EP0802328B1 - Hydraulic ram - Google Patents

Hydraulic ram Download PDFInfo

- Publication number

- EP0802328B1 EP0802328B1 EP96119475A EP96119475A EP0802328B1 EP 0802328 B1 EP0802328 B1 EP 0802328B1 EP 96119475 A EP96119475 A EP 96119475A EP 96119475 A EP96119475 A EP 96119475A EP 0802328 B1 EP0802328 B1 EP 0802328B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- ram

- bellows

- pressure

- jack

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 82

- 230000005540 biological transmission Effects 0.000 claims abstract 2

- 239000003380 propellant Substances 0.000 claims description 12

- 238000011144 upstream manufacturing Methods 0.000 claims description 2

- 230000035939 shock Effects 0.000 description 21

- 230000008901 benefit Effects 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 4

- 238000005192 partition Methods 0.000 description 4

- 238000007789 sealing Methods 0.000 description 4

- 238000006243 chemical reaction Methods 0.000 description 3

- 238000010276 construction Methods 0.000 description 3

- 230000008878 coupling Effects 0.000 description 3

- 238000010168 coupling process Methods 0.000 description 3

- 238000005859 coupling reaction Methods 0.000 description 3

- 238000009825 accumulation Methods 0.000 description 2

- 238000013016 damping Methods 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 210000000056 organ Anatomy 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000003139 buffering effect Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002352 surface water Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04F—PUMPING OF FLUID BY DIRECT CONTACT OF ANOTHER FLUID OR BY USING INERTIA OF FLUID TO BE PUMPED; SIPHONS

- F04F7/00—Pumps displacing fluids by using inertia thereof, e.g. by generating vibrations therein

- F04F7/02—Hydraulic rams

Definitions

- the invention relates to a hydraulic jack according to the preamble of claim 1, in particular for conversion less Amounts of water under great pressure into large amounts of water under little Print.

- Such jacks are already known from DE-C-804288.

- As a ram are referred to as jacks that reverse the conversion of large ones Amounts of water under low pressure into small amounts of water under large Pressure can be used.

- the jack according to the invention can both, i.e. it can optionally be used to increase pressure or flow become.

- Suction rams have been known at least since 1905 ("inertial machines as Possibility of hydraulic-mechanical energy conversion ", lecture by Ivan Cyphelly, Fegawerk / Switzerland, held at the IHP of the RWTH Aachen, Prof. Backé, June 21, 1991). They use a ram valve, which, like the hydraulic rams with drift pipe and natural slope through which hydrodynamic pressure drop caused by water flow through the valve is created, is closed suddenly.

- the ram valve is due to the sudden stopping of the propellant column exposed to a particularly high load, that of known suction rams is still considerably higher than with conventional hydraulic rams, at which by stopping the propellant column only the pressure at the valve is dammed up, which must be reached in order to convey into a wind boiler.

- This high load on the jack valve has an adverse effect on the Service life of the well-known suction ram.

- German patent application DE 19520343 described jack overcome, in which the jack valve is not as in the above mentioned prior art is formed as a check valve that by Spring force is kept open and closed by the motive water flow, but as closed by spring force and by the Driving water pressure open valve. Furthermore, the invention provides the jack valve in cooperation with one of the driving water acted upon pressure accumulator element in the manner of a resonant circuit cyclically actuate. Due to its construction, this suction ram can both work to increase pressure as well as increase volume flow.

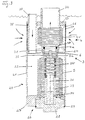

- Fig. 1 is a schematic representation of a first embodiment

- Fig. 2 shows a second embodiment of the in the not previously published DE 19520343 described jack.

- the hydraulic jack shown in Figs. 1 and 2 comprises in conventional Generally a driving water pipe 1, a delivery water pipe 2, a Jack valve 3 and a bottom valve 4 for sucking in conveyed water.

- the ram outlet 9 is located at the end of the production water line 2

- Jack valve 3 consists of a piston 3a and a piston 3a against a return spring 3b biasing a valve seat 6.

- the Shock valve 3 is held closed by a spring.

- the motive water line 1 is not only as in the state the technology with the pressure side of the jack valve 3, but also with a spring accumulator 5 is connected.

- the pressure storage element 5 is the one shown in FIGS. 1 and 2 Embodiments of the jack formed as a spring accumulator.

- the spring accumulator 5 has own housing 5c, which is upstream from the motive water line 1 Jack valve 3 communicates.

- housing 5c is a through Spring 5b biased piston 5a, which is the pressure-adjustable organ of the Accumulator element forms.

- the piston 3a, the return spring 3b and the valve seat of the jack valve 3 are also in in the embodiment of the jack shown in FIG its own, separate from the housing 5c housing 3c, so that the jack valve 3 and the spring accumulator 5 exclusively via the The motive water are in active connection with each other.

- the elements of the spring accumulator 5 and the jack valve 3 are in housed in a common housing 10 and mechanically with each other coupled: the piston 5a of the spring accumulator 5 is at the upper end of the coupled piston-spring system arranged, and the pressure spring 5b connects the piston 5a to the underlying piston 3a of the Shock valve 3, the return spring 3b extends in the downward direction and on a fixed abutment 11 is fixed in the housing 10. The bottom end of the housing is immersed in the pumped water and is through the bottom valve 4 locked.

- the driving water line opens into the housing 10 at the level of Storage spring 5b, while the production water pipe at the level of the lower End of the closing spring 3b branches from the housing.

- the closing spring 3b and the pressure spring 5b are in this Embodiment of the suction ram of Fig. 2 tension springs.

- shock jack shown in Figures 1 and 2 operates as follows:

- the motive water flows through the motive water line 1 and tensions the Accumulator spring 5b via the driving water pressure acting on the piston 5a (Accumulator phase) until the pressure on the surface of the jack valve piston 3a minus the area of the valve seat 6, the force of the reset or Shock valve closing spring 3b overcomes. Then the opens Shock valve 3 suddenly because with the beginning of the opening Driving water pressure acts on the surface of the entire lift valve piston 3a.

- the storage spring 5b now relaxes (relaxation phase) by the water mass in the delivery line 2 via a stroke movement of the piston 5a accelerates, causing the pressure in this line to drop until the force of the Closing spring 3b the pressure on the entire surface of the jack valve piston 3a overcomes and closes the jack valve.

- the now subsequent renewed pressure accumulation phase sucks the further flowing Water in the delivery line 2 water from the bottom valve 4 until the Water flow due to the counter pressure caused by the head to stop is coming. Thereupon, further relaxation and Pressure storage phases.

- the jack shown in FIG. 2 passes through like the one shown in FIG. 1 Shock lifter cyclical pressure storage and relaxation phases.

- the shock lifter shown in Fig. 1 takes over in the shock lifter of Fig. 2 Accumulator piston 5a due to its spring coupling to the Shock valve piston 3a partially its reversing function. That is, that Driving water tensions the pressure spring 5b over the piston 5a attacking motive water pressure (accumulator phase) until the pressure on his Area minus the area of the valve seat 6 the force of the reset or Shock valve closing spring 3b overcomes. Then the opens Shock valve 3 suddenly because with the beginning of the opening Driving water pressure acts on the surface of the entire pressure piston 5a.

- the pressure spring 5b now relaxes (relaxation phase) by the water mass in the delivery line 2 via a stroke movement of the piston 5a accelerates, causing the pressure in this line to drop until the force of the Closing spring 3b the pressure on the entire surface of the pressure accumulator piston 3a overcomes and closes the jack valve.

- the now subsequent renewed pressure accumulation phase sucks the further flowing Water in the delivery line 2 water from the bottom valve 4 until the Water flow due to the counter pressure caused by the head to stop is coming. Thereupon, further relaxation and Pressure storage phases.

- Fig. 2 is additionally in a free space of the housing 10 above the piston 3b an air-filled hose 8 is arranged, the pulsating movements of the Buffer valve piston 3b and the water in the delivery line 2, thereby ensuring a relatively quiet mass flow at the jack outlet 9 becomes.

- other known buffering means can also be used be used.

- the object of the present invention is a hydraulic To provide a jack that has a high efficiency with a compact structure and ensures a long service life, and both print and can be used to increase the volume flow.

- the hydraulic jack according to the invention is basically the same constructed as shown in Figs. 1 and 2 and explained above.

- a A special feature of the jack according to the invention is a mechanical one Coupling the valve seat of the jack valve with the valve seat of the Bottom valve in such a way that the kinetic energy, which when closing one Valve occurs on the other valve to open its valve member is transmitted. This is already achieved in addition to the above Treated advantages of such a jack an energetically more favorable Business.

- Another advantage is that the harmful route between the two Valves, which is a problem in the prior art because of the kinetic Energy of the water cannot be used in this link and can cause cavitation when the jack is closed, can be kept optimally short.

- this makes it more compact Construction of the jack ensures that the jack valve and Bottom valve are arranged in the immediate vicinity and axially.

- the compact structure benefits from a design of the pressure accumulator Shape of a bellows, the valve member of the Bump valve carries. It also works in favor of the compact design the arrangement of the return spring for the valve member of the jack valve inside the pressure bellows. Finally comes According to the compact structure, a formation of the return spring for the bottom valve in the form of a bellows, the so in the pump is arranged that it is penetrated by the pumped water.

- FIG. 3 shows a longitudinal sectional view through a preferred Embodiment of the jack according to the invention.

- Functionally identical parts As in FIGS. 1 and 2, the same reference numerals are used in FIG. 3.

- the jack shown in FIG. 3 has a generally tubular housing 20 on, with a cylindrical jacket 21 which at one, in Fig. 3 lower end, is closed by a bottom 22 and on its other, in Fig. 3rd upper end, is closed by a cover 23.

- the inside of the tubular housing 20 is axially through a partition 24 in a sub-chamber 24 with a larger volume and a sub-chamber 26 with a smaller volume divided.

- the bottom 22 of the housing 20 is in the illustrated embodiment formed in two parts and comprises a ring 27, the outer periphery of which Corresponds to the outer circumference of the jacket 21, and its eccentric inner circumference has an internal thread, into which a plug 28 with an external thread is screwed in.

- a ring 27 Corresponds to the outer circumference of the jacket 21, and its eccentric inner circumference has an internal thread, into which a plug 28 with an external thread is screwed in.

- an annular groove is formed on the outer circumference of the sealing plug 28, in which sits an O-ring 29 which is supported on the inner circumference of the ring 27.

- a motive water pipe is connected to an inlet pipe 30 connected, a hole in the cover 23 and a corresponding hole interspersed in the partition 24.

- Inlet pipe 30 tightly connected.

- a tubular valve seat carrier 31 is inserted tightly, one into the smaller one Has partial chamber 26 protruding ring part 4a, which with its cover 23rd facing outside forms a valve seat 4a of the bottom valve 4, the also has a return spring 4c, which is formed as a bellows, with one end of which the valve member 4b is fixedly connected, and the other End is firmly connected to a pipe connection 32, which has a hole in the lid 23, interspersed with this and connected to a not shown Delivery line is connected.

- valve seat 6 is formed in the form of a conical surface, which extends in the direction of the valve seat 4a of the bottom valve 4 tapers and to cooperate with a complementary spherical surface on the valve member 3a of the Shock valve 3 cooperates, also in the form of a circular disc is formed, which is fixed to the one, in Fig. 3 upper end of a bellows 5th is connected, which, as explained below, the pressure accumulator of the Shock lifter forms and with the other end firmly with the inner surface of the Sealing plug 28 is connected in the bottom of the housing 20.

- the valve body 3 a of the jack valve 3 has a central bore that of is penetrated by a cylindrical body 35 which with its bottom valve 4 facing end into the interior enclosed by the valve seat support 31 protrudes, and which is flared at the other end, this flange-like end part for fastening the valve body 3 to the bellows 5.

- a Bracket body for the return spring 3b formed by this spring is embraced. This body as well as the flange end of the cylindrical body 35 and this itself is completely penetrated by a capillary bore their extension takes place in a capillary tube 36, which is in the Bottom region of the holding tube 33 extends.

- the casing of the housing 20 is in the region of the smaller subchamber 26 preferably broken in several places, and in these openings sit metal screens 37 and 38.

- FIG. 3 schematically by a wavy line at the top of the Shown jack, this is under the surface of a water reservoir submerged.

- the pressure in sub-chamber 25 acts when open Shock valve 3 on the interior of the bellows 4c, which is the return spring forms for the bottom valve 4, which is still closed at this time, and that existing conveyor water in this interior, and accelerates it, whereby the pressure continues to drop until it falls below the value at which the return spring 3b presses the valve body 3 again against its valve seat and thereby closes the jack valve, the pressure in the sub-chamber 25 is rebuilt.

- valve seats for the bottom valve 4 and the jack valve 3 is the Closing energy of the respective valve advantageously for opening the respective other valve used.

- This advantage is with conventionally built Shock jacks cannot be achieved because the valve seats of the two in question Valves (the bottom valve is a reset valve!) Separated from each other are designed so that kinetic energy does not pass from one valve to another can be transferred. Rather, the one that is released when it is closed kinetic energy through damping, for example in the sealing rubber of the valve destroyed. Such damping is conventionally also required around the so-called bouncing of the respective valve member on the valve seat prevent. This hopping occurs in those trained according to the invention the valve seat interconnected or formed from the same material Valves on because the kinetic energy from the closing valve in the other valve is initiated in order to trigger or close it support.

- valve member is axially flowed against, and the flow runs radially apart after the flow between the valve member and through the valve seat.

- flow of the according to the invention with common valve seat designed valves between the valve members and the associated seats radially inwards together and then axially away from the respective valve. And that's the only way given a common valve seat.

- Another advantage of Coupling the valve seats of the two valves according to the invention consists in that the distance between the two valves is kept negligibly short can be.

- the jack according to the invention can also be operated as a normal ram. For this it is only necessary to provide an additional spring causes the bottom valve 4 to be open in the rest position.

- the way of working of this modified jack is as follows:

- the production water is due to its natural gradient accelerates, and it passes through the open bottom valve 4 on the Pipe connection 32 into the open until a hydrodynamic vacuum between the Valve member 4b and the valve seat 4a and a dynamic pressure in the bellows 4c Close the bottom valve 4.

- the jack valve 3 opens and the kinetic energy of the pumped water loads the spring accumulator (bellows 5), whereby the jack valve 3 closes again and the process as explained above, starts over.

- the spring accumulator bellows 5 however already loaded (i.e. no pressurized water is used) that excludes Bottom valve 4 not when the water has stopped, but only after the excess energy from the spring accumulator Pumped water has accelerated in reverse or backwards.

- the jack valve 3 After this Closing the jack valve 3 then sucks the pumped water through the bottom valve 4 water until the direction of flow reverses. The means, if no pressurized water is required, the consumption of the Pumped water back to a minimum.

- the purpose of the capillary tube 36 or the capillary opening in the valve member is that the pressure inside the bellows 5 is equal to the middle Pressure in the bellows 4c or in the delivery line is. This ensures that the pressure difference between motive water and production water, at which the The jack valve opens regardless of the delivery head. And that's what it is Load on the external motive water pump always the same regardless of whether the jack is used to remove large amounts of surface water or to pump small amounts of water from a great depth.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Reciprocating Pumps (AREA)

- Fluid-Pressure Circuits (AREA)

- Details Of Reciprocating Pumps (AREA)

- Surgical Instruments (AREA)

- Glass Compositions (AREA)

- Supply Devices, Intensifiers, Converters, And Telemotors (AREA)

- Switches With Compound Operations (AREA)

- Pipe Accessories (AREA)

- Vehicle Body Suspensions (AREA)

- Percussive Tools And Related Accessories (AREA)

- Braking Systems And Boosters (AREA)

- Lubrication Of Internal Combustion Engines (AREA)

- Valve Device For Special Equipments (AREA)

Abstract

Description

Die Erfindung betrifft einen hydraulischen Stoßheber gemäß Oberbegriff Anspruch 1, insbesondere zur Umwandlung geringer

Wassermengen unter großen Druck in große Wassermengen unter geringem

Druck. Derartige Stoßheber sind bereits aus der DE-C-804288 bekannt. Als Widder

werden Stoßheber bezeichnet, die umgekehrt zur Umwandlung von großen

Wassermengen unter geringem Druck in geringe Wassermengen unter großem

Druck eingesetzt werden können. Der erfindungsgemäße Stoßheber kann

beides, d.h. er kann wahlweise druck- oder volumenstromerhöhend eingesetzt

werden.The invention relates to a hydraulic jack according to the preamble of

Saugwidder sind mindestens seit 1905 bekannt ("Trägheitsmaschinen als Möglichkeit der hydraulisch-mechanischen Energieumformung", Vortrag von Ivan Cyphelly, Fegawerk/Schweiz, gehalten am IHP der RWTH Aachen, Prof. Backé, 21. Juni 1991). Sie verwenden ein Widderventil, das, wie bei den hydraulischen Widdern mit Treibwasserrohr und natürlichem Gefälle, durch den hydrodynamischen Druckabfall, der durch die Wasserströmung durch das Ventil hindurch entsteht, schlagartig geschlossen wird.Suction rams have been known at least since 1905 ("inertial machines as Possibility of hydraulic-mechanical energy conversion ", lecture by Ivan Cyphelly, Fegawerk / Switzerland, held at the IHP of the RWTH Aachen, Prof. Backé, June 21, 1991). They use a ram valve, which, like the hydraulic rams with drift pipe and natural slope through which hydrodynamic pressure drop caused by water flow through the valve is created, is closed suddenly.

Bei bekannten Saugwiddern (z.B. Deutsches Patent N 804 288, 1949, oder bei dem heute noch gebauten Saugwidder der Fa. Fegawert S.A. Le Locie/Schweiz) wird beim Schließen des Widderventils die kinetische Energie des fließenden Wassers in der Treibwasserleitung vernichtet, weil das Treibwasser abgestoppt wird. Um diesen Verlust möglichst klein zu halten, hat der Saugwidder des Fegawerks als Treibwasserleitung einen Schlauch mit extrem großem Querschnitt, wodurch außerdem hohe Geschwindigkeiten des Treibwassers vermieden werden.In known suction rams (e.g. German Patent N 804 288, 1949, or at the suction ram made by Fegawert S.A. Le Locie / Switzerland) when the ram valve closes, the kinetic energy of the flowing Water in the drift water pipe is destroyed because the drift water has stopped becomes. In order to keep this loss as small as possible, the Saugwidder has the Fegawerks as a drift water pipe a hose with an extremely large size Cross section, which also causes high speeds of the motive water be avoided.

Die vorstehend genannten, bekannten Saugwidder erfordern für eine einwandfreie Funktion einen bestimmten konstanten Treibwassermengenstrom, da dann, wenn der benötigte Treibwassermengenstrom unterschritten wird, das Stoßheberventil nicht mehr schließt und der Wirkungsgrad auf Null abfällt. The aforementioned known suction rams require for a perfect functioning of a certain constant motive water flow, because when the required motive water flow rate falls below that The jack valve no longer closes and the efficiency drops to zero.

Das Widderventil ist durch das schlagartige Abstoppen der Treibwassersäule einer besonders hohen Belastung ausgesetzt, die bei bekannten Saugwiddern noch erheblich höher ist als bei herkömmlichen hydraulischen Widdern, bei denen durch das Abstoppen der Treibwassersäule nur der Druck am Ventil aufgestaut wird, der erreicht werden muß, um in einen Windkessel zu fördern. Diese hohe Belastung des Stoßheberventils wirkt sich ungünstig auf die Standzeit des bekannten Saugwidders aus.The ram valve is due to the sudden stopping of the propellant column exposed to a particularly high load, that of known suction rams is still considerably higher than with conventional hydraulic rams, at which by stopping the propellant column only the pressure at the valve is dammed up, which must be reached in order to convey into a wind boiler. This high load on the jack valve has an adverse effect on the Service life of the well-known suction ram.

Diese Nachteile werden durch den in der nicht vorveröffentlichten (EPÜ Art. 54(3)) deutschen Patentanmeldung DE 19520343 beschriebenen Stoßheber überwunden, bei dem das Stoßheberventil nicht wie beim vorstehend genannten Stand der Technik als Rückschlagventil gebildet ist, das durch Federkraft offengehalten und durch die Treibwasserströmung geschlossen wird, sondern als durch Federkraft geschlossen gehaltenes und durch den Treibwasserdruck geöffnetes Ventil. Ferner ist erfindungsgemäß vorgesehen, das Stoßheberventil in Zusammenwirkung mit einem ebenfalls vom Treibwasser beaufschlagten Druckspeicherelement in Art eines Schwingkreises zyklisch zu betätigen. Dieser Saugwidder kann aufgrund seiner Konstruktion sowohl druckerhöhend als auch volumenstromerhöhend arbeiten.These disadvantages are exacerbated by the (EPC Art. 54 (3)) German patent application DE 19520343 described jack overcome, in which the jack valve is not as in the above mentioned prior art is formed as a check valve that by Spring force is kept open and closed by the motive water flow, but as closed by spring force and by the Driving water pressure open valve. Furthermore, the invention provides the jack valve in cooperation with one of the driving water acted upon pressure accumulator element in the manner of a resonant circuit cyclically actuate. Due to its construction, this suction ram can both work to increase pressure as well as increase volume flow.

Da der Treibwasserdruck bei diesem Stoßheber vor der Öffnung des Stoßheberventils durch das druckverstellbare Organ eines Druckspeicherelements aufgenommen wird, ist gewährleistet, daß das Treibwasser beim Betrieb des Stoßhebers nicht schlagartig abstoppt, sondern diesem kontinuierlich zugeführt werden kann, wodurch das Stoßheberventil im Vergleich zum Stand der Technik deutlich entlastet wird, was der Standzeit des Stoßhebers insgesamt zugute kommt.Because the propellant pressure in this jack before opening the Shock valve through the pressure-adjustable organ of a Pressure storage element is added, it is ensured that the Driving water does not suddenly stop when the jack is in operation, but instead this can be fed continuously, whereby the jack valve in Relative to the prior art is significantly relieved, which the service life of the Overall, the jack will benefit.

Erreicht wird durch den Aufbau des Stoßheberventils dieses Stoßhebers als Schließventil und dessen Ansteuerung durch das Treibwasser im Verbund mit einem Druckspeicherelement ferner, daß das Stoßheberventil auch bei kleinstem Treibwassermengenstrom noch öffnet, da der Öffnungsdruck für das Stoßheberventil durch das Druckspeicherelement auch bei minimalem Treibwasserstrom aufgebaut wird. Erreicht wird damit also eine deutliche Steigerung des Wirkungsgrads des Stoßhebers im Vergleich zu dem vorstehend abgehandelten Saugwidder. Is achieved by the construction of the jack valve of this jack as Closing valve and its control by the motive water in association with a pressure storage element that the jack valve even at the smallest The motive water flow still opens because the opening pressure for the Shock valve through the pressure storage element even with minimal Driving water flow is built up. So a clear one is achieved Increasing the efficiency of the jack compared to that above traded suction rams.

Weitere Einzelheiten dieses Stoßhebers sind nachfolgend anhand von Fig. 1 und 2 der Zeichnung näher erläutert, demnach zeigen:Further details of this jack are given below with reference to FIGS. 1 and 2 of the drawing explained in more detail:

Fig. 1 eine schematische Darstellung einer ersten Ausführungsform, und Fig. 2 eine zweite Ausführungsform des in der nicht vorveröffentlichten DE 19520343 beschriebenen Stoßhebers.Fig. 1 is a schematic representation of a first embodiment, and Fig. 2 shows a second embodiment of the in the not previously published DE 19520343 described jack.

Der in Fig. 1 und 2 gezeigte hydraulische Stoßheber umfaßt in herkömmlicher

Weise allgemein eine Treibwasserleitung 1, eine Förderwasserleitung 2, ein

Stoßheberventil 3 und ein Bodenventil 4 zum Ansaugen von Förderwasser. Am

Ende der Förderwasserleitung 2 befindet sich der Widderaustritt 9. Das

Stoßheberventil 3 besteht aus einem Kolben 3a und einer den Kolben 3a gegen

einen Ventilsitz 6 vorspannenden Rückstell- bzw. Schließfeder 3b. Das

Stoßheberventil 3 wird durch eine Feder zugehalten.The hydraulic jack shown in Figs. 1 and 2 comprises in conventional

Generally a

Ferner ist vorgesehen, daß die Treibwasserleitung 1 nicht nur wie beim Stand

der Technik mit der Druckseite des Stoßheberventils 3, sondern zusätzlich mit

einem Federspeicher 5 in Verbindung steht.It is also provided that the

Das Druckspeicherelement 5 ist bei den in den Fig. 1 und 2 gezeigten

Ausführungsformen des Stoßhebers als Federspeicher gebildet.The

Gemäß der in Fig. 1 gezeigten Ausführungsform weist der Federspeicher 5 ein

eigenes Gehäuse 5c, das mit der Treibwasserleitung 1 stromauf vom

Stoßheberventil 3 kommuniziert. Im Gehäuse 5c befindet sich ein durch eine

Feder 5b vorgespannter Kolben 5a, der das druckverstellbare Organ des

Druckspeicherelements bildet.According to the embodiment shown in FIG. 1, the

Der Kolben 3a, die Rückstellfeder 3b und der Ventilsitz des Stoßheberventils 3

sind bei der in Fig. 1 gezeigten Ausführungsform des Stoßhebers ebenfalls in

einem eigenen, vom Gehäuse 5c getrennten Gehäuse 3c untergebracht, so daß

das Stoßheberventil 3 und der Federspeicher 5 ausschließlich über das

Treibwasser in Wirkverbindung miteinander stehen. The piston 3a, the

In Fig. 2 sind die Elemente des Federspeichers 5 und des Stoßheberventils 3 in

einem gemeinsamen Gehäuse 10 untergebracht und mechanisch miteinander

gekoppelt: Der Kolben 5a des Federspeichers 5 ist am oberen Ende des

gekoppelten Kolben-Federsystems angeordnet, und die Druckspeicherfeder 5b

verbindet den Kolben 5a mit dem darunter liegenden Kolben 3a des

Stoßheberventils 3, dessen Rückstellfeder 3b in Abwärtsrichtung verläuft und an

einem ortsfesten Widerlager 11 im Gehäuse 10 festgesetzt ist. Das untere Ende

des Gehäuses taucht in das Förderwasser ein und ist durch das Bodenventil 4

verschlossen.In Fig. 2, the elements of the

Die Treibwasserleitung mündet in das Gehäuse 10 auf der Höhe der

Speicherfeder 5b, während die Förderwasserleitung auf der Höhe des unteren

Endes der Schließfeder 3b vom Gehäuse abzweigt.The driving water line opens into the

Die Schließfeder 3b und die Druckspeicherfeder 5b sind bei dieser

Ausführungsform des Saugwidders von Fig. 2 Zugfedern.The

Der in den Fig. 1 und 2 gezeigte Stoßheber arbeitet wie folgt:The shock jack shown in Figures 1 and 2 operates as follows:

Das Treibwasser strömt durch die Treibwasserleitung 1 und spannt die

Druckspeicherfeder 5b über den am Kolben 5a angreifenden Treibwasserdruck

(Druckspeicherphase), bis der Druck auf die Fläche des Stoßheberventilkolbens

3a abzüglich der Fläche des Ventilsitzes 6 die Kraft der Rückstell- bzw.

Stoßheberventil-Schließfeder 3b überwindet. Daraufhin öffnet das

Stoßheberventil 3 schlagartig, da mit dem Beginn des Öffnens der

Treibwasserdruck auf die Fläche des gesamten Stoßheberventilkolbens 3a wirkt.

Die Speicherfeder 5b entspannt sich nunmehr (Entspannungsphase), indem sie

die Wassermasse in der Förderleitung 2 über eine Hubbewegung des Kolbens 5a

beschleunigt, wodurch der Druck in dieser Leitung fällt, bis die Kraft der

Schließfeder 3b den Druck auf die gesamte Fläche des Stoßheberventilkolbens

3a überwindet und das Stoßheberventil schließt. In der sich nunmehr

anschließenden erneuten Druckspeicherphase saugt das weiterströmende

Wasser in der Förderleitung 2 Wasser aus dem Bodenventil 4, bis die

Wasserströmung aufgrund des Gegendrucks durch die Förderhöhe zum Erliegen

kommt. Daraufhin laufen zyklisch weitere Entspannungs- und

Druckspeicherphasen ab. The motive water flows through the

Der in der Fig. 2 gezeigte Stoßheber durchläuft wie der in Fig. 1 gezeigte

Stoßheber zyklisch Druckspeicher- und Entspannungsphasen. Im Gegensatz zu

dem in Fig. 1 gezeigten Stoßheber übernimmt bei dem Stoßheber von Fig. 2 der

Druckspeicher-Kolben 5a aufgrund seiner Federkopplung an den

Stoßheberventilkolben 3a partiell dessen Umsteuerfunktion. Das heißt, das

Treibwasser spannt die Druckspeicherfeder 5b über den am Kolben 5a

angreifenden Treibwasserdruck (Druckspeicherphase), bis der Druck auf seine

Fläche abzüglich der Fläche des Ventilsitzes 6 die Kraft der Rückstell- bzw.

Stoßheberventil-Schließfeder 3b überwindet. Daraufhin öffnet das

Stoßheberventil 3 schlagartig, da mit dem Beginn des Öffnens der

Treibwasserdruck auf die Fläche des gesamten Druckspeicher-Kolbens 5a wirkt.

Die Druckspeicherfeder 5b entspannt sich nunmehr (Entspannungsphase), indem

sie die Wassermasse in der Förderleitung 2 über eine Hubbewegung des Kolbens

5a beschleunigt, wodurch der Druck in dieser Leitung fällt, bis die Kraft der

Schließfeder 3b den Druck auf die gesamte Fläche des Druckspeicher-Kolbens

3a überwindet und das Stoßheberventil schließt. In der sich nunmehr

anschließenden erneuten Druckspeicherphase saugt das weiterströmende

Wasser in der Förderleitung 2 Wasser aus dem Bodenventil 4, bis die

Wasserströmung aufgrund des Gegendrucks durch die Förderhöhe zum Erliegen

kommt. Daraufhin laufen zyklisch weitere Entspannungs- und

Druckspeicherphasen ab.The jack shown in FIG. 2 passes through like the one shown in FIG. 1

Shock lifter cyclical pressure storage and relaxation phases. In contrast to

the shock lifter shown in Fig. 1 takes over in the shock lifter of Fig. 2

Accumulator piston 5a due to its spring coupling to the

Shock valve piston 3a partially its reversing function. That is, that

Driving water tensions the pressure spring 5b over the piston 5a

attacking motive water pressure (accumulator phase) until the pressure on his

Area minus the area of the

In Fig. 2 ist zusätzlich in einem Freiraum des Gehäuses 10 über dem Kolben 3b

ein luftgefüllter Schlauch 8 angeordnet, der die pulsierenden Bewegungen des

Stoßheberventilkolbens 3b und des Wassers in der Förderleitung 2 abpuffert,

wodurch am Stoßheberaustritt 9 ein relativ ruhiger Massenstrom gewährleistet

wird. Grundsätzlich können auch andere bekannte Mittel zur Pufferung

verwendet werden.In Fig. 2 is additionally in a free space of the

Die Aufgabe der vorliegenden Erfindung besteht darin, einen hydraulischen Stoßheber bereitzustellen, der bei kompaktem Aufbau einen hohen Wirkungsgrad und eine lange Standzeit gewährleistet, und sowohl druck- wie volumenstromerhöhend betrieben werden kann. The object of the present invention is a hydraulic To provide a jack that has a high efficiency with a compact structure and ensures a long service life, and both print and can be used to increase the volume flow.

Gelöst wird diese Aufgabe durch die Merkmale des Anspruchs 1. Vorteilhafte

Weiterbildungen der Erfindung sind in den Unteransprüchen angegeben.This problem is solved by the features of

Demnach ist der erfindungsgemäße hydraulische Stoßheber vom Prinzip her so aufgebaut, wie in Fig. 1 und 2 gezeigt und vorstehend erläutert. Eine Besonderheit des erfindungsgemäßen Stoßhebers besteht in einer mechanischen Kopplung des Ventilsitzes des Stoßheberventils mit dem Ventilsitz des Bodenventils derart, daß die kinetische Energie, die beim Schließen des einen Ventils auftritt, auf das andere Ventil zum Öffnen dessen Ventilorgans übertragen wird. Erreicht wird dadurch zusätzlich zu den vorstehend bereits abgehandelten Vorteilen eines derartigen Stoßhebers ein energetisch günstiger Betrieb. Ein weiterer Vorteil ist, daß die schädliche Strecke zwischen den beiden Ventilen, die beim Stand der Technik ein Problem darstellt, weil die kinetische Energie des Wassers in dieser Verbindungsstrecke nicht genutzt werden kann und beim Schließen des Stoßhebers zu Kavitation an diesem führen kann, optimal kurz gehalten werden kann. Schließlich wird dadurch ein kompakter Aufbau des Stoßhebers gewährleistet, daß das Stoßheberventil und das Bodenventil in unmittelbarer Nachbarschaft sowie axial angeordnet sind.Accordingly, the hydraulic jack according to the invention is basically the same constructed as shown in Figs. 1 and 2 and explained above. A A special feature of the jack according to the invention is a mechanical one Coupling the valve seat of the jack valve with the valve seat of the Bottom valve in such a way that the kinetic energy, which when closing one Valve occurs on the other valve to open its valve member is transmitted. This is already achieved in addition to the above Treated advantages of such a jack an energetically more favorable Business. Another advantage is that the harmful route between the two Valves, which is a problem in the prior art because of the kinetic Energy of the water cannot be used in this link and can cause cavitation when the jack is closed, can be kept optimally short. Ultimately, this makes it more compact Construction of the jack ensures that the jack valve and Bottom valve are arranged in the immediate vicinity and axially.

Dem kompakten Aufbau zugute kommt eine Ausbildung des Druckspeichers in Gestalt eines Faltenbalgs, der an einem Ende das Ventilorgan des Stoßheberventils trägt. Ebenfalls zugunsten des kompakten Ausbaus wirkt sich die Anordnung der Rückstellfeder für das Ventilorgan des Stoßheberventils innerhalb des Druckspeicher-Faltenbalgs aus. Schließlich kommt erfindungsgemäß dem kompakten Aufbau eine Bildung der Rückstellfeder für das Bodenventil in Gestalt eines Faltenbalgs zugute, der in der Pumpe so angeordnet ist, daß er vom Förderwasser durchsetzt ist.The compact structure benefits from a design of the pressure accumulator Shape of a bellows, the valve member of the Bump valve carries. It also works in favor of the compact design the arrangement of the return spring for the valve member of the jack valve inside the pressure bellows. Finally comes According to the compact structure, a formation of the return spring for the bottom valve in the form of a bellows, the so in the pump is arranged that it is penetrated by the pumped water.

Nachfolgend wird die Erfindung anhand von Fig. 3 der Zeichnung beispielhaft näher erläutert; diese zeigt eine Längsschnittansicht durch eine bevorzugte Ausführungsform des erfindungsgemäßen Stoßhebers. Funktionell gleiche Teile wie in Fig. 1 und 2 sind in Fig. 3 mit denselben Bezugsziffern bezeichnet.The invention will now be described by way of example with reference to FIG. 3 of the drawing explained in more detail; this shows a longitudinal sectional view through a preferred Embodiment of the jack according to the invention. Functionally identical parts As in FIGS. 1 and 2, the same reference numerals are used in FIG. 3.

Der in Fig. 3 gezeigte Stoßheber weist ein allgemein rohrförmiges Gehäuse 20

auf, mit einem zylindrischen Mantel 21, der an einem, in Fig. 3 unteren Ende,

durch einen Boden 22 verschlossen ist, und der an seinem anderen, in Fig. 3

oberen Ende, durch einen Deckel 23 verschlossenen ist. Das Innere des

rohrförmigen Gehäuses 20 ist durch eine Trennwand 24 axial in eine

volumengrößeren Teilkammer 24 und eine volumenkleineren Teilkammer 26

unterteilt.The jack shown in FIG. 3 has a generally

Der Boden 22 des Gehäuses 20 ist in der dargestellten Ausführungsform

zweiteilig gebildet und umfaßt einen Ring 27, dessen Außenumfang dem

Außenumfang des Mantel 21 entspricht, und dessen azentrischer Innenumfang

ein Innengewinde aufweist, in das ein Verschlußstopfen 28 mit Außengewinde

eingeschraubt ist. Zur Abdichtung der Teile 27 und 28 in bezug aufeinander ist

am Außenumfang des Verschlußstopfens 28 eine Ringnut ausgebildet, in

welcher ein O-Ring 29 sitzt, der sich am Innenumfang des Rings 27 abstützt.The

Eine nicht dargestellte Treibwasserleitung ist an ein Einlaßrohr 30

angeschlossen, das eine Bohrung im Deckel 23 und eine entsprechende Bohrung

in der Trennwand 24 durchsetzt. Zumindest mit der Trennwand 24 ist das

Einlaßrohr 30 dicht verbunden. In eine weitere Bohrung der Trennwand 24 ist

dicht ein rohrförmiger Ventilsitzträger 31 eingesetzt, der einen in die kleinere

Teilkammer 26 ragenden Ringteil 4a aufweist, der mit seiner zum Deckel 23

weisenden Außenseite einen Ventilsitz 4a des Bodenventils 4 bildet, das

außerdem eine Rückstellfeder 4c aufweist, die als Faltenbalg gebildet ist, mit

dessen einem Ende das Ventilorgan 4b fest verbunden ist, und dessen anderes

Ende fest mit einem Rohranschluß 32 verbunden ist, der eine Bohrung im Deckel

23, durchsetzt fest mit diesem verbunden und an eine nicht gezeigte

Förderleitung angeschlossen ist. Am anderen Ende des Ventilsitzträgers 31 ist

ein Ventilsitz 6 in Gestalt einer Konusfläche gebildet, die sich in Richtung auf

den Ventilsitz 4a des Bodenventils 4 verjüngt und zur Zusammenwirkung mit

einer komplementär dazu gebildeten Kugelfläche am Ventilorgan 3a des

Stoßheberventils 3 zusammenwirkt, das ebenfalls in Gestalt einer Kreisscheibe

gebildet ist, die fest mit dem einen, in Fig. 3 oberen Ende eines Faltenbalgs 5

verbunden ist, der, wie nachfolgend erläutert, den Druckspeicher des

Stoßhebers bildet und mit dem anderen Ende fest mit der Innenfläche des

Verschlußstopfens 28 im Boden des Gehäuses 20 verbunden ist. An der

Innenseite des ringförmigen Stoßheberventilorgans 3 stützt sich eine

Rückstellfeder 3b ab, deren anderes Ende am oberen Ende eines Stützrohrs 33

abgestützt ist, das mit seinem anderen Ende in einer Bohrung des

Verschlußstopfens 28 eingesetzt und mit diesem fest verbunden ist. Am unteren

Ende wird das Stützrohr 33 radial von Bohrungen 34 durchsetzt, die einerseits

in das Innere des Rohrs 33 und andererseits in den durch den Faltenbalg 5

umschlossenen Innenraum mündet.A motive water pipe, not shown, is connected to an

Der Ventilkörper 3a des Stoßheberventils 3 hat eine zentrale Bohrung, die von

einem zylindrischen Körper 35 durchsetzt ist, der mit seinem zum Bodenventil 4

weisenden Ende in den vom Ventilsitzträger 31 umschlossenen Innenraum

vorsteht, und der am anderen Ende flanschartig verbreitert ist, wobei dieses

flanschartige Endteil zur Befestigung des Ventilkörpers 3 am Faltenbalg 5 dient.

Auf der zum Faltenbalg 5 weisenden Seite des Flansches ist ein

Halterungskörper für die Rückstellfeder 3b gebildet, der von dieser Feder

umgriffen wird. Dieser Körper sowie das Flanschende des zylindrischen Körpers

35 und dieser selbst ist von einer Kapillarbohrung vollständig durchsetzt, die

ihre Verlängerung in einem Kapillarrohr 36 findet, das sich bis in den

Bodenbereich des Halterohrs 33 erstreckt.The valve body 3 a of the

Der Mantel des Gehäuses 20 ist im Bereich der kleineren Teilkammer 26

vorzugsweise an mehreren Stellen durchbrochen, und in diesen Durchbrüchen

sitzen Metallsiebe 37 und 38.The casing of the

Wie in Fig. 3 schematisch durch eine Wellenlinie am oberen Ende des Stoßhebers dargestellt, ist dieser unter die Oberfläche eines Wasserreservoirs getaucht.As shown in Fig. 3 schematically by a wavy line at the top of the Shown jack, this is under the surface of a water reservoir submerged.

Nachfolgend wird die Funktionsweise des erfindungsgemäßen Stoßhebers erläutert, der wie vorstehend anhand von Fig. 3 erläutert, aufgebaut ist.The mode of operation of the jack according to the invention is described below explained, which is constructed as explained above with reference to FIG. 3.

Von einer nicht dargestellten externen Pumpe wird Treibwasser über den

Anschlußstutzen 30 in die untere Teil- bzw. Druckkammer 1 des Stoßhebers

gepumpt. Da das Ventilorgan 3 durch die Rückstellfeder 3b in der

Schließstellung gegen den Ventilsitz 6 des Stoßheberventils 3 gehalten wird,

steigt der Druck in der Druckkammer außerhalb des Faltenbalgs 5, und dieser

steigende Druck führt zu einer elastischen Verformung des bevorzugt aus Metall

bestehenden Faltenbalgs 4. Das heißt, die Falten des Faltenbalgs 5 erfüllen die

Funktion eines Federspeichers für den hydraulischen Saugwidder. From an external pump, not shown, propellant is over the

Der sich in der Teilkammer 25 aufbauende Flüssigkeitsdruck bewirkt eine

steigende Kraft auf die das Stoßheberventilorgan 3a tragende Stirnfläche des

Faltenbalgs 5, und dieser Druck überwindet schließlich die Schließkraft der

Rückstellfeder 3b. Dadurch öffnet das Stoßheberventil 3 bzw. sein Ventilorgan

3a kommt von seinem Ventilsitz frei, und der in der Druckkammer 25

vorhandene Flüssigkeitsdruck wirkt nunmehr auf die gesamte Stirnfläche des

Faltenbalgs 5 bzw. die Außenfläche des Ventilorgans 3a, wodurch das

Stoßheberventil 3 noch weiter öffnet, und wodurch der Druck im Teilraum 25

geringfügig abfällt. Außerdem wirkt der Druck in der Teilkammer 25 bei offenem

Stoßheberventil 3 auf den Innenraum des Faltenbalgs 4c, der die Rückstellfeder

für das Bodenventil 4 bildet, das in diesem Zeitpunkt noch geschlossen, und das

in diesem Innenraum vorhandene Förderwasser, und beschleunigt dieses,

wodurch der Druck weiter abfällt, bis er denjenigen Wert unterschreitet, bei dem

die Rückstellfeder 3b den Ventilkörper 3 wieder gegen seinen Ventilsitz drückt

und dadurch das Stoßheberventil schließt, wobei der Druck in der Teilkammer

25 erneut aufgebaut wird.The liquid pressure building up in the sub-chamber 25 causes one

increasing force on the end face of the shock-absorbing valve element 3a

Bellows 5, and this pressure finally overcomes the closing force of the

Die durch das Schließen des Stoßheberventils 3 auf den zugehörigen Ventilsitz 6

übertragene kinetische Energie wird über den Ventilsitzträger 31 auf den

Ventilsitz 4a des Bodenventils 4 übertragen, und durch diesen elastischen Stoß

öffnet dieses Ventil. Gleichzeitig wird die dem Förderwasser mitgeteilte

kinetische Energie verbraucht, indem das Förderwasser durch das nunmehr

offene Bodenventil 4 - der Ventilkörper 4b ist vom Ventilsitz 4a abgehoben -

entgegen der Schwerkraft des Förderwassers Wasser aus der Umgebung

ansaugt. Dabei wird das Bodenventil 4 durch einen geringen Unterdruck im

Faltenbalg 4c offengehalten. Sobald die im Förderwasser enthaltene Energie

aufgebraucht ist, wird das Bodenventil 4 durch die im Faltenbalg 4c

innewohnende Federkraft wieder geschlossen.By closing the

Die kinetische Energie dieses Schließvorgangs wird durch einen elastischen Stoß

über den Ventilsitzträger 31 auf den Ventilsitz 6 des Stoßheberventils 3 und von

diesem auf das Ventilorgan 3a des Stoßheberventils 3 übertragen, wodurch

dieses geöffnet wird. Gleichzeitig schwingt das soeben stehengebliebene

Förderwasser aufgrund der Elastizität des Faltenbalgs 4c geringfügig zurück und

erzeugt einen kleinen Setzstoß, der das Öffnen des Stoßheberventils unterstützt. The kinetic energy of this closing process is caused by an elastic impact

via the

Aufgrund der erfindungsgemäß mechanisch gekoppelten bzw. einteilig

gebildeten Ventilsitze für das Bodenventil 4 und das Stoßheberventil 3 wird die

Schließenergie des jeweiligen Ventils vorteilhafterweise zum Öffnen des jeweils

anderen Ventils verwendet. Dieser Vorteil ist bei herkömmlich aufgebauten

Stoßhebern nicht erzielbar, weil die Ventilsitze der beiden in Rede stehenden

Ventile (das Bodenventil ist ein Rückstellventil!) voneinander getrennt

ausgebildet sind, so daß kinetische Energie nicht von einem Ventil zum anderen

übertragen werden kann. Vielmehr wird die beim Schließen freiwerdende

kinetische Energie durch Dämpfung, beispielsweise im Dichtgummi des Ventils

vernichtet. Eine derartige Dämpfung ist herkömmlicherweise auch erforderlich,

um das sogenannte Hüpfen des jeweiligen Ventilorgans auf dem Ventilsitz zu

unterbinden. Dieses Hüpfen tritt bei den erfindungsgemäß ausgebildeten über

den Ventilsitz miteinander verbundenen bzw. materialeinheitlich gebildeten

Ventilen nicht auf, weil die kinetische Energie von dem schließenden Ventil in

das andere Ventil eingeleitet wird, um dessen Öffnen auszulösen bzw. zu

unterstützen.Due to the mechanically coupled or one-piece according to the invention

formed valve seats for the bottom valve 4 and the

Herkömmlicherweise wird ein Ventilorgan axial angeströmt, und die Strömung verläuft nach der Anströmung radial auseinander zwischen dem Ventilorgan und dem Ventilsitz hindurch. Im Gegensatz hierzu verläuft die Strömung bei den erfindungsgemäß mit gemeinsamem Ventilsitz ausgebildeten Ventilen zwischen den Ventilorganen und den zugehörigen Sitzen radial einwärts zusammen und daraufhin axial vom jeweiligen Ventil weg. Und nur dadurch ist die Möglichkeit eines gemeinsamen Ventilsitzes gegeben. Ein weiterer Vorteil der erfindungsgemäßen Kopplung der Ventilsitze der beiden Ventile besteht darin, daß die Strecke zwischen den beiden Ventilen vernachlässigbar kurz gehalten werden kann.Traditionally, a valve member is axially flowed against, and the flow runs radially apart after the flow between the valve member and through the valve seat. In contrast to this, the flow of the according to the invention with common valve seat designed valves between the valve members and the associated seats radially inwards together and then axially away from the respective valve. And that's the only way given a common valve seat. Another advantage of Coupling the valve seats of the two valves according to the invention consists in that the distance between the two valves is kept negligibly short can be.

Durch eine einfache Maßnahme kann der vorstehend erläuterte erfindungsgemäße Stoßheber auch als normaler Widder betrieben werden. Hierzu ist es lediglich erforderlich, eine zusätzliche Feder vorzusehen, die bewirkt, daß das Bodenventil 4 in der Ruhelage geöffnet ist. Die Arbeitsweise dieses modifizierten Stoßhebers ist wie folgt: The one explained above can be implemented by a simple measure The jack according to the invention can also be operated as a normal ram. For this it is only necessary to provide an additional spring causes the bottom valve 4 to be open in the rest position. The way of working of this modified jack is as follows:

Zunächst wird das Förderwasser aufgrund seines natürlichen Gefälles

beschleunigt, und es tritt durch das geöffnete Bodenventil 4 über den

Rohranschluß 32 ins Freie, bis ein hydrodynamischer Unterdruck zwischen dem

Ventilorgan 4b und dem Ventilsitz 4a und ein Staudruck im Faltenbalg 4c das

Schließen des Bodenventils 4 bewirken. Dadurch öffnet das Stoßheberventil 3,

und die kinetische Energie des Förderwasser lädt den Federspeicher (Faltenbalg

5), wodurch das Stoßheberventil 3 wieder schließt und der Vorgang, wie

vorstehend erläutert, von vorne beginnt. Ist der Federspeicher (Faltenbalg 5)

jedoch bereits geladen (d.h. es wird kein Druckwasser verbraucht) schließt das

Bodenventil 4 nicht, wenn das Förderwasser zum Stillstand gekommen ist,

sondern erst nachdem die überschüssige Energie aus dem Federspeicher das

Förderwasser in umgekehrter Weise bzw. rückwärts beschleunigt hat. Nach dem

Schließen des Stoßheberventils 3 saugt dann das Förderwasser zunächst durch

das Bodenventil 4 Wasser an, bis sich die Strömungsrichtung umkehrt. Das

heißt, wird kein Druckwasser benötigt, geht auch der Verbrauch des

Förderwassers auf ein Minimum zurück.First of all, the production water is due to its natural gradient

accelerates, and it passes through the open bottom valve 4 on the

Pipe connection 32 into the open until a hydrodynamic vacuum between the

Valve member 4b and the valve seat 4a and a dynamic pressure in the bellows 4c

Close the bottom valve 4. As a result, the

Der Zweck des Kapillarrohrs 36 bzw. der Kapillaröffnung im Ventilorgan (Fig. 3)

besteht darin, daß der Druck im Innern des Faltenbalgs 5 gleich dem mittleren

Druck im Faltenbalg 4c bzw. in der Förderleitung wird. Damit wird erreicht, daß

die Druckdifferenz zwischen Treibwasser und Förderwasser, bei der das

Stoßheberventil öffnet, unabhängig von der Förderhöhe ist. Und dadurch ist die

Last an der externen Treibwasserpumpe immer die gleiche, unabhängig davon,

ob der Stoßheber eingesetzt wird, um große Mengen von Oberflächenwasser

oder geringe Mengen von Wasser aus großer Tiefe zu fördern.The purpose of the

Claims (9)

- Hydraulic ram, comprising:wherein the propellant water flows into the feed pipe when the ram valve (3) is open and, after the closure of the ram valve, the water column flowing further in the feed pipe sucks-in feedwater via the bottom valve (4), characterised in that the ram valve (3) is held in its closed position, separating the propellant water conduit from the feed pipe, by resilient force, and a pressure reservoir (5) is provided, which is connected to the propellant water conduit upstream of the ram valve (3) when viewed with respect to the direction of flow, a valve element (4b) of the bottom valve (4) having an annular configuration, being axially displaceable and being connected in a sealed manner to the feed pipe, the effective cross-section of this connection being greater than the cross-section of a valve seat (4a) of the bottom valve (4), and the valve seat (6) of the ram valve (3) and the valve seat (4a) of the bottom valve (4) being mechanically connected for the transmission of kinetic energy.a propellant water conduit supplied with propellant water (at 30),a feed pipe (at 32), which is connectable to feedwater via a bottom valve (4), anda ram valve (3), which communicates with the propellant water conduit (1) and feed pipe (2),

- Hydraulic ram according to claim 1, characterised in that the ram valve (3) and the bottom valve (4) are disposed substantially coaxially with valve seats abutting against each other.

- Hydraulic ram according to claim 2, characterised in that the two valve seats (4a, 6) are formed at the oppositely situated ends of a valve seat carrier (24).

- Hydraulic ram according to one of claims 1 to 3, characterised in that the pressure reservoir (5) comprises a bellows, which is supported with one end in a chamber portion (25) of a two-part housing and is acted-upon externally by the propellant water, which is conveyed into this chamber portion (25) via the propellant water conduit (30), and which bellows carries, at the other end, the valve element (3a) of the ram valve (3), the valve seat (6) of which sits in a dividing wall (24), dividing the housing (20), and is connected to the valve seat (4a) of the bottom valve (4), and which ram valve is disposed in the other chamber portion which communicates with the feedwater.

- Hydraulic ram according to claim 4, characterised in that the bellows (5) serves as a resilient, volume-variable component part of the pressure reservoir, without altering its axial extent for storing pressure.

- Hydraulic ram according to claim 4, characterised in that a non-return spring (3b) for the ram valve (3) is disposed in the interior of the pressure reservoir bellows (5), extends coaxially relative to said bellows and is supported with one end on the internal side of the valve element (6) of the ram valve (3) and with its other cnd on the housing (2).

- Hydraulic ram according to claim 4 or 5, characterised in that the valve seat (6) of the ram valve (3) is traversed by a capillary bore, which connects the interior of the pressure reservoir bellows (5) to the space between the valve seat (4a) of the bottom valve (4) and the valve seat (6) of the ram valve (3).

- Hydraulic ram according to claim 6, characterised in that a capillary tube (36), which extends to the bottom region of the pressure reservoir bellows (5), communicates with the capillary bore.

- Hydraulic ram according to one of claims 4 to 7, characterised in that the bottom valve (4) comprises a bellows (4c) which carries, on one of its ends, the valve seat (4a) of the bottom valve (4) and which, with its other end, is supported on the housing (20) in such a manner that this valve element (4b) is pressed against its valvc seat (4a) in the closed position.

Priority Applications (14)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU16354/97A AU708806B2 (en) | 1996-04-19 | 1997-03-14 | Hydraulic ram pump |

| IL12589397A IL125893A (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump |

| PCT/EP1997/001908 WO1997040277A1 (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump |

| AU26380/97A AU2638097A (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump |

| JP53770097A JP3853847B2 (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump |

| NZ331397A NZ331397A (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump with closing energy of one valve used to open another valve |

| CZ983322A CZ332298A3 (en) | 1996-04-19 | 1997-04-16 | Hydraulic plunger pump |

| RU98120702A RU2159361C2 (en) | 1996-12-04 | 1997-04-16 | Hydraulic plunger pump |

| CA002249263A CA2249263C (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump |

| PL97329346A PL182664B1 (en) | 1996-04-19 | 1997-04-16 | Hydraulic plunger pump |

| US09/142,312 US6234764B1 (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump |

| CN97192909A CN1081758C (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump |

| KR10-1998-0708318A KR100383489B1 (en) | 1996-04-19 | 1997-04-16 | Hydraulic ram pump |

| IDP971312A ID16633A (en) | 1996-04-19 | 1997-04-21 | HYDRAULIC COOLING PUMP |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19615689A DE19615689A1 (en) | 1996-04-19 | 1996-04-19 | Hydraulic suction ram inertia pump |

| DE19615689 | 1996-04-19 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0802328A1 EP0802328A1 (en) | 1997-10-22 |

| EP0802328B1 true EP0802328B1 (en) | 2001-07-18 |

Family

ID=7791876

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96119475A Expired - Lifetime EP0802328B1 (en) | 1996-04-19 | 1996-12-04 | Hydraulic ram |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0802328B1 (en) |

| KR (1) | KR100383489B1 (en) |

| AT (1) | ATE203307T1 (en) |

| BR (1) | BR9708769A (en) |

| DE (2) | DE19615689A1 (en) |

| ES (1) | ES2160758T3 (en) |

| GR (1) | GR3036876T3 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100412134B1 (en) * | 2001-06-27 | 2003-12-31 | 주식회사 하이닉스반도체 | A data output buffer operating on wide source voltage and a semiconductor memory device using this buffer |

| GB202105296D0 (en) * | 2021-04-14 | 2021-05-26 | Thermofluidics Ltd | Inlet end assemblies for hydraulic ram pumps |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE628113C (en) * | 1934-10-31 | 1936-03-30 | Harry Sauveur Dipl Ing | Liquid pump |

| DE804288C (en) * | 1949-06-28 | 1951-04-19 | Wilhelm Raub | Interrupter pump |

| CH666942A5 (en) * | 1985-09-10 | 1988-08-31 | Cyphelly Ivan J | SUCTION ARMS PUMPING DEVICE FOR A SHAFT. |

-

1996

- 1996-04-19 DE DE19615689A patent/DE19615689A1/en not_active Withdrawn

- 1996-12-04 DE DE59607317T patent/DE59607317D1/en not_active Expired - Fee Related

- 1996-12-04 EP EP96119475A patent/EP0802328B1/en not_active Expired - Lifetime

- 1996-12-04 AT AT96119475T patent/ATE203307T1/en not_active IP Right Cessation

- 1996-12-04 ES ES96119475T patent/ES2160758T3/en not_active Expired - Lifetime

-

1997

- 1997-04-16 BR BR9708769A patent/BR9708769A/en active Search and Examination

- 1997-04-16 KR KR10-1998-0708318A patent/KR100383489B1/en not_active IP Right Cessation

-

2001

- 2001-10-11 GR GR20010401739T patent/GR3036876T3/en not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| KR20000005524A (en) | 2000-01-25 |

| ATE203307T1 (en) | 2001-08-15 |

| DE19615689A1 (en) | 1997-10-23 |

| DE59607317D1 (en) | 2001-08-23 |

| BR9708769A (en) | 1999-08-03 |

| KR100383489B1 (en) | 2003-06-18 |

| ES2160758T3 (en) | 2001-11-16 |

| GR3036876T3 (en) | 2002-01-31 |

| EP0802328A1 (en) | 1997-10-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4291026C2 (en) | Vibration damper for a pumped liquid system | |

| EP2294316B1 (en) | Piston pump of a hydraulic vehicle brake system | |

| DE1117412B (en) | Hydropneumatic suspension, especially for motor vehicles | |

| DE2162320A1 (en) | ||

| EP0594537A1 (en) | Wave power device | |

| DE3900899A1 (en) | PRINT STORAGE | |

| DE3130830A1 (en) | SPRING ELEMENT AND ITS USE | |

| DE7111463U (en) | SOUND PULSE GENERATOR | |

| DE1528439C3 (en) | Pressure accumulator for maintaining a pressure working range in a hydraulic system | |

| DE1043102B (en) | Hydropneumatic suspension, especially for motor vehicles | |

| DE1294234B (en) | Suspension strut for motor vehicles formed from a telescopic fluid vibration damper and a coil spring surrounding it | |

| DE19857595A1 (en) | Piston pump of hydro-pneumatically operated strut is equipped with pressure relief valve | |

| DE102006004659A1 (en) | clamping device | |

| DE1936858A1 (en) | Shock absorbers | |

| DE1755237B1 (en) | Self-pumping hydropneumatic strut with internal level control for vehicles | |

| DE19602166B4 (en) | Self-pumping hydropneumatic vibration damper with devices for variable control of the damping force | |

| DE2419010B2 (en) | VALVE ASSEMBLY FOR AN AUTOMOTIVE HYDRAULIC SYSTEM | |

| DE3443768A1 (en) | HOSE PISTON PUMP | |

| WO1994000690A1 (en) | High-pressure cleaning device | |

| DE2715424A1 (en) | VALVE FOR A PRESSURE ACCUMULATOR | |

| EP0802328B1 (en) | Hydraulic ram | |

| DE1114684B (en) | Spring-loaded pressure relief valve for fluids, preferably for use with telescopic pit punches | |

| DE2322354A1 (en) | WORK CYLINDERS, IN PARTICULAR HYDRAULIC CYLINDERS, WITH A DAMPING DEVICE FOR THE END OF THE WORKING STROKE OF THE PISTON | |

| DE2213104A1 (en) | Valve for a liquid pump | |

| DE922952C (en) | Buffers for rail and tram cars or similar vehicles |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE ES FR GB GR IT LI |

|

| 17P | Request for examination filed |

Effective date: 19980324 |

|

| 17Q | First examination report despatched |

Effective date: 19990914 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SIEBHOLZ, DIETMAR |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: OBERMOSER, KARL |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB GR IT LI |

|

| REF | Corresponds to: |

Ref document number: 203307 Country of ref document: AT Date of ref document: 20010815 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BUECHEL, KAMINSKI & PARTNER PATENTANWAELTE ESTABLI |

|

| REF | Corresponds to: |

Ref document number: 59607317 Country of ref document: DE Date of ref document: 20010823 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20011018 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2160758 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20010401739 Country of ref document: GR |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20051220 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20051229 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20051230 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20060123 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20060124 Year of fee payment: 10 Ref country code: CH Payment date: 20060124 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20060127 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061231 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20061231 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070703 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20061204 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061204 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061204 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20061205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070102 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071204 |