EP0736735A2 - Safety workbench with arm rest - Google Patents

Safety workbench with arm rest Download PDFInfo

- Publication number

- EP0736735A2 EP0736735A2 EP96102500A EP96102500A EP0736735A2 EP 0736735 A2 EP0736735 A2 EP 0736735A2 EP 96102500 A EP96102500 A EP 96102500A EP 96102500 A EP96102500 A EP 96102500A EP 0736735 A2 EP0736735 A2 EP 0736735A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- ventilation openings

- safety workbench

- boundary plate

- supports

- armrest

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000009423 ventilation Methods 0.000 claims abstract description 18

- 210000000245 forearm Anatomy 0.000 description 2

- 102000006835 Lamins Human genes 0.000 description 1

- 108010047294 Lamins Proteins 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 210000005053 lamin Anatomy 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25H—WORKSHOP EQUIPMENT, e.g. FOR MARKING-OUT WORK; STORAGE MEANS FOR WORKSHOPS

- B25H1/00—Work benches; Portable stands or supports for positioning portable tools or work to be operated on thereby

- B25H1/20—Work benches; Portable stands or supports for positioning portable tools or work to be operated on thereby with provision for shielding the work area

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01L—CHEMICAL OR PHYSICAL LABORATORY APPARATUS FOR GENERAL USE

- B01L9/00—Supporting devices; Holding devices

- B01L9/02—Laboratory benches or tables; Fittings therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25H—WORKSHOP EQUIPMENT, e.g. FOR MARKING-OUT WORK; STORAGE MEANS FOR WORKSHOPS

- B25H1/00—Work benches; Portable stands or supports for positioning portable tools or work to be operated on thereby

- B25H1/02—Work benches; Portable stands or supports for positioning portable tools or work to be operated on thereby of table type

Definitions

- the invention relates to a safety workbench with a work opening, the lower boundary of which is formed by a boundary plate in which ventilation openings for generating a vertical air flow are arranged and with at least one armrest arranged in the lower region of the work opening.

- Safety cabinets are generally known, for example from the company brochure "Biological safety cabinets Heraeus Lamin Air HB and HBB" from Heraeus Instruments GmbH.

- Safety cabinets of this type are designed in such a way that a vertically directed air flow can be generated parallel to the working opening, which, as a kind of veil, prevents contaminated atmosphere from escaping from the working area of the safety cabinet through the working opening.

- ventilation openings are provided on the lower, essentially horizontal boundary plate of the working opening, through which an air flow directed vertically downwards is generated.

- the boundary plate can be rounded off on its outward edge facing the operator. If the boundary plate is used as an armrest in the manner shown, the ventilation openings are covered by the arms, so that a laminar air flow is prevented. This interferes with the function of this air flow. In addition, the boundary plate can be cleaned only with relatively great effort.

- GB 21 12 927 A discloses a safety workbench with an armrest arranged on the lower edge of the opening.

- the object of the present invention is to create, based on the known prior art, a safety workbench in which the armrests are easy to decontaminate and do not significantly reduce the effective cross section of the ventilation openings.

- the object for a safety workbench characterized in the introduction is achieved in that the armrest is designed as a separate component and is detachably held in the boundary plate in the ventilation openings and has a support plate and supports, the supports being held at the lower ends of the ventilation openings.

- a separate armrest can also be decontaminated separately and therefore very easily, and on the other hand, a separate armrest can be designed ergonomically, since it is not subject to the design principle of the boundary plate.

- the ventilation openings are closed in an uncontrolled manner by resting the arms on the boundary plate; with a separate armrest, the number of closed ventilation openings can be kept to a minimum.

- the supports are angled several times to form two horizontal sections, one horizontal section abutting the upper side of the boundary plate and the second horizontal section abutting the lower side of the boundary plate.

- the ventilation openings are designed as slots and that several rows of slots, each arranged parallel to one another, are arranged next to one another to form a grid.

- the slot-shaped design ensures a good fixation, since the supports within the slots can be moved in the longitudinal direction of the slots and are therefore easy to install, but there are narrow limits to the movement transverse to the slot, in particular if the width of the supports is only slightly less than is the width of the slots.

- the working opening of the safety workbench is delimited at its lower end by a limiting plate 1.

- the boundary plate 1 is arranged essentially horizontally and evenly and has slot-shaped ventilation openings 2 through which an air flow directed vertically upwards is guided.

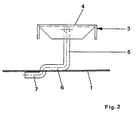

- the armrest 3 has a support plate 4 which is arranged approximately 50 mm above the boundary plate 1 and which is held with supports 5 in the boundary plate 1.

- the supports 5 point vertically downwards to the boundary plate 1 and are then angled to a horizontal section 6 which rests on the boundary plate 1. At the end of this first horizontal section 6, the supports 5 are angled downwards through a respective ventilation opening 2 and form below the limiting plate 1 a second horizontal section 7 which bears against the limiting plate 1 from below.

- the two horizontal sections 6; 7 can be arranged in a step-like manner, as shown in FIG. 2, or also in a U-shape. However, a U-shaped arrangement is less stable.

- the armrest 3 is made of stainless steel and is therefore easily autoclavable.

- the supports 5 are made of round steel and have a diameter which is only slightly smaller than the width of the slit-shaped ventilation openings 2, so that the armrest 3 is also well locked in the lateral direction.

- the supports can accordingly also be formed from flat material.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Health & Medical Sciences (AREA)

- Clinical Laboratory Science (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Apparatus Associated With Microorganisms And Enzymes (AREA)

- Ladders (AREA)

- Ventilation (AREA)

- Forklifts And Lifting Vehicles (AREA)

Abstract

Die Erfindung betrifft eine Sicherheitswerkbank mit einer Arbeitsöffnung, deren untere Begrenzung durch eine Begrenzungsplatte (1) gebildet ist, in der Lüftungsöffnungen (2) zur Erzeugung eines senkrechten Luftstroms angeordnet sind und mit mindestens einer im unteren Bereich der Arbeitsöffnung angeordneten Armauflage (3). Um eine Sicherheitswerkbank zu schaffen, bei der die Armauflagen (3) leicht zu dekontaminieren sind und den effektiven Querschnitt der Lüftungsöffnungen (2) nicht wesentlich verringern, sind die Armauflagen (3) als separates Bauteil ausgebildet und lösbar an der Begrenzungsplatte (1) beabstandet zu dieser gehaltert. <IMAGE>The invention relates to a safety workbench with a work opening, the lower boundary of which is formed by a boundary plate (1), in which ventilation openings (2) are arranged for generating a vertical air flow, and with at least one armrest (3) arranged in the lower region of the work opening. In order to create a safety workbench in which the armrests (3) are easy to decontaminate and do not significantly reduce the effective cross section of the ventilation openings (2), the armrests (3) are designed as a separate component and are detachably spaced from the boundary plate (1) this held. <IMAGE>

Description

Die Erfindung betrifft eine Sicherheitswerkbank mit einer Arbeitsöffnung, deren untere Begrenzung durch eine Begrenzungsplatte gebildet ist, in der Lüftungsöffnungen zur Erzeugung eines senkrechten Luftstroms angeordnet sind und mit mindestens einer im unteren Bereich der Arbeitsöffnung angeordneten Armauflage.The invention relates to a safety workbench with a work opening, the lower boundary of which is formed by a boundary plate in which ventilation openings for generating a vertical air flow are arranged and with at least one armrest arranged in the lower region of the work opening.

Derartige Sicherheitswerkbänke sind allgemein, beispielsweise aus dem Firmenprospekt "Biologische Sicherheitswerkbänke Heraeus Lamin Air HB und HBB" der Heraeus Instruments GmbH bekannt. Sicherheitswerkbänke dieser Art sind so ausgebildet, daß parallel zur Arbeitsöffnung ein senkrecht gerichteter Luftstrom erzeugt werden kann, der als eine Art Schleier verhindert, daß kontaminierte Atmosphäre aus dem Arbeitsraum der Sicherheitswerkbank durch die Arbeitsöffnung nach außen gelangt. Dazu sind an der unteren, im wesentlichen waagerechten Begrenzungsplatte der Arbeitsöffnung Lüftungsöffnungen vorgesehen, durch die ein senkrecht nach unten gerichteter Luftstrom erzeugt wird.Such safety cabinets are generally known, for example from the company brochure "Biological safety cabinets Heraeus Lamin Air HB and HBB" from Heraeus Instruments GmbH. Safety cabinets of this type are designed in such a way that a vertically directed air flow can be generated parallel to the working opening, which, as a kind of veil, prevents contaminated atmosphere from escaping from the working area of the safety cabinet through the working opening. For this purpose, ventilation openings are provided on the lower, essentially horizontal boundary plate of the working opening, through which an air flow directed vertically downwards is generated.

