EP1056903B1 - Feeding system in connection with the continuous cooking of cellulose containing material - Google Patents

Feeding system in connection with the continuous cooking of cellulose containing material Download PDFInfo

- Publication number

- EP1056903B1 EP1056903B1 EP99906650A EP99906650A EP1056903B1 EP 1056903 B1 EP1056903 B1 EP 1056903B1 EP 99906650 A EP99906650 A EP 99906650A EP 99906650 A EP99906650 A EP 99906650A EP 1056903 B1 EP1056903 B1 EP 1056903B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- flow

- high pressure

- feeding system

- liquid

- pressure feeder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 title claims abstract description 36

- 229920002678 cellulose Polymers 0.000 title claims abstract description 15

- 239000001913 cellulose Substances 0.000 title claims abstract description 15

- 238000010411 cooking Methods 0.000 title description 3

- 239000007788 liquid Substances 0.000 claims abstract description 93

- 238000012216 screening Methods 0.000 claims description 16

- 239000004576 sand Substances 0.000 claims description 10

- 230000001105 regulatory effect Effects 0.000 claims description 8

- 239000000203 mixture Substances 0.000 claims description 6

- 230000033228 biological regulation Effects 0.000 claims description 3

- 238000007689 inspection Methods 0.000 claims description 2

- 238000005470 impregnation Methods 0.000 description 11

- 230000001276 controlling effect Effects 0.000 description 6

- 230000008901 benefit Effects 0.000 description 5

- 239000012530 fluid Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000010025 steaming Methods 0.000 description 3

- 230000003134 recirculating effect Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 229920001131 Pulp (paper) Polymers 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 230000002028 premature Effects 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 230000009528 severe injury Effects 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21C—PRODUCTION OF CELLULOSE BY REMOVING NON-CELLULOSE SUBSTANCES FROM CELLULOSE-CONTAINING MATERIALS; REGENERATION OF PULPING LIQUORS; APPARATUS THEREFOR

- D21C7/00—Digesters

- D21C7/06—Feeding devices

Definitions

- the treatment vessel when a pocket of the high pressure feeder moves towards the low pressure position it is full with liquid from the return liquid flow from the digester or preimpregnation vessel, hereinafter called the treatment vessel.

- the pocket When the pocket reaches the low-pressure position, the liquid is displaced from above with the mixture of chips and liquid that is present in the chute, whereby the same filling degree as in the chute can be achieved.

- the filling degree in the chute is normally about 80-85 vol.-% since some excess liquid is demanded for the chip column to be able to move down into the high-pressure feeder.

- An additional advantage of the system according to the invention is that the pump, hereinafter called the first pump, in the recirculation flow can be coupled in series with a second pump, that pumps liquid from the low pressure recirculation flow to the high pressure return liquid flow from the treatment vessel.

- the pump head of the first pump can be added to the pump head of the second pump, whereby the second pump may be one standard pump instead of, as in the conventional system, two standard pumps or one high-pressure pump with several impellers.

- the second pump may be one standard pump instead of, as in the conventional system, two standard pumps or one high-pressure pump with several impellers.

- said recirculation flow that is the volumetric flow that exits the high-pressure feeder on its low-pressure side is related by a factor 0.8-1.5 to the volumetric chip flow which is handled by the high pressure feeder.

- the maximum theoretical volumetric flow can be calculated as the volume of the pockets in the high pressure feeder multiplied with the rotary speed of the high pressure feeder and by a factor two (since the pockets are filled twice in each complete rotation).

- Another way of calculating the volumetric flow is by dividing the incoming chip flow (as measured in a chip meter) by a factor 0.5-0.9.

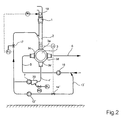

- the high pressure feeder comprises rotating pockets, whereby a first pocket, via the first opening 3a, is in open connection with the chute and, via a second opening 3b, which is equipped with a strainer plate, in the housing is connected to a recirculation flow 4 at the same time as a second pocket, via a third opening 3c in the housing, is in open connection with a return liquid flow 5, which comprises liquid that has been separated from the chips in a top separator in the treatment vessel, and, via a fourth opening 3d in the housing is in open connection with a sluicing flow 6 for feeding chips and impregnation liquid to the treatment vessel. Due to the strainer plate in the second opening 3b, chips are to a degree prevented from entering the recirculation flow 4.

- the pocket which is in open connection with the return liquid flow 5 is filled with liquid at a relatively high pressure at the same time as a mixture of chips and liquid, which was present in the pocket, is displaced into the sluicing flow 6.

- this pocket moves into the position of the first opening 3a, the liquid in the pocket is again displaced by a mixture of chips and liquid from the chute 2.

- the filling degree does however not reach optimum since the strainer plate becomes partially plugged by chips.

- the liquid which has been displaced enters the recirculation flow 4 and is pumped, by a first pump 7, to a sand trap 8, where sand and other particles are removed from the liquid flow. Thereafter, the liquid recirculation flow 4 continues through an in-line drainer 9 and back to the chute 2.

- the liquid level in the level tank is in its turn controlled by a valve 15 in the conduit 13 between the level tank 11 and the return liquid flow 5.

- the recirculation flow 4 is in reality controlled by the existence of a screening device in the high pressure feeder 3. When the screening device becomes plugged, the first pump 7 does not get any fluid to pump and thus the flow is interrupted.

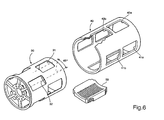

- a tramp material catcher 20 is arranged close to the inlet of the first pump 7.

- the design of the tramp material catcher 20 is shown in detail in figures 4 and 5 .

- the pump 7 is capable of maintaining a pumping action even if large amount of chips will enter the recirculation flow 4'.

- tramp material in form of bolts, nuts, tools and large stones needs to be separated in order not to destroy the pump 7.

- the tramp material catcher 20 is therefore designed with a pocket 24 in the lower part of the pump inlet.

- the central part of the pump wheel 22 extended, forming a boss 23 member.

- the boss member should preferably extend to such an extent that it could create a swirling motion in the flow 4' above the tramp material pocket 24.

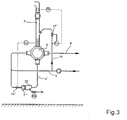

- Figure 3 represents a feeding system according to an alternative embodiment of the invention.

- the recirculation flow 4" (in this embodiment called a first recirculation flow) is led to the return liquid flow 5 from the treatment vessel and thereby to the high-pressure liquid inlet side of the high pressure feeder 3.

- a second recirculation flow 19 is led from the return liquid flow 5 to the chute 2 for adjustment of the liquid/wood ratio in the chute, and is controlled by the flow control valve 17" against the flow of chips that is entering the feeding system.

- the first recirculation flow 4" is regulated, by a chute liquid level control valve 14" or by controlling the rotary speed of the first pump 7", against the liquid level in the chute 2.

- a similar tramp material catcher 20 is located in the inlet of the pump 7".

- the safety pressure switches can be set at comfortable levels, e.g. at pressures above 3 bars, preferably above 5 bars, which allows for stable operation minimising costly unwanted interruptions of the production.

- the relevant opening in the high pressure feeder can be equipped with a screening device with slots narrow enough to make the chips stack up, if the screening device is movable and withdrawn from the opening for a major part of the time. If necessary, that is if the operating conditions otherwise result in an excess of chips entering the recirculation flow, such a screening device could be introduced in the opening just before a pocket is filled up with chips and be withdrawn immediately afterwards, when the pocket proceeds to its high pressure position.

Landscapes

- Paper (AREA)

- General Preparation And Processing Of Foods (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Formation And Processing Of Food Products (AREA)

- Feeding, Discharge, Calcimining, Fusing, And Gas-Generation Devices (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE9800476 | 1998-02-18 | ||

| SE9800476A SE9800476D0 (sv) | 1998-02-18 | 1998-02-18 | System in connection with the continuous cooking of cellulose containing material |

| PCT/SE1999/000162 WO1999042653A1 (en) | 1998-02-18 | 1999-02-09 | Feeding system in connection with the continuous cooking of cellulose containing material |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1056903A1 EP1056903A1 (en) | 2000-12-06 |

| EP1056903B1 true EP1056903B1 (en) | 2009-11-25 |

Family

ID=20410219

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99906650A Expired - Lifetime EP1056903B1 (en) | 1998-02-18 | 1999-02-09 | Feeding system in connection with the continuous cooking of cellulose containing material |

Country Status (11)

| Country | Link |

|---|---|

| EP (1) | EP1056903B1 (enExample) |

| JP (1) | JP4739518B2 (enExample) |

| AT (1) | ATE449881T1 (enExample) |

| AU (1) | AU2650599A (enExample) |

| BR (1) | BR9907838B1 (enExample) |

| CA (1) | CA2317750C (enExample) |

| DE (1) | DE69941682D1 (enExample) |

| ES (1) | ES2337532T3 (enExample) |

| PT (1) | PT1056903E (enExample) |

| SE (1) | SE9800476D0 (enExample) |

| WO (1) | WO1999042653A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE519262E (sv) * | 2002-03-15 | 2008-01-08 | Kvaerner Pulping Tech | Förfarande för matning av cellulosaflis vid kontinuerlig kokning |

| SE526704C2 (sv) * | 2003-12-30 | 2005-10-25 | Kvaerner Pulping Tech | Matning av cellulosaflis från en lågtrycksdel till en högtrycksdel med en slussmatare |

| US8672588B2 (en) | 2009-04-15 | 2014-03-18 | Andritz Inc. | Unobstructed low pressure outlet and screen grid for a high pressure feeder |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE174094C1 (enExample) * | ||||

| US5443162A (en) * | 1993-03-18 | 1995-08-22 | Glentech Inc. | High capacity high pressure feeding |

-

1998

- 1998-02-18 SE SE9800476A patent/SE9800476D0/xx unknown

-

1999

- 1999-02-09 DE DE69941682T patent/DE69941682D1/de not_active Expired - Lifetime

- 1999-02-09 AU AU26505/99A patent/AU2650599A/en not_active Abandoned

- 1999-02-09 ES ES99906650T patent/ES2337532T3/es not_active Expired - Lifetime

- 1999-02-09 BR BRPI9907838-4A patent/BR9907838B1/pt not_active IP Right Cessation

