EP0367102A2 - Short circuit indicator - Google Patents

Short circuit indicator Download PDFInfo

- Publication number

- EP0367102A2 EP0367102A2 EP89119880A EP89119880A EP0367102A2 EP 0367102 A2 EP0367102 A2 EP 0367102A2 EP 89119880 A EP89119880 A EP 89119880A EP 89119880 A EP89119880 A EP 89119880A EP 0367102 A2 EP0367102 A2 EP 0367102A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- slide

- short

- switch

- trigger

- circuit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H71/00—Details of the protective switches or relays covered by groups H01H73/00 - H01H83/00

- H01H71/10—Operating or release mechanisms

- H01H71/12—Automatic release mechanisms with or without manual release

- H01H71/46—Automatic release mechanisms with or without manual release having means for operating auxiliary contacts additional to the main contacts

- H01H71/462—Automatic release mechanisms with or without manual release having means for operating auxiliary contacts additional to the main contacts housed in a separate casing, juxtaposed to and having the same general contour as the main casing

Definitions

- the invention relates to a short-circuit detector for signaling overcurrent and short-circuit tripping, preferably in conjunction with a circuit breaker or motor protection switch, and the function of a short-circuit lock by manual reset on site.

- short-circuit detectors particularly if they are connected to a circuit breaker or motor protection switch, switch both in the event of a short-circuit and in the event of an overcurrent, it is important to be able to recognize the type of tripping from the outside, the short-circuit detector only detecting overcurrents above the approx. times the nominal current.

- a separate auxiliary switch can be assigned to each locking lever in such a circuit breaker.

- the invention has for its object to improve a short-circuit detector according to the preamble of claim 1 so that a high level of functions is achieved by a simple structure and the short-circuit display and the resetting can be done by hand with a single indicator plunger.

- the reset button of the short-circuit detector is connected to a switch-on slide, which is operatively connected via a deflection lever to a trigger-blocking slide which can be displaced in parallel with it, which can be displaced in the triggering direction of a triggering device of the circuit breaker or motor-protective circuit-breaker and via a trigger pin with this triggering device in the triggering direction in a positive manner is connected, there is a particularly compact design of such a short-circuit detector, since the switch-on slide and the combined trigger-lock slide can be arranged directly next to one another in the switch housing.

- a particularly reliable functioning of such a short-circuit detector is also achieved by the deflection lever, and it is also possible to arrange a test opening in the axial extension of the trigger slide on the front narrow side of the switch housing directly next to the reset button, through which the trigger slide by means of a pointed object, such as a Screwdriver or the like, even without a short circuit tripping and without the circuit breaker or motor protection switch to which the short-circuit detector is connected being supplied with current can be triggered purely mechanically by hand for test purposes.

- a pointed object such as a Screwdriver or the like

- the short-circuit detector 1 can, as shown in Fig. 1, be laterally attached to a circuit breaker or motor protection switch 2 such that it is in operative connection with a laterally protruding tripping pin 3 with a release device 4 on the circuit breaker or motor protection switch 2, which at a short-circuit or overcurrent triggering of the circuit breaker or motor protection switch 2 is moved in the triggering direction of the short-circuit detector 1.

- the short-circuit detector 1 has a manually operated reset button 5, which is arranged sunk in a recess 8 on the front narrow side 6 of the switch housing 7 such that it does not protrude beyond the level of the narrow side 6 of the housing and this level even in the OFF position thus is not interrupted by the reset button 5 even in the OFF position shown in FIGS. 1 and 4.

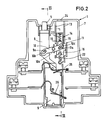

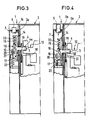

- the short-circuit detector 1 has a switch-on slide 9 which can be operated manually via the reset button 5 and which is operatively connected via a bell crank 10 to a combined trigger-lock slide 11 which can be displaced in parallel therewith stands, which is displaceable in the direction of displacement 12 (FIG. 4) of the tripping device 4 of the circuit breaker or motor protection switch 2 and is positively connected to this tripping device 4 in the tripping direction 12 via a tripping pin 3.

- the bell crank 10 is designed as a rocker such that the switch-on slide 9 and the combined trigger-lock slide 11 can be moved in opposite directions parallel to one another. It is pivotally mounted between the switch-on slide 9 and the parallel trigger-lock slide 11 about a pivot pin 10a fixed to the housing and is pivotably connected to the switch-on slide 9 as well as to the trigger-block valve 11 via slot-and-pin connections with play.

- the deflection lever 10 has two oblong holes 10b, 10c, which run parallel to one another in relation to its longitudinal axis, for the engagement of two driving pins 9a, 11a, which project to the side from the switch-on slide 9 and from the release lock slide 11.

- the combined trigger-blocking slide 11 is formed in two parts and consists of a on the switch housing 7 in lateral parallel guides 13 parallel to the switch-on slide About 9 displaceable trigger slide 14 and a locking slide 16 telescopically displaceable therebetween between lateral guide cheeks 15, which is in the ON position of the trigger slide 14 in a first locking position, from which it can be moved into a position after releasing a lock by moving the trigger slide 14 , in which the switch-on slide 9 has been moved via the switch lever 10 from its ON position shown in FIGS. 2 and 3 to its OFF position in FIG. 4.

- the trigger slide 14 on the housing 7 of the short-circuit detector 1 is guided in the triggering direction 12 of the triggering device 4 on the associated circuit breaker 1 and engages with its trigger pin 3, which passes through the housing walls 7a, 2a of the switches 1, 2 mounted directly next to one another in elongated holes 3a, 3b into a recess 4a on the triggering device 4 of the circuit breaker or motor protection switch 2.

- the locking slide 16 of the short-circuit detector 1 is displaceably arranged in the triggering direction 12 of the trigger slide 14 in its axial extension or coaxially to the trigger slide 14 in the switch housing 7 and engages with a pawl 17 which rests transversely to the triggering direction 12 and counteracts a web-shaped abutment 18 on the switch housing 7 the triggering direction 12 locking hook-shaped.

- the web-shaped abutment 18 is formed in the embodiment shown from the edge of the recess or opening 19 for the trigger pin 3, which protrudes laterally from the trigger slide 14 of the short-circuit detector 1 and is in operative connection with the trigger device 4 on the power or motor protection switch 2.

- the trigger slide 14 and the pawl 17 on the locking slide 16 have transverse to the triggering direction 12 of the short-circuit detector 1 parallel inclined surfaces 20, 21 which are inclined so that the pawl 17 is pushed aside when the trigger slide 14 is moved and with it Locking lug is released from the abutment web 18 or from the lower edge of the recess 19 on the switch housing 7, so that the locking slide 16 together with the release slide 14 can reach the OFF position of the short-circuit detector 1 from FIG. 4.

- the locking slide 16 is also under the action of a tension spring 22, which moves it after releasing the lock due to the displacement of the trigger slide 14 together with the bell crank 10 in the switch-off position and holds it in this position until it is actuated by the reset button 5 via the switch-on slide 9 and the bell crank 10 has been moved back into its locking position of FIGS. 2 and 3.

- a test opening 24 is arranged in the axial extension of the trigger slide 14 on the front narrow side 6 of the switch housing 7, through which the trigger slide 14 is by means of a sharp object, such as a screwdriver or the like, even without a short-circuit release and without the circuit breaker or motor protection switch 2, with which the short-circuit detector 1 is connected, supplied with current, can be triggered purely mechanically by hand for test purposes.

- the switch-on slide 9 is connected to at least two counter-acting auxiliary switches, a break contact 25 and a make contact 26.

Abstract

Description

Die Erfindung betrifft einen Kurzschlußmelder zur Signalisierung von Überstrom- und Kurzschlußauslösung, vorzugsweise in Verbindung mit einem Leistungs- oder Motorschutzschalter, und Funktion einer Kurzschlußsperre durch Rückstellung von Hand vor Ort.The invention relates to a short-circuit detector for signaling overcurrent and short-circuit tripping, preferably in conjunction with a circuit breaker or motor protection switch, and the function of a short-circuit lock by manual reset on site.

Da solche Kurzschlußmelder, insbesondere wenn sie mit einem Leistungs- oder Motorschutzschalter verbunden sind, sowohl bei einem Kurzschluß als auch bei einem Überstrom schalten, ist es wichtig, die Auslösungsart von außen erkennen zu können, wobei der Kurzschlußmelder erst auf Überströme oberhalb des etwa 16-fachen Nennstromes reagieren soll.Since such short-circuit detectors, particularly if they are connected to a circuit breaker or motor protection switch, switch both in the event of a short-circuit and in the event of an overcurrent, it is important to be able to recognize the type of tripping from the outside, the short-circuit detector only detecting overcurrents above the approx. times the nominal current.

Dies wird bei einem bekannten Schutzschalter mit Überstrom- und Kurzschlußauslösevorrichtung, die mit einem Hilfsschalter in Wirkverbindung steht und in der ausgelösten Stellung verriegelt gehalten ist (DE-OS 34 02 850), dadurch erreicht, daß für Kurzschluß- und Überstromauslösung getrennte Auslösewellen mit getrennten, mit dem Hilfsschalter in Wirkverbindung stehenden Verriegelungshebeln vorgesehen sind, die ihrerseits mit getrennten Anzeige- und Rückstellstößeln in Wirkverbindung stehen.This is achieved in a known circuit breaker with overcurrent and short-circuit tripping device which is operatively connected to an auxiliary switch and is locked in the tripped position (DE-OS 34 02 850), in that separate tripping shafts with separate, interlocking levers which are in operative connection with the auxiliary switch are provided, which in turn are operatively connected to separate display and reset plungers.

Um auch beispielsweise in einer zentralen Leitstelle die Unterscheidung vornehmen zu können, kann bei einem solchen Schutzschalter jedem Verriegelungshebel ein getrennter Hilfsschalter zugeordnet sein.In order to be able to make the distinction in a central control center, for example, a separate auxiliary switch can be assigned to each locking lever in such a circuit breaker.

Der Erfindung liegt die Aufgabe zugrunde, einen Kurzschlußmelder nach dem Oberbegriff des Ansprüches 1 dahingehend zu verbessern, daß durch einen einfachen Aufbau ein hohes Maß an Funktionen erreicht wird und die Kurzschlußanzeige und die Rückstellung von Hand durch einen einzigen Indikatorstößel erfolgen können.The invention has for its object to improve a short-circuit detector according to the preamble of

Diese Aufgabe wird gemäß der Erfindung durch den Kennzeichnungsteil des Ansprüches 1 gelöst, während in den Ansprüchen 2 bis 13 besonders vorteilhafte Weiterbildungen der Erfindung gekennzeichnet sind.This object is achieved according to the invention by the characterizing part of

Dadurch, daß der Rückstellknopf des Kurzschlußmelders mit einem Einschaltschieber verbunden ist, der über einen Umlenkhebel mit einem dazu parallel verschiebbaren Auslöse-Sperrschieber in Wirkverbindung steht, der in Auslöserichtung einer Auslösevorrichtung des Leistungs- oder Motorschutzschalters verschiebbar und über einen Auslösezapfen mit dieser Auslösevorrichtung in Auslöserichtung formschlüssig verbunden ist, ergibt sich eine besonders kompakte Bauweise eines solchen Kurzschlußmelders, da der Einschaltschieber und der kombinierte Auslöse-Sperrschieber im Schaltergehäuse unmittelbar nebeneinander angeordnet werden können. Auch wird durch den Umlenkhebel eine besonders zuverlässige Funktionsweise eines solchen Kurzschlußmelders erreicht, und es ist außerdem die Anordnung einer Testöffnung in axialer Verlängerung des Auslöseschiebers an der vorderen Schmalseite des Schaltergehäuses unmittelbar neben dem Rückstellknopf möglich, durch die der Auslöseschieber mittels eines spitzen Gegenstandes, wie ein Schraubendreher oder dergleichen, auch ohne Kurzschluß auslösung und ohne daß der Leistungs- oder Motorschutzschalter, mit dem der Kurzschlußmelder verbunden ist, mit Strom beaufschlagt wird, für Testzwecke von Hand rein mechanisch ausgelöst werden kann.Characterized in that the reset button of the short-circuit detector is connected to a switch-on slide, which is operatively connected via a deflection lever to a trigger-blocking slide which can be displaced in parallel with it, which can be displaced in the triggering direction of a triggering device of the circuit breaker or motor-protective circuit-breaker and via a trigger pin with this triggering device in the triggering direction in a positive manner is connected, there is a particularly compact design of such a short-circuit detector, since the switch-on slide and the combined trigger-lock slide can be arranged directly next to one another in the switch housing. A particularly reliable functioning of such a short-circuit detector is also achieved by the deflection lever, and it is also possible to arrange a test opening in the axial extension of the trigger slide on the front narrow side of the switch housing directly next to the reset button, through which the trigger slide by means of a pointed object, such as a Screwdriver or the like, even without a short circuit tripping and without the circuit breaker or motor protection switch to which the short-circuit detector is connected being supplied with current can be triggered purely mechanically by hand for test purposes.

Ein bevorzugtes Ausführungsbeispiel der Erfindung ist in der Zeichnung schematisch dargestellt. Es zeigen

- Fig. 1 einen an einen Leistungs- oder Motorschutzschalter anbaubaren Kurzschlußmelder in perspektivischer Ansicht,

- Fig. 2 eine Innenansicht des Kurzschlußmelders bei abgenommenem Gehäusedeckel,

- Fig. 3 einen Teilschnitt durch den Kurzschlußmelder gemäß Schnittlinie III - III von Fig. 2 in EIN-Stellung, wobei der Kurzschlußmelder in Verbindung mit einem Leistungs- oder Motorschutzschalter dargestellt ist, und

- Fig. 4 ebenfalls einen Teilschnitt durch die Schalterkombination in AUS-Stellung.

- 1 a short-circuit detector which can be attached to a circuit breaker or motor protection switch, in a perspective view,

- 2 shows an inside view of the short-circuit detector with the housing cover removed,

- Fig. 3 is a partial section through the short-circuit detector according to section line III - III of Fig. 2 in the ON position, the short-circuit detector is shown in connection with a circuit breaker or motor protection switch, and

- Fig. 4 also a partial section through the switch combination in the OFF position.

Der Kurzschlußmelder 1 kann, wie in Fig. 1 gezeigt ist, seitlich an einen Leistungs- oder Motorschutzschalter 2 derart angebaut werden, daß er mit einem seitlich hervorstehenden Auslösezapfen 3 in Wirkverbindung mit einer Auslösevorrichtung 4 an dem Leistungs- oder Motorschutzschalter 2 steht, die bei einer Kurzschluß- oder Überstromauslösung des Leistungs- oder Motorschutzschalters 2 in Auslöserichtung des Kurzschlußmelders 1 verschoben wird.The short-

Der Kurzschlußmelder 1 weist einen von Hand zu betätigenden Rückstellknopf 5 auf, der an der vorderen Schmalseite 6 des Schaltergehäuses 7 in einer Vertiefung 8 derart versenkt angeordnet ist, daß er auch in der AUS-Stellung nicht über die Ebene der Gehäuseschmalseite 6 hervorsteht und diese Ebene somit durch den Rückstellknopf 5 auch in der in Fig. 1 und 4 gezeigten AUS-Stellung nicht unterbrochen wird.The short-

Wie anhand der Darstellungen von Fig. 2 bis 4 im einzelnen zu erkennen ist, weist der Kurzschlußmelder 1 einen über den Rückstellknopf 5 von Hand zu betätigenden Einschaltschieber 9 auf, der über einen Umlenkhebel 10 mit einem dazu parallel verschiebbaren kombinierten Auslöse-Sperrschieber 11 in Wirkverbindung steht, der in Verschieberichtung 12 (Fig. 4) der Auslösevorrichtung 4 des Leistungs- oder Motorschutzschalters 2 verschiebbar ist und über einen Auslösezapfen 3 mit dieser Auslösevorrichtung 4 in Auslöserichtung 12 formschlüssig verbunden ist.As can be seen in detail from the representations of FIGS. 2 to 4, the short-

Der Umlenkhebel 10 ist als Wippe derart ausgebildet, daß der Einschaltschieber 9 und der kombinierte Auslöse-Sperrschieber 11 parallel zueinander gegenläufig bewegbar sind. Er ist zwischen dem Einschaltschieber 9 und dem dazu parallelen Auslöse-Sperrschieber 11 um einen gehäusefesten Drehzapfen 10a schwenkbar gelagert und sowohl mit dem Einschaltschieber 9 als auch mit dem Auslöse-Sperrschieber 11 über Langloch-Zapfen-Verbindungen mit Spiel schwenkbar verbunden. Der Umlenkhebel 10 weist zwei schräg zu seiner Längsachse parallel zueinander verlaufende Langlöcher 10b, 10c für den Eingriff von zwei Mitnahmezapfen 9a, 11a auf, die von dem Einschaltschieber 9 und von dem Auslöse-Sperrschieber 11 zur Seite hervorstehen.The

Der kombinierte Auslöse-Sperrschieber 11 ist zweiteilig ausgebildet und besteht aus einem am Schaltergehäuse 7 in seitlichen Parallelführungen 13 parallel zu dem Einschaltschie ber 9 verschiebbaren Auslöseschieber 14 und einem daran zwischen seitlichen Führungswangen 15 teleskopartig verschiebbaren Verriegelungsschieber 16, der sich in der EIN-Stellung des Auslöseschiebers 14 in einer ersten Verriegelungsstellung befindet, aus der er nach Lösen einer Sperre durch Verlagerung des Auslöseschiebers 14 in eine Stellung bewegbar ist, in der der Einschaltschieber 9 über den Umschalthebel 10 von seiner in Fig. 2 und 3 gezeigten EIN-Stellung in seine AUS-Stellung von Fig. 4 bewegt worden ist.The combined trigger-blocking

Wie in den Darstellungen von Fig. 2 bis 4 im einzelnen zu erkennen ist, ist der Auslöseschieber 14 am Gehäuse 7 des Kurzschlußmelders 1 in Auslöserichtung 12 der Auslösevorrichtung 4 an dem zugehörigen Leistungs- oder Motorschutzschalter 1 längsverschiebbar geführt und greift mit seinem Auslösezapfen 3, der die Gehäusewandungen 7a, 2a der unmittelbar nebeneinander montierten Schalter 1, 2 in Langlöchern 3a, 3b durchgreift, in eine Aussparung 4a an der Auslösevorrichtung 4 des Leistungs- oder Motorschutzschalters 2 formschlüssig ein.As can be seen in the illustrations of FIGS. 2 to 4 in detail, the

Der Verriegelungsschieber 16 des Kurzschlußmelders 1 ist in Auslöserichtung 12 des Auslöseschiebers 14 in dessen axialer Verlängerung bzw. koaxial zu dem Auslöseschieber 14 im Schaltergehäuse 7 verschiebbar angeordnet und hintergreift mit einer quer zur Auslöserichtung 12 federnd auslenkbaren Sperrklinke 17 ein stegförmiges Widerlager 18 an dem Schaltergehäuse 7 entgegen der Auslöserichtung 12 hakenförmig sperrend. Das stegförmige Widerlager 18 wird beim gezeigten Ausführungsbeispiel vom Rand der Aussparung oder Öffnung 19 für den Auslösezapfen 3 gebildet, der von dem Auslöseschieber 14 des Kurzschlußmelders 1 seitlich hervorsteht und mit der Auslösevorrichtung 4 an dem Leistungs- oder Motorschutzschalter 2 in Wirkverbindung steht.The

Der Auslöseschieber 14 und die Sperrklinke 17 an dem Verriegelungsschieber 16 weisen quer zur Auslöserichtung 12 des Kurzschlußmelders 1 parallel zueinander verlaufende Schrägflächen 20, 21 auf, die derart geneigt sind, daß die Sperrklinke 17 bei der Verlagerung des Auslöseschiebers 14 zur Seite weggedrückt wird und mit ihrer Sperrnase von dem Widerlagersteg 18 bzw. vom unteren Rand der Aussparung 19 an dem Schaltergehäuse 7 freikommt, so daß der Verriegelungsschieber 16 zusammen mit dem Auslöseschieber 14 in die AUS-Stellung des Kurzschlußmelders 1 von Fig. 4 gelangen kann.The

Der Verriegelungsschieber 16 steht auch unter der Wirkung einer Zugfeder 22, die ihn nach Lösen der Sperre infolge Verlagerung des Auslöseschiebers 14 zusammen mit dem Umlenkhebel 10 in die Ausschaltstellung bewegt und in dieser so lange festhält, bis er durch Betätigung des Rückstellknopfes 5 über den Einschaltschieber 9 und den Umlenkhebel 10 wieder in seine Verriegelungsstellung von Fig. 2 und 3 zurückbewegt worden ist.The

Zwischen dem Auslöseschieber 14 und dem Verriegelungsschieber 16 ist eine beide Schieber in Auslöserichtung 12 auseinanderdrückende Schraubendruckfeder 23 angeordnet, durch die der Verriegelungsschieber 16 zusätzlich zu der an ihm angreifenden Zugfeder 22 nach einer Auslösung ebenso wie der durch den wippenförmigen Umlenkhebel 10 mit ihm verbundene Einschaltschieber 9 so lange in der in Fig. 4 gezeigten AUS-Stellung gehalten wird, bis die Kurzschlußsperre durch Betätigung des Rückstellknopfes 5 von Hand wieder aufgehoben wird.Between the

Wie anhand von Fig. 2 weiterhin zu erkennen ist, ist in axialer Verlängerung des Auslöseschiebers 14 an der vorderen Schmalseite 6 des Schaltergehäuses 7 eine Testöffnung 24 angeordnet, durch die der Auslöseschieber 14 mittels eines spitzen Gegenstandes, wie ein Schraubendreher oder dergleichen, auch ohne Kurzschlußauslösung und ohne daß der Leistungs- oder Motorschutzschalter 2, mit dem der Kurzschlußmelder 1 verbunden ist, mit Strom beaufschlagt wird, für Testzwecke von Hand rein mechanisch ausgelöst werden kann.As can also be seen from FIG. 2, a

Für eine Fernanzeige beispielsweise in einer Leitzentrale ist der Einschaltschieber 9 mit mindestens zwei gegenläufig wirksamen Hilfsschaltern, einem Öffner 25 und einem Schließer 26, verbunden.For remote display, for example in a control center, the switch-on

Claims (13)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3837461A DE3837461A1 (en) | 1988-11-04 | 1988-11-04 | SHORT CIRCUIT DETECTOR |

| DE3837461 | 1988-11-04 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0367102A2 true EP0367102A2 (en) | 1990-05-09 |

| EP0367102A3 EP0367102A3 (en) | 1991-12-04 |

| EP0367102B1 EP0367102B1 (en) | 1995-06-14 |

Family

ID=6366488

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89119880A Expired - Lifetime EP0367102B1 (en) | 1988-11-04 | 1989-10-26 | Short circuit indicator |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0367102B1 (en) |

| AT (1) | ATE123902T1 (en) |

| DE (2) | DE3837461A1 (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2674370A1 (en) * | 1991-03-21 | 1992-09-25 | Telemecanique | PROTECTIVE SWITCHING APPARATUS ACCOUPABLE TO A CONTROL MODULE AND / OR A SIGNALING MODULE. |

| FR2684231A1 (en) * | 1991-11-22 | 1993-05-28 | Hager Electro | Auxiliary apparatus of electrical circuit breakers |

| EP0583762A1 (en) * | 1992-08-20 | 1994-02-23 | Moeller GmbH | Switching device |

| EP0612089A2 (en) * | 1993-02-17 | 1994-08-24 | Moeller GmbH | Switching device for circuit breakers |

| US6031195A (en) * | 1997-07-14 | 2000-02-29 | Allen-Bradley Company, Llc | Latching mechanism for an electrical overload protection switch, in particular for a motor-protection circuit breaker |

| EP0949647A3 (en) * | 1998-04-09 | 2000-05-10 | Eaton Corporation | Trip indicator and signalling switch assembly |

| EP1315190A2 (en) * | 2001-11-24 | 2003-05-28 | Moeller GmbH | Test device with short circuit indicator |

| FR2859570A1 (en) * | 2003-09-04 | 2005-03-11 | Fuji Elec Fa Components & Sys | AUXILIARY SWITCHING UNIT FOR A CIRCUIT BREAKER |

| EP1659602A2 (en) | 2004-11-23 | 2006-05-24 | ABB PATENT GmbH | Device for display of tripping of circuit breaker due to short circuit current |

| EP1670014A1 (en) * | 2004-12-10 | 2006-06-14 | EATON Corporation | Method of actuating a test function of an electrical switching apparatus and electrical switching apparatus employing the same |

| EP1659603A3 (en) * | 2004-11-23 | 2009-12-30 | ABB PATENT GmbH | Device for display and signalling of tripping of a circuit breaker due to short circuit current |

| CN103311057A (en) * | 2012-03-08 | 2013-09-18 | 西门子公司 | Short circuit indicator module for an electrical switching device and electrical switching device |

| EP2911176A1 (en) * | 2014-02-17 | 2015-08-26 | Abb Ag | Auxiliary switch with test button |

| US9853400B1 (en) | 2016-11-01 | 2017-12-26 | International Business Machines Corporation | Electrical arc protection using a trip jumper |

| US9893455B1 (en) | 2016-11-01 | 2018-02-13 | International Business Machines Corporation | Electrical arc protection using a trip contact |

| US10122123B1 (en) | 2017-07-07 | 2018-11-06 | International Business Machines Corporation | Electrical arc protection using a rotational shield |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010019741B4 (en) * | 2010-05-07 | 2022-05-05 | Siemens Aktiengesellschaft | Switching mechanism for a residual current circuit breaker and residual current circuit breaker |

| DE102016214681B4 (en) | 2016-08-08 | 2018-07-26 | Audi Ag | Actuating device for a motor vehicle |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3014553A1 (en) * | 1980-04-16 | 1981-10-22 | Condor-Werk Gebr. Frede KG Elektro- und Maschinenfabrik, 4722 Ennigerloh | Manual motor resetting mechanism - is for motor protection switch and has lever pushed down to break remote indicator circuit by reset button |

| DE3402850A1 (en) * | 1984-01-27 | 1985-08-01 | Siemens AG, 1000 Berlin und 8000 München | Protection circuit breaker having an overcurrent and short-circuit trip device |

| DE3603945A1 (en) * | 1986-02-07 | 1987-08-13 | Siemens Ag | Add-on switch for protection circuit breakers |

-

1988

- 1988-11-04 DE DE3837461A patent/DE3837461A1/en not_active Withdrawn

-

1989

- 1989-10-26 AT AT89119880T patent/ATE123902T1/en not_active IP Right Cessation

- 1989-10-26 EP EP89119880A patent/EP0367102B1/en not_active Expired - Lifetime

- 1989-10-26 DE DE58909294T patent/DE58909294D1/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3014553A1 (en) * | 1980-04-16 | 1981-10-22 | Condor-Werk Gebr. Frede KG Elektro- und Maschinenfabrik, 4722 Ennigerloh | Manual motor resetting mechanism - is for motor protection switch and has lever pushed down to break remote indicator circuit by reset button |

| DE3402850A1 (en) * | 1984-01-27 | 1985-08-01 | Siemens AG, 1000 Berlin und 8000 München | Protection circuit breaker having an overcurrent and short-circuit trip device |

| DE3603945A1 (en) * | 1986-02-07 | 1987-08-13 | Siemens Ag | Add-on switch for protection circuit breakers |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2674370A1 (en) * | 1991-03-21 | 1992-09-25 | Telemecanique | PROTECTIVE SWITCHING APPARATUS ACCOUPABLE TO A CONTROL MODULE AND / OR A SIGNALING MODULE. |

| FR2684231A1 (en) * | 1991-11-22 | 1993-05-28 | Hager Electro | Auxiliary apparatus of electrical circuit breakers |

| EP0583762A1 (en) * | 1992-08-20 | 1994-02-23 | Moeller GmbH | Switching device |

| EP0612089A2 (en) * | 1993-02-17 | 1994-08-24 | Moeller GmbH | Switching device for circuit breakers |

| EP0612089A3 (en) * | 1993-02-17 | 1994-12-21 | Kloeckner Moeller Gmbh | Switching device for circuit breakers. |

| US6031195A (en) * | 1997-07-14 | 2000-02-29 | Allen-Bradley Company, Llc | Latching mechanism for an electrical overload protection switch, in particular for a motor-protection circuit breaker |

| EP0949647A3 (en) * | 1998-04-09 | 2000-05-10 | Eaton Corporation | Trip indicator and signalling switch assembly |

| EP1315190A2 (en) * | 2001-11-24 | 2003-05-28 | Moeller GmbH | Test device with short circuit indicator |

| EP1315190A3 (en) * | 2001-11-24 | 2005-02-02 | Moeller GmbH | Test device with short circuit indicator |

| FR2859570A1 (en) * | 2003-09-04 | 2005-03-11 | Fuji Elec Fa Components & Sys | AUXILIARY SWITCHING UNIT FOR A CIRCUIT BREAKER |

| EP1659602A2 (en) | 2004-11-23 | 2006-05-24 | ABB PATENT GmbH | Device for display of tripping of circuit breaker due to short circuit current |

| EP1659603A3 (en) * | 2004-11-23 | 2009-12-30 | ABB PATENT GmbH | Device for display and signalling of tripping of a circuit breaker due to short circuit current |

| EP1659602A3 (en) * | 2004-11-23 | 2009-12-30 | ABB PATENT GmbH | Device for display of tripping of circuit breaker due to short circuit current |

| EP1670014A1 (en) * | 2004-12-10 | 2006-06-14 | EATON Corporation | Method of actuating a test function of an electrical switching apparatus and electrical switching apparatus employing the same |

| CN103311057A (en) * | 2012-03-08 | 2013-09-18 | 西门子公司 | Short circuit indicator module for an electrical switching device and electrical switching device |

| EP2911176A1 (en) * | 2014-02-17 | 2015-08-26 | Abb Ag | Auxiliary switch with test button |

| US9853400B1 (en) | 2016-11-01 | 2017-12-26 | International Business Machines Corporation | Electrical arc protection using a trip jumper |

| US9893455B1 (en) | 2016-11-01 | 2018-02-13 | International Business Machines Corporation | Electrical arc protection using a trip contact |

| US10229806B2 (en) | 2016-11-01 | 2019-03-12 | International Business Machines Corporation | Electrical arc protection using a trip jumper |

| US10230193B2 (en) | 2016-11-01 | 2019-03-12 | International Business Machines Corporation | Electrical arc protection using a trip contact |

| US10122123B1 (en) | 2017-07-07 | 2018-11-06 | International Business Machines Corporation | Electrical arc protection using a rotational shield |

Also Published As

| Publication number | Publication date |

|---|---|

| DE58909294D1 (en) | 1995-07-20 |

| DE3837461A1 (en) | 1990-05-10 |

| ATE123902T1 (en) | 1995-06-15 |

| EP0367102B1 (en) | 1995-06-14 |

| EP0367102A3 (en) | 1991-12-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0367102B1 (en) | Short circuit indicator | |

| EP1203385B1 (en) | Multipolar circuit-protection assembly for a collector rail system | |

| DE2438314C2 (en) | Residual current circuit breaker with a residual current circuit breaker that can be easily coupled to a circuit breaker | |

| DE670790C (en) | Thermal self-switch | |

| EP0897186A2 (en) | Switch mechanism for a circuit breaker | |

| EP0892420B1 (en) | Locking mechanism for an electrical excesscurrent switch for motor protection | |

| DE2403839C2 (en) | Circuit breaker with a locking device locking a releasable element | |

| DE4208716C2 (en) | Circuit breaker | |

| EP0195816B1 (en) | Bimetallic trigger | |

| DE3212474C2 (en) | Overcurrent protection switch | |

| DE2523507A1 (en) | OFF SWITCH | |

| DE19754071C1 (en) | Switchgear unit with leading auxiliary switch | |

| DE3341874C1 (en) | Switch arrangement having zero-voltage tripping | |

| DE1286188B (en) | Installation circuit breaker with auxiliary contact | |

| EP0630035B1 (en) | Auxiliary and signal switch for protective switching devices | |

| EP1671342B1 (en) | Protective circuit breaker | |

| DE3643511C2 (en) | ||

| DE2348568A1 (en) | SAFETY MACHINE | |

| DE4122268C2 (en) | ||

| DE4339425B4 (en) | Switch lock for a residual current circuit breaker | |

| EP0731979B1 (en) | Safety switch | |

| EP1315190B1 (en) | Test device with short circuit indicator | |

| DE3402850C2 (en) | ||

| DE2633774C3 (en) | Thermal overcurrent relay | |

| DE1909555B2 (en) | PUSH-BUTTON OPERATED SWITCH WITH THERMAL OVERCURRENT RELEASE |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KLOECKNER-MOELLER GMBH |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19920213 |

|

| 17Q | First examination report despatched |

Effective date: 19940121 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19950614 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19950614 Ref country code: GB Effective date: 19950614 Ref country code: BE Effective date: 19950614 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19950614 |

|

| REF | Corresponds to: |

Ref document number: 123902 Country of ref document: AT Date of ref document: 19950615 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 58909294 Country of ref document: DE Date of ref document: 19950720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950914 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19951026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19951031 Ref country code: LI Effective date: 19951031 |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19950614 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19971029 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19981021 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |