EP1234976A2 - Valve system for regulating the pressure of fuel supply in a combustion engine - Google Patents

Valve system for regulating the pressure of fuel supply in a combustion engine Download PDFInfo

- Publication number

- EP1234976A2 EP1234976A2 EP01129778A EP01129778A EP1234976A2 EP 1234976 A2 EP1234976 A2 EP 1234976A2 EP 01129778 A EP01129778 A EP 01129778A EP 01129778 A EP01129778 A EP 01129778A EP 1234976 A2 EP1234976 A2 EP 1234976A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- armature

- valve arrangement

- compression spring

- closing direction

- pressure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M69/00—Low-pressure fuel-injection apparatus ; Apparatus with both continuous and intermittent injection; Apparatus injecting different types of fuel

- F02M69/46—Details, component parts or accessories not provided for in, or of interest apart from, the apparatus covered by groups F02M69/02 - F02M69/44

- F02M69/54—Arrangement of fuel pressure regulators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M37/00—Apparatus or systems for feeding liquid fuel from storage containers to carburettors or fuel-injection apparatus; Arrangements for purifying liquid fuel specially adapted for, or arranged on, internal-combustion engines

- F02M37/0011—Constructional details; Manufacturing or assembly of elements of fuel systems; Materials therefor

- F02M37/0023—Valves in the fuel supply and return system

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/02—Fuel-injection apparatus having several injectors fed by a common pumping element, or having several pumping elements feeding a common injector; Fuel-injection apparatus having provisions for cutting-out pumps, pumping elements, or injectors; Fuel-injection apparatus having provisions for variably interconnecting pumping elements and injectors alternatively

- F02M63/0225—Fuel-injection apparatus having a common rail feeding several injectors ; Means for varying pressure in common rails; Pumps feeding common rails

Definitions

- the invention relates to a valve arrangement for regulating the pressure of the fuel supply in an internal combustion engine with at least one pressure control device and one shut-off device operated by an electromagnetic drive.

- Such valve arrangements are particularly in engines with a direct fuel injection known.

- Such engines require injection pressures of approx. 100 to 120 bar. This pressure is generated by high pressure pumps which are very are sensitive to cavitation, d. H. the fuel supplied must be free of vapor bubbles his. In normal engine operation, a supply pressure of approximately is sufficient 4 bar around the fuel without vapor bubbles from a pre-feed pump to the high pressure pump to promote.

- the admission pressure can be increased to approx. 7 bar in order to form vapor bubbles suppress and injection pressure at engine start without effective mechanical Ensure high pressure pump.

- the required pressure increase to 7 bar is thereby by an electromagnetically actuated shut-off device and achieved by a 4 bar pressure control device arranged upstream or downstream.

- the present invention is therefore based on the object of a remedy for the to create problems described above.

- a housing is provided with at least an inlet fitting and at least one outlet fitting, the are fluidly connected to one another via a connecting channel, the electromagnetic drive by means of an armature on a plunger with a Closing element acts that the connection channel opens or closes, and at least a compression spring element that directly or indirectly in the closing direction the closing element works.

- the magnetic force acts on the armature in the closing direction of the Closing element, wherein further a compression spring, which is located on a housing part supported, acts on the anchor in the closing direction.

- a compression spring which is located on a housing part supported, acts on the anchor in the closing direction.

- this version acts it is a so-called "normally open” variant. That is, in de-energized Condition is set via the compression spring to a low pressure level of approx. 4 bar. In the energized state, a magnetic force is applied to the plunger via the armature exercised, which together with the compression spring to a high pressure level of approx. 7 bar.

- the magnetic force acts on the armature against the Closing direction of the closing element, with a first compression spring in the closing direction acts on the armature and a second compression spring in the closing direction the plunger acts and both compression springs are supported on the housing parts.

- a "currentlessly closed” variant of the valve arrangement is realized.

- the spring forces of the two compression springs add up in the de-energized state Condition to approx. 7 bar.

- the magnetic force acts against the first compression spring, so that only the second compression spring with a pressure level of approx. 4 bar acts on the plunger in the closing direction.

- a particularly simple valve arrangement results when the housing has two inlet fittings and two outlet fittings.

- the first Inlet connector is to be connected to the pre-feed pump and that second inlet fitting with the return line from the high pressure pump.

- the first outlet connector is with the inlet line of the high pressure pump and the second outlet fitting with the return line to the fuel tank connect.

- the housing can have an armature core that can be moved in the closing direction, on which the compression spring acting on the armature is supported, whereby the The pressure level of the armature can be adjusted in a simple manner.

- the electromagnetic drive is a proportional magnet system has, wherein the anchor core has an elliptical outer contour has. The pressed-in armature core is thus at the touching magnetic flux transition point not exactly circular which results in a 90 ° rotation results in a minimum and a maximum of the magnetic force, which in turn is a Force adjustment enabled.

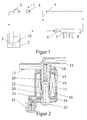

- FIG. 1 shows in schematic form the fuel flow in a not shown Internal combustion engine, wherein a pressure control of the fuel supply by means of a valve arrangement 1 according to the prior art.

- a pressure control of the fuel supply by means of a valve arrangement 1 according to the prior art.

- the fuel from a fuel tank 2 by means of a prefeed pump 3 to a high pressure pump 4, which directs the fuel at a pressure of approximately Feeds 100 to 120 bar of a fuel rail 5, one behind the rail arranged pressure regulator 6 excess fuel to a pressure regulated from up to 4 bar.

- This excess fuel is then directly or in Connection with the fuel present in the short-circuit line 7 to the valve arrangement 1 led.

- the valve arrangement 1 consists of a pressure control valve 8 and a shut-off valve 9. From the shut-off valve 9 Fuel is fed back into the fuel tank 2.

- the shut-off valve 9 is closed, so that Pressure control valve 8 that opens from a pressure number of approx. 4 bar out of operation becomes.

- the prefeed pump 3 thus delivers fuel at a pressure of approx. 7 bar, in the present case a pressure regulator 10 arranged in the fuel tank which opens at a pressure of more than 7 bar.

- the shut-off valve 9 is by means of opened an electromagnetic drive, so that now a pressure in the fuel circuit of about 4 bar is realized by the pressure control valve 8. It can Fuel before the high pressure pump 4 or after the pressure control valve 6 to the valve arrangement 1 and from there to be returned to the fuel tank 2.

- FIG. 2 now shows a first embodiment of the valve assembly according to the invention 1.

- This valve assembly 1 has an inlet fitting 11 and a Outlet connector 12, which are fluidly connected to one another via a connecting channel 13 are connected.

- the connecting channel can be closed by a closing element 14 be opened or closed.

- the closing element 14 is in a known manner arranged on a plunger 15 by an electromagnetic drive 16 is actuated and is mounted in a guide bush 20.

- the electromagnetic drive 16 consists of a known manner Coil body 17, which interacts with an electromagnetic yoke, wherein both parts are arranged in a housing 19 made of injection molding. Furthermore an armature 21 is displaceable in the longitudinal direction in a further guide bushing 20 stored. A compression spring 22 acts in the closing direction of the closing element 14 on the armature 21.

- the compression spring 22 is based on an im Housing 19 slidably arranged armature core 23 from. That way on the one hand, the spring force is set by the displaceable armature core 23 and on the other hand, if the armature core 23 has an elliptical outer contour has the magnetic force. The power supply of the electromagnetic drive guaranteed.

- valve arrangement 1 in FIG. 1 which is designed to be open when de-energized, functions in this case as follows:

- the electromagnetic drive 16 is not included Electricity supplied. Accordingly, there is no magnetic force on the armature 21 exercised.

- the valve arrangement 1 is in the “currentless open” state. Thereby owns the compression spring 22 has a low pressure level of approximately 4 bar. Will be in the fuel cycle now a system pressure of more than 4 bar is reached that opens Closing element 14 against the compression spring 22 and fuel can be in the fuel tank 2 can be returned.

- the armature 21 is through the magnetic force and the spring force are pressed against the plunger 15.

- the Magnetic force can be set so that a pressure level of approx. 7 bar is reached becomes.

- the valve arrangement 1 only opens at a pressure level in the fuel circuit, that is higher than 7 bar.

- the magnetic force is set here as already described, via the rotation of the armature core 23.

- FIG. 2 shows a cross section of a second embodiment of the valve arrangement 1.

- This valve assembly 1 has two inlet fittings 25 and 26 and two outlet fittings 27 and 28.

- the second inlet fitting 26 is with the pressure regulator 6 connected and leads excess fuel through the outlet fitting 28 back into the fuel tank 2.

- the connecting channel 13 takes over in In the present case, the function of the short-circuit line shown in Figure 1 7th

- valve arrangement 1 In contrast to the valve arrangement 1, the valve arrangement 1 according to FIG. 2 is made of Figure 1 switched "de-energized closed". That is, that in the de-energized state maximum pressure level of approx. 7 bar due to the closing force acting on the closing element 14 acts, is achieved.

- the present valve arrangement 1 has a first compression spring 29 which acts on the armature 21 in the closing direction and a second compression spring 30, which acts on the plunger 15 in the closing direction. Both Compression springs 29 and 30 are supported on housing parts and add up to maximum spring force, which corresponds to a pressure level of approx. 7 bar. In the In the starting phase, this valve arrangement 1 is therefore de-energized so that the fuel is conveyed to the high pressure pump 4 at 7 bar.

