EP0803012B1 - Process for producing tissue paper by using a treating agent - Google Patents

Process for producing tissue paper by using a treating agent Download PDFInfo

- Publication number

- EP0803012B1 EP0803012B1 EP95932724A EP95932724A EP0803012B1 EP 0803012 B1 EP0803012 B1 EP 0803012B1 EP 95932724 A EP95932724 A EP 95932724A EP 95932724 A EP95932724 A EP 95932724A EP 0803012 B1 EP0803012 B1 EP 0803012B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- weight

- parts

- polysiloxane

- treatment medium

- process according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H23/00—Processes or apparatus for adding material to the pulp or to the paper

- D21H23/02—Processes or apparatus for adding material to the pulp or to the paper characterised by the manner in which substances are added

- D21H23/22—Addition to the formed paper

- D21H23/24—Addition to the formed paper during paper manufacture

- D21H23/26—Addition to the formed paper during paper manufacture by selecting point of addition or moisture content of the paper

- D21H23/28—Addition before the dryer section, e.g. at the wet end or press section

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H17/00—Non-fibrous material added to the pulp, characterised by its constitution; Paper-impregnating material characterised by its constitution

- D21H17/20—Macromolecular organic compounds

- D21H17/33—Synthetic macromolecular compounds

- D21H17/46—Synthetic macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D21H17/59—Synthetic macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds obtained by reactions forming in the main chain of the macromolecule a linkage containing silicon

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H19/00—Coated paper; Coating material

- D21H19/10—Coatings without pigments

- D21H19/14—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12

- D21H19/24—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12 comprising macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D21H19/32—Coatings without pigments applied in a form other than the aqueous solution defined in group D21H19/12 comprising macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds obtained by reactions forming a linkage containing silicon in the main chain of the macromolecule

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H21/00—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties

- D21H21/14—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties characterised by function or properties in or on the paper

- D21H21/22—Agents rendering paper porous, absorbent or bulky

Definitions

- the present invention relates to a method for Manufacture of tissue paper and products made from it using a treatment agent as well as use a treatment agent.

- Softness is an important characteristic of tissue products such as Handkerchiefs, facial tissues, toilet paper, napkins and also hand or kitchen towels and describes the feeling which the tissue paper produces when it touches the skin.

- Softness can be characterized by its main characteristics: Surface softness and softness, break down:

- Under softness is meant the sensory impression, a tissue squeezed by hand during the Squeeze process created.

- tissue papers require different properties. So are kitchen towels and to an even greater extent with towels strength, in particular Strength when wet and high suction power required to meet the needs of the consumer.

- towels strength in particular Strength when wet and high suction power required to meet the needs of the consumer.

- handkerchiefs or facial tissues are softness of the surface and very smooth outstanding properties that in addition to strength Determine the utility value of these products.

- toilet paper determines a combination of dry strength in addition to good Softness and good thickness appearance, suitability for use and Consumer acceptance.

- the tissue making process includes regardless of its different variants the following procedural Steps:

- the processing process for example, to folding products such as Handkerchiefs or facial tissues are made in downstream, separate operations in special, for the task constructed processing machines, the processes like smoothing the tissue again, edge embossing, partially combined with flat and / or selective gluing to create layer adhesion of the composite individual layers (raw tissue) as well as longitudinal section, folding, Cross-section, storage and merging of several individual tissues and their packaging in so-called cloth bags or special jewelry boxes and their merging contain larger packaging or containers.

- Edge generation can also be achieved by layer adhesion Knurling are generated, as z. B. in cosmetic wipes is common.

- Tissue manufacturing processes are particularly common in the United States, today increasingly also in Europe, modified Process technologies in use, where a special Type of drying inside the tissue machine Improvement of specific volume and in this way a Improvement of the softness of the tissue produced in this way is achieved.

- TAD Through Air Drying

- Throughflow drying Its characteristic is that the "primary" nonwoven leaving the sheet formation before final contact drying on the Yankee cylinder a dry content of about 80% is pre-dried by Hot air is blown through the nonwoven.

- the nonwoven is supported by an air-permeable sieve or belt and led over the surface of one during its transport air-permeable, rotating cylinder drum.

- the support sieve or belt can be structured any pattern of compressed and by deformation in the damp state are generated on loosened zones that too increased, medium, specific volume and related thus lead to an increase in softness without the Strength of the nonwoven below that for use necessary measure drops.

- Another possibility to influence the Raw tissue production for softness and firmness consists in the Applying a stratification in which the primary to be formed Nonwoven fabric through a specially designed headbox in Form of different material layers is fed to the sheet formation together as a material jet become.

- nonwovens include consisting of two, three or more layers to the state of the Technology, for example DE-C 43 47 499.

- the use of chemicals is in the form of a Lotion order on the raw tissue during the raw tissue production process, the duplication or the subsequent one Processing known to improve softness.

- the term "Lotion” encompasses in general cosmetic usage Understanding aqueous or aqueous-alcoholic preparations emulsifying agents.

- EP-A-0 347 154 relates to tissue paper with a basis weight of 10 to 65 g / m 2 and a density of not more than 0.6 g / ml, this paper containing cellulosic fibers and a polysiloxane material, the amount at least 0.004% polysiloxane, based on the dry (fiber) weight of this nonwoven.

- US Patent 50 59 282 which results from this is correspondingly restricted a tissue paper with a basis weight of 10 to 65 g / m 2 and a density of not more than 0.6 g / ml, this paper being cellulose fibers and an effective content of a polysiloxane material contains, said polysiloxane being applied uniformly to the outward-facing surfaces of the tissue paper, this effective content of the polysiloxane being 0.004% to 2% of polysiloxane, based on the dry (fiber) weight of the tissue paper, which polysiloxane has a viscosity of 25 centistokes and has more and has a wetting time of not more than 2 minutes after an aging time of two weeks after its production.

- a manufacturing process for such a paper is the subject of EP-A-347 153 or the corresponding US patent 52 15 626.

- WO93 / 02252 relates to a production process for soft tissue paper with the step sequence of forming a sheet from aqueous suspension (wet laying) of cellulose fibers with formation of a nonwoven fabric (nonwoven fabric), drying the nonwoven fabric while increasing the temperature of the nonwoven fabric to at least 43 ° C., and creping the nonwoven fabric a temperature of at least 43 ° C, treating the nonwoven fabric at a temperature of at least 43 ° C with a sufficient amount of a polysiloxane so that 0.004% to 0.75% of this polysiloxane based on the dry (fiber) weight of this tissue paper in this nonwoven fabric remain, this tissue paper has a basis weight of 10 to 65 g / m 2 and a density of less than 0.6 g / m 3 .

- a water-soluble surfactant can be added at the same time as the polysiloxane. This subject is also described in US-A-50 59 282.

- WO94 / 05857 relates to a method for applying a chemical papermaking additive to a dry Tissue paper fleece (tissue paper fleece, raw tissue), whereby this method is characterized in that it follows Steps includes:

- plasticizers and their Mixtures preferably plasticizers, selected are made of lubricants, plasticizers and their Mixtures, these lubricants being polysiloxanes.

- a chemical softener which is primarily used as Plasticizer should serve, is desired, it can be made selected from a group of chemicals, for which purpose other polyethylene glycol, for example polyethylene glycol a molecular weight of 400 counts. From this U.S. Patent No. 5,246,545 has been filed.

- DE-A-28 00 132 relates to a soft, pliable Skin cleaning article with a fleece with a wiping surface and a low density wiping zone, the wiping surface represents a boundary of the low density wiping zone that Wipe zone low density is permeable to dirt and a Plenty of cavities in and under the surface and wherein the low density wiping zone is about 10 up to 150% lipophilic cleaning enamel, based on the Weight of the fleece, is treated.

- Lipophilic cleaning moles also fall, among other things Silicone oils and non-ionic surfactants.

- DE-C 34 20 940 relates to an agent for cleaning and Wiping the circuminal area comprising at least one Oil selected from the group of vegetable oils, animal oils and synthetic oils, characterized in that it is considered another Component comprises a silicone oil.

- EP-A-0 459 501 relates to a method for reducing the static charge and destruction during a Wet printing process, which is characterized in that on the paper is a silicone polymer emulsion, which is a Has particle size of less than 200 nm, a cationic Surfactant and a nonionic surfactant is applied.

- patents are known that use a Mixture of polyethylene glycol with quaternary amines Describe (cationic surfactants) as a treatment agent for example, US-A-5312522.

- So DE-C-34 47 499 relates to a non-drying Cleaning cloth, which is characterized in that an emulsion is applied to a carrier material at least from a moisture regulator, preferably Polyethylene glycol and at least one other liquid substance consists.

- a moisture regulator preferably Polyethylene glycol and at least one other liquid substance consists.

- EP-A-03 47 177 relates to a process for the production of Soft tissue paper, which has the following steps:

- Sheet formation from an aqueous suspension (wet laying) of cellulose fibers to form a fleece application of a sufficient amount of a water-soluble non-cationic surfactant in such a way that 0.01 to 2% of this non-cationic surfactant, based on the dry (fiber) weight of this tissue paper through the fleece are withheld, this application being carried out with a fiber consistency of 10 to 80% and drying and creping of the fleece, this tissue paper having a basis weight of 10 to 65 g / m 2 and a density of less than 0.6 g / m 3 .

- EP-A-0607796 relates to an organosilicon compound containing nonwovens, the improvement being that the organosilicon compound contains 45 to 98 wt .-% of a water soluble or water dispersible Polyether polysiloxane, the polyether groups being 30 to 100 mol% of oxyethylene units and oxypropylene units as the rest exist and the polysiloxane block 10 to 100 siloxane units comprises 1 to 20% by weight of a water-soluble or water-dispersible organopolysiloxane with at least one Ammonium group attached to the carbon atom and 1 to 20% by weight of water or a water-soluble alkylene glycol.

- the pre-filed post-published EP-A-0688901 relates a tissue paper containing 3 to 30% by weight of an aqueous softness mediating composition have been added, wherein said softening composition 20 to 98 wt .-% glycerol and 0.2 to 5% by weight of at least one quaternary Contains ammonium compound, which is, among others a special one containing a quaternary ammonium compound Polysiloxane compound of the general formula (6), such as defined below, can act.

- glycerol instead of glycerol in amounts of 0.5 to 50 % By weight either 0.5 to 50% by weight, based on the Main component, propylene glycol and / or polyethylene glycol to use.

- the present invention is based on the object Process for the production of tissue paper products under Use of a polysiloxane-containing treatment agent Provide improvement in softness, being it it is irrelevant which of the prescribed raw tissue production and processing methods the tissue product produces has been.

- a treatment agent is obtained from a mixture of special amounts of at least one polyhydroxy compound, except natural or chemically modified natural polymers especially one at room temperature, i.e. at 20 ° C, liquid polyethylene glycol and / or glycerin as further component, a portion of a polysiloxane and optionally up to 25 weight percent water.

- the Application of such a mixture surprisingly leads to a significantly improved softness of tissue products compared to a pure polysiloxane application as well as a pure polyethylene glycol or glycerin application (Synergy effect).

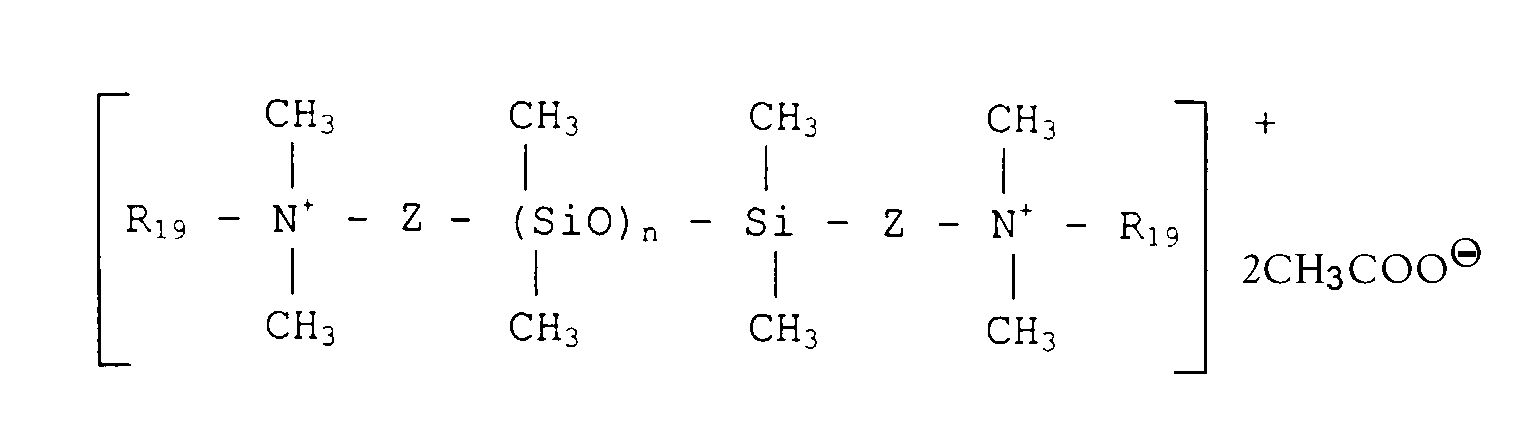

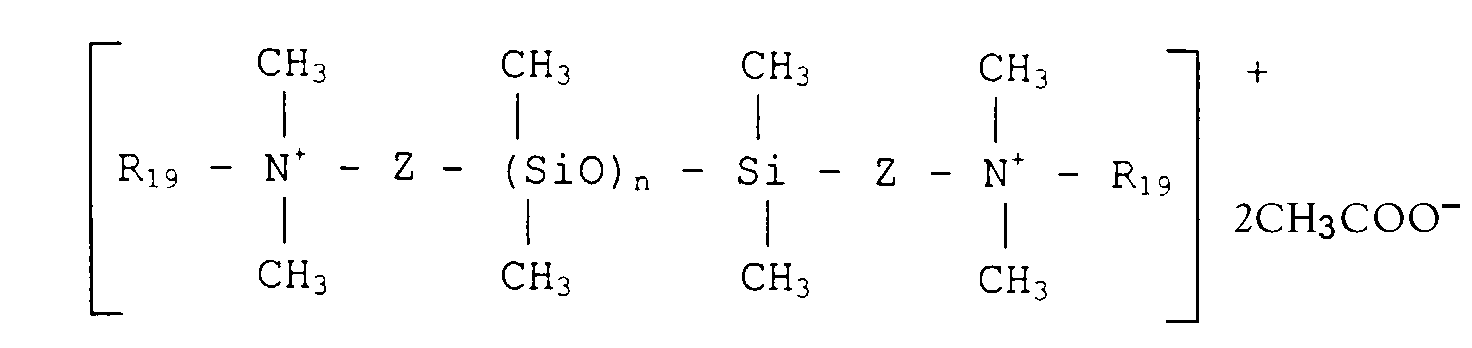

- the present invention thus relates to a process for the production of tissue paper products, characterized in that a treatment agent containing polysiloxane, which comprises 25 to 95 parts by weight, preferably 30 to 90 parts by weight of at least one polyhydroxy compound, in particular at least one polyethylene glycol and / or glycerol which is liquid at room temperature , 5 to 75 parts by weight, preferably 10 to 70 parts by weight of polysiloxane and, based on 100 parts by weight of this mixture, 0 to 35 parts by weight, preferably 1 to 30 parts by weight of water, with the exception of a treatment agent containing 5% by weight of a quaternary ammonium group-containing polysiloxane general formula in which and R 19 is a long-chain C 12 - C 18 alkyl group, onto the nonwoven or the "tissue web" within the wire / press section and / or dryer section, that is to say with a fiber density of 20 to 97%, based on the dry fiber weight of the web, in one Applied amount of

- polyhydroxy compound in the sense of Method used according to the invention is understood to be a low and macromolecular organic compound, the two or contain more hydroxy groups in the molecule.

- polyols called polyols belong by definition, especially polyhydric alcohols such as for example glycerol, polyethylene glycols, pentaerythritol, Sugar alcohols, such as B.

- tetrides pentites, hexites etc., especially threit, erythritol, adonite, arabitol, xylitol, dulcitol, Mannitol and sorbitol, carbohydrates for example D (+) - glucose, D (+) - fructose, D (+) - galactose, D (+) - mannose, L-gulose, Sucrose, galactose or maltose and synthetic polymers such as polyvinyl alcohol.

- any water-soluble component can be used as the polysiloxane component and / or water-dispersible compound which at Room temperature (20 ° C) liquid, pasty or waxy is present.

- This polysiloxane component includes polymers, oligomers, copolymers and others polymonomeric siloxanes. In the following one should under the Term polysiloxane any polymeric, oligomeric or understand other multi-monomeric siloxane material. Farther can the polysiloxane material both a linear structure, a have a branched structure or a cyclic structure.

- the polysiloxane component has monomeric siloxane units of the following structure: where R 1 and R 2 are the same or different for each monomeric siloxane unit and each is an alkyl, aryl, alkenyl, alkylaryl, arylalkyl, cycloalkyl, halogenated hydrocarbon or other group. Each of these groups can be substituted or unsubstituted. R 1 and R 2 groups of each particular monomeric unit may differ from the corresponding functional groups of the next attached monomeric unit. Furthermore, these groups can be both straight-chain and branched or have a cyclic structure.

- the groups R 1 and R 2 can furthermore and independently of one another be other silicone groups, but are not limited to siloxanes, polysiloxanes and polysilanes.

- the groups R 1 and R 2 can furthermore contain a large number of organic functional groups, for example alcohol, carboxylic acid and amino-functional groups.

- the degree of substitution and the type of substitution effect that relative degree of softness, silky feel and Hydrophilicity imparted to the tissue paper structure in the generally the degree of softness and silky increases Griffs, which is caused, among other things, by the polysiloxane, provided the hydrophilicity of the substituted Polysiloxane component decreases.

- Amino functional polysiloxanes and Polyetherpolysiloxane are as polysiloxane component in Treatment agent particularly preferred.

- Preferred polysiloxanes include linear organopolysiloxane compounds of the following general formula, where in each case the R 1 to R 9 groups are, independently of one another, C 1 to C 10 unsubstituted alkyl or aryl groups and R 10 is any substituted C 1 to C 10 alkyl or aryl radical.

- R 1 to R 9 group is independently a C 1 to C 10 unsubstituted alkyl group. It is known to those skilled in the art that it makes little difference whether, for example, R 9 or R 10 is the substituted group.

- the molar ratio of b to (a + b) is preferably between 0 and 20%, preferably between 0 and 10% and in particular between 1 and 5%.

- R 1 to R 9 are methyl groups and R 10 is a substituted or unsubstituted alkyl, aryl or alkenyl group.

- Such materials are generally referred to here as polydimethylsiloxanes, which have a special functionality as used in the present case.

- polydimethylsiloxanes can be: polydimethylsiloxanes such as Dow Corning® 200 Fluid, polydimethylcyclosiloxanes such as Dow Corning® 344 and 345, polydimethylsiloxane with an R 10 alkyl hydrocarbon group and a polydimethylsiloxane with one or more amino, carboxyl, hydroxyl Polyether, aldehyde, ketone, amide, ester, thiol and / or other R 10 functional groups, including alkyl and alkenyl analogs of such functional groups.

- an amino functional alkyl group such as R 10 can be an amino functional or an amino alkyl functional polydimethylsiloxane.

- the exemplary list of these polydimethylsiloxanes does not mean that others, not specifically mentioned here, are excluded from this.

