EP0141899B1 - Method and apparatus for coating sheet-like materials by foams or liquids - Google Patents

Method and apparatus for coating sheet-like materials by foams or liquids Download PDFInfo

- Publication number

- EP0141899B1 EP0141899B1 EP84105283A EP84105283A EP0141899B1 EP 0141899 B1 EP0141899 B1 EP 0141899B1 EP 84105283 A EP84105283 A EP 84105283A EP 84105283 A EP84105283 A EP 84105283A EP 0141899 B1 EP0141899 B1 EP 0141899B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pressure

- pressure stage

- medium

- width

- foam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000007788 liquid Substances 0.000 title claims description 25

- 238000000034 method Methods 0.000 title claims description 19

- 239000000463 material Substances 0.000 title claims description 5

- 239000006260 foam Substances 0.000 title abstract description 69

- 239000011248 coating agent Substances 0.000 title 1

- 238000000576 coating method Methods 0.000 title 1

- 239000004744 fabric Substances 0.000 claims abstract 4

- 238000009826 distribution Methods 0.000 claims description 22

- 230000008569 process Effects 0.000 claims description 9

- 238000002360 preparation method Methods 0.000 claims 1

- UQDJGEHQDNVPGU-UHFFFAOYSA-N serine phosphoethanolamine Chemical compound [NH3+]CCOP([O-])(=O)OCC([NH3+])C([O-])=O UQDJGEHQDNVPGU-UHFFFAOYSA-N 0.000 claims 1

- 238000007667 floating Methods 0.000 description 14

- 238000003860 storage Methods 0.000 description 10

- 230000032683 aging Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000523 sample Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000009969 flowable effect Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000005187 foaming Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000010327 methods by industry Methods 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B1/00—Applying liquids, gases or vapours onto textile materials to effect treatment, e.g. washing, dyeing, bleaching, sizing or impregnating

- D06B1/08—Applying liquids, gases or vapours onto textile materials to effect treatment, e.g. washing, dyeing, bleaching, sizing or impregnating from outlets being in, or almost in, contact with the textile material

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B19/00—Treatment of textile materials by liquids, gases or vapours, not provided for in groups D06B1/00 - D06B17/00

- D06B19/0088—Treatment of textile materials by liquids, gases or vapours, not provided for in groups D06B1/00 - D06B17/00 using a short bath ratio liquor

- D06B19/0094—Treatment of textile materials by liquids, gases or vapours, not provided for in groups D06B1/00 - D06B17/00 using a short bath ratio liquor as a foam

Definitions

- the invention relates to a method for applying media in the foamed state or of liquids to a carrier and an arrangement for carrying out the method.

- the medium or the liquid in the state desired for the application is conducted to the application area by means of a first pressure stage and is distributed there over the width of the carrier or the web of material, and then with that over the working width distributed medium, an almost evenly acting, slight pressure (second pressure stage) is built up over the entire working width, with which the medium is fed to a third pressure stage, and the medium is pressurized again in this third pressure stage and by means of this third pressure stage on the carrier or the web is applied.

- a processing device for the medium or the liquid has a pressure generator, the outlet of which opens via a line into a width distribution space, and that the width distribution space is connected to the entry into the third pressure stage, which in turn is a Includes pressure generator.

- the medium already in the desired state in a storage container is introduced into a width distribution device by means of a device which generates the first pressure stage according to the method, or is introduced into a storage space which extends over the working width.

- the measures according to the invention allow media in the foamed state of any type and consistency to be applied uniformly in any amount, even the smallest of amounts, whereby the difficulties previously encountered with foams are avoided.

- the invention can also be applied to liquids of the most varied viscosities.

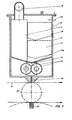

- Fig.1 1 shows the basic circuit diagram for the entire method

- Fig. The arrangement according to the invention. 6 to 6 show different possibilities for a foam feed.

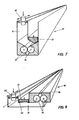

- 7 and 8 show two embodiments for the arrangement according to the invention.

- a first pressure stage 1 air is introduced from an inlet 3 into a mixing chamber 4 by an air pressure and volume control system 2.

- the medium to be foamed is introduced into this mixing chamber from a storage vessel 6 via the inlet 6a by means of a quantity-adjustable liquid pressure generation pump 5.

- the air and medium can be mixed statically or dynamically. If liquid and not foam is to be processed, the air supply and the mixing chamber can be omitted.

- the foam or the liquid is then pressed along a line 7 under a pressure of 3 to 5 bar into a hose line 8. From this hose line, the foam enters a width distribution space 9 under low pressure. This width distribution space 9 distributes the delivered foam almost uniformly over the entire working width of the application bar 10.

- the hose 8 must have a considerable length, 10 m and more, in order to ensure that the foam exits completely evenly at the other end without air pockets.

- the closer construction of the application bar 10 is shown.

- the application bar 10 has a housing 11 in which the width distribution space 9 is provided.

- This width distribution space 9 can be designed differently and it can have its own width distribution device; As shown in FIG. 3, this can either be constructed in the manner of a funnel or with more or less finely distributed branching channels or simply as a hollow shape for receiving in the form of a cone of pouring.

- the foam enters directly into the upper region of the width distribution space 9.

- the outlet occurs at the lower end of a width distribution device into a storage space 13.

- a foam supply is built up, the width of which is at least as large as the working width of the application bar 10.

- the foam enters a chamber 14, from where it is guided via the toothed rollers 15 to an outlet gap 16.

- the toothed rollers 15 form a pressure stage, since they exert a pressure on the foam which is sufficient to introduce the foam through the outlet gap into the web below. It goes without saying that this pressure level does not necessarily have to be provided by tooth rollers, but that other pressure-generating devices can also be used. It should be expressly emphasized that the first pressure stage formed by the foam generating device and the other pressure stages are independent of one another and can be set and regulated separately.