Häufig ist es erforderlich, daß über einen längeren Zeitraum hinweg in der Sicherheitswerkbank manuell gearbeitet wird. Die an der Sicherheitswerkbank arbeitende Person ist dabei einer relativ hohen körperlichen Belastung der Arme ausgesetzt. Um eine Ermüdung, insbesondere der Unterarme und der Hände zu vermeiden, wird daher die untere Begrenzungsplatte als Auflagefläche für die Unterarme benutzt. Dazu kann die Begrenzungsplatte an ihrer nach außen, zum Bediener hin gewandten Kante abgerundet sein. Wird die Begrenzungsplatte in der dargestellten Art als Armauflage benutzt, werden die Lüftungsöffnungen durch die Arme abgedeckt, so daß eine laminare Luftströmung verhindert wird. Dadurch wird die Funktion dieser Luftströmung gestört. Außerdem ist die Begrenzungsplatte nur relativ aufwendig reinigbar.It is often necessary to work manually in the safety workbench over a long period of time. The person working on the safety workbench is exposed to a relatively high physical strain on the arms. In order to avoid fatigue, especially of the forearms and hands, the lower limiting plate is therefore used as a support surface for the forearms. For this purpose, the boundary plate can be rounded off on its outward edge facing the operator. If the boundary plate is used as an armrest in the manner shown, the ventilation openings are covered by the arms, so that a laminar air flow is prevented. This interferes with the function of this air flow. In addition, the boundary plate can be cleaned only with relatively great effort.

Aus GB 21 12 927 A ist eine Sicherheitswerkbank mit an der unteren Kante der Öffnung angeordneter Armauflage bekannt.GB 21 12 927 A discloses a safety workbench with an armrest arranged on the lower edge of the opening.

Aufgabe der vorliegenden Erfindung ist es, ausgehend von dem bekannten Stand der Technik eine Sicherheitswerkbank zu schaffen, bei der die Armauflagen leicht zu dekontaminieren sind und den effektiven Querschnitt der Lüftungsöffnungen nicht wesentlich verringern.The object of the present invention is to create, based on the known prior art, a safety workbench in which the armrests are easy to decontaminate and do not significantly reduce the effective cross section of the ventilation openings.

Erfindungsgemäß wird die Aufgabe für eine eingangs charakterisierte Sicherheitswerkbank dadurch gelöst, daß die Armauflage als separates Bauteil ausgebildet und lösbar in der Begrenzungsplatte in den Lüftungsöffnungen gehaltert ist und eine Auflageplatte und Stützen aufweist, wobei die Stützen an ihren unteren Enden an den Lüftungsöffnungen gehaltert sind. Eine separate Armauflage kann zum einen auch separat und damit sehr einfach dekontaminiert werden, zum anderen kann eine separate Armauflage ergonomisch günstig gestaltet werden, da sie nicht dem Konstruktionsprinzip der Begrenzungsplatte unterliegt. Des weiteren wird vermieden, daß durch Auflage der Arme auf der Begrenzungsplatte die Lüftungsöffnungen unkontrolliert verschlossen werden; bei einer separaten Armauflage kann die Zahl der verschlossenen Lüftungsöffnungen auf ein Minimum begrenzt werden.According to the invention, the object for a safety workbench characterized in the introduction is achieved in that the armrest is designed as a separate component and is detachably held in the boundary plate in the ventilation openings and has a support plate and supports, the supports being held at the lower ends of the ventilation openings. On the one hand, a separate armrest can also be decontaminated separately and therefore very easily, and on the other hand, a separate armrest can be designed ergonomically, since it is not subject to the design principle of the boundary plate. Furthermore, it is avoided that the ventilation openings are closed in an uncontrolled manner by resting the arms on the boundary plate; with a separate armrest, the number of closed ventilation openings can be kept to a minimum.

Zweckmäßig für eine einfache Handhabung ist es, daß zwei separate Armauflagen vorgesehen sind, so daß die für jeden Arm benötigte Armauflage individuell angeordnet werden kann. Insbesondere ist es vorteilhaft, daß die Stützen unter Bildung zweier waagerechter Abschnitte mehrfach abgewinkelt sind, wobei ein waagerechter Abschnitt an der Oberseite der Begrenzungsplatte und der zweite waagerechte Abschnitt an der Unterseite der Begrenzungsplatte anliegt.It is expedient for simple handling that two separate armrests are provided, so that the armrest required for each arm can be arranged individually. In particular, it is advantageous that the supports are angled several times to form two horizontal sections, one horizontal section abutting the upper side of the boundary plate and the second horizontal section abutting the lower side of the boundary plate.

