EP0284593B1 - Cutting jib - Google Patents

Cutting jib Download PDFInfo

- Publication number

- EP0284593B1 EP0284593B1 EP88870050A EP88870050A EP0284593B1 EP 0284593 B1 EP0284593 B1 EP 0284593B1 EP 88870050 A EP88870050 A EP 88870050A EP 88870050 A EP88870050 A EP 88870050A EP 0284593 B1 EP0284593 B1 EP 0284593B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- kerving

- belt

- notched belt

- arm

- intended

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011435 rock Substances 0.000 claims description 6

- 210000000078 claw Anatomy 0.000 claims description 3

- 229920002994 synthetic fiber Polymers 0.000 claims description 3

- 238000007373 indentation Methods 0.000 claims description 2

- 230000000284 resting effect Effects 0.000 claims description 2

- 238000000465 moulding Methods 0.000 claims 1

- 239000000835 fiber Substances 0.000 abstract description 4

- 238000005452 bending Methods 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 230000003313 weakening effect Effects 0.000 description 2

- 239000003245 coal Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

- 230000002028 premature Effects 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21C—MINING OR QUARRYING

- E21C25/00—Cutting machines, i.e. for making slits approximately parallel or perpendicular to the seam

- E21C25/22—Machines slitting solely by one or more cutter chains moving unidirectionally along jibs

- E21C25/28—Chains or chain guides

- E21C25/34—Chains

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D1/00—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor

- B28D1/02—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor by sawing

- B28D1/12—Saw-blades or saw-discs specially adapted for working stone

- B28D1/124—Saw chains; rod-like saw blades; saw cables

Definitions

- the present invention relates to a lifting arm on which is stretched an endless element furnished externally with cutting tools intended to carry out the cutting and the felling of rocks and internally with guide shoes capable of following a groove formed along said arm. , the endless element being rotated by a drive wheel and a deflection wheel having at their periphery notches intended to receive the said guide pads.

- the drive wheel and the return wheel have a solid core of uniform thickness and circumferential circumference provided with a rough coating.

- German patent application DE-A 3128264 is a lifting arm of a coal cutting machine comprising an endless belt, of trapezoidal cross section, furnished externally with diamond cutting elements and internally with guide shoes.

- the belt is rotated by a drive wheel and by a return wheel provided with a trapezoidal groove whose inclined walls enclose the sides of the belt.

- the belt is provided on its outer face with slots on which are fixed by interlocking tool-holder elements fixed with pins engaged in transverse holes.

- This configuration makes it possible to fully absorb the considerable shocks to which the tool heads are subjected, using the bearing surfaces provided for this purpose between the tool head and the tool body.

- a lifting arm is known from BE-A-865189 on which is stretched an endless element driven in rotation by a driving wheel and a deflection wheel and externally equipped with cutting tools intended to carry out the cutting and the felling of rocks and internally guide shoes able to follow a groove formed along said arm.

- the drive wheel has notches at its periphery in which the pads mesh.

- the present invention aims to remedy the above drawbacks. It relates to a shearer comprising a shearer arm on which is stretched an endless element equipped externally with cutting tools intended to carry out the havage and the felling of rocks and internally with guide shoes able to follow a groove formed along said arm, the endless element being driven in rotation by a drive wheel and a return wheel having at their periphery, ridges separated by notches intended to receive the aforementioned guide pads.

- the endless element bears on the ridges, so as to avoid any contact of the guide pads against the wheels (8, 9).

- the endless element is a toothed belt.

- the ridges separating the aforementioned notches from the drive and deflection wheels are furnished with teeth which mesh in the corresponding notches of the toothed belt, bearing thereon so as to avoid any contact of the guide pads against the wheels.

- the upper face of the pad support has recesses intended to receive the crenellations of a toothed belt.

- the lower part of the metal tool body carries an optionally removable sole made of synthetic material.

- a lifting arm comprises a frame in one piece in the form of a welded construction.

- the chassis consists essentially of a upper spar 1 and a lower spar 2 formed of beams forming a frame 3 covered on both sides by side plates 4 and 5 projecting from the spars 1, 2 so as to form an upper groove 6 whose width is equal to that of side rails 1, 2.

- the groove 6 is supplied with water by injectors 7 formed at the bottom thereof.

- One end of the lifting arm carries a drive wheel 8, the other a return wheel 9. On these wheels is stretched an endless element consisting for example of a toothed belt 10.

- This belt 10 is externally equipped with elements carrying cutting tools 11 intended for carrying out the cutting and felling of rocks and internally of guide shoes 12 able to follow the groove 6 formed along the side members 1, 2 of the lifting arm.

- the drive wheel 8 and the return wheel 9 each comprise a solid core 13 of uniform thickness, mounted by screws 14 on a plate 15.

- the core is sandwiched between two flanges 16.

- the plate 15 is mechanically connected to a output shaft 17 of an electric motor not shown, mounted on the frame of the lifting arm.

- the core 13 of the drive wheel 8 and of the deflection wheel 9 have notches 18 separated from each other by ridges 19 furnished with teeth 20 which mesh in the notches 21 of the toothed belt 10.

- the guide parts slide in the grooves of the side members and penetrate into the notches 18, so as to allow the toothed belt to bear on the ridges furnished with teeth 20.

- the teeth mesh in the notches 21 of the toothed belt and force the latter to adhere to the drive wheel, excluding any slippage.

- This arrangement has the advantage of transmitting the traction torque to the belt by means of all of the fibers adjacent to the main fibers of the toothed belt and not by means of the pads. This increases the life of the belt.

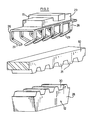

- FIGS 2 to 4 show from various angles a tool holder element designated as a whole by the reference symbol 23, for lifting arm and cutting device implementing an endless element 10.

- Each cutting tool 11 comprises a cutting element not shown brazed the tool member 23 having an inverted U-shaped section.

- the branches 26 in inverted U have on the inner side, preferably at their end, tenons 27 or claws intended to grip the notches 21 of the toothed belt 10.

- These claws 27 of the tool body 23 are folded in the sides lateral 28 of a shoe 12 disposed against the inner face of the endless element 10.

- the upper face 29 of the shoe 12 has recesses 30 intended to receive the notches 21 of the toothed belt 10.

- the pads 12 are fixed to the tool body 23, without altering or weakening the belt. They can optionally be fixed removably.

- the lifting arm according to the invention can be used for the calibration of plates or blocks of hard mineral materials.

- Calibration is a surfacing operation during which the above-mentioned arm, contained in a plane inclined by 45 ° relative to the surface to be calibrated, is moved parallel to itself along the surface, so as to sweep it this entirely.

Landscapes

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- Mechanical Engineering (AREA)

- Geology (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Processing Of Stones Or Stones Resemblance Materials (AREA)

- Food-Manufacturing Devices (AREA)

- Treatment Of Fiber Materials (AREA)

- Motorcycle And Bicycle Frame (AREA)

- Lubricants (AREA)

- Battery Electrode And Active Subsutance (AREA)

- Belt Conveyors (AREA)

Abstract

Description

La présente invention est relative à un bras haveur sur lequel est tendu un élément sans fin garni extérieurement d'outils coupants destinés à exécuter le havage et l'abattage de roches et intérieurement de patins de guidage aptes à suivre une rainure ménagée le long dudit bras, l'élément sans fin étant entraîné en rotation par une roue motrice et une roue de renvoi présentant à leur périphérie des échancrures destinées à recevoir les patins de guidage susdits.The present invention relates to a lifting arm on which is stretched an endless element furnished externally with cutting tools intended to carry out the cutting and the felling of rocks and internally with guide shoes capable of following a groove formed along said arm. , the endless element being rotated by a drive wheel and a deflection wheel having at their periphery notches intended to receive the said guide pads.