- the medium that is to say the foam or the liquid

- the medium is distributed in the storage space 13 over the working width in an almost depressurized or even depressurized state.

- a slight pressure is now exerted on the medium, i.e. the medium is subjected to a second pressure stage.

- the pressure exerted here only needs to be so great that the suction area for the third pressure stage is evenly supplied with foam or liquid. It should be noted that under certain circumstances you can also use the weight of the medium to build up the second pressure stage. The more fluid (watery) the medium, the easier it is to build up the suction pressure as a liquid pressure with the weight of a liquid.

- a floating body 17 is provided, which is designed in the form of a bar.

- the floating body 17 has an enlarged lower surface and essentially closes the open surface of the space 13.

- the floating body 17 can be moved up and down in the manner of a piston in the storage space 13, with a seal between the walls of the housing 11 and the floating body 17 the foam itself is given.

- the weight of the floating body exerts a slight overpressure on the foam, at the same time this floating body compensates for irregularities in the width distribution.

- the weight or the pressure generated thereby is sufficient to keep the suction part of the second pressure stage constant and pressure-balanced, i.e. without air holes to feed the foam.

- the float can be adapted to any foam density as required.

- the floating body 17 In addition to the function of building up an extremely minimal overpressure, the floating body 17 also has the function of keeping the foam supply free of undesired air influences and free of foam-destroying air inlets in addition to the function of the fine distribution of the foam already mentioned. In addition, however, it forms a mechanical control element between the foam consumption and the foam delivery, in that the control impulses for the control of the foam delivery quantity can be derived by any auxiliary devices from the change in height of the floating body.

- the sensor 18 is indicated schematically in FIGS. 1 and 2. It can be seen from FIG. 1 that this sensor 18 reacts back to stage 1 via a connection 19. Such sensors are known, whereby this sensor can be a rod probe which is pivoted by the floating body 17, the response of the probe can be capacitive, etc.

- Openings 20 can be seen in the upper part of the wall of the housing 11, through which excess foam can escape when the floating body 17 is in an upper position. This is particularly advantageous, since it is easy to remove the foam that has been standing for a long time and is already aging or decomposing. It is thus possible to supply the foam generating device with a pulse by hand, as a result of which a large amount of foam is delivered for a short time, which pushes the old foam upward and thus through the bores 20, from where the foam is then guided to a storage container (not shown) can. This is because the foam emerges from the width distribution device in the lower region of the space 13 near the second pressure stage and thus the foam already in the space 13 is pressed upwards when the foam is delivered in large quantities. Even during operation of the entire arrangement, from time to time, e.g. every 10 seconds, a larger amount of foam is automatically delivered to remove the longer standing foam.

- FIG. 2 also shows a perforated plate 21 a which serves as a protective device for the second pressure stage in order to prevent foreign bodies from entering the chamber 14.

- the foam can now be applied either directly from the exit gap 16 to the web 21 passing through with sliding contact or indirectly via a transfer roller 22, the application then with rolling contact and press-in action, for example with a magnet press-in effect, for example with a magnet system 23.

- the piston 17 can also be omitted if the dead weight of the foam in the space 13 is large enough to generate the pressure required for the second pressure stage.

- FIGS. 6 to 6 show different possibilities for supplying foam.

- the foam is introduced into a funnel 25 via a line 24.

- the line 24 is divided into a number of lines 26, which open out at different points in an outlet slot. According to FIG. 5, there is a fine division over lines 27.

- the line 24 opens into a closed space 28 in which a pouring cone 29 is formed from the foam.

- FIG. 7 shows an embodiment of the arrangement according to the invention which is somewhat modified compared to FIG. 2.

- a foam is introduced via the pressure connection 30 into the width distribution space 9 of the application bar 10.

- the hose connector 30 and the supply hose, not shown, can be moved back and forth in the longitudinal direction to the application bar 10, and the foam is distributed over the working width in such a way that the hose connector 30 is moved back and forth at a predetermined speed.

- the covering of the width distribution space 9 is moved along with the hose connector 30.

- the foam distributed in this way then comes into a storage space, the open area of which is essentially closed by a floating body 17.

- This float 17 gives the pressure required for the second pressure level, which approximately corresponds to the suction of the third pressure level.

- the third pressure stage is again formed here by the toothed rollers 15.

- FIG. 8 shows a different spatial arrangement of the application bar 10.

- the foam is again introduced into the width distribution space 9 via a pressure connection 30.

- the hose connector and the hose are also moved in the longitudinal direction of the application bar.

- the foam thus distributed over the working width reaches space 31, which has an open surface 32 that is essentially closed by floating body 17.

- the outlet gap 16 points upwards, so that the foam supplied via the second pressure stage of the third pressure stage has to be conveyed upward via the toothed rollers 15. So foam application from bottom to top is possible here. It has been shown that the pressure applied by the floating body 17 to the foam is sufficient to continuously and completely supply the required material to the third pressure stage.

- the principle of the present invention can be applied to any spatial position of the outlet gap 16.

- the invention has made it possible to use foamed media for process engineering in the treatment of carriers in webs without the problems mentioned at the outset adversely affecting the process.

- the inventive measures in the arrangement result in an improvement in process technology, the greater the lower the foam density or the lower the stability of the foam used, because it is now possible to work with an extremely minimal amount of foam.

- the foams of low density and those with low flowability according to the prior art were not reliably exact and could be manipulated and controlled in the smallest quantity ranges. This has now been changed by the invention. According to the current state of the art, either uncertainty factors with regard to reliability and uniformity or costly substance losses or those which aggravate the technology had to be accepted.

- the floating body 17 can also be omitted, in which case the control impulses can be taken directly from the liquid level.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Coating Apparatus (AREA)

- Manufacture Of Porous Articles, And Recovery And Treatment Of Waste Products (AREA)

- Treatment Of Fiber Materials (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Abstract

Description

Die Erfindung betrifft ein Verfahren zum Auftragen von Medien im aufgeschäumten Zustand bzw. von Flüssigkeiten auf einen Träger sowie eine Anordnung zur Durchführung des Verfahrens.The invention relates to a method for applying media in the foamed state or of liquids to a carrier and an arrangement for carrying out the method.

Das gleichmässige Auftragen von Medien auf einen Träger, insbesondere auf eine Warenbahn, ist ein Problem, das nur sehr schwierig zu lösen ist, insbesondere dann, wenn man kontinuierliche Warenbahnen grosser Breite, z.B. 5 m und mehr, mit grösseren Geschwindigkeiten behandeln will. Dieses Problem wird noch vergrössert, wenn nur ganz geringe Mengen dieser Medien gleichmässig aufzutragen sind. Man hat in letzter Zeit versucht, die erforderlichen chemischen Materialien in Form eines Schaumes auf den Träger und hier insbesondere auf die Warenbahn aufzutragen. Hier ergeben sich insofern Probleme, als der Schaum nach seiner Herstellung bis zum-Auftragen seine Konsistenz und seine Eigenschaften nicht ändern soll, nach dem Auftragen jedoch ohne Spuren zu hinterlassen aufgelöst werden soll. Dies bedeutet aber, dass man während der Herstellung und während des Transportes des Schaumes zum Auftragungsbereich darauf achten muss, dass der Schaum völlig gleichmässig ist, dass seine Alterung nach Möglichkeit unterbunden wird bzw. dass gealterter oder sich zersetzender Schaum auf einfache Weise vor der Auftragung entfernt werden kann und an derAuftragungsstelle gleichmässig über den gesamten Arbeitsbereich verteilt ist.The even application of media to a carrier, especially to a web, is a problem that is very difficult to solve, especially when large width continuous webs, e.g. 5 m and more, wants to treat at higher speeds. This problem is exacerbated if only very small amounts of these media have to be applied evenly. Attempts have recently been made to apply the required chemical materials in the form of a foam to the carrier and here in particular to the web. Problems arise here in that the foam should not change its consistency and properties after its production until it is applied, but should be dissolved after application without leaving any traces. However, this means that during production and during the transport of the foam to the application area, care must be taken to ensure that the foam is completely uniform, that its aging is prevented as far as possible, or that aged or decomposing foam is removed easily before application and can be distributed evenly over the entire work area at the application point.

Erfindungsgemäss wird nun bei dem eingangs erwähnten Verfahren vorgeschlagen, dass das Medium oder die Flüssigkeit in dem für die Auftragung gewünschten Zustand mittels einer ersten Druckstufe zum Auftragungsbereich geleitet und dort über die Breite des Trägers oder die Warenbahn verteilt wird, dass dann mit dem über die Arbeitsbreite verteilten Medium ein über die gesamte Arbeitsbreite annähernd gleichmässig wirkender, geringfügiger Druck (zweite Druckstufe) aufgebaut wird, mit dem das Medium einer dritten Druckstufe zugeleitet wird, und das Medium in dieser dritten Druckstufe erneut unter Druck gesetzt wird und mittels dieser dritten Druckstufe auf den Träger oder die Warenbahn aufgebracht wird.According to the invention, it is now proposed in the method mentioned at the outset that the medium or the liquid in the state desired for the application is conducted to the application area by means of a first pressure stage and is distributed there over the width of the carrier or the web of material, and then with that over the working width distributed medium, an almost evenly acting, slight pressure (second pressure stage) is built up over the entire working width, with which the medium is fed to a third pressure stage, and the medium is pressurized again in this third pressure stage and by means of this third pressure stage on the carrier or the web is applied.

Bei der Anordnung zur Durchführung des Verfahrens wird vorgeschlagen, dass eine Aufbereitungsvorrichtung für das Medium oder die Flüssigkeit einen Druckgenerator aufweist, dessen Ausgang über eine Leitung in einen Breitenverteilungsraum mündet, und dass der Breitenverteilungsraum mit dem Eintritt in die dritte Druckstufe verbunden ist, die wiederum einen Druckgenerator enthält.In the arrangement for carrying out the method, it is proposed that a processing device for the medium or the liquid has a pressure generator, the outlet of which opens via a line into a width distribution space, and that the width distribution space is connected to the entry into the third pressure stage, which in turn is a Includes pressure generator.

Eine andere Möglichkeit zur Durchführung des Verfahrens liegt darin, dass das bereits im gewünschten Zustand in einem Vorratsbehälter befindliche Medium mittels einer, die verfahrensgemässe erste Druckstufe erzeugenden Vorrichtung in einer Breitenverteilungsvorrichtung eingebracht bzw. in einen über die Arbeitsbreite erstreckenden Vorratsraum eingeleitet wird.Another possibility for carrying out the method is that the medium already in the desired state in a storage container is introduced into a width distribution device by means of a device which generates the first pressure stage according to the method, or is introduced into a storage space which extends over the working width.

Durch die erfinderischen Massnahmen können Medien im aufgeschäumten Zustand jeglicher Art und Konsistenz in beliebigen, auch allerkleinsten Mengen gleichmässig aufgetragen werden, wobei die bisher bei Schäumen auftretenden Schwierigkeiten vermieden sind. Die Erfindung lässt sich aber auch bei Flüssigkeiten der verschiedensten Viskositäten anwenden.The measures according to the invention allow media in the foamed state of any type and consistency to be applied uniformly in any amount, even the smallest of amounts, whereby the difficulties previously encountered with foams are avoided. However, the invention can also be applied to liquids of the most varied viscosities.

