EP0242094A2 - Selecting device for the transmission system of a four-wheel drive vehicle - Google Patents

Selecting device for the transmission system of a four-wheel drive vehicle Download PDFInfo

- Publication number

- EP0242094A2 EP0242094A2 EP87302931A EP87302931A EP0242094A2 EP 0242094 A2 EP0242094 A2 EP 0242094A2 EP 87302931 A EP87302931 A EP 87302931A EP 87302931 A EP87302931 A EP 87302931A EP 0242094 A2 EP0242094 A2 EP 0242094A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- toothing

- toothings

- overrunning clutch

- clutch

- chamfer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D41/00—Freewheels or freewheel clutches

- F16D41/06—Freewheels or freewheel clutches with intermediate wedging coupling members between an inner and an outer surface

- F16D41/08—Freewheels or freewheel clutches with intermediate wedging coupling members between an inner and an outer surface with provision for altering the freewheeling action

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K17/00—Arrangement or mounting of transmissions in vehicles

- B60K17/34—Arrangement or mounting of transmissions in vehicles for driving both front and rear wheels, e.g. four wheel drive vehicles

- B60K17/348—Arrangement or mounting of transmissions in vehicles for driving both front and rear wheels, e.g. four wheel drive vehicles having differential means for driving one set of wheels, e.g. the front, at one speed and the other set, e.g. the rear, at a different speed

- B60K17/35—Arrangement or mounting of transmissions in vehicles for driving both front and rear wheels, e.g. four wheel drive vehicles having differential means for driving one set of wheels, e.g. the front, at one speed and the other set, e.g. the rear, at a different speed including arrangements for suppressing or influencing the power transfer, e.g. viscous clutches

- B60K17/3505—Arrangement or mounting of transmissions in vehicles for driving both front and rear wheels, e.g. four wheel drive vehicles having differential means for driving one set of wheels, e.g. the front, at one speed and the other set, e.g. the rear, at a different speed including arrangements for suppressing or influencing the power transfer, e.g. viscous clutches with self-actuated means, e.g. by difference of speed

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D47/00—Systems of clutches, or clutches and couplings, comprising devices of types grouped under at least two of the preceding guide headings

- F16D47/04—Systems of clutches, or clutches and couplings, comprising devices of types grouped under at least two of the preceding guide headings of which at least one is a freewheel

Definitions

- the present invention relates to a transmission system of a four-wheel drive vehicle, the system having a mechanism for absorbing the difference between the speeds of the front and rear wheels.

- the overrunning clutch system comprises forward and reverse overrunning clutches each in the form of a freewheel and a sleeve for selecting forward driving mode, reverse driving mode or directly connected four-wheel driving mode for the locking of the system. These modes can be selected by engaging toothings of the sleeve with toothings of one or other of the clutches or with toothings of both clutches.

- each toothing is of a shape having a rectangular tooth crest

- toothings of the sleeve can collide with toothings of the selected clutches, when the sleeve approaches the clutch.

- further movement of the sleeve is stopped and proper engagement of the sleeve and the clutch is impossible unless their relative positions are changed by an external force.

- a chamfer of the selected clutch can possibly abut on an improper side of the chamfer of the sleeve. Namely, when one of the chamfers of the sleeve abut against one of the chamfers of the clutch, the clutch is forced to rotate in one direction. If the direction is the locking direction of the clutch, the clutch cannot rotate and shifting of the sleeve is stopped.

- An object of the present invention is to provide a transmission system for a four-wheel drive vehicle which prevents tight corner braking at corners by providing a double overrunning clutch system, wherein forward and reverse drivings are smoothly and quickly selected.