Vorteilhaft ist es auch, daß die Lüftungsöffnungen als Schlitze ausgebildet sind und daß mehrere Reihen von jeweils parallel zueinander angeordneten Schlitzen unter Bildung eines Rasters nebeneinander angeordnet sind. Eine derartige Anordnung ermöglicht eine nahezu unbegrenzte Variierbarkeit in der Anordnung der Armauflagen. Durch die schlitzförmige Ausbildung wird eine gute Fixierung gewährleistet, da die Stützen innerhalb der Schlitze zwar in Längsrichtung der Schlitze verschiebbar und damit leicht montierbar sind, quer zum Schlitz sind der Bewegung jedoch enge Grenzen gesetzt, insbesondere, wenn die Breite der Stützen nur wenig geringer als die Breite der Schlitze ist.It is also advantageous that the ventilation openings are designed as slots and that several rows of slots, each arranged parallel to one another, are arranged next to one another to form a grid. Such an arrangement allows an almost unlimited variability in the arrangement of the armrests. The slot-shaped design ensures a good fixation, since the supports within the slots can be moved in the longitudinal direction of the slots and are therefore easy to install, but there are narrow limits to the movement transverse to the slot, in particular if the width of the supports is only slightly less than is the width of the slots.

Nachfolgend wird ein Ausführungsbeispiel der Erfindung anhand einer Zeichnung näher erläutert.An exemplary embodiment of the invention is explained in more detail below with reference to a drawing.

In der Zeichnung zeigt

Figur 1 die Arbeitsöffnung einer Sicherheitswerkbank mit Armauflage undFigur 2 die Seitenansicht einer auf der Begrenzungsplatte montierten Armauflage.

- Figure 1 shows the work opening of a safety workbench with armrest and

- Figure 2 is a side view of an armrest mounted on the boundary plate.

Die Arbeitsöffnung der Sicherheitswerkbank ist an ihrem unteren Ende durch eine Begrenzungsplatte 1 begrenzt. Die Begrenzungsplatte 1 ist im wesentlichen waagerecht und eben angeordnet und weist schlitzförmige Lüftungsöffnungen 2 auf, durch die eine senkrecht nach oben gerichtete Luftströmung geführt wird. Die Armauflage 3 weist eine Auflageplatte 4 auf, die etwa 50 mm über der Begrenzungsplatte 1 angeordnet ist und die mit Stützen 5 in der Begrenzungsplatte 1 gehaltert ist.The working opening of the safety workbench is delimited at its lower end by a limiting

Die Stützen 5 weisen bis an die Begrenzungsplatte 1 senkrecht nach unten, sind dann zu einem waagerechten Abschnitt 6 abgewinkelt, der auf der Begrenzungsplatte 1 aufliegt. Am Ende dieses ersten waagerechten Abschnitts 6 sind die Stützen 5 durch je eine Lüftungsöffnung 2 hindurch nach unten abgewinkelt und bilden unterhalb der Begrenzungsplatte 1 einen zweiten waagerechten Abschnitt 7, der von unten an der Begrenzungsplatte 1 anliegt. Die beiden waagerechten Abschnitte 6; 7 können stufenartig hintereinander angeordnet sein, wie dies in Figur 2 dargestellt ist, oder auch u-förmig. Eine u-förmige Anordnung ist jedoch weniger stabil.The

Die Armauflage 3 ist aus Edelstahl gefertigt und damit leicht autoklavierbar. Die Stützen 5 sind aus Rundstahl gebildet und weisen einen Durchmesser auf, der nur geringfügig kleiner ist als die Breite der schlitzförmigen Lüftungsöffnungen 2, so daß die Armauflage 3 auch in seitlicher Richtung gut arretiert ist. Die Stützen können entsprechend auch aus Flachmaterial gebildet sein.The

Claims (4)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19512889 | 1995-04-06 | ||

| DE19512889A DE19512889C1 (en) | 1995-04-06 | 1995-04-06 | Safety workbench with air curtain |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0736735A2 true EP0736735A2 (en) | 1996-10-09 |

| EP0736735A3 EP0736735A3 (en) | 1997-05-02 |

| EP0736735B1 EP0736735B1 (en) | 2000-11-02 |

Family

ID=7758936

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96102500A Expired - Lifetime EP0736735B1 (en) | 1995-04-06 | 1996-02-20 | Safety workbench with arm rest |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US5662521A (en) |

| EP (1) | EP0736735B1 (en) |

| DE (2) | DE19512889C1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD835711S1 (en) | 2014-10-21 | 2018-12-11 | Steve Kenkman | Single claw drum display |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4179984A (en) * | 1978-09-05 | 1979-12-25 | Gorcey Raymond A | Slide mounting work station |

| GB2112927A (en) * | 1981-10-29 | 1983-07-27 | Howorth Air Eng Ltd | Air conditioned safety cabinet |

| EP0237969A2 (en) * | 1986-03-14 | 1987-09-23 | Hammerlit GmbH | Work bench for clean rooms |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3425335A (en) * | 1968-01-24 | 1969-02-04 | Purex Corp Ltd | Laboratory fume hood |

| US5288042A (en) * | 1992-08-12 | 1994-02-22 | Ergodyne Corporation | Wrist rest support system |

| US5385322A (en) * | 1993-10-01 | 1995-01-31 | Baxter International Inc. | Ergonomic elbow rest |

-

1995

- 1995-04-06 DE DE19512889A patent/DE19512889C1/en not_active Expired - Fee Related

-

1996

- 1996-02-20 DE DE59606065T patent/DE59606065D1/en not_active Expired - Lifetime

- 1996-02-20 EP EP96102500A patent/EP0736735B1/en not_active Expired - Lifetime

- 1996-03-29 US US08/625,476 patent/US5662521A/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4179984A (en) * | 1978-09-05 | 1979-12-25 | Gorcey Raymond A | Slide mounting work station |

| GB2112927A (en) * | 1981-10-29 | 1983-07-27 | Howorth Air Eng Ltd | Air conditioned safety cabinet |

| EP0237969A2 (en) * | 1986-03-14 | 1987-09-23 | Hammerlit GmbH | Work bench for clean rooms |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59606065D1 (en) | 2000-12-07 |

| US5662521A (en) | 1997-09-02 |

| EP0736735B1 (en) | 2000-11-02 |

| EP0736735A3 (en) | 1997-05-02 |

| DE19512889C1 (en) | 1996-05-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19653407C1 (en) | Holding device for a fixed roof, in particular for a hard top | |

| DE10057292C2 (en) | Device for receiving mirodissectates | |

| EP0022988B1 (en) | Holder for tubular vessels | |

| EP0736735B1 (en) | Safety workbench with arm rest | |

| DE3025974C2 (en) | Drive device for the cross table of a microscope or similar device | |

| DE19727168C2 (en) | Telescopic headrest | |

| DE102020107730B4 (en) | Cabel Canal | |

| EP3839356A1 (en) | Filter unit and fume extractor with filter unit | |

| DE20116511U1 (en) | Automatic pipetting head has pipette needles driven individually up or down by separate drive mechanisms | |

| EP0252217A1 (en) | Support element for the slats of a slatted mattress frame | |

| DE69102847T2 (en) | Bracket with adjustable spacing for plant pots. | |

| EP0190235B1 (en) | Selection apparatus for microscopic objects, especially micro-fossils | |

| DE10011940C2 (en) | Device for testing filter cartridges | |

| DE9417660U1 (en) | Instrument holder | |

| DE4227137C2 (en) | Filter device for liquid plastic pressure pipes | |

| DE3008467C2 (en) | Tool holder with coding | |

| EP0995373A1 (en) | Device for assembling multi-function chairs in a row | |

| EP1311305A1 (en) | Screen, particularly a sterilisation screen | |

| DE4304183C1 (en) | Holding table for large format writing and/or drawing blocks - has support column provided at upper end with inclined surface and fixed by conical insert connection to rear side of holding table | |

| DE20218282U1 (en) | Height adjustable table, comprising stand assembled of two carrying units and two supporting elements | |

| DE4017355C2 (en) | ||

| DE29804533U1 (en) | Oven rack or baking sheet | |

| DE20106535U1 (en) | Device for ascertainable change in length of two tubular bodies | |

| DE2421895B2 (en) | Auxiliary device for do-it-yourself machines for performing milling and rebating work, in particular for producing elongated holes | |

| DE202021104662U1 (en) | System comprising a filter element, preferably arranged in a filter frame, as well as a housing consisting of, preferably four housing parts arranged at right angles to one another, for reversibly receiving the filter element |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19960228 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HERAEUS INSTRUMENTS GMBH & CO. KG |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KENDRO LABORATORY PRODUCTS GMBH |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 20000427 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20001102 |

|

| REF | Corresponds to: |

Ref document number: 59606065 Country of ref document: DE Date of ref document: 20001207 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Ref country code: FR Ref legal event code: CA |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150219 Year of fee payment: 20 Ref country code: IT Payment date: 20150226 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20150218 Year of fee payment: 20 Ref country code: FR Payment date: 20150219 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59606065 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20160219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20160219 |