EP0133770A2 - Appareil distributeur de liquides - Google Patents

Appareil distributeur de liquides Download PDFInfo

- Publication number

- EP0133770A2 EP0133770A2 EP84305017A EP84305017A EP0133770A2 EP 0133770 A2 EP0133770 A2 EP 0133770A2 EP 84305017 A EP84305017 A EP 84305017A EP 84305017 A EP84305017 A EP 84305017A EP 0133770 A2 EP0133770 A2 EP 0133770A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- vessel

- pressure

- flow

- fluid

- resiliently

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant

- B65D83/44—Valves specially adapted therefor; Regulating devices

Definitions

- This invention relates to apparatus for dispensing fluids, e.g. liquids, from a vessel.

- the volumetric flow rate, Q, of a fluid through the outlet of a vessel depends on the difference, P, between the pressure on the fluid within the body of the vessel and the pressure at the vessel outlet, and the resistance, R, to flow of the fluid through the flow path for said fluid from the body of the outlet.

- P the pressure on the fluid within the body of the vessel and the pressure at the vessel outlet

- R the resistance

- R depends on a variety of factors including the dimensions and nature of the flow path and on the nature, in particular the viscosity, of the fluid. The viscosity will in turn depend on the temperature.

- the flow rate Q does not drop below a specified flow rate Q o by more than a specified proportion x, i o e. xoQo ⁇ Q ⁇ Q o ,

- R is variable so that R can increase with the pressure difference whereby the conditions x.Qo ⁇ Q ⁇ Q o can be achieved over a wider range of pressure differences than x.P o to P o .

- the present invention provides apparatus for dispensing a fluid comprising a vessel having an outlet and flow regulating means within said vessel defining the flow path for said fluid from the body of said vessel to said outlet, said means including a resiliently moveable element subject to the pressure within said body of said vessel whereby, at least over a range of pressure differences between the pressure in said body of said vessel and the pressure at said outlet, an increase in . said pressure difference causes movement of said element so as to provide an increased resistance to flow of said fluid through said flow path.

- the movement of the resiliently moveable element so as to increase the resistance to flow through the flowpath may be such as to increase the length of the flow path and/or, preferably, reduce the cross-sectional area of at least part of the flow path.

- the flow regulating means comprises conduit including a resiliently walled section so that, at least over a range of pressure differences between the pressure in the body of the vessel and the pressure at the outlet thereof, an increase in the pressure difference across the walls of said resiliently walled section causes an increase in the degree of collapse of said resiliently walled section.

- the flow regulating means gives rise to a flow rate/ pressure difference characteristic that has a non-linear portion.

- Typical flow rate/pressure difference characteristics of arrangements in accordance with the present invention are of the types depicted in Figures 1 to 3 which are plots of flow rate Q against pressure difference P o

- the pressure P represents the pressure difference, or in the case of the characteristic of Figure 2 the maximum pressure difference encountered under normal operating conditions, at which the flow rate is the desired maximum Q o .

- the specified flow rate Q o is deemed to be the maximum flow rate that is desired under normal conditions of use of the arrangement. It will be appreciated that if the flow rate/pressure difference characteristic is of the type shown in Figure 1, higher flow rates than Q o could be obtained if the pressure difference is higher than P .

- the point X is the point on the characteristic having the co-ordinates P o , Q o .

- the straight line OX represents the characteristic that would be required to give a flow rate Q o at pressure P o if there was no variation in the flow path resistance with pressure, i.e. if R is constant. It is seen that if Q 1 is x.Q o then the condition x.Q o ⁇ Q ⁇ Q o is satisfied for pressure differences ranging from P to P 2 whereas if R had been constant, providing x > 0, this condition is only satisfied over the smaller pressure difference range P 1 to P o .

- the upper pressure difference P 2 at which the specified condition is satisfied will exceed the maximum pressure P en- countered under normal operating conditions: in the case of the characteristic of the type shown in Figure 3, the pressure difference P 2 may be above or below the maximum encountered under normal operating conditions.

- the flow regulating means is such that, over a range of pressure differences embracing a pressure difference, e.g. P , at which the flow rate is Q , a 5% increase in the pressure difference effects an increase in resistance to flow of the fluid through the flow path of at least 1%, preferably at least 2%.

- the initial part of the flow rate/pressure difference characteristic may be essentially linear.

- the slope of this linear portion, for any given fluid will thus be determined essentially by the dimensions of the part of the flow path incorporating the moveable element with the latter in its zero pressure difference position and by the dimensions of any non-moveable, e.g. non-deformable, portion of the flow path. It is preferred that over such an initial linear portion of the characteristic, a significant part of the resistance to flow is given by such non-moveable portions of the flow path.

- non-moveable portions there will normally be such non-moveable portions both upstream and downstream of the moveable element, and/or there may be a non-moveable member within the moveable element or co-operating therewith.

- a regulator for mounting within a vessel for regulating the flow of a fluid from the body of said vessel to the outlet thereof comprising at least one non-deformable member and a resiliently moveable member disposed such that, when mounted within said vessel, said resiliently moveable member and said at least one nom-deformable member define the flow path for said fluid from said body of said vessel to said outlet with said resilient member subject to the pressure within said body of said vessel whereby, at least over a range of pressure differences between the pressure in said body of said vessel and the pressure at said outlet, an increase in said pressure difference causes movement of said resiliently moveable member so as to provide an increased resistance to the flow of said fluid through said flow path.

- the flow path includes a flow restrictor upstream of the moveable element, i.e. between the moveable element and the end of the flow path that is open to the fluid within the body of the vessel.

- flow restrictor we mean a device across which the pressure drop is a significant proportion of the pressure difference P, at least over the initial linear portion of the flow rate/pressure difference characteristic.

- the pressure drop across the flow restrictor is preferably at least 5% of the total pressure difference P at pressure differences corresponding to the initial linear portion of the characteristic.

- the point Y represents a point having the co-ordinates P , Qy on the linear portion of the characteristic.

- the line OF represents the characteristic given by the non-moveable elements of the flow path and the line OD represents the characteristic given by of any non-moveable element of the flow path downstream of the moveable element.

- pressure differences P referred to hereinbefore in relation to Figures 1 to 3 may be above or below the minimum pressure difference at which a 5% increase in the pressure difference causes an increase in resistance to flow of at least 1%.

- the resistance to flow given by a restrictor upstream of the resiliently moveable element is greater than that given by any non-moveable elements of the flow path downstream of the moveable element.

- valve or tap is provided at the outlet of the vessel or downstream thereof to open and shut the flow of fluid through the outlet.

- the flow regulator forms part of an assembly for fastening to an opening in the vessel.

- an assembly for fitting to a vessel to provide a flow path for a fluid from within the body of said vessel to the exterior thereof comprising a closure member adapted to be fastened to said vessel body to close an opening in said vessel, said closure member having a passage therethrough, a flow regulator communicating with the inlet of said passage of said closure member, said regulator and said passage defining said flow path for the fluid from within said body of said vessel to the exterior thereof, said regulator including a resiliently moveable member disposed such that when said closure member is fastened to said vessel body, said resiliently moveable member is within said vessel body and subject to the pressure therein, whereby at least over a range of pressure differences between the pressure within said body of said vessel and the pressure at the outlet of said passage, an increase in said pressure difference causes movement of said element so as to provide an increased resistance to flow of said fluid through said flow path.

- the above assembly conveniently incorporates an on/off valve, which is actuatable from outside the vessel and is preferably a mechanically actuated valve.

- the valve conveniently is located to open and close the passage through the closure member.

- FIG. 5 is a diagrammatic section through a container incorporating a flow regulator, for dispensing a liquid.

- a container 1 having a closure member 2 incorporating an on/off valve 3 has a resiliently walled tube 4 connected to valve 3 mounted within the container 1.

