EP0203405A1 - Automatic labelling apparatus - Google Patents

Automatic labelling apparatus Download PDFInfo

- Publication number

- EP0203405A1 EP0203405A1 EP86105952A EP86105952A EP0203405A1 EP 0203405 A1 EP0203405 A1 EP 0203405A1 EP 86105952 A EP86105952 A EP 86105952A EP 86105952 A EP86105952 A EP 86105952A EP 0203405 A1 EP0203405 A1 EP 0203405A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- labels

- sheet

- label

- section

- stripping

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F3/00—Labels, tag tickets, or similar identification or indication means; Seals; Postage or like stamps

- G09F3/02—Forms or constructions

- G09F3/0286—Forms or constructions provided with adaptations for labelling machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65C—LABELLING OR TAGGING MACHINES, APPARATUS, OR PROCESSES

- B65C9/00—Details of labelling machines or apparatus

- B65C9/0015—Preparing the labels or articles, e.g. smoothing, removing air bubbles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65C—LABELLING OR TAGGING MACHINES, APPARATUS, OR PROCESSES

- B65C9/00—Details of labelling machines or apparatus

- B65C9/08—Label feeding

- B65C9/18—Label feeding from strips, e.g. from rolls

- B65C9/1865—Label feeding from strips, e.g. from rolls the labels adhering on a backing strip

- B65C9/1869—Label feeding from strips, e.g. from rolls the labels adhering on a backing strip and being transferred directly from the backing strip onto the article

Definitions

- This invention relates to an automatic labelling apparatus for applying labels to objects to be labelled from a label-holding sheet to which they are provisionally attached in succession. Particularly, it relates to an automatic labelling apparatus for applying color-changeable labels which contain a pressure-sensitive microcapsular layer and have the function of changing in color depending upon temperature-time-relations after rupture of the microcapsules.

- a conventional automatic labelling apparatus is adapted to deliver by a guide roller a label-holding sheet having labels provisionally attached thereto, wrap the sheet around a front end portion of a stripping plate which is positioned immediately before an applicator roller and reverse it, allow it to ' travel in an opposite direction, strip the labels automatically from the sheet during the reversing of the sheet, and in the meantime, lower the applicator roller and press the labels onto articles to be labelled which have been transferred to a position immediately beneath the applicator roller.

- a color-changeable label is comprised of a base sheet 1, a developer layer 2 containing a developer 2a, a spacer layer 3 for controlling the developing time and a microcapsular layer 5 containing pressure-sensitive microcapsules 4 holding, a dye- precursor and a substance having a predetermined melting point (the contents of the capsules are indicated by 4a) formed in this order on the surface of the base sheet 1, and a pressure-sensitive adhesive layer 6 on the back of the base sheet 1.

- the color-changeable label is provisionally attached strippably to a separable layer 8 on a label-holding sheet 7.

- the developer 2a and the dye precursor do not react at a temperature below the melting point of the aforesaid substance having a predetermined melting point, and unless the microcapsules are ruptured, no color forming reaction occurs.

- the microcapsules 4 are ruptured and the label is exposed to a temperature above the melting point of the aforesaid substance, the substance melts, and the liquid containing the melted dye precursor passes through the spacer layer 3 over a predetermined time and reaches the developer layer 2.

- the developer 2a and the dye precursor react to form a color. This color reaction permits simple and convenient indication of improper temperature control.

- it is necessary to activate them by rupturing the microcapsules 4 prior to application to commodity packs. It has been desired therefore to develop an automatic labelling apparatus equipped with microcapsule rupturing mechanism.

- Another object of this invention is to provide an automatic labelling device equipped with a rupturing mechanism which can uniformly press the surface of a label entirely or partially and rupture microcapsules in the label easily and accurately without degrading the appearance of the label itself.

- an automatic labelling apparatus comprising

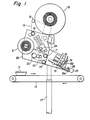

- the illustrated apparatus includes a pay-off section 13 for holding a roll of a label-holding sheet 12 having labels 11 provisionally attached thereto strippably and an applicator roller 14 (labelling section) for applying the label 11 to an object P to be labelled. Between the pay-off section 13 and the applicator roller 14 are disposed a tension roller 15, a holding roller 15 and a first guide roller 17.

- a stripping plate 18 having a front end portion 18 shaped at an acute angle is provided in front of the applicator roller 14, and the front end portion 18a is located immediately before the applicator roller 14,

- the applicator roller 14 is adapted to move (descend in the drawings) freely toward an object P to be labelled which has been conveyed by a conveying means 19 such as a belt conveyor.

- the apparatus also includes a wind-up section 21 for winding up the sheet 12' which has been wrapped around the front end portion 18a of the stripping plate 18 and reversed, and stripped of the labels 11.

- the sheet 12' is wound up via a second guide roll 22 and a pinch roller 23.

- the labels 11 are provisionally attached strippably to a separable layer of the sheet 12 via an adhesive layer formed on the back of the labels 11. Hence, when the sheet 12 is reversed after it has been turned at the front end portion 18a of the stripping plate 18, the labels 11 are automatically stripped off from the board 12 by the force of reaction at the time of reversing (see Figure 3), and applied to the object P by the pressing action of the applicator roller 14.

- a compression air nozzle for example, may be used instead of the applicator roller 14.

- the automatic labelling apparatus of this invention further includes a mechanism for applying pressure to the labels and thus rupturing the micro- capsules therein.

- the rupturing mechanism is comprised of a pair of press rollers 31 and 32 for holding and pressing the labels 11 on the travelling sheet 12.

- the pair of press rollers 31 and 32 are disposed on the sheet pay-off side of the front portion 18a of the stripping plate 18.

- the microcapsules in the labels are ruptured by the pressing action (application of a linear pressure of at least 100 kg) of the press rollers 31 and 32.

- the time of rupture is the starting point for the temperature handling function of the color-changeable labels.

- the labels then perform the function of color changing for ascertaining the state of temperature handling of the labelled object (for example, a labelled commodity pack) in the whole distribution chain.

- the apparatus additionally includes a label position detecting section 24 (photoelectric device), a plate 25 for preventing adhesion of labels to the applicator roller 14, a machine frame 26, and a mounting stand 27.

- FIG 2 Another embodiment of the apparatus of this invention is shown in Figure 2.

- Figure 2 the same reference numerals as in Figure 1 have the same meanings as in Figure 1.

- the apparatus of Figure 2 differs from the apparatus of Figure 1 in that a stamper 33 and a stamping stand 35 are used instead of the pair of press rollers in the apparatus of Figure 1.

- the microcapsule rupturing mechanism is comprised of the stamper 33 (metal stamp 34) for stamping the labels 11 on the sheet 12 and the stamping stand 35.

- the stamper devices 33 and 35 are disposed on the sheet pay-off side of the front end portion 18a of the stripping plate 18. During passage between the stamper devices 33 and 35, the microcapsules in the labels undergo stamping pressure and ruptured by the resulting impact.

- the color-changeable labels having the function of changing in colors are pressed by pressing means, for example a pair of press rollers or stamper means, to rupture the micro-capsules in the labels.

- pressing means for example a pair of press rollers or stamper means

- the labels can be uniformly pressed over their entire surfaces during the travelling of the label-holding sheet.

- the microcapsule rupturing effect is high, and the shape of the labels can be maintained in good condition without damaging the labels.

- the stamper means only a wanted portion of each label can be pressed, and stretching, warping, zigzag movement, etc. of the label-holding sheet can be reduced to a minimum.

- the rupturing mechanism comprised of a pair of press rollers or stamper means can be easily incorporated into existing automatic labellers at low cost without the need for any special remodelling, and therefore, is of great utilitarian value.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Labeling Devices (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP64281/85 | 1985-05-01 | ||

| JP6428185U JPS61180908U (enExample) | 1985-05-01 | 1985-05-01 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0203405A1 true EP0203405A1 (en) | 1986-12-03 |

Family

ID=13253688

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86105952A Ceased EP0203405A1 (en) | 1985-05-01 | 1986-04-30 | Automatic labelling apparatus |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0203405A1 (enExample) |

| JP (1) | JPS61180908U (enExample) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2191858B (en) * | 1986-06-18 | 1990-08-22 | Gen Electric Plc | Monitoring method and device |

| EP0734953A1 (en) * | 1995-03-27 | 1996-10-02 | Fuji Photo Film Co., Ltd. | Labelling method and labelling apparatus |

| ES2134693A1 (es) * | 1996-06-03 | 1999-10-01 | Etiquetas Autoadhesivas S A Et | Dispositivo aplicador de etiquetas autoadhesivas. |

| EP1372961A4 (en) * | 2001-03-26 | 2005-02-02 | Appleton Paper Inc | SYSTEM AND METHOD FOR BREAKING CAPSULE ADHESIVE IN SURFACES |

| WO2018233776A1 (de) * | 2017-06-23 | 2018-12-27 | Polytrade GmbH | Vorrichtung zur verpackung, insbesondere von obst und gemüse |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2176422A5 (enExample) * | 1972-03-15 | 1973-10-26 | Timm Hermann | |

| EP0103652A1 (de) * | 1982-09-18 | 1984-03-28 | Werner Hermann | Verfahren und Vorrichtung zum Etikettieren |

| EP0124360A2 (en) * | 1983-04-28 | 1984-11-07 | Kureha Kagaku Kogyo Kabushiki Kaisha | Printing bar-code labels |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5418700A (en) * | 1977-07-12 | 1979-02-10 | Technical Systems Inc | Automatic labelling machine |

