EP0199595A2 - Verbundanker für Mauerwerk - Google Patents

Verbundanker für Mauerwerk Download PDFInfo

- Publication number

- EP0199595A2 EP0199595A2 EP86303055A EP86303055A EP0199595A2 EP 0199595 A2 EP0199595 A2 EP 0199595A2 EP 86303055 A EP86303055 A EP 86303055A EP 86303055 A EP86303055 A EP 86303055A EP 0199595 A2 EP0199595 A2 EP 0199595A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- wall

- tongues

- plate

- body portion

- anchorage device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/38—Connections for building structures in general

- E04B1/41—Connecting devices specially adapted for embedding in concrete or masonry

- E04B1/4178—Masonry wall ties

Definitions

- This invention relates to the construction of walls, and it is particularly concerned with an improved design of wall anchorage device for use in building an extension wall of bricks or building blocks onto an existing wall structure and tying it in place in an angular relationship thereto.

- a so-called wall plate of a kind comprising a longitudinally flanged elongate metal plate which is fixed vertically to the face of the existing wall and used as a guide to align and position the end bricks of the extension wall as these are laid in position in abutting relationship with the wall plate, with the extension wall being tied in position and bonded to the existing wall by associated wall tie elements which are anchored to the wall plate and which extend into and are embedded and keyed into mortar joints between adjacent courses of the extension wall.

- wall tie elements which are anchored to the wall plate and which extend into and are embedded and keyed into mortar joints between adjacent courses of the extension wall.

- wall ties used with such wall plates have been separate elements, for example standard butterfly type wire ties or profiled metal strip ties, which are clipped or interlockingly engaged with the wall plate.

- wall ties used with such wall plates have been separate elements, for example standard butterfly type wire ties or profiled metal strip ties, which are clipped or interlockingly engaged with the wall plate.

- these known arrangements can be functionally satisfactory, the need to provide separate wall tie elements which have to be positioned and anchored to the wall plate during the construction of the extension wall can be a disadvantage.

- the present invention provides an improved form of wall anchorage device in the form of a wall plate of the kind referred to above having integral portions thereof adapted to form the requisite associated wall tie elements.

- the invention provides a wall anchorage device for use in building an extension wall of bricks or building blocks to extend outwardly in angular relationship from a face of an existing wall structure

- said anchorage device comprising an elongate plate having a generally flat body portion formed with upstanding integral longitudinal flange means along at least one edge thereof, said plate being adapted to be fixed in use in a vertical orientation to the face of the existing wall whereby the longitudinal flange means then provides a guide for locating and aligning the end bricks or blocks of the extension wall as these are laid in position in abutting relationship with said body portion, there being wall tie elements also provided which connect to said body portion and which can be arranged to extend into and to be embedded and keyed into jointing material between adjacent courses of the extension wall as it is being built thereby to tie said extension wall in position and bond it to the existing wall, characterised in that said plate is formed in said body portion with a series of longitudinally directed integral elongate tongues spaced apart at intervals and raised at a shallow angle to the plane

- the tongues will have a length which is at least five times greater than the width at their root end. It is preferred to arrange the aforesaid series of integral wall tie tongues either in a single row or in two side-by-side rows in which all the tongues extend initially in the same general longitudinal direction. Also, preferably, the design and material is such that the tongues can readily be bent out by hand to extend away from the plane of the body portion of the wall plate about a transverse axis lying at any position in the region adjacent their root ends, not necessarily actually at their root ends, up to a point at least one third of the way along their length.

- the shallow angle with respect to the plane of the body portion at which the tongues are initially raised is preferably less than 10° and is conveniently in the range of 1° to 5°.

- the invention also provides a method of building a wall of bricks or building blocks as an extension outwardly in angular relationship to a face of an existing wall structure, said method comprising applying a wall anchorage device as hereinabove defined to said face and fixing thereto said anchorage device plate in a vertical orientation, laying at least partially the lower courses of the bricks or building blocks of the extension wall until the upper surface of the endmost brick or block of the course being laid, which brick or block is butted up to the body portion of said plate, lies adjacent the level of the root end of the lowermost tongue in said body portion, bending said lowermost tongue outwards until it extends in a substantially horizontal plane lying immediately above said upper surface of the endmost brick or block of the last laid course, applying jointing material and laying the next course of bricks or blocks whereby said lowermost tongue is embedded in said jointing compound and is sandwiched between the two last laid courses of bricks or blocks, and continuing in the same manner laying successive courses and bending outwards each successive tongue as the level of the upper surface of

- the wall plates may be used with the tongues all initially directed either upwardly or downwardly as hereinafter described so that where there is a single longitudinal locating flange along one edge only this may be placed either to the left or to the right hand side.

