer weight (g/m 2 ) 225-300 207-300 207-300 225-300 Protective layer thickness (mm) (if present) 1-2 1-3 1-4 1-4 Protective layer weight (g/m 2 ) (if present) 270-300 270-350 270-400 270-400 Intended use hockey Football Multi-sport tennis Construction Figure 3 Figure 2 or Figure 2 or Figure 3

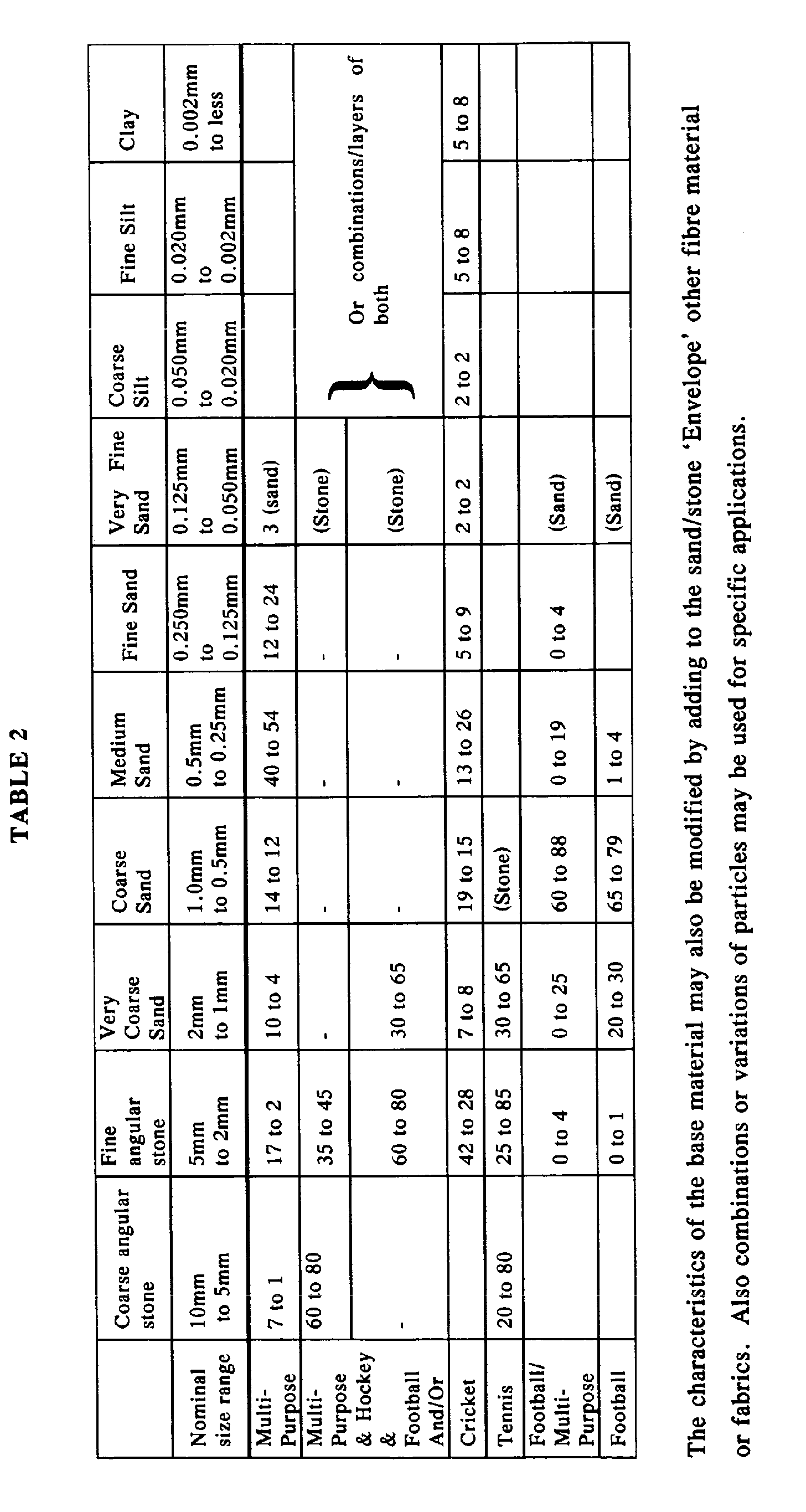

- compositions of particular examples of mineral beds (parts by weight of particles of particular nominal size ranges) for various stone or sand mixtures are shown in the following Table 2.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Road Paving Structures (AREA)