- valve arrangement 1 is energized and the magnetic force moves the armature 21 against the compression spring 29, so that only the compression spring 30 with a Pressure level of 4 bar acts on the plunger 15, so that the valve at one Pressure level that is greater than 4 bar opens and fuel through the connector 28 can be returned to the fuel tank 2.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fuel-Injection Apparatus (AREA)

Abstract

Ventilanordnung zur Druckregelung der Kraftstoffzufuhr bei einer Brennkraftmaschine mit zumindest einer Druckregeleinrichtung und einer durch einen elektromagnetischen Antrieb betätigbaren Absperreinrichtung, wobei ein Gehäuse (19) vorgesehen ist mit zumindest einem Einlaßanschlußstück (11, 25, 26) und zumindest einem Auslaßanschlußstück (12,27,28), die über einen Verbindungskanal (13) fluidisch miteinander verbunden sind, wobei der elektromagnetischer Antrieb (16) mittels eines Ankers (21) auf einen Stößel (15) mit einem Schließelement (14) wirkt, das den Verbindungskanal öffnet oder schließt, und mit zumindest einem Druckfederelement (22, 29,30), das direkt oder indirekt in Schließrichtung auf das Schließelement (14) wirkt. Valve arrangement for pressure control of the fuel supply in an internal combustion engine with at least one pressure control device and a shut-off device which can be actuated by an electromagnetic drive, a housing (19) being provided with at least one inlet connection piece (11, 25, 26) and at least one outlet connection piece (12, 27, 28) ), which are fluidly connected to one another via a connecting channel (13), the electromagnetic drive (16) acting by means of an armature (21) on a plunger (15) with a closing element (14) which opens or closes the connecting channel, and with at least one compression spring element (22, 29, 30) which acts directly or indirectly in the closing direction on the closing element (14).

Description

Die Erfindung betrifft eine Ventilanordnung zur Druckregelung der Kraftstoffzufuhr bei einer Brennkraftmaschine mit zumindest einer Druckregeleinrichtung und einer durch einen elektromagnetischen Antrieb betätigbaren Absperreinrichtung.The invention relates to a valve arrangement for regulating the pressure of the fuel supply in an internal combustion engine with at least one pressure control device and one shut-off device operated by an electromagnetic drive.

Derartige Ventilanordnungen sind insbesondere bei Motoren mit einer Kraftstoff-Direkteinspritzung bekannt. Derartige Motoren benötigen Einspritzdrücke von ca. 100 bis 120 bar. Dieser Druck wird dabei von Hochdruckpumpen erzeugt, die sehr kavitationsempfindlich sind, d. h. der zugeführte Kraftstoff muß frei von Dampfblasen sein. Im normalen Motorbetrieb genügt dazu ein Vorlaufdruck von ungefähr 4 bar um den Kraftstoff dampfblasenfrei von einer Vorförderpumpe zur Hochdruckpumpe zu fördern. In der Startphase des Motors muß im Leitungssystem jedoch der Vordruck auf ca. 7 bar erhöht werden, um eine Dampfblasenbildung zu unterdrücken und Einspritzdruck bei Motorstart ohne wirksame mechanische Hochdruckpumpe sicher zu stellen. Die erforderliche Druckerhöhung auf 7 bar wird dabei durch eine elektromagnetisch betätigbare Absperreinrichtung und durch eine davor oder dahinter angeordnete 4 bar - Druckregeleinrichtung erreicht.Such valve arrangements are particularly in engines with a direct fuel injection known. Such engines require injection pressures of approx. 100 to 120 bar. This pressure is generated by high pressure pumps which are very are sensitive to cavitation, d. H. the fuel supplied must be free of vapor bubbles his. In normal engine operation, a supply pressure of approximately is sufficient 4 bar around the fuel without vapor bubbles from a pre-feed pump to the high pressure pump to promote. In the starting phase of the engine, however, must be in the piping system the admission pressure can be increased to approx. 7 bar in order to form vapor bubbles suppress and injection pressure at engine start without effective mechanical Ensure high pressure pump. The required pressure increase to 7 bar is thereby by an electromagnetically actuated shut-off device and achieved by a 4 bar pressure control device arranged upstream or downstream.

Eine derartige Ventilanordnung benötigt relativ viel Bauraum und ist durch den erhöhten Montageaufwand des weiteren auch sehr kostenintensiv.Such a valve arrangement requires a relatively large amount of space and is increased by the Installation effort also very costly.

Der vorliegenden Erfindung liegt daher die Aufgabe zugrunde, eine Abhilfe für die vorstehend geschilderten Probleme zu schaffen. The present invention is therefore based on the object of a remedy for the to create problems described above.

Diese Aufgabe wird dadurch gelöst, daß ein Gehäuse vorgesehen ist mit zumindest einem Einlaßanschlußstück und zumindest einem Auslaßanschlußstück, die über einen Verbindungskanal fluidisch miteinander verbunden sind, wobei der elektromagnetische Antrieb mittels eines Ankers auf einen Stößel mit einem Schließelement wirkt, daß den Verbindungskanal öffnet oder schließt, und mit zumindest einem Druckfederelement, das direkt oder indirekt in Schließrichtung auf das Schließelement wirkt.This object is achieved in that a housing is provided with at least an inlet fitting and at least one outlet fitting, the are fluidly connected to one another via a connecting channel, the electromagnetic drive by means of an armature on a plunger with a Closing element acts that the connection channel opens or closes, and at least a compression spring element that directly or indirectly in the closing direction the closing element works.