- the wall plate 8 is a sheet metal structure, formed for example of stainless steel about 0.7 mm thick, comprising a main elongate flat plate-like body portion 10 provided along one longitudinal edge with an integral flange 12 upstanding at right angles to the plane of the body portion. The opposite longitudinal edge portion is turned over to provide a shallow rearwardly directed lip 14.

- the flange 12 has a series of plain holes 15.

- the body portion 10 is provided with a series of integral elongate tongues 16 which all extend in alignment in the same longitudinal direction forming, in this embodiment, a single row or column.

- Each tongue 16 has a slightly outwardly divergent tapering profile and is formed by punching or stamping the material of the wall plate so that the tongue is left integrally joined at its root end to the body portion 10 of the wall plate.

- Small holes 17 are formed at the root ends, as shown, to safeguard against cracks developing and initially each tongue lies slightly raised at a shallow angle, conveniently within a range of 1° to 5", to the plane of the body portion as shown in full lines in FIGURE 2.

- tongues 16 The material forming these tongues 16 is sufficiently ductile that when required for use these tongues 16 can readily be bent up, simply by hand pressure, so as to project outwardly substantially at right angles as indicated in FIGURE 2, or they may be bent through an even greater angle, up to substantially 180°, as required in some cases - according to the manner of use as hereinafter described.

- the wall tie tongue portions 16 are also formed, in the region extending over the outer two-thirds of their length, with a number of holes or apertures 18 punched out to leave a surrounding shallow raised rim 20 giving each hole or aperture a bell-shaped mouth.

- a further series of apertures in the form of short transverse slots 22 is provided in the body portion 10 throughout its length, one such slot being located between each adjacent pair of tongues 16, for receiving bolts, screws or similar fixing elements in order to secure the wall plate 8 to the face of an existing wall structure as hereinafter described.

- Each of these slots 22 is also punched out to provide a bell-shaped mouth and a surrounding raised rim 24 which projects rearwardly of the body portion 10 so as to act, in use, as a stand-off projection to space the body portion from the face of the existing wall structure.

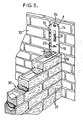

- each end brick 29 of the extension wall 30 are then laid course-by- course in the usual way with each end brick being butted up to the body portion 10 of the wall plate and aligned by abutting engagement with the retaining guide flange 12 at the one side.

- each wall tie tongue portion 16 Upon reaching each wall tie tongue portion 16, however, the latter is bent outwards so as to extend in a substantially horizontal plane which will lie immediately above an end brick in a course of the extension wall. An example of this is clearly shown in FIGURE 4 in relation to the uppermost brick laid in the extension wall.

- Each integral wall tie tongue 16 is thus sandwiched between different courses of bricks in the extension wall, and it will be appreciated that as the jointing compound or mortar is applied it will surround these tongues and key into the holes or apertures 18.

- each tongue 16 The raised rims 20 of these holes or apertures 18 in each tongue 16 enhances the keying effect and ensures that space is left to accommodate a sufficient thickness of mortar.

- the mortar will also generally penetrate into and key with adjacent holes 15 in the retaining guide flange 12 and into any open adjacent holes or apertures in the body portion 10.

- the courses of the extension wall 30 have a perfectly regular spacing and that the wall plate 8 is positioned such that the transverse axes defining the root ends of the tongues 16 lie at a level of the joint between two adjacent courses.

- This is the ideal situation in which the tongues 16 are each bent outwardly about their root ends in order to extend at right angles in the correct position to lie between two adjacent courses of the extension wall and is illustrated in the fragmentary sectional view of FIGURE 6.

- the courses of the extension wall may possibly not be spaced with perfect regularity, perhaps using bricks of different dimensions and/or the wall plate may not be fixed in quite the correct position. Or, the spacing of the tongues 16 may not match the spacing of the bricks.

- the sheet metal of which the wall plate is composed and the form of the tongue portions 16 is such that they can be readily bent not only at their root ends but also at any point in the region adjacent their root ends extending up to at least a third of the way along their length.

- This is in fact indicated in FIGURE 2.

- Tests have shown, somewhat surprisingly, that a strong bond and good stability can be obtained in many cases even if the point at which the tongues are bent lies at least as far as one third along their length. If necessary, the tongues may sometimes even be folded with a double bend. Thereby, irregularities in the vertical spacing of the courses in the extension wall and/or a certain degree of misalignment of the wall plate can be readily accommodated, as schematically indicated for example in FIGURE 7.

- the flange 12 lies on the righthand side of the extension wall.

- the flange 12 will be concealed by cladding but this may not be possible if the right-hand side of the extension wall is to be an exposed exterior face, and it may be desired to have the flange 12 on the opposite left-hand side.

- This can readily be arranged simply by turning the wall plate into a reversed position before securing it to the existing wall 32.

- the tongue portions 16 will initially be directed downwards so that each of them needs first to be bent upwards through an angle of more than 90°, possibly even an angle approaching 180°, before laying the bricks of the adjacent course or courses of the extension wall.

- the wall plate 8 is preferably composed of a material such as stainless steel to avoid any corrosion problems and may of course be manufactured in a series of standard lengths which can if necessary be cut, or joined in overlapping aligned relationship, to suit the required height of the extension wall which is to be built. Sheet metal thicknesses in the range of 0.5 mm to 1.00 mm are generally suitable and enable easy bending of the wall tie tongues.

- FIGURES 8 and 9 Two such wall plates arranged in side-by-side mirror image relationship can be used to construct a thick extension wall.

- a wider form of wall plate with a plurality of rows or columns of integral tongue portions will be used.

- FIGURES 8 and 9 one design of such wider form of wall plate 8a is shown in FIGURES 8 and 9. This is basically the same as the wall plate 8 already described but there are two spaced columns or rows of integral wall tie tongue portions 16a and 16b arranged in horizontal pairs as shown, and also horizontal pairs of fixing slots 22a, 22b, are provided between each pair of tongues 16a, 16b. Otherwise the structure corresponds with that already described, corresponding parts being indicated by the same reference numerals, and is used in substantially the same way.

- each adjacent pair again each extend in the same longititudinal direction and each have their root ends aligned in a common transverse plane so that when they are bent up at right angles to the body portion 10 they can both lie in side-by-side relationship in a common transverse plane.

- the body portion of the plates can be formed with a series of dish-like depressions and the apertures for the fixing elements are formed in a substantially flat base portion of such dish-like depressions.

- FIGURES 10 to 14 An example of such modified construction is illustrated in FIGURES 10 to 14.

- the wall plate shown in FIGURES 10 to 14 is basically the same as that described in connection with FIGURES 1 to 3 and the same reference numerals are again used to indieate similar parts.

- the body portion 10 is provided with short transverse slots 22' formed in a substantially flat base 70 of each of a series of dish-like depressions 72 located along the length of the wall plate.

- Each dish-like depression 72 has a shallow peripheral sloping wall 74 and the flat base part 70 is set rearwards from the main plane of the body part of the wall plate by a distance approximately equal to the depth of the edge lip 14 and together with the latter again act as stand-off projections to space the main body portion 10 from the face of the existing wall structure 32 when fixed to the latter.

- the fixing elements used for securing the wall plate to the existing wall will generally be headed screw-threaded fasteners such as the bolt 34 indicated in broken lines in FIGURE 12 and a flat washer 35 will be fitted under the head of this bolt, the dish-like depressions 72 being sufficiently large for such washer (e.g. 30mm diameter washer) to be accommodated wholly therein and to lie against the flat base 70.

- a flat washer 35 will be fitted under the head of this bolt, the dish-like depressions 72 being sufficiently large for such washer (e.g. 30mm diameter washer) to be accommodated wholly therein and to lie against the flat base 70.

- the spacing between the tongues 16 has been shown as corrresponding generally to the depth of two courses cf bricks, in fact for use at least in the United Kingdom the spacing will generally be set to correspond to the depth of three courses of standard size bricks or one course of standard size building blocks.