- a transmission arrangement for a four-wheel drive vehicle comprises first and second power transmission systems for transmitting driving power to the front and rear wheels, respectively, a forward overrunning clutch and a reverse overrunning clutch provided in one of the transmission systems and effective for forward drive and reverse drive, respectively, selecting means for selecting one of the clutches in order to transmit the driving power to the wheels through the selected clutch, each of said clutches having an outer race provided with outer toothings on a periphery thereof and the selecting means having an axially slidable sleeve provided with inner toothings engageable with the outer toothings of the outer races, each inner toothing of the selecting means having chamfers on both axial ends thereof, each outer toothing having a chamfer on an end opposing the inner toothing, and said opposed chamfers of the inner and outer toothings being angled so that a force component in the free rotational direction of the outer toothing is produced by the engagement of the chamfer of the inner toothing therewith.

- each inner toothing of the selecting means has chamfers on both axial ends thereof, and each outer toothing has a chamfer on an end opposing the inner toothing.

- the opposed chamfers of the inner and outer toothings have an angle so that a component in a free rotational direction of the outer toothing is produced by the engagement of chamfer of the inner toothing.

- an engine unit E is transversely mounted on a rear portion of a vehicle.

- the engine unit has an engine 1, clutch 2 and transmission 3.

- the output of the transmission 3 is transmitted to rear wheels 23 through a differential 4 and axles 22.

- the output of the transmission 3 is also transmitted to front wheels 10 through a front wheel drive transmission system comprising a transfer device 5, double overrunning clutch 6, propeller shaft 7, differential 8, and axles 9.

- Outer casing 13 of the clutch 6 is secured to outer casing 11 of the transmission 3 through an intermediate casing 12.

- the transmission 3 comprises an input shaft 15, output shaft 16, a plurality of change-speed gears 17, and synchronizers 18.

- An output gear 19 engages with a ring gear 20 secured to a casing 21 of the differential 4.

- the transfer device 5 comprises a gear 24 engaged with ring gear 20, bevel gear 26 on a shaft 25 of gear 24, and bevel gear 27 engaged with bevel gear 26.

- a transfer drive shaft 28 of the bevel gear 27 and a shaft 29 connected to the propeller shaft 7 are co-axially disposed, and both shafts 28 and 29 are coupled through double overrunning clutch 6.

- the double overrunning clutch 6 comprises a forward overrunning clutch 30 and reverse overrunning clutch 31 each of which is in the form of a freewheel.

- Clutches 30 and 31 comprise outer races 30a, 31a and spragges 30c, 31c disposed between the outer races 30a, 31a and shaft 29, respectively.

- the spragges on each clutch are able to rotate relative to the shaft 29 in one direction only.

- a forward/reverse selecting device 32 is provided.

- the device has a hub 33 secured to the shaft 28 and an axially slidable sleeve 34.

- the sleeve 34 has two inside toothings 34a and 34b.

- the toothing 34a is permanently engaged with a toothing 33a of the hub 33.

- the toothing 34b is selectively engaged with a toothing 30b of the forward clutch 30; with a toothing 31b of the reverse clutch 31; or it can engage with both toothings 30b and 31b at the same time.

- the selection is performed by shifting the sleeve 34 to one of three axial positions, namely, a forward position, reverse position and lock position.

- the forward overrunning clutch 30 is so arranged as to transmit the rotation of the outer race 30a in the forward driving direction to the shaft 29 and so as to allow the rotation of the shaft 29 in the direction at higher speed than the outer race in advance of the race.

- the reverse overrunning clutch 31 is arranged oppositely. As shown in Figure 4a, each of toothings 30b and 31b of the clutches 30 and 31 is chamfered at an end opposing the toothing 34b.

- a chamfer,30d of the toothing 30b is formed at an angle ⁇ toward a freely rotatable direction F1 of the outer race 30a.

- a chamfer 31d of the toothings 31b is also formed at the angle ⁇ toward a freely rotatable direction F2 of the outer race 31a, which is opposite to the rotatable direction F1 of the outer race 30a.

- the toothing 34b has chamfers 34c and 34d at both ends at angle ⁇ so that the chamfers 34c and 34d may engage with the chamfers 30d and 31d, respectively.

- the sleeve 34 has an annular groove on the periphery thereof, in which a shifter fork 38 is slidably engaged.

- the shifter fork 38 is operatively connected to a diaphragm 36 ( Figure 1) in a vacuum operated actuator 35 through a rod 37.

- a ball lock device 47 is provided to position the rod 37 at one of the three positions.

- the diaphragm 36 of the actuator 35 is held by springs 40 and 41 on both sides thereof to an intermediate lock position when both vacuum chambers 39a and 39b are defined by the diaphragm are communicated with the atmosphere as described hereinafter.

- the vacuum chambers 39a and 39b are communicated with ports 61a and 62a of solenoid operated valves 61 and 62, respectively.

- the solenoid operated valves 61 and 62 have atmosphere ports 61b and 62b, vacuum ports 61c and 62c; and solenoids 61d and 62d, respectively.

- Both vacuum ports 61c and 62c are communicated with an intake manifold 65 through a passage 44 having a check valve 45 so as to be supplied with vacuum pressure in the intake manifold 65.

- Each valve has a valve body 66 for selectively closing the atmosphere port or vacuum port in accordance with energisation or de-energisation of the solenoid.

- the solenoid is energised by the output of a control circuit 46

- the valve body 66 closes the atmosphere port and opens the vacuum port to communicate the vacuum chamber of the actuator 35 with the intake manifold 65.

- the control circuit 46 is provided with a reverse switch 50 which is closed when a reverse gear in the transmission 3 is selected, and a lock switch 51 for locking the overrunning clutches 30 and 31.

- the output of the change-speed transmission 3 is transmitted to front wheels 10 through shaft 28, forwrd overrunning clutch 30, shaft 29 and propeller shaft 7.

- the front wheels 10 rotate faster than the rear.wheels 23. That is, the shaft 29 rotates faster than the outer race 30a in advance of it.

- the overrunning clutch 30 permits such a faster rotation of the shaft 29.

- the difference between speeds of front and rear wheels is absorbed in the clutch, and the vehicle turns the corner smoothly without the braking phenomenon.

- the reverse switch 50 When the transmission 3 is changed to reverse driving state, the reverse switch 50 is closed. Accordingly, the solenoid 62d is energised so that the vacuum chamber 39b is communicated with the intake manifold 65, shifting the rod 37 to the right (reverse position).

- the reverse overrunning clutch 31 is selected in the same manner as described above but for the reverse driving. In reverse driving, the same operation as the forward driving is performed.

- solenoids 61d, 62d are de-energised to communicate vacuum chambers 39a, 39b with the atmosphere.

- the diaphragm 36 is located at the neutral position by springs 40, 41 to position the rod 37 at the lock position. Accordingly, the toothing 34b of the sleeve 34 engages with both toothings 30b and 31b to lock the double overrunning clutch 6.

- directly connected four- wheel driving mode is established. Therefore, the vehicle. is safely driven by four wheels without skidding of the wheels.

Abstract

Description

- The present invention relates to a transmission system of a four-wheel drive vehicle, the system having a mechanism for absorbing the difference between the speeds of the front and rear wheels.

- When a vehicle negotiates a corner, the front wheels run through an arc of greater radius than that of the rear wheels and, therefore, the first wheels tend to rotate faster than the rear wheels. In a four- wheel drive vehicle without a device for absorbing the difference between the speeds of front and rear wheels, the difference in speed causes braking of the vehicle, known as "tight corner braking". In order to prevent such a braking phenomenon, there has been proposed a power transmission system having a double overrunning clutch system for absorbing the difference of speeds of front and rear wheels, and a system for locking the system for preventing at least one of the wheels from slipping on slippery roads. The overrunning clutch system comprises forward and reverse overrunning clutches each in the form of a freewheel and a sleeve for selecting forward driving mode, reverse driving mode or directly connected four-wheel driving mode for the locking of the system. These modes can be selected by engaging toothings of the sleeve with toothings of one or other of the clutches or with toothings of both clutches.

