EP0168623A2 - Process for the improvement of the user features of a tufted floor covering - Google Patents

Process for the improvement of the user features of a tufted floor covering Download PDFInfo

- Publication number

- EP0168623A2 EP0168623A2 EP85107055A EP85107055A EP0168623A2 EP 0168623 A2 EP0168623 A2 EP 0168623A2 EP 85107055 A EP85107055 A EP 85107055A EP 85107055 A EP85107055 A EP 85107055A EP 0168623 A2 EP0168623 A2 EP 0168623A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- parts

- fluorosurfactant

- coat

- dan

- adhesive strength

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M13/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment

- D06M13/244—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing sulfur or phosphorus

- D06M13/248—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing sulfur or phosphorus with compounds containing sulfur

- D06M13/265—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing sulfur or phosphorus with compounds containing sulfur containing halogen atoms

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/693—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with natural or synthetic rubber, or derivatives thereof

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M13/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment

- D06M13/10—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing oxygen

- D06M13/165—Ethers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N7/00—Flexible sheet materials not otherwise provided for, e.g. textile threads, filaments, yarns or tow, glued on macromolecular material

- D06N7/0063—Floor covering on textile basis comprising a fibrous top layer being coated at the back with at least one polymer layer, e.g. carpets, rugs, synthetic turf

- D06N7/0071—Floor covering on textile basis comprising a fibrous top layer being coated at the back with at least one polymer layer, e.g. carpets, rugs, synthetic turf characterised by their backing, e.g. pre-coat, back coating, secondary backing, cushion backing

- D06N7/0073—Floor covering on textile basis comprising a fibrous top layer being coated at the back with at least one polymer layer, e.g. carpets, rugs, synthetic turf characterised by their backing, e.g. pre-coat, back coating, secondary backing, cushion backing the back coating or pre-coat being applied as an aqueous dispersion or latex

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2203/00—Macromolecular materials of the coating layers

- D06N2203/04—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06N2203/042—Polyolefin (co)polymers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2203/00—Macromolecular materials of the coating layers

- D06N2203/04—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06N2203/045—Vinyl (co)polymers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2203/00—Macromolecular materials of the coating layers

- D06N2203/06—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D06N2203/068—Polyurethanes

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2205/00—Condition, form or state of the materials

- D06N2205/04—Foam

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2209/00—Properties of the materials

- D06N2209/08—Properties of the materials having optical properties

- D06N2209/0807—Coloured

- D06N2209/0823—Coloured within the layer by addition of a colorant, e.g. pigments, dyes

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2209/00—Properties of the materials

- D06N2209/14—Properties of the materials having chemical properties

- D06N2209/142—Hydrophobic

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N2211/00—Specially adapted uses

- D06N2211/06—Building materials

- D06N2211/066—Floor coverings

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23907—Pile or nap type surface or component

- Y10T428/23979—Particular backing structure or composition

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23907—Pile or nap type surface or component

- Y10T428/23986—With coating, impregnation, or bond

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23907—Pile or nap type surface or component

- Y10T428/23993—Composition of pile or adhesive

Definitions

- the pile threads are integrated into the base fabric of tufted floor coverings by means of a so-called primer with natural latex, synthetic latex e.g. based on butadiene styrene 40:60 or 60:40, with plastic dispersions, for example based on polyvinyl acetate or with mixtures of polyvinyl acetate dispersions and synthetic or natural latex or with polyurethane.

- primer with natural latex, synthetic latex e.g. based on butadiene styrene 40:60 or 60:40

- plastic dispersions for example based on polyvinyl acetate or with mixtures of polyvinyl acetate dispersions and synthetic or natural latex or with polyurethane.

- Butadiene-styrene latex (approx. 50%) is preferred, e.g. in the ratio 40:60, 60:40 or 35:60 + 3.5 acrylic acid and polyvinyl acetate dispersions (50%), copolymers of vinyl acetate with maleic acid dibutyl ester e.g. in the ratio 77/23 (approx. 50%), copolymers of styrene / butyacrylate / acrylonitrile / methacrylic acid / acrylamide e.g.

