EP0332801A2 - Apparatus for changing the cross-sectional shape of can blanks - Google Patents

Apparatus for changing the cross-sectional shape of can blanks Download PDFInfo

- Publication number

- EP0332801A2 EP0332801A2 EP19890100226 EP89100226A EP0332801A2 EP 0332801 A2 EP0332801 A2 EP 0332801A2 EP 19890100226 EP19890100226 EP 19890100226 EP 89100226 A EP89100226 A EP 89100226A EP 0332801 A2 EP0332801 A2 EP 0332801A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- turret

- expanding

- axis

- cam body

- expanding mandrel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000005096 rolling process Methods 0.000 claims description 8

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 206010038743 Restlessness Diseases 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D51/00—Making hollow objects

- B21D51/16—Making hollow objects characterised by the use of the objects

- B21D51/26—Making hollow objects characterised by the use of the objects cans or tins; Closing same in a permanent manner

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D51/00—Making hollow objects

- B21D51/16—Making hollow objects characterised by the use of the objects

- B21D51/26—Making hollow objects characterised by the use of the objects cans or tins; Closing same in a permanent manner

- B21D51/2669—Transforming the shape of formed can bodies; Forming can bodies from flattened tubular blanks; Flattening can bodies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D15/00—Corrugating tubes

- B21D15/02—Corrugating tubes longitudinally

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D51/00—Making hollow objects

- B21D51/16—Making hollow objects characterised by the use of the objects

- B21D51/26—Making hollow objects characterised by the use of the objects cans or tins; Closing same in a permanent manner

- B21D51/2646—Of particular non cylindrical shape, e.g. conical, rectangular, polygonal, bulged

Definitions

- the invention relates to a device for changing the cross-sectional shape of can blanks with a revolver which can be driven in rotation about a central axis, - Several expanding mandrels, which are arranged on the revolver around the central axis and are essentially composed of each - A support body which is attached to the turret and defines an expanding mandrel axis, a plurality of segment rods which are arranged around the expanding mandrel axis and are guided on the supporting body in a radially adjustable manner, and a wedge which can be moved along the expanding mandrel axis to spread the segment rods apart, and - A common actuator with which the wedges are successively displaceable during one revolution of the turret.

- Such a device is the subject of the older German patent application P 3725186.4-14.

- there is a need to change the cross-sectional shape of can blanks for example when can bodies made of cylindrical truncated pyramids are to be produced from cylindrical can blanks len.

- the axes of all expanding mandrels extend parallel to the central axis of the revolver.

- a piston-cylinder unit is provided, with which all expanding mandrels are brought into alignment one after the other during one revolution of the revolver, and which is extended more or less abruptly in order to actuate the expanding mandrel aligned with it.

- the invention is therefore based on the object of designing a device for changing the cross-sectional shape of can bodies in such a way that it can continuously deform a larger number of can blanks per unit of time.

- the object is achieved according to the invention with a device of the type described in the introduction, in which the actuating member is a central cam body, on which each of the wedges is supported at least during a part of each revolution of the revolver corresponding to the distance between two adjacent expanding mandrels.

- the device according to the invention can have a central shaft which connects the turret to a drive. Proceeding from this, the invention can be further developed in that the cam body is mounted on the shaft and can be fixed in a selectable rotational angle position with an adjusting device. This gives the user of the device according to the invention the possibility, given the design of the cam body, to determine when the cam body acts on the individual expansion bodies in the course of each revolution of the revolver.

- the expanding mandrels are arranged in a star shape and the cam body has a radial curve, by the action of which the wedges can be displaced radially away from the central axis.

- the device shown and described in the aforementioned older patent application can be further developed according to the invention in that expanding mandrels arranged parallel to the central axis can be actuated by means of a central axial curve.

- each wedge is supported by a shaft which is guided in the associated support body and which can be rolled on the cam body.

- each wedge is biased by at least one spring against the direction in which it can be displaced by the action of the cam body in order to spread the associated segment rods apart.

- the rollers are preferably kept in constant contact with the cam body by the springs.

- a smooth running of the device according to the invention can also be promoted in that each of the segment rods is guided for their movements transversely to the associated expanding mandrel axis between a foot part and a head part of the associated supporting body by means of rolling element guides.

- rolling element guides absorb the force components that inevitably occur when the segment rods are spread apart and act in the direction of the expanding mandrel axis and make the segment rods move smoothly.

- a smooth running of the device can also be promoted in that each of the segment rods is supported on the associated wedge via a rolling element guide.

- the two rolling element guides described can also be advantageous regardless of the feature of the invention that the wedges are actuated by a central cam body.

- the gentle actuation of the wedges by the cam body which can extend over a large part of each revolution of the revolver, is particularly facilitated by the roller bearings according to the invention.

- the device shown has a drive 10, which is formed, for example, by an electric motor, a continuously variable transmission and a stepping mechanism and drives a shaft 12.

- the shaft 12 is horizontal in the example shown and is mounted in a manner not shown in the drive 10 and additionally at its free end in a bearing block 14.

- a cam body 18 is mounted on the shaft 12 by means of a pair of roller bearings 16, on which a radial curve 20 is formed.

- a bearing housing 24 or 26 is mounted on the cam body 18 on both sides of the radial curve 20 by means of a further roller bearing 22.

- the bearing housing 24, which is adjacent to the drive 10, is welded to an end wall 28 of a turret 30 and is by means of a fitting 32 with the Shaft 12 connected to rotate together.

- the other bearing housing 26 is screwed to a second end wall 28 of the turret 30.

- the turret 30 can thus be rotated together with the shaft 12 about a central axis A defined by it.

- An adjusting device 34 in the form of a lever which is radial with respect to the central axis A is fastened to an annular end face of the cam body 18 facing away from the drive 10.

- the latter At its end remote from the shaft 12, the latter has an arcuate slot 36 which is concentric with the shaft 12 and through which extends a screw 38 fastened to the bearing block 14.

- the screw 38 By tightening the screw 38, the cam body 18 is fixed in an angular position that can be selected in a range determined by the length of the elongated hole 36.