- In such a system, the selecting operation of the clutches must be swiftly completed. However, if each toothing is of a shape having a rectangular tooth crest, toothings of the sleeve can collide with toothings of the selected clutches, when the sleeve approaches the clutch. Thus, further movement of the sleeve is stopped and proper engagement of the sleeve and the clutch is impossible unless their relative positions are changed by an external force.

- If the corners of each toothing are chamfered to form a tapered crest as in toothings of a synchronizer of a transmission, a chamfer of the selected clutch can possibly abut on an improper side of the chamfer of the sleeve. Namely, when one of the chamfers of the sleeve abut against one of the chamfers of the clutch, the clutch is forced to rotate in one direction. If the direction is the locking direction of the clutch, the clutch cannot rotate and shifting of the sleeve is stopped.

- An object of the present invention is to provide a transmission system for a four-wheel drive vehicle which prevents tight corner braking at corners by providing a double overrunning clutch system, wherein forward and reverse drivings are smoothly and quickly selected.

- According to the present invention, a transmission arrangement for a four-wheel drive vehicle comprises first and second power transmission systems for transmitting driving power to the front and rear wheels, respectively, a forward overrunning clutch and a reverse overrunning clutch provided in one of the transmission systems and effective for forward drive and reverse drive, respectively, selecting means for selecting one of the clutches in order to transmit the driving power to the wheels through the selected clutch, each of said clutches having an outer race provided with outer toothings on a periphery thereof and the selecting means having an axially slidable sleeve provided with inner toothings engageable with the outer toothings of the outer races, each inner toothing of the selecting means having chamfers on both axial ends thereof, each outer toothing having a chamfer on an end opposing the inner toothing, and said opposed chamfers of the inner and outer toothings being angled so that a force component in the free rotational direction of the outer toothing is produced by the engagement of the chamfer of the inner toothing therewith.

- In the system, each inner toothing of the selecting means has chamfers on both axial ends thereof, and each outer toothing has a chamfer on an end opposing the inner toothing. The opposed chamfers of the inner and outer toothings have an angle so that a component in a free rotational direction of the outer toothing is produced by the engagement of chamfer of the inner toothing.

- In order that the invention may be more readily understood, it will now be described, by way of example only, wtith reference to the accompanying drawings, in which:-

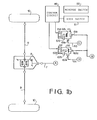

- Figures 1a and 1b schematically illustrate a power transmission system according to the present invention;

- Figure 2 is a sectional view of a main portion of the system;

- Figure 3 is an enlarged sectional view showing a part of Figure2; .

- Figure 4a is a sectional view taken along a line IV-IV of Figure 3; and

- Figure 4b is a sectional view of toothings explaining the engaging operation.

- Referring to Figures la and lb, an engine unit E is transversely mounted on a rear portion of a vehicle. The engine unit has an

engine 1, clutch 2 andtransmission 3. The output of thetransmission 3 is transmitted torear wheels 23 through a differential 4 andaxles 22. The output of thetransmission 3 is also transmitted tofront wheels 10 through a front wheel drive transmission system comprising atransfer device 5, double overrunning clutch 6, propeller shaft 7,differential 8, andaxles 9.Outer casing 13 of the clutch 6 is secured toouter casing 11 of thetransmission 3 through anintermediate casing 12. Thetransmission 3 comprises aninput shaft 15,output shaft 16, a plurality of change-speed gears 17, andsynchronizers 18. Anoutput gear 19 engages with aring gear 20 secured to acasing 21 of the differential 4. Thetransfer device 5 comprises agear 24 engaged withring gear 20,bevel gear 26 on ashaft 25 ofgear 24, andbevel gear 27 engaged withbevel gear 26. - Referring to Figure 2, a

transfer drive shaft 28 of thebevel gear 27 and ashaft 29 connected to the propeller shaft 7 are co-axially disposed, and bothshafts clutch 30 and reverse overrunningclutch 31 each of which is in the form of a freewheel.Clutches outer races spragges outer races shaft 29, respectively. The spragges on each clutch are able to rotate relative to theshaft 29 in one direction only. A forward/reverse selecting device 32 is provided. The device has ahub 33 secured to theshaft 28 and an axiallyslidable sleeve 34. Thesleeve 34 has two insidetoothings hub 33. The toothing 34b is selectively engaged with a toothing 30b of theforward clutch 30; with a toothing 31b of thereverse clutch 31; or it can engage with bothtoothings sleeve 34 to one of three axial positions, namely, a forward position, reverse position and lock position. The forward overrunningclutch 30 is so arranged as to transmit the rotation of theouter race 30a in the forward driving direction to theshaft 29 and so as to allow the rotation of theshaft 29 in the direction at higher speed than the outer race in advance of the race. The reverse overrunningclutch 31 is arranged oppositely. As shown in Figure 4a, each oftoothings clutches toothing 34b. A chamfer,30d of the toothing 30b is formed at an angle α toward a freely rotatable direction F1 of theouter race 30a. Achamfer 31d of thetoothings 31b is also formed at the angle α toward a freely rotatable direction F2 of theouter race 31a, which is opposite to the rotatable direction F1 of theouter race 30a. The toothing 34b has chamfers 34c and 34d at both ends at angle α so that thechamfers chamfers - The

sleeve 34 has an annular groove on the periphery thereof, in which ashifter fork 38 is slidably engaged. Theshifter fork 38 is operatively connected to a diaphragm 36 (Figure 1) in a vacuum operatedactuator 35 through arod 37. Aball lock device 47 is provided to position therod 37 at one of the three positions. - As shown in Figure la, the

diaphragm 36 of theactuator 35 is held bysprings 40 and 41 on both sides thereof to an intermediate lock position when bothvacuum chambers vacuum chambers ports valves valves atmosphere ports vacuum ports 61c and 62c; andsolenoids vacuum ports 61c and 62c are communicated with anintake manifold 65 through apassage 44 having acheck valve 45 so as to be supplied with vacuum pressure in theintake manifold 65. Each valve has avalve body 66 for selectively closing the atmosphere port or vacuum port in accordance with energisation or de-energisation of the solenoid. When the solenoid is energised by the output of a control circuit 46, thevalve body 66 closes the atmosphere port and opens the vacuum port to communicate the vacuum chamber of theactuator 35 with theintake manifold 65. The control circuit 46 is provided with areverse switch 50 which is closed when a reverse gear in thetransmission 3 is selected, and a lock switch 51 for locking theoverrunning clutches - When the vehicle is driven forward,

reverse switch 50 and lock switch 51 are both open so that thesolenoid 61d of thevalve 61 is energised to open thevacuum port 61c. Thevacuum chamber 39a ofactuator 35 is communicated with theintake manifold 65 throughpassage 63,valve 61 andpassage 44, and thediaphragm 36 is deflected to the left by the vacuum pressure in the intake manifold to draw therod 37 to the left (forward position). Thus, thesleeve 34 is shifted to the left so that toothing 34b engages with toothing 30b of the forward overrunningclutch 30. Even if the toothing 30b is positioned opposite to the toothing 34b, as shown in Figure 4b, thechamfer 34c abuts against thechamfer 30d to produce a component on the toothing 30b in the free direction Fl. Accordingly, theouter race 30a is rotated in the free direction so that thetoothings 34b can smoothly move to the left, as shown in Figure 4a. Thus, the engagement of thesleeve 34 and theclutch 30 is smoothly brought about. - When the clutch 2 is engaged, the output of the change-

speed transmission 3 is transmitted tofront wheels 10 throughshaft 28, forwrd overrunningclutch 30,shaft 29 and propeller shaft 7. When the vehicle turns a corner, thefront wheels 10 rotate faster than therear.wheels 23. That is, theshaft 29 rotates faster than theouter race 30a in advance of it. However, the overrunning clutch 30 permits such a faster rotation of theshaft 29. Thus, the difference between speeds of front and rear wheels is absorbed in the clutch, and the vehicle turns the corner smoothly without the braking phenomenon. - When the

transmission 3 is changed to reverse driving state, thereverse switch 50 is closed. Accordingly, thesolenoid 62d is energised so that thevacuum chamber 39b is communicated with theintake manifold 65, shifting therod 37 to the right (reverse position). Thus, thereverse overrunning clutch 31 is selected in the same manner as described above but for the reverse driving. In reverse driving, the same operation as the forward driving is performed. - When the lock switch 51 is closed,

solenoids vacuum chambers diaphragm 36 is located at the neutral position bysprings 40, 41 to position therod 37 at the lock position. Accordingly, thetoothing 34b of thesleeve 34 engages with bothtoothings - While the presently referred embodiment of the present invention has been shown and described, it is to be understood that this disclosure is for the purpose of illustration and that various changes and modifications may be made without departing from the scope of the invention as set forth in the appended claims.

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87302931T ATE55949T1 (en) | 1986-04-07 | 1987-04-03 | SELECTOR FOR THE TRANSMISSION SYSTEM OF A FOUR-WHEEL DRIVE VEHICLE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP80685/86 | 1986-04-07 | ||

| JP61080685A JPS62238115A (en) | 1986-04-07 | 1986-04-07 | Driving shaft selection device for four-wheel drive vehicle |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0242094A2 true EP0242094A2 (en) | 1987-10-21 |

| EP0242094A3 EP0242094A3 (en) | 1988-02-03 |

| EP0242094B1 EP0242094B1 (en) | 1990-08-29 |

Family

ID=13725193

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87302931A Expired - Lifetime EP0242094B1 (en) | 1986-04-07 | 1987-04-03 | Selecting device for the transmission system of a four-wheel drive vehicle |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4787491A (en) |

| EP (1) | EP0242094B1 (en) |

| JP (1) | JPS62238115A (en) |

| AT (1) | ATE55949T1 (en) |

| DE (1) | DE3764516D1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2669865A1 (en) * | 1990-12-01 | 1992-06-05 | Walterscheid Gmbh Jean | TRANSMISSION ASSEMBLY FOR ALL-TERRAIN VEHICLES WITH FOUR DRIVE WHEELS, ESPECIALLY TRACTORS. |

| WO1999004178A1 (en) * | 1997-07-15 | 1999-01-28 | Engelbert Gmeilbauer | Free-wheel engaging device |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5044479A (en) * | 1990-03-12 | 1991-09-03 | Boulder 12 Investments | Remote-activated, power shift clutch assembly |

| US5123513A (en) * | 1990-03-12 | 1992-06-23 | Boulder 12 Investments | Remote-activated, power shift clutch assembly with positive locking |

| US5542514A (en) * | 1993-06-10 | 1996-08-06 | Ntn Corporation | Rotational transmission device |

| US5937980A (en) * | 1997-02-24 | 1999-08-17 | Dana Corporation | Bi-directional one-way clutch |

| US5971123A (en) | 1998-10-09 | 1999-10-26 | Hilliard Corporation | Bi-directional overrunning clutch |

| US6691847B2 (en) * | 1998-11-26 | 2004-02-17 | Ker-Train Holdings Ltd. | Power transfer device |

| US6165103A (en) * | 1999-05-07 | 2000-12-26 | Visteon Global Technologies, Inc. | Shifting mechanism |

| US6193629B1 (en) * | 1999-05-07 | 2001-02-27 | Ford Global Technologies, Inc. | Shifting mechanism |

| US6622837B2 (en) | 2000-11-17 | 2003-09-23 | The Hilliard Corporation | Bi-directional overrunning clutch with automatic backdrive |

| US6629474B2 (en) * | 2001-04-27 | 2003-10-07 | New Venture Gear, Inc. | On-demand transfer case with controllable bi-directional overrunning clutch assembly |

| US7389863B2 (en) * | 2006-01-27 | 2008-06-24 | Warner Electric Technology, Llc | Automatically releaseable bidirectional overrunning clutch |

| US6739440B1 (en) | 2003-06-06 | 2004-05-25 | Torque-Traction Technologies, Inc. | Bi-directional one-way clutch |

| JP2006316984A (en) * | 2005-04-12 | 2006-11-24 | Kanzaki Kokyukoki Mfg Co Ltd | Bidirectional clutch |

| JP4760510B2 (en) * | 2005-08-09 | 2011-08-31 | 日産自動車株式会社 | Driving force transmission device |

| US7410042B2 (en) * | 2006-06-08 | 2008-08-12 | The Hilliard Corporation | Self-energizing pump for overrunning clutch |

| US9784355B1 (en) | 2016-08-31 | 2017-10-10 | Dana Heavy Vehicle Systems Group, Llc | Axle disconnect and differential lock combination |

| WO2020260745A1 (en) * | 2019-06-27 | 2020-12-30 | Auvinen Jukka | A braking control arrangement for a braking system of a vehicle |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2737975A1 (en) * | 1976-08-23 | 1978-03-02 | Borg Warner | TRANSMISSION |

| DE3510493A1 (en) * | 1984-03-23 | 1985-10-03 | Kabushiki Kaisha Daikin Seisakusho, Neyagawa, Osaka | POWER SWITCHING MECHANISM FOR INDUSTRIAL VEHICLES |

| GB2163107A (en) * | 1984-08-15 | 1986-02-19 | Fuji Heavy Ind Ltd | Four-wheel drive vehicle transmission |

| DE3508663A1 (en) * | 1985-03-12 | 1986-09-25 | Thyssen Industrie Ag, 4300 Essen | Motor vehicle with all-wheel drive |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2667251A (en) * | 1938-08-15 | 1954-01-26 | New Prod Corp | Clutch shifting means for transmissions |

| US2635478A (en) * | 1947-10-15 | 1953-04-21 | Chrysler Corp | Power transmission |

| US2850920A (en) * | 1950-12-21 | 1958-09-09 | Rockwell Spring & Axle Co | Vehicle drive mechanism |

| US2853890A (en) * | 1951-09-18 | 1958-09-30 | Borg Warner | Transmission |

| US3651907A (en) * | 1970-08-03 | 1972-03-28 | Boise Cascade Corp | Overrunning clutch for transfer case transmission |

| US4241621A (en) * | 1978-06-23 | 1980-12-30 | Fuji Jukogyo Kabushiki Kaisha | Transmission apparatus for motor vehicle |

| JPS5643035A (en) * | 1979-09-13 | 1981-04-21 | Fuji Heavy Ind Ltd | Four wheel drive with automatic transmission |

| JPS5715019A (en) * | 1980-06-27 | 1982-01-26 | Fuji Heavy Ind Ltd | Changeover device for 2, 4 wheel drive in 4-wheel drive vehicle |

-

1986

- 1986-04-07 JP JP61080685A patent/JPS62238115A/en active Pending

-

1987

- 1987-04-03 EP EP87302931A patent/EP0242094B1/en not_active Expired - Lifetime

- 1987-04-03 DE DE8787302931T patent/DE3764516D1/en not_active Expired - Fee Related

- 1987-04-03 US US07/035,639 patent/US4787491A/en not_active Expired - Fee Related

- 1987-04-03 AT AT87302931T patent/ATE55949T1/en not_active IP Right Cessation

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2737975A1 (en) * | 1976-08-23 | 1978-03-02 | Borg Warner | TRANSMISSION |

| DE3510493A1 (en) * | 1984-03-23 | 1985-10-03 | Kabushiki Kaisha Daikin Seisakusho, Neyagawa, Osaka | POWER SWITCHING MECHANISM FOR INDUSTRIAL VEHICLES |

| GB2163107A (en) * | 1984-08-15 | 1986-02-19 | Fuji Heavy Ind Ltd | Four-wheel drive vehicle transmission |

| DE3508663A1 (en) * | 1985-03-12 | 1986-09-25 | Thyssen Industrie Ag, 4300 Essen | Motor vehicle with all-wheel drive |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2669865A1 (en) * | 1990-12-01 | 1992-06-05 | Walterscheid Gmbh Jean | TRANSMISSION ASSEMBLY FOR ALL-TERRAIN VEHICLES WITH FOUR DRIVE WHEELS, ESPECIALLY TRACTORS. |

| GB2250551A (en) * | 1990-12-01 | 1992-06-10 | Walterscheid Gmbh Jean | A drive assembly including switchable freewheel clutches for a four wheel drive vehicle |

| WO1999004178A1 (en) * | 1997-07-15 | 1999-01-28 | Engelbert Gmeilbauer | Free-wheel engaging device |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0242094A3 (en) | 1988-02-03 |

| DE3764516D1 (en) | 1990-10-04 |

| ATE55949T1 (en) | 1990-09-15 |

| EP0242094B1 (en) | 1990-08-29 |

| JPS62238115A (en) | 1987-10-19 |

| US4787491A (en) | 1988-11-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0242094B1 (en) | Selecting device for the transmission system of a four-wheel drive vehicle | |

| US6846262B2 (en) | Transfer case shift system for controllable bi-directional overrunning clutch | |

| US4377093A (en) | Shift mechanism for a five speed transaxle transmission | |

| US7547265B2 (en) | Variable biasing differential | |

| US20060011001A1 (en) | Differential drive actuator | |

| US6557680B2 (en) | On-demand transfer case with integrated sprocket and bi-directional clutch assembly | |

| US9784355B1 (en) | Axle disconnect and differential lock combination | |

| KR19990077679A (en) | Bi-directional overrunning clutch assembly for transfer cases and the like | |

| WO2011072004A2 (en) | Disconnecting rear drive axle for longitudinally arranged powertrains | |

| US6520305B2 (en) | Clutch collar | |

| EP0226666B1 (en) | Four-wheel vehicle drive system | |

| US4805718A (en) | Power transmission system for a four-wheel drive | |

| US5295919A (en) | Power transmitting system for a four-wheel drive motor vehicle | |

| US4799399A (en) | Manually controlled multiple speed ratio transmission | |

| CN108626390B (en) | Actuator and fluid pressure control circuit provided with same | |

| GB2163107A (en) | Four-wheel drive vehicle transmission | |

| US5862900A (en) | Transmission synchronizer mechanism | |

| US9890819B2 (en) | Hydraulically operated clutch actuator | |

| US4727769A (en) | Integrated multi-function differential system | |

| US20090250309A1 (en) | Hydraulic Shift System for Power Transfer Devices | |

| JP4246301B2 (en) | Four-wheel drive device for vehicle | |

| EP4249776A1 (en) | Gearbox with improved parking lock, electric drivetrain and vehicle with such a drivetrain | |

| KR0146461B1 (en) | The transmission using bevel planetary gear | |

| JPS63301131A (en) | Four-wheel drive vehicle | |

| JPS63227421A (en) | Four-wheel drive vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19870410 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE GB LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE GB LI |

|

| 17Q | First examination report despatched |

Effective date: 19890818 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE GB LI |

|

| REF | Corresponds to: |

Ref document number: 55949 Country of ref document: AT Date of ref document: 19900915 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3764516 Country of ref document: DE Date of ref document: 19901004 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19910328 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19910402 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19910430 Year of fee payment: 5 Ref country code: AT Payment date: 19910430 Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19920403 Ref country code: AT Effective date: 19920403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19920430 Ref country code: CH Effective date: 19920430 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19930101 |