EP0217153B1 - Rotary snow cutter - Google Patents

Rotary snow cutter Download PDFInfo

- Publication number

- EP0217153B1 EP0217153B1 EP86112076A EP86112076A EP0217153B1 EP 0217153 B1 EP0217153 B1 EP 0217153B1 EP 86112076 A EP86112076 A EP 86112076A EP 86112076 A EP86112076 A EP 86112076A EP 0217153 B1 EP0217153 B1 EP 0217153B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- snow

- roller

- frame

- track

- tiller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009499 grossing Methods 0.000 claims description 20

- 239000004033 plastic Substances 0.000 claims description 6

- 229920003023 plastic Polymers 0.000 claims description 6

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 3

- 229910052782 aluminium Inorganic materials 0.000 claims description 3

- 230000000630 rising effect Effects 0.000 claims description 2

- 239000000463 material Substances 0.000 claims 2

- 239000004411 aluminium Substances 0.000 claims 1

- 239000011248 coating agent Substances 0.000 claims 1

- 238000000576 coating method Methods 0.000 claims 1

- 230000008878 coupling Effects 0.000 claims 1

- 238000010168 coupling process Methods 0.000 claims 1

- 238000005859 coupling reaction Methods 0.000 claims 1

- 230000005540 biological transmission Effects 0.000 abstract description 5

- 238000012423 maintenance Methods 0.000 abstract 3

- 238000003801 milling Methods 0.000 description 57

- 238000009434 installation Methods 0.000 description 2

- 230000002950 deficient Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01H—STREET CLEANING; CLEANING OF PERMANENT WAYS; CLEANING BEACHES; DISPERSING OR PREVENTING FOG IN GENERAL CLEANING STREET OR RAILWAY FURNITURE OR TUNNEL WALLS

- E01H4/00—Working on surfaces of snow or ice in order to make them suitable for traffic or sporting purposes, e.g. by compacting snow

- E01H4/02—Working on surfaces of snow or ice in order to make them suitable for traffic or sporting purposes, e.g. by compacting snow for sporting purposes, e.g. preparation of ski trails; Construction of artificial surfacings for snow or ice sports ; Trails specially adapted for on-the-snow vehicles, e.g. devices adapted for ski-trails

Definitions

- the present innovation relates to a snow blower for rear attachment to a snow groomer, with a gear for driving at least one milling shaft, a support frame for attaching the snow blower to the snow groomer and with a fixed to the support frame, which extends across the width of the snow blower and is trapezoidal in cross section Impact body on whose underside facing the runway a smoothing device is attached.

- Such a snow blower is already known in practice (see, for example, EP-A 0 139 865).

- the support frame of this snow blower extends essentially over its entire width.

- a gear is attached to one side end of the support frame and is used to drive the milling shaft, which also extends over the entire width of the snow blower.

- Side plates are attached to the side of the impact body, which are arranged next to the milling shaft and project beyond it in the direction of travel.

- the impact body has a cover plate located above the snow blower, which is connected in one piece to the impact body.

- a disadvantage of the known snow blower is that laborious work has to be carried out to replace wear parts, such as the cover, the smoothing device or the milling shafts.

- the milling shaft which extends across the entire width of the snow blower, is very difficult to handle for installation and removal. Replacing the cover practically requires the snow blower to be completely dismantled and the impact body to be replaced.

- the innovation is based on the task of creating a snow blower which is significantly improved in its handling, in particular with regard to the ease of repair and the replacement of wear parts.

- the impact body consists of a hollow profile and forms a central milling frame and the gear is mounted in the center of the milling frame and drives two milling shafts connected to the side of the gear, which at their ends facing away from the gear in at the ends of the Milling frame mounted side bearings are mounted, and that the milling frame is provided with fastening grooves running transversely to the direction of travel, with at least one interchangeable cover profile and an interchangeable smoothing device being inserted in an upper groove facing the milling shafts and in at least one lower groove facing the runway.

- the impact body now forms a central frame unit to which all essential parts of the snow blower are attached in the manner of the modular technology.

- To replace the milling shafts for example, only the side bearings have to be removed, after which a milling shaft, which is now only half as long as the conventional milling shaft, can be removed and replaced.

- the impact body now forms the central milling frame, it is also possible to make the supporting frame for attaching the snow blower to the snow groomer considerably easier.

- the central milling frame need only be screwed to the supporting frame at a few points, so that the complete replacement of the defective milling part on the snow blower can also be carried out quickly.

- the cover which is subject to heavy wear can now be simply pulled out of the fastening groove in the worn state and can be replaced by a new cover profile.

- the ends of the milling frame are freely accessible; the removal of the cover profile is no longer hindered by a gear or other disruptive components.

- the smoothing device, which is also subject to severe wear can be replaced without an at least partial disassembly of the snow blower being necessary.

- the milling frame is designed as an extruded or pressed profile made of aluminum.

- the snow blower is lightened in weight, which also leads to the fact that the support frame can be made considerably weaker.

- the milling frame has a parallelogram cross-section, a first parallelogram side facing the runway being approximately parallel to the runway and a second, subsequent parallelogram side forming a baffle surface rising obliquely upward in the direction of travel. It is particularly advantageous that in the parallelogram side of the milling frame facing the slope, two fastening grooves are incorporated at the edges for receiving the smoothing device. In this way, the smoothing device can be inserted into two spaced-apart grooves, as a result of which the smoothing device receives a certain rigidity at its part facing the milling frame. By installing two fastening grooves in the parallelogram side of the milling frame facing the slope, the smoothing device can connect seamlessly to the baffle surface of the milling frame.

- a fastening groove for receiving the cover profile is incorporated on the front edge in the direction of travel of a parallelogram side of the milling frame that faces away from the slope.

- the cover profile which extends over the milling shaft, can be supported at least partially on the upper parallelogram side of the milling frame.

- the cover profile is made of resilient plastic. Depending on which snow is milled, the cover profile can then move slightly upwards, thereby preventing damage to the snow blower by chunks of ice or the like.

- two cover profiles, each adapted to the milling shafts in terms of dimensions, are fitted in the fastening groove symmetrically to the gearbox.

- the side bearings are screwed onto the ends of the milling frame so that they can be replaced. If the milling shafts are then inserted in the gearbox on the one hand and in the side bearings on the other hand, the corresponding milling shaft can simply be pulled out of the gearbox after unscrewing one of the side bearings without any further work for replacing the milling shaft.

- the snow blower 1 comprises a support frame 2 for rear attachment to a snow groomer (not shown) and an impact body 3 fastened to the support frame 2 and extending over the entire width of the snow blower.

- the support frame 2 is fork-shaped and screwed symmetrically to the center of the snow blower 1 with the impact body 3.

- the impact body 3 itself is designed as a central milling frame, on which the following components are attached in a modular manner.

- a gear 4 is screwed, which drives two milling shafts 7 and 8 extending on both sides from the gear 4 to the lateral ends 5 and 6 of the milling frame 3.

- the outer ends 9 and 10 of the milling shafts 7 and 8 are held in side bearings 11 and 12 fastened to the lateral ends 5 and 6 of the milling frame 3.

- the milling frame 3 consists of a parallelogram-shaped hollow body which can be produced, for example, from aluminum by extrusion.

- a lower parallelogram side 13 of the milling frame 3 faces the slope and is aligned approximately parallel to it.

- the parallelogram side 13 is followed by a second parallelogram side 14, which rises obliquely upwards.

- This parallelogram side is designed as an impact surface and is provided with a wear-reducing plastic covering which is sprayed onto the parallelogram side 14 in the exemplary embodiment shown here.

- fastening grooves 17 and 18 are let in, which extend over the entire width of the milling frame 3.

- a smoothing device 19 is fastened in the fastening grooves 17 and 18 and is inserted with its projections 20 into the fastening grooves 17 and 18.

- the projections 20 are engaged behind by the fastening grooves 17 and 18, so that a further fastening of the smoothing device is not necessary.

- the smoothing device 19 extends over the entire width of the milling cutter and is made of plastic. In the front area, it has a part 21 which is approximately triangular in shape and which is joined to the rear by a plate-shaped, more flexible part 22.

- On the underside of the smoothing device relatively narrow ribs 23 extending in the direction of travel are attached in three transverse rows. The transverse rows of the ribs 23 extend over the entire width of the smoothing device 19.

- a fastening groove 26 is also incorporated in the region of the front edge 25, which extends over the entire width of the milling frame 3.

- a cover profile made of a resilient plastic is fastened, which extends in the extension of the parallelogram side 24 as seen in the direction of travel and ends in an arc directed towards the slope.

- This cover profile like the smoothing device, can also be inserted into the fastening groove 26, which engages behind a projection 28 of the cover profile 27, so that a further fastening of the cover profile 27 is not necessary.

- Two of the cover profiles 27 are provided side by side, one each extending from the gear unit to the lateral ends 5 and 6 of the milling frame 3.

- the milling shafts 7 and 8 are inserted into the gear 4 on the one hand and into the side bearings 11 and 12 screwed to the lateral ends 5 and 6 of the milling frame 3 on the other hand.

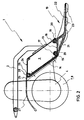

- FIG. 1 the components of the snow blower 1 are shown individually in plan view; they can also be seen in a side view. It can be seen particularly well that the snow blower 1 is constructed from only a very few parts which are very easy to replace. All wearing parts are attached to the central milling frame 3, so that depending on the wear of the snow blower, either the entire milling frame 3 is unscrewed from the supporting frame 2 and replaced by a new one, or only individual wearing parts are replaced.

- the smoothing device 19 designed as a wearing part can be removed from the central milling frame 3 simply by pulling out of the fastening grooves 17 and 18 and replaced by inserting a new smoothing device 19. In the same way, the replacement of the cover profiles 27 is possible.

- To replace a ver closed milling shaft only one side bearing 11 or 12 has to be unscrewed, after which the corresponding milling shaft 7 or 8 can then be pulled out of the transmission 4. The installation of a new milling shaft is carried out in the reverse order.

- the cover profile would have two projections.