Auf diese Weise wird eine Ventilanordnung geschaffen, die einfach und kostengünstig herzustellen ist und des weiteren wenig Bauraum sowie einen geringen Montageaufwand benötigt. Sowohl die Druckregelung der Kraftstoffzufuhr als auch die Absperrmöglichkeit wird durch dieses eine Bauteil gewährleistet. In einer ersten Ausführungsform wirkt die Magnetkraft auf den Anker in Schließrichtung des Schließelementes, wobei des weiteren eine Druckfeder, die sich an einem Gehäuseteil abstützt, in Schließrichtung auf den Anker wirkt. Bei dieser Ausführung handelt es sich um eine sogenannte "stromlos offene" Variante. D. h. in stromlosem Zustand wird über die Druckfeder ein niedriges Druckniveau von ca. 4 bar eingestellt. Im bestromten Zustand wird über den Anker eine Magnetkraft auf den Stößel ausgeübt, die sich zusammen mit der Druckfeder auf ein hohes Druckniveau von ca. 7 bar summiert.In this way, a valve arrangement is created that is simple and inexpensive is to manufacture and furthermore little space and a small Assembly effort required. Both the pressure control of the fuel supply as well the locking option is guaranteed by this one component. In a first Embodiment, the magnetic force acts on the armature in the closing direction of the Closing element, wherein further a compression spring, which is located on a housing part supported, acts on the anchor in the closing direction. In this version acts it is a so-called "normally open" variant. That is, in de-energized Condition is set via the compression spring to a low pressure level of approx. 4 bar. In the energized state, a magnetic force is applied to the plunger via the armature exercised, which together with the compression spring to a high pressure level of approx. 7 bar.

Bei einer zweiten Ausführungsform wirkt die Magnetkraft auf den Anker gegen die Schließrichtung des Schließelementes, wobei eine erste Druckfeder in Schließrichtung auf den Anker wirkt und eine zweite Druckfeder in Schließrichtung auf den Stößel wirkt und sich beide Druckfedern an Gehäuseteilen abstützten. Auf diese Weise wird eine "stromlos geschlossene" Variante der Ventilanordnung realisiert. Hierbei summieren sich die Federkräfte der zwei Druckfedern im stromlosen Zustand auf ca. 7 bar. In bestromten Zustand wirkt die Magnetkraft gegen die erste Druckfeder, so daß lediglich die zweite Druckfeder mit einem Druckniveau von ca. 4 bar in Schließrichtung auf den Stößel wirkt.In a second embodiment, the magnetic force acts on the armature against the Closing direction of the closing element, with a first compression spring in the closing direction acts on the armature and a second compression spring in the closing direction the plunger acts and both compression springs are supported on the housing parts. On in this way a "currentlessly closed" variant of the valve arrangement is realized. The spring forces of the two compression springs add up in the de-energized state Condition to approx. 7 bar. When energized, the magnetic force acts against the first compression spring, so that only the second compression spring with a pressure level of approx. 4 bar acts on the plunger in the closing direction.

Eine besonders einfache Ventilanordnung ergibt sich dann, wenn das Gehäuse zwei Einlaßanschlußstücke und zwei Auslaßanschlußstücke aufweist. Das erste Einlaßanschlußstück ist dabei mit der Vorförderpumpe zu verbinden und das zweite Einlaßanschlußstück mit der Rücklaufleitung von der Hochdruckpumpe. Das erste Auslaßanschlußstück ist mit der Zulaufleitung der Hochdruckpumpe und das zweite Auslaßanschlußstück mit der Rücklaufleitung zum Kraftstofftank zu verbinden.A particularly simple valve arrangement results when the housing has two inlet fittings and two outlet fittings. The first Inlet connector is to be connected to the pre-feed pump and that second inlet fitting with the return line from the high pressure pump. The first outlet connector is with the inlet line of the high pressure pump and the second outlet fitting with the return line to the fuel tank connect.

Das Gehäuse kann einen in Schließrichtung bewegbaren Ankerkern aufweisen, an dem sich die auf den Anker wirkende Druckfeder abstützt, wodurch sich das Druckniveau des Ankers auf einfache Weise einstellen läßt. Als besonders vorteilhaft hat es sich weiterhin erwiesen, daß der elektromagnetische Antrieb ein Proportional-Magnetsystem aufweist, wobei der Ankerkern eine elliptische Außenkontur besitzt. Der eingedrückte Ankerkern ist somit an der berührenden Magnetflußübergangsstelle nicht exakt kreisrund wodurch sich innerhalb einer 90° Drehung ein Minimum und ein Maximum der Magnetkraft ergibt, was wiederum eine Krafteinstellung ermöglicht.The housing can have an armature core that can be moved in the closing direction, on which the compression spring acting on the armature is supported, whereby the The pressure level of the armature can be adjusted in a simple manner. To be particularly advantageous it has also been found that the electromagnetic drive is a proportional magnet system has, wherein the anchor core has an elliptical outer contour has. The pressed-in armature core is thus at the touching magnetic flux transition point not exactly circular which results in a 90 ° rotation results in a minimum and a maximum of the magnetic force, which in turn is a Force adjustment enabled.

Ausführungsbeispiele der Erfindung sind in der Zeichnung dargestellt und werden nachfolgend beschrieben, hierin zeigt:

Figur 1- eine schematische Ansicht des Kraftstoffflusses bei einer Brennkraftmaschine,

Figur 2- ein Querschnitt einer ersten Ausführungsform der erfindungsgemäßen Ventilanordnung, und

Figur 3- ein Querschnitt einer zweiten Ausführungsform der erfindungsgemäßen Ventilanordnung.

- Figure 1

- 1 shows a schematic view of the fuel flow in an internal combustion engine,

- Figure 2

- a cross section of a first embodiment of the valve assembly according to the invention, and

- Figure 3

- a cross section of a second embodiment of the valve assembly according to the invention.

Figur 1 zeigt in schematischer Form den Kraftstofffluß bei einer weiter nicht dargestellten

Brennkraftmaschine, wobei eine Druckregelung der Kraftstoffzufuhr

durch eine Ventilanordnung 1 gemäß dem Stand der Technik stattfindet. Dabei

wird der Kraftstoff aus einem Kraftstofftank 2 mittels einer Vorförderpumpe 3 zu

einer Hochdruckpumpe 4 geleitet, die den Kraftstoff mit einem Druck von ungefähr

100 bis 120 bar einer Kraftstoffverteilerleiste 5 zuführt, wobei ein hinter der Verteilerleiste

angeordneter Druckregler 6 überschüssigen Kraftstoff auf einen Druck

von bis zu 4 bar abregelt. Dieser überschüssige Kraftstoff wird dann direkt oder in

Verbindung mit dem in der Kurzschlußleitung 7 vorhandenen Kraftstoff zur Ventilanordnung

1 geführt. Im herkömmlichen Fall besteht die Ventilanordnung 1 aus

einem Druckregelventil 8 und einem Absperrventil 9. Vom Absperrventil 9 aus wird

Kraftstoff wieder zurück in den Kraftstofftank 2 geführt.Figure 1 shows in schematic form the fuel flow in a not shown

Internal combustion engine, wherein a pressure control of the fuel supply

by means of a

Der dargestellte Kraftstoffkreislauf funktioniert nun wie folgt:The fuel circuit shown now works as follows:

In der Startphase des Motors ist das Absperrventil 9 geschlossen, so daß das

Druckregelventil 8 das ab einer Druckzahl von ca. 4 bar öffnet außer Betrieb gesetzt

wird. Die Vorförderpumpe 3 fördert damit Kraftstoff mit einem Druck von ca.

7 bar, wobei im vorliegenden Fall ein Druckregler 10 im Kraftstofftank angeordnet

ist, der bei einem Druck von mehr als 7 bar öffnet. Auf diese Weise wird während

der Startphase Kraftstoff dampfblasenfrei zur Hochdruckpumpe 4 gefördert, die

Einspritzdrücke von ca. 100 bis 120 bar realisiert und den Kraftstoff zur Verteilerleiste

5 führt. Während der normalen Betriebsphase wird das Absperrventil 9 mittels

einem elektromagnetischen Antrieb geöffnet, so daß nun ein Druck im Kraftstoffkreislauf

von ca. 4 bar durch das Druckregelventil 8 realisiert wird. Dabei kann

Kraftstoff vor der Hochdruckpumpe 4 oder nach dem Druckregelventil 6 zur Ventilanordnung

1 und von da aus in den Kraftstofftank 2 zurückgeführt werden.In the starting phase of the engine, the shut-off

Figur 2 zeigt nun eine erste Ausführungsform der erfindungsgemäßen Ventilanordnung

1. Diese Ventilanordnung 1 besitzt ein Einlaßanschlußstück 11 und ein

Auslaßanschlußstück 12, die über ein Verbindungskanal 13 fluidisch miteinander

verbunden sind. Der Verbindungskanal kann dabei durch ein Schließelement 14

geöffnet oder geschlossen werden. Das Schließelement 14 ist auf bekannte Weise

auf einem Stößel 15 angeordnet der durch einen elektromagnetischen Antrieb

16 betätigt wird und in einer Führungsbüchse 20 gelagert ist.Figure 2 now shows a first embodiment of the valve assembly according to the

Der elektromagnetische Antrieb 16 besteht dabei auf bekannte Weise aus einem

Spulenkörper 17, der mit einem elektromagnetischen Rückschluß zusammenwirkt,

wobei beide Teile in einem Gehäuse 19 aus Spritzguß angeordnet sind. Des weiteren

ist in einer weiteren Führungsbuchse 20 ein Anker 21 in Längsrichtung verschiebbar