- the primer also usually contains thickeners and chalk or aluminum hydroxide as a filler. This primer is applied to the back of the carpet by splashing.

- a back coating is generally applied to this primer, either a foam coat or a top coat, which is used to glue a second textile back.

- This second stroke is applied by squeegee application.

- the textile backing can also be glued when the pre-coat is applied, with the second back being guided and pressed by a pressure roller onto the adhesive, pigmented latex dispersion after the pre-coat has been applied.

- Preferred fluorosurfactants are those which consist of a mixture of different individual compounds with the same meaning of R, but different meaning of Rf.

- M has in particular the meaning of NH 4 and M 'of Na, where M and M' as cations and the corresponding sulfonic acid residues are present as anions. It is essential for the invention that the fluorosurfactant is first mixed separately with the latex or the dispersion before it is mixed then the primer or second coat mass is produced by adding the other components. The fluorosurfactant is added to the latex or the dispersion for the primer in an amount of 0.1 to 0.2% by weight.

- the amount of fluorosurfactant in the latex or in the dispersion for the primer is 0.1 to 0.5% by weight. If this textile backing is glued to the base fabric with a second coat, the latex or the dispersion for this second coat contain 0.1 to 0.3% by weight of fluorosurfactant.

- composition of the primer and second coat corresponds to the state of the art in this field, so that the type and amount of the various components need not be discussed in detail since they are sufficiently known to the person skilled in the art.

- Typical recipes for the primer contain e.g. 100 parts styrene-butadiene latex or natural latex, 200-400 parts chalk, 0.3 parts water softener, 2 parts thickener based on acrylates or cellulose derivatives.

- the second line can consist of 100 parts styrene-butadiene latex (soft) or natural latex and 150 parts chalk or aluminum hydroxide.

- fluorosurfactant as stated above.

- the fluorosurfactant can be applied either in the primer or in the second coat, but you can also mix the latex or the dispersion with these fluorosurfactants in both spreads.

- the bobbin binding of the pile threads increases as a result of improved penetration and adhesion.

- the addition of the fluorosurfactants significantly increases the adhesive strength of the back.

- the cut resistance of the floor covering is positively influenced and the tearing out of tufts in the cut area is reduced.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Synthetic Leather, Interior Materials Or Flexible Sheet Materials (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

- Laminated Bodies (AREA)

- Carpets (AREA)

- Paints Or Removers (AREA)

- Adhesives Or Adhesive Processes (AREA)

