EP0136076A2 - Verfahren und Vorrichtung zur Bildung einer Verpackung mittels eines geschlossenen Wickels - Google Patents

Verfahren und Vorrichtung zur Bildung einer Verpackung mittels eines geschlossenen Wickels Download PDFInfo

- Publication number

- EP0136076A2 EP0136076A2 EP84305783A EP84305783A EP0136076A2 EP 0136076 A2 EP0136076 A2 EP 0136076A2 EP 84305783 A EP84305783 A EP 84305783A EP 84305783 A EP84305783 A EP 84305783A EP 0136076 A2 EP0136076 A2 EP 0136076A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- panels

- containers

- folded

- panel

- tuck

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title claims abstract description 9

- 230000003068 static effect Effects 0.000 claims description 11

- 230000000694 effects Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 239000011087 paperboard Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B11/00—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material

- B65B11/06—Wrapping articles, or quantities of material, by conveying wrapper and contents in common defined paths

- B65B11/08—Wrapping articles, or quantities of material, by conveying wrapper and contents in common defined paths in a single straight path

- B65B11/10—Wrapping articles, or quantities of material, by conveying wrapper and contents in common defined paths in a single straight path to fold the wrappers in tubular form about contents

- B65B11/105—Wrapping articles, or quantities of material, by conveying wrapper and contents in common defined paths in a single straight path to fold the wrappers in tubular form about contents the axis of the tube being parallel to the conveying direction

Definitions

- This invention relates to a method and machine for forming a package of the wrap-around type accommodating a plurality of containers.

- the package is generally in the form of a sleeve but includes end panel elements at each end of the sleeve which restrain the endways movement of the containers to prevent them from becoming dislodged from the package.

- the machine of the present invention forms the folding operations on the package solely by means of static folding elements and substantially reduces the costs of such machinery.

- One aspect of the invention provides a machine for forming a wrap-around package accommodating a plurality of containers and of the type having a top panel, side wall panels, and base panels providing a sleeve-like structure and end panel structures at each end of the sleeve including an end panel and tuck panels joined to the end panel by gusset panels

- machine is characterised by a folding section having a series of static folding elements, comprising folding plates to deflect upwardly the side panels of the carton with respect to the top panel thereof in order to cause the tuck flaps to be folded into overlapping relationship with said side panels, static guide bars to maintain the tuck flaps in said overlapping relationship, counter-fold bars to cause the side wall panels to be folded downwardly with respect to the top panel whereby the tuck flaps are disposed between the containers being packaged and said side walls and static fold bars to cause said base panels to be folded into overlapping relationship beneath said containers.

- Another aspect of the invention provides a method of forming a wrap-around package accommodating a plurality of containers and of the type having a top panel, side wall panels and base panels providing a sleeve-like structure and end panel structures at each end of the sleeve including an end panel and tuck panels joined to the end panel by gusset panels which method is characterised by first deflecting upwardly the side panels of the carton with respect to the top panel thereof in order to cause said tuck flaps to be folded into overlapping realtionship with said side panels, thereafter. causing the side wall panels to be folded downwardly with respect to the top panel whereby the tuck flaps are disposed between the containers being packaged and said side walls and finally causing said base panels to be folded into overlapping relationship beneath said containers.

- FIGURE 1 of the drawings there is shown a blank 10 made from paperboard or similar foldable sheet material.

- the blank comprises, in series, a first base panel 12, a first side wall panel 14, a top panel 16 a second side wall panel 18 and a second base panel 20 hinged one to the next along fold lines 22, 24, 26 and 28, respectively.

- Base panel 12 is formed with a row of projecting locking tabs 30 which are received in cooperating locking slits 32 provided in base panel 20 in known manner in order to form a wrap-around type package.

- the blank further includes an end panel structure at each end of the top and side panels.

- the end panel structures comprise an end flap 34, 34a, hinged to top panel 16 along fold lines 36 and 36a and tuck flaps 38, 38a; 40, 40a, hinged to side wall panels 14 and 18, respectively along fold lines 42, 42a and 44, 44a.

- End flap 34 is foldably connected to tuck flap 38 by an integral gusset panel 46 which is hinged to tuck flap 38 along oblique fold line 48 and is also hinged to end flap 34 along oblique fold line 50.

- End flap 34 likewise is foldably connected to tuck flap 40 by an integral gusset panel 52 which is hinged to tuck flap 40 along oblique fold line 54 and is also hinged to end flap 34 along oblique fold line 56.

- end flap 34a is foldably connected to tuck flap 38a by an integral gusset panel 46a which is hinged to tuck flap 38a along an oblique fold line 48a and is also hinged to end flap 34a along oblique fold line 50a.

- End flap 34a likewise is foldably connected to tuck flap 40a by an integral gusset panel 52a which is hinged to tuck flap 40a along fold line 54a which is hinged to tuck flap 40a along fold line 54a and is also hinged to end flap 34a along oblique fold line 56a.

- angle 'p' is less than 90°.

- the angle ' ⁇ ' is a right angle.

- the other angles at which the fold lines are postioned at the package corners are not critical provided the end panels are held in a desired downward position in the completed package.

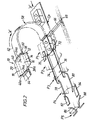

- the machine comprises a continuous blank feed conveyor 58 comprising parallel endless chains 60 and 62 which are driven in the direction of arrow 'A'.

- the blank feed conveyor is provided with a series of arrestor block pairs e.g 64,64a which extend transversely between the chains 60 and 62.

- the arrestor block pairs are spaced apart so that a blank is applied, by suitable feed means (not shown), into the space between the blocks and is held between a pair of the blocks with its end panel structures displaced into an upright position with respect to the top and side walls of the blank.

- the blanks are thus conveyed into a folding section of-the machine in which the blank feed conveyor moves directly above and parallel to a container feed path Cp.

- Container pairs e.g C 1 , C 2 ; C 3 , C 4 are moved into the folding section in the direction of arrow 'B' and are conveyed therealong by spaced chain driven flight-bars e. g 66,68 as is well known in the art.

- the blank feed conveyor 58 and the flight bars providing the container feed are driven in timed relationship so that successive blanks are applied atop successive container pairs and thereafter are moved through the folding section of the machine in synchronism.

- each blank proceeds along the folding section of the machine it first strikes a pair of upwardly inclined static folding plates 70, 72.

- the folding plates 70,72 are positioned so that they cause the side panels and integral base panels of the blank on each side of the associated containers e.g C 3 ,C 4 to be folded upwardly about fold lines 24 and 26 relative to the top panel of the blank. It will be appreciated that when a blank enters the folding section of the machine the end panel structures adjacent the arrestor block extend downwards at the respective ends of the containers to be packaged.

- the upward deflection of the side walls automatically causes the tuck flaps to 'flick' inwardly in relation to the ends of the blank so that they lie in overlapping relationship with the sides of the adjacent containers. It will be appreciated that all the tuck flaps are now internal of the side walls and lie in overlapping relationship with respect to their associated gusset panels. (Blank position P 4 ).

- each of the folding manipulations is effected by a static machine element in order to produce a wrap-around package with end flap panels at each of its ends.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Making Paper Articles (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB8323075 | 1983-08-26 | ||

| GB838323075A GB8323075D0 (en) | 1983-08-26 | 1983-08-26 | Wrap-around package |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0136076A2 true EP0136076A2 (de) | 1985-04-03 |

| EP0136076A3 EP0136076A3 (de) | 1986-06-04 |

Family

ID=10547951

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84305783A Withdrawn EP0136076A3 (de) | 1983-08-26 | 1984-08-23 | Verfahren und Vorrichtung zur Bildung einer Verpackung mittels eines geschlossenen Wickels |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0136076A3 (de) |

| GB (1) | GB8323075D0 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5035102A (en) * | 1990-09-19 | 1991-07-30 | Phillip Morris Incorporated | Methods and apparatus for applying C-shaped innerframes to cigarette bundles |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3295291A (en) * | 1963-06-17 | 1967-01-03 | Mead Corp | Packaging machine and method |

-

1983

- 1983-08-26 GB GB838323075A patent/GB8323075D0/en active Pending

-

1984

- 1984-08-23 EP EP84305783A patent/EP0136076A3/de not_active Withdrawn

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5035102A (en) * | 1990-09-19 | 1991-07-30 | Phillip Morris Incorporated | Methods and apparatus for applying C-shaped innerframes to cigarette bundles |

| EP0476804A1 (de) * | 1990-09-19 | 1992-03-25 | Philip Morris Products Inc. | Verfahren und Vorrichtung zum Anbringen von C-förmigen Innenkragen an Zigarettengruppen |

Also Published As

| Publication number | Publication date |

|---|---|

| GB8323075D0 (en) | 1983-09-28 |

| EP0136076A3 (de) | 1986-06-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0017333B1 (de) | Verpackungsmaschine | |

| US4642967A (en) | Packaging machine | |

| AU706176B2 (en) | Carrier for stacked bottles | |

| US4887414A (en) | Article separating and loading apparatus | |

| US6371287B1 (en) | Full protection basket carriers and method of forming | |

| EP0388238B1 (de) | Verpackung mit faltbaren Lappen zum Trennen von Reihen von Gegenständen | |

| US3728945A (en) | Apparatus for erecting cartons | |

| US4481750A (en) | Packaging apparatus and method | |

| US4416411A (en) | Sleeve-type carton for tapered articles | |

| US4188766A (en) | Packaging machine | |

| US2933867A (en) | Method and means for packaging cans having chines at the ends thereof | |

| US4373630A (en) | Wraparound article carrier with adjustable girth | |

| EP0061285A2 (de) | Verfahren und Vorrichtung zum Einbringen von Flaschen in oben offene Flaschenträger | |

| US3058271A (en) | Carton feeding, erecting, filling and closing mechanism | |

| EP0737151B1 (de) | Karton versehen mit unterteilungen für flaschen | |

| CA1325166C (en) | Dust flap tucking mechanism for use in forming sleeve-type carriers | |

| EP0622300A1 (de) | Verfahren und Vorrichtung zum Verpacken von Behältern in einem Trägerelement in zwei Reihen von mindestens zwei Behältern und Verpackungszuschnitt | |

| US3332199A (en) | Carton closing machine and method | |

| EP0136076A2 (de) | Verfahren und Vorrichtung zur Bildung einer Verpackung mittels eines geschlossenen Wickels | |

| US5154039A (en) | Packing method and machine | |

| GB1049429A (en) | Multi-container packaging apparatus and method | |

| US3064405A (en) | Apparatus and method for enclosing articles in paperboard carton structures | |

| US3061985A (en) | Method and machine for packaging articles | |

| EP0381465A1 (de) | Umhüllende Trageverpackung für Gegenstände mit auf verschiedenen Höhen einfaltbaren Endstreifen | |

| US3911644A (en) | Package forming machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT LU NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE DE FR GB IT LU NL |

|

| 18W | Application withdrawn |

Withdrawal date: 19860506 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: MUELLER, ROLF |