- the viscosity of the polysiloxanes used as a component in the process according to the invention can vary over a wide range, as long as the polysiloxane remains fluid and can be liquefied for use in the treatment agent according to the invention for application to the tissue paper. This includes, for example, viscosities from 25 x 10 -6 m 2 / s to 20,000,000 x 10 -6 m 2 / s or even higher. Viscosities of 15,000 x 10 -6 m 2 / s to 3,400,000 x 10 -6 m 2 / s are preferred here.

- Highly viscous polysiloxanes that are not themselves flowable can be applied as an ingredient of the treatment agent to tissue paper in an effective manner, for example by emulsifying the polysiloxane component according to the invention in PEG or glycerol or water or in a mixture thereof together with a surfactant or the polysiloxane, if it is not soluble in PEG or glycerol or water, by means of a solvent such as hexane. Special methods for applying the polysiloxane component to tissue paper are discussed below.

- polysiloxane components are, for example, in US-A-2826551, US-A-3964550, US-A-4364837, US-A-4395454, US-A-4950545, US-A-4921895 and British Patent 849433 described.

- the monograph "Silicon Compounds" pages 181 - 217, edited by Petrarch Systems, 1984, a detailed listing and description such polysiloxanes.

- polyethersiloxanes of the general average formula can be used as polysiloxane component in the treatment agents, in which R 12 in the molecule are the same or different and are an alkyl group having 1 to 12 carbon atoms or a polyether group - (C n H 2n O) x R 13 , where R 13 is hydrogen, hydroxyl, alkyl or an acyl group and n is a numerical value from 2 to 2.7 and x has a numerical value from 2 to 200, with the proviso that at least one of the R 12 groups in the average molecule is a polyether group; a has a numerical value from 0 to 98, b has a numerical value from 0 to 98 and a + b is 8 to 98.

- R 12 can be an alkyl group having 1 to 12 carbon atoms or a polyether group. However, the condition must be met that at least one R 12 in the average molecule is a polyether group. Preferably 2 to 5 of the R 12 groups are polyether groups and the remaining R 12 groups then have the meaning of an alkyl group, the methyl group being particularly preferred.

- the alkyl group can also have up to 12 carbon atoms. In this way it is possible to vary the properties of the treatment agent and in this way to improve the handling on tissue paper products.

- the polyether groups correspond to the formula (C n H 2n O) x R 13 .

- the index n has a numerical value from 2 to 2.7.

- the index x means the number of oxyalkylene units. This value is an average numerical value since a mixture of products of different chain lengths is usually obtained in the synthesis of polyethers.

- the index x has a numerical value of 2 to 200 and is preferably 10 to 50. Polyether groups with an average molecular weight of 600 to 4,000 are preferred.

- the index a means the number of methylsiloxane units carried by the R 12 group.

- the siloxanes with positive values for a are modified by the R 12 side chains. Siloxanes in which the R 12 groups are arranged in the side chain are preferred.

- the R 13 group can be hydrogen, hydroxyl, alkyl or also acyl. R 13 is preferably a hydrogen atom. If R 13 is an alkyl group, lower alkyl groups with 1 to 4 carbon atoms are preferred. The acetyl group is the preferred acyl group.

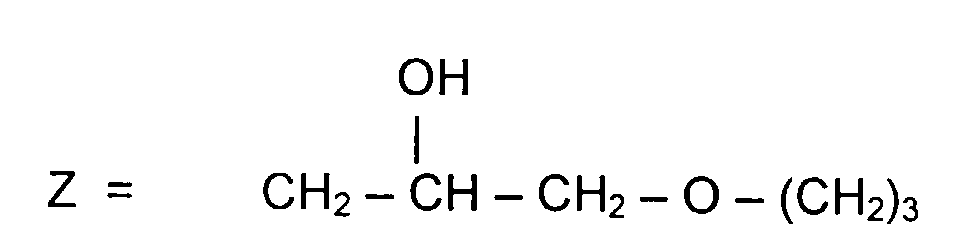

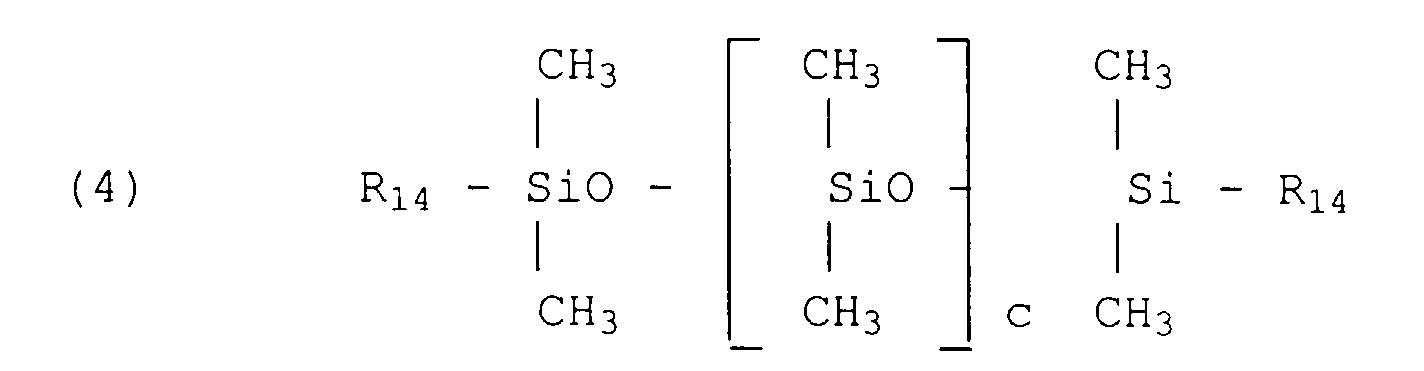

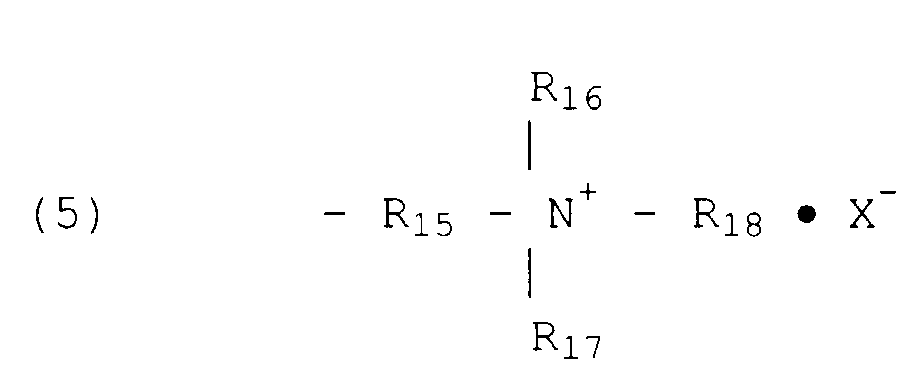

- the polysiloxane component has the following formula: where R 14 is a group of the formula and in which R 15 is a divalent hydrocarbon group whose carbon chain is interrupted by an oxygen atom, R 16 , R 17 , R 18 are the same or different and represent alkyl groups with 1 to 18 carbon atoms, one of the groups R 16 , R 17 , R 18 is a - (CH 2 ) 3 NHCOR 19 group, in which R 19 has an alkyl group with 7 to 17 carbon atoms and X- is a monovalent anion and c has a numerical value of 5 to 100.

- R 15 is a divalent hydrocarbon group, for example the group of the formula -CH 2 -C (OH) H-CH 2 -O- (CH 2 ) 3 -.

- the R 16 , R 17 , R 18 groups can be the same or different and are alkyl groups with 1 to 18 carbon atoms. However, one of the aforementioned groups R 16 , R 17 , R 18 can also have the meaning of a (CH 2 ) 3 NHCOR 19 group.

- R 16 , R 17 , R 18 groups are alkyl groups, these have 1 to 18 carbon atoms.

- R 14 groups are particularly preferred in which two of the aforementioned R 16 , R 17 and R 18 groups have 1 to 4 carbon atoms and the third group has up to 18 carbon atoms.

- one of the R 16 , R 17 and R 18 groups is a (CH 2 ) 3 NHCOR 19 group, the R 19 group is an alkyl group with 7 to 17 carbon atoms.

- X - is a monovalent anion, generally an acetate group. However, X can also be an inorganic group such as Cl - .

- the index "c” indicates the number of dimethylsiloxy units in the linear siloxane and has a numerical value from 5 to 100 and preferably 10 to 80.

- Particularly preferred of the aforementioned siloxanes are such polydimethylsiloxanes as well for example polyether, alkyl, and with quaternary or betainic groups, especially nitrogen groups modified polydimethylsiloxanes.

- Particularly preferred polysiloxanes are those under Designation Tegopren® distributed by Th. Goldschmidt AG organo-modified siloxanes with pronounced surface and Interface activity in aqueous and organic systems.

- polyether siloxanes as described in the company publication "Tegopren® Informative", undated, from Th. Goldschmidt AG at the trade name Tegopren® 3012, Tegopren® 3020, Tegopren® 3021, Tegopren® 3022, Tegopren® 3070, Tegopren® 5830, Tegopren® 5840, Tegopren® 5842, Tegopren® 5843, Tegopren® 5847, Tegopren® 5851, Tegopren® 5852, Tegopren® 5863, Tegopren® 5873, Tegopren® 5878, Tegopren® 5884 and Tegopren® 7006 are sold and Usually mean cloud points in the range below 25 ° C to 71 ° C and modified siloxanes in the form of Teopren silicone quats and betaines, such as those among the Designations Tegopren® 6920, Tegopren® 6922 and Tegopren

- tissue paper or tissue for short in the sense of the present invention is understood to mean all types of creped papers produced from aqueous dispersion with a basis weight range between 10 and 65 g / m 2 .

- tissue paper covers both the entire area of creped base papers, also called raw tissue, in particular the area of dry creped base tissue papers, regardless of whether single-layer or multilayer, as well as all end products made from these creped base papers, such as handkerchiefs , Facial and facial tissues, toilet paper, kitchen towels, hand towels and serviettes.