Abstract

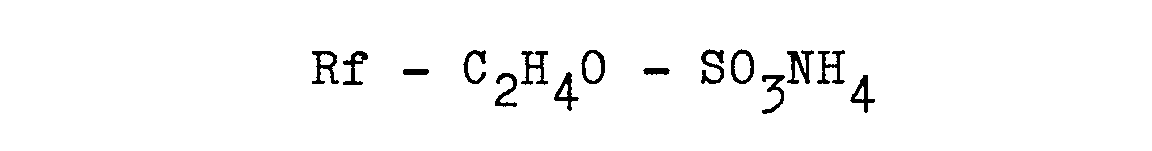

Verfahren zur Verbesserung der Gebrauchseigenschaften von Tufted-Bodenbelägen, das darin besteht, daß man bei der Herstellung der Tufted-Bodenbeläge die für den Vorstrich und/oder die für den Zweitstrich erforderlichen Dispersionen oder Latices vor ihrer Compoundierung mit einem Fluortensid der Formel Rf-C2H4O-R vermischt, wobei Rf einen Rest C6F13, C8F17, C10F21 oder C12F25, R eine Gruppe der Formeln <IMAGE> M und M' Na, K oder NH4 und n eine Zahl von 4 bis 8 bedeuten. Das Fluortensid erhöht die Noppenfestigkeit der Polfäden und die Haftfestigkeit des Zweitrückens.Process for improving the performance properties of tufted floor coverings, which consists in preparing the tufted floor coverings with the dispersions or latices required for the primer coat and / or the second coat coat before they are compounded with a fluorosurfactant of the formula Rf-C2H4O- R mixed, where Rf is a radical C6F13, C8F17, C10F21 or C12F25, R is a group of the formulas <IMAGE> M and M 'Na, K or NH4 and n is a number from 4 to 8. The fluorosurfactant increases the pimple strength of the pile threads and the adhesive strength of the second back.

Description

Die Einbindung der Polfäden in das Grundgewebe von Tufted-bodenbelägen erfolgt durch einen sogenannten Vorstrich mit Naturlatex, Syntheselatex z.B. auf der Basis Butadien Styrol 40 : 60 oder 60 : 40, mit Kunststoffdispersionen beispielsweise auf der Basis Polyvinylacetat oder mit Mischungen aus Polyvinylacetatdispersionen und Synthese-oder Naturlatex oder mit Polyurethan.The pile threads are integrated into the base fabric of tufted floor coverings by means of a so-called primer with natural latex, synthetic latex e.g. based on butadiene styrene 40:60 or 60:40, with plastic dispersions, for example based on polyvinyl acetate or with mixtures of polyvinyl acetate dispersions and synthetic or natural latex or with polyurethane.

Bevorzugt sind Butadien-Styrol-Latex (ca. 50 %) z.B. im Verhältnis 40 : 60, 60 : 40 oder 35 : 60 + 3,5 Acrylsäure und Polyvinylacetat-Dispersionen (50 %ig), Mischpolymerisate von Vinylacetat mit Maleinsäuredibutylester z.B. im Verhältnis 77/23 (ca. 50 %ig), Mischpolymerisate von Styrol/Butyacrylat/Acrylnitril/Methacrylsäure/Acrylamid z.B. im Verhältnis 16 : 61 : 25 : 2 : 1 oder 25 : 53 : 25 : 2 : 1, Mischpolymerisate von Ethylacrylat/Acrylnitril/N-Methylacrylamid 6 : 3 : 1, Mischpolymerisate von Butylacrylat/Vinylacetat/N-Methylolacrylamid 35 : 55 : 10, ferner Pfropfpolymerisate (partiell verseift) wie 50 % Polyvinylalkohol, 25 % Polyvinylacetat, 25 % Polyethylen.Butadiene-styrene latex (approx. 50%) is preferred, e.g. in the ratio 40:60, 60:40 or 35:60 + 3.5 acrylic acid and polyvinyl acetate dispersions (50%), copolymers of vinyl acetate with maleic acid dibutyl ester e.g. in the ratio 77/23 (approx. 50%), copolymers of styrene / butyacrylate / acrylonitrile / methacrylic acid / acrylamide e.g. in the ratio 16: 61: 25: 2: 1 or 25: 53: 25: 2: 1, copolymers of ethyl acrylate / acrylonitrile / N-methyl acrylamide 6: 3: 1, copolymers of butyl acrylate / vinyl acetate / N-methylolacrylamide 35: 55: 10, furthermore graft polymers (partially saponified) such as 50% polyvinyl alcohol, 25% polyvinyl acetate, 25% polyethylene.

Der Vorstrich enthält darüberhinaus noch üblicherweise Verdicker und Kreide oder Aluminiumhydroxyd als Füllmittel. Der Auftrag dieses Vorstrichs auf den Teppichrücken erfolgt durch Pflatschen.The primer also usually contains thickeners and chalk or aluminum hydroxide as a filler. This primer is applied to the back of the carpet by splashing.