- the curve body 18 is set such that the largest radius of the radial curve 20 points vertically upwards according to FIG. 2.

- the setting device 34 is normally coupled to a drive, not shown here, which moves the setting device 34 back and forth in cycles.

- the turret 30 has the formula of a polygon with eight flat frames 40 in the example shown, which extend parallel to the central axis A and at a right angle to the end walls 28 and are welded to them.

- Each of the frames 40 carries an expanding mandrel 42 with an expanding mandrel axis B intersecting the central axis A at a right angle.

- a cylindrical can blank C can be attached to each of the expanding mandrels 42, the cross section of which is originally circular and in the course of a rotation of the revolver 30 to be deformed by 270 ° into an oval or polygon in the example shown.

- Each of the total of eight expanding mandrels 42 has a multi-part support body 44 with a foot part 46 which is screwed to the associated frame 40, a head part 48 and a pair of prismatic supports 50 which firmly connect the head part 48 to the foot part 46 and leave gaps between them , in which two pairs of segment rods 52 are arranged.

- the supports 50 and segment rods 52 extend parallel to the expanding mandrel axis B.

- Each of the segment rods 52 is guided on the foot part 46 and on the head part 48 by a roller guide 54 which is radial with respect to the expanding mandrel axis B in such a way that the four segment rods in total can be spread apart radially.

- Each of the rolling element guides 54 consists essentially of a pair of radial grooves 56, one of which is formed in the foot part 46 or head part 48 and the other at the adjacent end of the relevant segment rod 52, as well as two cylindrical rolling elements 58 and a cage plate 60 holding them radial grooves 56 are prism-shaped with two flanks arranged at right angles to each other, on each of which one of the two associated rolling elements 58 can be rolled.

- Each of the segment rods 52 has a radial stepped bore 62 near its two ends, which receives a screw 64 fastened to the foot part 46 or head part 48 and a compression spring 66.

- the compression spring 66 is clamped between the head of the screw 64 and the step formed in the associated stepped bore in such a way that it tends to move the segment rod 52 radially inward toward the expanding mandrel axis B.

- an inclined surface 68 is formed such that it converges with the corresponding inclined surface 68 of the opposite segment rod 52 in the direction of the free end of the expanding mandrel 42 in question.

- a wedge 70 which has inclined surfaces 72 parallel to the inclined surfaces 68, belongs to each expanding mandrel 42. Between respective inclined surfaces 68 and 72, a roller guide 74 is arranged, which is formed by cylindrical rollers 76 and a ladder-like cage plate 78. The movement of each cage plate 78 in the direction of the free end of the associated expanding mandrel 42 is limited by a stop 80, which in the example shown is formed by a threaded bolt screwed into the associated inclined surface 68.

- a guide tube 82 is fastened in each foot part 46, to which a flange 84 is clamped in an adjustable manner in the direction of the expansion body axis B.

- Each wedge 70 has a cylindrical shaft 86 which extends through the associated guide tube 82 and is guided in it with ball guides 88.

- a roller 90 is mounted by means of a fork-shaped roller holder 92 such that the axis of the roller 90 extends parallel to the central axis A.

- a pair of springs 94 are clamped, which endeavor to hold the roller holder 92, and thus also the wedge 70 firmly connected to it, in a radially inner position, in which the wedge 70 is the associated one Segment rods 52 make it possible, under the action of the compression springs 66, to assume a radially inner position with respect to the expanding mandrel axis B.

- the springs 94 ensure that the associated roller 90 rolls continuously on the radial curve 20.

- each of the expanding mandrels 42 passes through a position in which its expanding mandrel axis B is aligned with a horizontal feed axis D.

- a circular cylindrical can blank C is pushed onto the respective expanding mandrel 42 of this feed axis D.

- a pair of spars 96 are arranged in a fixed manner parallel to the feed axis D, between which the expanding mandrels 42 can be moved, and on each of which a driver 98 for conveying a can blank C can be displaced.

- the drivers 98 are, for example, with magnets, suction cups, or the like. equipped so that they each capture a can blank C at a takeover point (not shown) and take it to the expanding mandrel 42 that is currently between the two spars 96.

- the can blank C is pushed onto an expanding mandrel 42 while the turret 30 is at a standstill.

- the locking device 34 is rotated slightly in time with the movement of the drivers 98 by the drive, not shown.

- the can blank C is clamped by the expanding mandrel 42, and the drivers 98 can be withdrawn without problems without pushing the can blank C back again.

- Each can blank C placed in this way on one of the expanding mandrels 42 is gradually deformed as the revolver 30 continues to rotate, by spreading the segment rods 52 apart.

- the segment rods 52 then return to their rest position, so that the deformed can blank C can be pulled off the expanding mandrel 42.

- this is the case after rotating the turret 30 by 270 °; the deformed can blanks are pulled vertically downwards.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Transmission Devices (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Filling Of Jars Or Cans And Processes For Cleaning And Sealing Jars (AREA)

- Preliminary Treatment Of Fibers (AREA)

- Wire Processing (AREA)

- Soil Working Implements (AREA)

- Basic Packing Technique (AREA)

- Specific Conveyance Elements (AREA)

- Making Paper Articles (AREA)

Abstract

Description

Die Erfindung betrifft eine Vorrichtung zum Verändern der Querschnittsform von Dosenrohlingen mit

- einem Revolver, der um eine zentrale Achse drehantreibbar ist,

- mehreren Spreizdornen, die am Revolver rings um die zentrale Achse angeordnet und im wesentlichen zusammengesetzt sind aus je

- einem Stützkörper, der am Revolver befestigt ist und eine Spreizdornachse definiert, mehreren Segmentstangen, die rings um die Spreizdornachse angeordnet und am Stützkörper radial verstellbar geführt sind, sowie einem Keil, der zum Auseinanderspreizen der Segmentstangen längs der Spreizdornachse verschiebbar ist, und

- einem gemeinsamen Betätigungsglied, mit dem die Keile während einer Umdrehung des Revolvers nacheinander verschiebbar sind.The invention relates to a device for changing the cross-sectional shape of can blanks with

a revolver which can be driven in rotation about a central axis,

- Several expanding mandrels, which are arranged on the revolver around the central axis and are essentially composed of each

- A support body which is attached to the turret and defines an expanding mandrel axis, a plurality of segment rods which are arranged around the expanding mandrel axis and are guided on the supporting body in a radially adjustable manner, and a wedge which can be moved along the expanding mandrel axis to spread the segment rods apart, and

- A common actuator with which the wedges are successively displaceable during one revolution of the turret.