-

1985

- 1985-05-01 JP JP6428185U patent/JPS61180908U/ja active Pending

-

1986

- 1986-04-30 EP EP86105952A patent/EP0203405A1/en not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2176422A5 (enExample) * | 1972-03-15 | 1973-10-26 | Timm Hermann | |

| EP0103652A1 (de) * | 1982-09-18 | 1984-03-28 | Werner Hermann | Verfahren und Vorrichtung zum Etikettieren |

| EP0124360A2 (en) * | 1983-04-28 | 1984-11-07 | Kureha Kagaku Kogyo Kabushiki Kaisha | Printing bar-code labels |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2191858B (en) * | 1986-06-18 | 1990-08-22 | Gen Electric Plc | Monitoring method and device |

| EP0734953A1 (en) * | 1995-03-27 | 1996-10-02 | Fuji Photo Film Co., Ltd. | Labelling method and labelling apparatus |

| US5714028A (en) * | 1995-03-27 | 1998-02-03 | Fuji Photo Film Co., Ltd. | Labeling method and labeling apparatus |

| ES2134693A1 (es) * | 1996-06-03 | 1999-10-01 | Etiquetas Autoadhesivas S A Et | Dispositivo aplicador de etiquetas autoadhesivas. |

| EP1372961A4 (en) * | 2001-03-26 | 2005-02-02 | Appleton Paper Inc | SYSTEM AND METHOD FOR BREAKING CAPSULE ADHESIVE IN SURFACES |

| WO2018233776A1 (de) * | 2017-06-23 | 2018-12-27 | Polytrade GmbH | Vorrichtung zur verpackung, insbesondere von obst und gemüse |

Also Published As

| Publication number | Publication date |

|---|---|

| JPS61180908U (enExample) | 1986-11-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4272311A (en) | Method and apparatus for automatically labelling containers | |

| EP0637547B1 (en) | Printing system for labels | |

| US5771664A (en) | Label for bags with wire loop closures | |

| US5935670A (en) | Thermoplastic adhesive dispensing method and apparatus | |

| JP5096330B2 (ja) | 温度監視機能を有するラベル、ラベルを備える商品用のパッケージ、同じく商品用のパッケージへのラベルの貼付けのための方法および機器 | |

| CA2208186C (en) | Printed tear tape | |

| US20050019081A1 (en) | Apparatus and method for handling linerless label tape | |

| US8156983B2 (en) | Auxiliary machine for labelling machines | |

| EP3612452B1 (en) | Label application systems | |

| US4655028A (en) | Method of producing film-wrapped packages or packaged units | |

| RU2190257C2 (ru) | Способ нанесения съемной рекламно-информационной маркировки | |

| EP0153185B1 (en) | Labels and manufacture thereof | |

| EP0203405A1 (en) | Automatic labelling apparatus | |

| CA2068260A1 (en) | Winder for winding webs of material | |

| US6689243B2 (en) | Apparatus and method for dispensing labels onto cylindrical items | |

| US20020184857A1 (en) | Packaging an article with a packaging sheet including a longitudinal fin seal and a transverse tear strip | |

| EP0035688A3 (en) | Device for printing, dispensing and applying self-adhesive labels sticking to a carrier strip | |

| US3088237A (en) | Snap-on marker | |

| GB1393963A (en) | Labes dispensing system | |

| CA2065977A1 (en) | Apparatus for applying heat sensitive labels and pressure sensitive labels | |

| EP0249242A1 (en) | Manual labelling apparatus | |

| EP0677013B2 (en) | Product labelling | |

| JPS6332A (ja) | 自動ラベル貼付装置 | |

| JP2961482B2 (ja) | 自動ラベリング装置 | |

| JPH055589Y2 (enExample) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB |

|

| 17P | Request for examination filed |

Effective date: 19870402 |

|

| 17Q | First examination report despatched |

Effective date: 19871218 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19890722 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KANAJI, TATSUO Inventor name: ASANO, MAKOTO |