On connaît déjà par le brevet européen n° 0014776 un bras haveur équipant une machine de havage de roches et comprenant un châssis bordé par des longerons aux extrémités desquels sont montées, respectivement une roue d'entraînement et une roue de renvoi d'un élément sans fin. Cet élément sans fin consiste généralement en une courroie portant extérieurement des outils coupants et intérieurement des patins de guidage constitués de blocs s'étendant dans une rainure. En service, les blocs glissent sur toute la largeur de la rainure sur une nappe de fluide amené à l'aide d'injecteurs ménagés au fond de la rainure. Dans les machines connues, les patins sont fixés sur la courroie à l'aide de vis traversant les courroies. L'inconvénient majeur de cette fixation consiste en un affaiblissement local de la courroie aux endroits de fixation puisque les trous de fixation constituent des discontinuités susceptibles d'induire des concentrations de contraintes de tension et de flexion.Already known from European Patent No. 0014776 a lifting arm equipping a rock cutting machine and comprising a chassis bordered by side members at the ends of which are mounted respectively a drive wheel and a return wheel of an element without end. This endless element generally consists of a belt externally carrying cutting tools and internally guide shoes consisting of blocks extending in a groove. In service, the blocks slide over the entire width of the groove on a sheet of fluid supplied using injectors formed at the bottom of the groove. In known machines, the pads are fixed to the belt using screws passing through the belts. The major drawback of this fixing consists in a local weakening of the belt at the fixing places since the fixing holes constitute discontinuities liable to induce concentrations of tension stresses and bending.

La roue motrice et la roue de renvoi comportent une âme pleine d'épaisseur uniforme et de pourtour circonférenciel garni d'un revêtement rugueux.The drive wheel and the return wheel have a solid core of uniform thickness and circumferential circumference provided with a rough coating.

En marche, les patins prennent appui sans glisser contre le revêtement rugueux de la roue motrice pour entraîner la courroie. Pour éviter le patinage des patins sur la roue motrice par manque d'adhérence, il est nécessaire de tendre au maximum la courroie entre la roue motrice et la roue de renvoi. Une telle précontrainte de traction entraîne bien sûr une usure prématurée de la courroie.When running, the pads press without sliding against the rough coating of the drive wheel to drive the belt. To avoid slipping of the pads on the drive wheel due to lack of grip, it is necessary to tension the belt as much as possible between the drive wheel and the idler wheel. Such tensile preload naturally leads to premature wear of the belt.

On connaît également par la demande de brevet allemand DE-A 3128264, un bras haveur d'une machine de havage de charbon comportant une courroie sans fin, de section trapézoïdale, garnie extérieurement d'éléments coupants diamantés et intérieurement de patins de guidage. La courroie est entraînée en rotation par une roue motrice et par une roue de renvoi munie d'une gorge trapézoïdale dont les parois inclinées enserrent les flancs de la courroie.Also known from German patent application DE-A 3128264 is a lifting arm of a coal cutting machine comprising an endless belt, of trapezoidal cross section, furnished externally with diamond cutting elements and internally with guide shoes. The belt is rotated by a drive wheel and by a return wheel provided with a trapezoidal groove whose inclined walls enclose the sides of the belt.

La courroie est munie sur sa face extérieure de créneaux sur lesquels sont fixés par emboîtement des éléments porte-outils fixés à l'aide de goupilles engagées dans des trous transversaux.The belt is provided on its outer face with slots on which are fixed by interlocking tool-holder elements fixed with pins engaged in transverse holes.

Cette configuration permet de reprendre entièrement les chocs considérables auquels sont soumises les têtes d'outils, à l'aide des surfaces d'appui prévues à cet effet entre la tête d'outil et le corps d'outil.This configuration makes it possible to fully absorb the considerable shocks to which the tool heads are subjected, using the bearing surfaces provided for this purpose between the tool head and the tool body.