- 1999-02-09 WO PCT/SE1999/000162 patent/WO1999042653A1/en not_active Ceased

- 1999-02-09 CA CA002317750A patent/CA2317750C/en not_active Expired - Lifetime

- 1999-02-09 EP EP99906650A patent/EP1056903B1/en not_active Expired - Lifetime

- 1999-02-09 PT PT99906650T patent/PT1056903E/pt unknown

- 1999-02-09 AT AT99906650T patent/ATE449881T1/de active

- 1999-02-09 JP JP2000532585A patent/JP4739518B2/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| CA2317750C (en) | 2007-11-27 |

| JP2002504631A (ja) | 2002-02-12 |

| DE69941682D1 (de) | 2010-01-07 |

| CA2317750A1 (en) | 1999-08-26 |

| BR9907838A (pt) | 2000-10-24 |

| EP1056903A1 (en) | 2000-12-06 |

| BR9907838B1 (pt) | 2009-12-01 |

| PT1056903E (pt) | 2010-02-11 |

| SE9800476D0 (sv) | 1998-02-18 |

| AU2650599A (en) | 1999-09-06 |

| ATE449881T1 (de) | 2009-12-15 |

| WO1999042653A1 (en) | 1999-08-26 |

| JP4739518B2 (ja) | 2011-08-03 |

| ES2337532T3 (es) | 2010-04-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| FI122896B (fi) | Menetelmä ja järjestelmä hienonnetun kuitumateriaalin syöttämiseksi | |

| US6436233B1 (en) | Feeding cellulose material to a treatment vessel | |

| CA2174873C (en) | Chip pumping to a continuous digester | |

| SE0500751A1 (sv) | Matning av finfördelat fibermaterial | |

| US6368453B1 (en) | Chip feeding to a comminuted cellulosic fibrous material treatment vessel | |

| EP0330387B1 (en) | Improved method and apparatus for processing pulp | |

| EP1056903B1 (en) | Feeding system in connection with the continuous cooking of cellulose containing material | |

| US6120646A (en) | Feeding system of feeding a cellulose material | |

| US4370172A (en) | Controlled vortex pump feed for supplying cellulose-containing material to reaction vessel | |

| CA2508087C (en) | Method and system for feeding cellulose chips to a high pressure continuous cooking system | |

| US6451172B1 (en) | In-line drainer enhancements | |

| US8974633B2 (en) | System and method for the pumped feed of chips to a continuous digester | |

| US20030102093A1 (en) | Processes and systems for handling knots in a chemical pulping process | |

| SE530999C2 (sv) | Förfarande för behandling av finfördelat fibermaterial vid kokning av pappersmassa | |

| US20030102092A1 (en) | Processes and systems for handling knots in a chemical pulping process | |

| US20160215450A1 (en) | A method of and an arrangement for introducing process liquid from a treatment step to a washing and/or filtering apparatus | |

| FI129118B (fi) | Menetelmä puuhakkeen syöttämiseksi esihydrolyysireaktoriin | |

| FI108652B (fi) | Menetelmä ja laitteisto paperi-, kartonki- tai vastaavan tuotantokoneen lyhyen kierron toiminnan ohjaamiseksi | |

| CA2455172C (en) | Feeding comminuted fibrous material using high pressure screw and centrifugal pumps | |

| WO2009116942A1 (en) | Feeding system comprising parallel pumps and individual flows for a digester |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20000719 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT DE ES FI FR PT SE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: METSO FIBER KARLSTAD AB |

|

| 17Q | First examination report despatched |

Effective date: 20071011 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE ES FI FR PT SE |

|

| REF | Corresponds to: |

Ref document number: 69941682 Country of ref document: DE Date of ref document: 20100107 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20100203 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2337532 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20100826 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: PC4A Owner name: METSO PAPER SWEDEN AKTIEBOLAG, SE Effective date: 20110208 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 69941682 Country of ref document: DE Owner name: METSO PAPER SWEDEN AB, SE Free format text: FORMER OWNER: METSO FIBER KARLSTAD AB, KARLSTAD, SE Effective date: 20110420 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: METSO PAPER SWEDEN AKTIEBOLAG Effective date: 20110629 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: PC Ref document number: 449881 Country of ref document: AT Kind code of ref document: T Owner name: METSO PAPER SWEDEN AKTIEBOLAG, SE Effective date: 20111223 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140219 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20140219 Year of fee payment: 16 Ref country code: ES Payment date: 20140219 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 69941682 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20151030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150302 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20160329 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150210 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20180219 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20180227 Year of fee payment: 20 Ref country code: PT Payment date: 20180206 Year of fee payment: 20 Ref country code: AT Payment date: 20180219 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 449881 Country of ref document: AT Kind code of ref document: T Effective date: 20190209 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20190219 |