- the lateral ends 5 and 6 of the milling frame 3 can be closed by side plates, which could then simultaneously take over the lateral locking of the two cover profiles and the smoothing device.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Soil Working Implements (AREA)

- Cleaning Of Streets, Tracks, Or Beaches (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- Buildings Adapted To Withstand Abnormal External Influences (AREA)

- Materials Applied To Surfaces To Minimize Adherence Of Mist Or Water (AREA)

- Harvester Elements (AREA)

- Shovels (AREA)

- Road Repair (AREA)

Abstract

Description

Die vorliegende Neuerung betrifft eine Schneefräse für den Heckanbau an ein Pistenfahrzeug, mit einem Getriebe zum Antrieb mindestens einer Fräswelle, einem Tragrahmen für die Anbringung der Schneefräse am Pistenfahrzeug und mit einem an dem Tragrahmen befestigten, sich über die Breite der Schneefräse erstreckenden und im Querschnitt trapezförmigen Prallkörper, an dessen der Piste zugewandten Unterseite eine Glätteinrichtung angebracht ist.The present innovation relates to a snow blower for rear attachment to a snow groomer, with a gear for driving at least one milling shaft, a support frame for attaching the snow blower to the snow groomer and with a fixed to the support frame, which extends across the width of the snow blower and is trapezoidal in cross section Impact body on whose underside facing the runway a smoothing device is attached.

Eine derartige Schneefräse ist aus der Praxis bereits bekannt (siehe z. B. EP-A 0 139 865). Der Tragrahmen dieser Schneefräse erstreckt sich im wesentlichen über deren gesamte Breite. An einem seitlichen Ende des Tragrahmens ist ein Getriebe angebracht, mit welchem die sich ebenfalls über die gesamte Breite der Schneefräse erstreckende Fräswelle angetrieben wird. Seitlich an dem Prallkörper sind Seitenbleche angebracht, welche neben der Fräswelle angeordnet sind und diese in Fahrtrichtung überragen. Der Prallkörper weist ein oberhalb der Schneefräse liegendes Abdeckblech auf, welches einstückig mit dem Prallkörper verbunden ist.Such a snow blower is already known in practice (see, for example, EP-A 0 139 865). The support frame of this snow blower extends essentially over its entire width. A gear is attached to one side end of the support frame and is used to drive the milling shaft, which also extends over the entire width of the snow blower. Side plates are attached to the side of the impact body, which are arranged next to the milling shaft and project beyond it in the direction of travel. The impact body has a cover plate located above the snow blower, which is connected in one piece to the impact body.

Nachteilig bei der bekannten Schneefräse ist es, daß zum Auswechseln von Verschleißteilen, wie beispielsweise der Abdeckung, der Glätteinrichtung oder auch der Fräswellen umständliche Arbeiten durchgeführt werden müssen. Die sich über die gesamte Breite der Schneefräse erstreckende Fräswelle ist zum Ein- und Ausbau nur sehr schwer handhabbar. Ein Auswechseln der Abdeckung erfordert praktisch die vollständige Zerlegung der Schneefräse und das Austauschen des Prallkörpers.A disadvantage of the known snow blower is that laborious work has to be carried out to replace wear parts, such as the cover, the smoothing device or the milling shafts. The milling shaft, which extends across the entire width of the snow blower, is very difficult to handle for installation and removal. Replacing the cover practically requires the snow blower to be completely dismantled and the impact body to be replaced.

Demgegenüber liegt der Neuerung die Aufgabe zugrunde, eine Schneefräse zu schaffen, welche in ihrer Handhabung wesentlich verbessert wird, insbesondere was die Reparaturfreundlichkeit und das Auswechseln von Verschleißteilen anbetrifft.In contrast, the innovation is based on the task of creating a snow blower which is significantly improved in its handling, in particular with regard to the ease of repair and the replacement of wear parts.

Diese Aufgabe wird dadurch gelöst, daß der Prallkörper aus einem Hohlprofil besteht und einen zentralen Fräsrahmen bildet und das Getriebe in der Mitte des Fräsrahmens angebracht ist und zwei seitlich mit dem Getriebe verbundene Fräswellen antreibt, die an ihren dem Getriebe abgewandten Enden in an den Enden des Fräsrahmens angebrachten Seitenlagern gelagert sind, und daß der Fräsrahmen mit quer zur Fahrtrichtung verlaufenden befestigungsnuten versehen ist, wobei in einer oberen, den Fräswellen zugewandten Nut mindestens ein auswechselbares Abdeckprofil und in zumindest einer unteren, der Piste zugewandten Nut eine auswechselbare Glätteinrichtung eingeschoben befestigt ist.This object is achieved in that the impact body consists of a hollow profile and forms a central milling frame and the gear is mounted in the center of the milling frame and drives two milling shafts connected to the side of the gear, which at their ends facing away from the gear in at the ends of the Milling frame mounted side bearings are mounted, and that the milling frame is provided with fastening grooves running transversely to the direction of travel, with at least one interchangeable cover profile and an interchangeable smoothing device being inserted in an upper groove facing the milling shafts and in at least one lower groove facing the runway.

Diese Lösung bringt bezüglich der Handhabung der Schneefräse gravierende Vorteile. Nunmehr bildet der Prallkörper eine zentrale Rahmeneinheit, an welcher nach Art der Modultechnik alle wesentlichen Teile der Schneefräse angebracht sind. Zum Auswechseln der Fräswellen sind beispielsweise lediglich die Seitenlager abzunehmen, wonach dann eine Fräswelle, die nun bloß noch halb so lang wie die herkömmliche Fräswelle ist, herausgenommen und ausgetauscht werden kann. Dadurch daß nunmehr der Prallkörper den zentralen Fräsrahmen bildet, ist es auch möglich, den Tragrahmen für die Anbringung der Schneefräse am Pistenfahrzeug erheblich leichter auszubilden. Der zentrale Fräsrahmen braucht lediglich an wenigen Stellen mit dem Tragrahmen verschraubt zu sein, so daß auch der vollständige Austausch des defekten Frästeiles an der Schneefräse schnell vonstatten geht. Ganz besonders günstig bei der neuerungsgemäßen Ausbildung der Schneefräse ist es, daß die starkem Verschleiß unterworfene Abdeckung nunmehr im verschlissenen Zustand einfach aus der Befestigungsnut herausgezogen werden kann und durch ein neues Abdeckprofil ersetzt werden kann. Dabei sind die Enden des Fräsrahmens frei zugänglich; die Herausnahme des Abdeckprofiles wird nicht mehr durch ein Getriebe oder andere störende Bauteile behindert. In gleicher Weise kann auch die einem ebenfalls starken Verschleiß unterliegende Glätteinrichtung ausgewechselt werden, ohne daß dazu eine zumindest teilweise Zerlegung der Schneefräse notwendig wäre.This solution has serious advantages when it comes to handling the snow blower. The impact body now forms a central frame unit to which all essential parts of the snow blower are attached in the manner of the modular technology. To replace the milling shafts, for example, only the side bearings have to be removed, after which a milling shaft, which is now only half as long as the conventional milling shaft, can be removed and replaced. Because the impact body now forms the central milling frame, it is also possible to make the supporting frame for attaching the snow blower to the snow groomer considerably easier. The central milling frame need only be screwed to the supporting frame at a few points, so that the complete replacement of the defective milling part on the snow blower can also be carried out quickly. It is particularly favorable with the new design of the snow blower that the cover which is subject to heavy wear can now be simply pulled out of the fastening groove in the worn state and can be replaced by a new cover profile. The ends of the milling frame are freely accessible; the removal of the cover profile is no longer hindered by a gear or other disruptive components. In the same way, the smoothing device, which is also subject to severe wear, can be replaced without an at least partial disassembly of the snow blower being necessary.

Vorteilhaft ist es, wenn der Fräsrahmen als Strangguß- oder -pressprofil aus Aluminium ausgebildet ist. Dadurch wird zum einen die Schneefräse gewichtsmäßig erleichtert, was darüberhinaus aber auch dazu führt, daß der Tragrahmen erheblich schwächer ausgebildet werden kann.It is advantageous if the milling frame is designed as an extruded or pressed profile made of aluminum. As a result, the snow blower is lightened in weight, which also leads to the fact that the support frame can be made considerably weaker.

Gemäß einer bevorzugten Ausführungsform ist der Fräsrahmen im Querschnitt parallelogrammförmig ausgebildet, wobei eine erste, der Piste zugewandte Parallelogrammseite etwa pistenparallel und eine zweite, sich daran anschließende Parallelogrammseite eine Prallfläche bildend in Fahrtrichtung schräg nach oben ansteigend ausgebildet ist. Dabei ist es besonders günstig, daß in der der Piste zugewandten Parallelogrammseite des Fräsrahmens jeweils an den Kanten zwei Befestigungsnuten zur Aufnahme der Glätteinrichtung eingearbeitet sind. Auf diese Weise kann die Glätteinrichtung in zwei voneinander beabstandeten Nuten eingeschoben werden, wodurch die Glätteinrichtung an ihrem dem Fräsrahmen zugewandten Teil eine gewisse Steifigkeit erhält. Durch die Anbringung zweier Befestigungsnuten in der der Piste zugewandten Parallelogrammseite des Fräsrahmens kann sich die Glätteineinrichtung nahtlos an die Prallfläche des Fräsrahmens anschließen.According to a preferred embodiment, the milling frame has a parallelogram cross-section, a first parallelogram side facing the runway being approximately parallel to the runway and a second, subsequent parallelogram side forming a baffle surface rising obliquely upward in the direction of travel. It is particularly advantageous that in the parallelogram side of the milling frame facing the slope, two fastening grooves are incorporated at the edges for receiving the smoothing device. In this way, the smoothing device can be inserted into two spaced-apart grooves, as a result of which the smoothing device receives a certain rigidity at its part facing the milling frame. By installing two fastening grooves in the parallelogram side of the milling frame facing the slope, the smoothing device can connect seamlessly to the baffle surface of the milling frame.

Es ist vorteilhaft, wenn an der in Fahrtrichtung vorderen Kante einer pistenparallelen, der Piste abgewandten Parallelogrammseite des Fräsrahmens eine Befestigungsnut zur Aufnahme des Abdeckprofiles eingearbeitet ist. Das Abdeckprofil, welches sich über die Fräswelle hinüberreichend erstreckt, kann sich so zumindest teilweise auf der oberen Parallelogrammseite des Fräsrahmens abstützen. Dabei ist es vorteilhaft, wenn das Abdeckprofil aus nachgiebigem Kunststoff ausgebildet ist. Je nachdem welcher Schnee gefräst wird, kann das Abdeckprofil dann leicht nach oben ausweichen, wodurch eine Beschädigung der Schneefräse durch Eisbrocken oder dergleichen vermieden wird. Zum Auswechseln der Abdeckprofile ist es günstig, wenn symmetrisch zum Getriebe zwei, in den Abmessungen jeweils den Fräswellen angepasste Abdeckprofile in der Befestigungsnut angebracht sind.It is advantageous if a fastening groove for receiving the cover profile is incorporated on the front edge in the direction of travel of a parallelogram side of the milling frame that faces away from the slope. The cover profile, which extends over the milling shaft, can be supported at least partially on the upper parallelogram side of the milling frame. It is advantageous if the cover profile is made of resilient plastic. Depending on which snow is milled, the cover profile can then move slightly upwards, thereby preventing damage to the snow blower by chunks of ice or the like. To replace the cover profiles, it is advantageous if two cover profiles, each adapted to the milling shafts in terms of dimensions, are fitted in the fastening groove symmetrically to the gearbox.

Für das Auswechseln der Fräswellen ist es von Vorteil, daß die Seitenlager an den Enden des Fräsrahmens auswechselbar angeschraubt sind. Wenn dann die Fräswellen einerseits im Getriebe und andererseits in den Seitenlagern eingesteckt gehalten sind, kann einfach nach Abschrauben eines der Seitenlager die entsprechende Fräswelle aus dem Getriebe herausgezogen werden, ohne daß weitere Arbeiten zum Auswechseln der Fräswelle vorzunehmen wären.For exchanging the milling shafts, it is advantageous that the side bearings are screwed onto the ends of the milling frame so that they can be replaced. If the milling shafts are then inserted in the gearbox on the one hand and in the side bearings on the other hand, the corresponding milling shaft can simply be pulled out of the gearbox after unscrewing one of the side bearings without any further work for replacing the milling shaft.

Verschleißmindernd für den Fräsrahmen wirkt es sich aus, wenn auf die Prallfläche des Fräsrahmens ein Kunststoffbelag aufgespritzt ist.It reduces wear on the milling frame if a plastic covering is sprayed onto the impact surface of the milling frame.

Im folgenden wird an Hand einer Zeichnung ein Ausführungsbeispiel der Neuerung näher erläutert. Es zeigen:

- Fig. 1 eine Draufsicht auf die Schneefräse, wobei ein Teil der Schneefräse weggebrochen wurde,

- Fig. 2 eine Schnittansicht der neuerungsgemäßen Schneefräse, entlang der Linie 11-11 aus Fig. 1 und

- Fig. 3 die neuerungsgemäße Schneefräse im zerlegten Zustand in Seitenansicht und Draufsicht,

- 1 is a plan view of the snow blower, with part of the snow blower broken away,

- Fig. 2 is a sectional view of the snow blower according to the innovation, along the line 11-11 of Fig. 1 and

- 3 the snow blower according to the invention in the disassembled state in a side view and a top view,

Wie am besten aus der Fig. 1 zu ersehen ist umfasst die Schneefräse 1 einen Tragrahmen 2 für den Heckanbau an ein nicht dargestelltes Pistenfahrzeug und einen an dem Tragrahmen 2 befestigten und sich über die gesamte Breite der Schneefräse erstreckenden Prallkörper 3.As can best be seen from FIG. 1, the snow blower 1 comprises a

Der Tragrahmen 2 ist gabelförmig ausgebildet und symmetrisch zur Mitte der Schneefräse 1 mit dem Prallkörper 3 verschraubt. Der Prallkörper 3 selbst ist als zentraler Fräsrahmen ausgebildet, an welchem modulartig die nachfolgenden Bauteile angebracht sind.The

In der Mitte des Tragrahmens, bzw. des Prallkörpers 3 ist ein Getriebe 4 angeschraubt, welches zwei sich beidseitig von dem Getriebe 4 bis zu den seitlichen Enden 5 und 6 des Fräsrahmens 3 erstreckende Fräswellen 7 und 8 antreibt. Die äußeren Enden 9 und 10 der Fräswellen 7 und 8 werden in an den seitlichen Enden 5 und 6 des Fräsrahmens 3 befestigten Seitenlagern 11 und 12 gehalten.In the middle of the support frame or the

Wie besser aus der Fig. 2 ersichtlich ist, besteht der Fräsrahmen 3 aus einem parallelogrammförmigen Hohlkörper, der beispielsweise durch Strangpressen aus Aluminium hergestellt werden kann. Eine untere Parallelogrammseite 13 des Fräsrahmens 3 ist der Piste zugewandt und etwa parallel dazu ausgerichtet. An die Parallelogrammseite 13 schließt sich in Fahrtrichtung gesehen nach vorne eine zweite Parallelogrammseite 14 an, welche schräg nach oben ansteigt.As can be seen more clearly from FIG. 2, the

Diese Parallelogrammseite ist als Prallfläche ausgebildet und mit einem verschleißmindernden Kunststoffbelag versehen, welcher bei dem hier gezeigten Ausführungsbeispiel auf die Parallelogrammseite 14 aufgespritzt ist.This parallelogram side is designed as an impact surface and is provided with a wear-reducing plastic covering which is sprayed onto the

Im Bereich der vorderen Kante 15 und der hinteren Kante 16 der ersten Parallelogrammseite 13 sind Befestigungsnuten 17 und 18 eingelassen, welche sich über die gesamte Breite des Fräsrahmens 3 erstrecken.In the area of the

In den Befestigungsnuten 17 und 18 ist eine Glätteinrichtung 19 befestigt, welche mit ihren Vorsprüngen 20 in die Befestigungsnuten 17 und 18 eingeschoben ist. Die Vorsprünge 20 werden dabei von den Befestigungsnuten 17 und 18 hintergriffen, so daß eine weitere Befestigung der Glätteinrichtung nicht notwendig ist. Die Glätteinrichtung 19 erstreckt sich über gesamte Breite der Fräse und besteht aus Kunststoff. Sie weist im vorderen Bereich einem im Querschnitt etwa dreiecksförmigen ausgesteiften Teil 21 auf an den sich heckwärts ein plattenförmiger nachgiebigerer Teil 22 anschließt. Auf der Unterseite der Glätteinrichtung sind in drei Querreihen relativ schmale, sich in Fahrtrichtung erstreckende Rippen 23 angebracht. Die Querreihen der Rippen 23 erstrecken sich über die gesamte Breite der Glätteinrichtung 19.A

Auf der der Parallelogrammseite 13 gegenüberliegenden, oberen Seite 24 des Fräsrahmens 3 ist im Bereich der vorderen Kante 25 ebenfalls eine Befestigungsnut 26 eingearbeitet, welche sich über die gesamte Breite des Fräsrahmens 3 erstreckt. In der Befestigungsnut 26 ist ein Abdeckprofil aus einem nachgiebigen Kunststoff befestigt, das sich in Verlängerung der Parallelogrammseite 24 in Fahrtrichtung gesehen nach vorne erstreckt und in einem pistenwärts gerichteten Bogen endet. Auch dieses Abdeckprofil kann ebenso wie die Glätteinrichtung in die Befestigungsnut 26 eingeschoben werden, welche einen Vorsprung 28 des Abdeckprofiles 27 hintergreift, so daß eine weitere Befestigung des Abdeckprofiles 27 nicht notwendig ist. Von den Abdeckprofilen 27 sind zwei nebeneinander vorgesehen, wobei sich jeweils eines von dem Getriebe aus bis zu den seitlichen Enden 5 bzw. 6 des Fräsrahmens 3 erstreckt.On the

Die Fräswellen 7 und 8 sind einerseits in das Getriebe 4 und andererseits in die an den seitlichen Enden 5 und 6 des Fräsrahmens 3 angeschraubten Seitenlager 11 und 12 eingesteckt. Dies ist aus der Fig. 1 zu ersehen. In der Fig. 3 sind zum einen die Bauteile der Schneefräse 1 in der Draufsicht einzeln dargestellt; daneben sind sie auch noch in einer Seitenansicht zu erkennen. Besonders gut zu ersehen ist, daß die Schneefräse 1 aus nur sehr wenigen Teilen aufgebaut ist, die sehr leicht austauschbar sind. Sämtliche Verschleißteile sind an dem zentralen Fräsrahmen 3 angebracht, so daß je nach Verschleiß der Schneefräse entweder der gesamte Fräsrahmen 3 von dem Tragrahmen 2 abgeschraubt wird und durch einen neuen ersetzt wird, oder lediglich einzelne Verschleißteile ausgewechselt werden.The milling shafts 7 and 8 are inserted into the gear 4 on the one hand and into the

Im folgenden wird die Wirkungsweise der Neuerung näher erläutert.The mode of operation of the innovation is explained in more detail below.

Die als Verschleißteil ausgelegte Glätteinrichtung 19 kann einfach durch Herausziehen aus den Befestigungsnuten 17 und 18 aus dem zentralen Fräsrahmen 3 entfernt werden und durch Einschieben einer neuen Glätteinrichtung 19 ersetzt werden. In gleicher Weise ist das Auswechseln der Abdeckprofile 27 möglich. Zum Auswechseln einer verschlissenen Fräswelle ist lediglich ein Seitenlager 11 bzw. 12 abzuschrauben, wonach dann die entsprechende Fräswelle 7 bzw. 8 aus dem Getriebe 4 herausgezogen werden kann. Der Einbau einer neuen Fräswelle wird in umgekehrter Reihenfolge vorgenommen.The smoothing

Es ist auch möglich, an der oberen Seite 24 des Fräsrahmens 3, ähnlich wie bei der unteren Parallelogrammseite 13 zwei Befestigungsnuten für die Aufnahme des Abdeckprofiles vorzusehen. Das Abdeckprofil würde in diesem Falle zwei Vorsprünge aufweisen. Die seitlichen Enden 5 und 6 des Fräsrahmens 3 können durch Seitenbleche verschlossen werden, die dann gleichzeitig die seitliche Arretierung der beiden Abdeckprofile sowie der Glätteinrichtung übernehmen könnten.It is also possible to provide two fastening grooves for receiving the cover profile on the

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT86112076T ATE54349T1 (en) | 1985-10-02 | 1986-09-01 | SNOW BLOWER. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8528096U | 1985-10-02 | ||

| DE8528096U DE8528096U1 (en) | 1985-10-02 | 1985-10-02 | Snow blower |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0217153A2 EP0217153A2 (en) | 1987-04-08 |

| EP0217153A3 EP0217153A3 (en) | 1988-01-20 |

| EP0217153B1 true EP0217153B1 (en) | 1990-07-04 |

Family

ID=6785877

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86112076A Expired - Lifetime EP0217153B1 (en) | 1985-10-02 | 1986-09-01 | Rotary snow cutter |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4718183A (en) |

| EP (1) | EP0217153B1 (en) |

| JP (1) | JPH0621442B2 (en) |

| AT (1) | ATE54349T1 (en) |

| CA (1) | CA1240193A (en) |

| DE (2) | DE8528096U1 (en) |

| YU (1) | YU166086A (en) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8801788U1 (en) * | 1988-02-11 | 1989-06-15 | Emitec Gesellschaft für Emissionstechnologie mbH, 53797 Lohmar | Catalyst carrier body with S-shaped, partially reinforced sheet metal layers |

| US4897941A (en) * | 1988-08-21 | 1990-02-06 | Logan Manufacturing Company | Snow grooming comb |

| CA2008235C (en) * | 1990-01-22 | 1999-08-31 | Michel Pelletier | Variable geometry tiller |

| US5077919A (en) * | 1991-05-13 | 1992-01-07 | Logan Manufacturing Company | Snow grooming comb with angularly positioned elongate teeth |

| DE9315880U1 (en) * | 1993-10-18 | 1994-02-03 | Karl Kässbohrer Fahrzeugwerke GmbH, 89077 Ulm | Slope grooming device |

| IT1313729B1 (en) * | 1999-09-15 | 2002-09-17 | Leitner Spa | MILLING GROUP FOR THE BEATING OF SNOWY SLOPES |

| US20060081381A1 (en) * | 2004-09-07 | 2006-04-20 | Kassbohrer All Terrain Vehicles, Inc. | Material handling apparatus |

| DE102006057272B4 (en) | 2006-11-23 | 2011-11-10 | Kässbohrer Geländefahrzeug AG | Piste grooming device for a motor vehicle, in particular a tracked vehicle |

| ITMI20070565A1 (en) * | 2007-03-21 | 2008-09-22 | Prinoth Spa | MILL FOR THE PREPARATION OF THE SNOWY SKI SLOPE |

| ITMI20131925A1 (en) * | 2013-11-20 | 2015-05-21 | Snowgrolic S A R L | SNOW MILL FOR THE PREPARATION OF THE SNOWY SKI SLOPE |

| CN105256297A (en) * | 2014-07-17 | 2016-01-20 | 烟台盛业钢格板有限公司 | High-corrosion-resistance phosphating solution and preparing method thereof |

| CN106884401B (en) * | 2017-04-07 | 2018-07-03 | 广西玉林悍牛工程机器有限公司 | Press sled snowplow scraper plate compaction apparatus |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE554075C (en) * | 1928-11-17 | 1932-07-04 | Max Pelikan | Device running on sliding rollers for roughening road surfaces |

| BE562724A (en) * | 1957-08-21 | |||

| US3692120A (en) * | 1970-05-13 | 1972-09-19 | Ted L Cline | Tilling apparatus |

| US3685404A (en) * | 1970-07-24 | 1972-08-22 | Thiokol Chemical Corp | Multi-way snow grooming apparatus for ski slopes |

| US3755930A (en) * | 1970-12-18 | 1973-09-04 | C Brandt | Snow grader |

| US3923103A (en) * | 1974-12-02 | 1975-12-02 | Jimmie L Davis | Cultivator skimmer device |

| CH591877A5 (en) * | 1976-04-02 | 1977-09-30 | Kempf & Co Ag | |

| US4056328A (en) * | 1977-02-17 | 1977-11-01 | Maxey Loren R | Snow groomer for snowmobile trails |

| FR2416634A1 (en) * | 1978-02-13 | 1979-09-07 | Crete Guerin | Side guard for ground preparation machine - has blades pivoted about vertical axes to ensure that soil treated is retained for a rolling |

| DE2946796A1 (en) * | 1979-11-20 | 1981-05-27 | Karl Kässbohrer Fahrzeugwerke GmbH, 7900 Ulm | CLEANING DEVICE FOR SNOW VEHICLES, IN PARTICULAR FOR SLOPE CARE |

| US4359831A (en) * | 1980-05-19 | 1982-11-23 | De Lorean Manufacturing Company | Reversibly powered rotary snow tiller |

| DE3247971A1 (en) * | 1982-12-24 | 1984-06-28 | Karl Kässbohrer Fahrzeugwerke GmbH, 7900 Ulm | SNOW VEHICLE FOR CROSS-COUNTRY CARE |

| DE3333942A1 (en) * | 1983-09-20 | 1985-03-28 | Karl Kässbohrer Fahrzeugwerke GmbH, 7900 Ulm | SNOW VEHICLE |

| DE3333941A1 (en) * | 1983-09-20 | 1985-04-04 | Karl Kässbohrer Fahrzeugwerke GmbH, 7900 Ulm | MRS |

-

1985

- 1985-10-02 DE DE8528096U patent/DE8528096U1/en not_active Expired

-

1986

- 1986-08-11 US US06/895,457 patent/US4718183A/en not_active Expired - Lifetime

- 1986-09-01 EP EP86112076A patent/EP0217153B1/en not_active Expired - Lifetime

- 1986-09-01 AT AT86112076T patent/ATE54349T1/en not_active IP Right Cessation

- 1986-09-01 DE DE8686112076T patent/DE3672432D1/en not_active Expired - Fee Related

- 1986-09-08 JP JP61211359A patent/JPH0621442B2/en not_active Expired - Fee Related

- 1986-09-26 YU YU01660/86A patent/YU166086A/en unknown

- 1986-10-01 CA CA000519496A patent/CA1240193A/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| YU166086A (en) | 1988-02-29 |

| JPS6282107A (en) | 1987-04-15 |

| US4718183A (en) | 1988-01-12 |

| JPH0621442B2 (en) | 1994-03-23 |

| EP0217153A2 (en) | 1987-04-08 |

| ATE54349T1 (en) | 1990-07-15 |

| CA1240193A (en) | 1988-08-09 |

| DE3672432D1 (en) | 1990-08-09 |

| DE8528096U1 (en) | 1985-11-14 |

| EP0217153A3 (en) | 1988-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0226711B1 (en) | Rotary snow cutter | |

| EP0217153B1 (en) | Rotary snow cutter | |

| DE2550790C2 (en) | Stripping device for slideways on machine tools | |

| DE8812647U1 (en) | Sieve bottom | |

| CH636812A5 (en) | TRACK CHAIN, ESPECIALLY FOR ARMORED VEHICLES. | |

| DE3333941A1 (en) | MRS | |

| DE8703695U1 (en) | Component set for a housing frame | |

| DE1608346A1 (en) | Fluid-cooled continuous casting mold made of plates | |

| DE3423119A1 (en) | Device for laying an elastomeric sealing profile in strip form in expansion joints of carriageways | |

| DE29603461U1 (en) | Halfpiperreamer | |

| DE102017116757B4 (en) | Scraper bar for a scraper blade on a road milling machine | |

| DE202007007362U1 (en) | Trough pan for mining unit, especially underground chain scraper conveyor, has fastening means with clamping pieces with wedge face which interacts with bevelled mating wedge face on exchangeable trough | |

| DE10202737B9 (en) | Linear guide unit | |

| DE2516082C2 (en) | Channel section for chain scraper conveyor | |

| DE3414440A1 (en) | Ski consisting of a ski member provided with a running surface | |

| DE19856338B4 (en) | Scraper for conveyor belts | |

| DE3216092C2 (en) | Shredders for plastic material | |

| DE3627733C2 (en) | ||

| DE2929550C2 (en) | Ice skate | |

| EP0600435A1 (en) | Ductor knife segment and ductor knife holder for an ink fountain of a rotary printing machine | |

| EP0085300A2 (en) | Track section for endless track vehicle | |

| DE3403092C2 (en) | Planer | |

| DE3522766C2 (en) | ||

| EP0695603A1 (en) | Toggle lever clamp | |

| DE3910126C2 (en) | Grate to form running mats or wipers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE FR IT LI SE |

|

| ITCL | It: translation for ep claims filed |

Representative=s name: STUDIO GILBERTO PETRAZ |

|

| EL | Fr: translation of claims filed | ||

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE FR IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19880719 |

|

| 17Q | First examination report despatched |

Effective date: 19890714 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 54349 Country of ref document: AT Date of ref document: 19900715 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3672432 Country of ref document: DE Date of ref document: 19900809 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 86112076.4 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: EVOBUS GMBH TRANSFER- KAESSBOHRER GELAENDEFAHRZEUG Ref country code: CH Ref legal event code: PFA Free format text: KARL KAESSBOHRER FAHRZEUGWERKE GMBH TRANSFER- EVOBUS GMBH |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Ref country code: FR Ref legal event code: CD |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20020913 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20020916 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20020919 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20020920 Year of fee payment: 17 Ref country code: CH Payment date: 20020920 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040401 |

|

| EUG | Se: european patent has lapsed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040528 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050901 |