Elle permet également d'éviter l'endommagement des goupilles de fixation, de manière sûre.It also prevents damage to the fixing pins, in a safe way.

L'inconvénient majeur de ce bras haveur connu réside dans le fait que la courroie est soumise à des flexions importantes et répétées aux extrémités de chacun des patins, lors de chaque passage sur les roues motrices et de renvoi. Ces flexions répétées entraînent la fatigue localisée de la courroie et provoquent la rupture progressive de celle-ci.The major drawback of this known lifting arm lies in the fact that the belt is subjected to significant and repeated bending at the ends of each of the pads, during each passage on the drive and return wheels. These repeated flexions cause localized fatigue of the belt and cause it to rupture progressively.

Enfin, un bras haveur est connu de BE-A-865189 sur lequel est tendu un élément sans fin entraîné en rotation par une roue motrice et une roue de renvoi et équipé extérieurement d'outils coupants destinés à exécuter le havage et l'abattage des roches et intérieurement de patins de guidage aptes à suivre une rainure ménagée le long dudit bras. La roue motrice présente à sa périphérie des échancrures dans lesquelles engrènent les patins.Finally, a lifting arm is known from BE-A-865189 on which is stretched an endless element driven in rotation by a driving wheel and a deflection wheel and externally equipped with cutting tools intended to carry out the cutting and the felling of rocks and internally guide shoes able to follow a groove formed along said arm. The drive wheel has notches at its periphery in which the pads mesh.

L'inconvénient majeur de ce bras haveur connu réside dans le fait que les échancrures sont peu profondes et que les patins reposent sur le fond des échancrures. La traction exercée sur l'élément sans fin par la roue motrice et la roue de renvoi est entièrement reprise à travers les patins de guidage, de sorte que des forces de pliage importantes et répétées sont appliquées sur l'élément sans fin aux extrémités de chacun des patins, à cause des couples transmis par ceux-ci.The major drawback of this known lifting arm lies in the fact that the notches are shallow and that the pads rest on the bottom of the notches. The traction exerted on the endless element by the drive wheel and the deflection wheel is fully taken up through the guide shoes, so that significant and repeated bending forces are applied to the endless element at the ends of each. skates, because of the couples transmitted by these.

Par le document US-A-3604755, on connaît un bras haveur comprenant une roue motrice et une roue de renvoi qui sont pourvues d'échancrures à flancs inclinés et sur lesquelles est tendue une chaîne sans fin dont les maillons sont formés de patins trapézoïdaux qui suivant une rainure ménagée le long du bras et qui engrènent dans les échancrures susdites en reposant sur les flancs inclinés des échancrures. Une telle chaîne sans fin est bruyante en raison du martellement de la roue motrice et de la roue de renvoi par les patins.Document US-A-3604755 discloses a lifting arm comprising a drive wheel and a drive wheel. return which are provided with notches with inclined sides and on which is stretched an endless chain whose links are formed by trapezoidal shoes which follow a groove formed along the arm and which mesh in the aforementioned notches by resting on the inclined sides of the indentations. Such an endless chain is noisy due to the hammering of the drive wheel and the return wheel by the pads.

La présente invention vise à remédier aux inconvénients susdits. Elle est relative à une haveuse comportant un bras haveur sur lequel est tendu un élément sans fin équipé extérieurement d'outils coupants destinés à exécuter le havage et l'abattage de roches et intérieurement de patins de guidage aptes à suivre une rainure ménagée le long dudit bras, l'élément sans fin étant entraîné en rotation par une roue motrice et une roue de renvoi présentant à leur périphérie, des crêtes séparées par des échancrures destinées à recevoir les patins de guidage susdits.The present invention aims to remedy the above drawbacks. It relates to a shearer comprising a shearer arm on which is stretched an endless element equipped externally with cutting tools intended to carry out the havage and the felling of rocks and internally with guide shoes able to follow a groove formed along said arm, the endless element being driven in rotation by a drive wheel and a return wheel having at their periphery, ridges separated by notches intended to receive the aforementioned guide pads.