Die Erfindung wird nun anhand der Zeichnungen beispielsweise näher beschrieben. Fig.1 1 zeigt das Prinzipschaltbild für das gesamte Verfahren, Fig. die Anordnung gemäss der Erfindung. Die Fig. bis 6 zeigen verschiedene Möglichkeiten für eine Schaumzuführung. Fig. 7 und 8 zeigen zwei Ausführungsformen für die Anordnung gemäss der Erfindung.The invention will now be described, for example, with reference to the drawings. Fig.1 1 shows the basic circuit diagram for the entire method, Fig. The arrangement according to the invention. 6 to 6 show different possibilities for a foam feed. 7 and 8 show two embodiments for the arrangement according to the invention.

Die Fig. 1 sei anhand der beschrieben, jedoch sei gleich darauf hingewiesen, dass in gleicher Weise auch Flüssigkeiten eingesetzt werden können. In einer ersten Druckstufe 1 wird von einem Luftdruck- und Mengenreguliersystem 2 Luft vom Eingang 3 in eine Mischkammer 4 eingebracht. In diese Mischkammer wird aus einem Vorratsgefäss 6 über den Eingang 6a mittels einer mengenregulierbaren Flüssigkeitsdruckerzeugungspumpe 5 das zu verschäumende Medium eingeleitet. Die Mischung von Luft und Medium kann statisch oder dynamisch erfolgen. Wenn Flüssigkeit und nicht Schaum verarbeitet werden soll, so können die Luftzufuhr und die Mischkammer weggelassen werden. Der Schaum oder die Flüssigkeit wird dann entlang der Leitung 7 unter einem Überdruck von 3 bis 5 bar in eine Schlauchleitung 8 hineingepresst. Aus dieser Schlauchleitung tritt der Schaum unter geringem Druck in einen Breitenverteilungsraum 9 ein. Dieser Breitenverteilungsraum 9 verteilt den angelieferten Schaum nahezu gleichmässig über die gesamte Arbeitsbreite der Aufbringsleiste 10. Der Schlauch 8 muss eine beträchtliche Länge haben, 10 m und mehr, um zu gewährleisten, dass der Schaum am anderen Ende völlig gleichmässig ohne Lufteinschlüsse austritt.1 is described with reference to FIG. 1, but it should be pointed out immediately that liquids can also be used in the same way. In a first pressure stage 1, air is introduced from an inlet 3 into a mixing chamber 4 by an air pressure and volume control system 2. The medium to be foamed is introduced into this mixing chamber from a

In Fig. 2 ist die nähere Konstruktion der Aufbringungsleiste 10 gezeigt. Bei dem hier dargestellten Beispiel besitzt die Aufbringungsleiste 10 ein Gehäuse 11, in dem der Breitenverteilungsraum 9 vorgesehen ist. Dieser Breitenverteilungsraum 9 kann verschieden ausgebildet sein, und er kann eine eigene Breitenverteilungseinrichtung aufweisen; diese kann, wie in Fig. 3 dargestellt, entweder in der Art eines Trichters oder mit mehr oder weniger fein verteilten Verzweigungskanälen oder einfach als Hohlform zur Aufnahme in Form eines Schüttkegels gebaut sein. Am Ende 12 des Schlauches tritt der Schaum direkt in den oberen Bereich des Breitenverteilungsraumes 9 ein. Der Austritt erfolgt bei dem dargestellten Beispiel am unteren Ende einer Breitenverteilungseinrichtung in einen Vorratsraum 13. Hier baut sich ein Schaumvorrat auf, dessen Breite mindestens gleich gross wie die Arbeitsbreite der Auftragungsleiste 10 ist. Vom Vorratsraum 13 tritt der Schaum in eine Kammer 14 ein, von wo er über die Zahnwalzen 15 zu einem Austrittsspalt 16 geführt wird. Die Zahnwalzen 15 bilden eine Druckstufe, da sie auf den Schaum einen Druck ausüben, der ausreicht, um den Schaum durch den Austrittsspalt hindurch in die darunter vorbeigeführte Warenbahn einzubringen. Es ist selbstverständlich, dass diese Druckstufe nicht unbedingt durch Zahnwalzen gegeben sein muss, sondern dass auch andere Druck erzeugende Einrichtungen verwendet werden können. Es sei ausdrücklich betont, dass die durch die Schaumerzeugungseinrichtung gebildete erste Druckstufe und die anderen Druckstufen voneinander unabhängig sind und getrennt eingestellt und geregelt werden können.In Fig. 2 the closer construction of the

Im Vorratsraum 13 befindet sich das Medium, also der Schaum oder die Flüssigkeit, über die Arbeitsbreite verteilt in nahezu drucklosem oder sogar in drucklosem Zustand. Auf das Medium wird nun ein geringfügiger Druck ausgeübt, d.h., das Medium wird einer zweiten Druckstufe ausgesetzt. Der hier ausgeübte Druck braucht nur so gross sein, dass der Ansaugbereich für die dritte Druckstufe gleichmässig mit Schaum oder Flüssigkeit versorgt wird. Hiebei ist zu beachten, dass man unter Umständen zum Aufbau der zweiten Druckstufe auch das Eigengewicht des Mediums heranziehen kann. Je fliessfähiger (wässriger) das Medium ist, um so einfacher kann der Ansaugdruck als Flüssigkeitsdruck mit dem Eigengewicht einer Flüssigkeit aufgebaut werden. Je höher jedoch der Viskositätsgrad bzw. der Verschäumungsgrad der Flüssigkeit ist bzw. um so schlechter deren Fliessverhalten, um so mehr zusätzliche mechanische Hilfsmittel sind erforderlich, um den zur luftfreien und druckkonstanten Zuführung des Mediums zum Arbeitsteil erforderlichen Vor- bzw. Ansaugdruck aufzubauen. Erst in der dritten Druckstufe erhält dann das Medium den eigentlichen Arbeitsdruck.The medium, that is to say the foam or the liquid, is distributed in the

Ist der im Vorratsraum befindliche Schaum nicht oder nur ungenügend fliessfähig, so ist es am günstigsten, auf die Oberfläche des Schaumvorrates den erforderlichen geringfügigen Druck aufzubringen. Dieser Druck muss der jeweiligen Schaumart angepasst sein, um zu vermeiden, dass durch diesen Druck der Schaum zu stark zusammengepresst wird und dann seine Eigenschaften ändert. Zu diesem Zweck ist ein Schwimmkörper 17 vorgesehen, der in Form einer Leiste ausgebildet ist. Der Schwimmkörper 17 hat eine vergrösserte untere Fläche und verschliesst im wesentlichen die offene Fläche des Raumes 13. Der Schwimmkörper 17 kann nach Art eines Kolbens im Vorratsraum 13 auf- und abbewegt werden, wobei eine Abdichtung zwischen den Wandungen des Gehäuses 11 und dem Schwimmkörper 17 durch den Schaum selbst gegeben wird. Durch das Gewicht des Schwimmkörpers ist ein geringfügiger Überdruck auf den Schaum ausgeübt, wobei gleichzeitig dieser Schwimmkörper Unregelmässigkeiten in der Breitenverteilung ausgleicht. Das Gewicht oder der dadurch erzeugte Druck reicht aus, um dem Ansaugteil der zweiten Druckstufe konstant und druckausgeglichen, d.h. ohne Luftlöcher, den Schaum zuzuführen. Durch Änderung des Gewichtes kann der Schwimmkörper jeder Schaumdichte je nach Bedarf angepasst werden.If the foam in the storage room is not or only insufficiently flowable, it is best to apply the required slight pressure to the surface of the foam supply. This pressure must be adapted to the respective type of foam in order to avoid that this pressure compresses the foam too much and then changes its properties. For this purpose, a

Der Schwimmkörper 17 hat ausser Funktion einen äusserst minimalen Überdruck aufzubauen und ausser der bereits erwähnten Funktion der feinen Breitenverteilung des Schaumes auch die Funktion, den Schaumvorrat frei von unerwünschten Lufteinflüssen und frei von schaumzerstörend wirkenden Luftzutritten zu halten. Ausserdem bildet er aber ein mechanisches Steuerglied zwischen dem Schaumverbrauch und der Schaumanlieferung, indem nämlich aus der Höhenänderung des Schwimmkörpers die Steuerimpulse für die Steuerung der Schaumanlieferungsmenge durch beliebige Hilfseinrichtungen abgeleitet werden können. Der Sensor 18 ist in den Fig. 1 und 2 schematisch angedeutet. Aus der Fig. 1 kann man erkennen, dass dieser Sensor 18 über eine Verbindung 19 auf die Stufe 1 zurückwirkt. Derartige Sensoren sind bekannt, wobei dieser Sensor eine Stabsonde sein kann, die vom Schwimmkörper 17 verschwenkt wird, das Ansprechen der Sonde kann kapazitiv erfolgen usw.In addition to the function of building up an extremely minimal overpressure, the

Im oberen Teil der Wand des Gehäuses 11 sind Öffnungen 20 zu erkennen, durch die dann, wenn sich der Schwimmkörper 17 in einer oberen Lage befindet, überschüssiger Schaum austreten kann. Dies ist besonders vorteilhaft, da man auf diese Weise einfach den länger stehenden Schaum, der bereits altert oder sich zersetzt, entfernen kann. So ist es möglich, der Schaumerzeugungseinrichtung händisch einen Impuls zuzuführen, wodurch für kurze Zeit eine grosse Schaumanlieferung erfolgt, die den alten Schaum nach oben drückt und somit durch die Bohrungen 20 hindurch, von wo der Schaum dann zu einem Lagerbehälter (nicht dargestellt) geführt werden kann. Dies deshalb, weil der Schaum aus der Breitenverteilungseinrichtung im unteren Bereich des Raumes 13 nahe der zweiten Druckstufe austritt und somit bei einer grösseren Schaumanlieferung der bereits im Raum 13 befindliche Schaum nach oben gedrückt wird. Auch während des Betriebes der gesamten Anordnung kann von Zeit zu Zeit, z.B. alle 10 Sek., automatisch eine grössere Schaummenge angeliefert werden, um den länger stehenden Schaum zu entfernen.

In der Fig. 2 ist noch ein Lochblech 21 a gezeigt, das als Schutzvorrichtung für die zweite Druckstufe dient, um zu vermeiden, dass Fremdkörper in die Kammer 14 eindringen.FIG. 2 also shows a

Wie in Fig. 2 gezeigt, kann das Aufbringen des Schaumes nun einerseits direkt aus dem Austrittsspalt 16 auf die mit Schleifkontakt durchlaufende Warenbahn 21 erfolgen oder anderseits indirekt über eine Übertragungsrolle 22, wobei dann die Aufbringung mit rollendem Kontakt und einpressender Wirkung, z.B. mit einem Magneteinpressender Wirkung, z.B. mit einem Magnetsystem 23, durchgeführt wird.As shown in Fig. 2, the foam can now be applied either directly from the

Der Kolben 17 kann auch entfallen, wenn das Eigengewicht des im Raum 13 befindlichen Schaumes gross genug ist, um den für die zweite Druckstufe erforderlichen Druck zu erzeugen.The

Die Fig. bis 6 zeigen verschiedene Möglichkeiten der Schaumzuführung. In der Fig.3 wird der Schaum über eine Leitung 24 in einen Trichter 25 eingebracht. In Fig.4 wird die Leitung 24 in mehrere Leitungen 26 aufgeteilt, die an verschiedenen Stellen eines Austrittsschlitzes münden. Gemäss Fig. 5 erfolgt eine feine Aufteilung über Leitungen 27. Bei der Ausführungsform nach Fig. 6 mündet die Leitung 24 in einen geschlossenen Raum 28, in dem aus dem Schaum ein Schüttkegel 29 gebildet wird.FIGS. 6 to 6 show different possibilities for supplying foam. In FIG. 3, the foam is introduced into a

Die Fig. 7 zeigt eine gegenüber der Fig. 2 etwas abgeänderte Ausführungsform der Anordnung gemäss der Erfindung. Hier wird ein Schaum über den Druckstutzen 30 in den Breitenverteilungsraum 9 der Aufbringungsleiste 10 eingebracht. Der Schlauchstutzen 30 und der nichtdargestellte Zuführungschlauch sind in Längsrichtung zur Aufbringungsleiste 10 hin und her beweglich, und die Verteilung des Schaumes über die Arbeitsbreite erfolgt derart, dass man den Schlauchstutzen 30 mit einer vorbestimmten Geschwindigkeit hin und her bewegt. Die Abdekkung des Breitenverteilungsraumes 9 wird mit dem Schlauchstutzen 30 mitbewegt. Auch hier kommt der so verteilte Schaum dann in einen Vorratsraum, dessen offene Fläche im wesentlichen durch einen Schwimmkörper 17 verschlossen ist. Dieser Schwimmkörper 17 gibt den für die zweite Druckstufe erforderlichen Druck, der dem Ansaugsog der dritten Druckstufe ungefähr entspricht. Die dritte Druckstufe wird auch hier wieder durch die Zahnwalzen 15 gebildet.FIG. 7 shows an embodiment of the arrangement according to the invention which is somewhat modified compared to FIG. 2. Here, a foam is introduced via the

Die Ausführungsform gemäss Fig. 8 zeigt eine andere räumliche Anordnung der Aufbringungsleiste 10. Auch hier wird der Schaum wieder über einen Druckstutzen 30 in den Breitenverteilungsraum 9 eingebracht. Wie bei der Fig. 7 wird auch hier der Schlauchstutzen und der Schlauch in Längsrichtung der Aufbringungsleiste bewegt. Der so über die Arbeitsbreite verteilte Schaum gelangt in den Raum 31, der eine vom Schwimmkörper 17 im wesentlichen verschlossene, offene Fläche 32 aufweist. Im Gegensatz zu den bisherigen Ausführungsformen weist hier jedoch der Austrittsspalt 16 nach oben, so dass der über die zweite Druckstufe der dritten Druckstufe zugeführte Schaum über die Zahnwalzen 15 nach oben gefördert werden muss. Hier ist also eine Schaumauftragung von unten nach oben möglich. Es hat sich gezeigt, dass der von dem Schwimmkörper 17 auf den Schaum aufgebrachte Druck ausreicht, um der dritten Druckstufe kontinuierlich und völlig konstant das erforderliche Material zuzuführen. Das Prinzip der vorliegenden Erfindung lässt sich bei jeder räumlichen Lage des Austrittsspaltes 16 anwenden.The embodiment according to FIG. 8 shows a different spatial arrangement of the

Durch die Erfindung ist es gelungen, für die Verfahrenstechnik beim Behandeln von Trägern in Warenbahnen aufgeschäumte Medien einsetzen zu können, ohne dass die eingangs erwähnten Probleme das Verfahren negativ beeinflussen. Durch die erfinderischen Massnahmen bei der Anordnung ergibt sich eine Verbesserung der Verfahrenstechnik, die um so grösser ist, je geringer die Schaumdichte bzw. je geringer die Stabilität des jeweils verwendeten Schaumes ist, weil es jetzt möglich ist, mit einer äusserst minimalen Schaumvorratsmenge zu arbeiten. Es sei nochmals betont, dass die Schäume geringer Dichte und jene mit geringer Fliessfähigkeit nach dem bisherigen Stand der Technik nicht zuverlässig exakt und in kleinsten Mengenbereichen manipulierbar und steuerbar waren. Dies wurde jetzt durch die Erfindung geändert. Nach dem bisherigen Stand der Technik mussten entweder Unsicherheitsfaktoren in bezug auf Zuverlässigkeit und Gleichmässigkeit oder kostspielige bzw. die Technologie erschwerende Substanzverluste in Kauf genommen werden. So war es notwendig, da bisher keine Breitenverteilung und Mengensteuerungen durchgeführt werden konnten, die Schaumzufuhr mit Überschuss durchzuführen, wobei man dann diese Überschussmengen vor Beginn von Verfallserscheinungen wieder abführen musste. Das erfindungsgemässe neue Verfahren vermeidet alle diese technischen und wirtschaftlichen Nachteile.The invention has made it possible to use foamed media for process engineering in the treatment of carriers in webs without the problems mentioned at the outset adversely affecting the process. The inventive measures in the arrangement result in an improvement in process technology, the greater the lower the foam density or the lower the stability of the foam used, because it is now possible to work with an extremely minimal amount of foam. It should be emphasized again that the foams of low density and those with low flowability according to the prior art were not reliably exact and could be manipulated and controlled in the smallest quantity ranges. This has now been changed by the invention. According to the current state of the art, either uncertainty factors with regard to reliability and uniformity or costly substance losses or those which aggravate the technology had to be accepted. So it was necessary, since it was previously not possible to distribute the width and control the quantities, to carry out the foam supply with excess, in which case these excess quantities had to be removed again before signs of deterioration began. The new method according to the invention avoids all these technical and economic disadvantages.