Eine solche Vorrichtung ist Gegenstand der älteren deutschen Patentanmeldung P 3725186.4-14. Wie dort beschrieben, ergibt sich das Bedürfnis, die Querschnittsform von Dosenrohlingen zu verändern, beispielsweise dann, wenn aus zylindrischen Dosenrohlingen mit kreisförmigem Querschnitt pyramidenstumpfförmige Dosenzargen hergestellt werden sol len. Es kann aber auch erforderlich sein, aus ursprünglich kreiszylindrischen Rohlingen Dosenzargen von auf ihrer gesamten Länge gleichem ovalem oder polygonalem Querschnitt herzustellen, beim Verändern der Querschnittsform also jegliche Konizität oder Pyramidenstumpfform der Dosenzargen zu vermeiden.Such a device is the subject of the older German patent application P 3725186.4-14. As described there, there is a need to change the cross-sectional shape of can blanks, for example when can bodies made of cylindrical truncated pyramids are to be produced from cylindrical can blanks len. However, it may also be necessary to produce can frames from originally circular cylindrical blanks with the same oval or polygonal cross-section over their entire length, so avoiding any conicity or truncated pyramid shape of the can bodies when changing the cross-sectional shape.

Bei der in der älteren Patentanmeldung dargestellten und beschriebenen Vorrichtung erstrecken sich die Achsen sämtlicher Spreizdorne parallel zur zentralen Achse des Revolvers. Als gemeinsames Betätigungsglied ist eine Kolbenzylindereinheit vorgesehen, mit der sämtliche Spreizdorne während einer Umdrehung des Revolvers nacheinander in Fluchtung gebracht werden, und die jeweils mehr oder weniger stoßartig ausgefahren wird, um den mit ihr fluchtenden Spreizdorn zu betätigen. Diese Betätigungsweise hat sich grundsätzlich bewährt; sie führt aber jedenfalls dann zu einem unruhigen Lauf der Maschine, wenn eine große Anzahl von Dosenrohlingen je Zeiteinheit verformt werden soll und dementsprechend die Betätigungszeit für jeden Spreizdorn kurzgehalten werden muß.In the device shown and described in the earlier patent application, the axes of all expanding mandrels extend parallel to the central axis of the revolver. As a common actuator, a piston-cylinder unit is provided, with which all expanding mandrels are brought into alignment one after the other during one revolution of the revolver, and which is extended more or less abruptly in order to actuate the expanding mandrel aligned with it. This method of operation has proven itself in principle; in any case, it leads to a restless running of the machine if a large number of can blanks per time unit is to be deformed and accordingly the actuation time for each expanding mandrel must be kept short.

Der Erfindung liegt deshalb die Aufgabe zugrunde, eine Vorrichtung zum Verändern der Querschnittsform von Dosenzargen derart zu gestalten, daß sie ruhig laufend eine größere Anzahl von Dosenrohlingen je Zeiteinheit verformen kann.The invention is therefore based on the object of designing a device for changing the cross-sectional shape of can bodies in such a way that it can continuously deform a larger number of can blanks per unit of time.

Die Aufgabe ist erfindungsgemäß mit einer Vorrichtung der eingangs beschriebenen Gattung gelöst, bei der das Betätigungsglied ein zentraler Kurvenkörper ist, an dem sich jeder der Keile mindestens während eines dem Abstand zwischen zwei benachbarten Spreizdornen entsprechenden Teils jeder Umdrehung des Revolvers abstützt.The object is achieved according to the invention with a device of the type described in the introduction, in which the actuating member is a central cam body, on which each of the wedges is supported at least during a part of each revolution of the revolver corresponding to the distance between two adjacent expanding mandrels.

Damit wird erreicht, daß die Verformung der Dosenrohlinge während der Drehung des Revolvers stattfindet. Stillstandszeiten sind, wenn überhaupt, nur für das Aufschieben der unverformten Dosenrohlinge auf die Spreizdorne sowie für das Entfernen der verformten Dosenrohlinge von den Spreizdornen erforderlich. Diese Beschickungs- und Entnahmevorgänge lassen sich in sehr kurzen Zeitspannen durchführen, so daß ein verhältnismäßig großer Anteil der Zeit, die der Revolver für jede Umdrehung benötigt, für das Verformen der Dosenrohlinge zur Verfügung steht.This ensures that the deformation of the can blanks takes place during the rotation of the revolver. Downtimes, if at all, are only necessary for pushing the undeformed can blanks onto the expanding mandrels and for removing the deformed can blanks from the expanding mandrels. These loading and unloading operations can be carried out in very short periods of time, so that a relatively large proportion of the time that the revolver takes for each revolution is available for deforming the can blanks.

Übereinstimmend mit der in der genannten älteren Patentanmeldung dargestellten und beschriebenen Vorrichtung kann die erfindungsgemäße Vorrichtung eine zentrale Welle haben, die den Revolver mit einem Antrieb verbindet. Davon ausgehend kann die Erfindung dadurch weitergebildet sein, daß der Kurvenkörper auf der Welle gelagert und mit einer Einstellvorrichtung in einer wählbaren Drehwinkelstellung festsetzbar ist. Dadurch erhält der Benutzer der erfindungsgemäßen Vorrichtung die Möglichkeit, bei gegebener Gestaltung des Kurvenkörpers zu bestimmen, wann der Kurvenkörper im Verlauf jeder Umdrehung des Revolvers auf die einzelnen Spreizkörper einwirkt.In accordance with the device shown and described in the above-mentioned earlier patent application, the device according to the invention can have a central shaft which connects the turret to a drive. Proceeding from this, the invention can be further developed in that the cam body is mounted on the shaft and can be fixed in a selectable rotational angle position with an adjusting device. This gives the user of the device according to the invention the possibility, given the design of the cam body, to determine when the cam body acts on the individual expansion bodies in the course of each revolution of the revolver.

Bei einer bevorzugten Ausführungsform der Erfindung sind die Spreizdorne sternförmig angeordnet und der Kurvenkörper weist eine Radialkurve auf, durch deren Einwirkung die Keile radial von der zentralen Achse weg verschiebbar sind. Als Alternative dazu kann die in der genannten älteren Patentanmeldung dargestellte und beschriebene Vorrichtung erfindungsgemäß dadurch weitergebildet werden, daß parallel zur zentralen Achse angeordnete Spreizdorne mittels einer zentralen Axialkurve betätigbar sind.In a preferred embodiment of the invention, the expanding mandrels are arranged in a star shape and the cam body has a radial curve, by the action of which the wedges can be displaced radially away from the central axis. As an alternative to this, the device shown and described in the aforementioned older patent application can be further developed according to the invention in that expanding mandrels arranged parallel to the central axis can be actuated by means of a central axial curve.

Unabhängig davon, welche der beiden im vorstehenden beschriebenen Ausgestaltungen gewählt wird, ist es zweckmäßig, daß jeder Keil über einen im zugehßrigen Stützkörper geführten Schaft an einer Rolle abgestützt ist, die auf dem Kurvenkörper abwälzbar ist.Regardless of which of the two configurations described above is chosen, it is expedient for each wedge to be supported by a shaft which is guided in the associated support body and which can be rolled on the cam body.

Es ist ferner vorteilhaft, wenn jeder Keil von mindestens einer Feder entgegen der Richtung vorgespannt ist, in der er durch Einwirkung des Kurvenkörpers verschiebbar ist, um die zugehörigen Segmentstangen auseinanderzuspreizen. Vorzugsweise sind die Rollen durch die Federn ständig am Kurvenkörper anliegend gehalten.It is also advantageous if each wedge is biased by at least one spring against the direction in which it can be displaced by the action of the cam body in order to spread the associated segment rods apart. The rollers are preferably kept in constant contact with the cam body by the springs.

Ein ruhiger Lauf der erfindungsgemäßen Vorrichtung kann zusätzlich dadurch gefördert werden, daß jede der Segmentstangen für Ihre Bewegungen quer zur zugehörigen Spreizdornachse zwischen einem Fußteil und einem Kopfteil des zugehörigen Stützkörpers mittels Wälzkörperführungen geführt ist. Diese Wälzkörperführungen nehmen die beim Auseinanderspreizen der Segmentstangen unvermeidlich auftretenden, in Richtung der Spreizdornachse wirkenden Kraftkomponenten auf und machen die Segmentstangen leichtgängig.A smooth running of the device according to the invention can also be promoted in that each of the segment rods is guided for their movements transversely to the associated expanding mandrel axis between a foot part and a head part of the associated supporting body by means of rolling element guides. These rolling element guides absorb the force components that inevitably occur when the segment rods are spread apart and act in the direction of the expanding mandrel axis and make the segment rods move smoothly.

Ein ruhiger Lauf der Vorrichtung kann ferner dadurch gefördert werden, daß jede der Segmentstangen am zugehörigen Keil über eine Wälzkörperführung abgestützt ist.A smooth running of the device can also be promoted in that each of the segment rods is supported on the associated wedge via a rolling element guide.

Die beiden beschriebenen Wälzkörperführungen können zwar auch unabhängig von dem Erfindungsmerkmal vorteilhaft sein, daß die Keile von einem zentralen Kurvenkörper betätigt werden. Die sanfte Betätigung der Keile durch den Kurvenkörper, die sich über einen großen Teil jedes Umlaufs des Revolvers erstrecken kann, wird aber durch die erfindungsgemäßen Wälzlager in besonderer Weise erleichtert.The two rolling element guides described can also be advantageous regardless of the feature of the invention that the wedges are actuated by a central cam body. The gentle actuation of the wedges by the cam body, which can extend over a large part of each revolution of the revolver, is particularly facilitated by the roller bearings according to the invention.

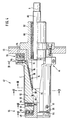

Ein Ausführungsbeispiel der Erfindung wird im folgenden mit weiteren Einzelheiten anhand schematischer Zeichnungen erläutert. Es zeigt:

- Fig. 1 eine Schrägansicht einer erfindungsgemäßen Vorrichtung zum Verändern der Querschnittsform von Dosenrohlingen,

- Fig. 2 einen vergrößerten Ausschnitt aus Fig. 1 mit aufgeschnitten dargestellten Einzelteilen,

- Fig. 3 einen senkrechten axialen Schnitt durch die Vorrichtung,

- Fig. 4 einen Längsschnitt durch einen Spreizdorn,

- Fig. 5 Teilquerschnitte je zu einem Viertel gemäss den Richtungen I bis IV in Fig. 4,

- Fig. 6 einen Querschnitt gemäss der Linie V - V in Fig. 4, und

- Fig. 7 eine Vorderansicht der Vorrichtung nach Fig. 1

- 1 is an oblique view of a device according to the invention for changing the cross-sectional shape of can blanks,

- 2 shows an enlarged detail from FIG. 1 with individual parts shown cut away,

- 3 shows a vertical axial section through the device,

- 4 shows a longitudinal section through an expanding mandrel,

- 5 partial cross sections each to a quarter according to the directions I to IV in Fig. 4,

- Fig. 6 is a cross section along the line V - V in Fig. 4, and

- 7 is a front view of the device of FIG .. 1

Die dargestellte Vorrichtung hat einen Antrieb 10, der beispielsweise von einem Elektromotor, einem stufenlos einstellbaren Getriebe und einem Schrittschaltwerk gebildet ist und eine Welle 12 antriebt. Die Welle 12 ist im dargestellten Beispiel waagerecht und ist in nicht dargestellter Weise im Antrieb 10 sowie zusätzlich an ihrem freien Ende in einem Lagerbock 14 gelagert.The device shown has a

Auf der Welle 12 ist gemäß Fig. 2 und 3 mittels eines Paars Wälzlager 16 ein Kurvenkörper 18 gelagert, an dem eine Radialkurve 20 ausgebildet ist. Auf dem Kurvenkörper 18 ist beiderseits der Radialkurve 20 mittels je eines weiteren Wälzlagers 22 je ein Lagergehäuse 24 bzw. 26 gelagert. Das Lagergehäuse 24, das dem Antrieb 10 benachbart ist, ist mit einer Stirnwand 28 eines Revolvers 30 verschweißt und ist mittels eines Paßstücks 32 mit der Welle 12 zu gemeinsamer Drehung verbunden. Das andere Lagergehäuse 26 ist mit einer zweiten Stirnwand 28 des Revolvers 30 verschraubt. Der Revolver 30 ist somit gemeinsam mit der Welle 12 um eine durch diese definierte zentrale Achse A drehbar.2 and 3, a

An einer vom Antrieb 10 abgewandten ringförmigen Stirnfläche des Kurvenkörpers 18 ist eine Einstellvorrichtung 34 in Gestalt eines in bezug auf die zentrale Achse A radialen Hebels befestigt. Dieser hat an seinem von der Welle 12 entfernten Ende ein bogenförmiges, mit der Welle 12 konzentrisches Langloch 36, durch das sich eine am Lagerbock 14 befestigte Schraube 38 erstreckt. Durch Festziehen der Schraube 38 wird der Kurvenkörper 18 in einer Winkelstellung festgesetzt, die sich in einem durch die Länge des Langlochs 36 bestimmten Bereich wählen läßt. Beispielsweise ist der Kurvenkörper 18 so eingestellt, daß der größte Radius der Radialkurve 20 gemäß Fig. 2 senkrecht nach oben weist.An adjusting

Die Einstellvorrichtung 34 ist jedoch normalerweise an einem hier nicht-dargestellten Antrieb gekoppelt, der die Einstellvorrichtung 34 taktweise hin- und herbewegt.However, the

Der Revolver 30 hat die Formel eines Polygons mit im dargestellten Beispiel acht ebenen Rahmen 40, die sich parallel zur zentralen Achse A und im rechten Winkel zu den Stirnwänden 28 erstrecken und mit diesen verschweißt sind. Jeder der Rahmen 40 trägt einen Spreizdorn 42 mit einer die zentrale Achse A im rechten Winkel schneidenden Spreizdornachse B. Auf jeden der Spreizdorne 42 läßt sich gemäß Fig. 1 ein zylinderischer Dosenrohling C aufstecken, dessen Querschnitt ursprünglich kreisförmig ist und im Verlauf einer Drehung des Revolvers 30 um im dargestellten Beispiel 270° in ein Oval oder Polygon verformt werden soll.The

Jeder der insgesamt acht Spreizdorne 42 hat einen mehrteiligen Stützkörper 44 mit einem Fußteil 46, das mit dem zugehörigen Rahmen 40 verschraubt ist, einem Kopfteil 48 und einem Paar prismatischer Stützen 50, die das Kopfteil 48 fest mit dem Fußteil 46 verbinden und zwischen sich Zwischenräume freilassen, in denen zwei Paar Segmentstangen 52 angeordnet sind. Die Stützen 50 und Segmentstangen 52 erstrecken sich parallel zur Spreizdornachse B.Each of the total of eight expanding

Jede der Segmentstangen 52 ist am Fußteil 46 und am Kopfteil 48 durch je eine in bezug zur Spreizdornachse B radiale Wälzkörperführung 54 derart geführt, daß die insgesamt vier Segmentstangen radial auseinanderspreizbar sind. Jede der Wälzkörperführungen 54 besteht im wesentlichen aus einem Paar radialer Nuten 56, von denen eine im Fußteil 46 bzw. Kopfteil 48 und die andere am benachbarten Ende der betreffenden Segmentstange 52 ausgebildet ist, sowie zwei zylindrischen Wälzkörpern 58 und einer diese haltenden Käfigplatte 60. Die radialen Nuten 56 sind prismenförmig mit zwei im rechten Winkel zueinander angeordneten Flanken, an denen je einer der beiden zugehörigen Wälzkörper 58 abwälzbar ist.Each of the

Jede der Segmentstangen 52 hat in der Nähe ihrer beiden Enden je eine radiale Stufenbohrung 62, die eine am Fußteil 46 bzw. Kopfteil 48 befestigte Schraube 64 und ein Druckfeder 66 aufnimmt. Die Druckfeder 66 ist zwischen dem Kopf der Schraube 64 und der in der zugehörigen Stufenbohrung ausgebildeten Stufe derart eingespannt, daß sie bestrebt ist, die Segmentstange 52 radial nach innen, zur Spreizdornachse B hin, zu verschieben. An der in bezug auf die Spreizdornachse B inneren Seite jeder Segmentstange 52 ist eine Schrägfläche 68 derart ausgebildet, daß sie mit der entsprechenden Schrägfläche 68 der gegenüberliegenden Segmentstange 52 in Richtung zum freien Ende des betreffenden Spreizdorns 42 hin konvergiert.Each of the

Zum Auseinanderspreizen der Segmentstangen 52 gehört zu jedem Spreizdorn 42 ein Keil 70, der zu den Schrägflächen 68 parallele Schrägflächen 72 aufweist. Zwischen zusammengehörigen Schrägflächen 68 und 72 ist je eine Wälzkörperführung 74 angeordnet, die von zylindrischen Wälzkörpern 76 sowie einer leiterartigen Käfigplatte 78 gebildet ist. Die Bewegung jeder Käfigplatte 78 in richtung zum freien Ende des zugehörigen Spreizdorns 42 ist durch einen Anschlag 80 begrenzt, der im dargestellten Beispiel von einem in die zugehörige Schrägfläche 68 eingeschraubten Gewindebolzen gebildet ist.For spreading apart the

In jedem Fußteil 46 ist ein Führungsrohr 82 befestigt, an dem ein Flansch 84 in Richtung der Spreizkörperachse B einstellbar festgeklemmt ist. Jeder Keil 70 hat einen zylindrischen Schaft 86, der sich durch das zugehörige Führungsrohr 82 hindurcherstreckt und in diesem mit Kugelführungen 88 geführt ist. Am in bezug auf die zentrale Achse A inneren Ende des Schafts 86 ist eine Rolle 90 mittels eines gabelförmigen Rollenhalters 92 derart gelagert, daß die Achse der Rolle 90 sich parallel zur zentralen Achse A erstreckt. Zwischen dem Rollenhalter 92 und dem Flansch 84 ist ein Paar Federn 94 eingespannt, die bestrebt sind, den Rollenhalter 92, und damit auch den fest mit ihm verbundenen Keil 70, in einer radial inneren Stellung zu halten, in welcher der Keil 70 es den zugehörigen Segmentstangen 52 ermöglicht, unter der Wirkung der Druckfedern 66 eine in bezug auf die Spreizdornachse B radial innere Stellung einzunehmen. Die Federn 94 sorgen dafür, daß die zugehörige Rolle 90 sich ununterbrochen auf der Radialkurve 20 abwälzt.A

Bei jeder Umdrehung des Revolvers 30 durchläuft jeder der Spreizdorne 42 eine Stellung, in der seine Spreizdornachse B mit einer waagerechten Zuführachse D fluchtet. Längs dieser Zuführachse D wird jeweils ein kreiszylindrischer Dosenrohling C auf den betreffenden Spreizdorn 42 aufgeschoben. Zu diesem Zweck ist parallel zur Zuführachse D ein Paar Holme 96 ortsfest angordnet, zwischen denen die Spreizdorne 42 hindurchbewegbar sind, und auf denen je ein Mitnehmer 98 zum Fördern jeweils eines Dosenrohlings C verschiebbar ist. Die Mitnehmer 98 sind beispielsweise mit Magneten, Saugnäpfen, o.dgl. ausgerüstet, damit sie jeweils einen Dosenrohling C an einer nicht dargestellten Übernahmestelle erfassen und zu dem gerade zwischen den beiden Holmen 96 stehenden Spreizdorn 42 mitnehmen.With each revolution of the

Der Dosenrohling C wird auf einen Spreizdorn 42 aufgeschoben, während der Revolver 30 kurzzeitig stillsteht. Gleichzeitig wird die Feststellvorrichtung 34 im Takt mit der Bewegung der Mitnehmer 98 von dem nicht-dargestellten Antrieb geringfügig gedreht. Dadurch wird der Dosenrohling C vom Spreizdorn 42 festgeklemmt, und können die Mitnehmer 98 problemlos zurückgezogen werden, ohne den Dosenrohling C wieder zurückzuschieben.The can blank C is pushed onto an expanding

Jeder in dieser Weise auf einen der Spreizdorne 42 aufgesteckte Dosenrohling C wird beim Weiterdrehen des Revolvers 30 allmählich verformt, indem die Segmentstangen 52 auseinandergespreizt werden. Anschließend kehren die Segmentstangen 52 in ihre Ruhestellung zurück, so daß der verformte Dosenrohling C vom Spreizdorn 42 abgezogen werden kann. Dies ist beim dargestellten Beispiel nach einer Drehung des Revolvers 30 um 270° der Fall; die verformten Dosenrohlinge werden senkrecht nach unten abgezogen.Each can blank C placed in this way on one of the expanding

Claims (8)

- einem Revolver (30), der um eine zentrale Achse (A) drehantreibbar ist,

- mehreren Spreizdornen (42), die am Revolver (30) rings um die zentrale Achse (A) angeordnet und im wesentlichen zusammengesetzt sind aus je

- einem Stützkörper (44), der am Revolver (30) befestigt ist und eine Spreizdornachse (B) definiert, mehreren Segmentstangen (52), die rings um die Spreizdornachse (B) angeordnet und am Stützkörper (44) radial verstellbar geführt sind, sowie einem Keil (70), der zum Auseinanderspreizen der Segmentstangen (52) längs der Spreizdornachse (B) verschiebbar ist, und

- einem gemeinsamen Betätigungsglied, mit dem die Keile (70) während einer Umdrehung des Revolvers (30) nacheinander verschiebbar sind,

dadurch gekennzeichnet, daß das Betätigungsglied ein zentraler Kurvenkörper (18) ist, an dem sich jeder der Keile (70) mindestens während eines dem Abstand zwischen zwei benachbarten Spreizdornen (52) entsprechenden Teils jeder Umdrehung des Revolvers (30) abstützt.1. Device for changing the cross-sectional shape of can blanks with

a revolver (30) which can be driven in rotation about a central axis (A),

- Several expanding mandrels (42) which are arranged on the turret (30) around the central axis (A) and are composed essentially of each

- A support body (44) which is attached to the turret (30) and defines an expanding mandrel axis (B), a plurality of segment rods (52) which are arranged around the expanding mandrel axis (B) and are radially adjustable on the supporting body (44), and a wedge (70) which is displaceable along the expanding mandrel axis (B) for spreading apart the segment rods (52), and

a common actuator with which the wedges (70) can be moved one after the other during one revolution of the turret (30),

characterized in that the actuator is a central cam body (18) on which each of the wedges (70) is supported at least during a part of each revolution of the turret (30) corresponding to the distance between two adjacent expanding mandrels (52).

dadurch gekennzeichnet, daß der Kurvenkörper (18) auf der Welle (12) gelagert und mit einer Einstellvorrichtung (34) in einer wählbaren Drehwinkelstellung verstellbar ist.2. Device according to claim 1 with a central shaft (12) which connects the turret (30) with a drive (10),

characterized in that the cam body (18) is mounted on the shaft (12) and can be adjusted in a selectable angular position by means of an adjusting device (34).

dadurch gekennzeichnet, daß die Spreizdorne (42) sternförmig angeordnet sind und der Kurvenkörper (18) eine Radialkurve (20) aufweist, durch deren Einwirkung die Keile (70) radial von der zentralen Achse (A) weg verschiebbar sind.3. Device according to claim 1 or 2,

characterized in that the expanding mandrels (42) are arranged in a star shape and the cam body (18) has a radial curve (20), by the action of which the wedges (70) can be displaced radially away from the central axis (A).

dadurch gekennzeichnet, daß jeder Keil (70) über einen im zugehörigen Stützkörper (44) geführten Schaft (86) an einer Rolle (90) abgestützt ist, die auf dem Kurvenkörper (18) abwälzbar ist.4. Device according to one of claims 1 to 3,

characterized in that each wedge (70) is supported by a shaft (86) guided in the associated support body (44) on a roller (90) which can be rolled on the cam body (18).

dadurch gekennzeichnet, daß jeder Keil (7) von mindestens einer Feder (94) entgegen der Richtung vorgespannt ist, in der er durch Einwirkung des Kurvenkörpers (18) verschiebbar ist, um die zugehörigen Segmentstangen (52) auseinanderzuspreizen.5. The device according to claim 4,

characterized in that each wedge (7) is biased by at least one spring (94) against the direction in which it can be displaced by the action of the cam body (18) in order to spread apart the associated segment rods (52).

dadurch gekennzeichnet, daß die Rollen (90) durch die Federn (94) ständig am Kurvenkörper (18) anliegend gehalten sind.6. Device according to claim 5,

characterized in that the rollers (90) are constantly held against the cam body (18) by the springs (94).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH973/88A CH674165A5 (en) | 1988-03-15 | 1988-03-15 | |

| CH973/88 | 1988-03-15 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0332801A2 true EP0332801A2 (en) | 1989-09-20 |

| EP0332801A3 EP0332801A3 (en) | 1990-10-03 |

| EP0332801B1 EP0332801B1 (en) | 1992-11-11 |

Family

ID=4199511

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89100226A Expired - Lifetime EP0332801B1 (en) | 1988-03-15 | 1989-01-07 | Apparatus for changing the cross-sectional shape of can blanks |

Country Status (17)

| Country | Link |

|---|---|

| US (1) | US4936130A (en) |

| EP (1) | EP0332801B1 (en) |

| JP (1) | JPH0780019B2 (en) |

| KR (1) | KR920004665B1 (en) |

| CN (1) | CN1024398C (en) |

| AU (1) | AU605078B2 (en) |

| BR (1) | BR8901191A (en) |

| CA (1) | CA1333974C (en) |

| CH (1) | CH674165A5 (en) |

| DE (2) | DE3811995A1 (en) |

| DK (1) | DK164774C (en) |

| ES (1) | ES2035956T3 (en) |

| FI (1) | FI891214A (en) |

| GR (1) | GR3006880T3 (en) |

| NO (1) | NO172218C (en) |

| SU (1) | SU1722215A3 (en) |

| ZA (1) | ZA89827B (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH676210A5 (en) * | 1988-07-19 | 1990-12-28 | Elpatronic Ag | |

| BR9905474B1 (en) * | 1999-10-27 | 2009-01-13 | device for expanding and shaping tin bodies. | |

| US6233992B1 (en) * | 2000-04-03 | 2001-05-22 | Lomar Machine & Tool Co. | Multi-station rotary endform machine |

| DE102008053825A1 (en) * | 2008-10-27 | 2010-04-29 | Cmc Kuhnke Gmbh | Positioning device for the investigation of a Dosenfalzquerschnittes and the can folding fold formation by means of X-rays |

| CN103831318B (en) * | 2014-03-20 | 2015-08-12 | 蚌埠通达汽车零部件有限公司 | A kind of tank truing machine improving shaping stability |

| JP6482332B2 (en) * | 2015-03-10 | 2019-03-13 | 昭和アルミニウム缶株式会社 | Can transporting apparatus and printing apparatus |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2175746A (en) * | 1936-12-16 | 1939-10-10 | Crown Can Company | Apparatus for forming can bodies |

| FR1455019A (en) * | 1963-05-02 | 1966-04-01 | Machine for notching and folding box bodies | |

| EP0172252A1 (en) * | 1984-01-25 | 1986-02-26 | Toyo Seikan Kaisha Limited | Method of and apparatus for covering weld zone of vertical wall of welded can with resin tape |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US996122A (en) * | 1908-01-20 | 1911-06-27 | Francis C Osborn | Container-body-forming machine. |

| US983278A (en) * | 1909-09-24 | 1911-02-07 | Emory F Hartlove | Device for re-forming can ends. |

| US2161963A (en) * | 1938-07-23 | 1939-06-13 | Bliss E W Co | Apparatus for shaping tubes, shells, or the like |

| US2872887A (en) * | 1953-03-06 | 1959-02-10 | Praturlon Joseph | Rotary press comprising a plurality of tool groups |

| US3222910A (en) * | 1962-02-23 | 1965-12-14 | Wallace Expanding Machines | Method of forming metallic sheet members |

| GB1060316A (en) * | 1963-03-05 | 1967-03-01 | Smith Olof Ab | Device for production of sheet metal objects of truncated cone shape |

| DE2738863C3 (en) * | 1977-08-29 | 1981-07-23 | Kurt G. 7332 Eislingen Hinterkopf | Device for conical expansion of tubes |

-

1988

- 1988-03-15 CH CH973/88A patent/CH674165A5/de not_active IP Right Cessation

- 1988-04-11 DE DE3811995A patent/DE3811995A1/en active Granted

-

1989

- 1989-01-07 ES ES198989100226T patent/ES2035956T3/en not_active Expired - Lifetime

- 1989-01-07 EP EP89100226A patent/EP0332801B1/en not_active Expired - Lifetime

- 1989-01-07 DE DE8989100226T patent/DE58902635D1/en not_active Expired - Fee Related

- 1989-01-18 AU AU28556/89A patent/AU605078B2/en not_active Ceased

- 1989-01-30 US US07/303,838 patent/US4936130A/en not_active Expired - Lifetime

- 1989-02-02 ZA ZA89827A patent/ZA89827B/en unknown

- 1989-02-10 DK DK064589A patent/DK164774C/en not_active IP Right Cessation

- 1989-02-20 KR KR1019890002001A patent/KR920004665B1/en not_active IP Right Cessation

- 1989-03-14 SU SU894613624A patent/SU1722215A3/en active

- 1989-03-14 NO NO891103A patent/NO172218C/en unknown

- 1989-03-14 CA CA000593654A patent/CA1333974C/en not_active Expired - Fee Related

- 1989-03-15 BR BR898901191A patent/BR8901191A/en unknown

- 1989-03-15 FI FI891214A patent/FI891214A/en not_active Application Discontinuation

- 1989-03-15 CN CN89101370A patent/CN1024398C/en not_active Expired - Fee Related

- 1989-03-15 JP JP1061085A patent/JPH0780019B2/en not_active Expired - Fee Related

-

1993

- 1993-01-26 GR GR920402667T patent/GR3006880T3/el unknown

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2175746A (en) * | 1936-12-16 | 1939-10-10 | Crown Can Company | Apparatus for forming can bodies |

| FR1455019A (en) * | 1963-05-02 | 1966-04-01 | Machine for notching and folding box bodies | |

| EP0172252A1 (en) * | 1984-01-25 | 1986-02-26 | Toyo Seikan Kaisha Limited | Method of and apparatus for covering weld zone of vertical wall of welded can with resin tape |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3811995C2 (en) | 1990-06-07 |

| DE58902635D1 (en) | 1992-12-17 |

| DK64589D0 (en) | 1989-02-10 |

| EP0332801A3 (en) | 1990-10-03 |

| DK64589A (en) | 1989-09-16 |

| FI891214A (en) | 1989-09-16 |

| DK164774C (en) | 1992-12-28 |

| NO891103L (en) | 1989-09-18 |

| CN1037853A (en) | 1989-12-13 |

| SU1722215A3 (en) | 1992-03-23 |

| JPH01273633A (en) | 1989-11-01 |

| FI891214A0 (en) | 1989-03-15 |

| NO891103D0 (en) | 1989-03-14 |

| ES2035956T3 (en) | 1993-05-01 |

| AU605078B2 (en) | 1991-01-03 |

| CA1333974C (en) | 1995-01-17 |

| AU2855689A (en) | 1989-09-21 |

| NO172218B (en) | 1993-03-15 |

| US4936130A (en) | 1990-06-26 |

| NO172218C (en) | 1993-06-23 |

| DK164774B (en) | 1992-08-17 |

| ZA89827B (en) | 1989-10-25 |

| KR890014184A (en) | 1989-10-23 |

| JPH0780019B2 (en) | 1995-08-30 |

| KR920004665B1 (en) | 1992-06-13 |

| BR8901191A (en) | 1989-10-31 |

| EP0332801B1 (en) | 1992-11-11 |

| CN1024398C (en) | 1994-05-04 |

| GR3006880T3 (en) | 1993-06-30 |

| DE3811995A1 (en) | 1989-09-28 |

| CH674165A5 (en) | 1990-05-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3110577B1 (en) | Ring rolling device | |

| DE2610467A1 (en) | DEVICE FOR CUTTING PIPES | |

| EP0079587A1 (en) | Wire-bending machine | |

| DE60000994T2 (en) | MACHINE FOR AUTOMATIC BENDING TUBES AND SIMILAR PARTS | |

| DE3327258C2 (en) | ||

| EP0622136B1 (en) | Device for the production of reinforcement meshes for concrete panels | |

| EP0196523B1 (en) | Radial press | |

| EP0332801B1 (en) | Apparatus for changing the cross-sectional shape of can blanks | |

| DE4494432B4 (en) | Punching press with a tool magazine | |

| DE4419827A1 (en) | Apparatus and method for reducing the diameter of a cylindrical workpiece | |

| DE2237345C3 (en) | Alignment station for sheets of electrical machines on an automatic slot punching system | |

| DE2533484A1 (en) | ROLLING MACHINE FOR ROLLING RING-SHAPED WORKPIECES | |

| CH678501A5 (en) | ||

| DE2801107C3 (en) | Method and device for manufacturing cylindrical coil springs from wire | |

| EP3456443B1 (en) | Material bar supply device | |

| DE2748235B2 (en) | Drop forging press | |

| DE69934374T2 (en) | Forming tool and use of this tool for roll forming a workpiece | |

| EP0371960B1 (en) | Method for bending bar-shaped materials | |

| EP0125540B1 (en) | Apparatus for making tubes with holes in the walls | |

| EP1345715B1 (en) | Forging press comprising an adjusting device on the matrix side thereof | |

| DE2420584C3 (en) | Winding machine for tape material or the like. | |

| EP4272887B1 (en) | Tool unit for a cold rolling machine | |

| DE3703700C2 (en) | Punching press with an automatic tool changing device | |

| DE19953283A1 (en) | Adjustable carriage unit for stamping, bending and assembling machines, tool carrier of which is separate from carriage | |

| DE3924414A1 (en) | Storage and feed mechanism for rod material on notching machine - has several stacked inclined surfaces with adjustable side walls forming magazine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): CH DE ES FR GB GR IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): CH DE ES FR GB GR IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900823 |

|

| 17Q | First examination report despatched |

Effective date: 19910809 |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ELPATRONIC AG |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB GR IT LI NL SE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 58902635 Country of ref document: DE Date of ref document: 19921217 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2035956 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3006880 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19931221 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19931230 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19940120 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19941222 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19950105 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950108 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 89100226.3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19950731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19950929 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: MM2A Free format text: 3006880 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 89100226.3 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19960107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19960108 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19960107 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990405 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: ELPATRONIC AG,HERTIZENTRUM 6,6303 ZUG (CH) TRANSFER- ELPATRONIC AG,INDUSTRIESTRASSE 35,8962 BERGDIETIKON (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20040109 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20040123 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20040126 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050802 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20050801 |