Selon l'invention, l'élément sans fin prend appui sur les crêtes, de manière à éviter tout contact des patins de guidage contre les roues (8,9).According to the invention, the endless element bears on the ridges, so as to avoid any contact of the guide pads against the wheels (8, 9).

Dans une forme de réalisation préférée, l'élément sans fin est une courroie crantée.In a preferred embodiment, the endless element is a toothed belt.

Les crêtes séparant les échancrures susdites des roues motrice et de renvoi, sont garnies de dents qui engrènent dans les crénelures correspondantes de la courroie crantée, en y prenant appui de manière à éviter tout contact des patins de guidage contre les roues.The ridges separating the aforementioned notches from the drive and deflection wheels are furnished with teeth which mesh in the corresponding notches of the toothed belt, bearing thereon so as to avoid any contact of the guide pads against the wheels.

Suivant une particularité de l'invention la face supérieure du support de patin présente des évidements destinés à recevoir les crénelures d'une courroie crantée.According to a feature of the invention, the upper face of the pad support has recesses intended to receive the crenellations of a toothed belt.

Dans une forme de réalisation particulière, la partie inférieure du corps d'outil en métal porte une semelle éventuellement amovible en matière synthétique.In a particular embodiment, the lower part of the metal tool body carries an optionally removable sole made of synthetic material.

D'autres particularités et détails de l'invention apparaîtront au cours de la description détaillée suivante faisant référence aux dessins ci-annexés et qui représentent schématiquement et à titre non limitatif, une forme de réalisation du dispositif suivant l'invention.Other features and details of the invention will appear during the following detailed description referring to the attached drawings and which schematically and without limitation, an embodiment of the device according to the invention.

Dans ces dessins:

- ― la figure 1 est une vue en élévation partiellement arrachée, d'un bras haveur suivant l'invention;

- ― la figure 2 montre en vue éclatée un élément porte-outil muni d'un patin;

- ― la figure 3 est une vue en élévation latérale de l'élément porte-outil montré à la figure 2 et

- ― la figure 4 est une vue en bout de l'élément porte-outil montré aux figures 2 et 3.

- - Figure 1 is a partially broken away elevation view of a lifting arm according to the invention;

- - Figure 2 shows in exploded view a tool holder element provided with a shoe;

- FIG. 3 is a side elevation view of the tool-carrying element shown in FIG. 2 and

- FIG. 4 is an end view of the tool-carrying element shown in FIGS. 2 and 3.

Dans ces figures, les mêmes signes de références désignent des éléments identiques ou analogues.In these figures, the same reference signs designate identical or analogous elements.

Comme illustré à la figure 1, un bras haveur comprend un châssis en une seule pièce sous forme de construction soudée.As illustrated in FIG. 1, a lifting arm comprises a frame in one piece in the form of a welded construction.

Le châssis est constitué essentiellement d'un longeron supérieur 1 et d'un longeron inférieur 2 formés de poutrelles formant une ossature 3 recouverte des deux côtés par des tôles latérales 4 et 5 débordant des longerons 1, 2 de manière à former une rainure supérieure 6 dont la largeur est égale à celle des longerons 1, 2.The chassis consists essentially of a upper spar 1 and a lower spar 2 formed of beams forming a frame 3 covered on both sides by

Comme décrit dans le brevet européen 0014776, la rainure 6 est alimentée en eau par des injecteurs 7 ménagés au fond de celle-ci.As described in European patent 0014776, the

Une extrémité du bras haveur porte une roue motrice 8, l'autre une roue de renvoi 9. Sur ces roues est tendu un élément sans fin constitué par exemple d'une courroie crantée 10. Cette courroie 10 est équipée extérieurement d'éléments portant des outils coupants 11 destinés à exécuter le havage et l'abattage de roches et intérieurement de patins de guidage 12 aptes à suivre la rainure 6 ménagée le long des longerons 1, 2 du bras haveur.One end of the lifting arm carries a

La roue motrice 8 et la roue de renvoi 9 comportent chacune une âme pleine 13 d'une épaisseur uniforme, montée par des vis 14 sur un plateau 15. L'âme est enserrée entre deux flasques 16. Le plateau 15 est relié mécaniquement à un arbre de sortie 17 d'un moteur électrique non montré, monté sur l'ossature du bras haveur.The

L'âme 13 de la roue motrice 8 et de la roue de renvoi 9 présentent des échancrures 18 séparées entre elles par des crêtes 19 garnies de dents 20 qui engrènent dans les crénelures 21 de la courroie crantée 10.The

Lorsque la courroie crantée 10 se déplace sous l'action de la roue motrice 8, les parties de guidage coulissent dans les rainures des longerons et pénèrent dans les échancrures 18, de manière à permettre à la courroie crantée de prendre appui sur les crêtes garnies de dents 20.When the

Les dents engrènent dans les crénelures 21 de la courroie crantée et forcent celle-ci à adhérer à la roue motrice en excluant tout patinage.The teeth mesh in the

Cette disposition a l'avantage de transmettre le couple de traction à la courroie par l'intermédiaire de l'ensemble des fibres voisines des fibres principales de la courroie crantée et non pas par l'intermédiaire des patins. On augmente ainsi la durée de vie de la courroie.This arrangement has the advantage of transmitting the traction torque to the belt by means of all of the fibers adjacent to the main fibers of the toothed belt and not by means of the pads. This increases the life of the belt.

Les figures 2 à 4 représentent sous divers angles un élément porte-outil désigné dans son ensemble par le signe de référence 23, pour bras haveur et dispositif de havage mettant en oeuvre un élément sans fin 10. Chaque outil coupant 11 comprend un élément coupant non montré brasé l'élément porte-outil 23 ayant une section en forme de U renversé. Les branches 26 en U renversé présentent du côté intérieur, de préférence à leur extrémité, des tenons 27 ou griffes destinés à s'agripper aux crénelures 21 de la courroie crantée 10. Ces griffes 27 du corps d'outil 23 sont repliées dans les flancs latéraux 28 d'un patin 12 disposé contre la face intérieure de l'élément sans fin 10.Figures 2 to 4 show from various angles a tool holder element designated as a whole by the

Lorsque l'élément sans fin est une courroie crantée, la face supérieure 29 du patin 12 présente des évidements 30 destinés à recevoir les crénelures 21 de la courroie crantée 10.When the endless element is a toothed belt, the

Les patins 12 sont fixés au corps d'outil 23, sans altérer ni affaiblir la courroie. Ils peuvent éventuellement être fixés amoviblement.The

Il est évident que l'invention n'est pas exclusivement limitée à la forme de réalisation représentée et que bien des modifications peuvent être apportées dans la forme, la disposition et la constitution de certains éléments intervenant dans la réalisation à condition que ces modifications ne soient pas en contradiction avec l'objet des revendications suivantes.It is obvious that the invention is not exclusively limited to the embodiment shown and that many modifications can be made in the form, arrangement and constitution of certain elements involved in the realization provided that these modifications are not not contradict the subject of the following claims.

Ainsi le bras haveur selon l'invention, peut être utilisé pour le calibrage de plaques ou blocs de matériaux minéraux durs. Le calibrage est une opération de surfaçage au cours de laquelle le bras susdit, contenu dans un plan incliné de 45° par rapport à la surface à calibrer, est mû parallèlement à lui-même le long de la surface, de manière à balayer celle-ci entièrement.Thus the lifting arm according to the invention can be used for the calibration of plates or blocks of hard mineral materials. Calibration is a surfacing operation during which the above-mentioned arm, contained in a plane inclined by 45 ° relative to the surface to be calibrated, is moved parallel to itself along the surface, so as to sweep it this entirely.

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88870050T ATE70890T1 (en) | 1987-03-23 | 1988-03-22 | SCRATCHING ARM. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BE8700290 | 1987-03-23 | ||

| BE8700290A BE1000418A4 (en) | 1987-03-23 | 1987-03-23 | Cutting arm. |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0284593A1 EP0284593A1 (en) | 1988-09-28 |

| EP0284593B1 true EP0284593B1 (en) | 1991-12-27 |

Family

ID=3882581

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88870050A Expired - Lifetime EP0284593B1 (en) | 1987-03-23 | 1988-03-22 | Cutting jib |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4856719A (en) |

| EP (1) | EP0284593B1 (en) |

| AT (1) | ATE70890T1 (en) |

| BE (1) | BE1000418A4 (en) |

| DE (1) | DE3867101D1 (en) |

| ES (1) | ES2029079T3 (en) |

| GR (1) | GR3004132T3 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE9108725U1 (en) * | 1991-07-16 | 1992-11-19 | Maschinenfabrik Korfmann Gmbh, 5810 Witten | Cutting arm for cutting machines for cutting natural stone, concrete or similar. |

| DE9110796U1 (en) * | 1991-07-16 | 1991-11-14 | Maschinenfabrik Korfmann Gmbh, 5810 Witten | Cutting arm for cutting machines for cutting hard rock |

| JP4357402B2 (en) * | 2004-10-18 | 2009-11-04 | 株式会社椿本チエイン | Transport device |

| EP3524797A3 (en) * | 2013-10-22 | 2019-10-16 | United Technologies Corporation | Piloted retaining plate for a face seal arrangement |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2344750A (en) * | 1942-11-27 | 1944-03-21 | Goodman Mfg Co | Cutter chain |

| US2354781A (en) * | 1943-10-30 | 1944-08-01 | Goodman Mfg Co | Cutter chain and bit |

| US2664120A (en) * | 1948-09-13 | 1953-12-29 | C & H Dev Company | Saw chain |

| US3604755A (en) * | 1969-07-24 | 1971-09-14 | Cincinnati Mine Machinery Co | Cutter bar, cutter chain and sprocket assembly |

| BE865189A (en) * | 1978-03-22 | 1978-07-17 | Madrigali Luigi | ROCK HAVING DEVICE |

| EP0014776B1 (en) * | 1979-02-22 | 1982-01-20 | Honoré Joseph Lambot | Rock cutter jib |

| DE3128264A1 (en) * | 1981-07-17 | 1983-02-03 | Maschinenfabrik Korfmann Gmbh, 5810 Witten | ARMING ARM ON A MASTERING MACHINE |

| AU8752782A (en) * | 1981-08-24 | 1983-03-03 | Cornelis Johannes Maria Beerens | Chain saw bar and sprocket |

| DE3209391A1 (en) * | 1982-03-15 | 1983-09-22 | Maschinenfabrik Korfmann Gmbh, 5810 Witten | CUTTING TOOL FOR A SLEEVE CHAIN OR A SLEEVE BELT |

-

1987

- 1987-03-23 BE BE8700290A patent/BE1000418A4/en not_active IP Right Cessation

-

1988

- 1988-03-22 EP EP88870050A patent/EP0284593B1/en not_active Expired - Lifetime

- 1988-03-22 AT AT88870050T patent/ATE70890T1/en active

- 1988-03-22 DE DE8888870050T patent/DE3867101D1/en not_active Expired - Fee Related

- 1988-03-22 ES ES198888870050T patent/ES2029079T3/en not_active Expired - Fee Related

- 1988-03-23 US US07/172,092 patent/US4856719A/en not_active Expired - Lifetime

-

1992

- 1992-03-24 GR GR920400514T patent/GR3004132T3/el unknown

Also Published As

| Publication number | Publication date |

|---|---|

| DE3867101D1 (en) | 1992-02-06 |

| EP0284593A1 (en) | 1988-09-28 |

| BE1000418A4 (en) | 1988-12-06 |

| ES2029079T3 (en) | 1992-07-16 |

| ATE70890T1 (en) | 1992-01-15 |

| GR3004132T3 (en) | 1993-03-31 |

| US4856719A (en) | 1989-08-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2201856A1 (en) | Assembly including ratchet device and belt | |

| FR2589386A1 (en) | SAWING CHAIN | |

| EP0284593B1 (en) | Cutting jib | |

| FR2582249A1 (en) | LAMIER FOR A CHAIN SAW | |

| FR2571113A1 (en) | TORQUE TRANSMISSION DEVICE, PARTICULARLY FOR CONTINUOUS DRIVE TRANSMISSION | |

| EP0014776B1 (en) | Rock cutter jib | |

| FR2486998A1 (en) | MINING EXTRACTION MACHINE | |

| EP1029623B2 (en) | Bandsaw with at least two individually driven saw blade pulleys | |

| FR2565570A1 (en) | ROLLING STAIRCASE TO COMPENSATE FOR EFFORTS TO AVOID UNUSUAL OPERATION AND UNUSUAL WEAR | |

| WO1998032578A1 (en) | Saw member, link of saw member and a method of producing a saw member | |

| US5735325A (en) | Tree feeding device of a tree handling machine | |

| FR2774302A1 (en) | Binding to hold boot on snow board | |

| FR2793827A1 (en) | V-shaped beam for building floor comprises first, second and third plates fitted in longitudinal grooves along first, second, and third soles | |

| FR2484375A1 (en) | CARRIER SCRAPER WITH DOUBLE CHAIN SCRAPERS | |

| EP0449706A1 (en) | Handling system for objects | |

| EP1418140B1 (en) | Accumulation conveyor with load carriers | |

| EP0055162A1 (en) | Endless chain or belt tensioning and guiding device | |

| FR2634250A1 (en) | ADVANCE DEVICE FOR ROCK DRILLING MACHINE | |

| FR2585980A1 (en) | GUIDE BAR FOR A SAW CHAIN OF A CHAIN MOTOR SAW | |

| FR2613320A1 (en) | APPARATUS FOR APPLYING A BAND OF THERMOPLASTIC SYNTHETIC MATERIAL AROUND A PRODUCT | |

| FR2768641A1 (en) | Buffing wheel head for polishing stones | |

| FR2674173A1 (en) | Flexible linear tool for cutting stone materials | |

| FR2663099A1 (en) | ELASTIC SUPPORT COMPRISING AN ELASTOMER LAYER AND TWO END PIECES, IN PARTICULAR FOR A MARINE ENGINE. | |

| FR2721291A1 (en) | Fastener for transverse floor batten of waste skip | |

| FR2495562A1 (en) | TRACK FOR TRACKED VEHICLES, ESPECIALLY FOR ARMORED TANKS |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19890204 |

|

| 17Q | First examination report despatched |

Effective date: 19900221 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19911227 Ref country code: NL Effective date: 19911227 Ref country code: AT Effective date: 19911227 |

|

| REF | Corresponds to: |

Ref document number: 70890 Country of ref document: AT Date of ref document: 19920115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3867101 Country of ref document: DE Date of ref document: 19920206 |

|

| ITF | It: translation for a ep patent filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19920320 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19920331 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2029079 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3004132 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19930322 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19930322 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19970402 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19980224 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000101 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20030212 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20040224 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20040228 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20040319 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040331 |

|

| BERE | Be: lapsed |

Owner name: S.A. *DIAMANT BOART Effective date: 20040331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051004 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20051130 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20050323 |