- tissue paper is still to be seen regardless of the fiber raw material to be used, in particular regardless of whether the fiber raw material is produced exclusively or predominantly from native pulps by the sulfate or sulfite process, or is used in a mixture with chemo-thermomechanical wood pulps (CTMP), or whether the fiber raw material used originates from a secondary fiber preparation process and accordingly the fiber raw material required for tissue production consists entirely or partially of "recycled fibers".

- CTMP chemo-thermomechanical wood pulps

- nonwovens nonwovens

- vegetable pulp fibers is characteristic for tissue paper production, a proportionate use by refinement of modified pulp fibers in a range of 10 to 50% or even one Use of plastic fibers suitable for papermaking in a proportion of 10 to 30% falls under the aforementioned definition of tissue.

- An application of the treatment agent is possible beyond the area of tissue production to corresponding areas of the non-woven area and the textile area in analog transmission.

- the binary, polysiloxane-containing treatment agent from 5 to 75 parts by weight (or% by weight) of at least one aforementioned polysiloxane and 25 to 95 parts by weight (or % By weight) of the aforementioned polyethylene glycol.

- 10 to 70 is preferred in this treatment agent Parts by weight of polysiloxane, in particular 40 to 60 parts by weight Polysiloxane and as a further component 30 to 90 parts by weight, but in particular 40 to 60 parts by weight of the aforementioned use liquid polyethylene glycol.

- the present invention is what is used in the method Treatment agent from 5 to 75 parts by weight (or% by weight) at least one polysiloxane and 25 to 95 parts by weight (or% by weight) glycerin.

- Treatment agent with 10 to 70 parts by weight, preferably 40 up to 60 parts by weight of at least one polysiloxane and 30 to 90 parts by weight, in particular 40 to 60 parts by weight Glycerin.

- Polyethylene glycol and glycerin can be used in the treatment agent can be exchanged in any quantity. But also mixtures of polyethylene glycol and glycerin can in particular under Economic aspects are used, whereby preferably the mixing ratios 20 to 80% by weight or Parts by weight, preferably 30 to 70% by weight or parts by weight of the aforementioned polyethylene glycol and 20 to 80% by weight or Parts by weight, preferably 30 to 70 wt .-% glycerol turn off.

- the treatment agent 30 to 90 parts by weight at least one polyhydroxy compound, i.e. at 20 ° C, in particular at least one liquid at room temperature Polyethylene glycol and / or glycerin, 10 to 70 parts by weight Polysiloxane and, based on 100 parts by weight of this Mixture, 1 to 30 parts by weight of water.

- such a ternary Treatment mixture 20 to 70 parts by weight of at least one Polyhydroxy compound, in particular at least one Polyethylene glycol and / or glycerin liquid at room temperature, 30 to 70 parts by weight of polysiloxane and, based on 100 Parts by weight of this mixture, 5 to 25 parts by weight of water contains.

- the treatment agents then consist of 5 to 75 parts by weight at least one polysiloxane, 25 to 95 parts by weight at least one polyhydroxy compound, especially the aforementioned polyethylene glycol and, based on 100 1 to 30 parts by weight of the above mixture Parts by weight of water.

- Treatment agent as a further agent with cosmetic agents special properties as well as other usual auxiliary substances contain.

- skin active ingredients are to be mentioned here based on vitamins or plant extracts, such as for example extracts of horse chestnut seeds, birch, arnica, Chamomile or bisabolol itself, St. John's wort, cucumber, aloe vera or witch hazel, which is partly due to their astringent and healing effects are known.

- Other active ingredients here are skin care products, for example sorbitan fatty acid esters and oxyethylated, homologous compounds of glycerin, esters of oxethylated Fatty alcohols, fatty alcohol alkanolamides, oxetylated Fatty alcohols, ethoxylated wool fatty alcohols, Glycerol monostearate, stearic acid, cetylstearyl alcohol, To name Vaseline and Lanolin.

- lanolin itself lanolin derivatives are also used, for example Lanolin alcohols or wool wax alcohols, which under the Designation Amerchol® from Union Carbide Inc. in conjunction are sold with mineral oils.

- lanolin derivatives are the acetylated lanolins, and hydrophilic lanolin derivatives, for example lanolin-polyoxyethylene compounds.

- treatment agents can also be used as other additives hydrotropic solubilizers for fatty substances, such as Polyalcohol ethers and ethoxylated fatty alcohols are used become.

- Another group that is used as an additional component in the treatment agents according to the invention can be used are quaternary ammonium compounds, but especially quaternary ammonium salts, as described, for example, in the US patents 5312522, 5397435, 5405501, 5427696 and the international patent applications WO 95/11344, WO95 / 11343, WO 95/01478, WO 95/01479, WO94 / 29521, WO94 / 29520, WO94 / 16143 and WO94 / 19381 are described.

- fragrances of the usual type can also be added that are selected from natural, nature-identical or artificial fragrances, the corresponding Fragrances are preferred.

- Agricultural oils such as lemon oil, bergamot oil, orange oil, Petitgrain oil, softwood oils, foin-coupe fragrance compositions or flower oils such as B. Rose, Jasmine, lilac, lavender, as well as synthetic fragrances based on menthol etc.

- An overview is provided by Ullmanns Encyclopedia of Technical Chemistry, 4th ed. 1981, volume 20, p. 199-285.

- inorganic pigment or organic dyes can be added, as is usually the case with Tissue paper production can be used.

- physiologically safe and non-irritating dyes, especially the corresponding natural dyes preferred. All of the aforementioned additives and auxiliaries in Treatment agents used method according to the invention can be contained individually or as a combination.

- the treatment agent for Tissue paper products come in an order quantity in the range of 0.01 to 15 percent by weight, preferably 0.5 to 10 Percent by weight, most preferably 2 to 6 percent by weight, based on the dry weight of the fibers.

- a single or multi-layer, preferably at least two-layer and particularly preferably three or four-layer unembossed or embossed tissue paper is preferably used as the carrier material to which the treatment agent is to be applied.

- the individual paper webs can be mechanically connected to one another by edge embossing or knurling, glued flat or punctually or else connected to one another in some other way.

- the Carrier material can also be solidified wet, the usual safe wet strength agents, such as Epichlorohydrin resins, urea-formaldehyde resins, melamine-formaldehyde resins as well as cross-linked cationic polyalkylene amines be used.

- the usual safe wet strength agents such as Epichlorohydrin resins, urea-formaldehyde resins, melamine-formaldehyde resins as well as cross-linked cationic polyalkylene amines be used.

- the treatment agent which in a preferred Embodiment is in the form of an emulsion, can be used with any any roller and spray application process or in one Impregnation process can be applied to the carrier material. It is always important to ensure that it does not become a Segregation of the emulsion can occur, d. that is, during the Applying the components of the treatment agent well must be mixed to prevent segregation. This happens, for example, by high shear forces for example due to high-speed stirrers, frequent pumping or by ultrasonic mixing.

- the treatment agent which to a noticeably improved Softness of tissue products can be used in can be used in a wide variety of product areas. As Its use, for example, has proven to be particularly advantageous on napkins, toilet paper and hand and kitchen towels, Handkerchiefs, facial tissues and facial tissues.

- composition of the treatment solution is sized so that it can be used during the period at the consumer at the usually annual average prevailing air humidity due to the water content Long-term use does not cause skin irritation (drying out due to the hygroscopic properties of polyethylene glycol or Glycerin) can come. Also a water vapor proof, reclosable packaging is no longer necessary.

- the treatment solution can both in the wet part Tissue paper machine (cotton machine), at the end of the wire section, in front of or within the press section (mechanical Drainage), d. H. with solids contents between 20 and 50% just as in the one arranged after the press section Dryer section with solids contents from 40 to 97% Dry fiber weight can be added.

- State of the art Dispatch locations on the transfer screen / belt, e.g. B. before Fleece transfer with a TAD arrangement and the feed on the moist nonwoven fabric after its transfer to the transport (Dry) felt in a conventional one- or two-felt tissue production machine.

- Treatment chemicals are sprayed onto the Yankee cylinder.

- An addition of the treatment agent is preferred in the Tissue production machine by spraying on the Pope-Roller producing a treatment agent film and its then transfer to the tissue web during the Roll-up process - usually the already creped one "Tissue web" as a result of the previous drying process a residual temperature between 20 ° C on the Yankee cylinder and about 70 ° C, which for the distribution of Treatment agent and its penetration into the raw tissue is favorable - on the contact surface of the single-layer Tissue web with the surface of the drum of the Pope-Roller.

- the Use of centrifugal rotors or brushing plants as well as the indirect transmission of a treatment agent film via Roller applicators come into question.

- the job can also directly on the tissue paper web.

- Particularly preferred is an addition of the treatment agent within the Duplicating machine or within the processing machine the outer layers of the multilayered web before or during calibration / smoothing. The order is most preferred of the treatment agent within the processing machine the single or multi-layer web.

- the Get tissue paper products in such a way that one polysiloxane-containing treatment agent of the above type the tissue web or the nonwoven fabric after the dryer section in the tissue paper machine and particularly preferably within the Doubling machine or within the processing machine in an amount of 0.01 to 15% applied to the web and that Subsequent smoothing of fiber fleece after application.

- one polysiloxane-containing treatment agent of the above type the tissue web or the nonwoven fabric after the dryer section in the tissue paper machine and particularly preferably within the Doubling machine or within the processing machine in an amount of 0.01 to 15% applied to the web and that Subsequent smoothing of fiber fleece after application.

- polysiloxane-containing treatment agents at one Fiber density from 35 to 97%, based on the Dry fiber weight of the single-ply web, in an amount of 0.5 up to 10% applied to the single-layer web.