- the wall plates could have a retaining guide flange along each longitudinal edge, and many other detail modifications can be made within the scope of the invention, especially in relation to the arrangement and form of the apertures and of the integral wall tie tongues.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Conveying And Assembling Of Building Elements In Situ (AREA)

- Bulkheads Adapted To Foundation Construction (AREA)

- Load-Bearing And Curtain Walls (AREA)

- Finishing Walls (AREA)

- Piles And Underground Anchors (AREA)

- Farming Of Fish And Shellfish (AREA)

- Sewage (AREA)

- Surgical Instruments (AREA)

- Working Measures On Existing Buildindgs (AREA)

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB858510321A GB8510321D0 (en) | 1985-04-23 | 1985-04-23 | Wall plate |

| GB8510321 | 1985-04-23 | ||

| GB868602103A GB8602103D0 (en) | 1986-01-29 | 1986-01-29 | Wall plate |

| GB8602103 | 1986-01-29 | ||

| GB868604576A GB8604576D0 (en) | 1986-02-25 | 1986-02-25 | Wall construction device |

| GB8604576 | 1986-02-25 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0199595A2 true EP0199595A2 (de) | 1986-10-29 |

| EP0199595A3 EP0199595A3 (en) | 1987-05-27 |

| EP0199595B1 EP0199595B1 (de) | 1995-03-22 |

Family

ID=27262659

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86303055A Expired - Lifetime EP0199595B1 (de) | 1985-04-23 | 1986-04-23 | Verbundanker für Mauerwerk |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0199595B1 (de) |

| AT (1) | ATE120249T1 (de) |

| AU (1) | AU587247B2 (de) |

| DE (1) | DE3650275T2 (de) |

| GB (1) | GB2174432B (de) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2229465A (en) * | 1989-03-21 | 1990-09-26 | James Savage Pritchard | Plaster panels |

| WO1992002694A1 (en) * | 1990-08-07 | 1992-02-20 | Andrew Barker | Construction joints |

| AU688443B2 (en) * | 1994-03-09 | 1998-03-12 | Abey Australia Pty Ltd | Improvements in brick ties |

| AT403596B (de) * | 1989-06-19 | 1998-03-25 | Eggert Heinz | Gebäudewand-verkleidung |

| CN101736814B (zh) * | 2009-12-15 | 2012-05-23 | 浙江宝业建设集团有限公司 | 建筑墙体抗震构造柱连接件及其施工方法 |

| US10407892B2 (en) | 2015-09-17 | 2019-09-10 | Columbia Insurance Company | High-strength partition top anchor and anchoring system utilizing the same |

| CN112025970A (zh) * | 2020-08-14 | 2020-12-04 | 中建科技成都有限公司 | 一种构造柱拼接块的加工装置及构造柱施工方法 |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2227777A (en) * | 1989-02-02 | 1990-08-08 | David John Landeg | Reinforcement to brickwork or blockwork retaining walls |

| DE102005026797A1 (de) * | 2005-06-10 | 2006-12-14 | Wahls, Manfred, Dipl.-Ing. | Dämmstoff-Verbundwand |

| GB2443485B (en) * | 2006-11-02 | 2011-09-14 | Victor Joseph Wigley | Insulated structural tie for external masonry wall and internal abutting wall |

| CA2809080C (en) | 2012-03-14 | 2017-03-07 | Mitek Holdings, Inc. | Mounting arrangement for panel veneer structures |

| US8800241B2 (en) | 2012-03-21 | 2014-08-12 | Mitek Holdings, Inc. | Backup wall reinforcement with T-type anchor |

| US8904730B2 (en) | 2012-03-21 | 2014-12-09 | Mitek Holdings, Inc. | Thermally-isolated anchoring systems for cavity walls |

| US8739485B2 (en) | 2012-06-28 | 2014-06-03 | Mitek Holdings, Inc. | Low profile pullout resistant pintle and anchoring system utilizing the same |

| US8839581B2 (en) | 2012-09-15 | 2014-09-23 | Mitek Holdings, Inc. | High-strength partially compressed low profile veneer tie and anchoring system utilizing the same |

| US8898980B2 (en) | 2012-09-15 | 2014-12-02 | Mitek Holdings, Inc. | Pullout resistant pintle and anchoring system utilizing the same |