Wird das vorbeschriebene Verfahren bzw. die erfinderische Anordnung für die Verarbeitung von gut fliessfähigem Schaum bzw. von Flüssigkeiten eingesetzt, so kann der Schwimmkörper 17 auch entfallen, wobei dann die Steuerimpulse direkt vom Flüssigkeitsniveau abgenommen werden können.If the above-described method or the inventive arrangement is used for the processing of free-flowing foam or liquids, the floating

Claims (18)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT1911/83A AT393464B (en) | 1983-05-25 | 1983-05-25 | DEVICE FOR APPLYING FOAMED OR HIGH-VISCOSE MEDIA |

| AT1911/83 | 1983-05-25 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0141899A2 EP0141899A2 (en) | 1985-05-22 |

| EP0141899A3 EP0141899A3 (en) | 1986-03-12 |

| EP0141899B1 true EP0141899B1 (en) | 1988-07-13 |

Family

ID=3523688

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84105283A Expired EP0141899B1 (en) | 1983-05-25 | 1984-05-10 | Method and apparatus for coating sheet-like materials by foams or liquids |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4552778A (en) |

| EP (1) | EP0141899B1 (en) |

| JP (1) | JPS59225768A (en) |

| AT (2) | AT393464B (en) |

| BR (1) | BR8402504A (en) |

| DE (1) | DE3472689D1 (en) |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT383290B (en) * | 1983-06-23 | 1987-06-10 | Johannes Zimmer | METHOD FOR LIQUID FOAM APPLICATION USING AN APPLICATION DEVICE |

| US4622239A (en) * | 1986-02-18 | 1986-11-11 | At&T Technologies, Inc. | Method and apparatus for dispensing viscous materials |

| DE3839100A1 (en) * | 1988-11-18 | 1990-05-23 | Bematec S A | COATING DEVICE FOR MATERIAL RAILS |

| US5611274A (en) * | 1993-05-19 | 1997-03-18 | Tani Denkikogyo Co., Ltd. | Apparatus for screen printing of viscous materials |

| TW288254B (en) * | 1993-05-19 | 1996-10-11 | Tani Denki Kogyo Kk | |

| EP0956192A4 (en) * | 1996-12-06 | 2002-06-05 | Bba Nonwovens Simpsonville Inc | Nonwoven web laminate having relatively hydrophilic zone and related method for its manufacture |

| US6503412B1 (en) | 2000-08-24 | 2003-01-07 | Kimberly-Clark Worldwide, Inc. | Softening composition |

| US6607783B1 (en) | 2000-08-24 | 2003-08-19 | Kimberly-Clark Worldwide, Inc. | Method of applying a foam composition onto a tissue and tissue products formed therefrom |

| CA2423827C (en) | 2000-11-08 | 2010-07-27 | Kimberly-Clark Worldwide, Inc. | Foam treatment of tissue products |

| US6805965B2 (en) | 2001-12-21 | 2004-10-19 | Kimberly-Clark Worldwide, Inc. | Method for the application of hydrophobic chemicals to tissue webs |

| US6797319B2 (en) | 2002-05-31 | 2004-09-28 | Kimberly-Clark Worldwide, Inc. | Application of foam to tissue products using a liquid permeable partition |

| US6797116B2 (en) | 2002-05-31 | 2004-09-28 | Kimberly-Clark Worldwide, Inc. | Method of applying a foam composition to a tissue product |

| US6835418B2 (en) | 2002-05-31 | 2004-12-28 | Kimberly-Clark Worldwide, Inc. | Use of gaseous streams to aid in application of foam to tissue products |

| US6977026B2 (en) | 2002-10-16 | 2005-12-20 | Kimberly-Clark Worldwide, Inc. | Method for applying softening compositions to a tissue product |

| US6761800B2 (en) | 2002-10-28 | 2004-07-13 | Kimberly-Clark Worldwide, Inc. | Process for applying a liquid additive to both sides of a tissue web |

| US7029756B2 (en) | 2002-11-06 | 2006-04-18 | Kimberly-Clark Worldwide, Inc. | Soft tissue hydrophilic tissue products containing polysiloxane and having unique absorbent properties |

| US6964725B2 (en) | 2002-11-06 | 2005-11-15 | Kimberly-Clark Worldwide, Inc. | Soft tissue products containing selectively treated fibers |

| US6949168B2 (en) | 2002-11-27 | 2005-09-27 | Kimberly-Clark Worldwide, Inc. | Soft paper product including beneficial agents |

| US20040121680A1 (en) * | 2002-12-23 | 2004-06-24 | Kimberly-Clark Worldwide, Inc. | Compositions and methods for treating lofty nonwoven substrates |

| US7396593B2 (en) | 2003-05-19 | 2008-07-08 | Kimberly-Clark Worldwide, Inc. | Single ply tissue products surface treated with a softening agent |

| US7204882B2 (en) * | 2005-01-12 | 2007-04-17 | Lung-Wen Chou | Polyurethane resin coating device |

| CN101883682B (en) * | 2007-12-10 | 2012-10-10 | 株式会社理光 | Imager forming apparatus and foam application device |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2474254A (en) * | 1946-11-18 | 1949-06-28 | Leroy A Kauffman | Machine for impregnating material with liquids |

| CH1157969A4 (en) * | 1969-07-30 | 1971-07-15 | ||

| ATA1146270A (en) * | 1970-12-21 | 1976-08-15 | Zimmer Peter | DEVICE FOR APPLYING A LIQUID OR LIQUID MASS |

| US3921521A (en) * | 1970-07-23 | 1975-11-25 | Zimmer Peter | Squeegee device |

| CS155341B1 (en) * | 1971-01-07 | 1974-05-30 | ||

| AT357506B (en) * | 1973-02-07 | 1980-07-10 | Zimmer Peter Ag | Squeegee device with a squeegee housing closed on all sides |

| DE2523062C3 (en) * | 1975-05-24 | 1980-02-28 | Hoechst Ag, 6000 Frankfurt | Device for the continuous application of a liquid treatment liquor in the form of foam to wide-spread textile material |

| DE2537324A1 (en) * | 1975-08-21 | 1977-03-03 | Bayer Ag | PROCESS FOR THE EVEN APPLICATION OF LIQUID SYSTEMS IN FOAMED FORM IN A DISPOSABLE PROCESS ON MONOFILES, FILAMENT YARN, CABLES, FIBER TAPES AND TEXTILE FABRICS |

| DE2929699C2 (en) * | 1979-07-21 | 1984-06-14 | Mathias 4815 Schloss Holte Mitter | Device for applying paint or the like. in a screen printing machine or similar machine |

| US4307240A (en) * | 1980-05-30 | 1981-12-22 | General Electric Company | Alkoxysilanes and method for making |

| US4297860A (en) * | 1980-07-23 | 1981-11-03 | West Point Pepperell, Inc. | Device for applying foam to textiles |

| DE3034804C2 (en) * | 1980-09-16 | 1983-12-08 | Mathias 4815 Schloss Holte Mitter | Device for applying a medium to a screen stencil, in particular for printing or dyeing |

| DE3108963C2 (en) * | 1981-03-10 | 1983-10-20 | Mathias 4815 Schloss Holte Mitter | Applicator for applying chemicals in foamed form |

| DE3150936A1 (en) * | 1981-12-23 | 1983-06-30 | Mathias 4815 Schloss Holte Mitter | Device for supplying foam to a user, for example an application station |

| CH652157A5 (en) * | 1984-10-17 | 1985-10-31 | Gilbert Hirt | Three dimensional frame buildings. |

-

1983

- 1983-05-25 AT AT1911/83A patent/AT393464B/en not_active IP Right Cessation

-

1984

- 1984-05-10 DE DE8484105283T patent/DE3472689D1/en not_active Expired

- 1984-05-10 AT AT84105283T patent/ATE35704T1/en not_active IP Right Cessation

- 1984-05-10 EP EP84105283A patent/EP0141899B1/en not_active Expired

- 1984-05-24 BR BR8402504A patent/BR8402504A/en not_active IP Right Cessation

- 1984-05-25 US US06/614,417 patent/US4552778A/en not_active Expired - Fee Related

- 1984-05-25 JP JP59104886A patent/JPS59225768A/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| DE3472689D1 (en) | 1988-08-18 |

| AT393464B (en) | 1991-10-25 |

| EP0141899A3 (en) | 1986-03-12 |

| JPS59225768A (en) | 1984-12-18 |

| BR8402504A (en) | 1985-04-02 |

| ATE35704T1 (en) | 1988-07-15 |

| US4552778A (en) | 1985-11-12 |

| ATA191183A (en) | 1984-08-15 |

| EP0141899A2 (en) | 1985-05-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0141899B1 (en) | Method and apparatus for coating sheet-like materials by foams or liquids | |

| DE3309731C2 (en) | Device for the even application of determinable amounts of liquid | |

| CH644284A5 (en) | METHOD AND DEVICE FOR COATING A MOVING MATERIAL RAIL. | |

| DE2653108A1 (en) | Constant pressure of foam in coating fountain - is maintained by pressure sensor in fountain controlling air supply to foam generator and flow to fountain | |

| EP0147536A2 (en) | Apparatus for evenly distributing a liquid flow over a given width | |

| DE3044408A1 (en) | METHOD AND DEVICE FOR THE EVEN APPLICATION OF LIQUID TREATMENT FLEETS ON TEXTILE AREAS, LIKE TRACKS OF PRODUCTS | |

| DE102014117734A1 (en) | Apparatus and method for loading a liquid with a gas | |

| DE3421316C2 (en) | ||

| DE2228685A1 (en) | STRAIN BAR | |

| DE2123653C3 (en) | Device for the production of an eluent | |

| EP0239720A1 (en) | Process and apparatus for preparing a fluid foaming reaction mixture from fluid components | |

| DE2313626B2 (en) | Device for continuously dissolving a powdery substance in a liquid | |

| DE3139123A1 (en) | DEVICE FOR PRODUCING FOAM | |

| DE1928708A1 (en) | Device and method for the transfer of substances, preferably through a selectively permeable membrane | |

| DE69717317T2 (en) | METHOD AND DEVICE FOR APPLYING A COATING TO A PAPER RAIL RUNNING AT HIGH SPEED | |

| DE2045142A1 (en) | Device for treating thread with liquid | |

| DE1519700A1 (en) | Method and device for establishing contact between liquids and gases | |

| CH656559A5 (en) | DEVICE FOR ONE- OR TWO-SIDED COATING OF RAILWAY MATERIAL. | |

| DE3150936A1 (en) | Device for supplying foam to a user, for example an application station | |

| DE1473045A1 (en) | Method and device for the automatic regulation of the continuous introduction or application of certain amounts of solids or liquids on a moving material plate, sheet, web of material or the like. | |

| WO2018228713A1 (en) | Method and mixing device for controlling the introduction of a pulverulent material into a liquid for a batch mixing method | |

| AT378133B (en) | METHOD AND DEVICE FOR APPLYING LOW OR LOWEST AMOUNTS OF FLOWABLE MEDIA | |

| DE19508178A1 (en) | Process and plant for treating coating color when applied to a paper web | |

| AT401622B (en) | DEVICE FOR APPLYING A FLOWABLE VISCOSE SUBSTANCE | |

| DE3524127A1 (en) | Application device or slotted doctor for continuously applying a foamed, pasty or dry application medium |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE DE FR GB IT NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE DE FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19860507 |

|

| 17Q | First examination report despatched |

Effective date: 19871009 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE FR GB IT NL |

|

| REF | Corresponds to: |

Ref document number: 35704 Country of ref document: AT Date of ref document: 19880715 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3472689 Country of ref document: DE Date of ref document: 19880818 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19940426 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19950509 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19950510 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19950516 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19950519 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19950531 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19950627 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19960510 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19960531 |

|

| BERE | Be: lapsed |

Owner name: ZIMMER JOHANNES Effective date: 19960531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19961201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19960510 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19970131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19970201 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19961201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |