EP0501840A2 - Belüftende Wand - Google Patents

Belüftende Wand Download PDFInfo

- Publication number

- EP0501840A2 EP0501840A2 EP92301772A EP92301772A EP0501840A2 EP 0501840 A2 EP0501840 A2 EP 0501840A2 EP 92301772 A EP92301772 A EP 92301772A EP 92301772 A EP92301772 A EP 92301772A EP 0501840 A2 EP0501840 A2 EP 0501840A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- panel

- ventilation

- louvres

- sheet

- apertures

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/08—Air-flow control members, e.g. louvres, grilles, flaps or guide plates

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/08—Air-flow control members, e.g. louvres, grilles, flaps or guide plates

- F24F13/082—Grilles, registers or guards

Definitions

- the following invention relates to a ventilated wall and more particularly, though not exclusively to a ventilated wall panel formed from a continuous sheet of corrugated material having ventilation apertures consecutively staggered between adjacent louvres of the corrugated material.

- the invention also relates to a method of manufacturing such a ventilated wall panel.

- Known louvred walls which aim at allowing ventilation therethrough while preventing the ingress of rain for example are formed of separate longitudinal metal louvre blades which are mounted on some form of mounting frame, one above the other.

- Such a method of constructing a louvred wall is inefficient in that vertical uprights must first be provided onto which individual horizontal slats must be separately attached. This process is labour intensive and expensive.

- louvre units such as that disclosed in US Patent No. 3302554.

- Such a louvre unit comprises a frame surrounding a moulded louvre panel of a discrete size so as to fit within a frame of a specific dimensions.

- a disadvantage of such a method of constructing a ventilated wall panel is that where panels of different size are required, separate mouldings of appropriate shape and size must be produced. The cost involved in such moulding is high.

- a method of manufacturing a ventilation panel so that lengths may be cut therefrom to form discrete panel modules including the steps of: forming a series of ventilation apertures through a sheet of metal, providing forming means, passing said sheet of metal having said apertures therethrough through the forming means to provide elongated corrugations therein, the corrugations running longitudinally of the sheet and providing louvres and ventilation regions corresponding to said apertures interposed between the louvres, the louvres in the finished product serving as an impediment to ingress of rain for example through the ventilation regions.

- such a ventilated panel may be manufactured off-site, cut to size and erected as a single unit which may in turn result in more time efficient construction of a finished wall.

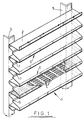

- Panel 1 comprises a sheet of corrugated material 2 formed into a plurality of adjacent louvre fins 6 having louvres 3 which are downwardly sloping for drainage purposes.

- Each louvre 3 may comprise a longitudinal deformation, such as a dog-leg bend as indicated at 9, or alternatively, may be substantially planar.

- the wall panel 1 may for example be any form of coated steel or aluminium, either of which may be zinc coated and painted, mill finished and/or anodised. Alternatively, the wall panel 1 may be formed of any suitable plastics material.

- each louvre 3 Extending essentially horizontally from the outer extremity of each louvre 3 to the inner extremity of the next below louvre is a ventilation strip 7 perforated so as to have a plurality of ventilation apertures 4.

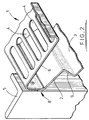

- the ventilated wall panel 1 is adapted to be attached by way of bolts for example to a pair of vertical uprights 5. It should be appreciated that vertical uprights 5 are located on an interior side of wall panel 1 such that the ventilation apertures 4 are protected from downward ingress of water for example due to the presence of the louvres 3 thereabove.

- the sheet of corrugated material 2 may be formed in continuous lengths, though should extra vertical extension of the ventilated wall panel be required, a lower edge of one panel may be overlapped with an upper edge of a downwardly adjacent panel as depicted at 8 in Figure 2.

- the ventilated wall panel 1 is typically roll formed, though pressing is an alternative method of forming individual panel lengths.

- the method of manufacturing the ventilated wall panel 1, typically comprises punching apertures 4 in desired locations in a flat elongated sheet of metal or other suitable material. Once the apertures 4 are punched in the metal sheet, the sheet may be formed into the corrugated configuration depicted by conventional roll forming techniques.

- the sheet is to be manufactured by pressing, the sheet again would be punched to provide the apertures 4, and then pressed to have the corrugations.

- Ventilation apertures 4 being provided in the essentially horizontal strip 7 may be of any suitable shape such as the elongate slots depicted, or circular for example.

- the holes 4 would preferably be punched in the sheet material before forming to the corrugated configuration.

- the wall panel 1 need not be attached to a vertical support bracket 5 as depicted, though edges of panel 1 may be located within a recess of a suitable U-section for example.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Building Environments (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU4893/91 | 1991-03-01 | ||

| AUPK489391 | 1991-03-01 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0501840A2 true EP0501840A2 (de) | 1992-09-02 |

| EP0501840A3 EP0501840A3 (en) | 1993-04-28 |

Family

ID=3775257

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19920301772 Withdrawn EP0501840A3 (en) | 1991-03-01 | 1992-03-02 | Ventilated wall |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0501840A3 (de) |

| GB (1) | GB9204457D0 (de) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19729015A1 (de) * | 1997-07-02 | 1999-01-07 | Karl Kern | Verkleidungsblech und Verfahren zu seier Herstellung |

| FR2792168A1 (fr) * | 1999-04-15 | 2000-10-20 | Pab Nord | Batiment d'elevage d'animaux a ventelles |

| WO2004073793A1 (de) * | 2003-02-20 | 2004-09-02 | Adolf Wiebecke | Vorrichtung zur beeinflussung, ablenkung und/oder reflexion terrestrischer und atmosphärischer strahlungen oder felder |

| EP1455144A1 (de) * | 2003-03-07 | 2004-09-08 | Uebigauer Elektro- und Schaltanlagen UESA GmbH | Lüftungsgitter |

| EP2847518A4 (de) * | 2012-04-02 | 2016-03-23 | Dantherm Cooling As | Lufteinlass |

| EP3412843A1 (de) | 2017-06-09 | 2018-12-12 | Daw Se | Ventilationssystem für die wandfläche eines gebäudes und verwendung des ventilationssystems für die trocknung von fassadenoberflächen oder für die verhinderung der kondensation von wasser an fassadenoberflächen |

| IT201900019220A1 (it) * | 2019-10-18 | 2021-04-18 | Maria Incampo | Griglia di aerazione a filo muro |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3302554A (en) * | 1965-01-05 | 1967-02-07 | Leslie Welding Co Inc | One piece louver unit |

| DE2411728A1 (de) * | 1974-03-12 | 1975-09-18 | Gervin Mueller | Luefterwand zum einbau in die aussenwand eines gebaeudes |

-

1992

- 1992-03-02 EP EP19920301772 patent/EP0501840A3/en not_active Withdrawn

- 1992-03-02 GB GB929204457A patent/GB9204457D0/en active Pending

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19729015A1 (de) * | 1997-07-02 | 1999-01-07 | Karl Kern | Verkleidungsblech und Verfahren zu seier Herstellung |

| DE19729015C2 (de) * | 1997-07-02 | 2000-08-17 | Karl Kern | Verkleidungsblech |

| FR2792168A1 (fr) * | 1999-04-15 | 2000-10-20 | Pab Nord | Batiment d'elevage d'animaux a ventelles |

| LU90560B1 (fr) * | 1999-04-15 | 2001-11-23 | Pab Nord | B-timent d'-levage d'animaux - ventelles |

| WO2004073793A1 (de) * | 2003-02-20 | 2004-09-02 | Adolf Wiebecke | Vorrichtung zur beeinflussung, ablenkung und/oder reflexion terrestrischer und atmosphärischer strahlungen oder felder |

| EP1455144A1 (de) * | 2003-03-07 | 2004-09-08 | Uebigauer Elektro- und Schaltanlagen UESA GmbH | Lüftungsgitter |

| EP2847518A4 (de) * | 2012-04-02 | 2016-03-23 | Dantherm Cooling As | Lufteinlass |

| EP3412843A1 (de) | 2017-06-09 | 2018-12-12 | Daw Se | Ventilationssystem für die wandfläche eines gebäudes und verwendung des ventilationssystems für die trocknung von fassadenoberflächen oder für die verhinderung der kondensation von wasser an fassadenoberflächen |

| IT201900019220A1 (it) * | 2019-10-18 | 2021-04-18 | Maria Incampo | Griglia di aerazione a filo muro |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0501840A3 (en) | 1993-04-28 |

| GB9204457D0 (en) | 1992-04-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5465486A (en) | Siding panel and support strip assembly and method of production | |

| CA1081912A (en) | Cladding panel | |

| EP0397516B1 (de) | Wandvertäfelungssystem | |

| US4280399A (en) | Roof ridge ventilator | |

| US5288269A (en) | Continuous in-line method of fabricating a variable pitch roof ridge vent assembly and the assembly thereof | |

| US5181350A (en) | Leaf deflecting cover device for a rain gutter | |

| GB2328013A (en) | Louver assembly | |

| EP1452658B1 (de) | Gerader Träger zur Verwendung in gebogenen abgehängten Decken und Verfahren zur dessen Herstellung | |

| AU658244B2 (en) | Equipment for the ventilation of the passenger space of rapidly moving lift | |

| SE469562B (sv) | Haengande tak samt daeri ingaaende plaat | |

| EP0501840A2 (de) | Belüftende Wand | |

| GB2199857A (en) | Building panels | |

| US3015135A (en) | Ventilated metal awning | |

| CA1180162A (en) | Grid supported structure | |

| US5728000A (en) | Eave vent | |

| US3931725A (en) | Mobile machine for producing metal siding | |

| US2828711A (en) | Method of making louver type ventilators | |

| CA2568111C (en) | Light weight metal framing member | |

| US20030074844A1 (en) | Stormwater downpipe | |

| US3625136A (en) | Louver assembly | |

| RU69895U1 (ru) | Поперечный потолочный профиль | |

| EP2155981B1 (de) | Stützrahmen | |

| CN221503131U (zh) | 一种组合式百叶窗 | |

| EP2063196B1 (de) | Jalousiesystem und Verfahren zur Herstellung einer Jalousieeinheit für ein solches System | |

| JP3806136B1 (ja) | 建造物用通気板 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL PT SE |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE DE DK ES FR GB IT NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19930303 |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19931026 |