gelagert. Eine Druckfeder 22 wirkt in Schließrichtung des Schließelementes

14 auf den Anker 21. Die Druckfeder 22 stützt sich dabei auf einen im

Gehäuse 19 verschiebbar angeordneten Ankerkern 23 ab. Auf diese Weise kann

durch den verschiebbaren Ankerkern 23 zum einem die Federkraft eingestellt

werden und zum anderen, wenn der Ankerkern 23 eine elliptische Außenkontur

aufweist, die Magnetkraft. Über den Stecker 24 wird die Stromversorgung des

elektromagnetischen Antriebes gewährleistet.The

Die als stromlos offen ausgelegte Ventilanordnung 1 in Figur 1 funktioniert dabei

wie folgt:The

In der Betriebsphase des Motors wird der elektromagnetische Antrieb 16 nicht mit

Strom versorgt. Es wird dementsprechend keine Magnetkraft auf den Anker 21

ausgeübt. Die Ventilanordnung 1 ist im "stromlos offenen" Zustand. Dabei besitzt

die Druckfeder 22 ein niedriges Druckniveau von ungefähr 4 bar. Wird im Kraftstoffkreislauf

nun ein Systemdruck erreicht der größer ist als 4 bar öffnet das

Schließelement 14 entgegen der Druckfeder 22 und Kraftstoff kann in den Kraftstofftank

2 zurückgeführt werden. Im bestromten Zustand wird der Anker 21 durch

die Magnetkraft und die Federkraft gegen den Stößel 15 gedrückt. Dabei kann die

Magnetkraft so eingestellt werden, daß ein Druckniveau von ca. 7 bar erreicht

wird. Die Ventilanordnung 1 öffnet lediglich bei einem Druckniveau im Kraftstoffkreislauf,

das höher ist als 7 bar. Die Einstellung der Magnetkraft erfolgt hierbei,

wie bereits beschrieben, über die Drehung des Ankerkerns 23.In the operating phase of the engine, the

Figur 2 zeigt einen Querschnitt einer zweiten Ausführungsform der Ventilanordnung

1. Gleiche Teile mit gleichen Funktionen haben hierbei das gleiche Bezugszeichen

erhalten. Diese Ventilanordnung 1 weist zwei Einlaßanschlußstücke 25

und 26 sowie zwei Auslaßanschlußstücke 27 und 28 auf. Dabei ist die Ventilanordnung

1 über das Einlaßanschlußstück 25 direkt mit der Vorförderpumpe 3

verbunden und über das Auslaßanschlußstück 27 wird der Kraftstoff zur Hochdruckpumpe

4 geleitet. Das zweite Einlaßanschlußstück 26 ist mit dem Druckregler

6 verbunden und führt überschüssigen Kraftstoff über das Auslaßanschlußstück

28 in den Kraftstofftank 2 zurück. Der Verbindungskanal 13 übernimmt im

vorliegenden Fall gleichzeitig die Funktion der in Figur 1 dargestellten Kurzschlußleitung

7.Figure 2 shows a cross section of a second embodiment of the

Die Ventilanordnung 1 gemäß Figur 2 ist im Gegensatz zur Ventilanordnung 1 aus

Figur 1 "stromlos geschlossen" geschaltet. D. h. das im stromlosen Zustand das

maximale Druckniveau von ca. 7 bar durch die Schließkraft, die auf das Schließelement

14 wirkt, erreicht wird. Hierzu besitzt die vorliegende Ventilanordnung 1

eine erste Druckfeder 29, die in Schließrichtung auf den Anker 21 wirkt und eine

zweite Druckfeder 30, die in Schließrichtung auf den Stößel 15 wirkt. Beide

Druckfedern 29 und 30 stützen sich an Gehäuseteilen ab und summieren sich zur

maximalen Federkraft, die einem Druckniveau von ca. 7 bar entspricht. In der

Startphase ist diese Ventilanordnung 1 also stromlos geschaltet, so daß der Kraftstoff

mit 7 bar zur Hochdruckpumpe 4 gefördert wird. Bei Überschreitung des

Druckniveaus von 7 bar öffnet das Schließelement 14 und gibt so die Kurzschlußleitung

7 über den Verbindungskanal 13 frei, so daß Kraftstoff zurück in den

Kraftstofftank 2 geführt werden kann. In der Betriebsphase der Brennkraftmaschine

wird die Ventilanordnung 1 bestromt und die Magnetkraft bewegt den Anker 21

gegen die Druckfeder 29, so daß lediglich noch die Druckfeder 30 mit einem

Druckniveau von 4 bar auf den Stößel 15 wirkt, so daß das Ventil bei einem

Druckniveau, das größer ist als 4 bar öffnet und Kraftstoff durch das Anschlußstück

28 zum Kraftstofftank 2 zurückgeführt werden kann.In contrast to the

Claims (6)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10107618 | 2001-02-17 | ||

| DE10107618A DE10107618A1 (en) | 2001-02-17 | 2001-02-17 | Valve arrangement for pressure control of the fuel supply in an internal combustion engine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1234976A2 true EP1234976A2 (en) | 2002-08-28 |

| EP1234976A3 EP1234976A3 (en) | 2003-05-21 |

| EP1234976B1 EP1234976B1 (en) | 2006-06-21 |

Family

ID=7674501

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01129778A Expired - Lifetime EP1234976B1 (en) | 2001-02-17 | 2001-12-14 | Valve system for regulating the pressure of fuel supply in a combustion engine |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6659424B2 (en) |

| EP (1) | EP1234976B1 (en) |

| DE (2) | DE10107618A1 (en) |

| ES (1) | ES2266081T3 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008149384A1 (en) * | 2007-06-08 | 2008-12-11 | Ucal Fuel Systems Limited | Variable pressure fuel injection system |

| EP2380811A1 (en) | 2010-04-23 | 2011-10-26 | Francisco Monente Plösser | Packaging machine |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060118486A1 (en) * | 2004-12-06 | 2006-06-08 | Sower Larry P | Evaporation of water from a dilute waste slurry to produce a concentrated waste slurry |

| JP4535033B2 (en) * | 2005-10-14 | 2010-09-01 | 株式会社デンソー | Pressure reducing valve and fuel injection device |

| DE102008060889B4 (en) * | 2008-12-09 | 2022-08-25 | Pierburg Gmbh | pressure control valve |

| DE102009032367B4 (en) * | 2009-07-08 | 2011-04-28 | Pierburg Gmbh | Electromagnetic actuator for a valve |

| DE102009032365B4 (en) * | 2009-07-08 | 2011-04-28 | Pierburg Gmbh | Electromagnetic actuator for a valve |

| CN106032852B (en) * | 2015-03-11 | 2019-10-11 | 德昌电机(深圳)有限公司 | Solenoid valve |

| CN204756101U (en) * | 2015-06-05 | 2015-11-11 | 厦门科际精密器材有限公司 | Electromagnetic valve |

| DE102018222614A1 (en) * | 2018-12-20 | 2020-06-25 | Robert Bosch Gmbh | Electromagnetic actuator |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2158612A (en) * | 1984-04-05 | 1985-11-13 | Diesel Kiki Co | Fuel injection system for internal combustion engine |

| EP0267162A2 (en) * | 1986-11-07 | 1988-05-11 | ELASIS SISTEMA RICERCA FIAT NEL MEZZOGIORNO Società Consortile per Azioni | Pressure-regulating solenoid valve, particularly for high-pressure circuits of fuel injection systems for internal combustion engines |

| US4971115A (en) * | 1989-07-27 | 1990-11-20 | Humphrey Products Company | Four-way poppet valve with hollow stem and four-port body |

| US5275207A (en) * | 1991-09-07 | 1994-01-04 | Mercedes-Benz Ag | Multiway valve |

| US5570721A (en) * | 1995-03-29 | 1996-11-05 | Caterpillar Inc. | Double acting solenoid and poppet valve servomechanism |

| US5626325A (en) * | 1995-09-14 | 1997-05-06 | Cummins Engine Company, Inc. | High pressure control valve for a fuel injection system |

| US5676345A (en) * | 1994-08-30 | 1997-10-14 | Pierburg Gmbh | Electromagnetic valve |

| US5947442A (en) * | 1997-09-10 | 1999-09-07 | Cummins Engine Company, Inc. | Solenoid actuated valve assembly |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3974998A (en) * | 1972-07-28 | 1976-08-17 | Crown Cork & Seal Company, Inc. | Spray coating apparatus |

| US4251051A (en) * | 1979-04-19 | 1981-02-17 | The Jacobs Manufacturing Company | Solenoid structure having a relatively unrestrained generally flat armature member |

| US5546987A (en) * | 1981-11-06 | 1996-08-20 | Sule; Akos | Solenoid valve |

| US4750704A (en) * | 1983-12-21 | 1988-06-14 | Robert W. Brundage | Solenoid controlled fluid flow valve |

| US4712767A (en) * | 1986-10-29 | 1987-12-15 | Allied Corporation | Solenoid control valve |

| US4998559A (en) * | 1988-09-13 | 1991-03-12 | Coltec Industries Inc. | Solenoid operated pressure control valve |

| US5462253A (en) * | 1994-07-22 | 1995-10-31 | General Motors Corporation | Dual slope flow control valve |

| DE4431459C2 (en) * | 1994-09-03 | 2000-02-10 | Bosch Gmbh Robert | Solenoid valve and process for its manufacture |

| DE19652410C2 (en) * | 1996-12-06 | 1999-12-09 | Mannesmann Ag | Electropneumatic valve |

| US6199533B1 (en) * | 1999-02-01 | 2001-03-13 | Cummins Engine Company, Inc. | Pilot valve controlled three-way fuel injection control valve assembly |

| US6279603B1 (en) * | 1998-10-01 | 2001-08-28 | Ambac International | Fluid-cooled injector |

-

2001

- 2001-02-17 DE DE10107618A patent/DE10107618A1/en not_active Withdrawn

- 2001-12-14 ES ES01129778T patent/ES2266081T3/en not_active Expired - Lifetime

- 2001-12-14 EP EP01129778A patent/EP1234976B1/en not_active Expired - Lifetime

- 2001-12-14 DE DE50110244T patent/DE50110244D1/en not_active Expired - Fee Related

