EP0447906B1 - Locking device for unlocking or locking by the insertion of a card key provided with a plurality of holes - Google Patents

Locking device for unlocking or locking by the insertion of a card key provided with a plurality of holes Download PDFInfo

- Publication number

- EP0447906B1 EP0447906B1 EP91103649A EP91103649A EP0447906B1 EP 0447906 B1 EP0447906 B1 EP 0447906B1 EP 91103649 A EP91103649 A EP 91103649A EP 91103649 A EP91103649 A EP 91103649A EP 0447906 B1 EP0447906 B1 EP 0447906B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tumblers

- slider

- locking device

- card key

- tapered tips

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000037431 insertion Effects 0.000 title description 3

- 238000003780 insertion Methods 0.000 title description 3

- 238000007373 indentation Methods 0.000 claims 10

- 230000000694 effects Effects 0.000 abstract description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 1

- 229910001234 light alloy Inorganic materials 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B27/00—Cylinder locks or other locks with tumbler pins or balls that are set by pushing the key in

- E05B27/0028—Other locks than cylinder locks with tumbler pins or balls

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B35/00—Locks for use with special keys or a plurality of keys ; keys therefor

- E05B35/007—Locks for use with special keys or a plurality of keys ; keys therefor the key being a card, e.g. perforated, or the like

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B65/00—Locks or fastenings for special use

- E05B65/52—Other locks for chests, boxes, trunks, baskets, travelling bags, or the like

Definitions

- This invention relates to a locking device for unlocking or locking by the insertion of a lock card or card key therein provided with a plurality of holes according to the first part of claim 1.

- the known locking devices comprise a slider having a plurality of tumblers, a card key provided with several holes through which pre-determined portions of the tumblers project out, a groove to guide the card key to the tips of the tumblers, a mechanism to slide the slider when the pre-determined portions of each tumbler project out, and a mechanism for unlocking or locking by sliding the slider.

- the slider comprises a step portion which the card key pushes to move the slider.

- the edge of the card key pushes the step portion of the slider for unlocking or locking, the sliding of the card key and the slider are stopped by the step portion. This stop is often bothersome, especially in these days when other computer-controlled card keys used for hotels and the like only slide in a groove without stops.

- the slider of the known locking devices can move only one way for unlocking or locking.

- the object of this invention is to provide a locking device for unlocking or locking which requires only sliding of a card key without stops by a step portion.

- the card key moves the slider by means of the tumblers.

- the tumblers are mounted on the slider and can freely advance and retreat.

- each tumbler retreats and disengages from the holes of the card key. Namely, when the card key continuously moves along the points of the tumblers, the tumblers engage with the holes of the card key for unlocking or locking, and then the tumblers once inserted into the holes of the card key disengange from the holes. Therefore, the card key effects unlocking or locking without stopping of the sliding by a step portion.

- Fig. 1 is a partial sectional view of a locking device of the present invention.

- Fig. 2 is a sectional view of Fig. 1 taken along the line A-A.

- Fig. 3 is a plan view of a card key of the first embodiment.

- Fig. 4 is a front view of the card key of Fig. 3.

- Fig. 5 is an external view of a suitcase incorporating the present invention.

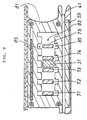

- Figs. 6, 7 and 8 are sectional views around a slider of the first embodiment.

- Fig. 9 is an explanatory view of a groove member of the present invention.

- Fig. 10 is a front view of a slider of the second embodiment.

- Fig. 11 is a plan view of the slider of Fig. 10.

- Fig. 12 is a bottom view of the slider of Fig. 10.

- Fig. 13 is a left side view of the slider of Fig. 10.

- Fig. 14 is a sectional view of the slider of Fig. 10 taken along F-F.

- Fig. 15 is a plan view of tumblers of the second embodiment.

- Fig. 16 is a sectional view of the tumblers of Fig. 15 taken along G-G.

- Fig. 17 is a bottom view of the tumblers of Fig. 15.

- Fig. 18 is a front view of the tumblers of Fig. 15.

- Fig. 19 is a plan view of the tumblers of the second embodiment.

- Fig. 20 is a sectional view of the tumblers of Fig. 19 taken along the line H-H.

- Fig. 21 is a bottom view of the tumblers of Fig. 19.

- Fig. 22 is a front view of the tumblers of Fig. 19.

- Fig. 23 is a plan view of a card key of the second embodiment.

- a suitcase 1 comprises a grip 7 and a case member 9 as shown in Fig. 5.

- the case member 9 consists of a first case 9A and a second case 9B.

- the grip 7 is positioned on the suitcase 9 at the point the first case 9A and the second case 9B are combined.

- a locking device 3 is constructed between the first case 9A and the second case 9B adjacent to the grip 7.

- the locking device 3 comprises a slider 11, five tumblers 21 through 25, a first engaging projection 31, a first receiving portion 33, a second engaging projection 35, a second receiving portion 37, a first main body 41 and a second main body 43.

- the second main body 43 is fixed to the second case 9B by means of a plurality of fixing machine screws 45.

- An aperture 43a is formed on the second main body 43 in the direction where the first case 9A is moved to close the two cases 9A and 9B.

- the second main body 43 further comprises an aperture 43b in the first main body 41 side.

- the second receiving portion 37 is a cast made of light alloy, and has a pre-determined thickness of da as illustrated in Fig. 2.

- One end 37a of the second receiving portion 37 is T-shaped, while the other end 37b which projects out of the second main body 43 through the aperture 43b is U-shaped.

- This projecting portion of the end 37b is rotatably fixed to an axis member 46. Both ends of the axis member 46 are fixed to the first main body 41.

- a hook 37c is formed in the middle of the second receiving portion 37.

- the second receiving portion 37 is prevented from moving in the transverse and the height directions by the second main body 43.

- the second receiving portion 37 is

- the second engaging projection 35 is fixed to the first case 9A by means of two fixing machine screws 47.

- This second engaging projection 35 is constructed such that the hook 35a of the projection 35 is inserted into the second main body 43 through the aperture 43a of the second main body 43 when the first case 9A and the second case 9B are combined.

- the hook 35a of the second engaging projection 35 meshes with the hook 37c of the second receiving portion 37 as shown in Fig. 1 in order to keep the two cases 9A and 9B combined.

- An iron framework member 51 is fixed to the second main body 43 between the second receiving portion 37 and the second case 9B by means of a plurality of fixing machine screws 45.

- One end 51a of the framework member 51 is formed between the first main body 41 and the second case 9B, and stretches to the middle of the first main body 41. This end 51a thus supports a first axis member 53 such that the first axis member 53 is fixed to a pre-determined point of the second case 9B in the first main body 41.

- One end of a linking member 55 is rotatably fixed to the first axis member 53, and a second axis member 57 is supported on the other end of the linking member 55.

- the second axis member 57 rotates along a circumference EK shown with an alternate long and two short dashes line in Fig. 2 with the center being the first axis member 53.

- Both ends of the second axis member 57 are rotatably fixed to the first main body 41 as shown in Figs. 1 and 2.

- the components of the instant invention act in cooperation with each other as follows.

- the first main body 41 fluctuates along an alternate long and two short dashes line with the first and second axis members 53 and 57 being its axes.

- the first main body 41 then moves in the directions of the arrow YA and an arrow YB.

- the second receiving portion 37 linked to the first main body 41 slides in the direction of the arrow YB in accordance with the movement of the body 41. Consequently, as illustrated in Fig. 1, the hook 35a of the second engaging projection 35 engages with the hook 37c of the second receiving portion 37 until the second receiving portion 37 moves in the direction of the arrow YB such that the suitcase 1 is locked.

- the hooks 35a and 37c are disengaged. The suitcase 1 is thus unlocked, enabling the first case 9A and the second case 9B to be separated.

- the slider 11 is mounted inside the first main body 41, and can slide in the longitudinal direction of the first main body 41. The movement of the slider 11 in the transverse and the height directions is controlled.

- a slit 59 is formed in the first main body 41 along one side 11b of the slider 11 as illustrated in Fig. 1, Fig. 6 describing the details of the slider 11 and Fig. 7 showing a sectional view taken along B-B of Fig. 6.

- a concave member 60 is formed adjacent to the slit 59 in opposition to the side 11b of the slider 11. The slit 59 guides the card key 5 along the side 11b of the slider 11. The concave member 60 determines the maximum amount of projections of the tumblers 21 through 25.

- the first engaging projection 31 is connected with the slider 11a in the second case 9B side of the slider 11. As shown in Fig. 2 and Fig. 8 illustrating the details of Fig. 2, the first engaging projection 31 is L-shaped, and is inserted into the second case 9B through an opening 9Ba formed in the second case 9B. Adjacent to the opening 9Ba is the first receiving portion 33 which is a part of the second case 9B.

- the first engaging projection 31 is positioned such that a projecting portion 31a of the engaging projection 31 is opposite to the first receiving portion 33 when the slider 11 is located as illustrated in Fig. 2. Since the projecting portion 31a engages with the first receiving portion 33, the first main body 41 cannot be pulled up in the direction of the arrow YA.

- the tumblers 21 through 25 are provided on the slider 11 at the same intervals in the longitudinal direction of the slider 11.

- the tumblers 21 through 25 are slidingly inserted into the slider 11 in the transverse direction of the slider 11. Openings 11a1 through 11a5 are formed along the tumblers 21 through 25 in the side of case 9B as shown in Figs. 2, 7 and 8.

- the tumblers 21 through 25 are equipped with tapered tips 21a through 25a and body portions 21b through 25b as shown in Fig. 6.

- Coil springs 61 are provided inside the body portions 21b through 25b in the slider 11. The coil springs 61 actuate the tumblers 21 through 25 in the direction from the slider 11 to the slit 59.

- rectangular engaging projections 71 through 75 are located on pre-determined points of the tumblers 25 in the side of the second case 9B.

- the engaging projections 71 through 75 protrude outside the slider 11 in the side of the second case 9B via the openings 11al through 11a5 of the slider 11.

- a groove-forming member 81 is provided adjacent to the openings 11a1 through 11a5 of the slider 11 in the side of the second case 9B of the first main body 41.

- the groove-forming member 81 is equipped with a groove 83 and side slots 85 as shown in Fig. 9 which shows a sectional view of Fig. 2 taken on the line C-C.

- Fig. 9 illustrates, the slider 11 freely slides in the longitudinal direction when all of the engaging projections 71 through 75 are positioned inside the groove 83.

- the slider 11 cannot slide in the longitudinal direction.

- Relative positions of the engaging projections 71 through 75 and the groove 83 are determined in accordance with the projections of the tumblers 21 through 25 from the slider 11 into the slit 59.

- the projections into the slit 59 change according to the sliding of the card key 5 shown in Figs. 3 and 4.

- the card key has a plurality of holes 87 at the same intervals as the tumblers 21 through 25.

- the holes 87 receive the acuminate members 21a through 25a.

- the holes 87 are formed at the pre-determined points A through E.

- a pre-determined size e.g. full, large, medium, small or none, is selected for each of the points A through E.

- the holes 87 are formed at predetermined points of the card key 5.

- the points A, B, C, D and E are bilaterally symmetrical with their center being the center line in the longitudinal direction of the card key 5. The card key 5 is thus able to be inserted into the slit 59 from both directions.

- the diameters of the holes 87 of the card key 5 and the positions of the engaging projections 71 through 75 of the tumblers 21 through 25 are orderly determined. As shown in Fig. 6, all of the engaging projections 71 through 75 are located inside the groove 83 as illustrated in Fig. 9 only when the tumblers 21 through 25 engage with the card key 5, and thus the slider 11 can slide in the longitudinal direction.

- At least one of the points A through E of the holes 87 is a full hole.

- This hole indicates, for instance, a hole through which the tumbler 23 protrudes till the tapered tip 23a reaches the concave member 60 as shown in Fig. 6.

- the tumblers 21 through 25 are constructed, in the case of the tumbler 23, such that a boundary member 23c separating the tapered tip 23a and the body portion 23b abuts an inside edge 5E of the full hole at point C.

- the boundary member 23C is formed between the tapered tip 23a and the body portion 23b.

- the boundary member 23c abuts the card key 5 more vertically than the tapered tip 23a.

- the tumblers 21 through 25 engage with the smaller holes (large, medium and small), the inside edge 5E abuts the tapered tips 21a through 25a. In this case, the tumblers 21 through 25 do not receive great pushing force in the sliding direction of the card key 5 even when the card key 5 slides. The tumblers 21 through 25 receive great pushing force in the direction where the tumblers 21 through 25 are pushed.

- the card 5 key slides in the slit 59 till the key 5 engages with the tumblers 21 through 25 as shown in Fig. 6.

- the tumblers 21 through 25 are successively pushed into the slider 11 in accordance with the sliding of the card key 5 and the card key 5 slides in the slit 59.

- at least one of the engaging projections 71 through 75 is positioned inside the engaging concave member 85, and thus the slide 11 cannot slide.

- the first engaging projection 31 moves in the direction of the arrow YB when the card key slides in the direction of the arrow YB in Fig. 2. Accordingly, the first main body 41 can be pulled up in the direction of the arrow YA, so that the locking device 3 is unlocked without stopping of the card key 5 by steps or the like.

- the first engaging projection 31 moves in the reverse direction of the arrow YB when the card key 5 slides in the slit 59 in the reverse direction of the arrow YB. Therefore, the first main body 41 cannot be pulled up in the direction of the arrow YA, so that the locking device 3 is also locked without stopping of the card key 5 by steps or the like.

- the suitcase 1 in the aforementioned embodiment can be unlocked or locked by sliding the card key 5 in the slit 59 mounted adjacent to the grip 7 without stopping of the card key by steps or the like. Therefore, the card key 6 can effect unlocking or locking more smoothly than a conventional card key.

- a slider 111, tumblers 121 through 125, and a card key 105 are employed in this embodiment instead of the slider 11, the tumblers 21 through 25, and the card key 5 of the first embodiment, respectively.

- the slider 111 comprises a first engaging projection 131, openings 111a1 through 111a5 and receiving chambers 111b1 through 111b5.

- the first engaging projection 131 and the openings 111a1 through 111a5 have almost the same structures as the first engaging projection 31 and the openings 11a1 through 11a5 of the first embodiment.

- the receiving chambers 111b1 through 111b5 have quadrilateral sections.

- the tumblers 121 through 125 are slidingly inserted into the receiving chambers lllbl through 111b5.

- the tumblers 121, 123 and 125 comprise tapered tips 121a, 123a and 125a, quadrilateral tube-like body portions 121b, 123b and 125b, and engaging projections 171, 173 and 175, respectively.

- the tapered tips 121a, 123a and 125a are formed below an axis JC of the quadrilateral body portions 121b, 123b and 125b as shown in Fig. 16.

- Dimensions L1 and L2 of the engaging projections 171, 173 and 175 in Fig. 16 are selected from Table 1, No. 1 through No. 3.

- the tumblers 122 and 124 comprise tapered tips 122a and 124a, quadrilateral tube-like body portions 122b and 124b, and engaging projections 172 and 174, respectively, as shown in Figs. 19 and 20.

- the tapered tips 122a and 124a are formed above the axis JC of thequadrilateral body portions 122b and 124b as illustrated in Fig. 20.

- Dimensions L1 and L2 of the engaging projections 172 and 174 in Fig 20 are selected from Table 1, No. 1 through No. 3 shown above.

- the card key 105 shown in Fig. 23 changes the projecting portions of the tumblers 121 through 125 inserted into the slider 111.

- the card key 105 is provided with a plurality of holes 187.

- the holes 187 are positioned at points AL, BL, CL, DL and EL in Fig. 23 in accordance with the positions of the tumblers 121 through 125.

- the points AL, CL and EL are provided along a line LL1, and the points BL and DL are along a line LL2.

- the centers of the tapered tips 121a, 123a and 125s are on the line LL1 during engagement with the holes 187.

- the centers of the tapered tips 122a and 124a are on the line LL2 during engagement with the holes 187.

- Dimensions D1 and D2 of the holes 187 are selected from Table 2, No. 1 through No. 3.

- Table 1 and Table 2 are selected for each tumbler, the predetermined portions of the tumblers project out and the slider 111 can slide in the longitudinal direction.

- At least one of the points AL through EL for the holes 187 is a full hole.

- the tapered tips 121a through 125a reach the concave member 60 through the full hole, wherein boundary members 220 of the tumblers 121 through 125 in Figs. 15 and 19 abut an inner edge 230 of the full hole in Fig. 23, as in the first embodiment.

- the boundary members 220 are formed between the tapered tips 121a through 125a and the quadrilateral body portions 121b and 125b. The boundary members 220 abut the card key 105 more vertically in the sliding direction than the tapered tips 121a through 125a.

- the tumblers 121 through 125 engage with the smaller hole (No. 2 in Table 2), the inner edge 230 of the smaller hole abuts the tapered tips 121a through 125a. If No.3 in Table 2 is selected for the holes which does not form a hole, the tapered tips 121a through 125a are not inserted into the card key 105. If No. 2 or No. 3 in Table 2 is selected, the tumblers 121 through 125 does not receive great pushing force in the sliding direction from the card key 105 during sliding of the card key. When No. 2 in Table 2 is selected, the tumblers 121 through 125 receive great pushing force in the direction where the tumblers are pushed into the slider 111.

- the locking device 3 can attain locking or unlocking operation by sliding the card key without stops by a step portion.

- the tapered tips 121a, 123a and 125a are formed in the upper position, and the tapered tips 122a and 124a are in the lower position.

- the tumblers 121 through 125 are placed in a line, but the holes 187 and the tapered tips 121a through 125a are positioned in two lines. Accordingly, a wider variety of alternatives for unlocking or locking operation can be made in this embodiment than simply selecting from three types of dimensions for five tumblers placed in a line. A locking device difficult to break with simple structure can be thus provided.

- This invention is not limited to the embodiment illustrated and described as above, but can be applied to a wide variety of locking devices.

- the configuration of the card key and the holes, the number of the holes and the tumblers and the like do not have to be the same as in this embodiment.

- pushing force can be adjusted by changing the quality or configuration of the tapered tips of the tumblers, though the pressure is controlled by changing the angle at which the tumblers abuts the edges of the holes of the card key in the instant invention.

- the tapered tips of the tumblers can be positioned in the left or right of the axis of the tumblers instead of the tapered tips the centers of which are positioned along the axis or above or below the axis as in the aforementioned embodiments.

- the tapered tips can be also located on pre-determined area of the front of the tumblers with the front being divided lengthwise and crosswise into a pre-determined number of the predetermined area.

Landscapes

- Lock And Its Accessories (AREA)

- Purses, Travelling Bags, Baskets, Or Suitcases (AREA)

- Bag Frames (AREA)

- Closures For Containers (AREA)

Abstract

Description

- This invention relates to a locking device for unlocking or locking by the insertion of a lock card or card key therein provided with a plurality of holes according to the first part of claim 1.

- Currently, locking devices for unlocking or locking by the insertion of a card key provided with a plurality of holes are disclosed, for example, in US-A-4,754,630 (cf. preamble of claim 1), JP-A-62-268481 and JP-A-62-228578. The known locking devices comprise a slider having a plurality of tumblers, a card key provided with several holes through which pre-determined portions of the tumblers project out, a groove to guide the card key to the tips of the tumblers, a mechanism to slide the slider when the pre-determined portions of each tumbler project out, and a mechanism for unlocking or locking by sliding the slider. In addition, the slider comprises a step portion which the card key pushes to move the slider.

- Since the edge of the card key pushes the step portion of the slider for unlocking or locking, the sliding of the card key and the slider are stopped by the step portion. This stop is often bothersome, especially in these days when other computer-controlled card keys used for hotels and the like only slide in a groove without stops. Moreover, the slider of the known locking devices can move only one way for unlocking or locking.

- Wherefore, the object of this invention is to provide a locking device for unlocking or locking which requires only sliding of a card key without stops by a step portion.

- Other objects and benefits of the invention will become apparent from the detailed description which follows hereinafter when taken in conjunction with the drawing figures which accompany it.

- The above-mentioned object is attained by the characterizing features of claim 1.

- The card key moves the slider by means of the tumblers. The tumblers are mounted on the slider and can freely advance and retreat. When the card key continues moving in the direction in which the slider moves after unlocking or locking is completed and the slider stops moving, each tumbler retreats and disengages from the holes of the card key. Namely, when the card key continuously moves along the points of the tumblers, the tumblers engage with the holes of the card key for unlocking or locking, and then the tumblers once inserted into the holes of the card key disengange from the holes. Therefore, the card key effects unlocking or locking without stopping of the sliding by a step portion.

- Fig. 1 is a partial sectional view of a locking device of the present invention.

- Fig. 2 is a sectional view of Fig. 1 taken along the line A-A.

- Fig. 3 is a plan view of a card key of the first embodiment.

- Fig. 4 is a front view of the card key of Fig. 3.

- Fig. 5 is an external view of a suitcase incorporating the present invention.

- Figs. 6, 7 and 8 are sectional views around a slider of the first embodiment.

- Fig. 9 is an explanatory view of a groove member of the present invention.

- Fig. 10 is a front view of a slider of the second embodiment.

- Fig. 11 is a plan view of the slider of Fig. 10.

- Fig. 12 is a bottom view of the slider of Fig. 10.

- Fig. 13 is a left side view of the slider of Fig. 10.

- Fig. 14 is a sectional view of the slider of Fig. 10 taken along F-F.

- Fig. 15 is a plan view of tumblers of the second embodiment.

- Fig. 16 is a sectional view of the tumblers of Fig. 15 taken along G-G.

- Fig. 17 is a bottom view of the tumblers of Fig. 15.

- Fig. 18 is a front view of the tumblers of Fig. 15.

- Fig. 19 is a plan view of the tumblers of the second embodiment.

- Fig. 20 is a sectional view of the tumblers of Fig. 19 taken along the line H-H.

- Fig. 21 is a bottom view of the tumblers of Fig. 19.

- Fig. 22 is a front view of the tumblers of Fig. 19.

- Fig. 23 is a plan view of a card key of the second embodiment.

- Illustrative embodiments of the present invention are described hereinafter with reference to the drawings.

- A suitcase 1 comprises a grip 7 and a case member 9 as shown in Fig. 5. The case member 9 consists of a

first case 9A and asecond case 9B. The grip 7 is positioned on the suitcase 9 at the point thefirst case 9A and thesecond case 9B are combined. Alocking device 3 is constructed between thefirst case 9A and thesecond case 9B adjacent to the grip 7. - As can be seen in Figs. 1 and 2, the

locking device 3 comprises aslider 11, fivetumblers 21 through 25, a firstengaging projection 31, a first receivingportion 33, a secondengaging projection 35, a second receivingportion 37, a firstmain body 41 and a secondmain body 43. - The second

main body 43 is fixed to thesecond case 9B by means of a plurality offixing machine screws 45. Anaperture 43a is formed on the secondmain body 43 in the direction where thefirst case 9A is moved to close the twocases main body 43 further comprises anaperture 43b in the firstmain body 41 side. The second receivingportion 37 is a cast made of light alloy, and has a pre-determined thickness of da as illustrated in Fig. 2. Oneend 37a of the second receivingportion 37 is T-shaped, while the other end 37b which projects out of the secondmain body 43 through theaperture 43b is U-shaped. This projecting portion of the end 37b is rotatably fixed to anaxis member 46. Both ends of theaxis member 46 are fixed to the firstmain body 41. Ahook 37c is formed in the middle of the second receivingportion 37. The second receivingportion 37 is prevented from moving in the transverse and the height directions by the secondmain body 43. The second receivingportion 37 is movable in the longitudinal direction. - The second

engaging projection 35 is fixed to thefirst case 9A by means of twofixing machine screws 47. This secondengaging projection 35 is constructed such that thehook 35a of theprojection 35 is inserted into the secondmain body 43 through theaperture 43a of the secondmain body 43 when thefirst case 9A and thesecond case 9B are combined. As mentioned later, thehook 35a of the secondengaging projection 35 meshes with thehook 37c of the second receivingportion 37 as shown in Fig. 1 in order to keep the twocases - An

iron framework member 51 is fixed to the secondmain body 43 between the second receivingportion 37 and thesecond case 9B by means of a plurality offixing machine screws 45. Oneend 51a of theframework member 51 is formed between the firstmain body 41 and thesecond case 9B, and stretches to the middle of the firstmain body 41. Thisend 51a thus supports afirst axis member 53 such that thefirst axis member 53 is fixed to a pre-determined point of thesecond case 9B in the firstmain body 41. - One end of a linking

member 55 is rotatably fixed to thefirst axis member 53, and asecond axis member 57 is supported on the other end of the linkingmember 55. Thesecond axis member 57 rotates along a circumference EK shown with an alternate long and two short dashes line in Fig. 2 with the center being thefirst axis member 53. Both ends of thesecond axis member 57 are rotatably fixed to the firstmain body 41 as shown in Figs. 1 and 2. - According to the aforementioned structure of the first

main body 41 and the secondmain body 43 shown above, the components of the instant invention act in cooperation with each other as follows. - When an

eaves member 41a at the end of the firstmain body 41 in the state illustrated in Fig. 2 is pulled up in a direction of an arrow YA, the firstmain body 41 fluctuates along an alternate long and two short dashes line with the first andsecond axis members main body 41 then moves in the directions of the arrow YA and an arrow YB. - The

second receiving portion 37 linked to the firstmain body 41 slides in the direction of the arrow YB in accordance with the movement of thebody 41. Consequently, as illustrated in Fig. 1, thehook 35a of the secondengaging projection 35 engages with thehook 37c of the second receivingportion 37 until the second receivingportion 37 moves in the direction of the arrow YB such that the suitcase 1 is locked. When theeaves member 41a is pulled up in the direction of the arrow YA and the second receivingportion 37 moves in the direction of the arrow YB, thehooks first case 9A and thesecond case 9B to be separated. - Following next is the first embodiment of the present invention, describing the structures of the

slider 11, thetumblers 21 through 25 and the like which effect or prevent the movement of the firstmain body 41 in the direction of the arrow YA. - As can be seen in Figs. 1 and 2, the

slider 11 is mounted inside the firstmain body 41, and can slide in the longitudinal direction of the firstmain body 41. The movement of theslider 11 in the transverse and the height directions is controlled. - A

slit 59 is formed in the firstmain body 41 along one side 11b of theslider 11 as illustrated in Fig. 1, Fig. 6 describing the details of theslider 11 and Fig. 7 showing a sectional view taken along B-B of Fig. 6. Aconcave member 60 is formed adjacent to theslit 59 in opposition to the side 11b of theslider 11. Theslit 59 guides thecard key 5 along the side 11b of theslider 11. Theconcave member 60 determines the maximum amount of projections of thetumblers 21 through 25. - The first

engaging projection 31 is connected with theslider 11a in thesecond case 9B side of theslider 11. As shown in Fig. 2 and Fig. 8 illustrating the details of Fig. 2, the firstengaging projection 31 is L-shaped, and is inserted into thesecond case 9B through an opening 9Ba formed in thesecond case 9B. Adjacent to the opening 9Ba is the first receivingportion 33 which is a part of thesecond case 9B. The firstengaging projection 31 is positioned such that a projectingportion 31a of the engagingprojection 31 is opposite to the first receivingportion 33 when theslider 11 is located as illustrated in Fig. 2. Since the projectingportion 31a engages with the first receivingportion 33, the firstmain body 41 cannot be pulled up in the direction of the arrow YA. On the other hand, when theslider 11 positioned as shown in Fig. 2 is moved in the direction of the arrow YB, the projectingportion 31a is not opposite to the first receivingportion 33. Therefore, the projectingportion 31a disengages from the first receivingportion 33, and the firstmain body 41 can be pulled up in the direction of the arrow YA. - The

tumblers 21 through 25 are provided on theslider 11 at the same intervals in the longitudinal direction of theslider 11. Thetumblers 21 through 25 are slidingly inserted into theslider 11 in the transverse direction of theslider 11. Openings 11a1 through 11a5 are formed along thetumblers 21 through 25 in the side ofcase 9B as shown in Figs. 2, 7 and 8. Thetumblers 21 through 25 are equipped withtapered tips 21a through 25a andbody portions 21b through 25b as shown in Fig. 6. Coil springs 61 are provided inside thebody portions 21b through 25b in theslider 11. The coil springs 61 actuate thetumblers 21 through 25 in the direction from theslider 11 to theslit 59. - As shown in Figs. 2, 7 and 8, rectangular

engaging projections 71 through 75 are located on pre-determined points of thetumblers 25 in the side of thesecond case 9B. The engagingprojections 71 through 75 protrude outside theslider 11 in the side of thesecond case 9B via the openings 11al through 11a5 of theslider 11. - A groove-forming

member 81 is provided adjacent to the openings 11a1 through 11a5 of theslider 11 in the side of thesecond case 9B of the firstmain body 41. The groove-formingmember 81 is equipped with agroove 83 andside slots 85 as shown in Fig. 9 which shows a sectional view of Fig. 2 taken on the line C-C. As Fig. 9 illustrates, theslider 11 freely slides in the longitudinal direction when all of the engagingprojections 71 through 75 are positioned inside thegroove 83. On the other hand, if any of the engagingprojections 71 through 75 are inserted into theside slots 85, theslider 11 cannot slide in the longitudinal direction. - Relative positions of the engaging

projections 71 through 75 and thegroove 83 are determined in accordance with the projections of thetumblers 21 through 25 from theslider 11 into theslit 59. The projections into theslit 59 change according to the sliding of thecard key 5 shown in Figs. 3 and 4. - The card key has a plurality of holes 87 at the same intervals as the

tumblers 21 through 25. When thecard key 5 is inserted into theslit 59, the holes 87 receive theacuminate members 21a through 25a. The holes 87 are formed at the pre-determined points A through E. A pre-determined size, e.g. full, large, medium, small or none, is selected for each of the points A through E. The holes 87 are formed at predetermined points of thecard key 5. The points A, B, C, D and E are bilaterally symmetrical with their center being the center line in the longitudinal direction of thecard key 5. Thecard key 5 is thus able to be inserted into theslit 59 from both directions. - The diameters of the holes 87 of the

card key 5 and the positions of the engagingprojections 71 through 75 of thetumblers 21 through 25 are orderly determined. As shown in Fig. 6, all of the engagingprojections 71 through 75 are located inside thegroove 83 as illustrated in Fig. 9 only when thetumblers 21 through 25 engage with thecard key 5, and thus theslider 11 can slide in the longitudinal direction. - At least one of the points A through E of the holes 87 is a full hole. This hole indicates, for instance, a hole through which the

tumbler 23 protrudes till the taperedtip 23a reaches theconcave member 60 as shown in Fig. 6. Thetumblers 21 through 25 are constructed, in the case of thetumbler 23, such that aboundary member 23c separating the taperedtip 23a and thebody portion 23b abuts an inside edge 5E of the full hole at point C. The boundary member 23C is formed between thetapered tip 23a and thebody portion 23b. Theboundary member 23c abuts thecard key 5 more vertically than the taperedtip 23a. - When the

card key 5 slides with thetumblers 21 through 25 engaging with the full hole, thetumblers 21 through 25 engaging with the full hole receive great pushing force in the sliding direction of thecard key 5. - While the

tumblers 21 through 25 engage with the smaller holes (large, medium and small), the inside edge 5E abuts the taperedtips 21a through 25a. In this case, thetumblers 21 through 25 do not receive great pushing force in the sliding direction of thecard key 5 even when thecard key 5 slides. Thetumblers 21 through 25 receive great pushing force in the direction where thetumblers 21 through 25 are pushed. - The

card 5 key slides in theslit 59 till thekey 5 engages with thetumblers 21 through 25 as shown in Fig. 6. When thecard key 5 does not engage with thetumblers 21 through 25, thetumblers 21 through 25 are successively pushed into theslider 11 in accordance with the sliding of thecard key 5 and thecard key 5 slides in theslit 59. In this case, at least one of the engagingprojections 71 through 75 is positioned inside the engagingconcave member 85, and thus theslide 11 cannot slide. - When the

card key 5 thus engages with thetumblers 21 through 25 as shown in Fig. 6, all of the engagingprojections 71 through 75 are positioned inside thegroove 83, so that theslider 11 can slide in the longitudinal direction. The tumbler engaging with the full hole is forcefully pushed in the sliding direction of thecard key 5. Theslider 11 thus slides in accordance with the sliding of thecard key 5. Theslider 11 stops when theslider 11 reaches a pre-determined point. Thecard key 5 then continues sliding in theslit 59 with pushing thetumblers 21 through 25 into theslider 11. - As mentioned above, in the

locking device 3 the firstengaging projection 31 moves in the direction of the arrow YB when the card key slides in the direction of the arrow YB in Fig. 2. Accordingly, the firstmain body 41 can be pulled up in the direction of the arrow YA, so that thelocking device 3 is unlocked without stopping of thecard key 5 by steps or the like. - On the other hand, the first

engaging projection 31 moves in the reverse direction of the arrow YB when thecard key 5 slides in theslit 59 in the reverse direction of the arrow YB. Therefore, the firstmain body 41 cannot be pulled up in the direction of the arrow YA, so that thelocking device 3 is also locked without stopping of thecard key 5 by steps or the like. - The suitcase 1 in the aforementioned embodiment can be unlocked or locked by sliding the

card key 5 in theslit 59 mounted adjacent to the grip 7 without stopping of the card key by steps or the like. Therefore, the card key 6 can effect unlocking or locking more smoothly than a conventional card key. - Following next is the second embodiment of the invention. A

slider 111, tumblers 121 through 125, and acard key 105 are employed in this embodiment instead of theslider 11, thetumblers 21 through 25, and thecard key 5 of the first embodiment, respectively. - The

slider 111 comprises a firstengaging projection 131, openings 111a1 through 111a5 and receiving chambers 111b1 through 111b5. The firstengaging projection 131 and the openings 111a1 through 111a5 have almost the same structures as the firstengaging projection 31 and the openings 11a1 through 11a5 of the first embodiment. - The receiving chambers 111b1 through 111b5 have quadrilateral sections. The tumblers 121 through 125 are slidingly inserted into the receiving chambers lllbl through 111b5.

- As can be seen in Figs 15 through 18, the

tumblers 121, 123 and 125 comprise taperedtips like body portions projections 171, 173 and 175, respectively. The taperedtips quadrilateral body portions projections 171, 173 and 175 in Fig. 16 are selected from Table 1, No. 1 through No. 3. - The

tumblers 122 and 124 comprise taperedtips like body portions tips thequadrilateral body portions - The

card key 105 shown in Fig. 23 changes the projecting portions of the tumblers 121 through 125 inserted into theslider 111. Thecard key 105 is provided with a plurality ofholes 187. Theholes 187 are positioned at points AL, BL, CL, DL and EL in Fig. 23 in accordance with the positions of the tumblers 121 through 125. - The points AL, CL and EL are provided along a line LL1, and the points BL and DL are along a line LL2. The centers of the tapered

tips holes 187. The centers of the taperedtips holes 187. - Dimensions D1 and D2 of the

holes 187 are selected from Table 2, No. 1 through No. 3. When the same numbers of Table 1 and Table 2 are selected for each tumbler, the predetermined portions of the tumblers project out and theslider 111 can slide in the longitudinal direction. - At least one of the points AL through EL for the

holes 187 is a full hole. The taperedtips 121a through 125a reach theconcave member 60 through the full hole, whereinboundary members 220 of the tumblers 121 through 125 in Figs. 15 and 19 abut aninner edge 230 of the full hole in Fig. 23, as in the first embodiment. Theboundary members 220 are formed between thetapered tips 121a through 125a and thequadrilateral body portions boundary members 220 abut thecard key 105 more vertically in the sliding direction than the taperedtips 121a through 125a. - When the

card key 105 slides with the tumblers 121 through 125 engaging with the full hole, the tumblers 121 through 125 engaging with the full hole receive great pushing force in the sliding direction of thecard key 105. - While the tumblers 121 through 125 engage with the smaller hole (No. 2 in Table 2), the

inner edge 230 of the smaller hole abuts the taperedtips 121a through 125a. If No.3 in Table 2 is selected for the holes which does not form a hole, the taperedtips 121a through 125a are not inserted into thecard key 105. If No. 2 or No. 3 in Table 2 is selected, the tumblers 121 through 125 does not receive great pushing force in the sliding direction from thecard key 105 during sliding of the card key. When No. 2 in Table 2 is selected, the tumblers 121 through 125 receive great pushing force in the direction where the tumblers are pushed into theslider 111. - When the

card key 105 meshes with the tumblers 121 through 125, the slider moves till a pre-determined point by sliding the card key in theslit 59, as in the first embodiment. Therefore, thelocking device 3 can attain locking or unlocking operation by sliding the card key without stops by a step portion. Additionally, in the second embodiment, the taperedtips tips holes 187 and the taperedtips 121a through 125a are positioned in two lines. Accordingly, a wider variety of alternatives for unlocking or locking operation can be made in this embodiment than simply selecting from three types of dimensions for five tumblers placed in a line. A locking device difficult to break with simple structure can be thus provided. - This invention is not limited to the embodiment illustrated and described as above, but can be applied to a wide variety of locking devices. For example, the configuration of the card key and the holes, the number of the holes and the tumblers and the like do not have to be the same as in this embodiment. Additionally, pushing force can be adjusted by changing the quality or configuration of the tapered tips of the tumblers, though the pressure is controlled by changing the angle at which the tumblers abuts the edges of the holes of the card key in the instant invention.

- Furthermore, the tapered tips of the tumblers can be positioned in the left or right of the axis of the tumblers instead of the tapered tips the centers of which are positioned along the axis or above or below the axis as in the aforementioned embodiments. The tapered tips can be also located on pre-determined area of the front of the tumblers with the front being divided lengthwise and crosswise into a pre-determined number of the predetermined area.

Claims (11)

- Locking device comprising a lock body (81) having a groove (83) therein, said groove (83) having a plurality of side slots (85) perpendicular to said groove (83); a slider (11; 111) connected for engaging and disengaging an engaging projection (31; 131) upon sliding motion of the slider (11; 111) between a locked position and an unlocked position; a plurality of tumblers (21 - 25; 121 - 125) carried by the slider (11; 111) and being slidable between an advanced position and a retracted position, each of the plurality of tumblers (21 - 25; 121 - 125) having a tapered tip (21a - 25a; 121a - 125a) on an outer end of a body portion (21b - 25b; 121b - 125b) and a projection (71 - 75; 171 - 175) on this body portion engaged with the groove (83); and guide means for guiding a lock card (5; 105) along and in a longitudinal path adjacent to the slider (11; 111) and the tapered tips (21a - 25a; 121a - 125a) of the plurality of tumblers (21 - 25; 121 - 125), said lock card (5; 105) having indentations (A - E; AL - EL) therein spaced to receive the tapered tips (21a - 25a; 121a - 125a) of the tumblers (21 - 25; 121 - 125) and sized to receive the tapered tips (21a - 25a; 121a - 125a) of respective ones of said plurality of tumblers to a depth which places each of the tumblers (21 - 25; 121 - 125) at a point where said projection (71 - 75; 171 - 175) thereof is positioned to slide in said groove (83), characterized in that at least one of the indentations (C; AL - EL) is sized to receive the tapered tip (23a; 121a - 125a) of a respective one of the plurality of tumblers (21 - 25; 121 - 125) to a depth where a side of the indentation (C; AL - EL) contacts this tumbler disposed therein at a point of a boundary member (23c; 220) formed between the tapered tip (23a; 121a - 125a) and the body portion (23b; 121b - 125b) adjacent to the body portion (23b; 121b - 125b) thereof whereby sliding of said lock card (5; 105) along the path in a given direction pushes those tumblers whose said tapered tips have been received in said indentations and the slider (11; 111) in combination therewith along the path between the locked position and the unlocked position, and whereby after the slider has reached its extreme position further sliding of the lock card in the same direction and out of the path is enabled by disengagement of the tumblers (21 -25; 121 - 125) from the indentations (A - E; AL - EL).

- Locking device of claim 1, wherein said tumblers (21 - 25; 121 - 125) are slidable perpendicular to said groove (83) and parallel to said side slots (85) for sliding movement therein between said advanced position and said retracted position.

- Locking device of claim 1 or 2, wherein said tumblers (21 - 25; 121 - 125) have bias means (61) on an inner end of said body portion (21b - 25b) for biasing said tapered tip (21a - 25a; 121a - 125a) towards said advanced position, said projection (71 - 75; 171 - 175) of each of the tumblers (21 - 25; 121 - 125) being positioned along a length thereof so that said slider (11; 111) can slide between said locked position and said unlocked position only when each of the tumblers (21 - 25; 121 - 125) is disposed between said advanced position and said retracted position at a point where said projection (71 - 75; 171 - 175) is positioned to slide in said groove (83).

- Locking device according to any one of the preceding claims, wherein said guide means comprises a guide member disposed in parallel, spaced relationship to said path adjacent to said slider (11; 111) and said tapered tips (21a - 25a; 121a - 125a) of the tumblers (21 - 25; 121 - 125).

- Locking device according to claim 4, wherein said guide member is a concave member (60).

- Locking device according to claim 5, wherein said concave member (60) is formed as a slot disposed in parallel, spaced relationship to said path adjacent to said slider (11; 111) and said tapered tips (21a - 25a; 121a - 125a) of the tumblers (21 - 25; 121 - 125) for receiving tapered tips thereof while supporting said lock card (5; 105) adjacent said slider (11; 111).

- Locking device according to any one of the preceding claims, wherein said indentations (A - E; AL - EL) in said lock card comprise bores through said lock card (5; 105).

- Locking device according to claim 7, whereina) said tapered tips (21a - 25a) are generally frusto-conical in shape, andb) said indentations (A - E) in said lock card (5) comprise circular bores.

- Locking device according to claim 7, whereina) said tapered tips (121a - 125a) are generally rectangular in cross-section, andb) said indentations (AL - EL) in said lock card (105) comprise rectangular bores.

- Locking device according to claim 8 or 9, whereina) said tapered tips (21a - 25a; 121a - 125a) are generally of the same size, andb) said indentations (A - E; AL - EL) in said lock card (5; 105) comprise bores of different sizes.

- Locking device according to any one of claims 8 to 10, whereina) some of said tapered tips (121a, 123a, 125a) are disposed along a line offset from others of said tapered tips (122a, 124a), andb) said indentations (AL - EL) through said lock card (105) are offset in a pattern to match said tapered tips (121a - 125a).

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP6759790 | 1990-03-16 | ||

| JP67597/90 | 1990-03-16 | ||

| JP3030991A JPH04213674A (en) | 1990-03-16 | 1991-02-26 | Locking device |

| JP30991/91 | 1991-02-26 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0447906A2 EP0447906A2 (en) | 1991-09-25 |

| EP0447906A3 EP0447906A3 (en) | 1991-10-16 |

| EP0447906B1 true EP0447906B1 (en) | 1994-08-03 |

Family

ID=26369451

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91103649A Expired - Lifetime EP0447906B1 (en) | 1990-03-16 | 1991-03-09 | Locking device for unlocking or locking by the insertion of a card key provided with a plurality of holes |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0447906B1 (en) |

| AT (1) | ATE109540T1 (en) |

| CA (1) | CA2037759A1 (en) |

| DE (1) | DE69103182T2 (en) |

| MX (1) | MX173355B (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TW205081B (en) * | 1991-10-24 | 1993-05-01 | Cardlock Pty Ltd | |

| JPH0711208B2 (en) * | 1991-11-29 | 1995-02-08 | 田村プラスチック製品株式会社 | Locking device |

| SE508334C2 (en) | 1996-09-16 | 1998-09-28 | Assa Ab | Locking |

| FR2779561B1 (en) * | 1998-06-09 | 2001-01-19 | Valeo Securite Habitacle | ARRANGEMENT FOR LONGITUDINAL LOCKING OF A RIGID DATA MEDIUM IN A DATA EXCHANGE DEVICE |

| CN112012587B (en) * | 2020-09-15 | 2024-07-12 | 杭州小安物联科技有限公司 | Double-control lock for cabinet |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1010520A (en) * | 1948-09-04 | 1952-06-12 | Safety lock | |

| US4754630A (en) * | 1985-12-18 | 1988-07-05 | Kabushiki Kaisha Saikousha | Locking device |

-

1991

- 1991-03-07 CA CA002037759A patent/CA2037759A1/en not_active Abandoned

- 1991-03-09 AT AT91103649T patent/ATE109540T1/en not_active IP Right Cessation

- 1991-03-09 DE DE69103182T patent/DE69103182T2/en not_active Expired - Fee Related

- 1991-03-09 EP EP91103649A patent/EP0447906B1/en not_active Expired - Lifetime

- 1991-03-11 MX MX024850A patent/MX173355B/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| MX173355B (en) | 1994-02-22 |

| EP0447906A3 (en) | 1991-10-16 |

| ATE109540T1 (en) | 1994-08-15 |

| DE69103182T2 (en) | 1995-03-23 |

| CA2037759A1 (en) | 1991-09-17 |

| DE69103182D1 (en) | 1994-09-08 |

| EP0447906A2 (en) | 1991-09-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1942243B1 (en) | A multifunctional lock | |

| US4518212A (en) | Multiple pin electrical plug | |

| US5375444A (en) | Multi-key core lock assembly | |

| US5020342A (en) | Safety lock | |

| CA1161656A (en) | Resettable lock assembly | |

| US5417092A (en) | Padlock | |

| EP0447906B1 (en) | Locking device for unlocking or locking by the insertion of a card key provided with a plurality of holes | |

| US3910083A (en) | Combination changing cylinder lock | |

| EP2406444A1 (en) | Cylinder lock and key combination | |

| US4332153A (en) | Dual key locks with multi-function tumblers | |

| DE4134812A1 (en) | Magnetic tape cassette container | |

| GB2082667A (en) | Fastening device for apertured members | |

| EP0903455A2 (en) | Effraction-resistant device for a lock with flat tumblers | |

| US4667493A (en) | Disc type cylinder lock | |

| US20120160000A1 (en) | locking mechanism and a locking device comprising the same | |

| US4838058A (en) | Card lock | |

| SI9200156A (en) | Locking system consisting of a key and its associated locking cylinder | |

| US3230749A (en) | Key-operated lock | |

| US6186606B1 (en) | Lateral File Locking System | |

| US3068682A (en) | Padlock with dual blockers | |

| GB1115085A (en) | Lock assembly | |

| US3978700A (en) | Safe deposit lock construction with changeable tumbler mechanism | |

| JP2022529143A (en) | Zipper locks for suitcases and suitcases | |

| US4756173A (en) | Zipper lock | |

| US3514981A (en) | Lock box |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19920302 |

|

| 17Q | First examination report despatched |

Effective date: 19920717 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940803 Ref country code: LI Effective date: 19940803 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19940803 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19940803 Ref country code: DK Effective date: 19940803 Ref country code: CH Effective date: 19940803 Ref country code: BE Effective date: 19940803 Ref country code: AT Effective date: 19940803 |

|

| REF | Corresponds to: |

Ref document number: 109540 Country of ref document: AT Date of ref document: 19940815 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 69103182 Country of ref document: DE Date of ref document: 19940908 |

|

| ITF | It: translation for a ep patent filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941103 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19950331 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19970122 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19970226 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19970228 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980309 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19980331 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19980309 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050309 |