- a flow restrictor 5, e.g. a length of narrow bore tubing, opening into the fluid e.g. liquid 6 to be dispensed, is connected to the other end of tube 4.

- the container 1 is pressurised by a gas in the space 7 above liquid 6.

- valve 3 With valve 3 closed, the pressure inside tube 4 equals that exerted by the gas in space 7. On opening valve 3, a pressure drop occurs across the valve 3 causing the liquid inside the tube 4 to be dispensed. The flow of liquid out through valve 3 provides a pressure drop across restrictor 5 causing a flow of liquid 6 through restrictor 5 into tube 4. Because of the pressure drop across restrictor 5, a pressure difference occurs across the walls of tube 4 causing the walls to collapse towards each other. This collapse of tube 4 acts as a further flow restrictor in series with restrictor 5.

- the degree of collapse of tube 4, and hence R 4 will depend on the pressure difference across the walls of tube 4. This pressure difference is P 3 + P 4 , i.e. P - Q.R 3 . It is therefore seen that R 4 will depend on the overall pressure difference, P, and on the flow rate, Q: the relationship of R 4 to P and Q will be determined by the resilience of the walls of tube 4 and the length of that tube and the wall dimensions and configuration. It will be appreciated that the tube 4 does not necessarily collapse uniformly: thus the transition from the uncollapsed state to the collapsed state at one end of the tube may be sharper than at the other end of the tube.

- the pressure difference at which the effect of the collapsible tube 4 becomes significant is largely determined by the resilience of the tube walls: As the modulus decreases, this pressure difference reduces.

- the vessel is a container used for dispensing a liquid and is pressurised with a pressurising fluid, e.g. a gas or volatile liquid, pressure fluctuations may occur.

- a pressurising fluid e.g. a gas or volatile liquid

- the container is initially charged with the liquid to be dispensed and the pressurising fluid, the pressure exerted by the pressurising fluid may fall simply as a result of the increase in volume occupied by the pressurising fluid as the liquid is dispensed; or pressure fluctuations may occur where the container is pressurised intermittently, eg by a hand pump, or continuously from a source that is liable to pressure fluctuations.

- the feed of liquid from the container may simply be a gravity feed.

- the head of liquid in the container gives rise to the pressure differential to which the moveable element, eog. the walls of the collapsible tubing is subject.

- Variations in the head of liquid, i.e. as the container empties, thus gives rise to the pressure difference variations for which compensation can be provided by the pressure difference dependent movement of the moveable element.

- the vessel is pressurised with a pressurising fluid.

- the pressurising fluid is a gas at ambient temperatures and atmospheric pressure but is a liquid at the pressure prevailing within the vessel.

- pressurising agent e.g. a flurocarbon such as dichlorodifluromethane or a hydrocarbon such as butane

- these types of pressurising agent are widely used as aerosol propellants and the invention is applicable to such aerosol configurations.

- this type of pressurising agent because of the significant changes of vapour pressure of the pressurising agent that occur with relatively small changes in temperature, variations in the ambient temperature can cause considerable variation in the pressure within the vessel: in the absence of apparatus in accordance with the invention, such pressure variations would give rise to substantial variations in the liquid flow rate.

- the gauge pressure within the vessel at an ambient temperature of 10°C is typically about 0.3 MPa whereas at 35 0 C it is about 0.66 MPa.

- a temperature variation would give rise to a flow rate change of a factor of 2 or more.

- the rate at which the fluid will be dispensed will also depend inversely on the viscosity of the fluid: this viscosity will generally decrease with increasing temperature and so the flow rate will generally increase as the temperature increases. Consequently a flow rate/temperature characteristic of the type shown in Figure 6, which is plot of flow rate Q against temperature T, would be achieved if the flow path had no moveable element.

- the invention is of particular utility where a liquid is dispensed under the action of a pressurised propellant,e.g. a compressed gas, within the vessel.

- a pressurised propellant e.g. a compressed gas

- the propellant is a volatile liquid at the pressure prevailing in the vessel and/or has an appreciable solubility in the liquid to be dispensed

- some of the propellant may be dispensed with the liquid and may tend to volatilise within the flow path. In some cases this may cause the flow rate/pressure difference characteristic to be modified.

- the vessel is arranged such that the propellant cannot be dispe sed with the liquid, e.g.

- the liquid to be dispensed is separated from the propellant by a flexible membrane.

- the liquid to be dispensed is contained within a collapsible bag located within the outer vessel with the propellant fluid in the space between the bag and the outer vessel.

- the propellant is enclosed within a flexible container within the outer vessel with the liquid to be dispensed in the space between the flexible container and the outer vessel.

- the invention is of particular utility in aerosol-type packages where the required flow rate is in the range 0.01 to 2.5 ml/sec.

- the container gauge pressure is preferably within the range 0.03 to 1 MPa.

- the fluid being dispensed preferably has a viscosity, at the dispensing temperature, of 1.5 x 107 4 to 2 Faos, particularly 5 x 10 -4 to 5 x 10 -2 Pa . s .

- the flow regulator preferably comprises a conduit having a resiliently walled portion as the moveable element.

- the resiliently walled portion may simply be a length of resilient tubing e.g. tubing of an elastomeric material.

- the resiliently walled portion may be a sleeve of the resiliently walled material over a non-deformable core member.

- the flow regulator comprises a sleeve of tubing of elastomeric material mounted on a mandrel having one or more grooves or projections along its length.

- Such grooves or projections serve to define channels for the passage of fluid between the resilient sleeve and the mandrel.

- the sleeve deforms to restrict the channels. It will be appreciated that the slope, size, and position of the grooves or projections will influence the flow ratelpressure difference characteristic.

- a pathway for the passage of fluid when the resilient sleeve has deformed to such an extent that the flow of fluid between the sleeve and the core member is stopped may be provided.

- a pathway may be provided by a suitably sized bore through the core member.

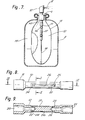

- Figure 7 is a longitudinal section through a container fitted with the above type of flow regulator ineorporating an elastomeric sleeve on a mandrel.

- Figure 8 is an elevation of the mandrel with the sleeve shown dotted.

- Figure 9 is a longitudinal section of the mandrel along line 1X - 1X of Figure 8 and

- Figure 10 is a cross section of the mandrel along the line X - X of Figure 8 with the sleeve shown dotted.

- the container is a barrier pack type aerosol comprising an outer canister 8 to which is crimped or clinched, in conventional fashion, an aerosol valve 9 having a spray button 10 arranged so that depression of button 10 towards valve 9 effects opening of the valve 9 to cause liquid within the canister 8 to be dispensed through valve 9 and through button 10 as a spray 11.

- the liquid 12 to be dispensed is endorsed within a flexible bag 13 clamped between the fixing of valve 9 to canister 8.

- Attached to the inlet 14 of valve 9 is one end of a bobbin 15 having a waisted section l6 on which is located a rubber sleeve 17..

- Attached to the other end of bobbin 15 is a fine capillary tube restrictor 18.

- the space 19 between bag 13 and the canister 8 is filled with the propellant.

- the bobbin 15 is of circular cross section and is provided at each end with blind bores 20, 21 and the waisted portion 16 is provided with diametrically opposed flattened portions 22, 23. Holes 24, 25 drilled through the waisted section 16 connect respectively with bores 20, 21. Between holes 24 and 25, the flats 22, 23 are provided with grooves 26, 27.

- each flat 22, 23 of the bobbin is provided with one or more ribs 28 to define the channels for the passage of liquid between the resilient walls of sleeve 17 and the body of the bobbin.

- One advantage of the present invention viz the extension of the pressure difference range over which an acceptable flow rate can be achieved, has the result that aerosols of the type where the propellant is a compressed, but not liquified, gas are a viable proposition thus avoiding the mviron- mental objections to the use of liquified gas por such as fluorocarbons or the safety hazards of flammable propellants such as propane or butane

- a barrier pack construction is adopted to avoid wastage of the compressed gas in the event of misuse of the aerosol, e.g. operation of the valve with the container inverted.

- an upstream flow restrictor in the form of a length of flexible capillary tube may be employed with its free end weighted so that that free end is always immersed in the liquid to be dispensed irrespective of the spatial orientation of the container.

- electrostatic spraying apparatus for example for agricultural or horticultural use, comprising a portable spray gun including a spray nozzle, means for applying a high electrical potential to said nozzle, and means for supplying to said nozzle liquid to be sprayed from a container of the liquid mounted on the spray gun•

- electrostatic spraying apparatus examples include described in, inter alia, US-A-4356528.

- the liquid is supplied to the nozzle from a container containing the liquid and a compressed pressurising agent, e.g. a flurocarbono

- the container is arranged so that the propellant is not dispensed through the nozzle with the liquid to be sprayed, e.g. by the use of a barrier pack configuration as mentioned hereinbefore. In this way the atomisation of the liquid by the electrostatic forces is not affected by the emergence of the propellant.

- the pressure exerted by the pressurising agent is liable to considerable fluctuation as the ambient temperature varies, with the result that the liquid supply rate to the nozzle is also liable to considerable fluctuation: indeed over the range of ambient temperatures liable to be encountered in use of the spray gun, particularly where such use is outdoor, the pressure exerted by the pressurising agent, and consequently the flow rate, may vary, in some cases, by a factor of four or more.

- the desired volumetric flow rates are normally relatively low, typically within the range 0.002 to 0.3 ml/sec.

- the apparatus of the present invention is particularly suited to such flow rates.

- a flow restrictor is provided upstream of the resiliently mgveable element in the flow path, this restrictor is typically a length of very fine bore tubing, e.g. 0.5 to 15 cm of tubing of internal diameter 0.1 to 1 mm, or a plug of porous material

- the moveable element preferably comprises a length, e.g. 1 to 20 cm, of resiliently walled tubing, typically of internal diameter 2 to 6 mm, of an elastomeric material such as silicone, neoprene, or nitrile, rubber or a plasticised vinyl chloride polymer.

- the moveable element is a resiliently walled tube

- this may be of any convenient cross section and may be fluted or provided with a non-deformable core to modify its collapsing characteristics.

- the flow regulator When used in conjunction with an aerosol-type container (whether or not the liquid in the container is in fact to be atomised upon dispensing) the flow regulator is conveniently attached to or forms part of the inlet of the aerosol valve and includes a flow restrictor upstream of the moveable element, e.g. resiliently walled tube.

- the moveable element and flow restrictor may be wholly or partially within the collapsible inner container: where the moveable element is within the collapsible inner container the pressure exerted by the propellant will be transferred to the moveable element through the liquid within the collapsible inner container.

- the system can act as a metering valve to dispense a predetermined quantity of the liquid.

- the pressure drop, P 5 , across restrictor 5 is zero and so the pressure inside the collapsible tube 4 equals that, P, outside the collapsible tube 4: therefore the walls of tube 4 are not collapsed, i.e. are as shown dotted in Figure 5.

- a predetermined amount of the liquid is thus located within tube 4 between restrictor 5 and valve 3. This amount will depend on the dimensions of tube 4.

- valve 3 On opening the valve 3, if the resistance R 3 is small, this predetermined amount of liquid will be dispensed rapidly, causing the pressure within tube 4 to fall. The pressure difference across the walls of tube 4 thus increases from zero, causing the walls to collapse, possibly even to the extent of totally sealing tube 4. As the liquid is dispensed from tube 4 via port 2, the pressure difference across restrictor 5 increases from zero, thus causing flow of liquid through restrictor 5 into tube 4, thereby tendiag to reduce the pressure difference across the walls of tube 4. If valve 3 is closed before tube 4 has refilled to any appreciable extent via restrictor 5, it will be seen that only the predetermined amount of liquid will be dispensed.

- the invention is also of utility as a flow regulator in a fluid flow line where the pressure difference between the ends thereof is liable to fluctuation, e.g. as a result of a varying hydrostatic head.

- the flow regulator of the invention can be employed as an insert in the flow line: the vessel here comprises part of the flow line to which the liquid is continuously supplied.

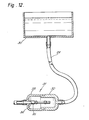

- Figure 12 An example of this form of the invention is illustrated in Figure 12 which an elevation, part in section, of a flow line incorporating such a flow regulator.

- a liquid is supplied via an inlet line 29 from a source 30, which may simply be a reservoir giving a gravity feed, to a casing 31.

- the casing 31 comprises two mouldings 32, 33 which snap-fit together to form a liquid-tight enclosure.

- a conduit incorporating a resiliently walled portion 35 To the outlet port 34 in one of the mouldings is fitted a conduit incorporating a resiliently walled portion 35.

- This conduit conveniently comprises a bobbin assembly of the type shown in Figures 8 - 10.

- the flow regulator is located towards the outlet end of the liquid flow line.

- One possible application of this embodiment of the invention is as a flow regulator for medical uses where the liquid is for example blood or a saline solution being supplied to a patient.

- the dimensions of the bobbin were as follows:

- the sleeve 17 was a 22 mm length of neoprene rubber tube (laboratory size N3 - British Standard 2775/67) having, in the free state, i.e. unstretched and before mounting on the bobbin 15, an internal diameter of 3 mm and a wall thickness of 0.75 mm.

- the upstream restrictor 18 was a length, approximately 1 cm of 0.25 mm internal diameter nylon capillary tubing.

- the canister was filled with a pesticidal composition of 5 x 14 -3 Pa.s viscosity at room temperature and pressurised with compressed air to various pressures. The flow rate at the various pressures was measured.

- Example 1 was repeated but replacing the bobbin/ capillary tube restrictor by a 175 mm length of the neoprene tubing to the free end of which a flow restrictor was fitted.

- the flow restrictor was a metal cup of about 3 mm internal diameter and 1 cm height having a base of 0.5 mm thickness with a 0.5 mm diameter hole therethrough.

- liquid was water (viscosity approx 10 -3 Pa.s.).

- the flow rate is within 15% of the maximum for all pressures, at least up to the maximum pressure tested, above about 0.06 MFa.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Nozzles (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB838321568A GB8321568D0 (en) | 1983-08-10 | 1983-08-10 | Apparatus for dispensing liquids |

| GB8321568 | 1983-08-10 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0133770A2 true EP0133770A2 (fr) | 1985-03-06 |

| EP0133770A3 EP0133770A3 (fr) | 1986-05-14 |

Family

ID=10547123

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84305017A Withdrawn EP0133770A3 (fr) | 1983-08-10 | 1984-07-24 | Appareil distributeur de liquides |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0133770A3 (fr) |

| JP (1) | JPS6058258A (fr) |

| AU (1) | AU3136884A (fr) |

| ES (1) | ES535094A0 (fr) |

| GB (1) | GB8321568D0 (fr) |

| NZ (1) | NZ209067A (fr) |

| ZA (1) | ZA846001B (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4892232A (en) * | 1988-07-25 | 1990-01-09 | Martin James H | Unit dose dispenser |

| WO1990005580A1 (fr) * | 1988-11-22 | 1990-05-31 | Dunne Miller Weston Limited | Soupape de decharge de fluide |

| US5042697A (en) * | 1988-03-08 | 1991-08-27 | National Research Development Corporation | Pressure regulators |

| US5083685A (en) * | 1990-06-28 | 1992-01-28 | Mitsui Toatsu Chemicals, Inc. | Vessel for aerosol |

| US5341968A (en) * | 1992-08-19 | 1994-08-30 | Belgium Spray Accessory Factory | Spray can incorporating a discharge pressure regulating system |

| WO2003064286A1 (fr) * | 2002-01-31 | 2003-08-07 | Primepak Pty Ltd | Dispositif regulateur de pression dans un recipient de distribution comprime |

| WO2011134928A3 (fr) * | 2010-04-28 | 2012-01-05 | The Coca-Cola Company | Distributeur à bouton-poussoir pour bouteilles contenant des boissons gazéifiées |

| CN102906006A (zh) * | 2010-04-28 | 2013-01-30 | 可口可乐公司 | 用于饮料瓶的具有压缩气体囊的按钮式分配器 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IL67635A (en) * | 1983-01-07 | 1988-03-31 | Rosenberg Peretz | Fluid flow control device particularly useful as a drip irrigation emitter |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4062475A (en) * | 1975-04-25 | 1977-12-13 | S. C. Johnson & Son, Inc. | Pressurized container for two-phase system |

| WO1982000450A1 (fr) * | 1980-08-06 | 1982-02-18 | W Werding | Regulateur de poussee dispose a l'interieur d'un recipient a pression |

| DE3107921A1 (de) * | 1981-03-02 | 1982-09-16 | Ekkehard Dipl.-Ing. 7000 Stuttgart Flaischlen | Mengenregler fuer kleine foerderstroeme |

-

1983

- 1983-08-10 GB GB838321568A patent/GB8321568D0/en active Pending

-

1984

- 1984-07-24 EP EP84305017A patent/EP0133770A3/fr not_active Withdrawn

- 1984-07-31 NZ NZ209067A patent/NZ209067A/en unknown

- 1984-08-01 AU AU31368/84A patent/AU3136884A/en not_active Abandoned

- 1984-08-02 ZA ZA846001A patent/ZA846001B/xx unknown

- 1984-08-10 JP JP59167725A patent/JPS6058258A/ja active Pending

- 1984-08-10 ES ES535094A patent/ES535094A0/es active Granted

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4062475A (en) * | 1975-04-25 | 1977-12-13 | S. C. Johnson & Son, Inc. | Pressurized container for two-phase system |

| WO1982000450A1 (fr) * | 1980-08-06 | 1982-02-18 | W Werding | Regulateur de poussee dispose a l'interieur d'un recipient a pression |

| DE3107921A1 (de) * | 1981-03-02 | 1982-09-16 | Ekkehard Dipl.-Ing. 7000 Stuttgart Flaischlen | Mengenregler fuer kleine foerderstroeme |

Cited By (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5042697A (en) * | 1988-03-08 | 1991-08-27 | National Research Development Corporation | Pressure regulators |

| US4892232A (en) * | 1988-07-25 | 1990-01-09 | Martin James H | Unit dose dispenser |

| WO1990005580A1 (fr) * | 1988-11-22 | 1990-05-31 | Dunne Miller Weston Limited | Soupape de decharge de fluide |

| GB2242237A (en) * | 1988-11-22 | 1991-09-25 | Dunne Miller Weston Ltd | Flow discharge valve |

| US5125546A (en) * | 1988-11-22 | 1992-06-30 | Dmw (Technology) Limited | Flow discharge valve |

| GB2242237B (en) * | 1988-11-22 | 1992-12-16 | Dunne Miller Weston Ltd | Flow discharge valve |

| AU634190B2 (en) * | 1988-11-22 | 1993-02-18 | Aptar Group, Inc. | Flow discharge valve |

| US5083685A (en) * | 1990-06-28 | 1992-01-28 | Mitsui Toatsu Chemicals, Inc. | Vessel for aerosol |

| US5341968A (en) * | 1992-08-19 | 1994-08-30 | Belgium Spray Accessory Factory | Spray can incorporating a discharge pressure regulating system |

| WO2003064286A1 (fr) * | 2002-01-31 | 2003-08-07 | Primepak Pty Ltd | Dispositif regulateur de pression dans un recipient de distribution comprime |

| US7021559B2 (en) | 2002-01-31 | 2006-04-04 | Primepak Pty Ltd | Pressure regulating device for a pressurized dispensing vessel |

| CN100339276C (zh) * | 2002-01-31 | 2007-09-26 | 普赖姆帕克有限公司 | 用于加压分配容器的压力调节装置 |

| WO2011134928A3 (fr) * | 2010-04-28 | 2012-01-05 | The Coca-Cola Company | Distributeur à bouton-poussoir pour bouteilles contenant des boissons gazéifiées |

| CN102906006A (zh) * | 2010-04-28 | 2013-01-30 | 可口可乐公司 | 用于饮料瓶的具有压缩气体囊的按钮式分配器 |

| CN102906005A (zh) * | 2010-04-28 | 2013-01-30 | 可口可乐公司 | 用于装有碳酸饮料的瓶子的按钮式分配器 |

| US8870038B2 (en) | 2010-04-28 | 2014-10-28 | The Coca-Cola Company | Push-button dispenser for bottles with carbonated beverages |

| AU2011246511B2 (en) * | 2010-04-28 | 2015-08-20 | The Coca-Cola Company | Push-button dispenser for bottles with carbonated beverages |

| CN102906005B (zh) * | 2010-04-28 | 2015-09-16 | 可口可乐公司 | 用于装有碳酸饮料的瓶子的按钮式分配器 |

| CN102906006B (zh) * | 2010-04-28 | 2015-09-16 | 可口可乐公司 | 用于饮料瓶的具有压缩气体囊的按钮式分配器 |

Also Published As

| Publication number | Publication date |

|---|---|

| GB8321568D0 (en) | 1983-09-14 |

| ES8505604A1 (es) | 1985-06-01 |

| NZ209067A (en) | 1987-02-20 |

| JPS6058258A (ja) | 1985-04-04 |

| EP0133770A3 (fr) | 1986-05-14 |

| AU3136884A (en) | 1985-02-14 |

| ZA846001B (en) | 1985-06-26 |

| ES535094A0 (es) | 1985-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4067499A (en) | Non-aerosol continuous spray dispenser | |

| US4175704A (en) | Non-aerosol continuous spray dispenser | |

| US5755361A (en) | Pump sprayer | |

| US5785681A (en) | Flow rate controller for a medication infusion pump | |

| EP0133770A2 (fr) | Appareil distributeur de liquides | |

| US6152898A (en) | Overfill protection systems for implantable drug delivery devices | |

| US6026850A (en) | Pressure regulating valve | |

| JP2634258B2 (ja) | 加圧分配容器から液状物を分配するための計量分配装置 | |

| AU658859B2 (en) | Spraying of liquids | |

| US4892232A (en) | Unit dose dispenser | |

| US7022107B1 (en) | Infusion pump with pressure regulator | |

| EP0520571A1 (fr) | Buse d'atomisation | |

| JPH03502193A (ja) | 一回分づつに分けるキヤツプ | |

| US5755364A (en) | Device for dispensing fluid at very low flow rates from a container | |

| US5277342A (en) | Sealless dispensing apparatus | |

| EP0536617A1 (fr) | Pompe manuelle pour la distribution de substances liquides ou crèmenses à une pression constante predéterminée | |

| EP3378569A1 (fr) | Dispositif de distribution | |

| US4328820A (en) | Constant-flow regulator for gravity-fed liquids | |

| US20080017672A1 (en) | Flow Rate Regulator Unit For Aerosol Container, Flow Rate Regulator Mechanism For Aerosol Container And Aerosol Type Product | |

| WO2000023354A1 (fr) | Dispositif distributeur de fluide | |

| WO1999053388A1 (fr) | Regulateur de fluides et ameliorations correspondantes | |

| US20070235623A1 (en) | Method and apparatus for regulating hydrostatic pressure | |

| JPS6335309B2 (fr) | ||

| US5535737A (en) | Anesthetic vaporizers | |

| EP0500560A1 (fr) | Appareil de mesure du volume et du debit d'un liquide |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19861018 |

|

| 17Q | First examination report despatched |

Effective date: 19870827 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19880201 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: CONNOLLY, ANTHONY |