-

2002

- 2002-02-05 US US10/068,206 patent/US6659424B2/en not_active Expired - Fee Related

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2158612A (en) * | 1984-04-05 | 1985-11-13 | Diesel Kiki Co | Fuel injection system for internal combustion engine |

| EP0267162A2 (en) * | 1986-11-07 | 1988-05-11 | ELASIS SISTEMA RICERCA FIAT NEL MEZZOGIORNO Società Consortile per Azioni | Pressure-regulating solenoid valve, particularly for high-pressure circuits of fuel injection systems for internal combustion engines |

| US4971115A (en) * | 1989-07-27 | 1990-11-20 | Humphrey Products Company | Four-way poppet valve with hollow stem and four-port body |

| US5275207A (en) * | 1991-09-07 | 1994-01-04 | Mercedes-Benz Ag | Multiway valve |

| US5676345A (en) * | 1994-08-30 | 1997-10-14 | Pierburg Gmbh | Electromagnetic valve |

| US5570721A (en) * | 1995-03-29 | 1996-11-05 | Caterpillar Inc. | Double acting solenoid and poppet valve servomechanism |

| US5626325A (en) * | 1995-09-14 | 1997-05-06 | Cummins Engine Company, Inc. | High pressure control valve for a fuel injection system |

| US5947442A (en) * | 1997-09-10 | 1999-09-07 | Cummins Engine Company, Inc. | Solenoid actuated valve assembly |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008149384A1 (en) * | 2007-06-08 | 2008-12-11 | Ucal Fuel Systems Limited | Variable pressure fuel injection system |

| EP2380811A1 (en) | 2010-04-23 | 2011-10-26 | Francisco Monente Plösser | Packaging machine |

Also Published As

| Publication number | Publication date |

|---|---|

| US20020113220A1 (en) | 2002-08-22 |

| EP1234976B1 (en) | 2006-06-21 |

| DE10107618A1 (en) | 2002-08-29 |

| ES2266081T3 (en) | 2007-03-01 |

| US6659424B2 (en) | 2003-12-09 |

| EP1234976A3 (en) | 2003-05-21 |

| DE50110244D1 (en) | 2006-08-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2009013041A1 (en) | High-pressure pump for a fuel system of an internal combustion engine | |

| EP0558715B1 (en) | Electromagnetically operable injection valve | |

| DE19810867A1 (en) | Fuel pump system used with fuel injected internal combustion engines of motor vehicles | |

| DE10247436A1 (en) | Metering valve gear for fuel injection pump of diesel engine, includes valve whose opening amount is smaller than full open state of fluid route, when electric current applied to coil is greater than predetermined valve | |

| DE19630938C2 (en) | Fuel supply line with a volume flow control valve and volume flow control valve | |

| EP1234976B1 (en) | Valve system for regulating the pressure of fuel supply in a combustion engine | |

| WO2016015912A1 (en) | High-pressure pump | |

| DE102004057011B4 (en) | Automotive fuel injection system with control valve for high throughput | |

| EP1561026B1 (en) | Fuel metering unit for the fuel injection system of a combustion engine | |

| DE102016220364A1 (en) | Electromagnetically actuated inlet valve and high-pressure pump with inlet valve | |

| EP1203151A1 (en) | Two-stage electromagnetic valve for an injector of internal combustion engines | |

| DE112011105898T5 (en) | High pressure fuel pump | |

| DE10236387A1 (en) | Device for the metered admixture of volatilized fuel in an intake pipe of an internal combustion engine | |

| DE102009046088B4 (en) | Quantity control valve, in particular in a high-pressure fuel pump, for metering a fluid medium | |

| DE60207025T2 (en) | Electromagnet with two anchors | |

| EP1861617A1 (en) | Fuel injection device | |

| DE10334474A1 (en) | High-flow control valve for motor vehicle fuel injection systems | |

| EP0408915B1 (en) | Fuel injection pump for internal combustion engines | |

| WO2001050009A2 (en) | Fuel injection valve | |

| WO2001027463A1 (en) | Injector for a fuel injection system for internal combustion engines comprising an injector needle that projects into the valve control space | |

| EP2758653A1 (en) | Pressure control system and pressure control valve | |

| DE19908418C1 (en) | Control valve for diesel engine fuel injection system | |

| WO2008083882A1 (en) | Injector for injecting fuel | |

| DE112006000387T5 (en) | Common pressure line system with pressure boost | |

| DE102004019850A1 (en) | Electromagnetic control valve |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20011214 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7F 16K 31/02 B Ipc: 7F 02M 69/54 A Ipc: 7F 02M 59/46 B |

|

| 17Q | First examination report despatched |

Effective date: 20031208 |

|

| AKX | Designation fees paid |

Designated state(s): DE ES FR GB IT |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060628 |

|

| REF | Corresponds to: |

Ref document number: 50110244 Country of ref document: DE Date of ref document: 20060803 Kind code of ref document: P |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2266081 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070322 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20081217 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20081212 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081219 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081216 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20081224 Year of fee payment: 8 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20091214 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091214 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091215 |