| US8881488B2 (en) | 2012-12-26 | 2014-11-11 | Mitek Holdings, Inc. | High-strength ribbon loop anchors and anchoring systems utilizing the same |

| US9038351B2 (en) | 2013-03-06 | 2015-05-26 | Columbia Insurance Company | Thermally coated wall anchor and anchoring systems with in-cavity thermal breaks for cavity walls |

| US8863460B2 (en) | 2013-03-08 | 2014-10-21 | Columbia Insurance Company | Thermally coated wall anchor and anchoring systems with in-cavity thermal breaks |

| US8978326B2 (en) | 2013-03-12 | 2015-03-17 | Columbia Insurance Company | High-strength partition top anchor and anchoring system utilizing the same |

| US8833003B1 (en) | 2013-03-12 | 2014-09-16 | Columbia Insurance Company | High-strength rectangular wire veneer tie and anchoring systems utilizing the same |

| US8844229B1 (en) * | 2013-03-13 | 2014-09-30 | Columbia Insurance Company | Channel anchor with insulation holder and anchoring system using the same |

| US8910445B2 (en) | 2013-03-13 | 2014-12-16 | Columbia Insurance Company | Thermally isolated anchoring system |

| US8904726B1 (en) | 2013-06-28 | 2014-12-09 | Columbia Insurance Company | Vertically adjustable disengagement prevention veneer tie and anchoring system utilizing the same |

| US9121169B2 (en) | 2013-07-03 | 2015-09-01 | Columbia Insurance Company | Veneer tie and wall anchoring systems with in-cavity ceramic and ceramic-based thermal breaks |

| US8978330B2 (en) | 2013-07-03 | 2015-03-17 | Columbia Insurance Company | Pullout resistant swing installation tie and anchoring system utilizing the same |

| US9038350B2 (en) | 2013-10-04 | 2015-05-26 | Columbia Insurance Company | One-piece dovetail veneer tie and wall anchoring system with in-cavity thermal breaks |

| US8904727B1 (en) | 2013-10-15 | 2014-12-09 | Columbia Insurance Company | High-strength vertically compressed veneer tie anchoring systems utilizing and the same |

| US9140001B1 (en) | 2014-06-24 | 2015-09-22 | Columbia Insurance Company | Thermal wall anchor |

| US9334646B2 (en) | 2014-08-01 | 2016-05-10 | Columbia Insurance Company | Thermally-isolated anchoring systems with split tail veneer tie for cavity walls |

| US9273461B1 (en) | 2015-02-23 | 2016-03-01 | Columbia Insurance Company | Thermal veneer tie and anchoring system |

| USD846973S1 (en) | 2015-09-17 | 2019-04-30 | Columbia Insurance Company | High-strength partition top anchor |

| US20170159285A1 (en) | 2015-12-04 | 2017-06-08 | Columbia Insurance Company | Thermal wall anchor |

| US10738476B2 (en) * | 2018-04-29 | 2020-08-11 | Reza Moghimi | Support structure for installing thin bricks |

| CN119981473B (zh) * | 2025-04-15 | 2025-11-21 | 中国建筑第五工程局有限公司 | 一种市政工程铺装对缝装置 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB940664A (en) * | 1961-02-23 | 1963-10-30 | Ray Edward Omholt | Wooden floors |

| GB1010933A (en) * | 1962-06-14 | 1965-11-24 | Milton Oswald Hemming | Improvements in or relating to means for providing anchorage points in ceilings |

| GB1575501A (en) * | 1976-11-05 | 1980-09-24 | Ellidge A | Tie means for brick walls |

| ZA78948B (en) * | 1978-02-17 | 1979-09-26 | R Geraghty | A device for use in building |

| GB1604941A (en) * | 1978-05-26 | 1981-12-16 | Furr D | Wall construction method |

-

1986

- 1986-04-23 AU AU56535/86A patent/AU587247B2/en not_active Ceased

- 1986-04-23 EP EP86303055A patent/EP0199595B1/de not_active Expired - Lifetime

- 1986-04-23 AT AT86303055T patent/ATE120249T1/de not_active IP Right Cessation

- 1986-04-23 GB GB08609949A patent/GB2174432B/en not_active Expired

- 1986-04-23 DE DE3650275T patent/DE3650275T2/de not_active Expired - Fee Related

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2229465A (en) * | 1989-03-21 | 1990-09-26 | James Savage Pritchard | Plaster panels |

| AT403596B (de) * | 1989-06-19 | 1998-03-25 | Eggert Heinz | Gebäudewand-verkleidung |

| WO1992002694A1 (en) * | 1990-08-07 | 1992-02-20 | Andrew Barker | Construction joints |

| GB2262951A (en) * | 1990-08-07 | 1993-07-07 | Andrew Barker | Construction joints |

| GB2262951B (en) * | 1990-08-07 | 1994-06-01 | Andrew Barker | Construction joints |

| AU688443B2 (en) * | 1994-03-09 | 1998-03-12 | Abey Australia Pty Ltd | Improvements in brick ties |

| CN101736814B (zh) * | 2009-12-15 | 2012-05-23 | 浙江宝业建设集团有限公司 | 建筑墙体抗震构造柱连接件及其施工方法 |

| US10407892B2 (en) | 2015-09-17 | 2019-09-10 | Columbia Insurance Company | High-strength partition top anchor and anchoring system utilizing the same |

| CN112025970A (zh) * | 2020-08-14 | 2020-12-04 | 中建科技成都有限公司 | 一种构造柱拼接块的加工装置及构造柱施工方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0199595B1 (de) | 1995-03-22 |

| GB2174432A (en) | 1986-11-05 |

| EP0199595A3 (en) | 1987-05-27 |

| GB8609949D0 (en) | 1986-05-29 |

| DE3650275D1 (de) | 1995-04-27 |

| AU5653586A (en) | 1986-10-30 |

| DE3650275T2 (de) | 1995-08-24 |

| AU587247B2 (en) | 1989-08-10 |

| ATE120249T1 (de) | 1995-04-15 |

| GB2174432B (en) | 1988-10-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0199595B1 (de) | Verbundanker für Mauerwerk | |

| US4922680A (en) | Systems and methods for connecting masonry veneer to structural support substrates | |

| CA2054503C (en) | Fence post | |

| US5150553A (en) | Holdown strap | |

| US4698947A (en) | Concrete wall form tie system | |

| US7469511B2 (en) | Masonry anchoring system | |

| US4669235A (en) | Spacing and support construction member | |

| US5987830A (en) | Insulated concrete wall and tie assembly for use therein | |

| US4047349A (en) | Sheet material attaching device and wall arrangement using this device | |

| US7549262B2 (en) | Roof boundary clip | |

| US6629393B2 (en) | Masonry reinforcing tie | |

| US6237300B1 (en) | Wall stud connectors | |

| US20020014048A1 (en) | Tie for forms for pouring concrete | |

| US2005030A (en) | Veneer fastening means | |

| US5299403A (en) | Insulation fastener | |

| US6658806B1 (en) | Support for a strap holdown | |

| US3782058A (en) | Tying devices for tying wooden members to composite brick and masonry walls | |

| US2003996A (en) | Veneer wall construction | |

| EP1668199B1 (de) | Vorrichtung und verfahren zur befestigung einer isolierplatte in einer hohlwand | |

| US3236016A (en) | Siding fastener | |

| US5860261A (en) | Building block retainer apparatus | |

| WO2003093594A1 (en) | Framework and hold down connector | |

| EP0357279B1 (de) | Unterstützung für Gipskartonplatten und Dachdämmung | |

| US2015020A (en) | Roof and elements for the construction thereof | |

| EP0240510B1 (de) | Befestigungsvorrichtung für ziegel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19871125 |

|

| 17Q | First examination report despatched |

Effective date: 19891030 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 120249 Country of ref document: AT Date of ref document: 19950415 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3650275 Country of ref document: DE Date of ref document: 19950427 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19970411 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19970416 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19970428 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19970429 Year of fee payment: 12 Ref country code: AT Payment date: 19970429 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19970430 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19970627 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19970703 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980423 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980423 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980430 Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19980430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980430 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980430 |

|

| BERE | Be: lapsed |

Owner name: THE EXPANDED METAL CY LTD Effective date: 19980430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981101 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19981101 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 86303055.7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990202 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050423 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |