EP0612959A1 - Venturi Brenner - Google Patents

Venturi Brenner Download PDFInfo

- Publication number

- EP0612959A1 EP0612959A1 EP94200429A EP94200429A EP0612959A1 EP 0612959 A1 EP0612959 A1 EP 0612959A1 EP 94200429 A EP94200429 A EP 94200429A EP 94200429 A EP94200429 A EP 94200429A EP 0612959 A1 EP0612959 A1 EP 0612959A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- burner

- gas

- outlet openings

- series

- gas outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000002485 combustion reaction Methods 0.000 claims abstract description 44

- 239000000446 fuel Substances 0.000 claims abstract description 13

- 238000002347 injection Methods 0.000 claims abstract description 12

- 239000007924 injection Substances 0.000 claims abstract description 12

- 238000011144 upstream manufacturing Methods 0.000 claims abstract description 9

- 238000010438 heat treatment Methods 0.000 claims abstract description 5

- 238000004891 communication Methods 0.000 claims abstract description 4

- 238000009434 installation Methods 0.000 claims abstract description 3

- 239000003546 flue gas Substances 0.000 description 29

- 239000007789 gas Substances 0.000 description 22

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 20

- 239000000203 mixture Substances 0.000 description 8

- 230000000694 effects Effects 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 239000000567 combustion gas Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 230000001737 promoting effect Effects 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/34—Burners specially adapted for use with means for pressurising the gaseous fuel or the combustion air

- F23D14/36—Burners specially adapted for use with means for pressurising the gaseous fuel or the combustion air in which the compressor and burner form a single unit

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/20—Non-premix gas burners, i.e. in which gaseous fuel is mixed with combustion air on arrival at the combustion zone

- F23D14/22—Non-premix gas burners, i.e. in which gaseous fuel is mixed with combustion air on arrival at the combustion zone with separate air and gas feed ducts, e.g. with ducts running parallel or crossing each other

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C2201/00—Staged combustion

- F23C2201/20—Burner staging

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C2201/00—Staged combustion

- F23C2201/30—Staged fuel supply

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C2202/00—Fluegas recirculation

- F23C2202/30—Premixing fluegas with combustion air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2900/00—Special features of, or arrangements for burners using fluid fuels or solid fuels suspended in a carrier gas

- F23D2900/14—Special features of gas burners

- F23D2900/14003—Special features of gas burners with more than one nozzle

Definitions

- the invention relates to a burner, in particular a gas-fired fan burner for a central heating installation.

- Such a burner comprising a substantially cylindrical burner housing, of which one end, being the outlet end, is connectable to an opening in a furnace wall of a central heating boiler, while to the other end thereof, being the inlet end of the burner housing, a burner fan for forced supply of combustion air and a fuel supply line are connectable, a mixing tube extending concentrically within the burner housing and connecting to a burner head at the outlet end of the burner housing, which burner head, in mounted condition of the burner, extends into the furnace by a flame cup surrounding the burner head, while an annular space between the burner housing wall and the mixing tube is in open communication with the furnace at the outlet end and with the inner space of the mixing tube at the inlet end of the burner housing, is described as a burner for liquid fuel in U.S. patent specification 3,741,166.

- combustion air is blown by the fan in a forced manner through the mixing tube to the burner head, while fuel is supplied to the burner head.

- the combustible mixture is combusted at the burner head, the flame being stabilized within the flame cup. Due to the pressure prevailing in the furnace and also due to the underpressure created in the mixing tube by the air flowing through, a portion of the combustion or flue gases is returned from the furnace via the annular channel and mixed with the combustion air in the mixing tube.

- the flue gas thus recirculated reduces the partial oxygen pressure, thereby increasing the heat capacity of the flue gas and reducing the flame temperature.

- a reduction of the NO x emission is achieved.

- the flue gas recirculation does not decrease in proportion to the air flow rate when the burner is modulated, for instance adjusted from full load to partial load.

- An excess of recirculated flue gas (more than 20-30%) has an adverse effect on the combustion process and may cause an unstable flame.

- the burner housing construction were used in gas burners of the type as described in NL patent No. 153322, where the burner head is designed as one or more concentric, hollow gas-conducting rings round which axially supplied air flows, each ring having gas outlet openings in a plane perpendicular to the burner axis and distributed in circumferential direction, while upstream of the gas outlet openings flange-shaped radial projections have been provided forming vortex elements promoting the gas/air mixture, the outflowing air may also meet with so much resistance that even in the case of full load more flue gas is being recirculated than is desirable for a stable combustion with low NO x emission.

- the object of the invention is to provide a gas burner of the type described in the preamble, in which the above-mentioned drawbacks of the known burner are avoided.

- the inner side of the mixing tube in the burner chamber is designed as a venturi.

- Air injected by the fan at the inlet end of the mixing tube is compressed in the venturi throat and, after the throat, expanded over a particular distance. Due to the underpressure generated thereby, substantially proportional to the air flow rate, flue gas is drawn in from the furnace via the annular channel and mixed with through-flowing air in the mixing tube. From the furnace to the inlet in the mixing tube, the recirculated flue gas is cooled (from approx. 1,000°C to approx. 600°C), and at the burner head a flue gas/air mixture of relatively low temperature is delivered to be mixed with combustion gas, which contributes to the reduction of the flame temperature and hence to a reduction of the NO x emission.

- the percentage of flue gas in the combustion air can be kept the same at full load and partial load, so that the NO x reduction remains the same throughout the entire control range.

- the blow-in speed at the inlet of the venturi, and hence the amount of recirculated flue gas, can be controlled without having to deploy a fan with adjustable rotational speed.

- the burner may comprise an intermediate ring, accommodated concentrically in the burner housing, downstream from the air injection nozzle and upstream from the mixing tube inlet, which intermediate ring is provided with a flange.

- the burner head may be adapted for two-stage combustion, by providing, in addition to a first series of gas outlet openings, a second series of gas outlet openings downstream from the first series.

- the amount of air supplied via the mixing tube is sufficient for combusting a specific amount of gas. As only a portion of this gas amount flows out via the first series of gas outlet openings, an excess of air is present at that location. The relatively large amount of air can take up heat of the flames at the first series of gas outlet openings. The combustion air is consumed entirely only at the second series of gas outlet openings. Because the second, downstream combustion zone is located in the vicinity of the open end of the flame cup, the heat developed at that location can quickly be delivered to the furnace. In total, this yields a significant reduction of the flame temperature and, accordingly, a reduction of the NO x emission.

- the gas outlet openings are adjusted such that at the first series approx. 25% and at the second series approx. 75% of the gas flows out.

- one or several hollow gas-conducting rings may be provided with tubes, directed downstream, whose ends are closed off, which tubes, in the vicinity of the closed ends thereof, comprise gas outlet openings in a plane perpendicular to the burner axis, forming the second series of gas outlet openings.

- the tubes and/or gas-conducting rings may be provided with axial, plate-shaped elements increasing the heated surface, which elements have a cooling effect on the air and the flue gases from the first combustion stage flowing past.

- the furnace wall through which, in mounted condition, a burner extends, is covered with a fire-resisting brickwork at the furnace side thereof.

- the burner housing at the outlet end thereof, may be extended by an outer flame cup which, when the burner is in mounted condition, extends into the furnace and surrounds the mixing tube at a radial distance.

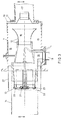

- Fig. 1 shows a boiler 1 with a burner 3 connected to the boiler front 2, which burner comprises a burner housing 4 and an air supply fan 5.

- the boiler comprises a furnace 6, a heat exchanger 7 and a flue gas discharge 8.

- the burner housing 4 of the burner 3 is connected to an opening in the boiler front 2 by an outlet end 9 and to the blow-out opening 11 of the air supply fan 5 by the inlet end 10.

- the burner 3, shown in detail in Figs 2 and 3 comprises a mixing tube 12, extending concentrically within the burner housing 4 and connecting to a burner head 13 at the outlet end of the burner housing 4.

- the burner head 13 is surrounded by a flame cup 14.

- the burner head 13 and the flame cup 14 extend into the furnace 6 of the boiler 1.

- an annular space 15 Located between the burner housing 4 and the mixing tube 12 is an annular space 15, being in open communication with the furnace 6 at the outlet end and with the inner space 16 of the mixing tube 12 at the inlet end of the burner housing 4.

- the fan 5 blows combustion air into the inner space 16 of the mixing tube 12.

- the flow rate of the combustion air at the inlet of the mixing tube 12 depends on the distance of the injection nozzle 17 from the inlet of the mixing tube 12. In the case of a greater distance, the combustion air must travel a greater distance before it reaches the mixing tube 12 and, accordingly, has a lower flow rate at the inlet of the mixing tube 12.

- the injection nozzle 17 being axially adjustable, the fan 5 need only be designed for rotation at a fixed speed.

- the fuel is supplied via the fuel connection 18 and passed to the burner head 13 via a fuel channel 19.

- the mixing tube 12 is designed as a venturi. As the combustion air coming from the fan 5 is compressed in the venturi and, after the throat, expanded over a particular distance, an underpressure is produced at the venturi inlet which is proportional to the combustion air flow rate. Due to the underpressure and the overpressure prevailing in the furnace 6, a portion of the flue gas is conducted via the annular space from the furnace 6 to the inlet of the mixing tube 12. Mixture of the combustion air with flue gas reduces the partial oxygen pressure of the combustion air, so that the heat capacity of the flue gas is increased and, accordingly, the flame temperature is reduced, so that the NO x emission is reduced. As the underpressure in the mixing tube 12 is substantially proportional to the combustion air flow rate, the amount of flue gas that is recirculated will decrease proportionally to the combustion air flow rate even when the burner 3 is modulated.

- Figs 6 and 7 show an alternative exemplary embodiment of the burner according to the invention, wherein the parts with the same function as the parts of the exemplary embodiment shown in Figs 2 and 3 are designated by the same reference numerals.

- the alternative exemplary embodiment comprises an intermediate ring 28, accommodated concentrically in the burner housing 4 downstream from the air injection nozzle 17 and upstream from the mixing tube inlet 12, which intermediate ring 28 comprises a flange 29.

- the flange 29, extending perpendicularly to the burner housing center line in the exempary embodiment shown, may be funnel-shaped, the wide mouth of the funnel being directed to the injection nozzle 17.

- Such design of the flange 29 reduces the chance of combustion air, injected via air injector 17, being blown directly into the boiler furnace via the annular space 15 round the venturi 12.

- the burner head 13 comprises two concentric burner rings 20, 21, the inner ring being designed as a burner plate 21.

- the flue gas/combustion air mixture flows round the burner ring 20 and the burner plate 21 in axial direction, i.e. in the direction of the burner axis.

- the burner ring 20 and the burner plate 21 comprise radial combustion medium outlet openings 22 which are directed radially, i.e. perpendicularly to the burner axis. Arranged upstream from these outlet openings are radial projections 23 promoting the fuel/air mixture by causing a vortex in the combustion air.

- Such burner head provides a stable flame front.

- an alternative burner head 13a is proposed, shown in detail in Figs 4 and 5.

- the burner head 13a is designed for two-stage combustion in that, in addition to the fuel outlet openings 22a of the or each burner ring 20a, a second series of fuel outlet openings 24 is arranged downstream therefrom.

- this is realized through the arrangement of tubes 25, directed axially downstream, on the outer burner ring 20a, which tubes 25 are closed at the outer ends thereof and which comprise radially directed outlet openings 24.

- radial projections are provided for obtaining a proper mixture, created by vortex, between the outflowing gas and the combustion air.

- the flow-through surface of the first series of outlet openings 22a is 25% and the flow-through area of the second series of outlet openings 24 is 75% of the total flow-through area.

- an excess of air is present at that location.

- the relatively large amount of air can take up the heat of the flames at the hollow rings.

- the combustion air is consumed entirely.

- the second, downstream combustion zone is located in the vicinity of the open end of the flame cup 14, the heat developed at that location can be delivered directly to the furnace 6. In total, this yields a significant reduction of the flame temperature and, accordingly, a reduction of the NO x emission.

- the burner plate 21a and the tubes 25 comprise plate-shaped elements 26 and 26a, increasing the heated surface and having a cooling effect on the air and the flue gases from the first combustion zone flowing past.

- the burner housing 4 at the outlet side thereof, has been extended to include a flame cup 27, exending into the furnace 6 and surrounding mixing tube 12 at a radial distance.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| NL9300335 | 1993-02-23 | ||

| NL9300335A NL9300335A (nl) | 1993-02-23 | 1993-02-23 | Venturibrander. |

| NL9301757A NL9301757A (nl) | 1993-10-11 | 1993-10-11 | Venturibrander. |

| NL9301757 | 1993-10-11 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0612959A1 true EP0612959A1 (de) | 1994-08-31 |

Family

ID=26647072

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94200429A Withdrawn EP0612959A1 (de) | 1993-02-23 | 1994-02-21 | Venturi Brenner |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0612959A1 (de) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL1008233C2 (nl) | 1998-02-06 | 1999-08-09 | Clysan D W Bv | Gasbrander. |

| EP1026445A1 (de) * | 1999-02-08 | 2000-08-09 | D.W. Clysan B.V. | Gasbrenner |

| FR2794521A1 (fr) * | 1999-06-04 | 2000-12-08 | Geminox | Bruleur a gaz a ventilation forcee pour chaudiere |

| KR100365652B1 (ko) * | 2000-10-30 | 2002-12-26 | 주식회사 경동보일러 | 가스보일러 송풍기용 오리피스 믹서 |

| FR2914398A1 (fr) * | 2007-04-02 | 2008-10-03 | Pillard Chauffage | Bruleur a combustible gazeux |

| EP2098782A1 (de) * | 2007-12-02 | 2009-09-09 | Beru Aktiengesellschaft | Vorrichtung und Verfahren zum Betreiben von Flammstartanlagen, Abgasreinigungsvorrichtungen von Verbrennungskraftmaschinen (Abgas-Partikelfilter) insbesondere an Lastkraftwagen, von Blockheizkraftwerken oder Stirlingmotoren |

| CN105674269A (zh) * | 2016-03-21 | 2016-06-15 | 浙江尚鼎工业炉有限公司 | 一种带有文丘里管的弯状非对称式燃烧器 |

| CN107559824A (zh) * | 2016-06-30 | 2018-01-09 | 深圳市爱可机器人技术有限公司 | 全预混燃烧器及包括其的烹调设备 |

| CN113915613A (zh) * | 2020-07-10 | 2022-01-11 | 欧科燃烧器有限公司 | 用于分级地燃烧燃料的方法和燃烧头 |

| EP4375571A3 (de) * | 2022-11-23 | 2024-06-12 | Beckett Thermal Solutions | Brenner mit integriertem mischer |

| EP4168712B1 (de) * | 2020-06-17 | 2024-08-07 | C.I.B. Unigas S.p.A. | Wärmeerzeugungssystem mit einem brenner mit gasturbine zur erzeugung einer flamme |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3741166A (en) * | 1972-02-10 | 1973-06-26 | F Bailey | Blue flame retention gun burners and heat exchanger systems |

| US4130388A (en) * | 1976-09-15 | 1978-12-19 | Flynn Burner Corporation | Non-contaminating fuel burner |

| JPS55107811A (en) * | 1979-02-14 | 1980-08-19 | Daido Steel Co Ltd | Radiant tube heating device |

| EP0347834A2 (de) * | 1988-06-21 | 1989-12-27 | Walter Dreizler | Brennerkopf für einen Gebläsegasbrenner |

| EP0378517A2 (de) * | 1989-01-09 | 1990-07-18 | Füllemann Patent Ag | Brenner zur Verbrennung von gasförmigen Brennstoffen und/oder flüssigen Brennstoffen in gasförmigem Zustand |

| EP0433554A1 (de) * | 1989-11-23 | 1991-06-26 | Elco Energiesysteme Ag | Brenner zur Verbrennung von flüssigen oder gasfÀ¶rmigen Brennstoffen |

-

1994

- 1994-02-21 EP EP94200429A patent/EP0612959A1/de not_active Withdrawn

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3741166A (en) * | 1972-02-10 | 1973-06-26 | F Bailey | Blue flame retention gun burners and heat exchanger systems |

| US4130388A (en) * | 1976-09-15 | 1978-12-19 | Flynn Burner Corporation | Non-contaminating fuel burner |

| JPS55107811A (en) * | 1979-02-14 | 1980-08-19 | Daido Steel Co Ltd | Radiant tube heating device |

| EP0347834A2 (de) * | 1988-06-21 | 1989-12-27 | Walter Dreizler | Brennerkopf für einen Gebläsegasbrenner |

| EP0378517A2 (de) * | 1989-01-09 | 1990-07-18 | Füllemann Patent Ag | Brenner zur Verbrennung von gasförmigen Brennstoffen und/oder flüssigen Brennstoffen in gasförmigem Zustand |

| EP0433554A1 (de) * | 1989-11-23 | 1991-06-26 | Elco Energiesysteme Ag | Brenner zur Verbrennung von flüssigen oder gasfÀ¶rmigen Brennstoffen |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 004, no. 158 (M - 039) 5 November 1980 (1980-11-05) * |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL1008233C2 (nl) | 1998-02-06 | 1999-08-09 | Clysan D W Bv | Gasbrander. |

| EP1026445A1 (de) * | 1999-02-08 | 2000-08-09 | D.W. Clysan B.V. | Gasbrenner |

| FR2794521A1 (fr) * | 1999-06-04 | 2000-12-08 | Geminox | Bruleur a gaz a ventilation forcee pour chaudiere |

| KR100365652B1 (ko) * | 2000-10-30 | 2002-12-26 | 주식회사 경동보일러 | 가스보일러 송풍기용 오리피스 믹서 |

| FR2914398A1 (fr) * | 2007-04-02 | 2008-10-03 | Pillard Chauffage | Bruleur a combustible gazeux |

| EP1980788A1 (de) * | 2007-04-02 | 2008-10-15 | Fives Pillard | Brenner für gasförmigen Kraftstoff |

| EP2098782A1 (de) * | 2007-12-02 | 2009-09-09 | Beru Aktiengesellschaft | Vorrichtung und Verfahren zum Betreiben von Flammstartanlagen, Abgasreinigungsvorrichtungen von Verbrennungskraftmaschinen (Abgas-Partikelfilter) insbesondere an Lastkraftwagen, von Blockheizkraftwerken oder Stirlingmotoren |

| CN105674269A (zh) * | 2016-03-21 | 2016-06-15 | 浙江尚鼎工业炉有限公司 | 一种带有文丘里管的弯状非对称式燃烧器 |

| CN105674269B (zh) * | 2016-03-21 | 2017-12-01 | 长兴金诺机械有限公司 | 一种带有文丘里管的弯状非对称式燃烧器 |

| CN107559824A (zh) * | 2016-06-30 | 2018-01-09 | 深圳市爱可机器人技术有限公司 | 全预混燃烧器及包括其的烹调设备 |

| EP4168712B1 (de) * | 2020-06-17 | 2024-08-07 | C.I.B. Unigas S.p.A. | Wärmeerzeugungssystem mit einem brenner mit gasturbine zur erzeugung einer flamme |

| CN113915613A (zh) * | 2020-07-10 | 2022-01-11 | 欧科燃烧器有限公司 | 用于分级地燃烧燃料的方法和燃烧头 |

| EP3940293A1 (de) * | 2020-07-10 | 2022-01-19 | ELCO Burners GmbH | Verfahren zur gestuften verbrennung eines brennstoffes und brennkopf |

| EP4375571A3 (de) * | 2022-11-23 | 2024-06-12 | Beckett Thermal Solutions | Brenner mit integriertem mischer |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR910006234B1 (ko) | 석탄 연소장치 | |

| US9822967B2 (en) | Apparatus for burning pulverized solid fuels with oxygen | |

| US5603906A (en) | Low NOx burner | |

| US4748919A (en) | Low nox multi-fuel burner | |

| KR100472900B1 (ko) | 미분탄용 연소기 | |

| US4930430A (en) | Burners | |

| JP2868515B2 (ja) | ガスタービン用燃焼室システム | |

| US4488869A (en) | High efficiency, low NOX emitting, staged combustion burner | |

| CA2226809C (en) | Flare apparatus and methods | |

| JP3404981B2 (ja) | 気体加熱装置 | |

| US5791892A (en) | Premix burner | |

| US5975887A (en) | Compact hi-spin gas burner assembly | |

| US20030233833A1 (en) | Pressure ram device on a gas turbine combustor | |

| EP0612959A1 (de) | Venturi Brenner | |

| US4115050A (en) | Burner construction and method for burning liquid and/or gaseous fuel | |

| JP2001510885A (ja) | 燃焼設備用特にガスタービン燃焼器用のバーナ装置 | |

| US6050809A (en) | Immersion tube burner with improved flame stability | |

| JP2003207132A (ja) | 液体及び/又は気体燃料で動作するガスタービンのための汚染物質低排出の予混合室及び燃焼室の改良された組合せ | |

| US3529917A (en) | Air-mixing device for fuel burner | |

| US6029647A (en) | Recuperative radiant tube with hot side vitiation | |

| US6145450A (en) | Burner assembly with air stabilizer vane | |

| US5666944A (en) | Water heating apparatus with passive flue gas recirculation | |

| US4979894A (en) | Arrangement for burning fuels in a narrow combustion space | |

| US5934898A (en) | Burner nozzle with improved flame stability | |

| JPS5827216Y2 (ja) | バ−ナ−アセンブリ− |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB IT LI LU NL SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19950301 |