Auf diesen Vorstrich wird im allgemeinen noch eine Rückenbeschichtung aufgetragen, entweder ein Schaumstrich oder ein Deckstrich, der zum Verkleben eines textilen Zweitrückens dient. Die Applikation dieses Zweitstrichs erfolgt durch Rakelauftrag. Eine Verklebung des textilen Zweitrückens kann aber auch beim Auftrag des Vorstrichs erfolgen, wobei nach dem Pflatschauftrag des Vorstrichs der Zweitrücken von einer Anpreßwalze an die klebende, pigmentierte Latexdispersion geführt und angepreßt wird.A back coating is generally applied to this primer, either a foam coat or a top coat, which is used to glue a second textile back. This second stroke is applied by squeegee application. However, the textile backing can also be glued when the pre-coat is applied, with the second back being guided and pressed by a pressure roller onto the adhesive, pigmented latex dispersion after the pre-coat has been applied.

Es wurde nun gefunden, daß man sowohl die Einbindung der Polfäden in den Vorstrich als auch die Verklebung eines textilen Zweitrückens durch Zugabe von Fluortensiden zum Vorstrich oder zum Zweitstrich wesentlich verbessern kann.It has now been found that both the incorporation of the pile threads in the primer and the bonding of a textile backing can be significantly improved by adding fluorosurfactants to the primer or the second coat.

Gegenstand der Erfindung ist somit ein Verfahren zur Verbesserung der Gebrauchseigenschaften von Tufted-Bodenbelägen, das darin besteht, daß man bei der Herstellung der Tufted-Bodenbeläge die für den Vorstrich und/oder die für den Zweitstrich erforderlichen Dispersionen oder Latices vor ihrer Compoundierung mit einem Fluortensid der Formel

vermischt, wobei Rf einen Rest C6F13' C8F17, C 10 F 21 oder C12F25, R eine Gruppe der Formeln

- -(C2H4O)n-H, -S03M oder

M und M' Na, K oder NH4 und n eine Zahl von 4 bis 8 bedeuten.

mixed, where Rf is a radical C 6 F 13 ' C 8 F 17 , C 10 F 21 or C 12 F 25 , R is a group of the formulas

- - (C 2 H 4 O) n -H, -S0 3 M or

M and M 'Na, K or NH 4 and n are a number from 4 to 8.

Bevorzugt sind solche Fluortenside, die aus einem Gemisch verschiedener Einzelverbindungen bestehen mit gleicher Bedeutung von R, aber unterschiedlicher Bedeutung von Rf. M hat insbesondere die Bedeutung von NH4 und M' von Na, wobei M bzw. M' als Kationen und die entsprechenden Sulfonsäurereste als Anionen vorliegen. Wesentlich für die Erfindung ist, daß das Fluortensid zunächst mit dem Latex oder der Dispersion separat vermischt wird, bevor aus dieser Mischung dann durch Zugabe der anderen Komponenten die Vorstrich- bzw. Zweitstrichmasse hergestellt wird. Das Fluortensid wird dem Latex oder der Dispersion für den Vorstrich in einer Menge von 0,1 bis 0,2 Gew-% zugegeben. Wird gleichzeitig ein textiler Zweitrücken kaschiert, beträgt die Menge an Fluortensid im Latex oder in der Dispersion für den Vorstrich 0,1 bis 0,5 Gew-%. Wird dieser textile Zweitrücken durch einen Zweitstrich mit dem Grundgewebe verklebt, so enthalten der Latex oder die Dispersion für diesen Zweitstrich 0,1 bis 0,3 Gew-% an Fluortensid.Preferred fluorosurfactants are those which consist of a mixture of different individual compounds with the same meaning of R, but different meaning of Rf. M has in particular the meaning of NH 4 and M 'of Na, where M and M' as cations and the corresponding sulfonic acid residues are present as anions. It is essential for the invention that the fluorosurfactant is first mixed separately with the latex or the dispersion before it is mixed then the primer or second coat mass is produced by adding the other components. The fluorosurfactant is added to the latex or the dispersion for the primer in an amount of 0.1 to 0.2% by weight. If a secondary textile backing is concealed at the same time, the amount of fluorosurfactant in the latex or in the dispersion for the primer is 0.1 to 0.5% by weight. If this textile backing is glued to the base fabric with a second coat, the latex or the dispersion for this second coat contain 0.1 to 0.3% by weight of fluorosurfactant.

Die Zusammensetzung von Vorstrich und Zweitstrich im einzelnen entspricht dem Stand der Technik auf diesem Gebiet, so daß Art und Menge der verschiedenen Komponenten nicht im einzelnen erörtert werden müssen, da sie dem Fachmann hinreichend bekannt sind. Typische Rezepturen für den Vorstrich enthalten z.B. 100 Teile Styrol-Butadien Latex oder Naturlatex, 200-400 Teile Kreide, 0,3 Teile Wasserenthärter, 2 Teile Verdicker auf Basis von Acrylaten oder Cellulosederivaten. Der Zweitstrich kann beispielsweise bestehen aus 100 Teilen Styrol-Butadien Latex (weich) oder Naturlatex und 150 Teilen Kreide oder Aluminiumhydroxid. Hinzu kommt dann noch das Fluortensid wie oben angegeben. Das Fluortensid kann entweder in den Vorstrich oder in den Zweitstrich eingebracht werden, man kann aber auch bei beiden Aufstrichmassen den Latex oder die Dispersion mit diesen Fluortensiden vermischen.The composition of the primer and second coat corresponds to the state of the art in this field, so that the type and amount of the various components need not be discussed in detail since they are sufficiently known to the person skilled in the art. Typical recipes for the primer contain e.g. 100 parts styrene-butadiene latex or natural latex, 200-400 parts chalk, 0.3 parts water softener, 2 parts thickener based on acrylates or cellulose derivatives. The second line can consist of 100 parts styrene-butadiene latex (soft) or natural latex and 150 parts chalk or aluminum hydroxide. Then there is the fluorosurfactant as stated above. The fluorosurfactant can be applied either in the primer or in the second coat, but you can also mix the latex or the dispersion with these fluorosurfactants in both spreads.

Durch die Zugabe der Fluortenside zum Latex oder zur Dispersion mit anschließender Kompoundierung erhöht sich die Noppeneinbindung der Polfäden, auch solcher aus hydrophoben Garnen, infolge verbesserter Penetration und Haftung. Bei Verklebung mit einem textilen Zweitrücken wird durch die Zugabe der Fluortenside die Haftfestigkeit des Rückens deutlich erhöht. Gleichzeitig wird die Schnittfestigkeit des Bodenbelags positiv beeinflußt und das Ausreißen von Flornoppen im Schnittbereich vermindert.By adding the fluorosurfactants to the latex or to the dispersion followed by compounding, the bobbin binding of the pile threads, including those made of hydrophobic yarns, increases as a result of improved penetration and adhesion. When gluing with a second textile back, the addition of the fluorosurfactants significantly increases the adhesive strength of the back. At the same time, the cut resistance of the floor covering is positively influenced and the tearing out of tufts in the cut area is reduced.

Claims (4)

Bei Verwendung von 0,2 Teilen des gleichen Fluortensids erreicht man eine Haftfestigkeit des Zweitrückens von 0,82 dan. Ohne Fluortensid aber unter sonst gleichen Bedingungen, beträgt die Haftfestigkeit nur 0,497 dan.2. Apply a primer compound using a plaster application, then glue a textile polypropylene ribbon backing:

If 0.2 parts of the same fluorosurfactant are used, the adhesive strength of the second backing is 0.82 dan. Without fluorosurfactant but under otherwise identical conditions, the adhesive strength is only 0.497 dan.

Auftrag: Pflatschapplikation, anschließende Zuführung des Zweitrückens

Arbeitet man in der gleichen Weise, aber ohne Fluortensid, so beträgt die Noppenfestigkeit nur 1,86 kp und die Haftfestigkeit nur 0,6977 dan. Verfahren zur Verbesserung der Gebrauchseigenschaften von Tufted-Bodenbelägen, dadurch gekennzeichnet, daß man bei der Herstellung der Tufted-Bodenbeläge die für den Vorstrich und/oder die für den Zweitstrich erforderlichen Dispersionen oder Latics vor ihrer Compoundierung mit einem Fluortensid der Formel

Order: splash application, subsequent feeding of the second back

If you work in the same way, but without fluorosurfactant, the nub strength is only 1.86 kp and the adhesive strength is only 0.6977 dan. Process for improving the performance properties of tufted floor coverings, characterized in that, in the manufacture of the tufted floor coverings, the dispersions or latics required for the primer coat and / or the second coat coat before they are compounded with a fluorosurfactant of the formula

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3422289 | 1984-06-15 | ||

| DE19843422289 DE3422289A1 (en) | 1984-06-15 | 1984-06-15 | METHOD FOR IMPROVING THE USE PROPERTIES OF TUFTED FLOORING |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0168623A2 true EP0168623A2 (en) | 1986-01-22 |

Family

ID=6238457

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85107055A Withdrawn EP0168623A2 (en) | 1984-06-15 | 1985-06-07 | Process for the improvement of the user features of a tufted floor covering |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US4579765A (en) |

| EP (1) | EP0168623A2 (en) |

| JP (1) | JPS6119888A (en) |

| KR (1) | KR860000439A (en) |

| AU (1) | AU4370985A (en) |

| DE (1) | DE3422289A1 (en) |

| GR (1) | GR851441B (en) |

| PT (1) | PT80629B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0226111A2 (en) * | 1985-12-09 | 1987-06-24 | The Dow Chemical Company | A method for improving the tuft bind of textile coverings |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4460734A (en) * | 1983-04-19 | 1984-07-17 | Rohm And Haas Company | Self-leveling floor polish compositions |

| AU1214197A (en) * | 1995-12-21 | 1997-07-17 | Wool Research Organisation Of New Zealand Inc. | A method for insect-resist treatment of carpet and textiles |

| DE19948651B4 (en) * | 1999-09-29 | 2006-10-05 | Schering Ag | Galenic formulations containing para and diamagnetic perfluorinated compounds, their preparation and use |

| CN1209392C (en) * | 2001-05-14 | 2005-07-06 | 阿姆诺洼化学有限公司 | Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups |

| US6660828B2 (en) | 2001-05-14 | 2003-12-09 | Omnova Solutions Inc. | Fluorinated short carbon atom side chain and polar group containing polymer, and flow, or leveling, or wetting agents thereof |

| US20030096079A1 (en) * | 2001-11-21 | 2003-05-22 | Anthony Messina | Sound attenuating/absorbing laminates and methods of making same |

| TWI821234B (en) | 2018-01-09 | 2023-11-11 | 美商康寧公司 | Coated articles with light-altering features and methods for the production thereof |

| US20220009824A1 (en) | 2020-07-09 | 2022-01-13 | Corning Incorporated | Anti-glare substrate for a display article including a textured region with primary surface features and secondary surface features imparting a surface roughness that increases surface scattering |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4439474A (en) * | 1981-10-30 | 1984-03-27 | The Procter & Gamble Company | Disposable floor mat with improved wet soil absorptivity |

| CA1163876A (en) * | 1982-03-24 | 1984-03-20 | Michael Zegota | Carpets |

-

1984

- 1984-06-15 DE DE19843422289 patent/DE3422289A1/en not_active Withdrawn

-

1985

- 1985-06-07 EP EP85107055A patent/EP0168623A2/en not_active Withdrawn

- 1985-06-12 PT PT80629A patent/PT80629B/en unknown

- 1985-06-13 US US06/744,409 patent/US4579765A/en not_active Expired - Fee Related

- 1985-06-13 GR GR851441A patent/GR851441B/el unknown

- 1985-06-14 KR KR1019850004196A patent/KR860000439A/en not_active Application Discontinuation

- 1985-06-14 AU AU43709/85A patent/AU4370985A/en not_active Abandoned

- 1985-06-14 JP JP60128394A patent/JPS6119888A/en active Pending

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0226111A2 (en) * | 1985-12-09 | 1987-06-24 | The Dow Chemical Company | A method for improving the tuft bind of textile coverings |

| EP0226111A3 (en) * | 1985-12-09 | 1989-07-19 | The Dow Chemical Company | A method for improving the tuft bind of textile coverings |

Also Published As

| Publication number | Publication date |

|---|---|

| AU4370985A (en) | 1985-12-19 |

| GR851441B (en) | 1985-11-25 |

| US4579765A (en) | 1986-04-01 |

| KR860000439A (en) | 1986-01-28 |

| PT80629B (en) | 1987-04-28 |

| PT80629A (en) | 1985-07-01 |

| JPS6119888A (en) | 1986-01-28 |

| DE3422289A1 (en) | 1985-12-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2543137C2 (en) | Fabric composition for hot-melt backing for dimpled carpets | |

| DE69015596T2 (en) | Emulsion binders for carpets and carpet tiles. | |

| EP0014347B1 (en) | Coating composition applied on the backside of adhesive papers | |

| DE3043674A1 (en) | EXTRUDABLE DIMENSIONS FOR THE PRODUCTION OF A THERMOPLASTIC, SOUND AND THERMAL INSULATING UNDER LAYER FOR CARPETS AND CARPETS WITH SUCH A, EXTRUDED UNDER LAYER AND METHOD FOR THE PRODUCTION THEREOF | |

| EP0168623A2 (en) | Process for the improvement of the user features of a tufted floor covering | |

| DE20121705U1 (en) | Flooring made of plastic material | |

| WO1999037716A1 (en) | Polymer composition for use as aqueous floor adhesive | |

| DE3842650C1 (en) | Aqueous release agent, and the use thereof | |

| DE2161408A1 (en) | Latex compound and process for its manufacture | |

| EP0244602B1 (en) | Process for finishing leather | |

| DE3687958T2 (en) | METHOD FOR IMPROVING THE BONDING OF Tufted Pole Covering Textiles. | |

| DE2916750C3 (en) | Foam auxiliaries and their use for producing a foam | |

| DE2827700A1 (en) | LATEX STRETCHED WITH GOVERNED MINERAL OIL | |

| DE2911679A1 (en) | METHOD FOR PRODUCING COATED PAPER AND CARDBOARD AND COATING MATERIAL FOR CARRYING OUT THE METHOD | |

| DE2401222A1 (en) | ANTISTATIC COATING COMPOUNDS AND METHOD FOR MANUFACTURING IT | |

| DE2640424A1 (en) | METHOD OF MANUFACTURING A WALL CLADDING FROM A COMPOSITE WEB | |

| DE69414978T2 (en) | Adhesive compositions based on aqueous dispersions of synthetic resins and their use for gluing wall and floor coverings | |

| DE1719168C3 (en) | Adhesive mix | |

| EP1165877B1 (en) | Production of a multilayered, textile floor covering using an aqueous polymeric dispersion as adhesive | |

| EP0730061B1 (en) | Offset printing process | |

| DE1289818B (en) | Method of manufacturing carpets doubled with a coarse fabric | |

| LU85880A1 (en) | COMPOSITE FLOORING MATERIAL | |

| DE863540C (en) | Process for finishing split leather, leather waste u. like | |

| DE2351756C3 (en) | Process for the removable bonding of carpets to floors | |

| DE1671601A1 (en) | Pressure sensitive ink transfer sheet or ribbon and method for making the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19860621 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHACHTNER, GERT |