- a multi-layer web as a tissue web and that Treatment agent with a fiber density of more than 90%, based on the dry fiber weight, on at least one of the The outer layers of the multilayered web amount to 1 to 7% apply. It is very particularly preferred that Treatments on the multi-layer tissue web on both Apply outer layers in an amount of 3 to 6%.

- the Smoothing through at least one pass of the tissue web through a nip of a pair of rollers in which one Roll with a steel surface of a counter roll with a Steel, plastic, paper or rubber surface, preferably but is assigned to a plastic surface.

- the smoothing of the tissue web after application of the treatment agent is therefore usually carried out in the manner that the tissue webs sprayed on both sides by a smoothing unit be performed.

- This calender generally consists of two smooth rollers with steel surfaces (steel rollers) whose Surfaces are usually hard chrome-plated. These reels will be hydraulically or pneumatically compressed or for Calibration run on gap. That is, one of the two Rolling is firmly positioned. The second or counter roll will pressed against a stop, so that the two Can not touch steel rollers, but in a certain, measurable and reproducible distance from each other.

- the tissue webs guided through this gap are opened Gap width compressed and smoothed.

- the Structural structure of the surface unified, d. H. a uniform thickness.

- the result is smoothing by leveling the surface in connection with a Uniformity of the thickness profile under the premise of a as little volume loss as possible.

- a calender can also be used, whereby together with a steel roller or steel counter roller a roller or counter roll is used, which is a rubber or Has paper surface.

- German patent DE-A-1804418 the German DE-A-2455895, the German patent specification DE-A-2528803, EP-A-0033559, US patent US-A-2179057, US patent US-A-3337388, British patent GB-A-827735, and the German Patents DE-C-822228 and DE-B-1045783.

- the present invention relates to the use of the aforementioned polysiloxane-containing treatment agent for Softening tissue paper products, in particular Handkerchiefs, facial tissues, facial tissues, napkins, Toilet paper, hand and kitchen towels.

- the application was carried out symmetrically on the outer surfaces of this fabric.

- the product thus obtained was referred to as A.

- Example 2 The application procedure according to Example 1 was repeated, however, instead of a ternary mix, it became a binary one Mixture of 50 percent by weight polyethylene glycol, Molecular weight 200 and 50 percent by weight of the polysiloxane used according to Example 1. The sample thus obtained was called B designated.

- Example 1 The procedure of Example 1 was repeated, however was instead of the ternary mixture according to the invention pure polysiloxane according to Example 1 in an amount of 6% applied and designated the product obtained with C.

- Example 1 The procedure of Example 1 was repeated, however instead of the ternary mixture according to the invention, a pure one Polyethylene glycol with a molecular weight of 200 in one amount applied by 6%. The product obtained in this way was treated with D designated. All wipes of Examples 1 and 2 and the Comparative tests 1 and 2 were carried out in a 2-roll (steel / plastic) smoothing unit under identical conditions (Speed, temperature, contact pressure) reproducible smoothed.

- the haptic properties of the products A and B were compared with the corresponding haptic results of the Comparative products C (pure polysiloxane) and D (pure Polyethylene glycol) (PEG) compared and these products in As part of a so-called panel test (based on "Manual on Sensory Testing Methods, ASTM, Special Technical Publication 434, p. 22; Test form D-Ranking Methods-Rank Order, Elevents Printings February 1993) was evaluated.

- panel test based on "Manual on Sensory Testing Methods, ASTM, Special Technical Publication 434, p. 22; Test form D-Ranking Methods-Rank Order, Elevents Printings February 1993.

- the increasing softness defined here as the sum of Surface softness and softness of one Group of 9 people according to the following procedure rated:

- the paper tissues to be checked were two halves folded so that the sample identifier is not for the test subject is recognizable and in any case the same outside of the Evaluation is presented.

- the cloths folded in this way were given to the test subjects with the instruction that folded towels between thumb, ball of thumb and finger rubbing and crumpling with regard to their softness and Check the surface softness and then the cloths to put increasing, subjective feeling of quality in line.

- the patterns were ranked 1, i.e. H. best to 4, d. H. worst rated.

- the test showed that products A and B according to the invention out of 7 of the 9 test subjects as very good in softness referred to and in relation to the comparative products C and D as were clearly labeled softer. In contrast felt only one of the 9 test subjects compared the product D as softer the product A according to the invention, and one of 9 test subjects the comparative product C softer than that of the invention Products A and B.

- the panel test also shows that the Products A and B according to the invention are significantly better in relation on crumple softness and surface softness are than that Comparative products C and D.

- Example 1 In addition to this first in-house panel test, it continued conducted a studio consumer test with 160 people. Here were samples with a lotion composition Polyethylene glycol / polysiloxane / water in a ratio of 72/10/18 with a 3% order quantity as significantly softer judged as a corresponding comparison pattern with pure Siloxane.

- polysiloxane used in Example 1 described polysiloxane and as polyethylene glycol in Example 1 described polyethylene glycol with a Molecular weight of 200 used.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Paper (AREA)

- Sanitary Thin Papers (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft ein Verfahren zur Herstellung von Tissuepapier und daraus hergestellten Produkten unter Verwendung eines Behandlungsmittels sowie die Verwendung eines Behandlungsmittels.The present invention relates to a method for Manufacture of tissue paper and products made from it using a treatment agent as well as use a treatment agent.

Weichheit ist eine wichtige Eigenschaft von Tissueprodukten wie Taschentüchern, Kosmetiktüchern, Toilettenpapier, Servietten und auch Hand- oder Küchentüchern und beschreibt das Gefühl, welches das Tissuepapier bei Berührung der Haut erzeugt.Softness is an important characteristic of tissue products such as Handkerchiefs, facial tissues, toilet paper, napkins and also hand or kitchen towels and describes the feeling which the tissue paper produces when it touches the skin.

Wie im Wochenblatt für Papierfabrikation Heft 11/12, 1988, auf Seite 435 ff. in dem Artikel ,,Weichheit und Weichmachen von Hygiene-Tissue" beschrieben, ist der Begriff Weichheit zwar allgemein verständlich, aber äußerst schwierig zu definieren, da keine physikalische Bestimmungsmethode und deshalb auch keine anerkannte Industrienorm als Standard zur Einstufung verschiedener Weichheitsgrade vorhanden ist.As in the weekly paper for paper manufacture issue 11/12, 1988 Page 435 ff. In the article ,, Softness and Softening of Hygiene Tissue ", the term softness is indeed generally understandable, but extremely difficult to define, since no physical method of determination and therefore also not a recognized industry standard as the standard for classification different degrees of softness is present.

Um die Weichheit wirklich erfassen zu können, muß sie durch eine subjektive Methode ermittelt werden, d. h. sie wird durch einen sogenannten Panel-Test ermittelt, bei dem mehrere geschulte Testpersonen ein vergleichendes Urteil abgeben.In order to really grasp the softness, it has to go through a subjective method is determined, d. H. it is through a so-called panel test, in which several trained test subjects make a comparative judgment.

Weichheit läßt sich über ihre Haupt charakteristika, die Oberflächenweichheit und die Knüllweichheit, untergliedern:Softness can be characterized by its main characteristics: Surface softness and softness, break down:

Oberflächenweichheit beschreibt das Gefühl, welches man empfindet, wenn man mit den Fingerkuppen leicht über die Oberfläche des Tissueblattes fährt.Surface softness describes the feeling which one feels when you move your fingertips lightly over the Surface of the tissue sheet moves.

Unter Knüllweichheit versteht man den sensorischen Eindruck, den ein mit den Händen zusammengedrücktes Tissue während des Vorgangs des Zusammendrückens erzeugt.Under softness is meant the sensory impression, a tissue squeezed by hand during the Squeeze process created.

Die zur Erzeugung bzw. Verbesserung der Weichheit eines

Tissuepapiers üblichen Maßnahmen lassen sich in drei

Hauptkategorien einteilen:

Tissuepapiere erfordern, je nach Verwendungszweck, unterschiedliche Eigenschaften. So sind bei Küchentüchern und in noch höherem Maße bei Handtüchern Festigkeit, insbesondere Festigkeit in nassem Zustand und hohe Saugleistung erforderlich, um den Ansprüchen des Verbrauchers zu genügen. Bei anderen Produkten, wie Taschentüchern oder Gesichtstüchern sind Weichheit der Oberfläche und sehr gute Anschmiegsamkeit hervorstechende Eigenschaften, die neben Festigkeit den Gebrauchswert dieser Produkte bestimmen. Bei Toilettenpapieren bestimmt eine Kombination von Trockenfestigkeit neben guter Weichheit und guter Dickenanmutung die Gebrauchseignung und die Verbraucherakzeptanz. Depending on the intended use, tissue papers require different properties. So are kitchen towels and to an even greater extent with towels strength, in particular Strength when wet and high suction power required to meet the needs of the consumer. For other products, such as handkerchiefs or facial tissues are softness of the surface and very smooth outstanding properties that in addition to strength Determine the utility value of these products. With toilet paper determines a combination of dry strength in addition to good Softness and good thickness appearance, suitability for use and Consumer acceptance.

Für die Papiermacher ist es eine besondere Herausforderung, die verschiedenen, einander oft widersprechenden Einflußfaktoren in eine besondere Balance zu bringen, um hieraus die vom Verbraucher geforderten optimalen Eigenschaftskombinationen für die angestrebten Endprodukte darzustellen.It is a special challenge for the paper makers different, often contradicting influencing factors in to bring a special balance, from which the Optimal combinations of properties demanded by consumers to present the desired end products.

Es ist heute ein Zeichen der Zeit, daß quer über alle Produktbereiche bei Hygieneartikeln eine Verbesserung der Weichheit eine der wichtigsten Forderungen an den Papiermacher ist. Eigenschaften wie Weichheit eines Tissueproduktes werden in ihrer Grundausbildung durch den Herstellungsprozeß und die Auswahl der Roh- und Hilfsstoffe bestimmt, wie bereits vorher erörtert.It is a sign of the times today that across everyone Product areas for hygiene articles an improvement of Softness is one of the most important requirements for the papermaker is. Properties like softness of a tissue product in their basic training through the manufacturing process and Selection of raw and auxiliary materials determines, as before discussed.

Der Tissueherstellungsprozeß umfaßt unabhängig von seinen verschiedenen Varianten die folgenden verfahrenstechnischen Schritte:The tissue making process includes regardless of its different variants the following procedural Steps:

Suspendieren der Faserstoffe in Wasser, eventuell Zugabe von chemischen Hilfsmitteln zur gezielten Beeinflussung von Produkteigenschaften und Verfahrensablauf, Aktivierung der Faseroberflächen zur Erschließung des Festigkeitspotentials der Faserrohstoffe durch mechanische Behandlung wie Mahlung in einem Refiner, Blattbildung durch Ablegen der Fasern, orientiert oder in Wirrlage auf einem oder zwischen zwei endlos umlaufenden Sieben der Papiermaschine unter gleichzeitiger Entfernung der Hauptmenge an Verdünnungswasser bis auf Trockengehalte zwischen 12 und 35 %, Trocknen des gebildeten primären Faservlieses in einem oder mehreren Schritten auf mechanischem und thermischem Wege bis zu einem Endtrockengehalt von rund 93 bis 97 %. Zu den für die Tissueerzeugung relevantesten Schritten gehört weiterhin der Kreppvorgang, der beim konventionellen Prozeß dominierend die Eigenschaften des fertigen Tissueprodukts beeinflußt. Beim heute überwiegend angewandten Trockenkreppverfahren geschieht die Kreppung auf einem Trockenzylinder, mit üblicherweise 4,5 bis 6 m Durchmesser, dem sogenannten Yankeezylinder, mit Hilfe eines Kreppschabers bei dem vorgenannten Endtrockengehalt des Tissuerohpapiers. Bei älteren Verfahren mit geringeren Anforderungen an die Tissuequalität wird auch das Naßkreppverfahren angewandt, das ähnlich dem Trockenkreppverfahren, jedoch bei niedrigeren Trockengehalten unter 80 %, üblicherweise bei etwa 55 bis 65 % Trockengehalt abläuft, mit einer Nachtrocknung auf anschließenden Trockenzylindern einer Trockenpartie bis zum Endtrockengehalt. Das gekreppte, endtrockene Rohtissuepapier (Rohtissue) wird in einem folgenden Schritt auf einen tragenden Kern zu einem sogenannten Tambour oder längsgeschnitten auf Hülsen zu Mutterrollen aufgewickelt und steht in der Form für die weitere Verarbeitung zu Fertigprodukten zur Verfügung.Suspend the fiber in water, possibly adding chemical aids for the targeted influencing of Product properties and process flow, activation of Fiber surfaces to develop the strength potential of the Fiber raw materials by mechanical treatment such as grinding in a refiner, sheet formation by laying down the fibers, oriented or in confusion on one or between two endless revolving seven of the paper machine under simultaneous Removal of the bulk of the dilution water up to Dryness between 12 and 35%, drying the formed primary nonwoven in one or more steps mechanical and thermal path to a final dry content from around 93 to 97%. Among those for tissue production The most relevant steps still include the creping process, the in the conventional process, the properties of the finished tissue product. Mostly today applied creping occurs on the creping a drying cylinder, usually 4.5 to 6 m Diameter, the so-called Yankee cylinder, with the help of a Crepe doctor at the aforementioned final dry content of Tissue paper. In older procedures with fewer That will also make demands on tissue quality Wet crepe process applied, similar to that Dry crepe process, but at lower dry contents below 80%, usually around 55 to 65% dryness expires, with subsequent drying on subsequent Drying cylinders of a dryer section up to the final dry content. The creped, finally dry raw tissue paper (raw tissue) is in a subsequent step on a core to one so-called drum or cut lengthways on sleeves Mother rolls wound up and stands in the form for the further Processing to finished products available.

Zur Erzeugung mehrlagiger Tissuepapiere, wie z. B. Taschentücher, Toilettenpapier, Handtücher oder Küchentücher erfolgt vielfach ein Zwischenschritt mit der sogenannten Doublierung, bei der üblicherweise die Rohwatte (Rohtissue) in einer der gewünschten Lagenzahl des Fertigprodukts entsprechenden Tambour-Zahl abgewickelt und zu einer gemeinsamen, mehrlagigen Mutterrolle aufgewickelt wird. In diesem Verarbeitungsschritt ist häufig eine Glättung oder Kalibrierung in Zwei- oder Mehrwalzenglättwerken einbezogen. Die Glättung (Kalibrierung) kann jedoch auch in der Tissueerzeugungsmaschine nach erfolgter Trocknung und Kreppung direkt vor der Aufrollung durchgeführt werden.For the production of multi-layer tissue papers, such as. B. Handkerchiefs, toilet paper, hand towels or kitchen towels there is often an intermediate step with the so-called Doubling, in which usually the raw cotton (raw tissue) in one of the desired number of layers of the finished product according to the corresponding drum number and to a common, multilayer mother roll is wound. In this processing step is often a smoothing or Calibration in two- or multi-roll smoothing plants included. However, the smoothing (calibration) can also be done in the Tissue production machine after drying and creping be carried out directly before the reeling.

Der Verarbeitungsprozeß beispielsweise zu Faltprodukten wie Taschentüchern oder Kosmetiktüchern (facials) erfolgt in nachgeschalteten, separaten Arbeitsgängen in speziellen, für die Aufgabe konstruierten Verarbeitungsmaschinen, die Vorgänge wie nochmaliges Glätten des Tissues, Randprägung, teilweise kombiniert mit einer flächigen und/oder punktuellen Verleimung zur Erzeugung von Lagenhaftung der miteinander in Verbund zu bringenden Einzellagen (Rohtissue) sowie Längsschnitt, Faltung, Querschnitt, Ablage und Zusammenführen mehrerer Einzeltücher und deren Verpackung in sogenannten Tüchertaschen oder speziellen Schmuckkartons sowie deren Zusammenführung zu größeren Umverpackungen oder Gebinden beinhalten. Anstelle der Randprägung kann die Lagenhaftungserzeugung auch durch Rändelung erzeugt werden, wie dies z. B. bei Kosmetitktüchern üblich ist.The processing process, for example, to folding products such as Handkerchiefs or facial tissues are made in downstream, separate operations in special, for the task constructed processing machines, the processes like smoothing the tissue again, edge embossing, partially combined with flat and / or selective gluing to create layer adhesion of the composite individual layers (raw tissue) as well as longitudinal section, folding, Cross-section, storage and merging of several individual tissues and their packaging in so-called cloth bags or special jewelry boxes and their merging contain larger packaging or containers. Instead of Edge generation can also be achieved by layer adhesion Knurling are generated, as z. B. in cosmetic wipes is common.

Neben dem beschriebenen, konventionellen Tissueherstellungsprozeß sind insbesondere in den USA, heute in zunehmendem Maße auch in Europa, abgewandelte Verfahrenstechniken in Gebrauch, bei denen durch eine spezielle Art der Trocknung innerhalb der Tissuemaschine eine Verbesserung von spezifischem Volumen und über diesen Weg eine Verbesserung der Knüllweichheit des so hergestellten Tissues erreicht wird. Diese in verschiedenen Unterarten existierenden Verfahren werden als TAD (Through Air Drying)-Verfahren (Durchströmtrocknung) bezeichnet. Ihr Charakteristikum ist, daß das die Blattbildung verlassende ,,primäre" Faservlies vor der abschließenden Kontakttrocknung auf dem Yankeezylinder auf einen Trockengehalt von etwa 80 % vorgetrocknet wird, indem Heißluft durch das Faservlies geblasen wird. Das Faservlies wird dabei durch ein luftdurchlässiges Sieb oder Belt gestützt und geführt während dessen Transport über die Oberfläche einer luftdurchlässigen, rotierenden Zylindertrommel. Durch Strukturieren des Stützsiebes oder des Beltes kann dabei ein beliebiges Muster an verdichteten und durch Verformung im feuchten Zustand auf gelockerten Zonen erzeugt werden, die zu erhöhten, mittleren, spezifischen Volumen und in Zusammenhang damit zu einer Erhöhung der Knüllweichheit führen, ohne daß die Festigkeit des Faservlieses unter das für den Gebrauch notwendige Maß absinkt. Eine weitere Einflußmöglichkeit bei der Rohtissueerzeugung auf Weichheit und Festigkeit besteht in der Anwendung einer Schichtung, bei der das zu bildende primäre Faservlies durch einen speziell konstruierten Stoffauflauf in Form stofflich unterschiedlicher Faserstoffschichten aufgebaut wird, die als Stoffstrahl gemeinsam der Blattbildung zugeführt werden. Bei der Anwendung von Schichtung gehören Faservliese, bestehend aus zwei, drei oder mehr Schichten zum Stand der Technik, beispielsweise der DE-C 43 47 499. Durch geeignete Rohstoffauswahl in den die Schichtung bestimmenden Kanälen der Stoffauflaufaustrittsdüse, beispielsweise die Verwendung von Eukalyptusfasern auf der der Yankee-Zylinderoberfläche zugewandten Vliesseite kann die Oberflächenweichheit signifikant erhöht werden, was den aus der Rohtissueerzeugung hergestellen Produkten zugute kommt.In addition to the described, conventional Tissue manufacturing processes are particularly common in the United States, today increasingly also in Europe, modified Process technologies in use, where a special Type of drying inside the tissue machine Improvement of specific volume and in this way a Improvement of the softness of the tissue produced in this way is achieved. These exist in different subspecies Procedures are called TAD (Through Air Drying) procedures (Throughflow drying). Its characteristic is that the "primary" nonwoven leaving the sheet formation before final contact drying on the Yankee cylinder a dry content of about 80% is pre-dried by Hot air is blown through the nonwoven. The nonwoven is supported by an air-permeable sieve or belt and led over the surface of one during its transport air-permeable, rotating cylinder drum. By The support sieve or belt can be structured any pattern of compressed and by deformation in the damp state are generated on loosened zones that too increased, medium, specific volume and related thus lead to an increase in softness without the Strength of the nonwoven below that for use necessary measure drops. Another possibility to influence the Raw tissue production for softness and firmness consists in the Applying a stratification in which the primary to be formed Nonwoven fabric through a specially designed headbox in Form of different material layers is fed to the sheet formation together as a material jet become. When using layering, nonwovens include consisting of two, three or more layers to the state of the Technology, for example DE-C 43 47 499. By suitable Selection of raw materials in the stratification channels Headbox exit nozzle, for example the use of Eucalyptus fibers on the surface of the Yankee cylinder facing fleece side can be the surface softness be significantly increased, which is the result of the raw tissue production manufactured products.

Darüber hinaus ist der Einsatz von Chemikalien in Form eines Lotionsauftrags auf das Rohtissue während des Rohtissue-Erzeugungsprozesses, der Doublierung oder der nachfolgenden Verarbeitung zur Weichheitsverbesserung bekannt. Der Begriff "Lotion" umfaßt im kosmetischen Sprachgebrauch nach allgemeinem Verständnis wäßrige oder wäßrig-alkoholische Zubereitungen mit emulgierenden Wirkstoffen. Insbesondere sind die Verwendung wäßriger Lösungen oder Emulsionen von Polyhydroxyverbindungen wie Glykol oder Polyethylenglykol oder die Verwendung von Polysiloxanen zur Weichheitsverbesserung von Tissue beschrieben. Bisher nicht bekannt ist allerdings, daß eine signifikante Weichheitssteigerung als Synergieeffekt einer Mischung eines Polysiloxans mit einem Polyethylenglykol in wäßriger Emulsion erzielt werden kann.In addition, the use of chemicals is in the form of a Lotion order on the raw tissue during the raw tissue production process, the duplication or the subsequent one Processing known to improve softness. The term "Lotion" encompasses in general cosmetic usage Understanding aqueous or aqueous-alcoholic preparations emulsifying agents. In particular, the use aqueous solutions or emulsions of polyhydroxy compounds such as glycol or polyethylene glycol or the use of Polysiloxanes to improve tissue softness described. So far it is not known that a significant increase in softness as a synergy effect Mixture of a polysiloxane with a polyethylene glycol in aqueous emulsion can be achieved.

Die Verwendung von Polysiloxanen als Behandlungsmittel zur Weichheitsverbesserung von Tissue in der Patentliteratur beschrieben. Bisher nicht bekannt ist allerdings, daß eine signifikante Weichheitssteigerung als Synergieeffekt der Verwendung einer Mischung eines Polysiloxans mit einer Polyhydroxy-Verbindung, wie z. B. Polyethylenglykol oder Glycerin in wäßriger Emulsion als Behandlungsmittel für Tissue erzielt werden kann. So betrifft die WO 90/09807 ein Tissueprodukt, welches wenigstens eine Tissueschicht enthält, wobei dieses Tissueprodukt 0,1 bis 5 Gewichtsprozent an Feststoffen einer Silikonverbindung enthält. Hierbei handelt es sich vorzugsweise um eine wäßrige Emulsion und/oder Lösung dieser Silikonverbindungen. Aus diese Patentanmeldung ist das US-Patent 49 50 545 hervorgegangen. The use of polysiloxanes as a treatment agent Softness improvement of tissue in the patent literature described. So far it is not known that a significant increase in softness as a synergy effect Use of a mixture of a polysiloxane with a Polyhydroxy compound, such as. B. polyethylene glycol or Glycerin in aqueous emulsion as a treatment agent for tissue can be achieved. For example, WO 90/09807 relates to Tissue product containing at least one layer of tissue, this tissue product being 0.1 to 5 percent by weight Contains solids of a silicone compound. This is what it is about preferably an aqueous emulsion and / or solution of these silicone compounds. From this patent application it is U.S. Patent 4,950,545 emerged.

Die EP-A-0 347 154 betrifft ein Tissuepapier mit einem Basisgewicht von 10 bis 65 g/m2 und einer Dichte von nicht mehr als 0,6 g/ml, wobei dieses Papier zellulosische Fasern und ein Polysiloxanmaterial enthält, wobei die Menge wenigstens 0,004 % Polysiloxan, bezogen auf das Trocken(faser)Gewicht dieses Vliesstoffs beträgt. Gegenstand des hieraus hervorgegangen US-Patents 50 59 282 ist entsprechend eingeschränkter ein Tissuepapier mit einem Basisgewicht von 10 bis 65 g/m2 und einer Dichte von nicht mehr als 0,6 g/ml, wobei dieses Papier Zellulosefasern und einen wirksamen Gehalt eines Polysiloxanmaterials enthält, wobei besagtes Polysiloxan gleichförmig auf den nach außen gerichteten Flächen des Tissuepapiers aufgetragen ist, wobei dieser wirksame Gehalt des Polysiloxans 0,004 % bis 2 % Polysiloxan, bezogen auf das Trocken(faser)gewicht des Tissuepapiers betrifft, wobei dieses Polysiloxan eine Viskosität von 25 Centistokes und mehr aufweist und nach einer Alterungszeit von zwei Wochen nach seiner Herstellung eine Benetzungszeit von nicht mehr als 2 Minuten hat. Ein Herstellungsverfahren für ein derartiges Papier ist Gegenstand der EP-A-347 153 bzw. des entsprechenden US-Patents 52 15 626.EP-A-0 347 154 relates to tissue paper with a basis weight of 10 to 65 g / m 2 and a density of not more than 0.6 g / ml, this paper containing cellulosic fibers and a polysiloxane material, the amount at least 0.004% polysiloxane, based on the dry (fiber) weight of this nonwoven. The subject of US Patent 50 59 282 which results from this is correspondingly restricted a tissue paper with a basis weight of 10 to 65 g / m 2 and a density of not more than 0.6 g / ml, this paper being cellulose fibers and an effective content of a polysiloxane material contains, said polysiloxane being applied uniformly to the outward-facing surfaces of the tissue paper, this effective content of the polysiloxane being 0.004% to 2% of polysiloxane, based on the dry (fiber) weight of the tissue paper, which polysiloxane has a viscosity of 25 centistokes and has more and has a wetting time of not more than 2 minutes after an aging time of two weeks after its production. A manufacturing process for such a paper is the subject of EP-A-347 153 or the corresponding US patent 52 15 626.

Die WO93/02252 betrifft ein Herstellungsverfahren für Softtissuepapier mit der Schrittfolge einer Blattbildung aus wäßriger Suspension (wet laying) von Zellulosefasern unter Bildung eines Faservlieses (Vliesstoffs), Trocknung des Vliesstoffs unter Erhöhung der Temperatur des Vliesstoffs auf wenigstens 43 °C, Kreppung des Vliesstoffs bei einer Temperatur von wenigstens 43 °C, Behandlung des Vliesstoffs bei einer Temperatur von wenigstens 43 °C mit einer ausreichenden Menge eines Polysiloxans, so daß 0,004 % bis 0,75 % dieses Polysiloxans bezogen auf das Trocken(faser)gewicht dieses Tissuepapiers in diesem Vliesstoff verbleiben, wobei dieses Tissuepapier ein Basisgewicht von 10 bis 65 g/m2 und eine Dichte von weniger als 0,6 g/m3 aufweist. Nach einer bevorzugten Ausführungsform kann unter anderem gleichzeitig mit dem Polysiloxan ein wasserlösliches Tensid zugefügt werden. Dieser Gegenstand ist auch in der US-A-50 59 282 beschrieben.WO93 / 02252 relates to a production process for soft tissue paper with the step sequence of forming a sheet from aqueous suspension (wet laying) of cellulose fibers with formation of a nonwoven fabric (nonwoven fabric), drying the nonwoven fabric while increasing the temperature of the nonwoven fabric to at least 43 ° C., and creping the nonwoven fabric a temperature of at least 43 ° C, treating the nonwoven fabric at a temperature of at least 43 ° C with a sufficient amount of a polysiloxane so that 0.004% to 0.75% of this polysiloxane based on the dry (fiber) weight of this tissue paper in this nonwoven fabric remain, this tissue paper has a basis weight of 10 to 65 g / m 2 and a density of less than 0.6 g / m 3 . According to a preferred embodiment, a water-soluble surfactant can be added at the same time as the polysiloxane. This subject is also described in US-A-50 59 282.

Die WO94/05857 betrifft ein Verfahren zur Applikation eines chemischen Papierherstellungsadditivs zu einem trockenen Tissuepapiervlies (Tissuepapiervliesstoff, Rohtissue), wobei dieses Verfahren dadurch gekennzeichnet ist, daß es folgende Schritte enthält:WO94 / 05857 relates to a method for applying a chemical papermaking additive to a dry Tissue paper fleece (tissue paper fleece, raw tissue), whereby this method is characterized in that it follows Steps includes:

Zurverfügungstellung eines trockenen Tissuepapiervliesstoffs, das Verdünnen eines chemischen Papierherstellungsadditivs mit einem geeigneten Lösemittel zur Bildung einer verdünnten chemischen Lösung, die Applikation dieser verdünnten chemischen Lösung auf einer erhitzten Transferoberfläche, das teilweise Verdampfen des Lösemittels durch die Transferoberfläche unter Bildung eines dieses Papierherstellungsadditiv enthaltenden Films und die Übertragung des Films von der erhitzten Transferoberfläche auf die Oberfläche des Tissuevliesstoffs, daß eine ausreichende Menge des chemischen Papierherstellungsadditivs in der Weise erfolgt, daß 0,004 bis 2 % dieses chemischen Papierherstellungsadditivs, bezogen auf das Trocken(faser)gewicht dieses Tissuevliesstoffs in diesem Tissuevliesstoff zurückbleibt. Vorzugsweise versteht man unter diesem Papierherstellungsadditiv Weichmachungsmittel und deren Mischungen, vorzugsweise Weichmachungsmittel, die ausgewählt sind aus Schmierstoffen, Plastifizierungsmitteln und deren Mischungen, wobei diese Schmiermittel Polysiloxane sind. Sofern ein chemisches Weichmachungsmittel, welches primär als Plastifizierungsmittel dienen soll, erwünscht ist, kann es aus einer Gruppe von Chemikalien ausgewählt werden, wozu unter anderem Polyethylenglykol, beispielsweise Polyethylenglykol mit einem Molekulargewicht von 400 zählt. Aus dieser Patentanmeldung ist die US-5 246 545 hervorgegangen.Providing a dry tissue paper nonwoven, the dilution of a chemical papermaking additive with a suitable solvent to form a dilute chemical solution, the application of this dilute chemical Solution on a heated transfer surface, partially Evaporation of the solvent through the transfer surface below Formation of one containing this papermaking additive Films and the transfer of the film from the heated Transfer surface to the surface of the tissue nonwoven, that a sufficient amount of the chemical Papermaking additive is made in such a way that 0.004 to 2% of this chemical paper making additive based on the dry (fiber) weight of this tissue nonwoven in it Tissue nonwoven remains. Preferably one understands this papermaking additive plasticizers and their Mixtures, preferably plasticizers, selected are made of lubricants, plasticizers and their Mixtures, these lubricants being polysiloxanes. Provided a chemical softener, which is primarily used as Plasticizer should serve, is desired, it can be made selected from a group of chemicals, for which purpose other polyethylene glycol, for example polyethylene glycol a molecular weight of 400 counts. From this U.S. Patent No. 5,246,545 has been filed.

Die DE-A-28 00 132 betrifft einen weichen, schmiegsamen Hautreinigungsartikel mit einem Vlies mit einer Wischoberfläche und einer Wischzone niedriger Dichte, wobei die Wischoberfläche eine Grenze der Wischzone niedriger Dichte darstellt, die Wischzone niedriger Dichte schmutzdurchlässig ist und eine Vielzahl von in und unter der Oberfläche liegenden Hohlräumen aufweist und wobei die Wischzone niedriger Dichte mit etwa 10 bis 150 % lipophilem Reinigungsemoliens, bezogen auf das Gewicht des Vlieses, behandelt ist. Unter dem Begriff des lipophilen Reinigungsemoliens fallen unter anderem auch Silikonöle sowie nichtionische Tenside.DE-A-28 00 132 relates to a soft, pliable Skin cleaning article with a fleece with a wiping surface and a low density wiping zone, the wiping surface represents a boundary of the low density wiping zone that Wipe zone low density is permeable to dirt and a Plenty of cavities in and under the surface and wherein the low density wiping zone is about 10 up to 150% lipophilic cleaning enamel, based on the Weight of the fleece, is treated. Under the concept of Lipophilic cleaning moles also fall, among other things Silicone oils and non-ionic surfactants.

Die DE-C 34 20 940 betrifft ein Mittel zum Reinigen und Abwischen des cirkumanalen Bereichs, umfassend mindestens ein Öl ausgewählt aus der Gruppe der Pflanzenöle, Tieröle und synthetischen Öle, dadurch gekennzeichnet, daß es als weitere Komponente ein Silikonöl umfaßt.DE-C 34 20 940 relates to an agent for cleaning and Wiping the circuminal area comprising at least one Oil selected from the group of vegetable oils, animal oils and synthetic oils, characterized in that it is considered another Component comprises a silicone oil.

Die EP-A-0 459 501 betrifft ein Verfahren zur Reduktion der statischen Aufladung und der Zerstörung während eines Naßdruckverfahrens, welches dadurch gekennzeichnet ist, daß auf das Papier eine Silikonpolymeremulsion, welche eine Partikelgröße von weniger als 200 nm aufweist, ein kationisches Tensid und ein nichtionisches Tensid aufgebracht wird.EP-A-0 459 501 relates to a method for reducing the static charge and destruction during a Wet printing process, which is characterized in that on the paper is a silicone polymer emulsion, which is a Has particle size of less than 200 nm, a cationic Surfactant and a nonionic surfactant is applied.

Weiterhin sind Patente bekannt, die die Verwendung einer Mischung aus Polyethylenglykol mit quaternären Aminen (Kationtenside) als Behandlungsmittel beschreiben, beispielsweise die US-A-5312522.Furthermore, patents are known that use a Mixture of polyethylene glycol with quaternary amines Describe (cationic surfactants) as a treatment agent for example, US-A-5312522.

So betrifft die DE-C-34 47 499 ein nichttrocknendes Reinigungstuch, welches dadurch gekennzeichnet ist, daß auf einem Trägermaterial eine Emulsion aufgebracht ist, die mindestens aus einem Feuchtigkeitsregulator, vorzugsweise Polyethylenglykol und mindestens einem weiteren flüssigen Stoff besteht. So DE-C-34 47 499 relates to a non-drying Cleaning cloth, which is characterized in that an emulsion is applied to a carrier material at least from a moisture regulator, preferably Polyethylene glycol and at least one other liquid substance consists.

Weiterhin ist es bekannt, als Weichmacher bei der Herstellung von Softtissuepapier ein anionisches Tensid, nichtionisches Tensid oder deren Mischungen einzusetzen.It is also known as a plasticizer in the manufacture of soft tissue paper an anionic surfactant, non-ionic Use surfactant or mixtures thereof.

Die EP-A-03 47 177 betrifft ein Verfahren zur Herstellung von Softtissuepapier, welches folgende Schritte aufweist:EP-A-03 47 177 relates to a process for the production of Soft tissue paper, which has the following steps:

Blattbildung aus wäßriger Suspension (wet laying) von Zellulosefasern unter Bildung eines Vlieses, Applikation einer ausreichenden Menge eines wasserlöslichen nichtkationischen Tensids, dergestalt, daß 0,01 bis 2 % dieses nichtkationischen Tensids, bezogen auf das Trocken(faser)gewicht dieses Tissuepapiers durch das Vlies zurückgehalten werden, wobei diese Applikation bei einer Faserkonsistenz von 10 bis 80 % erfolgt sowie Trocknung und Kreppung des Vlieses, wobei dieses Tissuepapier ein Basisgewicht von 10 bis 65 g/m2 und eine Dichte von weniger als 0,6 g/m3 aufweist.Sheet formation from an aqueous suspension (wet laying) of cellulose fibers to form a fleece, application of a sufficient amount of a water-soluble non-cationic surfactant in such a way that 0.01 to 2% of this non-cationic surfactant, based on the dry (fiber) weight of this tissue paper through the fleece are withheld, this application being carried out with a fiber consistency of 10 to 80% and drying and creping of the fleece, this tissue paper having a basis weight of 10 to 65 g / m 2 and a density of less than 0.6 g / m 3 .

Die EP-A-0607796 betrifft eine eine Organo-Silikonverbindung enthaltendes Non-wovens, wobei die Verbesserung darin besteht, daß die Organo-Silikonverbindung enthält 45 bis 98 Gew.-% eines wasserlöslichen oder wasserdispergierbaren Polyetherpolysiloxans, wobei die Polyethergruppen zu 30 bis 100 mol-% aus Oxyethyleneinheiten und Oxypropyleneinheiten als Rest bestehen und der Polysiloxanblock 10 bis 100 Siloxaneinheiten umfaßt, 1 bis 20 Gew.-% eines wasserlöslichen oder wasserdispergierbaren Organo-Polysiloxans mit wenigstens einer Ammoniumgruppe, die am Kohlenstoffatom angebracht ist und 1 bis 20 Gew.-% Wasser oder eines wasserlöslichen Alkylenglykols.EP-A-0607796 relates to an organosilicon compound containing nonwovens, the improvement being that the organosilicon compound contains 45 to 98 wt .-% of a water soluble or water dispersible Polyether polysiloxane, the polyether groups being 30 to 100 mol% of oxyethylene units and oxypropylene units as the rest exist and the polysiloxane block 10 to 100 siloxane units comprises 1 to 20% by weight of a water-soluble or water-dispersible organopolysiloxane with at least one Ammonium group attached to the carbon atom and 1 to 20% by weight of water or a water-soluble alkylene glycol.

Die voreingereichte nachveröffentlichte EP-A-0688901 betrifft ein Tissuepapier, dem 3 bis 30 Gew.-% einer wäßrigen, Weichheit vermittelnden Zusammensetzung zugefügt worden sind, wobei besagte weichmachende Zusammensetzung 20 bis 98 Gew.-% Glycerin und 0,2 bis 5 Gew.-% wenigstens einer quaternären Ammoniumverbindung enthält, bei der es sich unter anderem um eine spezielle, eine quaternäre Ammoniumverbindung enthaltende Polysiloxanverbindung der allgemeinen Formel (6), wie nachstehend definiert, handeln kann. Weiter ist dort beschrieben, anstelle von Glycerin in Mengen von 0,5 bis 50 Gew.-% entweder 0,5 bis 50 Gew.-%, bezogen auf die Hauptkomponente, Propylenglykol und/oder Polyethylenglykol einzusetzen.The pre-filed post-published EP-A-0688901 relates a tissue paper containing 3 to 30% by weight of an aqueous softness mediating composition have been added, wherein said softening composition 20 to 98 wt .-% glycerol and 0.2 to 5% by weight of at least one quaternary Contains ammonium compound, which is, among others a special one containing a quaternary ammonium compound Polysiloxane compound of the general formula (6), such as defined below, can act. Next is there described, instead of glycerol in amounts of 0.5 to 50 % By weight either 0.5 to 50% by weight, based on the Main component, propylene glycol and / or polyethylene glycol to use.