- Laminated Bodies (AREA)

Abstract

Description

| Example | 1 | 2 | 3 | 4 |

| Upper textile layer thickness | 1-2mm 200-350g/mm2 | |||

| Rubber particle density (kg/m2) | 1.5-2.3 | 2.0-3.0 | 0.5-3.0 | 0.5-1.2 |

| Rubber layer thickness (mm) | 4-6 | 4-8 | 1-8 | 1-3 |

| Mineral | Stone | Sand or stone | Sand or Stone stone | |

| Mineral layer thickness (mm) | 50-75 | 50-100 | 50-100 | 50-75 |

| Bottom textile layer thickness | 1-3mm | |||

| Lower textile layer weight (g/m2) | 225-300 | 207-300 | 207-300 | 225-300 |

| Protective layer thickness (mm) (if present) | 1-2 | 1-3 | 1-4 | 1-4 |

| Protective layer weight (g/m2) (if present) | 270-300 | 270-350 | 270-400 | 270-400 |

| Intended use | hockey | Football | Multi-sport | tennis |

| Construction | Figure 3 | Figure 2 or | Figure 2 or | Figure 3 |

Claims (30)

- A playing surface for sports or other recreational activities which comprises a water permeable textile envelope containing a layer of mineral particles, an upper layer of the textile envelope bearing a resin bound, adherent, subjacent layer of discrete rubber particles.

- A playing surface according to claim 1 which is overlain by a layer of artificial turf.

- A playing surface according to claim 1 or 2, wherein a water-permeable protective interlayer is provided between the rubber-containing layer and the layer of mineral particles.

- A playing surface according to any preceding claim, wherein said mineral particles substantially all have grain sizes below 10mm.

- A playing surface according to claim 4 wherein said mineral particles are selected from one or more of:coarse angular stone (nominal grain sizes between 10mm and 5mm)fine angular stone (nominal grain sizes between 5mm and 2mm)very coarse sand (nominal grain sizes between 2mm and 1mm)coarse sand (nominal grain sizes between 1mm and 0.5mm)medium sand (nominal grain sizes between 0.5mm and 0.25mm)fine sand (nominal grain sizes between 0.25mm and 0.125mm)very fine sand (nominal grain sizes between 0.125mm and 0.050mm)coarse silt (nominal grain sizes between 0.050mm and 0.020mm)fine silt (nominal grain sizes between 0.020mm and 0.002mm)clay (nominal grain sizes below 0.002mm).

- A playing surface according to claim 5, wherein said layer of mineral particles substantially consists of at least two of: coarse angular stone, fine angular stone, very coarse sand, coarse sand, medium sand, fine sand, coarse silt, fine silt, clay.

- A playing surface according to any preceding claim, wherein at least one textile layer is formed as a resin bonded non-woven mat of synthetic fibre.

- A playing surface according to any preceding claim, wherein at least one textile layer is formed from a substantially non-degradable polymeric fibre such as polyester, polypropylene or polyamide.

- A playing surface according to any preceding claim, wherein said envelope has at least one textile layer having a fibre density of between 150 and 500 g/m2.

- A playing surface according to claim 9, wherein said envelope has an upper textile layer having a fibre density of between 150 and 400 g/m2.

- A playing surface according to claim 9 or 10, wherein said envelope has a lower textile layer having a fibre density of between 150 and 350 g/m2.

- A playing surface according to any of claims 9 to 11 as dependent on claim 3, wherein said protective layer has a fibre density of between 250 and 400 g/m2.

- A playing surface according to any preceding claim, wherein the layer of mineral particles has a thickness between 40 and 150mm.

- A playing surface according to any preceding claim, wherein the layer of rubber particles has a thickness between 1 and 15mm.

- A playing surface according to any preceding claim, wherein the rubber particles in said layer have a density of between 0.4 and 4.0 kg/m2.

- A method of preparing a playing surface for sports or other recreational activities which comprises laying a first water permeable textile layer to ground, applying thereto a layer of mineral particles, and applying an upper water permeable textile layer bearing a resin bound, adherent, subjacent layer of discrete rubber particles over the mineral layer to form, with the first textile layer, an envelope containing the mineral particles.

- A method of preparing a playing surface according to claim 16 wherein a layer of artificial turf is laid over the upper textile layer of said envelope.

- A method of preparing a playing surface according to claim 16 or 17, wherein a water-permeable protective interlayer is provided between the rubber-containing layer and the layer of mineral particles.

- A method of preparing a playing surface according to any of claims 16 to 18, wherein said mineral particles substantially all have grain sizes below 10mm.

- A method of preparing a playing surface according to claim 19 wherein said mineral particles are selected from one or more of:coarse angular stone (nominal grain sizes between 10mm and 5mm)fine angular stone (nominal grain sizes between 5mm and 2mm) very coarse sand (nominal grain sizes between 2mm and 1mm)coarse sand (nominal grain sizes between 1mm and 0.5mm)medium sand (nominal grain sizes between 0.5mm and 0.25mm)fine sand (nominal grain sizes between 0.25mm and 0.125mm)very fine sand (nominal grain sizes between 0.125mm and 0.050mm)coarse silt (nominal grain sizes between 0.050mm and 0.020mm)fine silt (nominal grain sizes between 0.020mm and 0.002mm)clay (nominal grain sizes below 0.002mm).

- A method of preparing a playing surface according to claim 20, wherein said layer of mineral particles is formed using at least two of: coarse angular stone, fine angular stone, very coarse sand, coarse sand, medium sand, fine sand, coarse silt, fine silt, clay.

- A method of preparing a playing surface according to any of claims 16 to 22, wherein at least one textile layer is formed as a resin bonded non-woven mat of synthetic fibre.

- A method of preparing a playing surface according to any of claims 16 to 22, wherein at least one textile layer is formed from a substantially non-degradable polymeric fibre such as polyester, polypropylene or polyamide.

- A method of preparing a playing surface according to any preceding claim, wherein said envelope has at least one textile layer having a fibre density of between 150 and 500 g/m2.

- A method of preparing a playing surface according to claim 24, wherein said envelope has an upper textile layer having a fibre density of between 150 and 400 g/m2.

- A method of preparing a playing surface according to claim 24 or 25, wherein said envelope has a lower textile layer having a fibre density of between 150 and 350 g/m2.

- A method of preparing a playing surface according to any of claims 24 to 26 as dependent on claim its, wherein said protective layer has a fibre density of between 250 and 400 g/m2.

- A method of preparing a playing surface according to any of claims 16 to 27, wherein the layer of mineral particles is applied to a thickness between 40 and 150mm.

- A method of preparing a playing surface according to any of claims 16 to 28, wherein the layer of rubber particles is formed with a thickness between 1 and 15mm.

- A method of preparing a playing surface according to any of claims 16 to 29, wherein the rubber particles in said layer are applied to a density of between 0.4 and 4.0 kg/m2.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB0229181 | 2002-12-14 | ||

| GB0229181A GB2396117B (en) | 2002-12-14 | 2002-12-14 | Improvements relating to the construction of playing surfaces |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1428935A2 true EP1428935A2 (en) | 2004-06-16 |

| EP1428935A3 EP1428935A3 (en) | 2005-02-02 |

Family

ID=9949683

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03257849A Withdrawn EP1428935A3 (en) | 2002-12-14 | 2003-12-13 | Improvements relating to the construction of playing surfaces |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1428935A3 (en) |

| GB (1) | GB2396117B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013009174A1 (en) | 2011-07-13 | 2013-01-17 | Desso Sports Systems N.V. | Substructure for an artificial lawn |

| WO2016129995A1 (en) | 2015-02-10 | 2016-08-18 | Desso Sports B.V. | Substructure for an artificial lawn |

| EP3885400A1 (en) | 2020-03-27 | 2021-09-29 | Innograaf B.V. | A polymeric foam material for shock pads in artificial grass systems |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8112126U1 (en) * | 1981-04-23 | 1982-10-07 | J.F. Adolff Ag, 7150 Backnang | Mat, especially as a sub-layer for an artificial lawn |

| NZ203964A (en) * | 1982-04-27 | 1985-04-30 | Nottingham County Council | Artificial playing surface |

| US4497853A (en) * | 1984-02-09 | 1985-02-05 | Tomarin Seymour A | Synthetic turf carpet game playing surface |

| DE59101869D1 (en) * | 1991-01-14 | 1994-07-14 | Setpoint Int Ag | Flooring for tennis courts. |

| US5976645A (en) * | 1998-06-01 | 1999-11-02 | Safturf International Limited | Vertically draining, rubber-filled synthetic turf and method of manufacture |

-

2002

- 2002-12-14 GB GB0229181A patent/GB2396117B/en not_active Expired - Fee Related

-

2003

- 2003-12-13 EP EP03257849A patent/EP1428935A3/en not_active Withdrawn

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013009174A1 (en) | 2011-07-13 | 2013-01-17 | Desso Sports Systems N.V. | Substructure for an artificial lawn |

| WO2016129995A1 (en) | 2015-02-10 | 2016-08-18 | Desso Sports B.V. | Substructure for an artificial lawn |

| EP3885400A1 (en) | 2020-03-27 | 2021-09-29 | Innograaf B.V. | A polymeric foam material for shock pads in artificial grass systems |

| NL2025222B1 (en) | 2020-03-27 | 2021-10-20 | Innograaf B V | A polymeric foam material for shock pads in artificial grass systems. |

Also Published As

| Publication number | Publication date |

|---|---|

| GB2396117A (en) | 2004-06-16 |

| GB2396117B (en) | 2006-06-28 |

| GB0229181D0 (en) | 2003-01-22 |

| EP1428935A3 (en) | 2005-02-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4564310A (en) | Resilient paving composition for playfields sports fields and recreation areas | |

| JP4098078B2 (en) | Artificial lawn with a top layer of elastic particles | |

| US7357966B2 (en) | Synthetic turf system and method | |

| US5746546A (en) | Soil stabilization composition and method | |

| JP3305323B2 (en) | Basic structure of synthetic tennis court and its manufacturing method | |

| US7186450B2 (en) | Construction of playing surfaces | |

| KR100982233B1 (en) | Water permeable polymer road pavement having increased moisture content and durability and method for constructing the pavement | |

| EP0260769A1 (en) | Method of providing a substructure construction for an artificial grassfield and an artificial grassfield having such a substructure construction | |

| EP1428935A2 (en) | Improvements relating to the construction of playing surfaces | |

| NZ203964A (en) | Artificial playing surface | |

| US9539490B2 (en) | Low-maintenance bocce court | |

| JP2010077794A (en) | Artificial turf laying structure | |

| AU2013270530A1 (en) | Artificial Surfaces and Methods for their Production | |

| KR102170750B1 (en) | The all-weather hard court | |

| WO2007123493A1 (en) | A playing field and a method of constructing a playing field | |

| RU2306381C1 (en) | All-weather ground composition for equestrian sport facility | |

| JPH089847B2 (en) | Playground surface | |

| JPH0559204B2 (en) | ||

| JPH11241306A (en) | Tennis court | |

| JPH0115641B2 (en) | ||

| JPS6354083B2 (en) | ||

| JPS6145004A (en) | Construction of pavement in athletic field | |

| JPS5996304A (en) | Construction of ground such as athletic field | |

| JPS6259706A (en) | Surface layer structure of athletic field | |

| HK1091878A (en) | Synthetic grass with resilient granular top surface layer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050728 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20080625 |