EP0814552B1 - Terminal and terminal assembly for a shielded coaxial cable - Google Patents

Terminal and terminal assembly for a shielded coaxial cable Download PDFInfo

- Publication number

- EP0814552B1 EP0814552B1 EP19960109865 EP96109865A EP0814552B1 EP 0814552 B1 EP0814552 B1 EP 0814552B1 EP 19960109865 EP19960109865 EP 19960109865 EP 96109865 A EP96109865 A EP 96109865A EP 0814552 B1 EP0814552 B1 EP 0814552B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- terminal

- teeth

- pair

- base portion

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/24—Connections using contact members penetrating or cutting insulation or cable strands

- H01R4/2495—Insulation penetration combined with permanent deformation of the contact member, e.g. crimping

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/03—Connectors arranged to contact a plurality of the conductors of a multiconductor cable, e.g. tapping connections

- H01R9/05—Connectors arranged to contact a plurality of the conductors of a multiconductor cable, e.g. tapping connections for coaxial cables

- H01R9/053—Connectors arranged to contact a plurality of the conductors of a multiconductor cable, e.g. tapping connections for coaxial cables using contact members penetrating insulation

Definitions

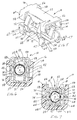

- Terminals or terminal assemblies often are used to terminate the conductive shield of the coaxial cable. Typically, this is accomplished by a terminal with some form of crimp barrel or other means having teeth which pierce the outer insulating jacket and contact the strands of the braided shield. Many such teeth are required to provide an adequate contacting interface. The pressure against the braid by such teeth is quite random, and the combination affects the dielectric properties of the cable. Specifically, the cable impedance can be affected by such terminals, because the terminals often result in considerable deformation of the dielectric sheath about the center conductor.

Landscapes

- Multi-Conductor Connections (AREA)

- Details Of Connecting Devices For Male And Female Coupling (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

Description

Claims (15)

- A terminal assembly (10) comprising:characterized in thata shielded insulated cable (14) having a conductor core (20), a dielectric sheath (22), a shield (12) and an outer insulating jacket (24), with the shield (12) disposed between the dielectric sheath (22) and the insulating jacket (24);a dielectric housing (16) having a terminal receptacle (38); anda terminal (18) received in the receptacle (38) of the housing and including a pair of teeth (68,70) movable toward each other to displace the outer insulating jacket (24)

the teeth (68,70) are arranged in a direction (B) generally tangentially of the dielectric sheath (22) so as to clamp a portion (80) of the shield (12) between the teeth (68,70) without substantially disturbing the dielectric sheath (22). - The terminal assembly of claim 1 wherein the terminal (18) includes two pairs of said teeth (68,70), with one pair on each opposite diametral side of the cable (14).

- The terminal assembly of claim 1 or 2 wherein the terminal (18) includes a deformable arm (72) integrally joining the teeth in said pair thereof.

- The terminal assembly of claims 1, 2 or 3 wherein the terminal (18) is fabricated of sheet metal material.

- The terminal assembly of any of claims 1 to 4 wherein the terminal (18) includes a base portion (50) positioned a predetermined distance above a fixed wall (32) of the receptacle of the housing and a pressure portion (52) movable toward the base portion, with one of the teeth (68,70) in said pair thereof being on each of the base portion (50) and the pressure portion (52) of the terminal.

- The terminal assembly of any of claims 1 to 5 wherein the terminal (18) includes a deformable arm (72) integrally joining the base portion (50) and the pressure portion (52) of the terminal.

- The terminal assembly of any of claims 5 and 6 wherein the terminal (18) is fabricated of sheet metal material.

- The terminal assembly of any of claims 1 to 5, including complementary interengaging latch means (46,60) between the housing (16) and the movable pressure portion (52) of the terminal (18) to hold the pressure portion in an actuated position and, thereby, to hold the teeth (68,70) in clamping position.

- The terminal assembly (10) as defined in any of claims 1 to 8, wherein the dielectric housing (16) includes an access opening (40) through a wall (34) of the housing to the receptacle (38); and the pair of teeth (68,70) is arranged at each opposite side of the receptacle (38) with one of the teeth in each pair thereof being on each of the base portion (50) and the pressure portion (52) of the terminal (18).

- The terminal assembly of any of claims 1 to 9 wherein the housing includes a hole (42) into which the deformable arm (72) projects when the pressure portion (52) of the terminal (18) is moved toward the base portion (50) of the terminal.

- A terminal (18) for terminating a shield (12) of a shielded insulated cable (14) having a conductor core (20) with a dielectric sheath (22) therearound, and an outer insulating jacket (24) with the shield disposed between the dielectric sheath and the insulating jacket, comprising a collapsible body with opposing teeth (68,70) thereon movable toward each other to displace the outer insulating jacket (24),

characterized in thatthe teeth (68,70) form two pairs of opposing teeth,the teeth of one pair are arranged in a lateral distance corresponding to the diameter of the sheath (22) and opposite to the teeth of the other pair, so that whenopposing teeth of one pair are moved in a direction (B) generally tangentially of the dielectric sheath (22) a portion (80) of the shield (12) is clamped between the teeth (68,70) without the dielectric sheath (22) being disturbed. - The terminal of claim 11, including a deformable arm (72) integrally joining the teeth in said pair thereof.

- The terminal of claims 11 or 12, including a base portion (50) and a pressure portion (52) movable toward the base portion, with one of the teeth (68,70) on said pair thereof being on each of the base portion (50) and the pressure portion (52).

- The terminal of any of claims 11 to 13, including a deformable arm (72) integrally joining the base portion (50) and the pressure portion (52).

- The terminal of any of claims 11 to 14 wherein the terminal (18) is fabricated of sheet metal material.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE1996618449 DE69618449T2 (en) | 1996-06-19 | 1996-06-19 | Connection and connection assembly for a shielded coaxial cable |

| EP19960109865 EP0814552B1 (en) | 1996-06-19 | 1996-06-19 | Terminal and terminal assembly for a shielded coaxial cable |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP19960109865 EP0814552B1 (en) | 1996-06-19 | 1996-06-19 | Terminal and terminal assembly for a shielded coaxial cable |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0814552A1 EP0814552A1 (en) | 1997-12-29 |

| EP0814552B1 true EP0814552B1 (en) | 2002-01-09 |

Family

ID=8222908

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19960109865 Expired - Lifetime EP0814552B1 (en) | 1996-06-19 | 1996-06-19 | Terminal and terminal assembly for a shielded coaxial cable |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0814552B1 (en) |

| DE (1) | DE69618449T2 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6135805A (en) * | 1998-08-04 | 2000-10-24 | Mandex Manufacturing Corporation | Insulation displacement device for wire termination |

| FR2786929B1 (en) * | 1998-12-07 | 2006-09-29 | Cahors App Elec | DEVICE FOR CONNECTING AN INSULATED ELECTRIC CABLE WITH AN OUTER SHEATH TO ONE OR MORE OTHER CONDUCTORS |

| DE102004004309B4 (en) * | 2004-01-28 | 2005-11-03 | U.I. Lapp Gmbh | Device for contacting a shielding braid of a shielded electrical cable |

| US6988911B2 (en) * | 2004-03-02 | 2006-01-24 | Tyco Electronics Corporation | Coaxial cable connector with improved shielding |

| CN118884021B (en) * | 2024-07-08 | 2025-03-18 | 北京中科飞龙传感技术有限责任公司 | Hard plate voltage monitoring device with shielding cavity, assembly method and system |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2124041B (en) * | 1982-07-23 | 1985-11-27 | Molex Inc | Insulation displacement terminal for an electrical connector and environmental sealing means therefor |

| US5066248A (en) * | 1991-02-19 | 1991-11-19 | Lrc Electronics, Inc. | Manually installable coaxial cable connector |

| US5362251A (en) * | 1993-02-09 | 1994-11-08 | Switchcraft Inc. | Solderless coaxial connector plug |

-

1996

- 1996-06-19 DE DE1996618449 patent/DE69618449T2/en not_active Expired - Fee Related

- 1996-06-19 EP EP19960109865 patent/EP0814552B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0814552A1 (en) | 1997-12-29 |

| DE69618449D1 (en) | 2002-02-14 |

| DE69618449T2 (en) | 2002-09-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0653803B1 (en) | Insulation displacement electrical connector with improved strain relief | |

| US5542861A (en) | Coaxial connector | |

| US5716236A (en) | System for terminating the shield of a high speed cable | |

| EP0793305B1 (en) | Twisted pair cable and connector assembly | |

| US4737118A (en) | Hermaphroditic flat cable connector | |

| US5711686A (en) | System for terminating the shield of a high speed cable | |

| EP1003250B1 (en) | A shield connector, a set of shielded connectors and method for connecting a shielded connector with a shielded cable | |

| US5123864A (en) | Coaxial contact with sleeve | |

| US5120235A (en) | Insulation displacement connector | |

| US20050266727A1 (en) | Coaxial cable shielding terminal | |

| US4097106A (en) | Terminal housing having an integral strain relief | |

| US6068505A (en) | Electrical contact for flexible flat cable | |

| CA1070401A (en) | Electrical contact | |

| US6007370A (en) | Crimpable strain relief ferrule having a retention tab thereupon | |

| US5338233A (en) | Structure for electrically connecting a terminal and a wire | |

| EP0527399B1 (en) | Insulation displacement terminal | |

| US4373769A (en) | Electrical connector including insulation-opening contact | |

| US5807133A (en) | Insulation displacement connector | |

| US4820191A (en) | Connection device | |

| EP0814552B1 (en) | Terminal and terminal assembly for a shielded coaxial cable | |

| US6361352B2 (en) | Insulation-displacement connector | |

| EP0637101B1 (en) | Waterproof plug and wire terminal with the waterproof plug | |

| US6186828B1 (en) | Electrical connector including coaxial cable management system | |

| US5186656A (en) | Miniature coaxial electrical connector | |

| US5252094A (en) | Electrical connector with improved terminal retention |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19980603 |

|

| 17Q | First examination report despatched |

Effective date: 20000202 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT SE |

|

| REF | Corresponds to: |

Ref document number: 69618449 Country of ref document: DE Date of ref document: 20020214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020409 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20020501 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20020605 Year of fee payment: 7 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030619 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20030619 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040227 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20050630 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060630 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070619 |